Logistic commodity sorting device and system

A technology of sorting device and sorting system, which is applied in the direction of sorting, etc., can solve the problems of low efficiency of logistics commodity sorting, high labor intensity of workers, and manual sorting can not achieve the expected effect, so as to achieve accurate sorting and improve Efficiency, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in detail.

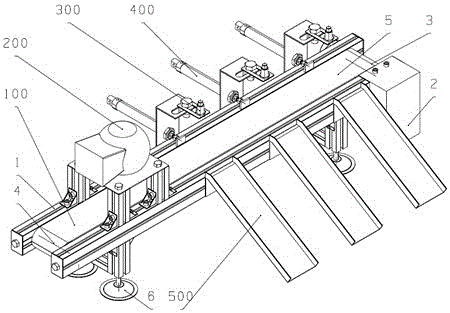

[0017] Such as figure 1 Shown is the schematic diagram of the structure of the present invention, including a conveyor belt device 100, an automatic scanner device 200, a signal detection device 300, a sorting power device 400 and a shunt channel 500, and the conveyor belt device 100 includes a conveyor belt support 1, a motor 2, a drive roller 3, The driving roller 4, the conveyor belt 5, the adjustable base 6, the motor 2 drives the driving roller 3 to rotate through the sprocket transmission device installed on the motor shaft, and the driving roller 3 drives the driven roller 4 to rotate through the conveyor belt 5, thereby realizing the cycle of the conveyor belt 5 run;

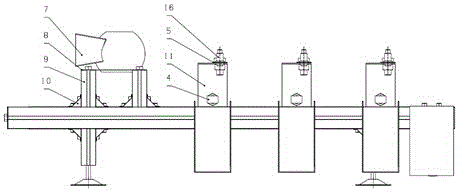

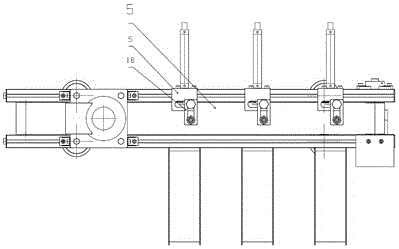

[0018] Such as figure 2 , image 3 , Figure 4 Shown is an automatic scanner device 200, including an automatic scanner 7, a scanner fixing plate 8, a scanner bracket 9 and a profile connector 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com