A spiral disc belt type low temperature dryer device

A spiral disc and dryer technology, applied in heating devices, drying solid materials, local stirring dryers, etc., can solve the problems of unsuitable drying equipment, low production capacity, and large floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

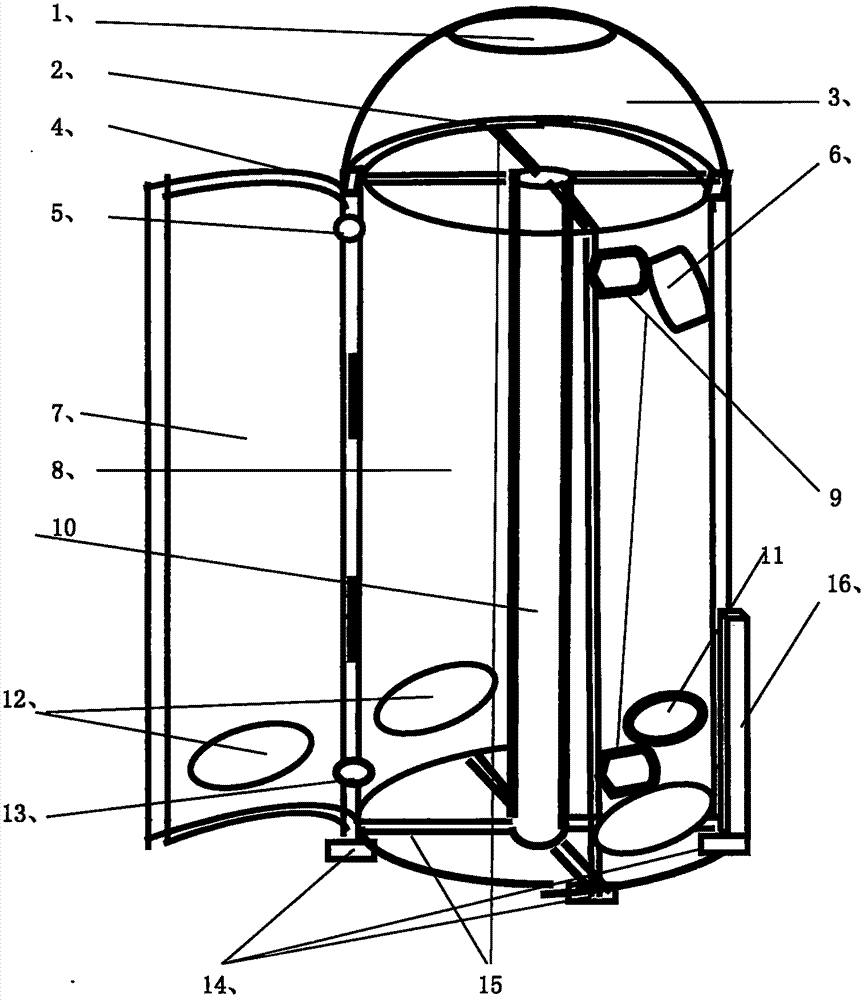

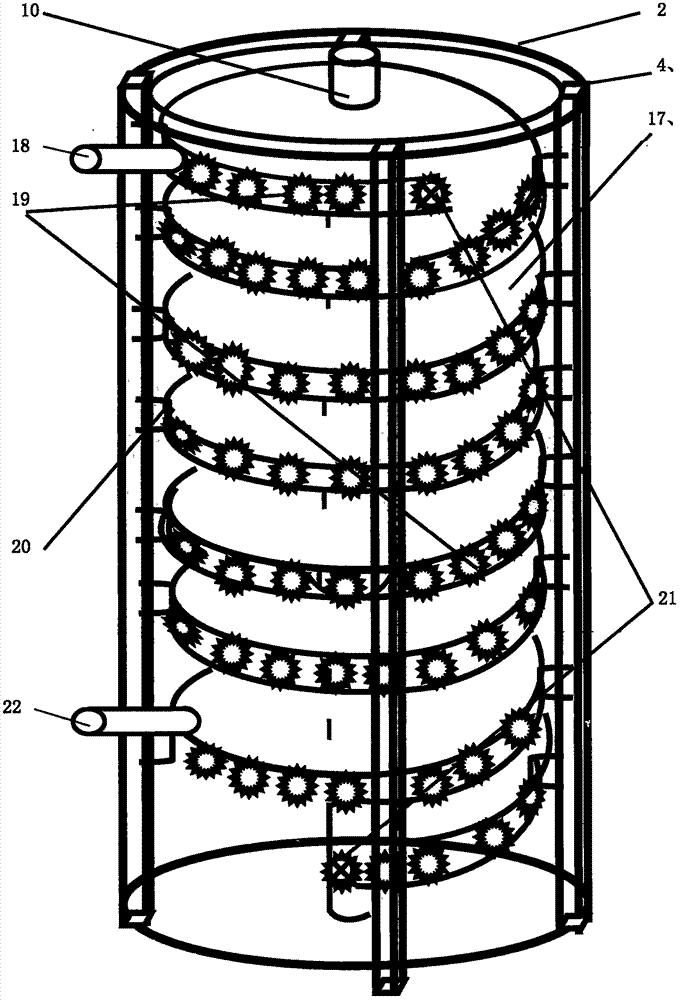

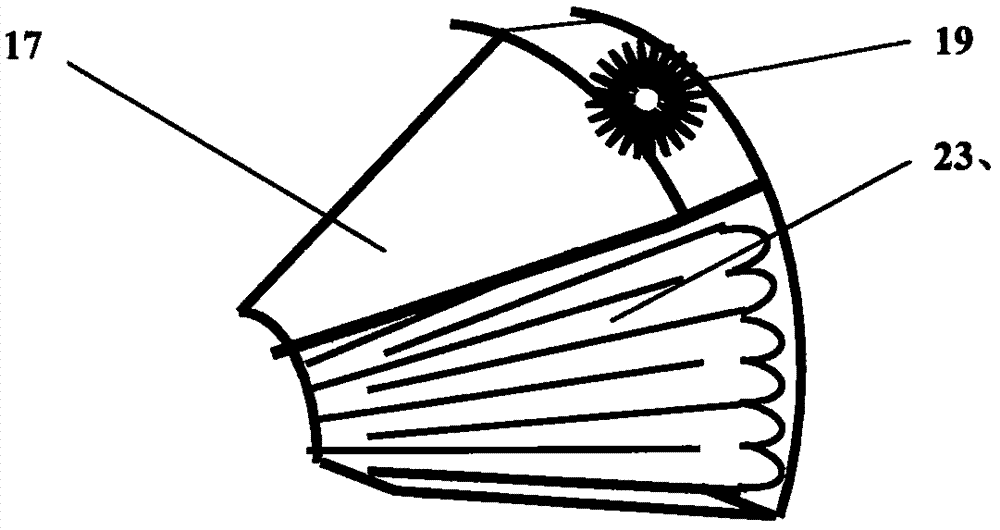

[0055] Embodiment: take radius 1.25 meters, spiral heat dissipation disk thickness 8cm, spiral layer spacing 20cm, accommodate 15 layers of spiral disks, device total height 4.48 meters of the device specifications of the present invention, carrying dry matter with a water content of 60% as an example. First press the 60% moisture content button on the console, (such as figure 1 Middle 16), the water supply pipe and the motor are automatically turned on, (such as figure 1 middle 9 and figure 2 , Figure 5 , Figure 9 9 and 22), the spiral drying plate starts to move helically along the surface of the heating plate at a predetermined speed. Open the inspection door, (such as figure 1 In 7), after confirming that all parts of the equipment are operating normally, close the inspection door. Open the supply pipe valve, (such as Figure 5 Middle 33), then the feeding nozzle starts to spray the dried material to the lower surface of the drying disc with a predetermined flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com