Construction garbage crushing, sorting and recycling treatment device

A construction waste and processing device technology, which is applied in the field of construction waste crushing, sorting, and reuse processing devices, can solve problems such as the consumption of land acquisition fees, construction funds, service life limitations, and environmental pollution, so as to be beneficial to environmental protection and realize Circular operation, convenient reuse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

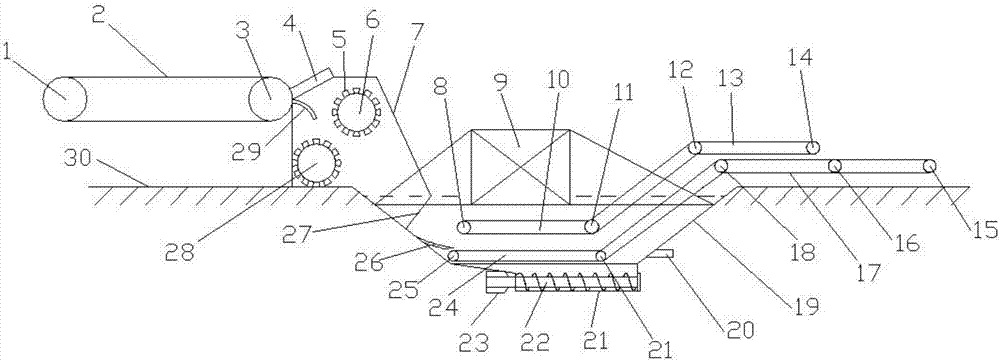

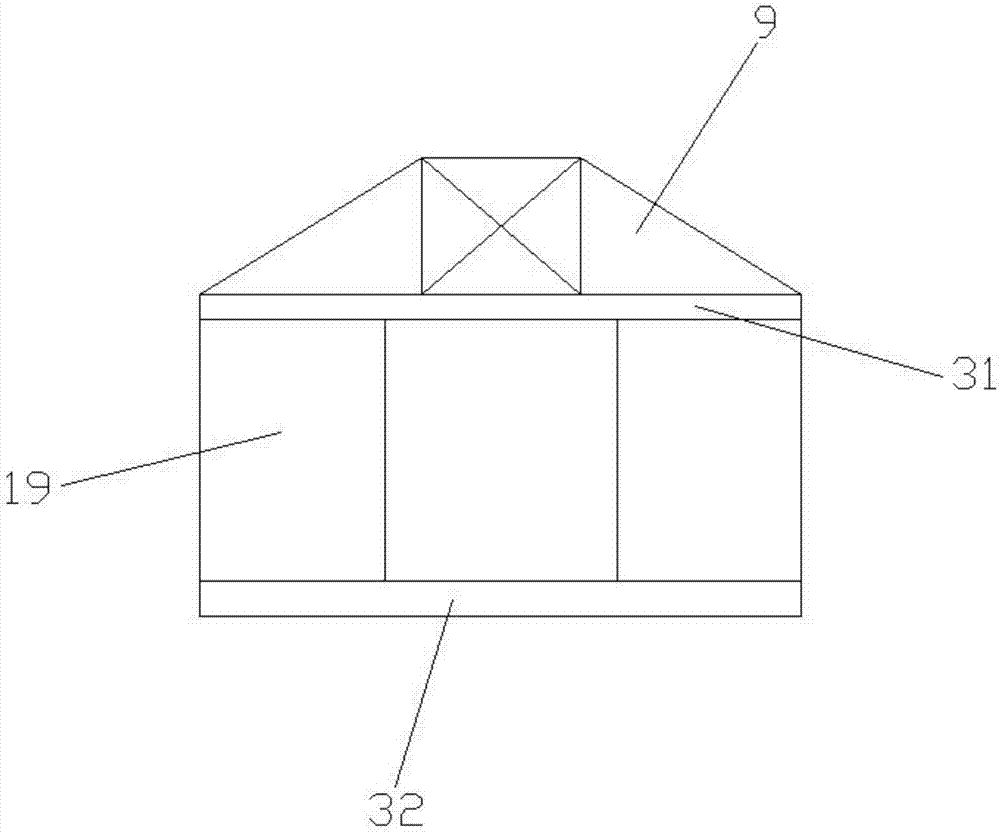

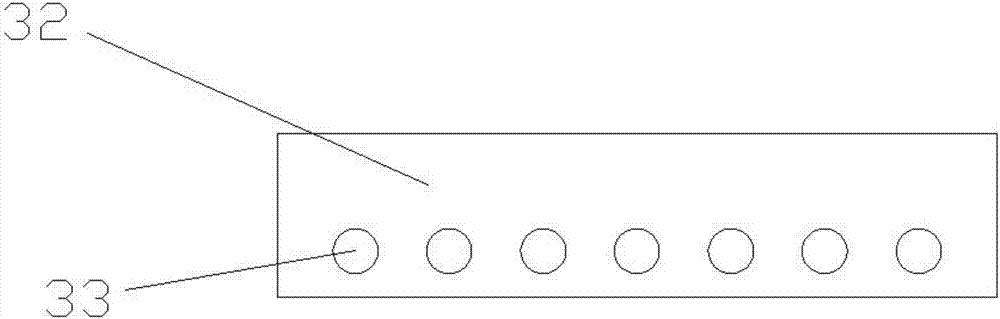

[0016] see Figure 1-3 , a device for crushing, sorting, and reusing construction waste, including a water tank 19 filled with water, the water tank 19 is a V-shaped structure, and banks 30 are arranged on the left and right sides of the water tank, and the left bank 30 of the water tank is A crushing mechanism is arranged on it, and the crushing mechanism includes a shell 7, which is a folded cylindrical structure; the shell 7 is installed on the top embankment 30 on the left side of the water tank 19; the bottom end of the shell 7 is open and extends into The lower side of the water surface of the tank 19 is 10-20 cm; the right side of the top of the housing 7 is provided with a feed inlet 4 inclined to the left, and the first crushing roller 6 and the second crushing roller 29 are arranged in the casing, and the first crushing roller 6 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com