Automatic stacking device for grinding tools

An automatic code and tool technology, applied in grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problems of wasting manpower and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

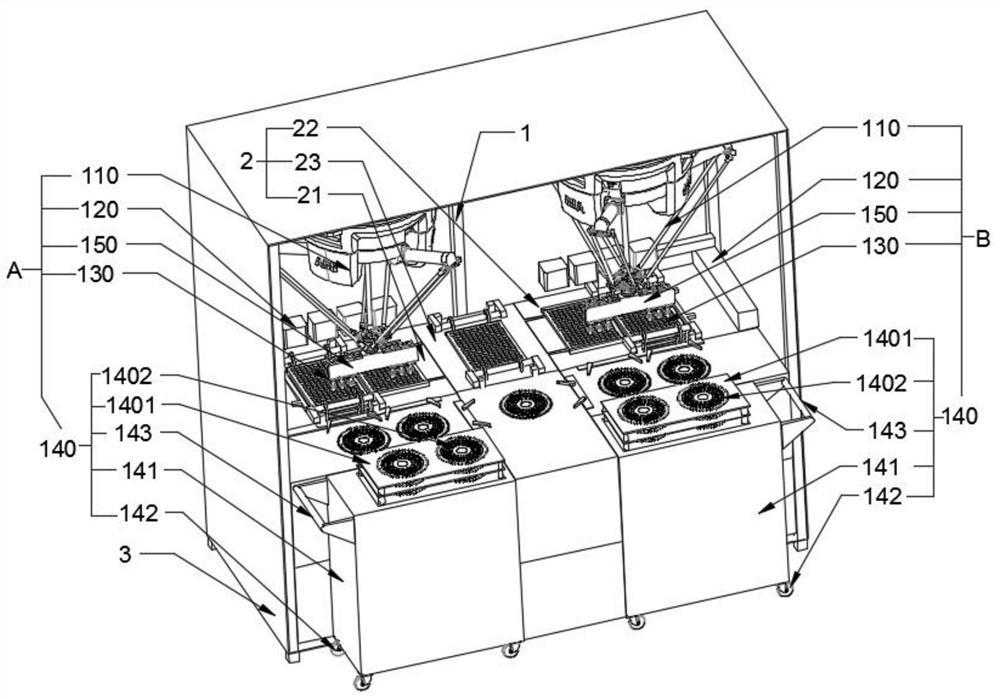

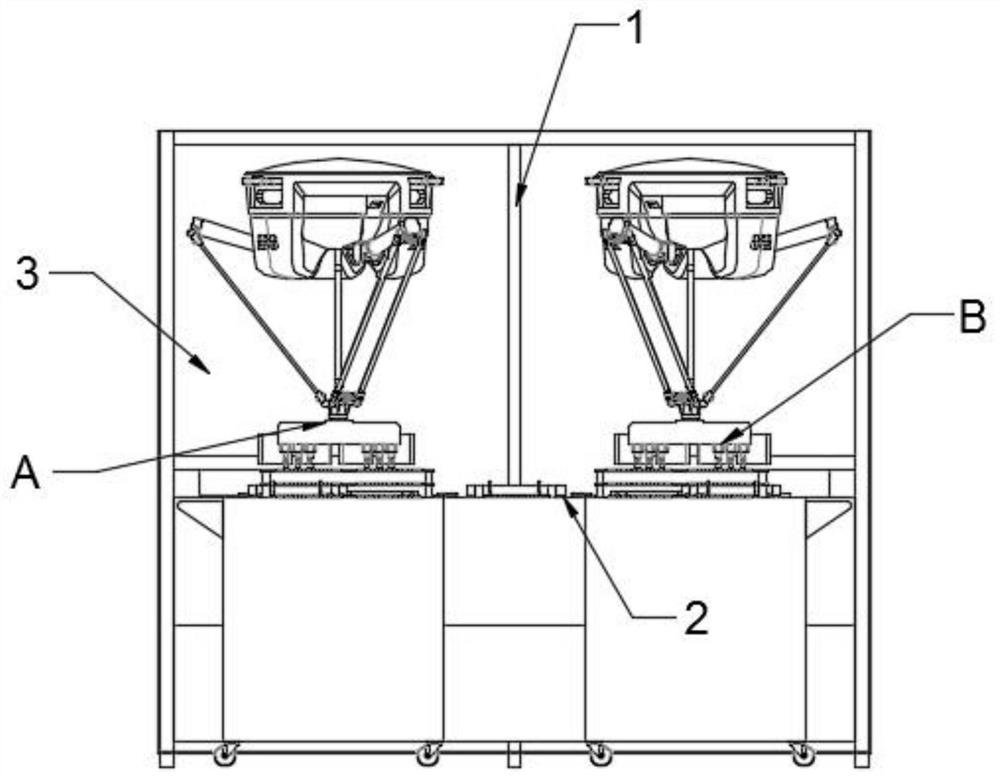

[0048] Such as figure 1 and figure 2 Shown: an automatic stacking device for grinding tools, including a frame 1, a workbench 2 fixed on the frame 1, a protective plate 3 fixed on the outer wall of the frame 1, a stacking system A before grinding and a stacking system B after grinding , the workbench 2 is divided into a first processing area 21, a second processing area 22 and a temporary storage area 23 in the lateral direction, and the first processing area 21 and the second processing area 22 are arranged symmetrically with respect to the temporary storage area 23; the stacking system before grinding A and the post-grinding stacking system B are respectively set in the first processing area 21 and the second processing area 22 . Among them, frame 1 is used to install workbench 2, pre-grinding stacking system A and pre-grinding stacking system B, pre-grinding stacking system A and pre-grinding stacking system B can realize automatic transfer and stacking of blades, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com