Patents

Literature

94results about How to "Accurate Defect Detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

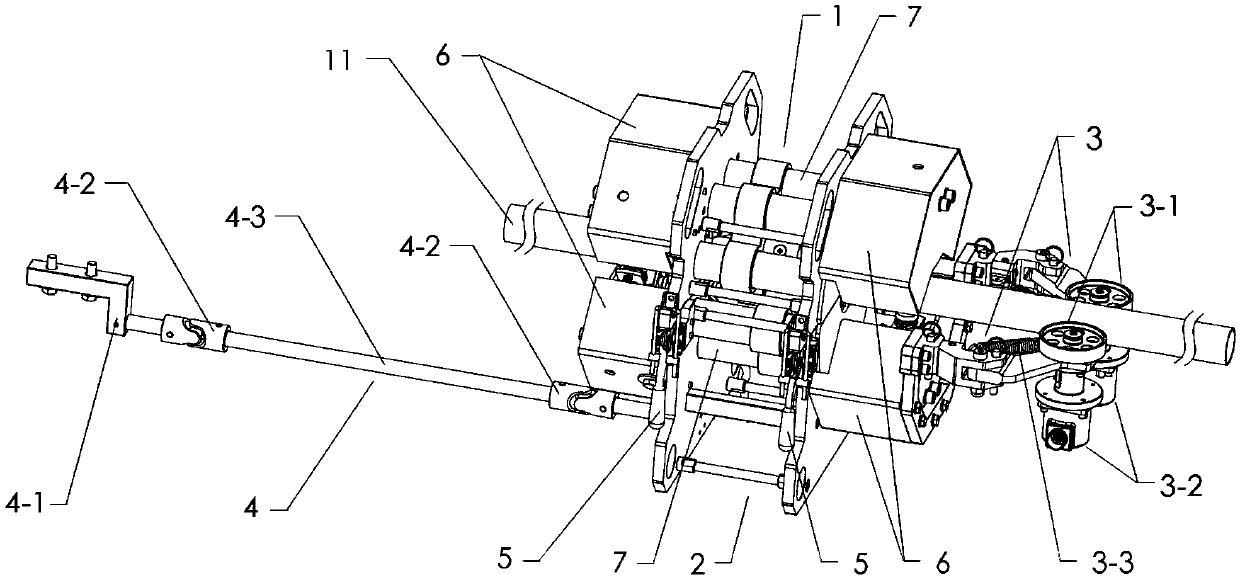

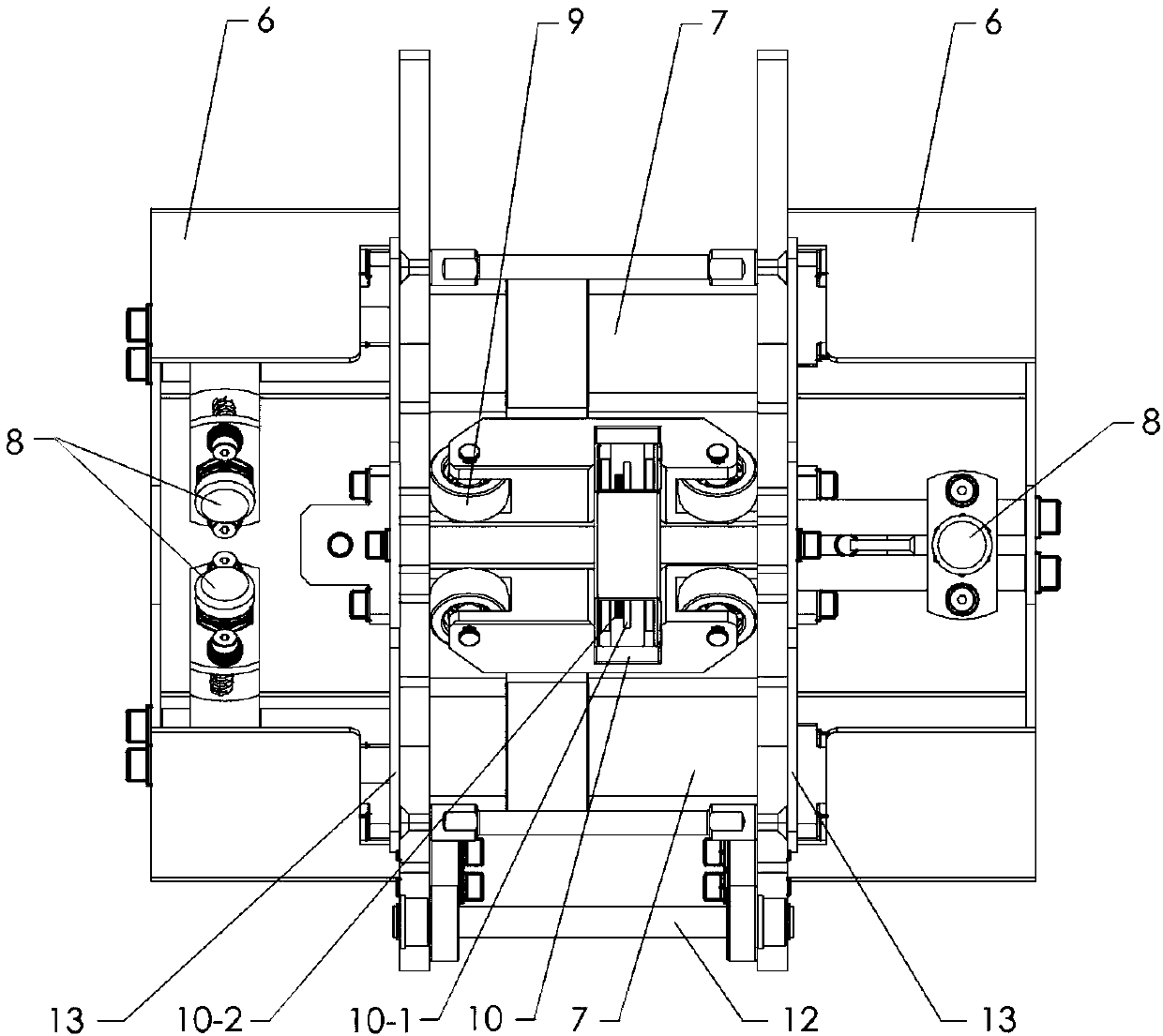

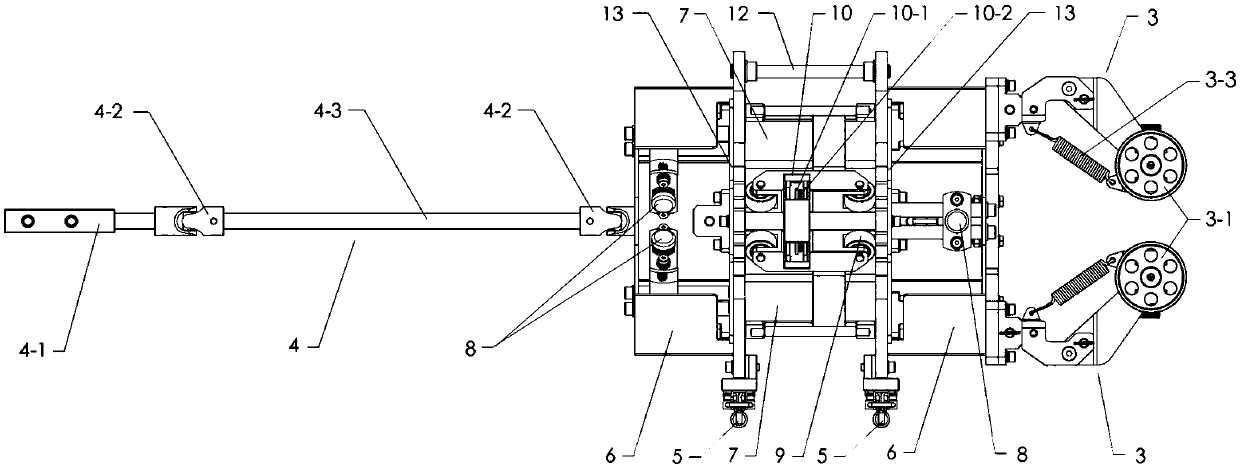

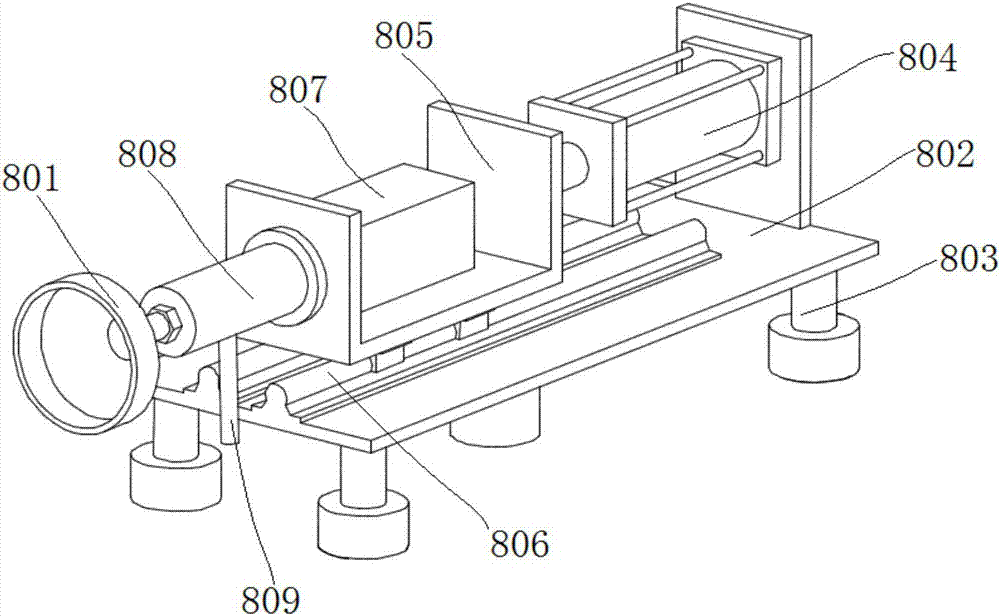

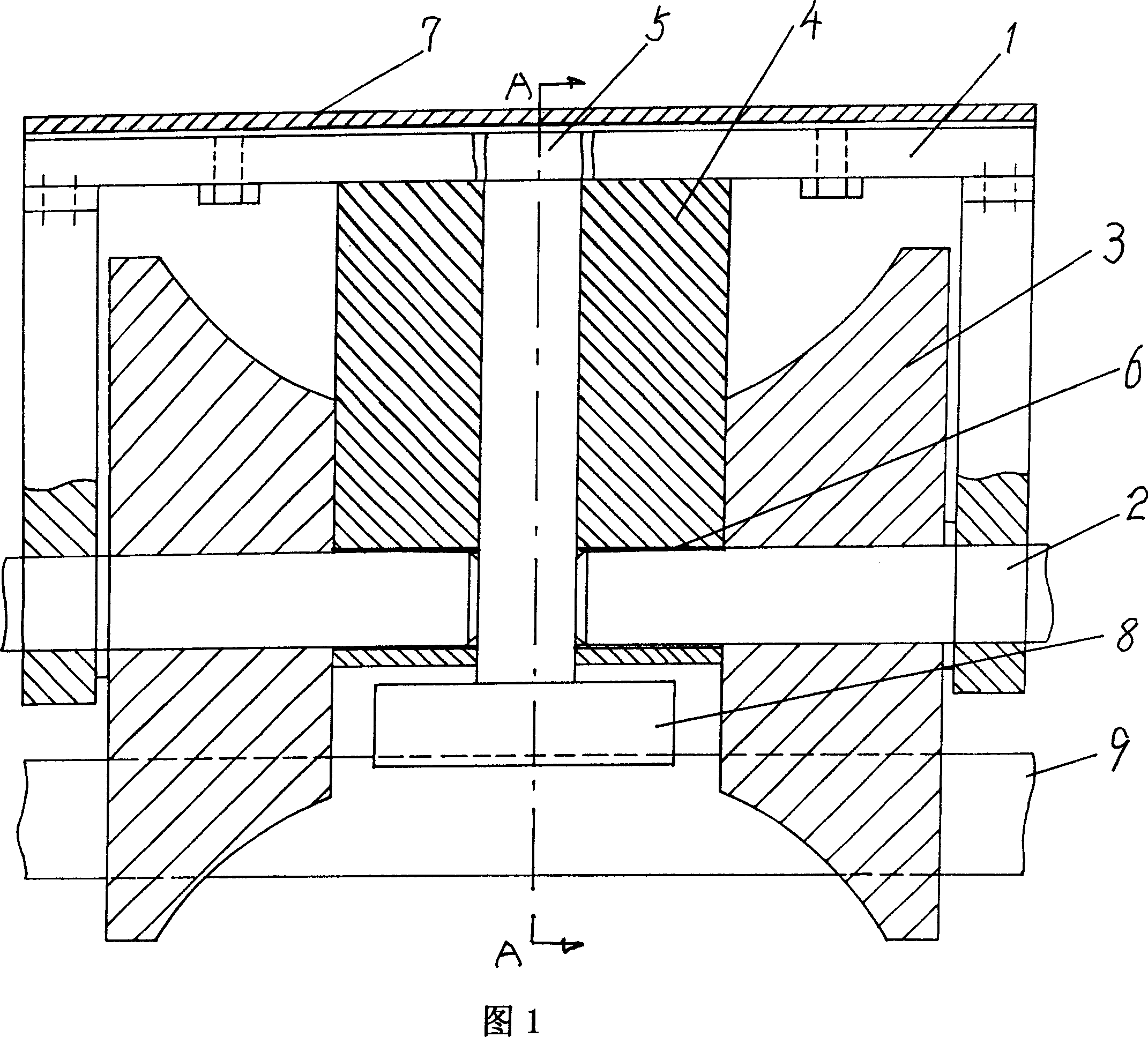

Integrated coiled tubing defect detection device

PendingCN109682881AAccurate defect detectionAccurate detection of wall thicknessElectric/magnetic contours/curvatures measurementsUsing electrical meansCoiled tubingEngineering

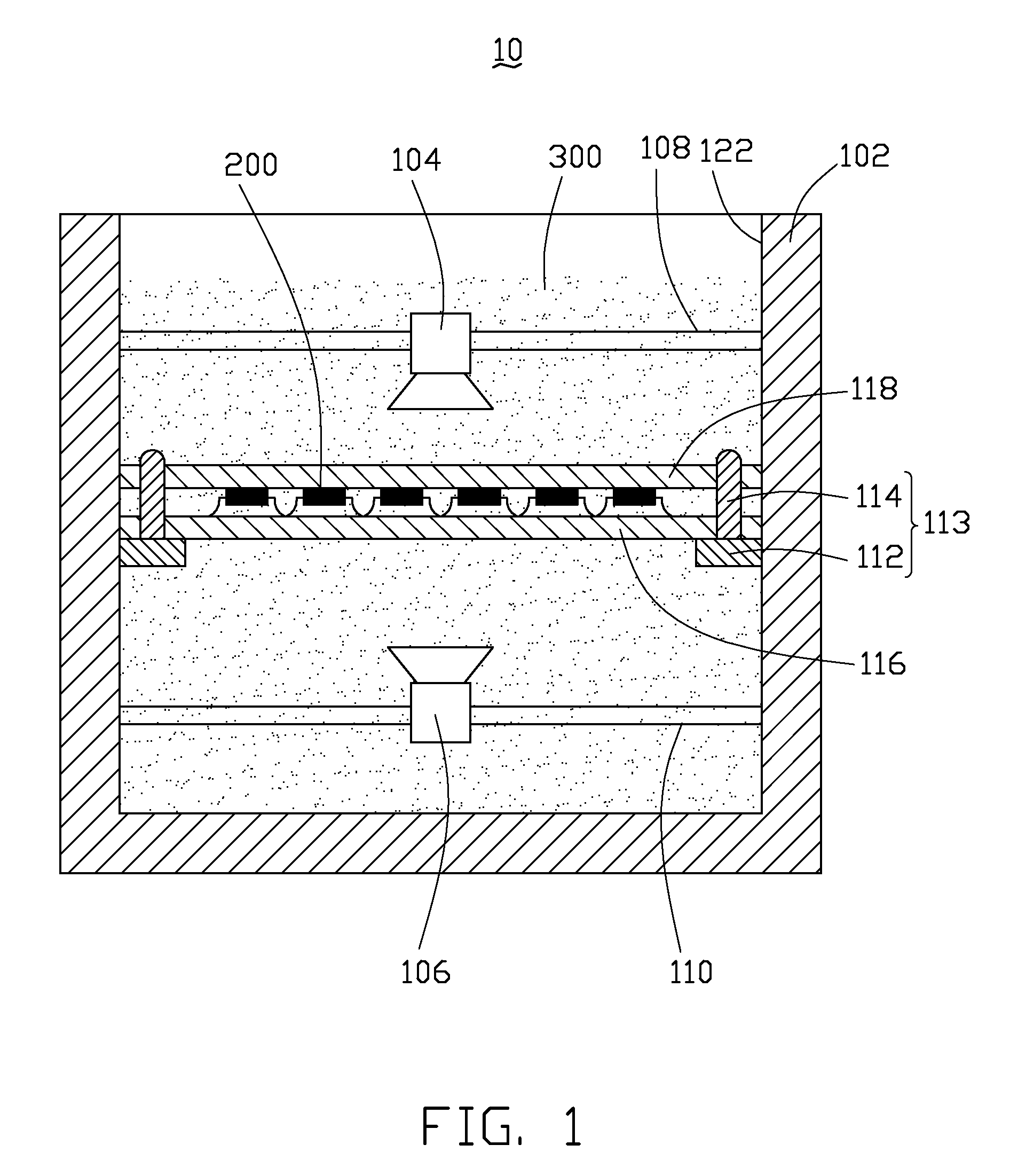

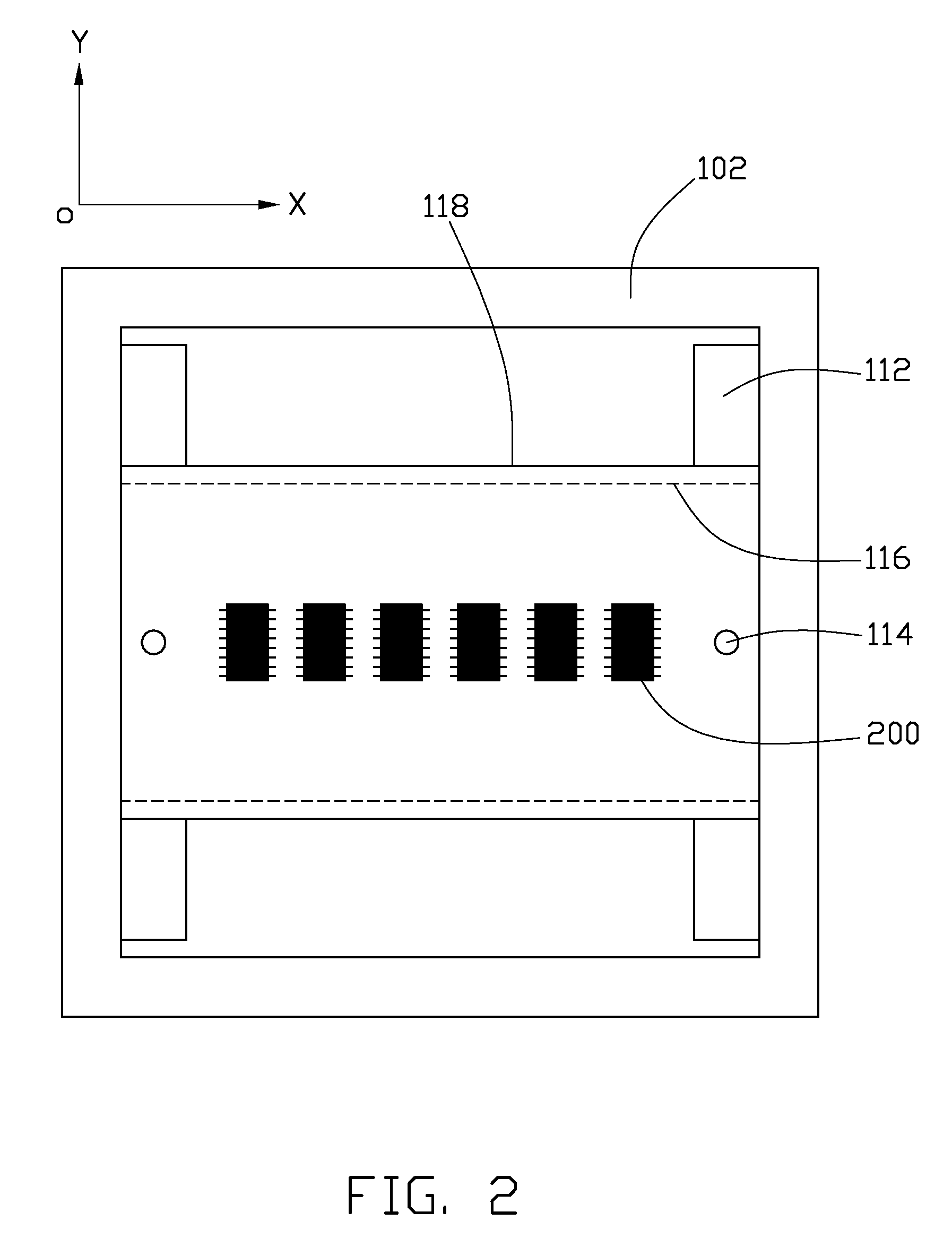

The invention provides an integrated coiled tubing defect detection device. The coiled tubing defect detection device comprises an upper half detection unit and a lower half detection unit, and a passage for coiled tubing to pass through is formed between the two detection units after the two detection units are matched and assembled with each other, and internally provided with a magnetism generating device, a magnetism leakage detection probe, an ellipticity detection probe and a guide device which are arranged on the two detection units; a measuring arm assembly kit for guiding the two detection units in moving along the coiled tubing is connected to the outsides of the detection units. The device can achieve real-time and precise detection of the wall thickness, outer diameter, ovalityand various physical defects such as corrosion, cracks, mechanical damage and pitting corrosion of coiled tubing columns.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

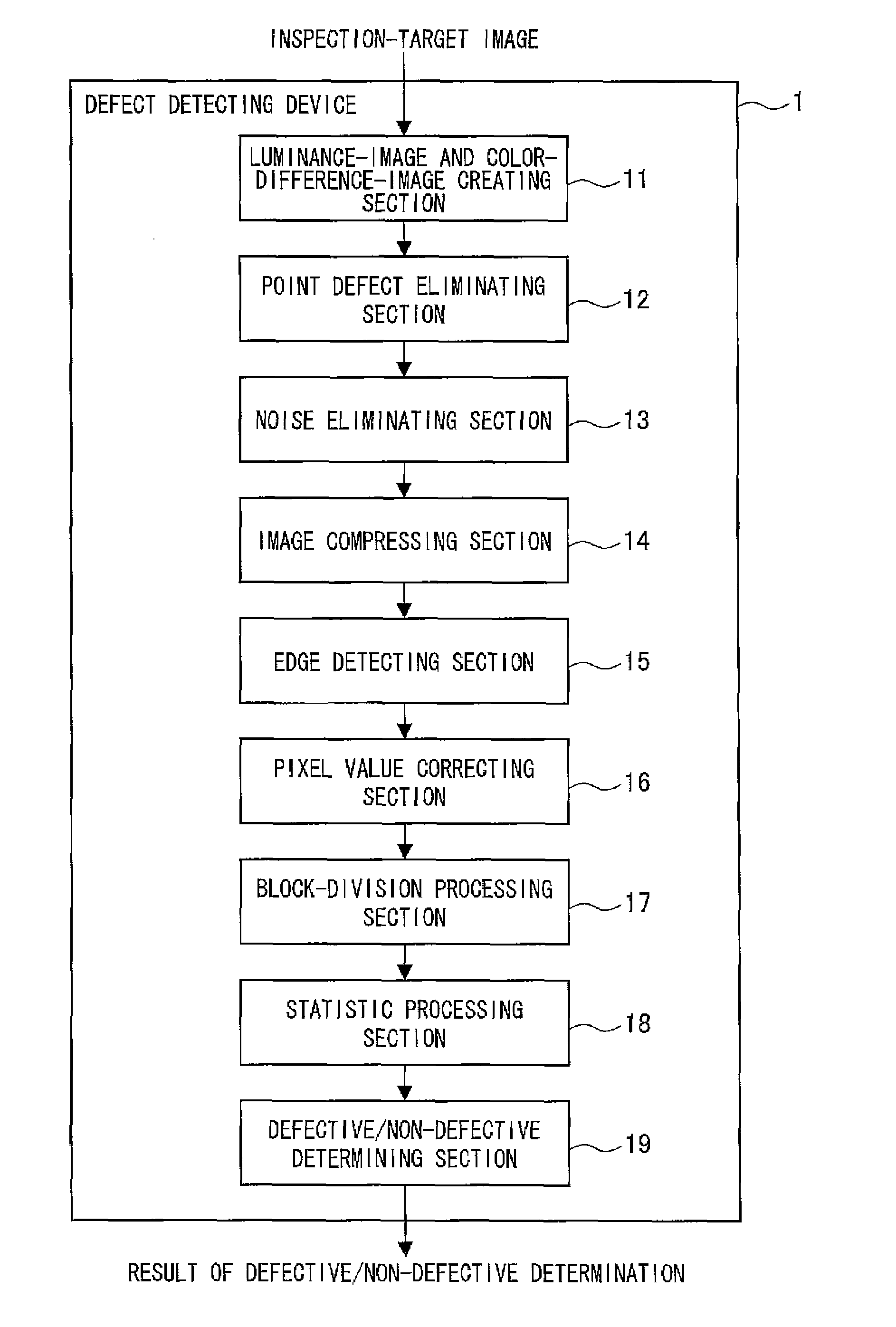

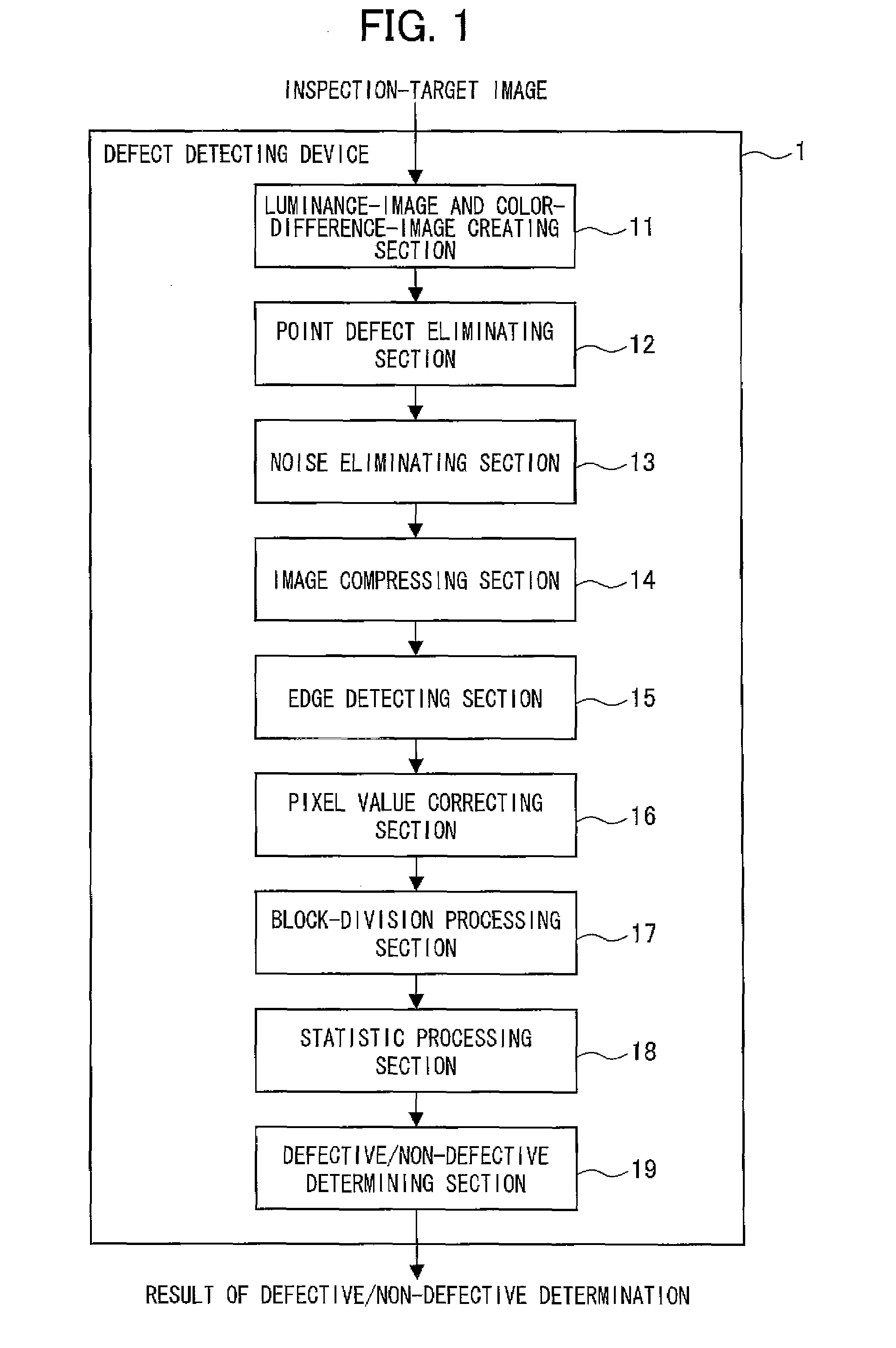

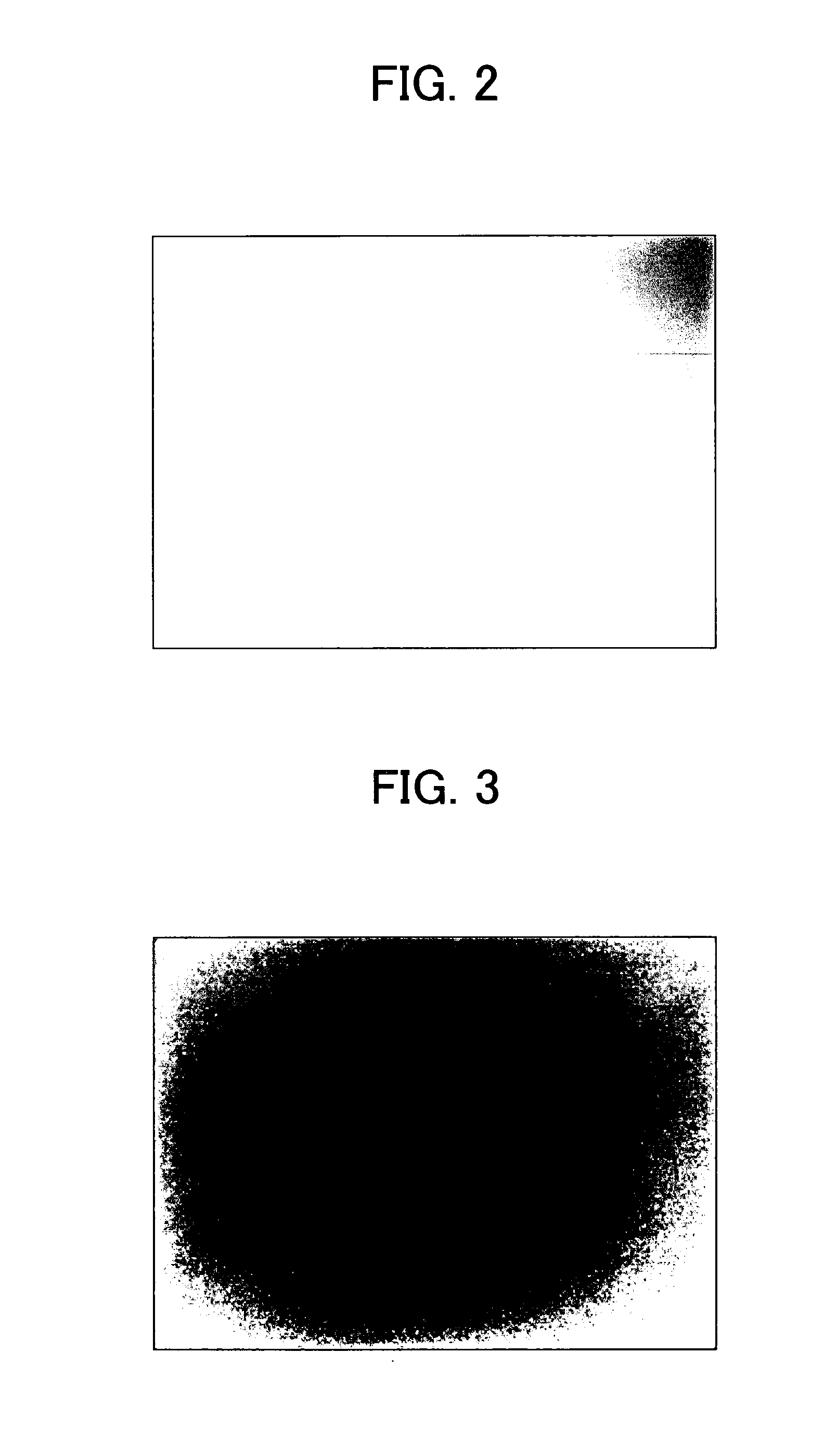

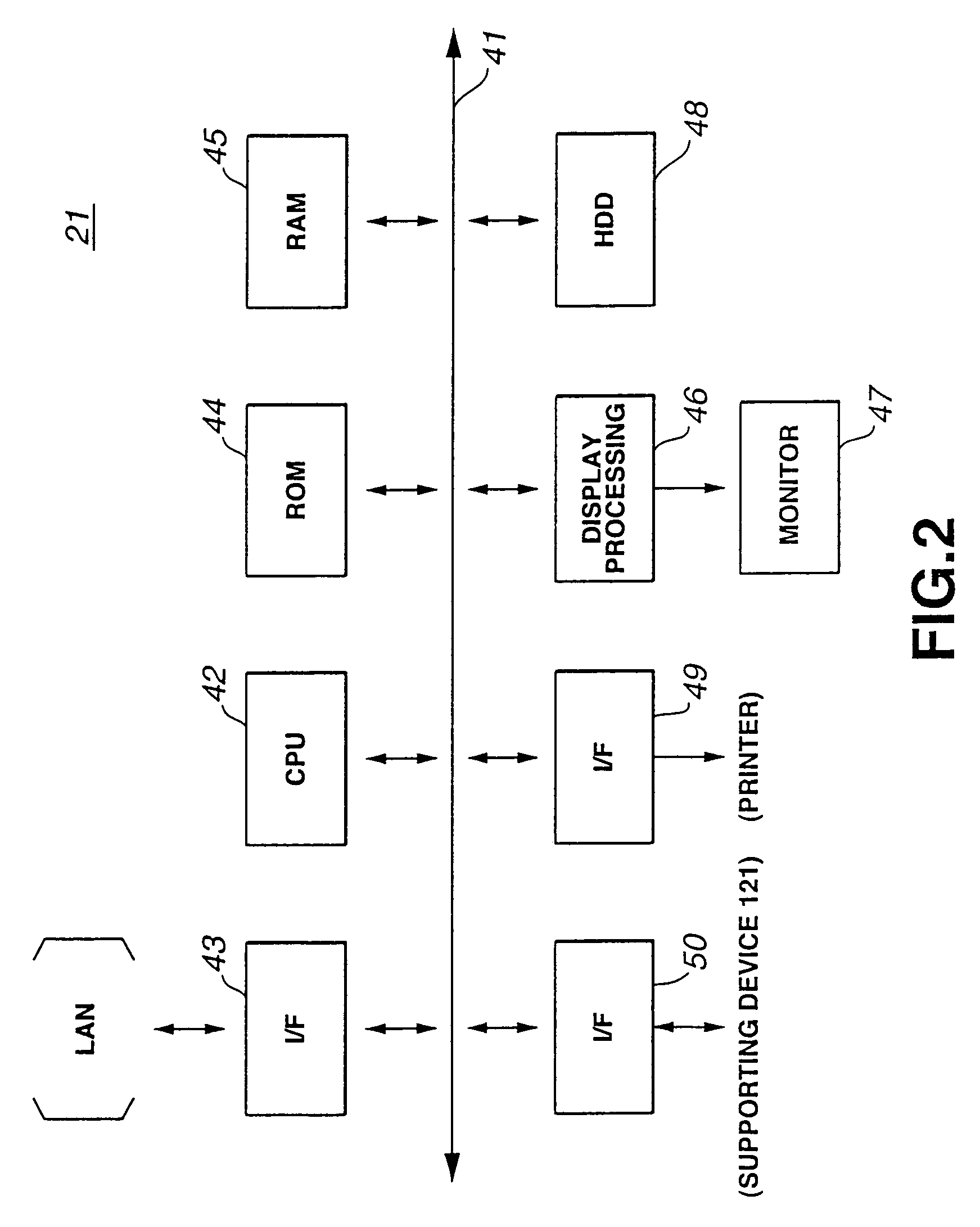

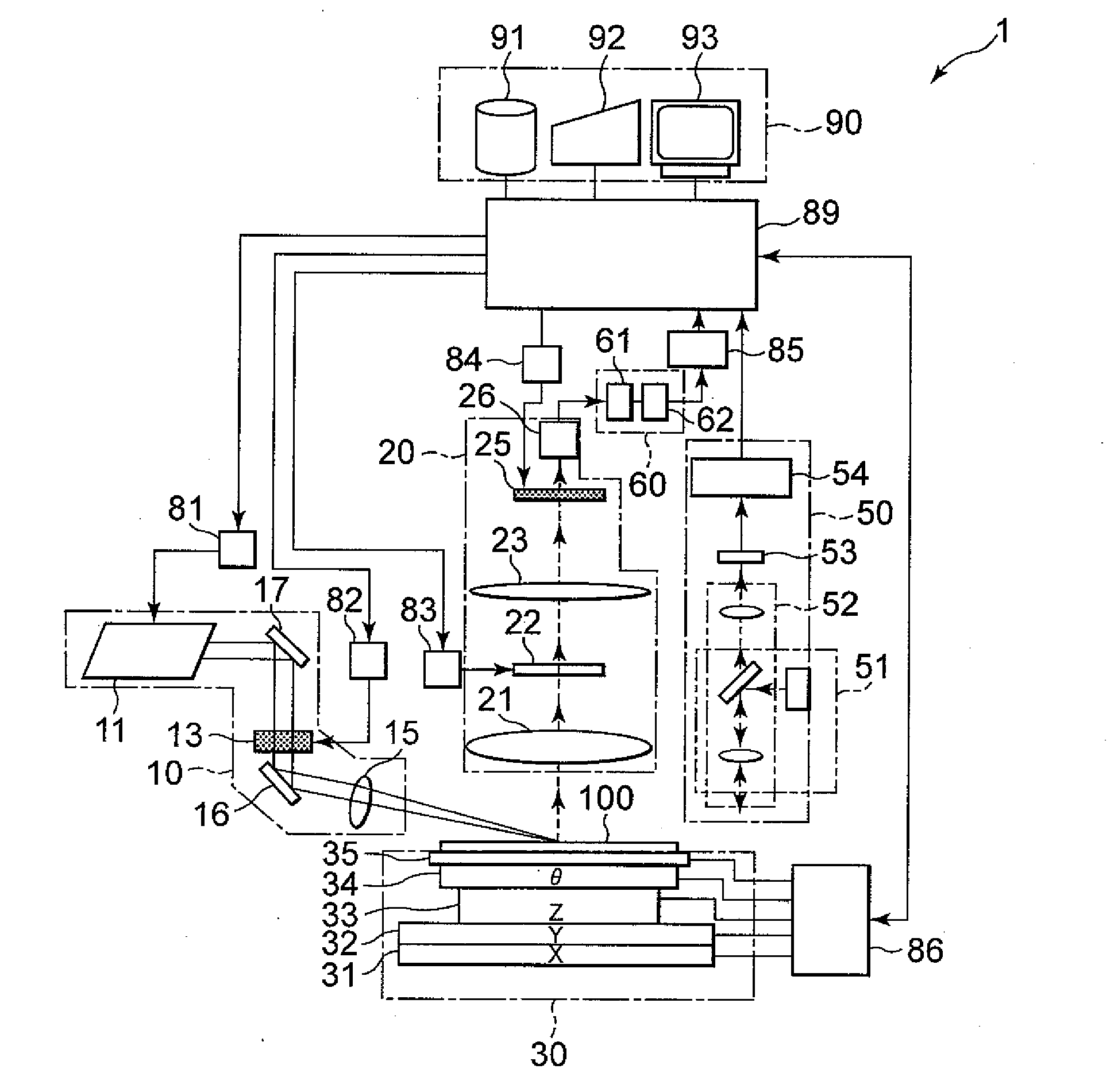

Defect detecting device, defect detecting method, image sensor device, image sensor module, defect detecting program, and computer-readable recording medium

InactiveUS20080205747A1Accurate detectionReduce misjudgmentImage enhancementImage analysisPattern recognitionOutlier

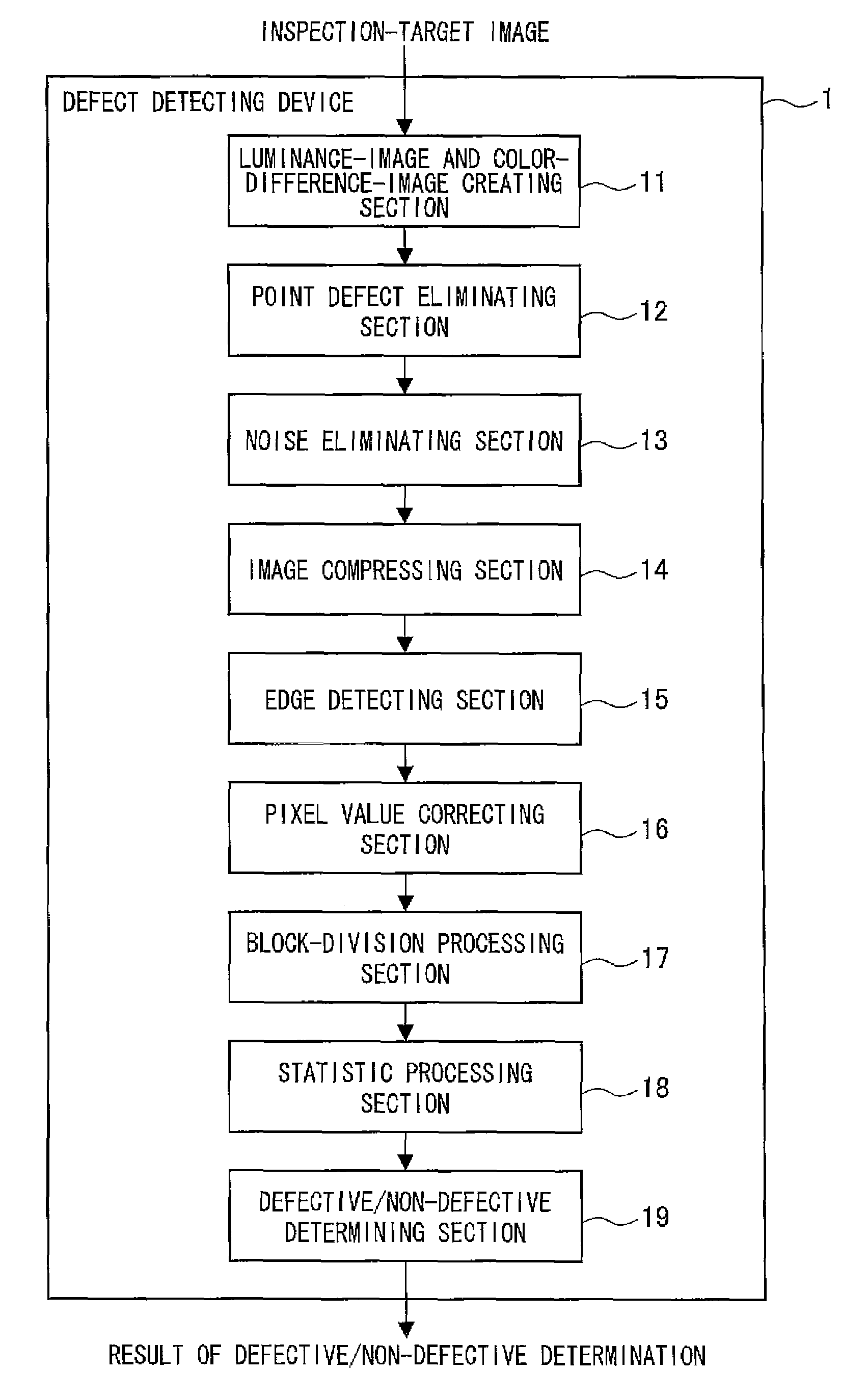

A defect detecting device 1 includes a pixel value correcting section 16, a block-division processing section 17, and a defective / non-defective determining section 19. The pixel value correcting section 16 corrects a pixel value of an inspection-target image, on which detection of a defective area is to be carried out, in such a manner that the defective area of the inspection-target image is emphasized with respect to the other areas of the inspection-target image. The block-division processing section 17 divides, into plural blocks, the inspection-target image with pixel values having been corrected, and obtains a block addition value, which is a value obtained by adding pixel values of pixels present in a block, or a block mean value, which is a value obtained by dividing the block addition value by the number of pixels present in the block. The defective / non-defective determining section 19 determines whether the defective area is present or not, by carrying out statistical processing of a statistic processing section 18 to determine whether an outlier of the block addition value or an outlier of the block mean value is present or not. The foregoing realizes a defect detecting device and a defect detecting method, by which defective areas of image-sensor images are emphasized to enable accurate detection of the defective areas.

Owner:SHARP KK

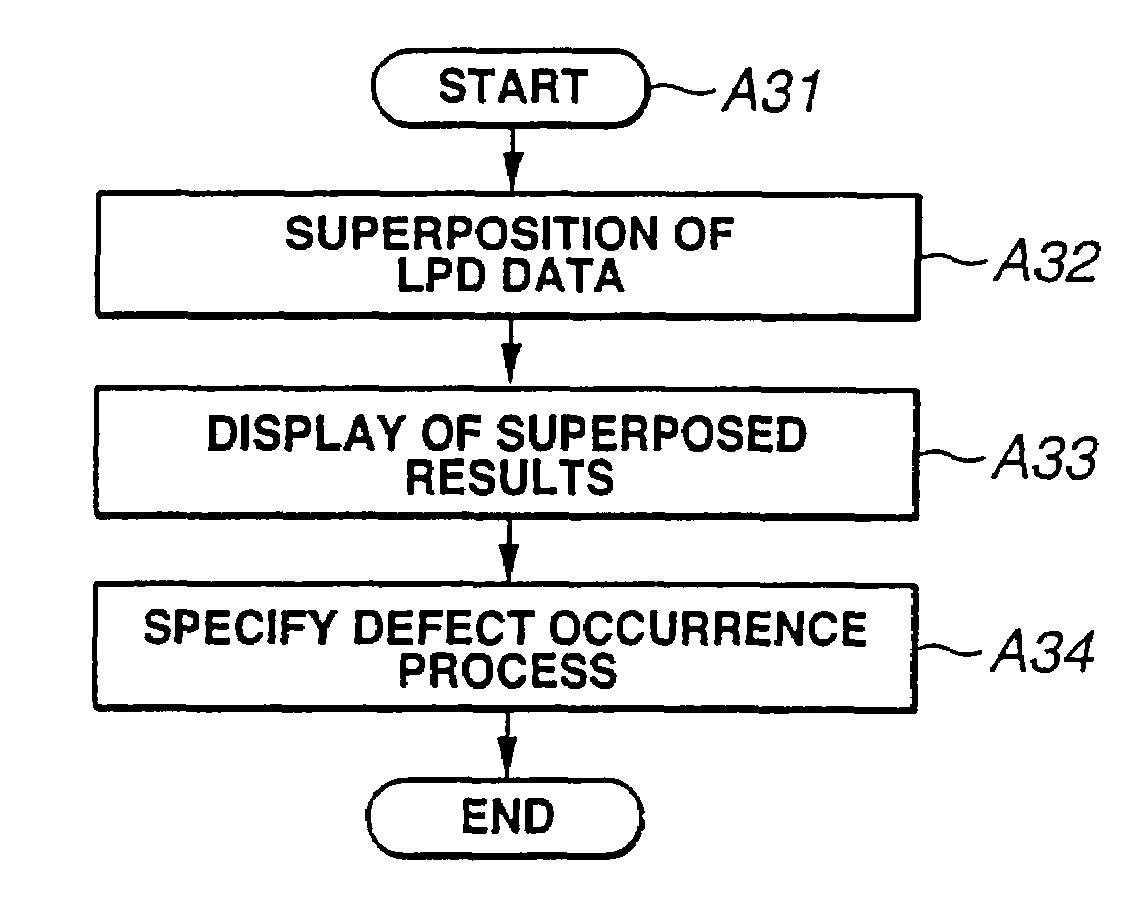

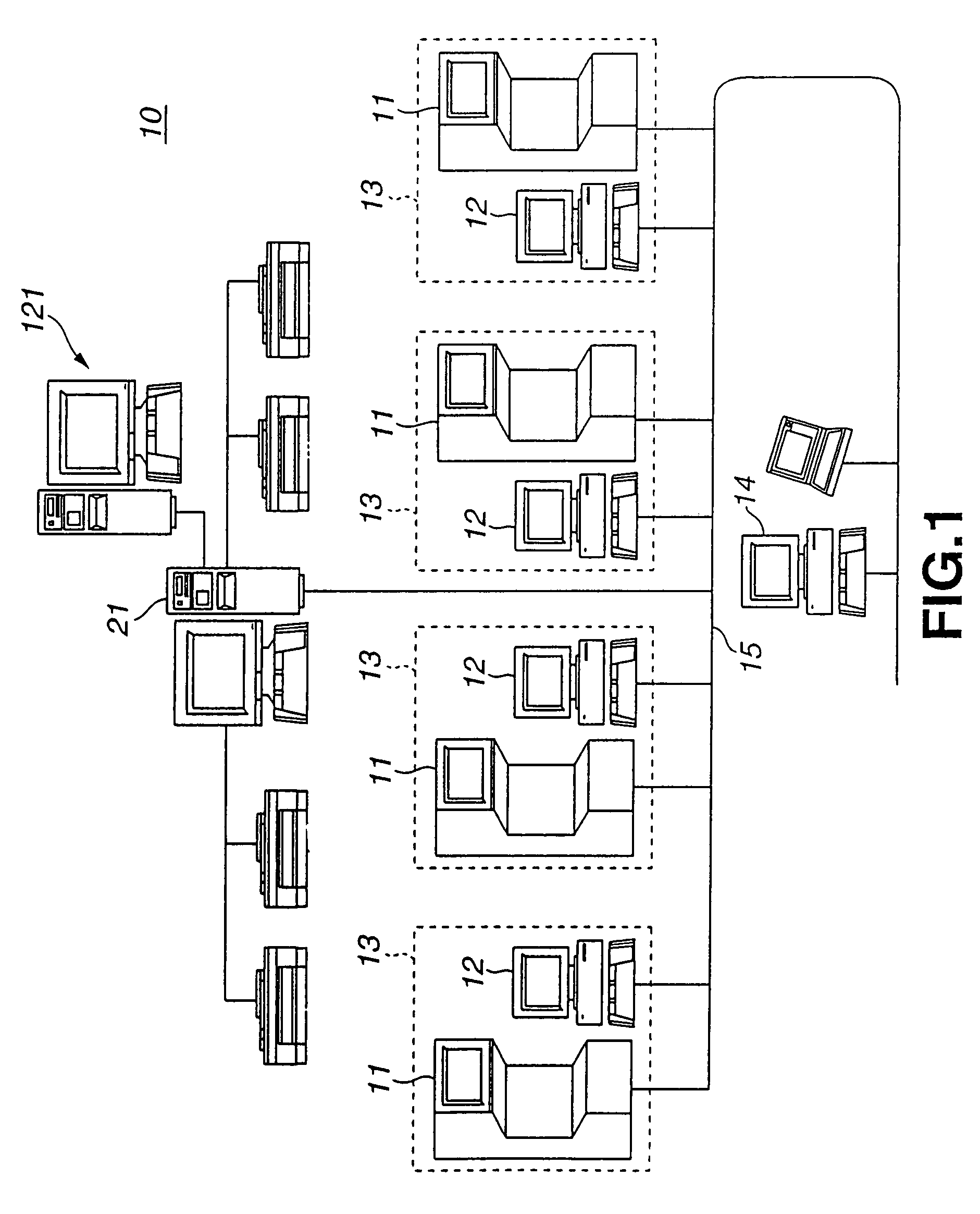

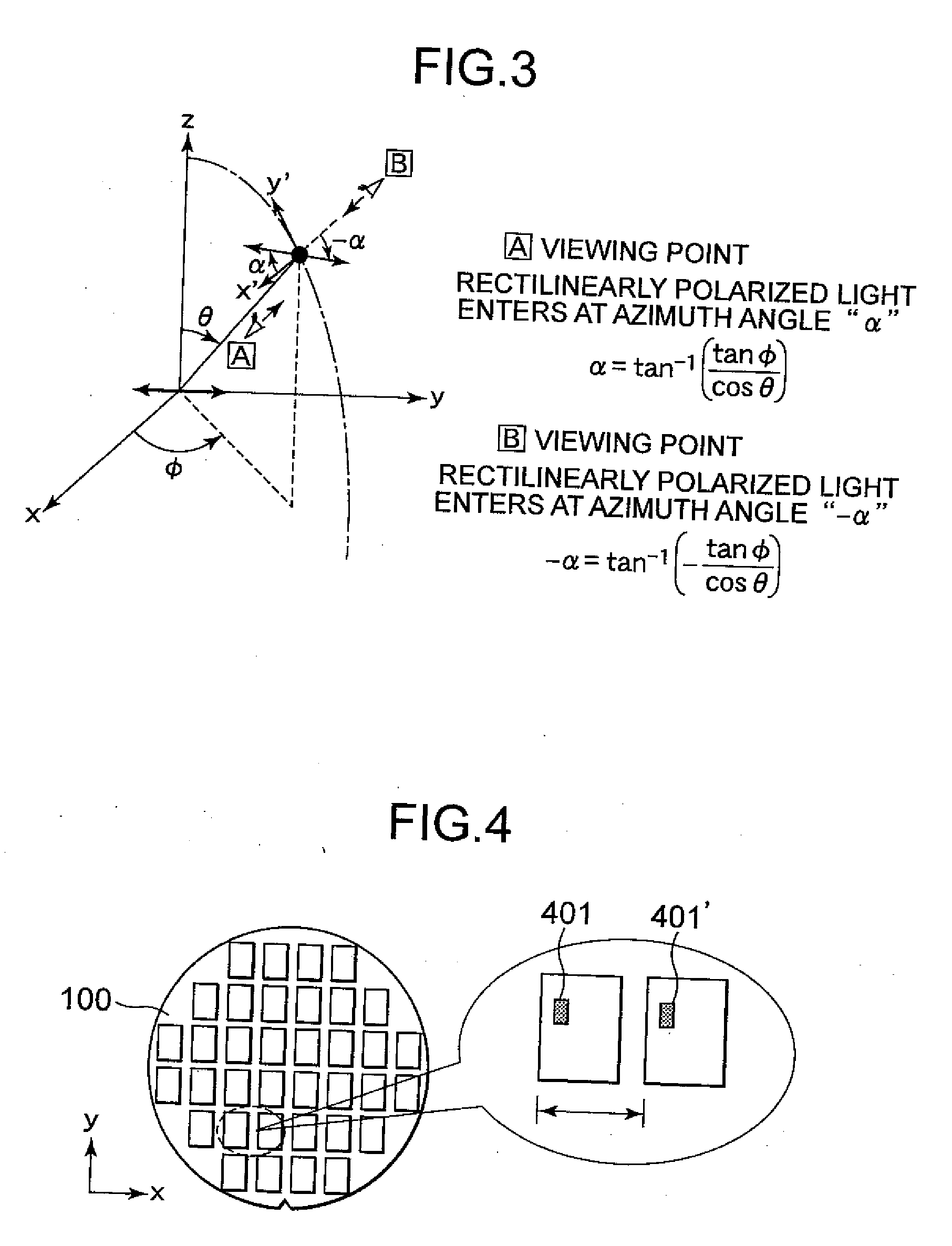

Apparatus for inspecting wafer surface, method for inspecting wafer surface, apparatus for judging defective wafer, method for judging defective wafer, and apparatus for processing information on wafer surface

InactiveUS7383156B2Accurate defect detectionEasy to detectSemiconductor/solid-state device testing/measurementNuclear monitoringPhysicsScratch marks

It is possible to inspect scratches and staining on a wafer surface on the basis of an LPD map obtained from a particle counter 11, by providing a means 21 for detecting aggregation of clustered point defects (LPD) from two-dimensional distribution information 30 for such fine LPD on the surface of a silicon wafer, and an improvement in the inspection efficiency and the precision of judgements of “defective” status can be achieved. Furthermore, the system is devised so that the trend of generation of scratches and staining in a specified process can easily be detected by accumulating wafer surface information such as scratch information, staining information and the like for the wafer surface detected by a wafer surface inspection device 11 (especially as image information or numerical information), and superposing sets of information thus accumulated. Plans for improving processes can be made by both the wafer supplier and wafer consumer by sharing such information with both parties.

Owner:SUMCO TECHXIV

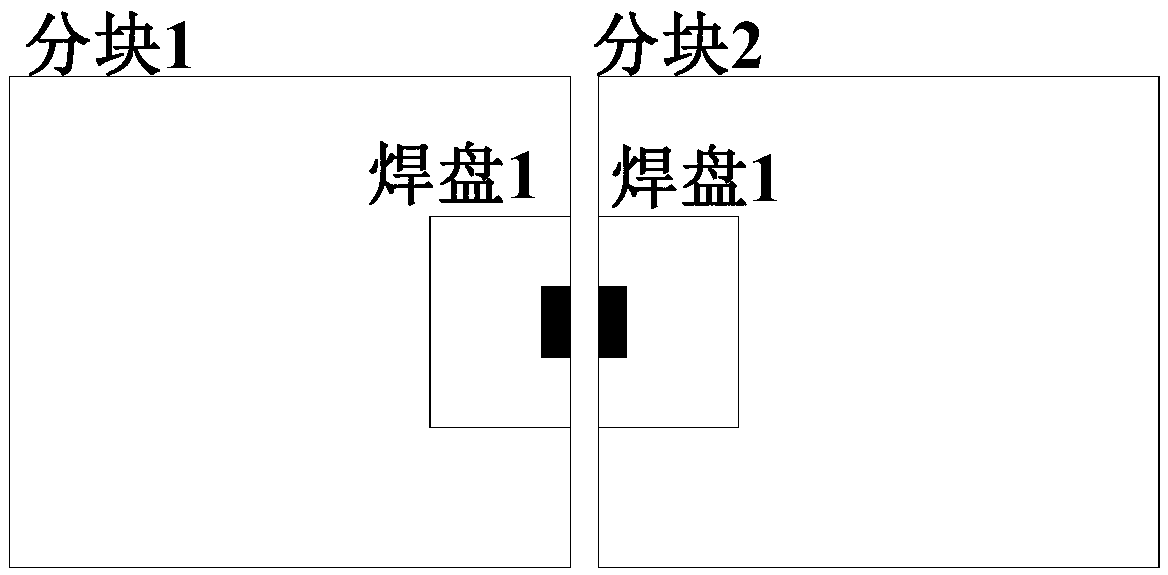

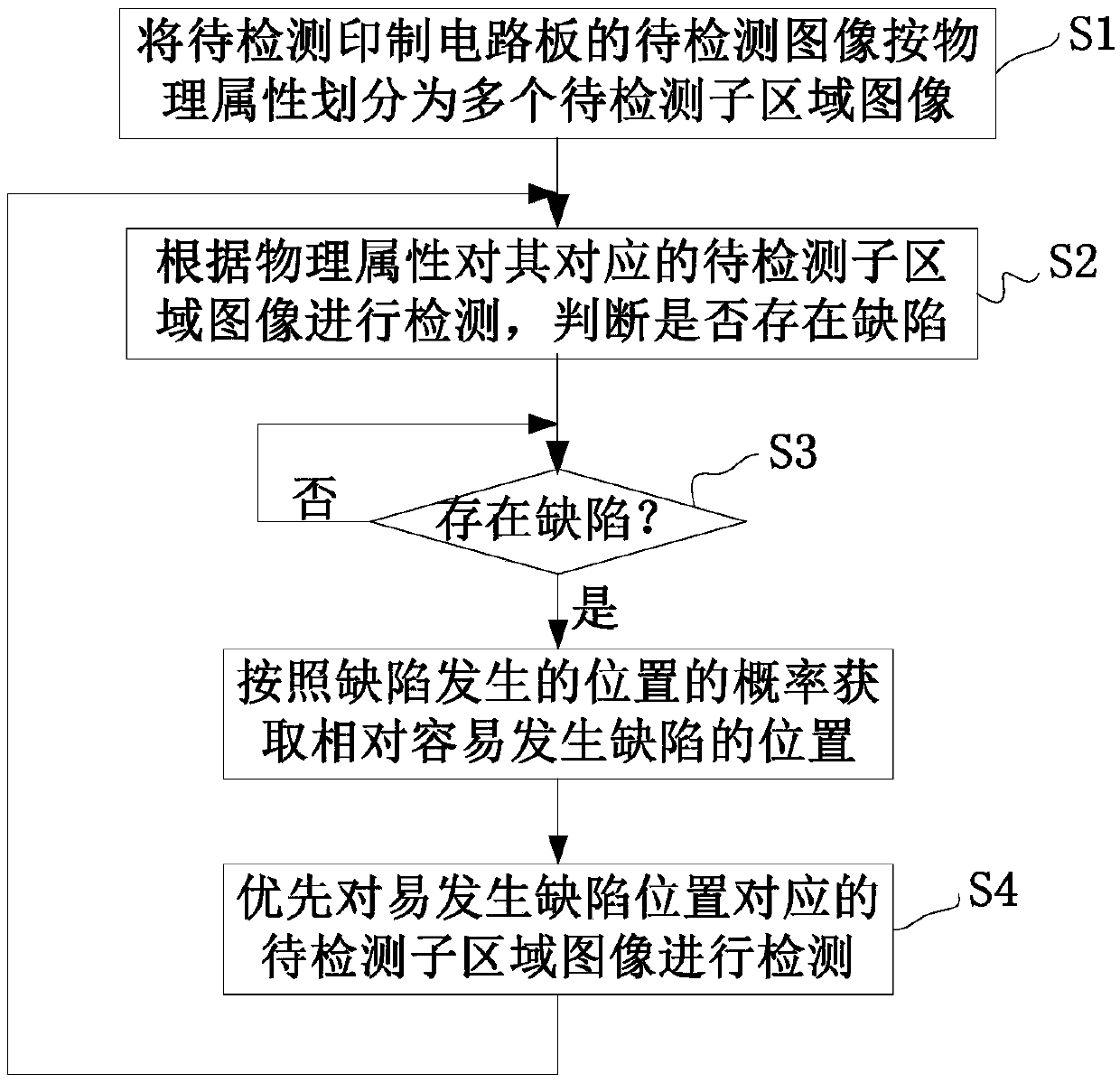

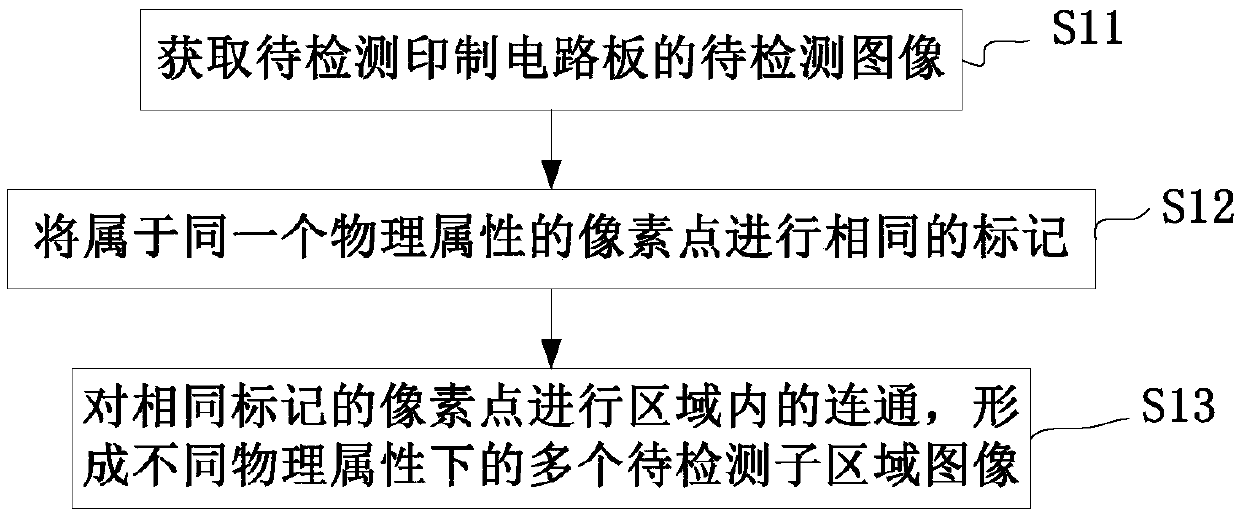

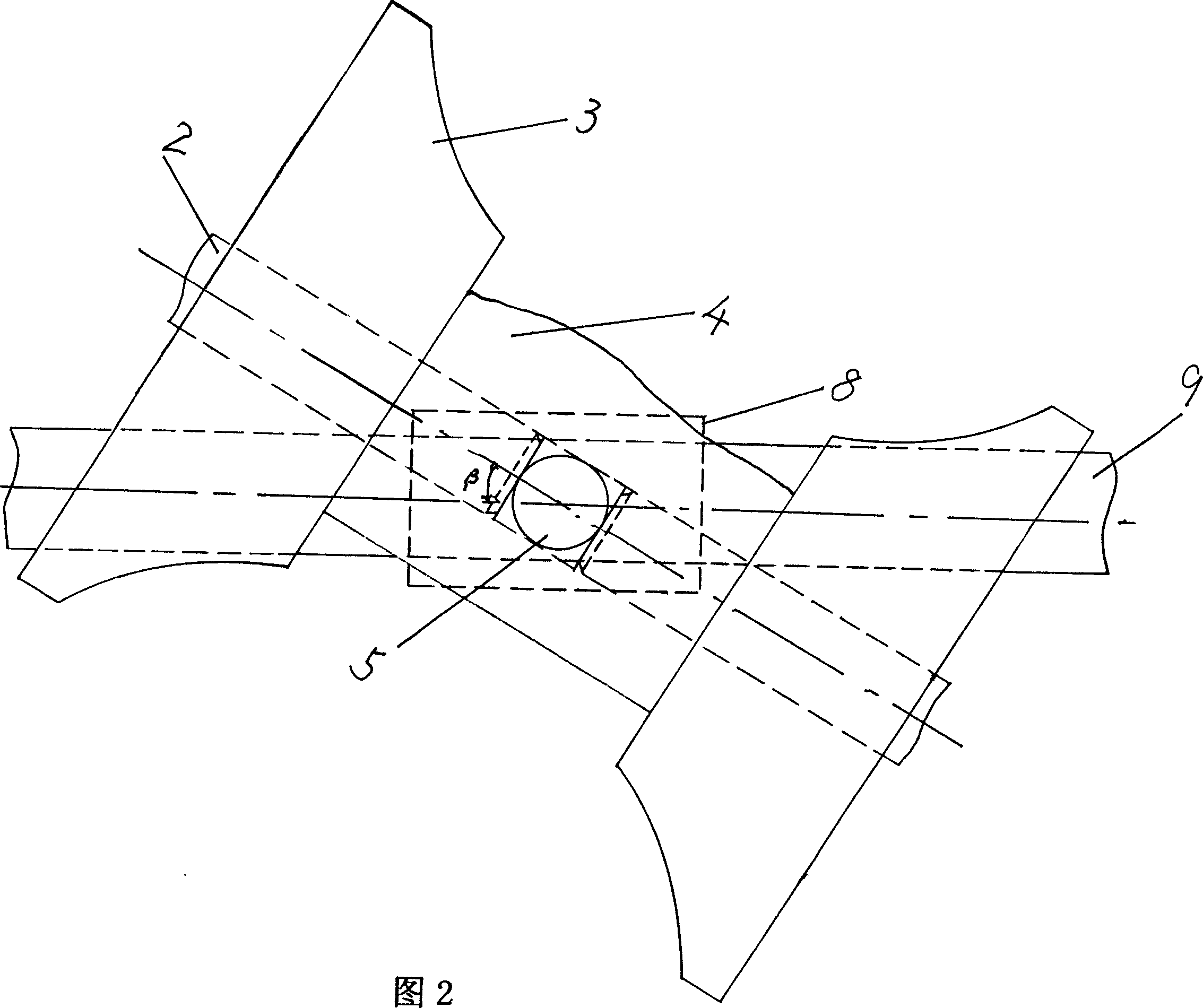

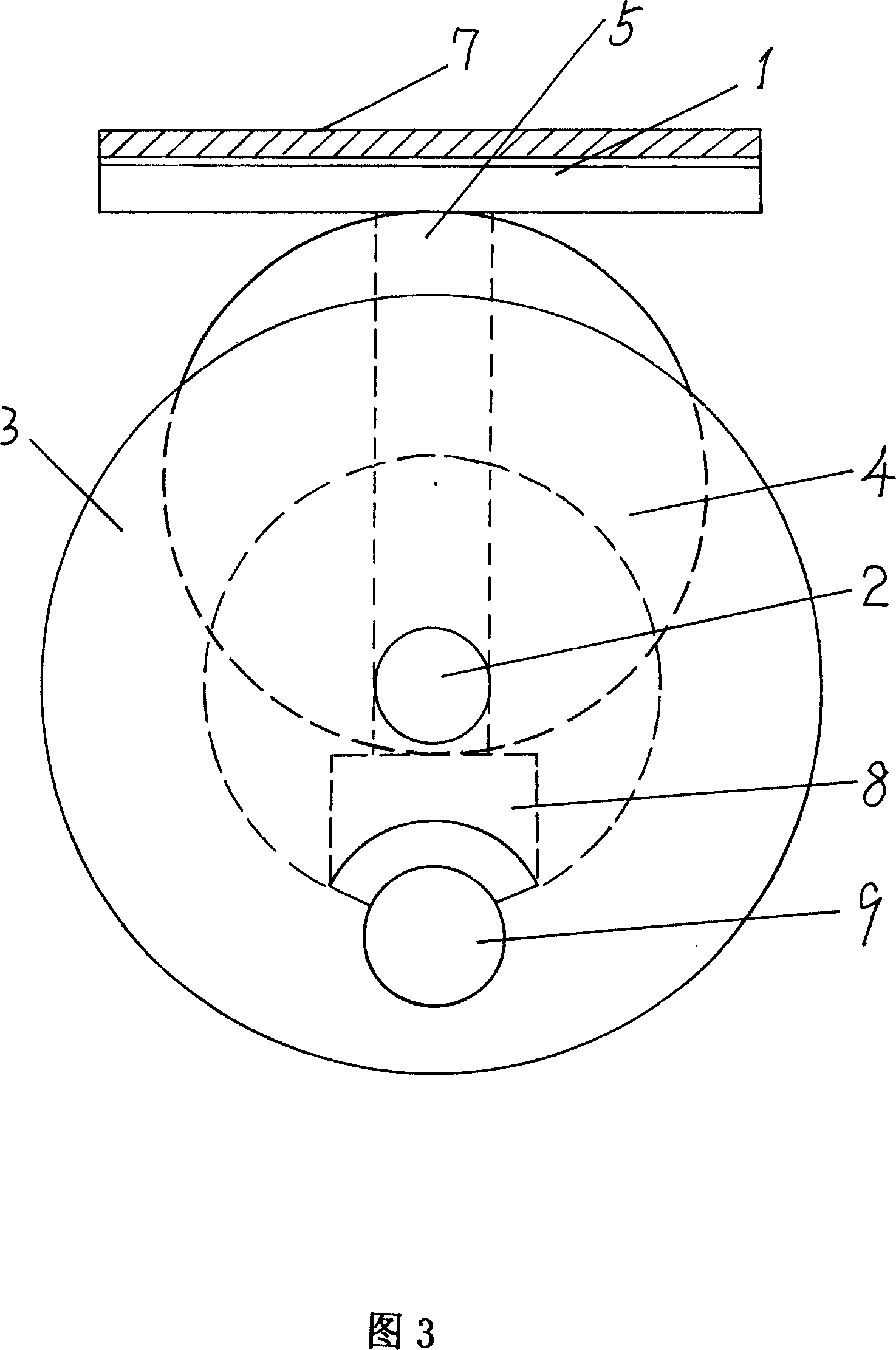

Flaw detection method and device of printed circuit board and detection equipment

InactiveCN105510348AAccurate Defect DetectionGuaranteed uniformityOptically investigating flaws/contaminationEdge effectsPrinted circuit board

The invention provides a flaw detection method and device of a printed circuit board and detection equipment. The flaw detection method of the printed circuit board comprises the following steps: dividing an image to be detected of a printed circuit board to be detected into a plurality of sub-region images to be detected according to physical properties; detecting the sub-region images to be detected corresponding to the physical properties according to the physical properties; and judging whether the printed circuit board to be detected has flaws or not. By dividing the image to be detected of the printed circuit board to be detected into the plurality of sub-region images to be detected according to the physical properties, the images corresponding to the same physical property in the printed circuit board to be detected can be located in the same sub-region image to be detected and a phenomenon that the images are divided into the two different sub-region images to be detected to cause leaked detection by a partitioning edge effect is avoided, so that the flaw detection is relatively accurate.

Owner:JOINT STARS TECH

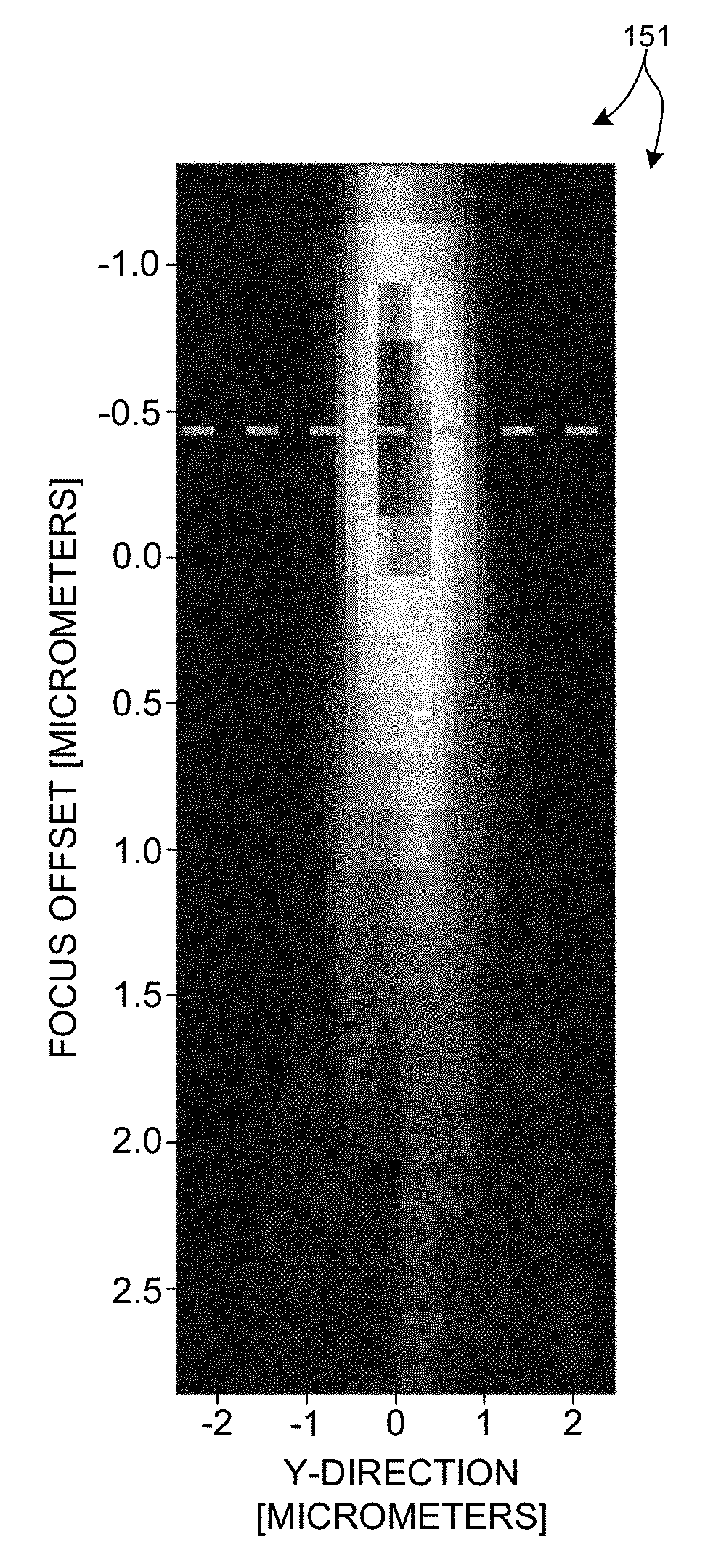

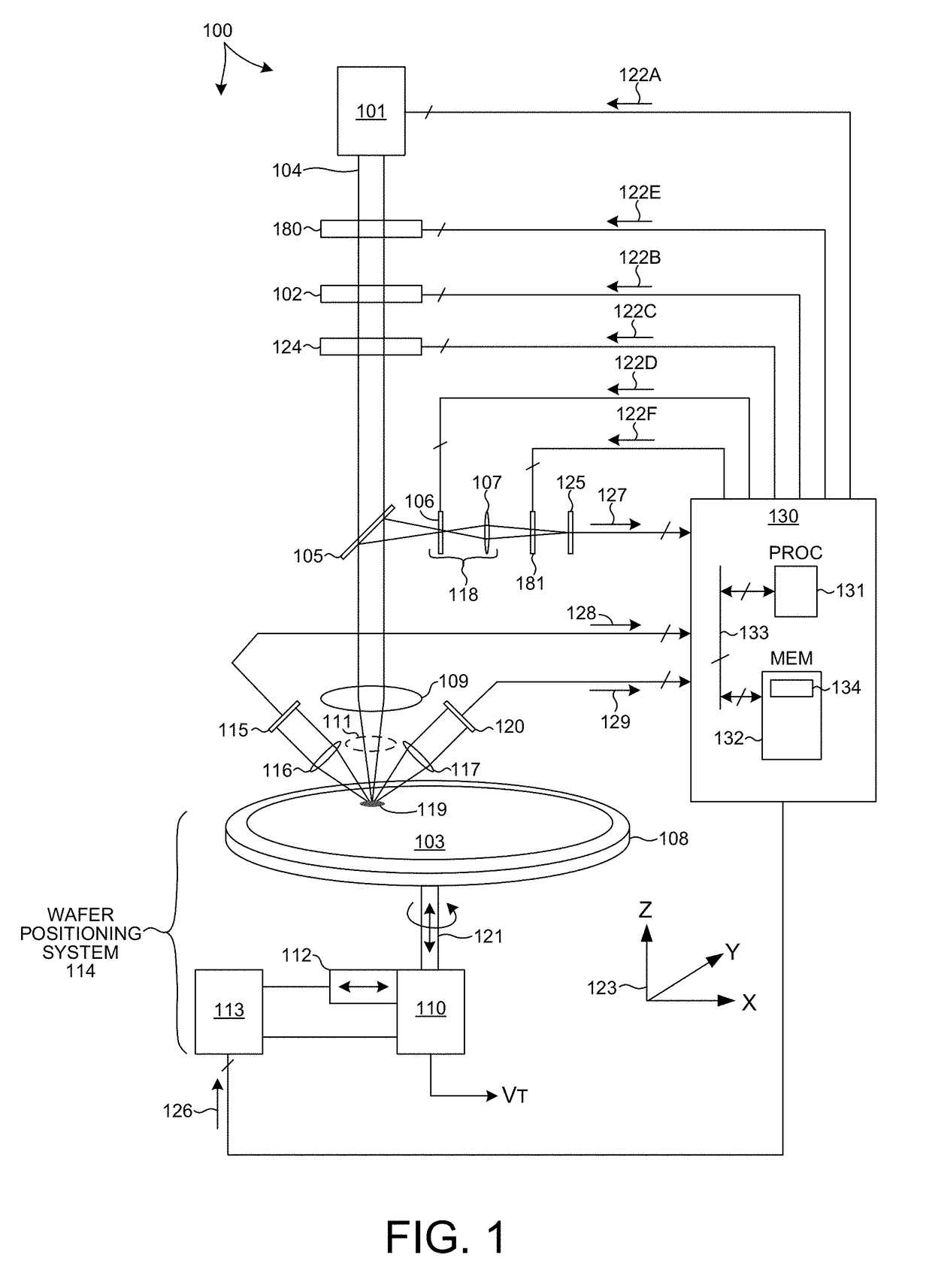

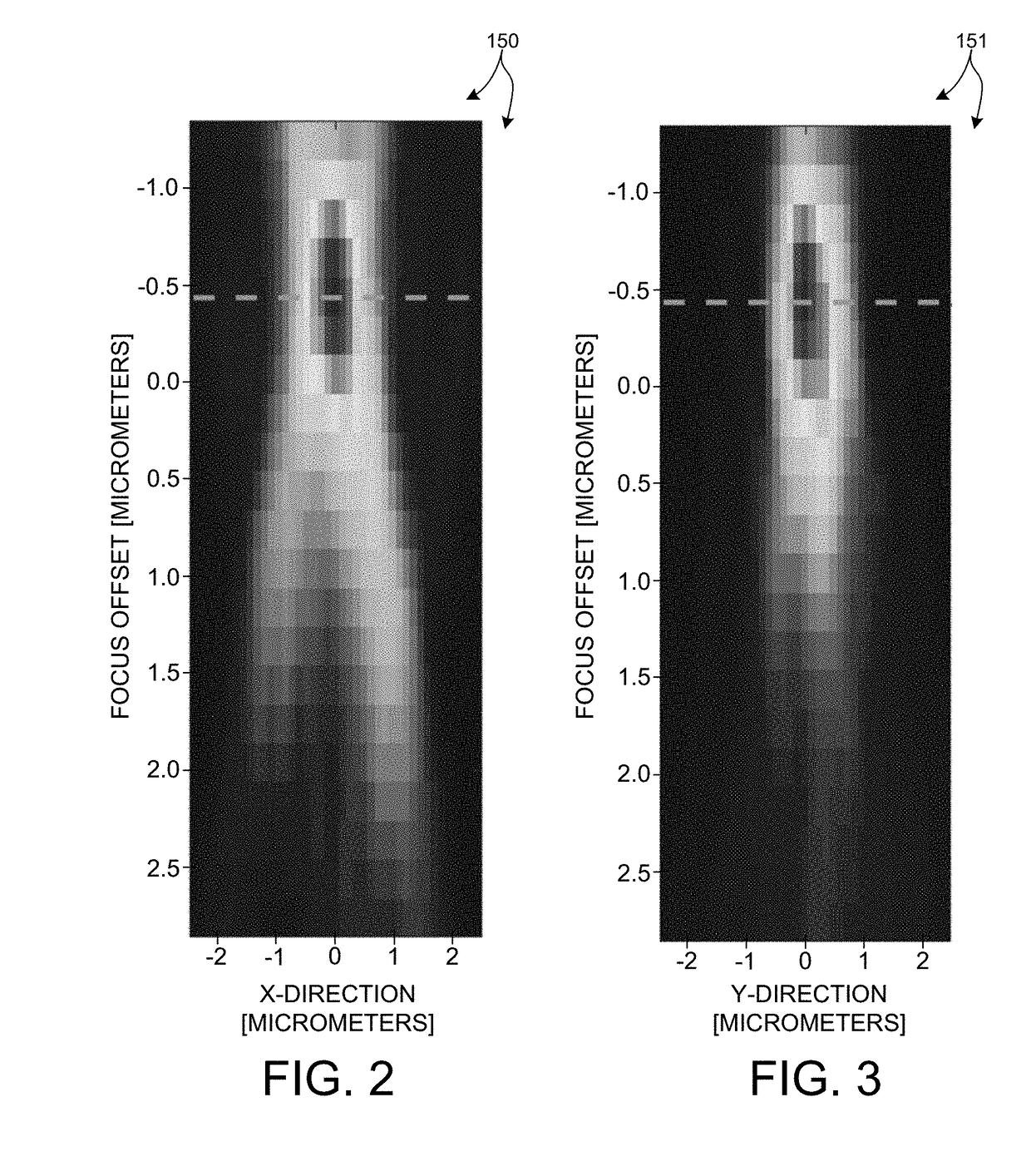

Three-Dimensional Imaging For Semiconductor Wafer Inspection

ActiveUS20180103247A1Easy to detectAccurate Defect DetectionImage enhancementImage analysisSemiconductor structureDimensional modeling

Methods and systems for improved detection and classification of defects of interest (DOI) on semiconductor wafers based on three-dimensional images are described herein. Three dimensional imaging of volumes of thick, layered structures enables accurate defect detection and estimation of defect location in three dimensions at high throughput. A series of images are acquired at a number of different wafer depths. A three dimensional image of a thick semiconductor structure is generated from the series of images. Defects are identified and classified based on an analysis of the three dimensional image of the thick semiconductor structure. In some examples, the three-dimensional image stack is visualized by contour plots or cross-sectional plots to identify a characteristic defect response. In some examples, the three-dimensional image is processed algorithmically to identify and classify defects. In another aspect, the location of a defect is estimated in three dimensions based on the three dimensional image.

Owner:KLA CORP

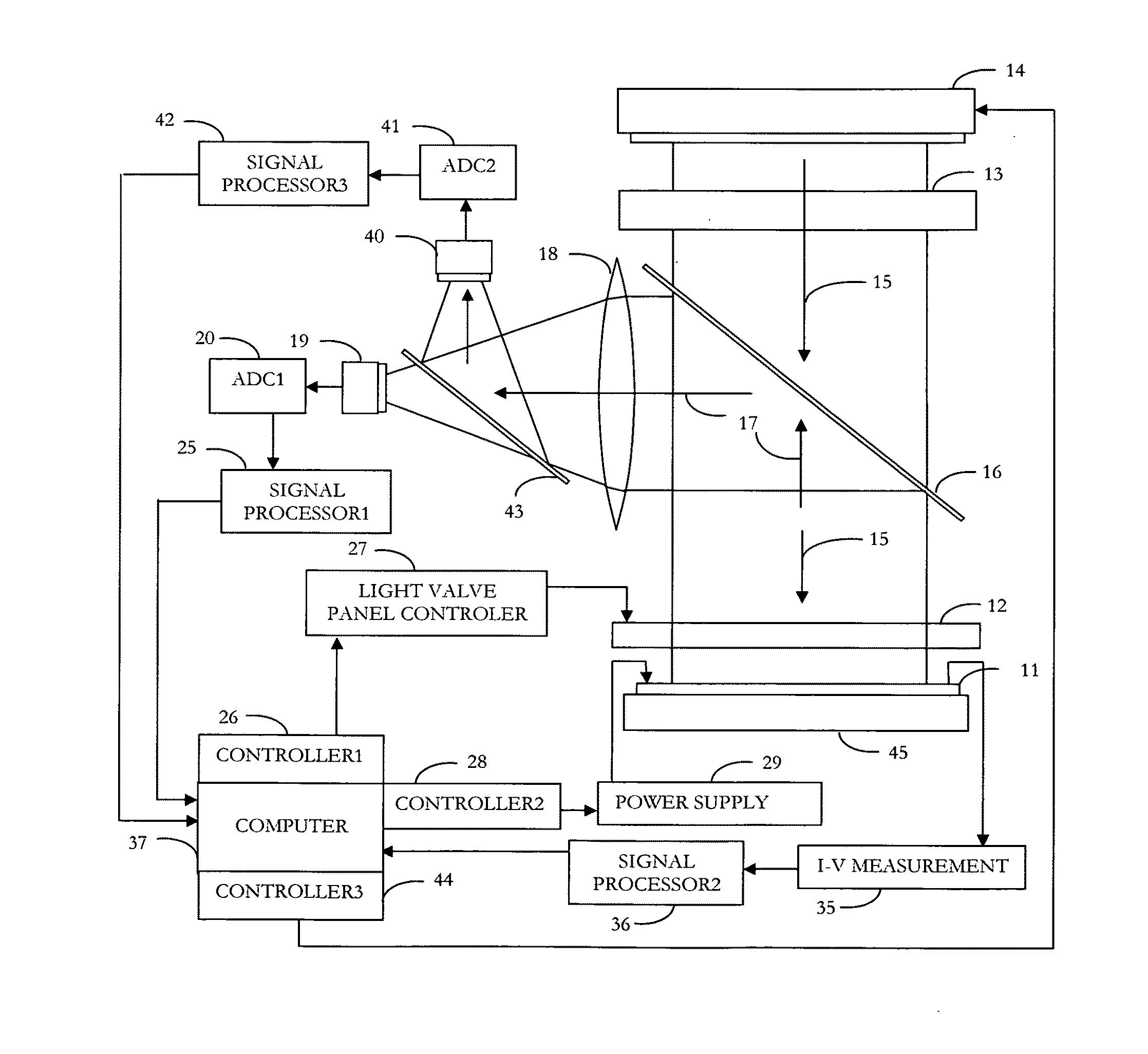

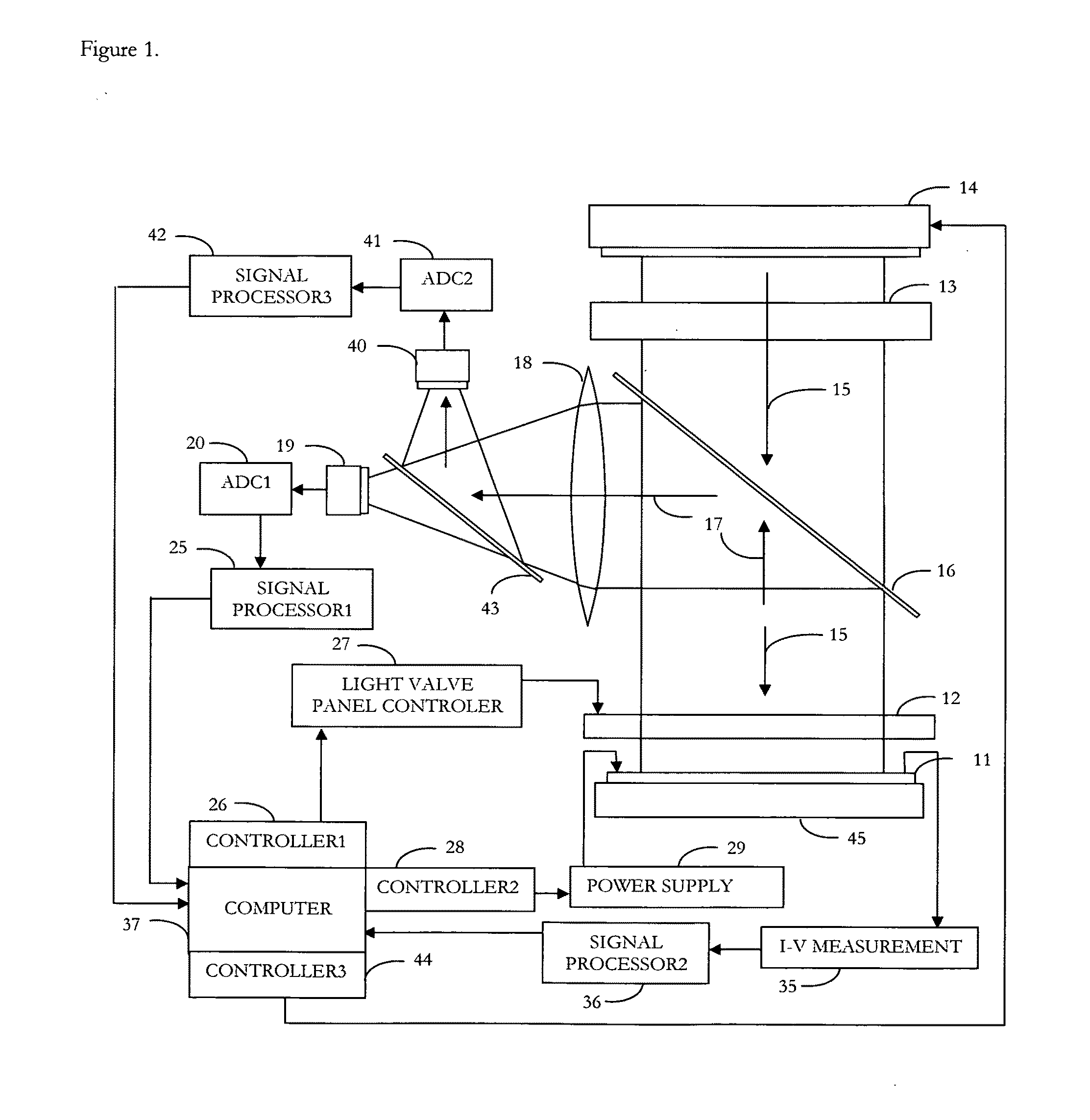

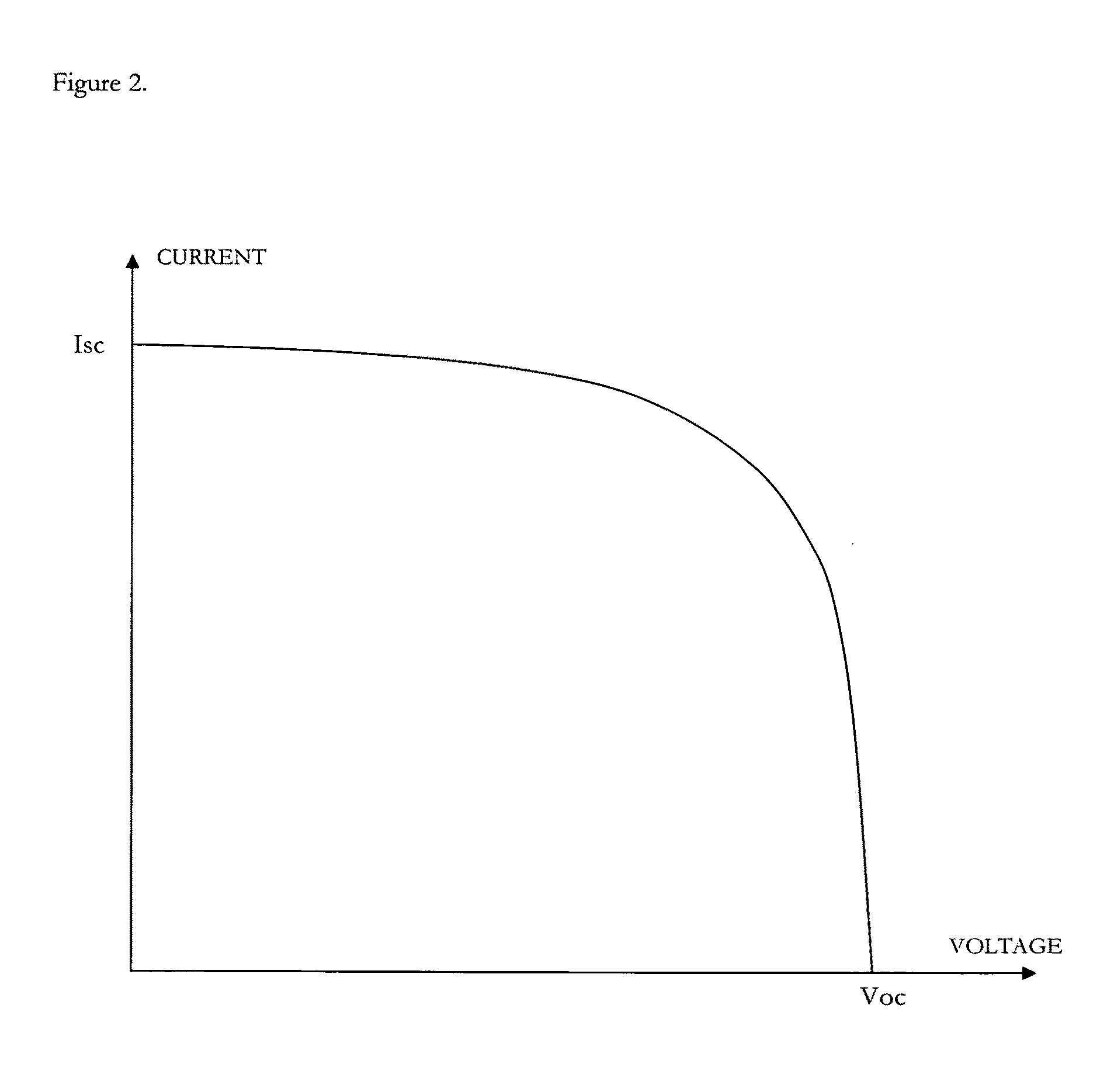

System and method for characterizing solar cell conversion performance and detecting defects in a solar cell

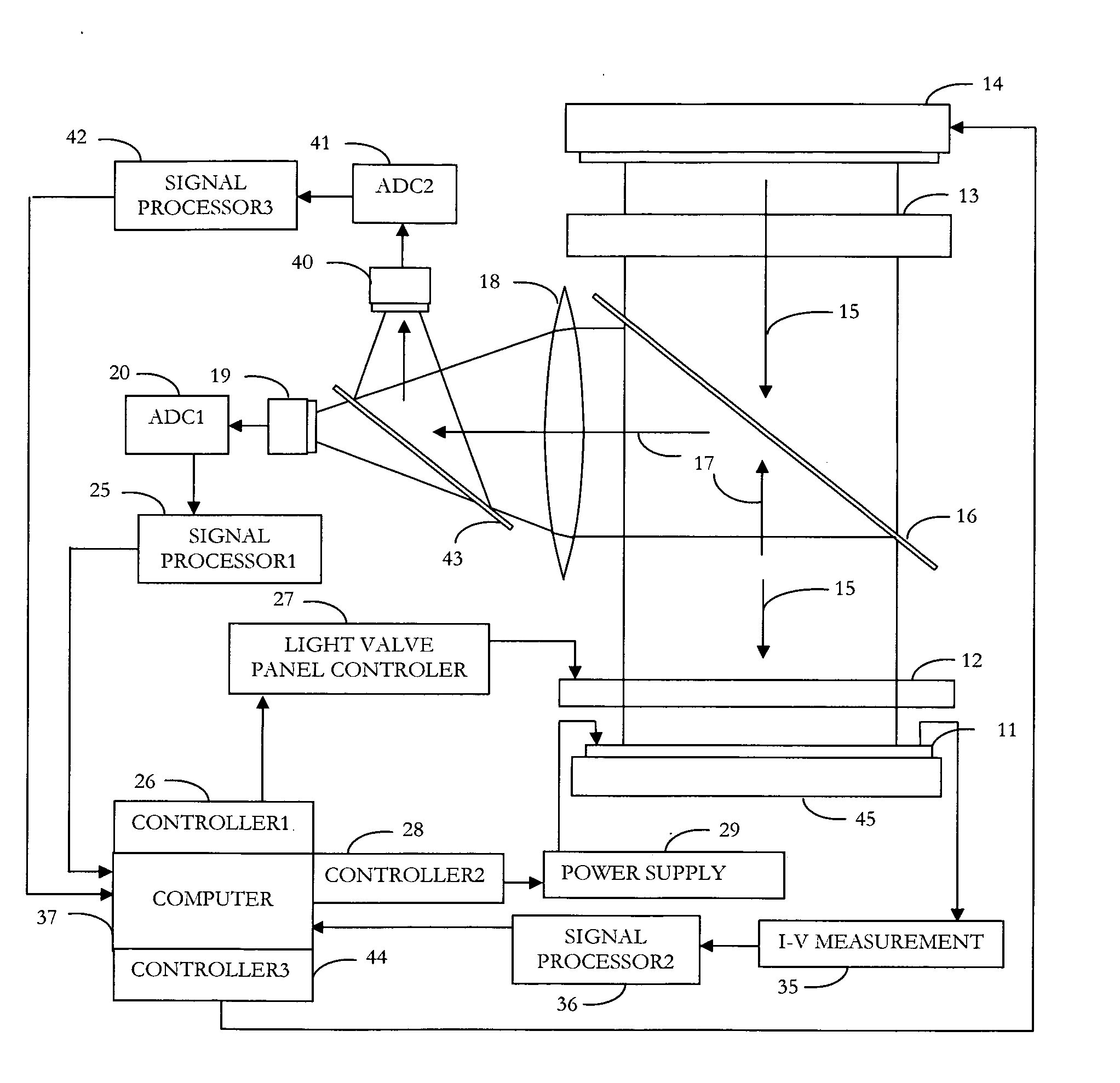

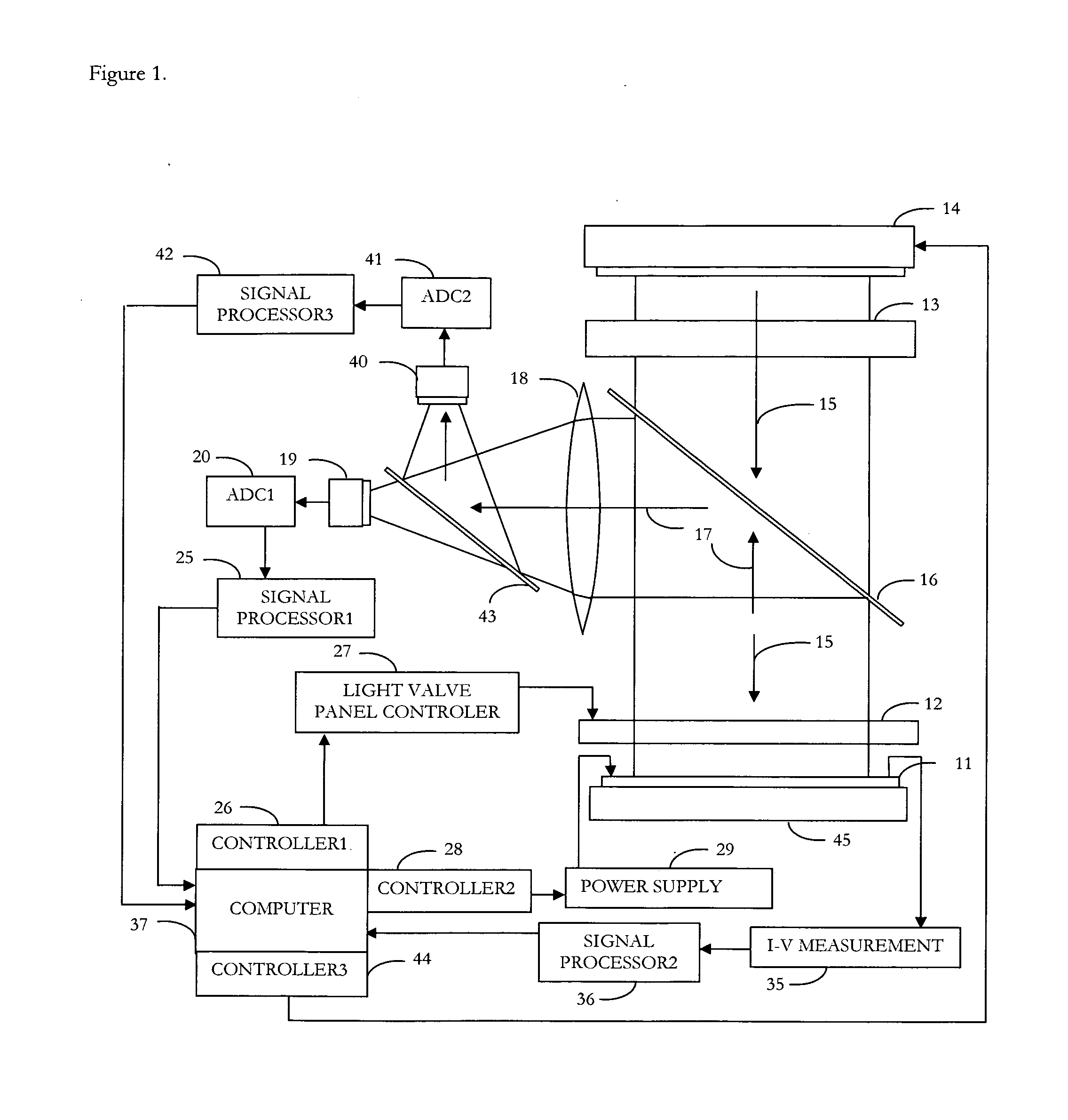

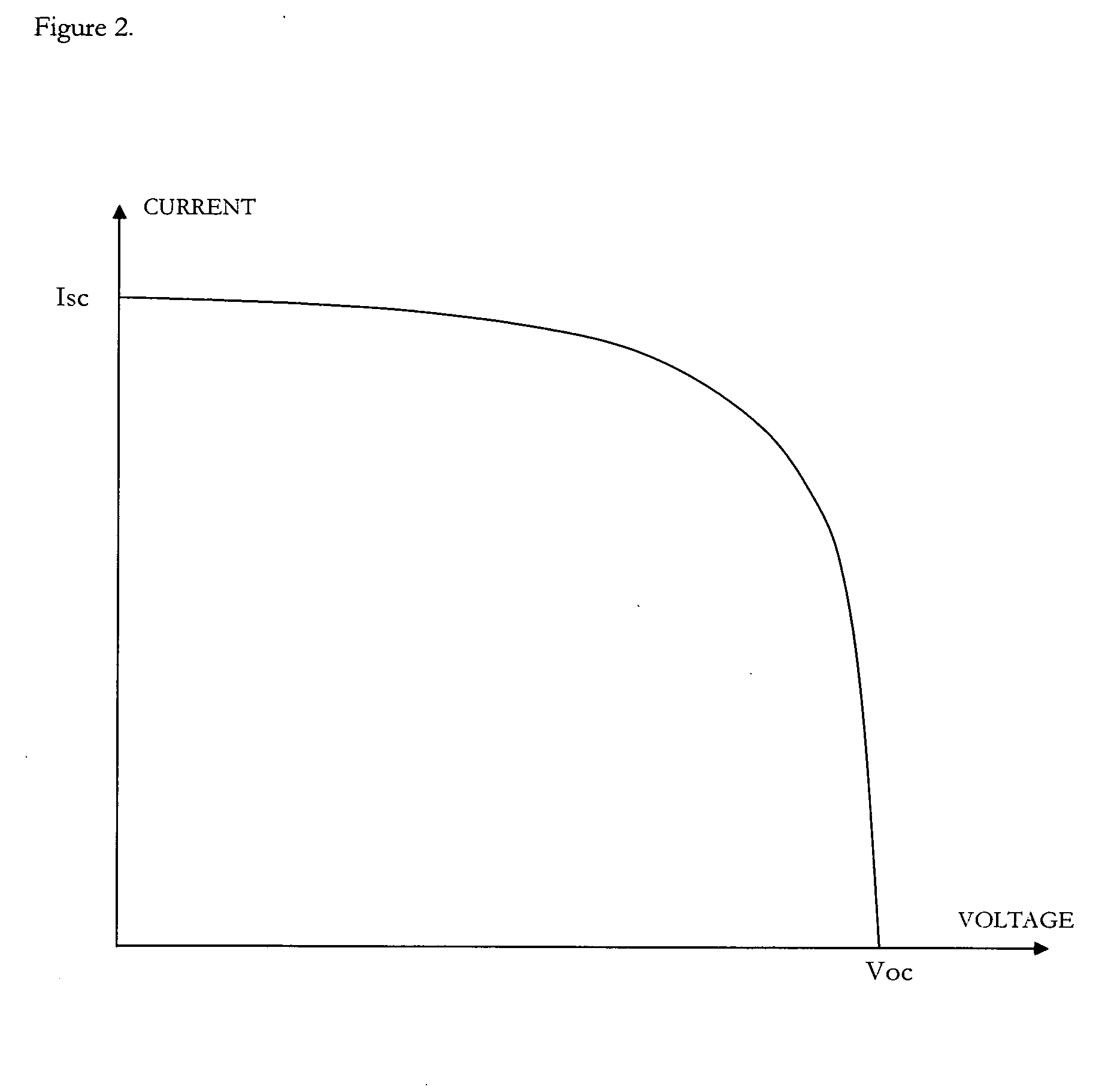

InactiveUS20100237895A1Ensure high efficiency and accuracyAccurate defect detectionPhotovoltaic monitoringPhotometryActive-matrix liquid-crystal displayLiquid-crystal display

A system and method for characterizing the solar cell conversion performance and detecting a defect in a solar cell includes applying an optical test signal to the solar cell using the multiple-scanning method, measuring the solar cell photocurrent in response to the solar cell illumination by the multiple-scanning method, and detecting a defect and finding its location based on the characteristic mapping of solar cell photocurrent, which is obtained by the multiple-scanning method through the divisional control of light transmittance by the LVP (light valve panel). The defect may be a solar cell subsection which has abnormally low photocurrent below a critical value and can be caused by a short between the emitter and the base of solar cell. The LVP may be realized in any one of a variety of ways. For example, the LVP may be a flat-panel display such as AMLCD (Active-Matrix Liquid Crystal Display) and AMOLED (Active-Matrix Organic Light Emitting Diode).

Owner:YIELDBOOST TECH

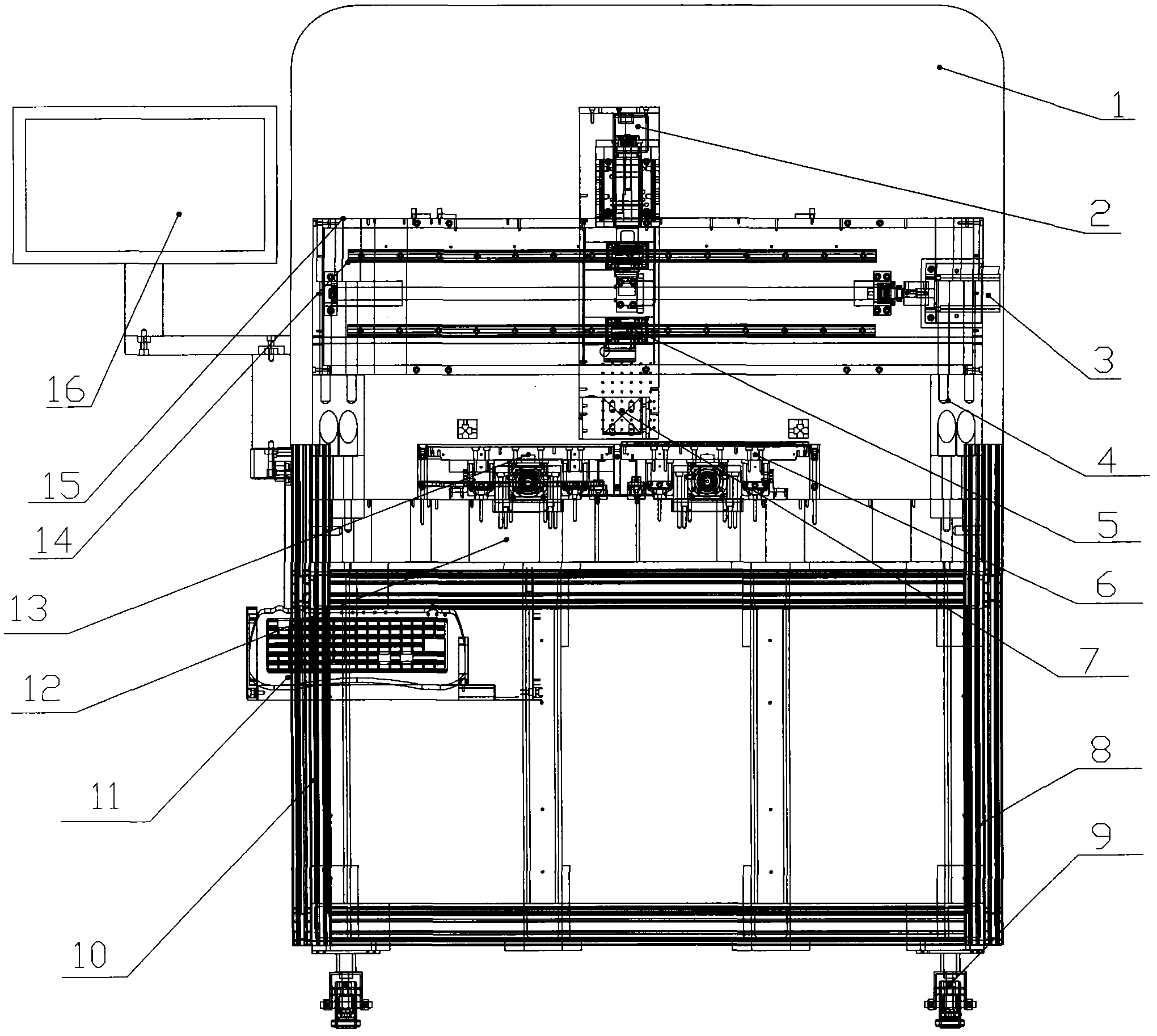

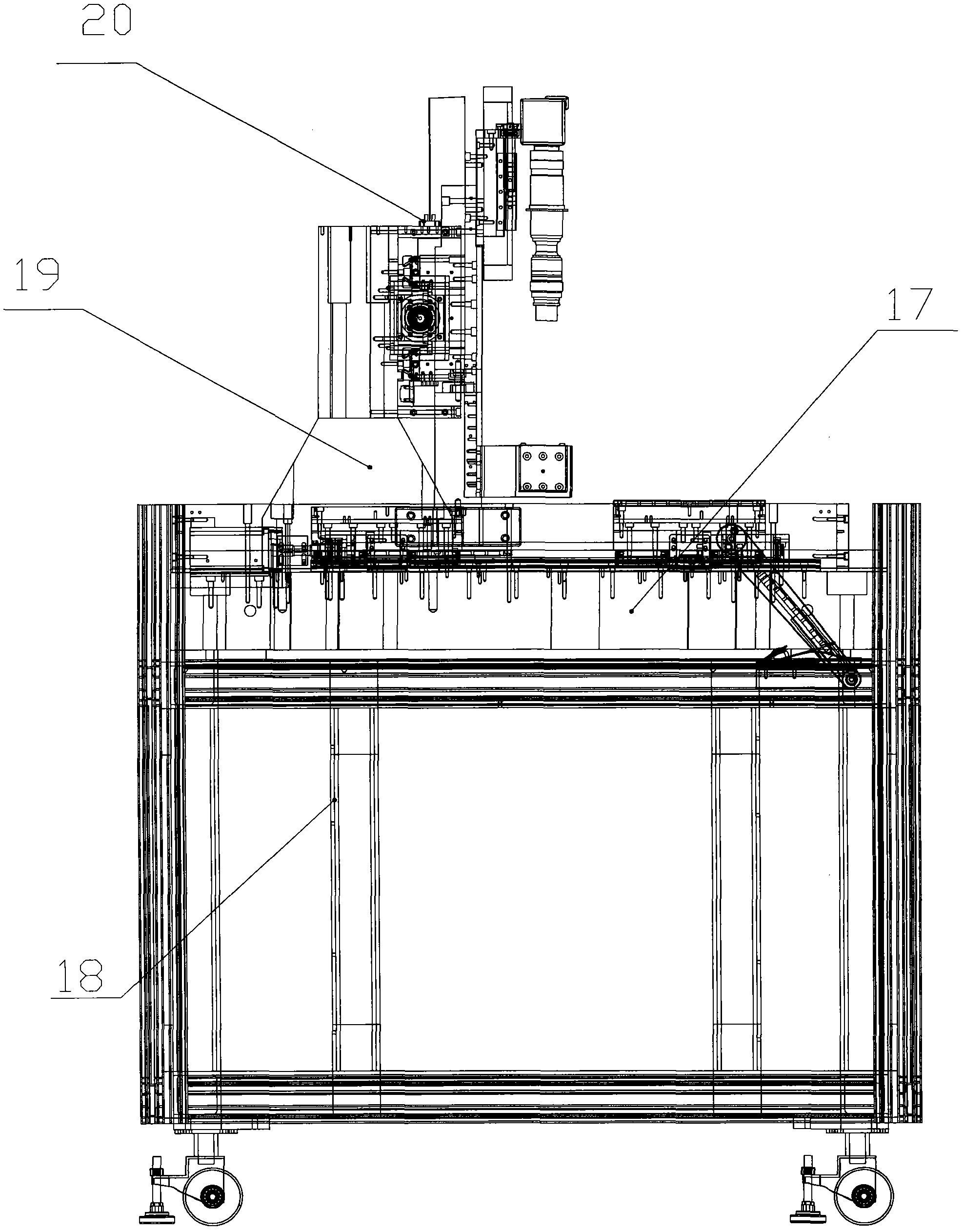

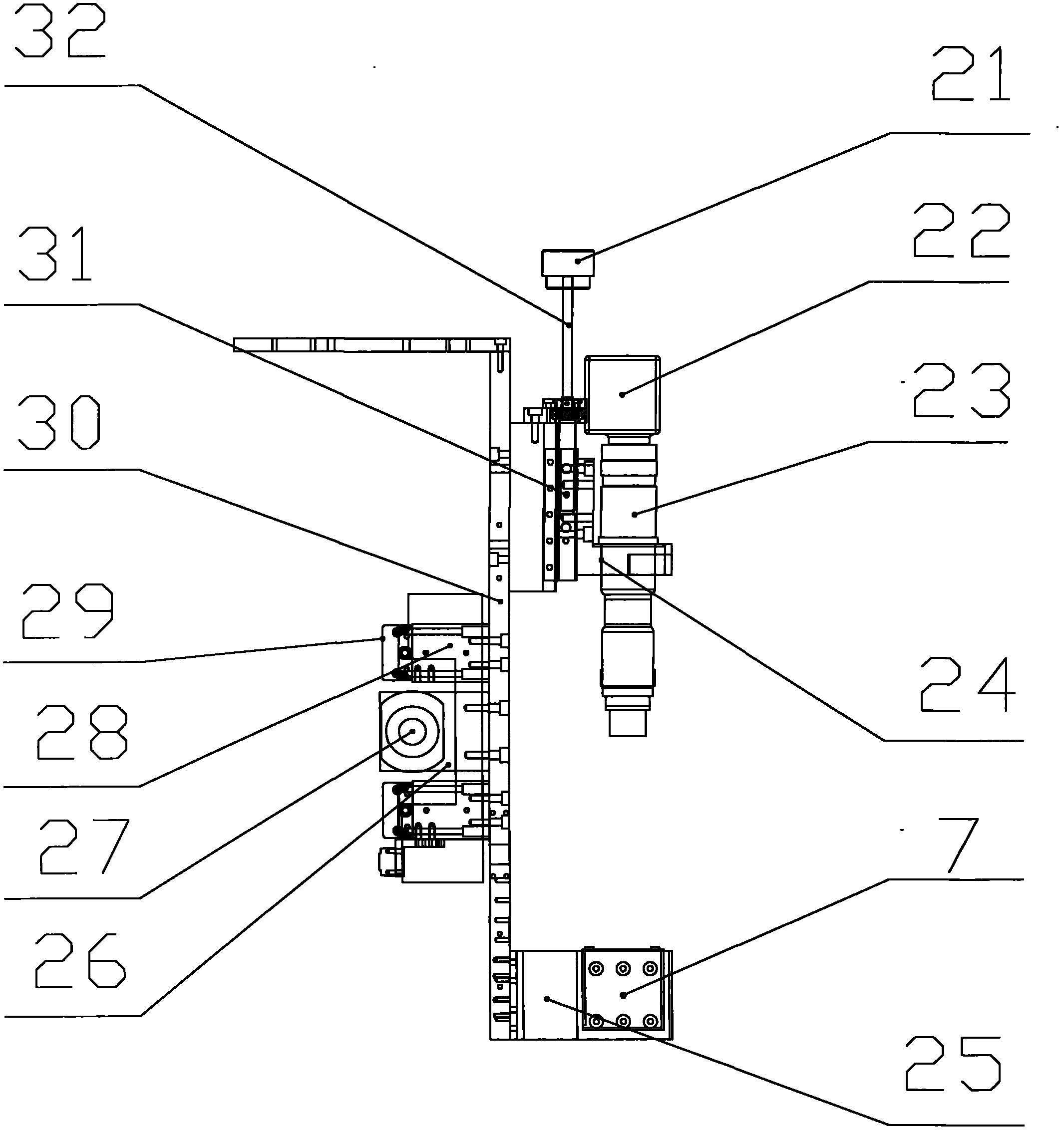

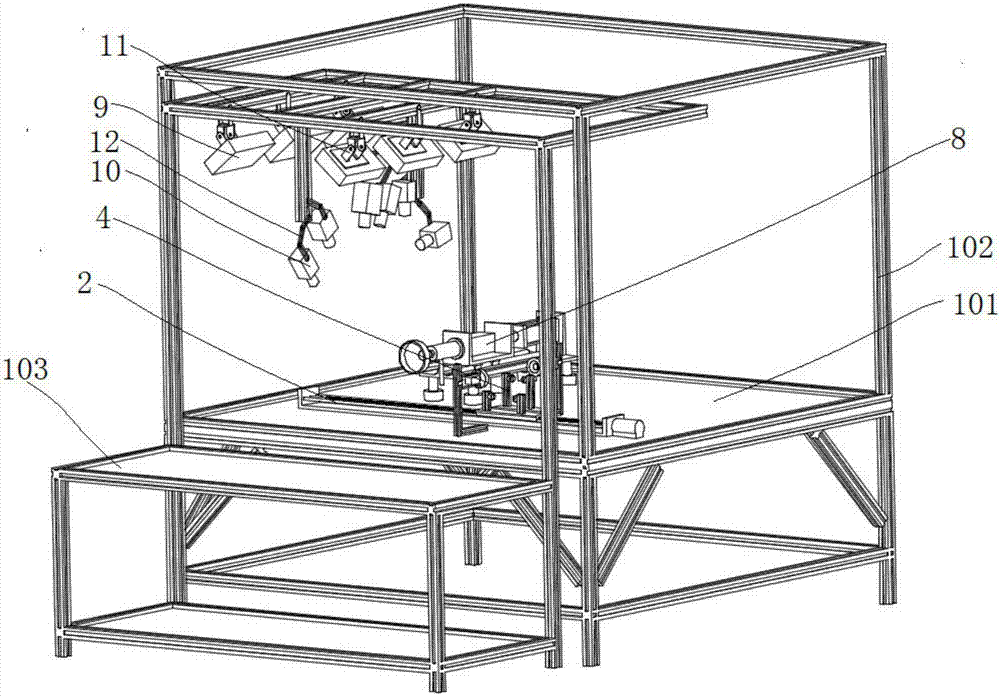

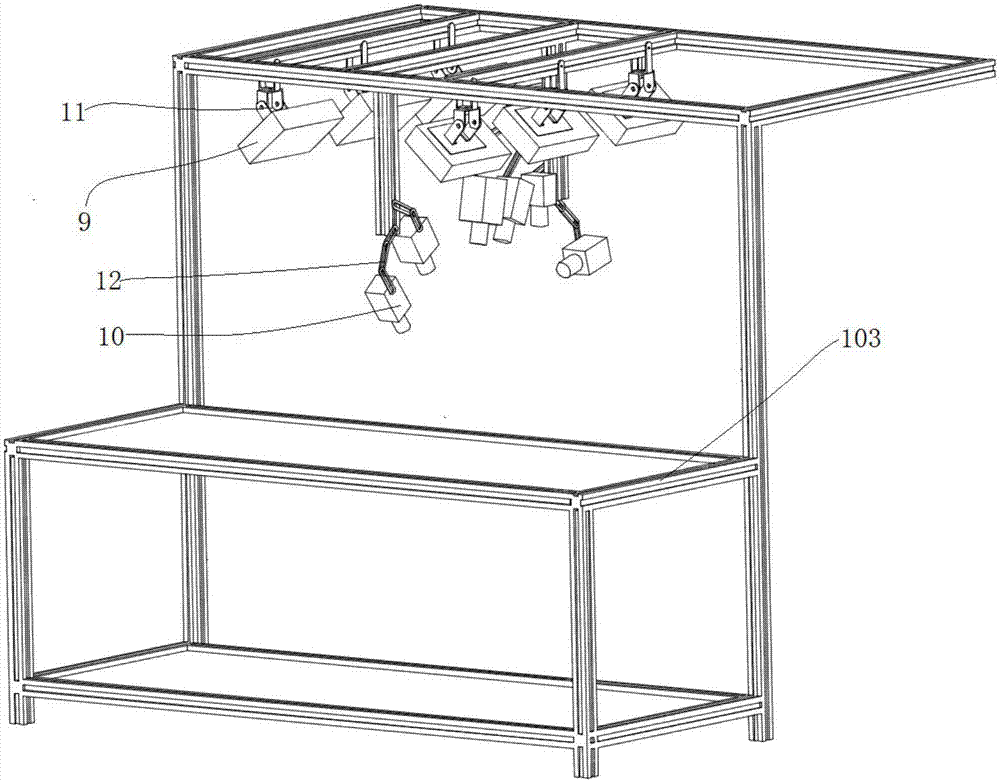

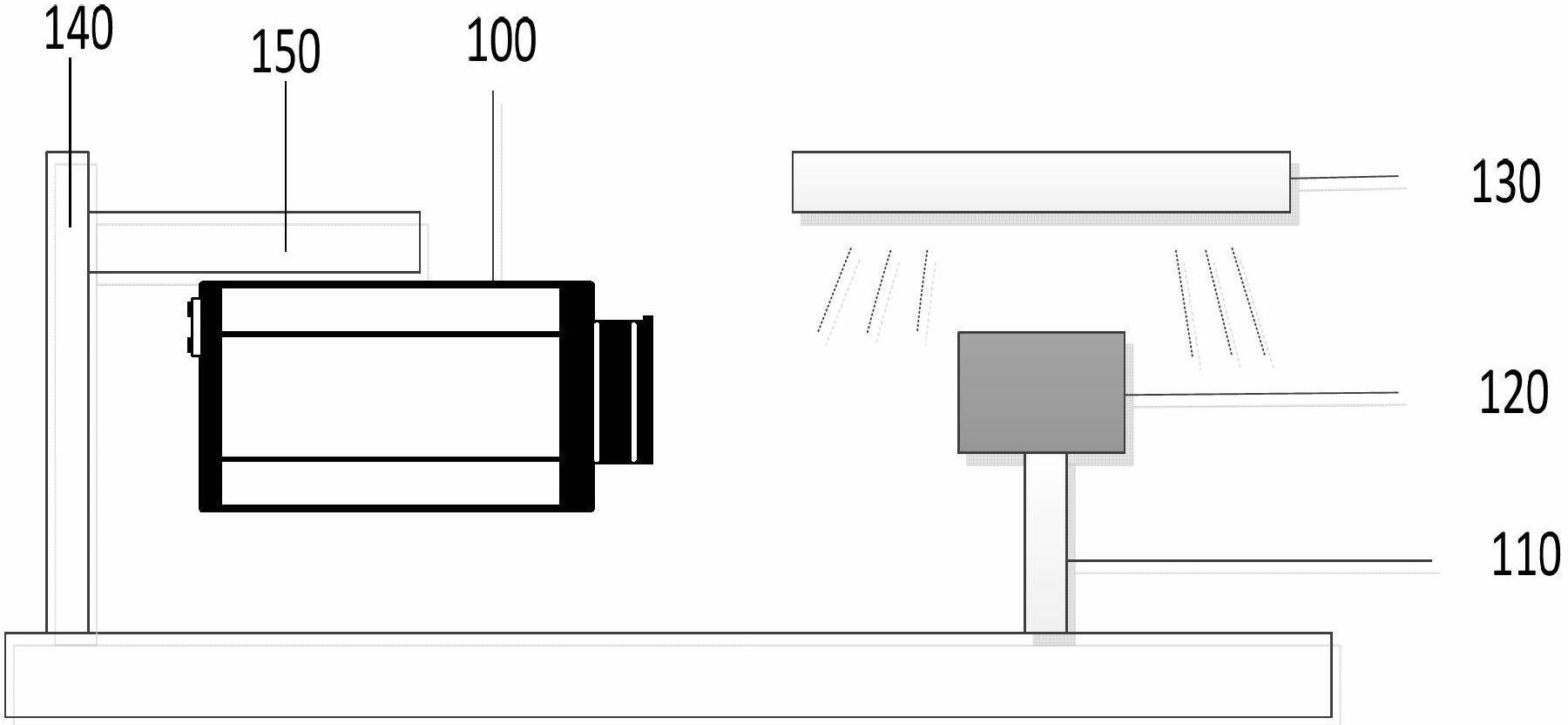

Dual-working-platform surface fault automatic detector for flexible printed circuit

InactiveCN102147375AAchieve protectionEfficient automatic identificationMaterial analysis by optical meansGratingClosed loop

The invention provides a detector for efficiently and automatically identifying faults of a flexible printed circuit board (FPCB). According to the invention, a high-precision marble platform is connected with a base through bolts, a table top of the marble platform is used for bearing an X-axis portal frame structure and two moving platforms in a Y-axis direction, the parts of two working platforms on the marble platform in the Y-axis direction are symmetrical and consistent and are free of mutual interference during working, and high-precision grating bars are respectively arranged on the moving platforms in the X-axis direction and the Y-axis direction so as to ensure that the closed-loop high-precision position motion control of the three platforms is realized, thus, the purpose of efficiently and automatically identifying the faults of the FPCB is achieved. The detector provided by the invention has the beneficial effect of being capable of detecting the faults of the FPCB stably and accurately at a high speed.

Owner:东莞市升力智能科技有限公司

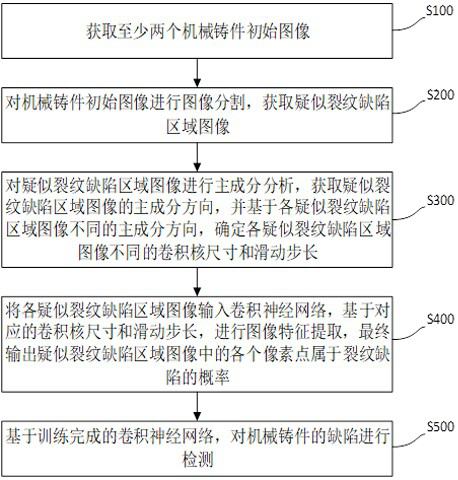

Mechanical casting defect detection method and system based on artificial intelligence

ActiveCN113538433AImprove accuracyIncrease convolution speedImage enhancementImage analysisImage segmentationImaging Feature

The invention relates to the technical field of mechanical part detection, in particular to a mechanical casting defect detection method and system based on artificial intelligence. The method comprises the following steps: acquiring at least two mechanical casting initial images; performing image segmentation on the image to obtain a suspected crack defect area image; obtaining principal component directions of the suspected crack defect area images, and determining different convolution kernel sizes and sliding step lengths of the suspected crack defect area images based on different principal component directions; inputting each suspected crack defect area image into a convolutional neural network for image feature extraction, and finally outputting the probability that each pixel point in the image belongs to the crack defect; and detecting the defects of the mechanical casting based on the trained convolutional neural network. The method and device greatly improve the speed of network training, improve the details of feature comparison in the network training process, improve the detection accuracy, and improvs the efficiency of defect recognition.

Owner:NANTONG YOUYUAN ART PATTERN DESIGN CO LTD

System and method for detecting defects in a solar cell and repairing and characterizing a solar cell

InactiveUS20100236035A1Improve accuracyImprove efficiencyPhotovoltaic monitoringMaterial analysis by electric/magnetic meansActive-matrix liquid-crystal displayLiquid-crystal display

A system and method for detecting a defect in a solar cell and repairing and characterizing a solar cell includes applying a test signal to the solar cell, monitoring the response of solar cell, detecting a defect associated with its location during the monitoring step, removing or isolating the defect from a solar cell and characterizing solar cell performance. The defect may be a short between the emitter and the base of solar cell. The system and method also detect a precise location of the defect based on the use of light valve panel (LVP), which can control the input beam to or output beam from the solar cell in terms of size, position, gray level, and wavelength of the transmitted light. The LVP may be realized in any one of a variety of ways. For example, the active matrix liquid crystal display (AMLCD) such as Thin Film Transistor driven LCD (TFT-LCD) may be used as the LVP.

Owner:YIELDBOOST TECH

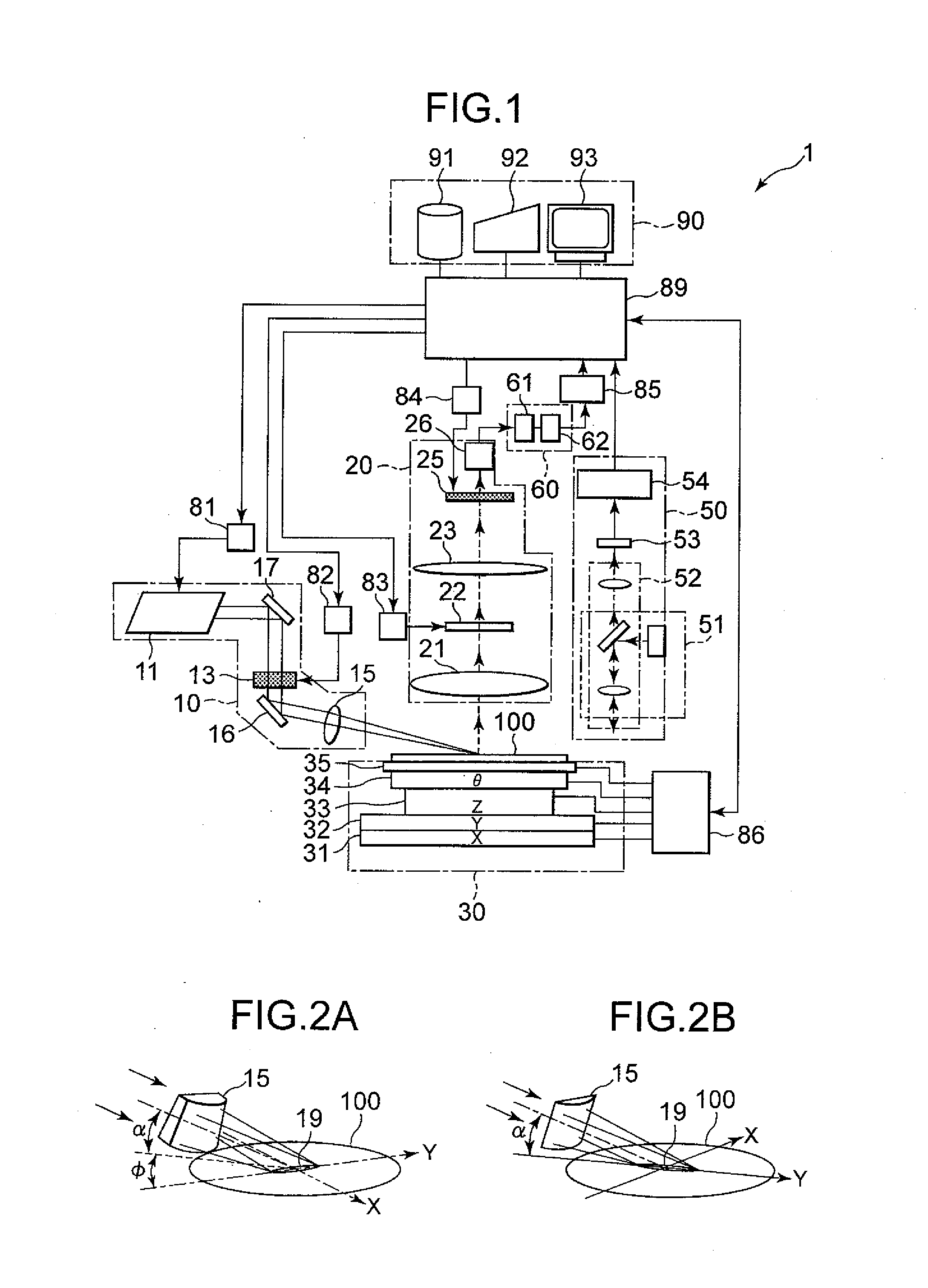

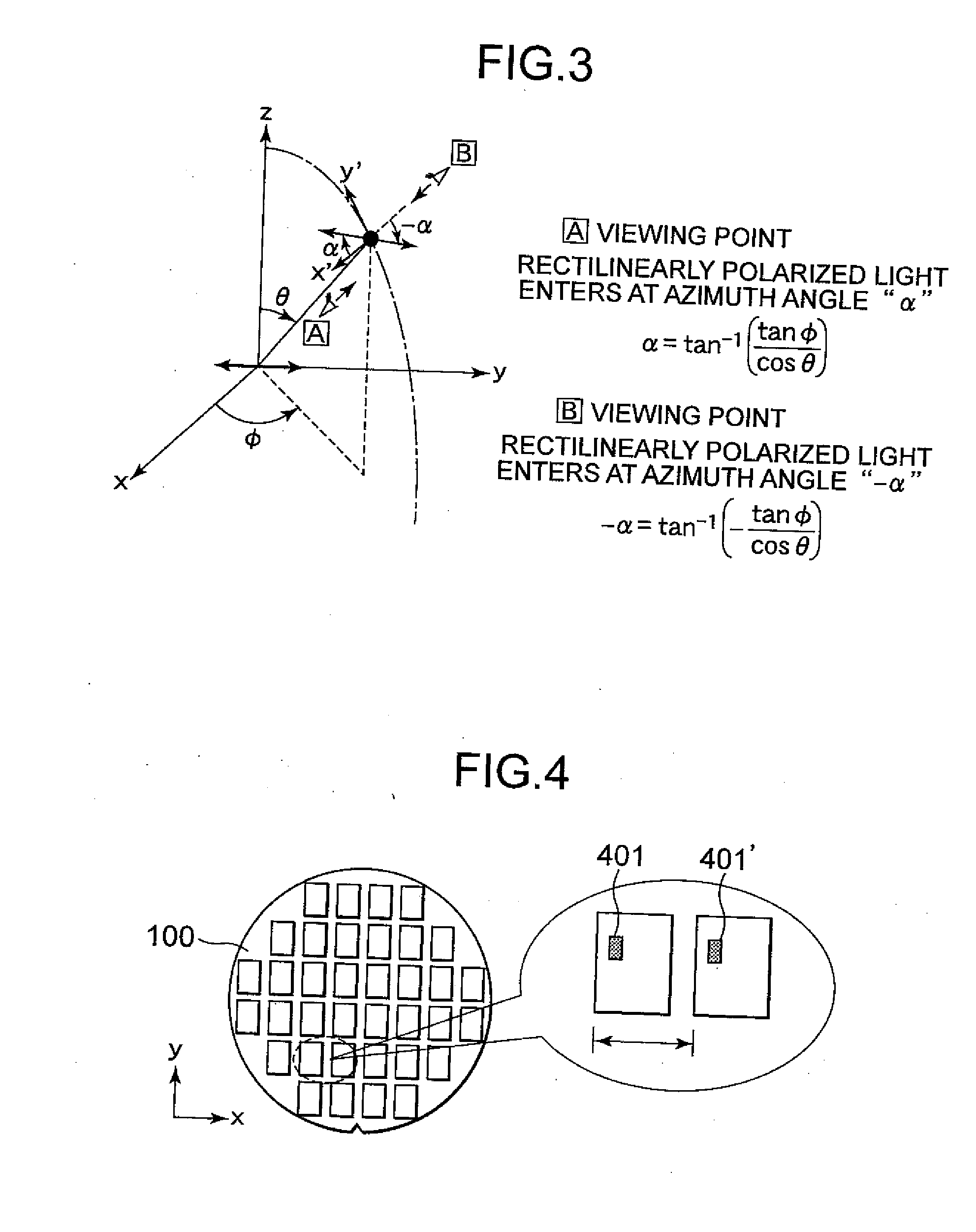

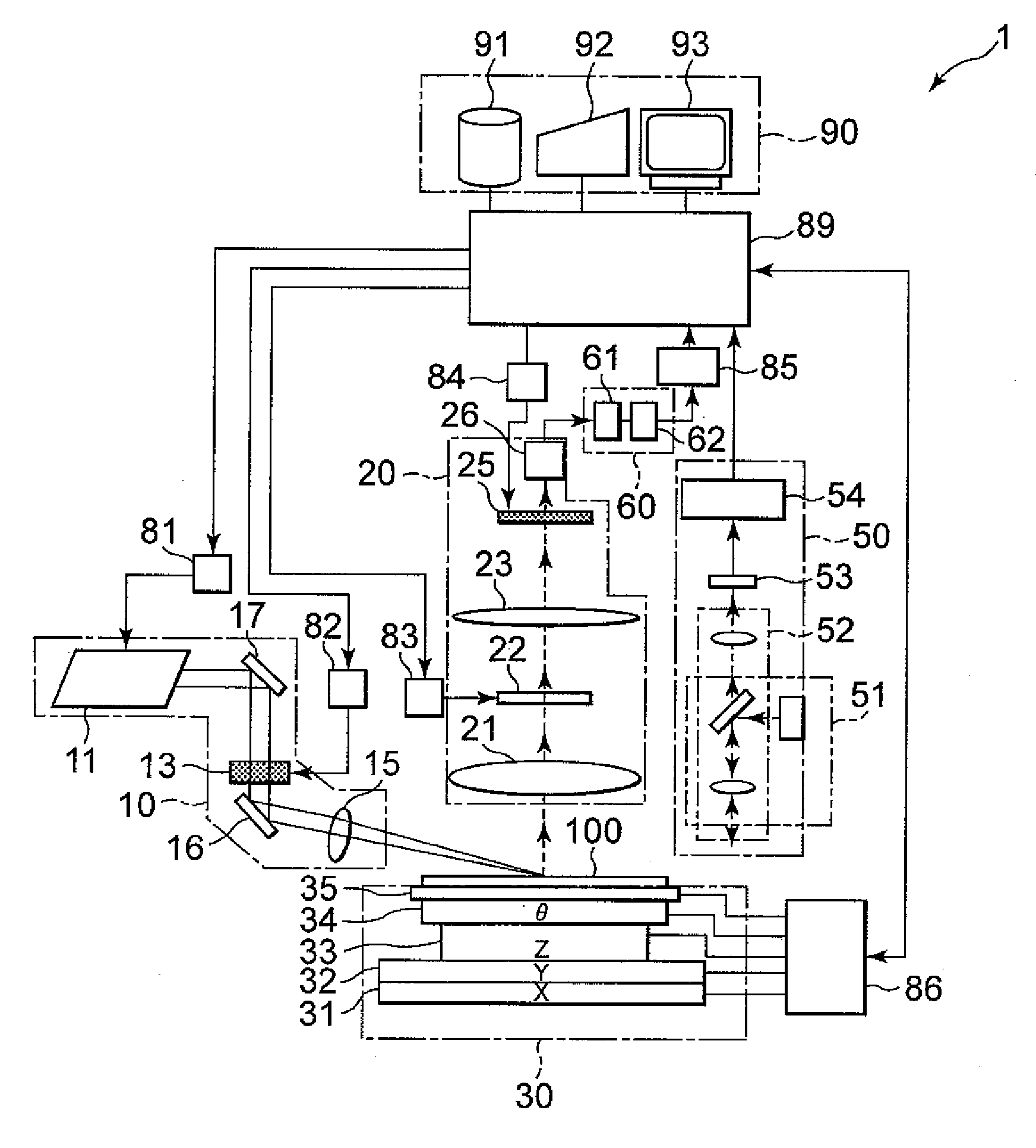

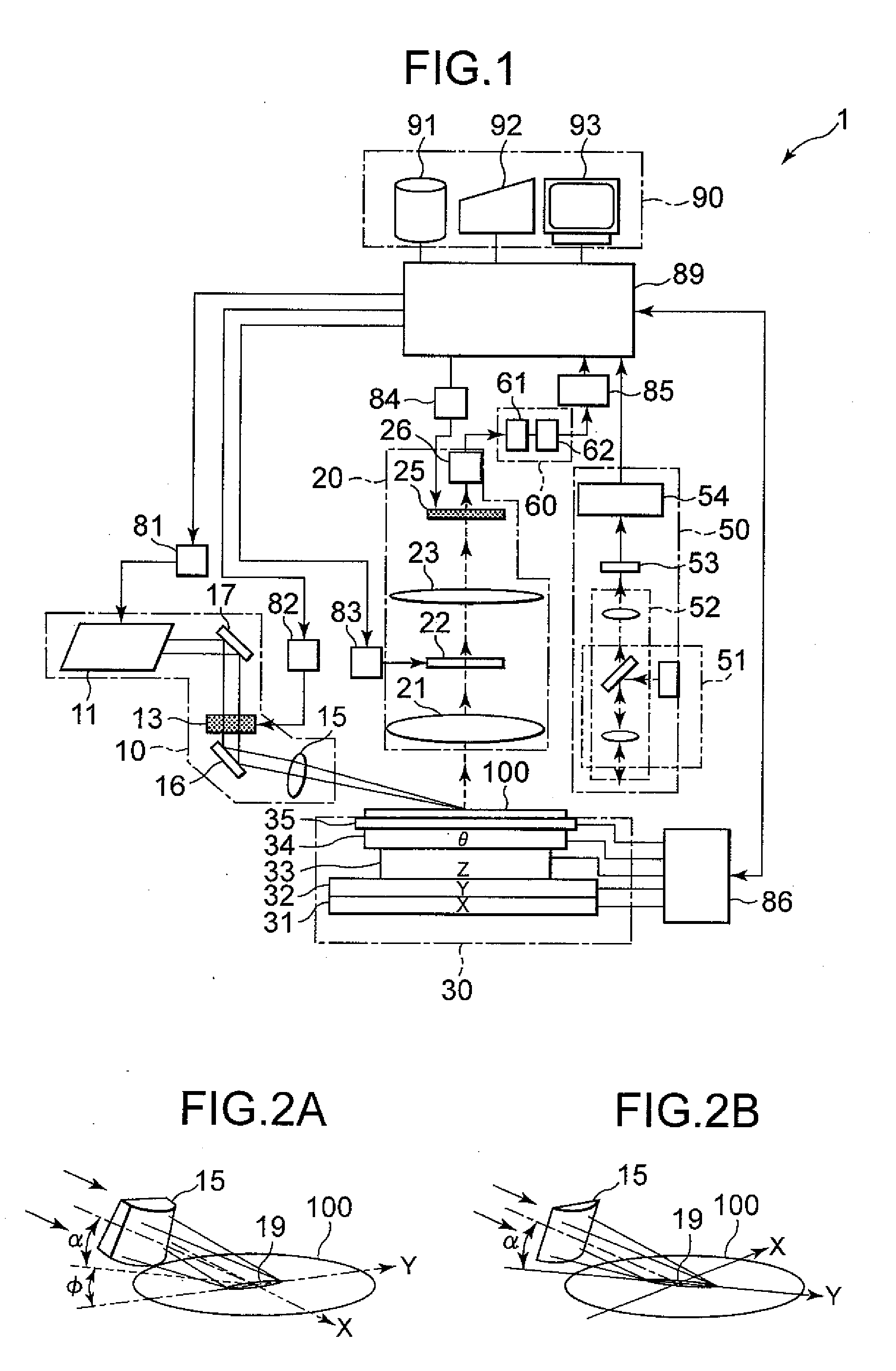

Method and Apparatus for Inspecting Defects

InactiveUS20100014083A1Accurate Defect DetectionMaterial analysis by optical meansLight polarisation measurementReference imageSubstrate surface

An apparatus for inspecting a substrate surface is provided, which includes illumination optics for irradiating the substrate surface linearly with rectilinearly polarized light from an oblique direction, detection optics for acquiring images of the substrate surface, each of the images being formed by the light scattered from the light-irradiated substrate surface, and means for comparing an image selected as an inspection image from the plurality of substrate surface images that the detection optics has acquired to detect defects, and another image selected from the plural images of the substrate surface as a reference image different from the inspection image; the illumination optics being formed with polarization control means for controlling a polarizing direction of the light according to a particular scanning direction of the substrate or a direction orthogonal to the scanning direction.

Owner:HITACHI HIGH-TECH CORP

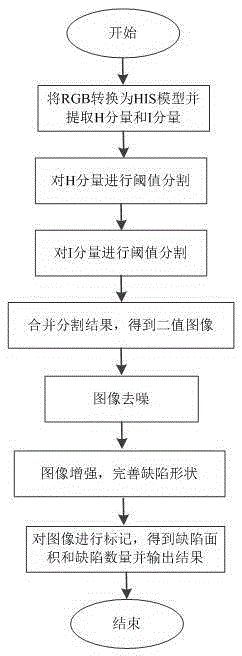

Fruit surface defect detection method based on image marking

InactiveCN105424709AReduce labor intensity and error rateIncrease productivityOptically investigating flaws/contaminationImage basedHistogram

A fruit surface defect detection method based on image marking includes the following steps that firstly, a surface picture of a to-be-detected fruit is taken and saved, and an original image is obtained; secondly; the original picture is uploaded to a server to be analyzed and processed; processing of the server includes the steps that a, the obtained original image is converted into a space where the visual system of human beings is applied, and an H component and an I component are extracted; b, dynamic threshold segmentation is performed on the H component; c, gray histogram statistics is performed on the I component, segmentation is performed through a fixed threshold method, and a threshold is selected between two wave peaks; d, the H value segmentation result and the I value segmentation result are operated, and a binary image with defect areas is obtained; denoising is performed on the obtained binary image; f, the binary image is enhanced, hole noise may exist in the defect areas, and filling is performed on the noise; g, the obtained binary image is marked, and the number and the area of defects are calculated; a detection result is output; labor intensity of workers is reduced, and production efficiency is improved.

Owner:SHAANXI UNIV OF SCI & TECH

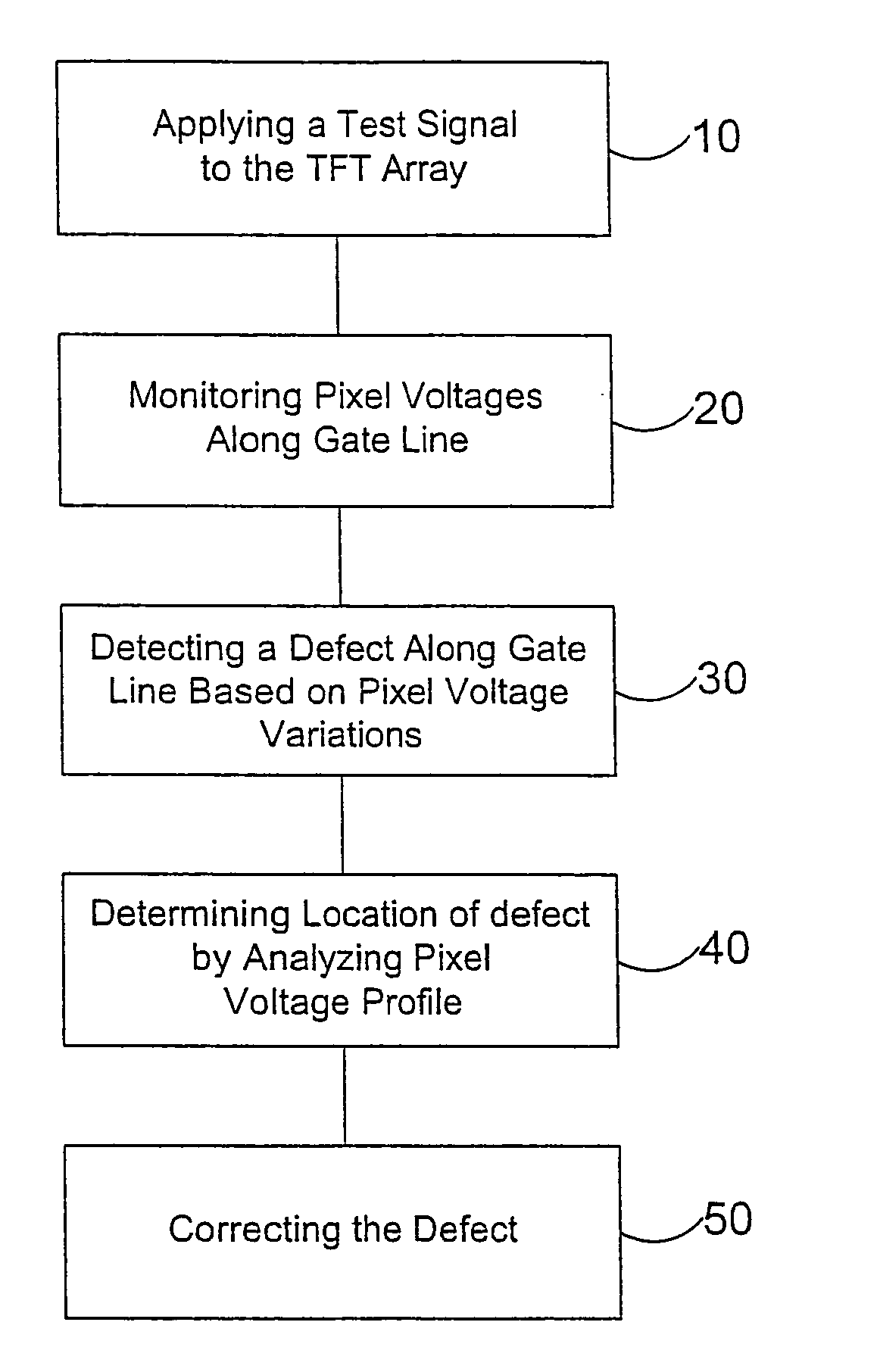

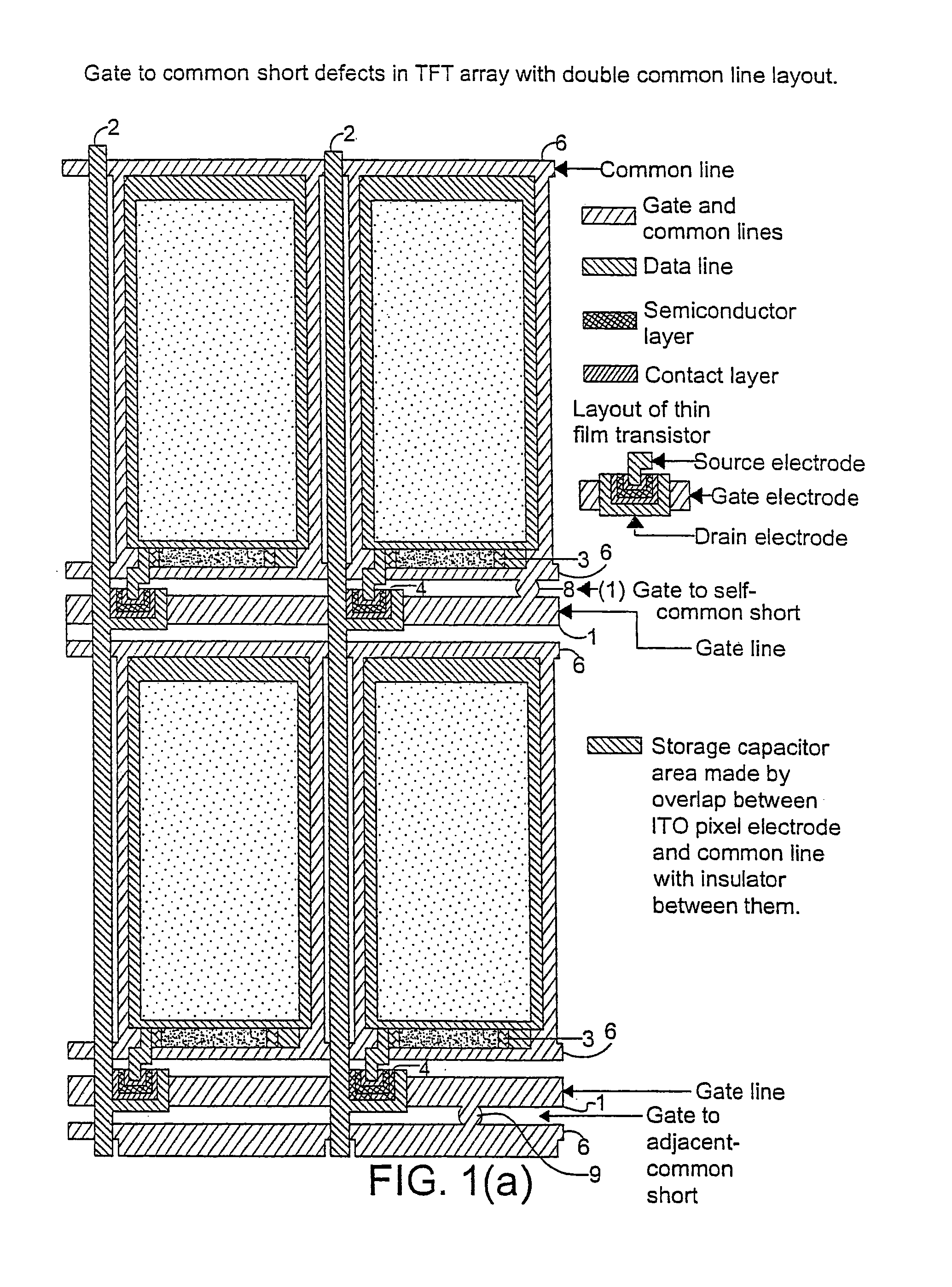

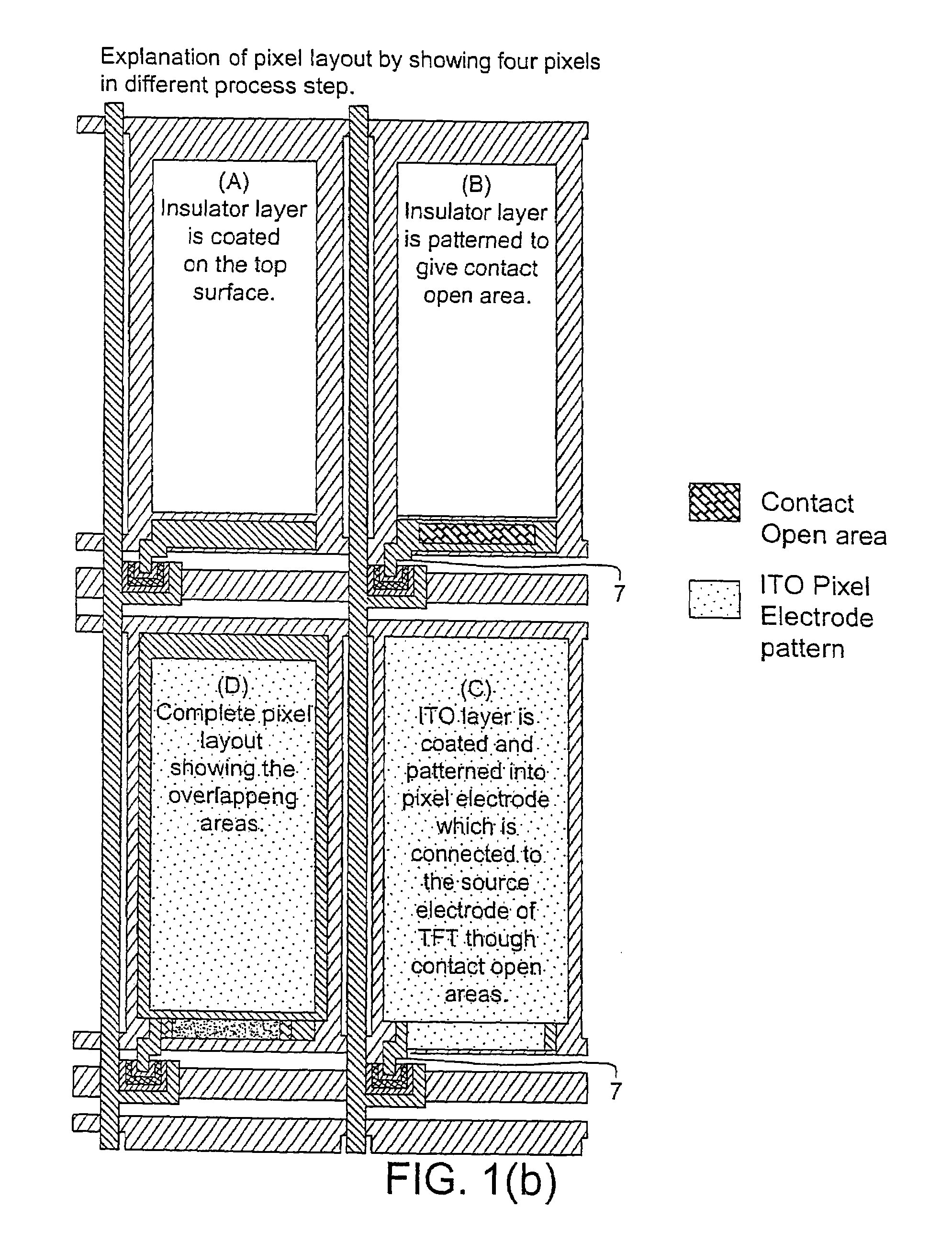

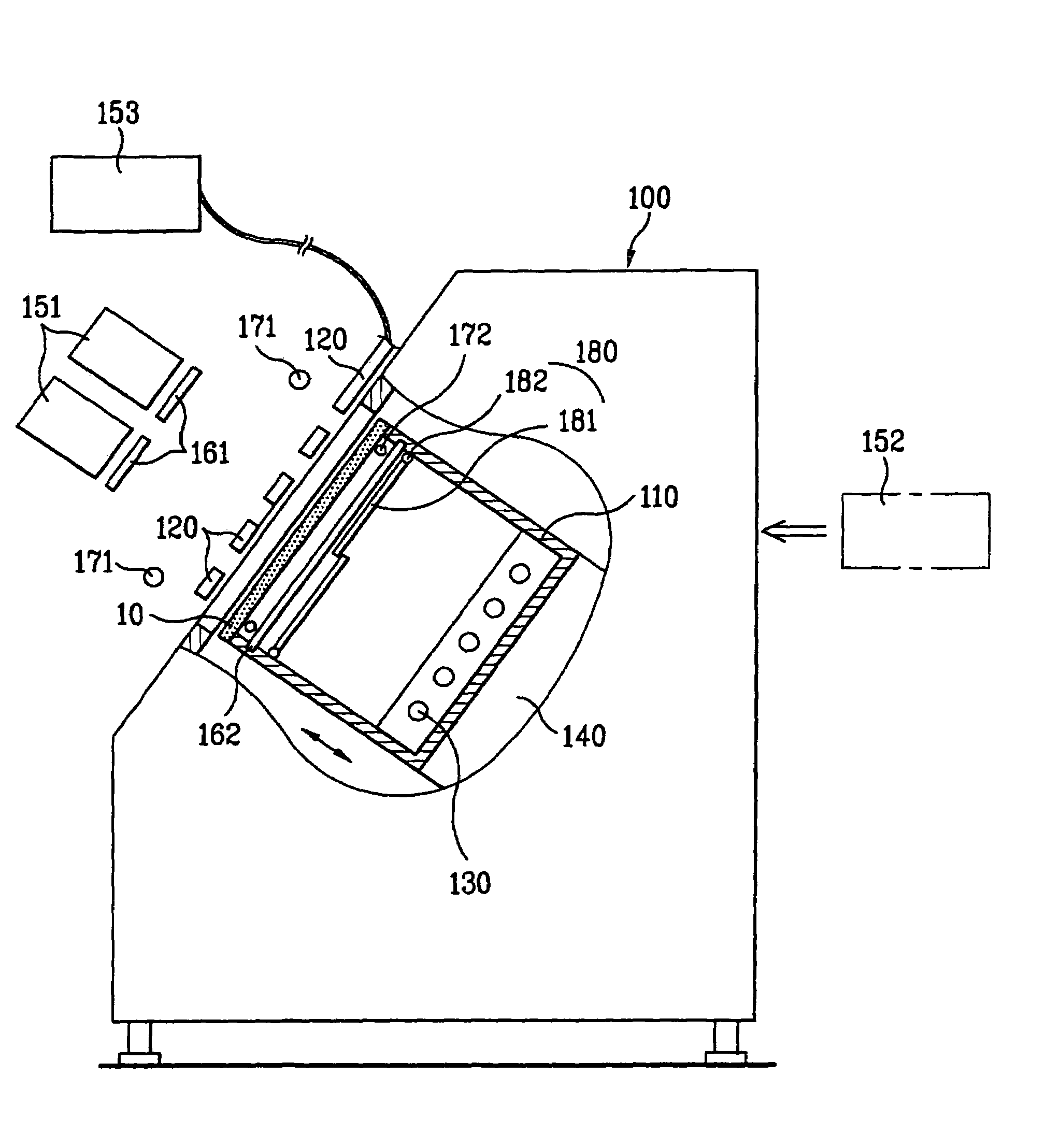

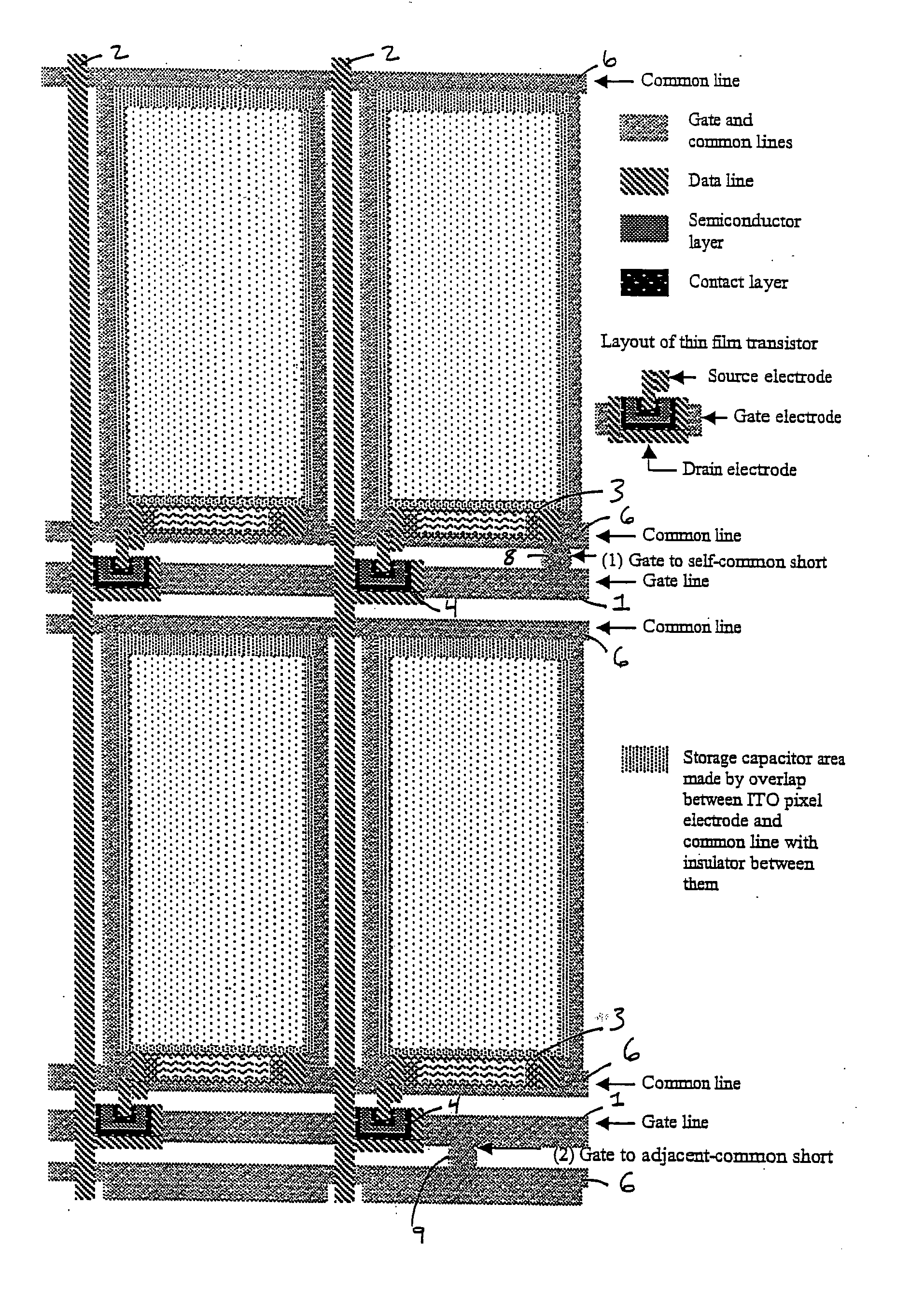

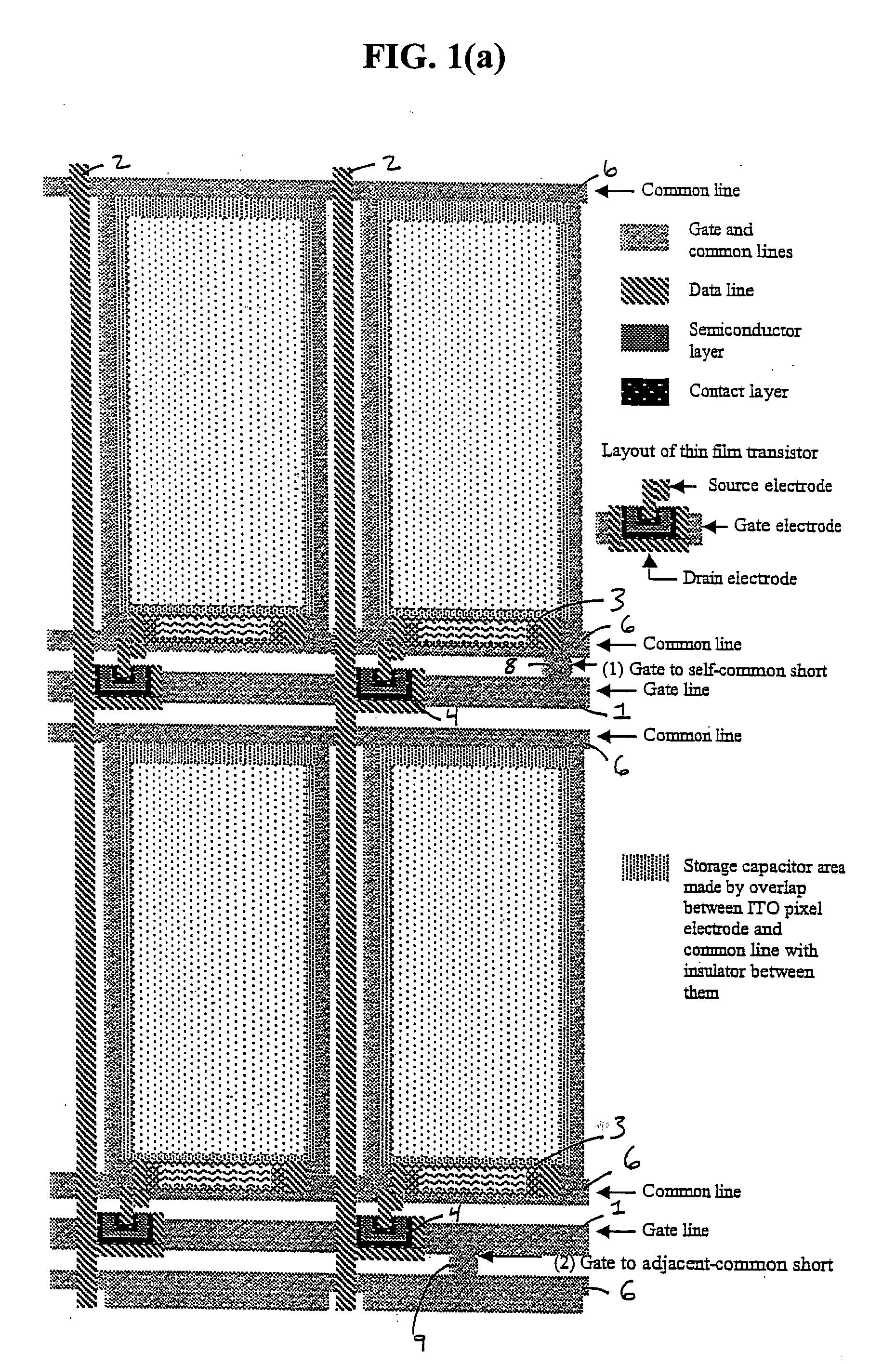

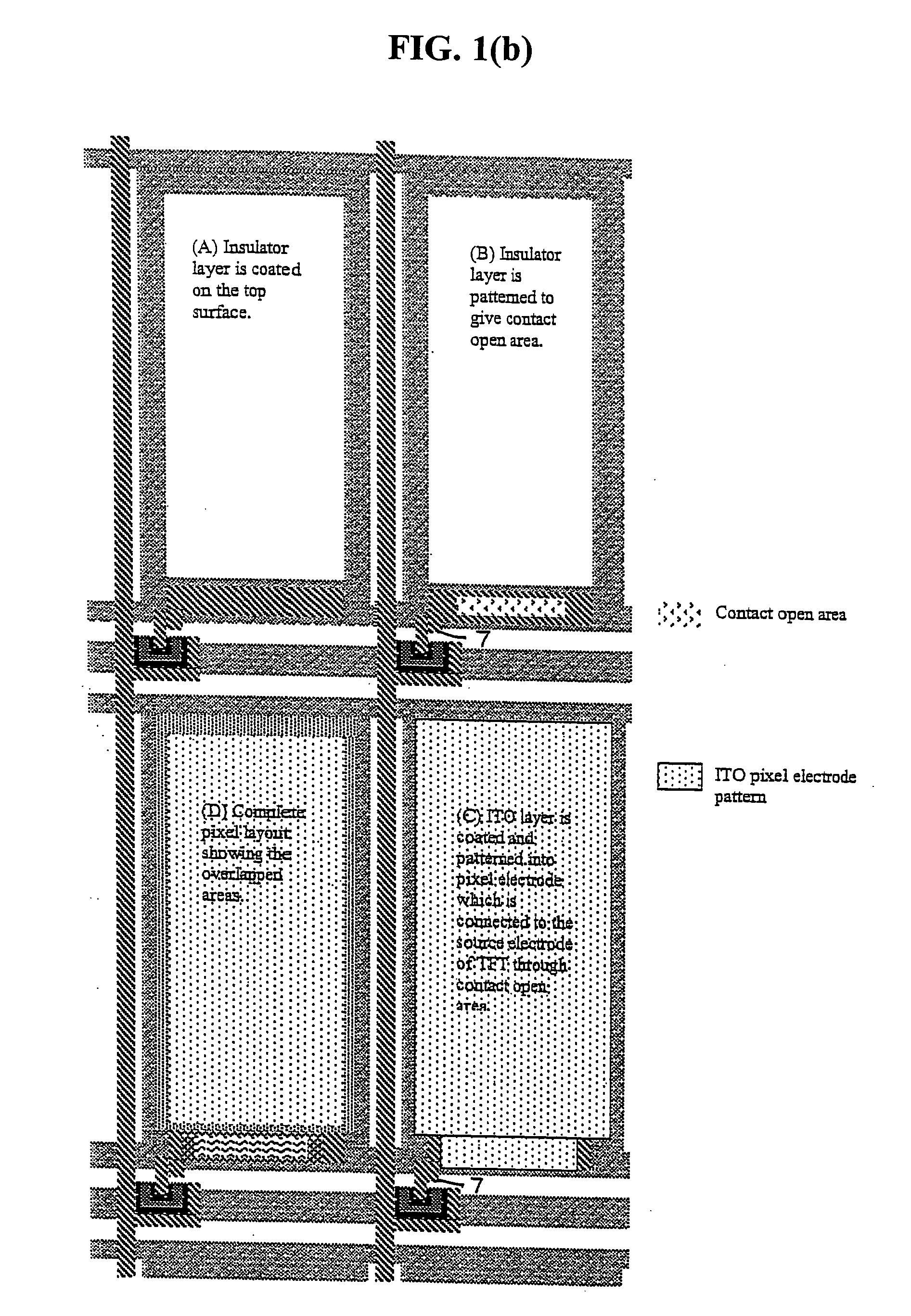

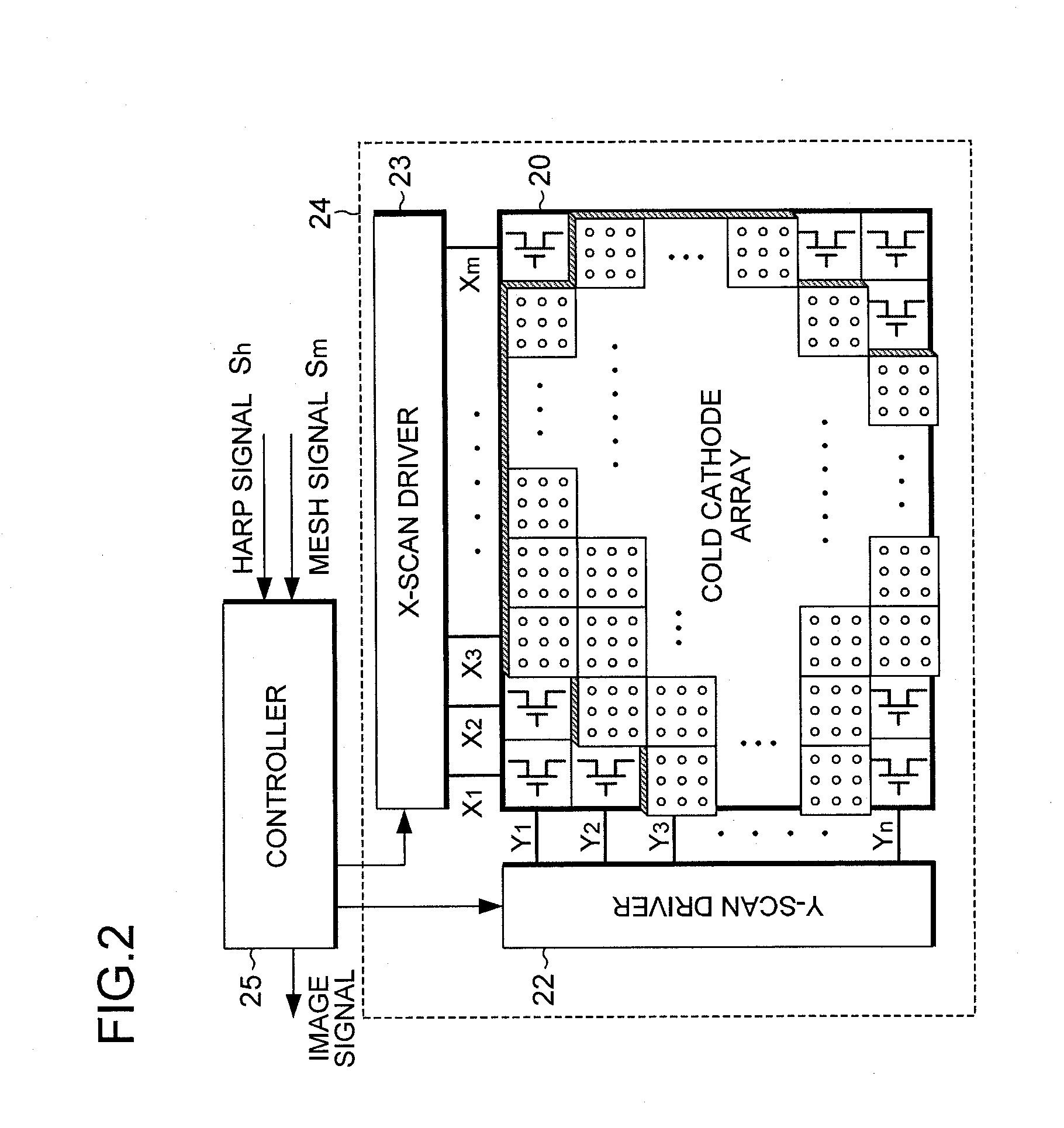

System and method for detecting defects in a thin-film-transistor array

InactiveUS7053645B2Improve efficiency and accuracyEnsure high efficiency and accuracyStatic indicating devicesTelevision systemsTransistor arrayThin-film transistor

A system and method for detecting a defect in a transistor array includes applying a test signal to the array, monitoring pixel voltages along a gate line of the array, and detecting a defect associated with the gate line based on a variation in the pixel voltages along the gate line during the monitoring step. The system and method can also detect a precise location of the defect based on a rate of change in the variation of the pixel voltages along the gate line.

Owner:YIELDBOOST TECH

Apparatus and method for inspecting liquid crystal display

ActiveUS7439757B2Reduce maintenance costsMiniaturizationStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

Owner:LG DISPLAY CO LTD

System and method for classifying defects in and identifying process problems for an electrical circuit

InactiveUS20050001646A1Improve accuracyImprove efficiencyCurrent/voltage measurementElectronic circuit testingHigh probabilityProblem identification

A method for performing circuit defect analysis and process problem identification includes applying a test signal to a circuit, obtaining a signal generated in response to the test signal, comparing the response signal to reference information, classifying a defect in the circuit based on a result of the comparing step, and identifying a problem in a manufacturing process which caused the defect based on the classification. The reference information may include one or more signal profiles corresponding to predefined types of defects that can occur during the manufacturing process. Defect classification is preferably performed by determining whether the response signal falls within one or more of the signal profiles. If the response signal falls within two or more signal profiles, then probabilities may be determined for each profile. The defect may then be classified as corresponding to the defect type whose signal profile has the highest probability. A processing system performs defect classification and process problem identification using a similar approach.

Owner:YIELDBOOST TECH

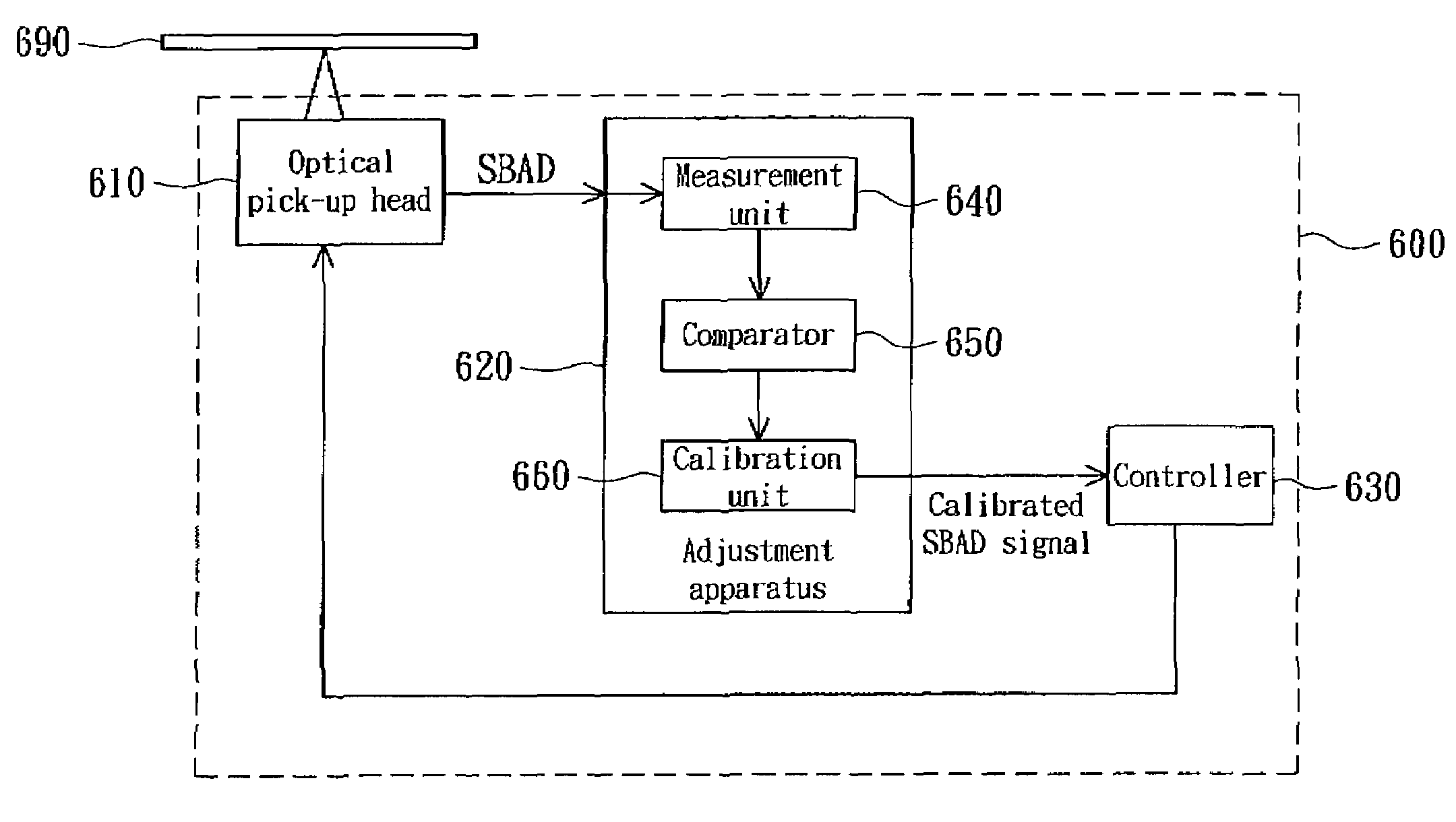

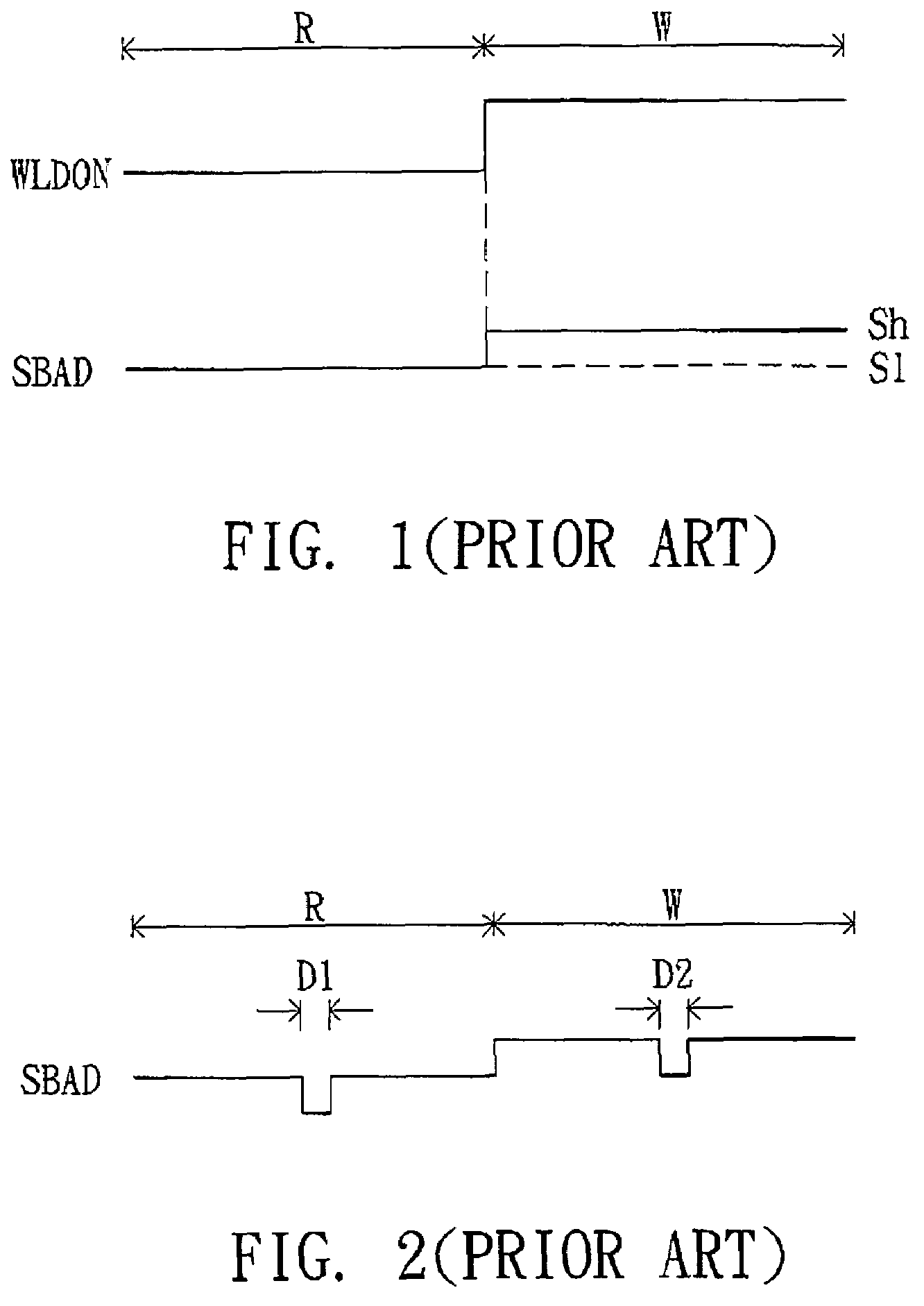

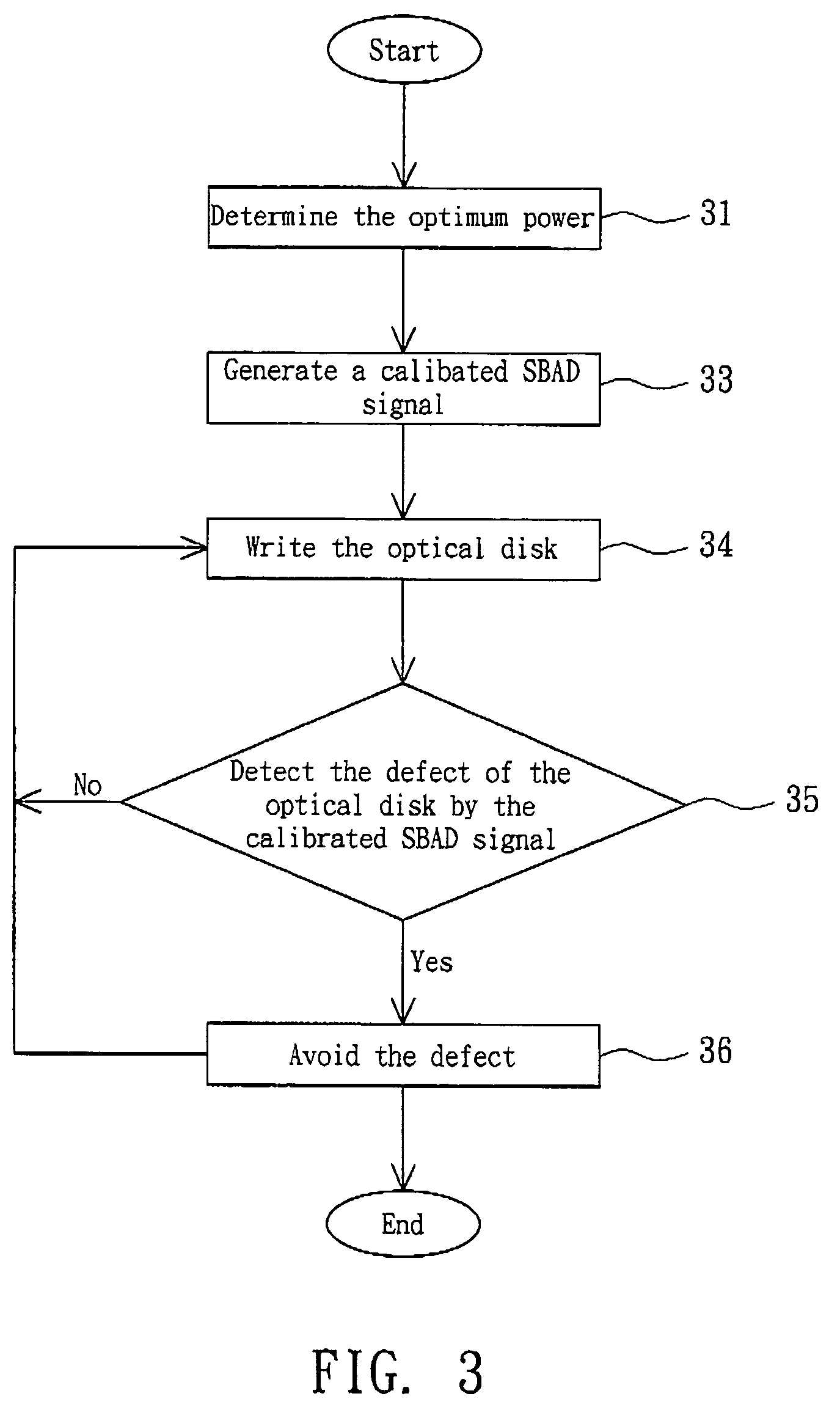

Optical disk drive for writing a re-writable optical disk and method thereof

ActiveUS7349310B2Accurate defect detectionFilamentary/web record carriersOptical beam sourcesEngineeringData recording

Owner:TIAN HLDG LLC

Method of detecting a defect on an object

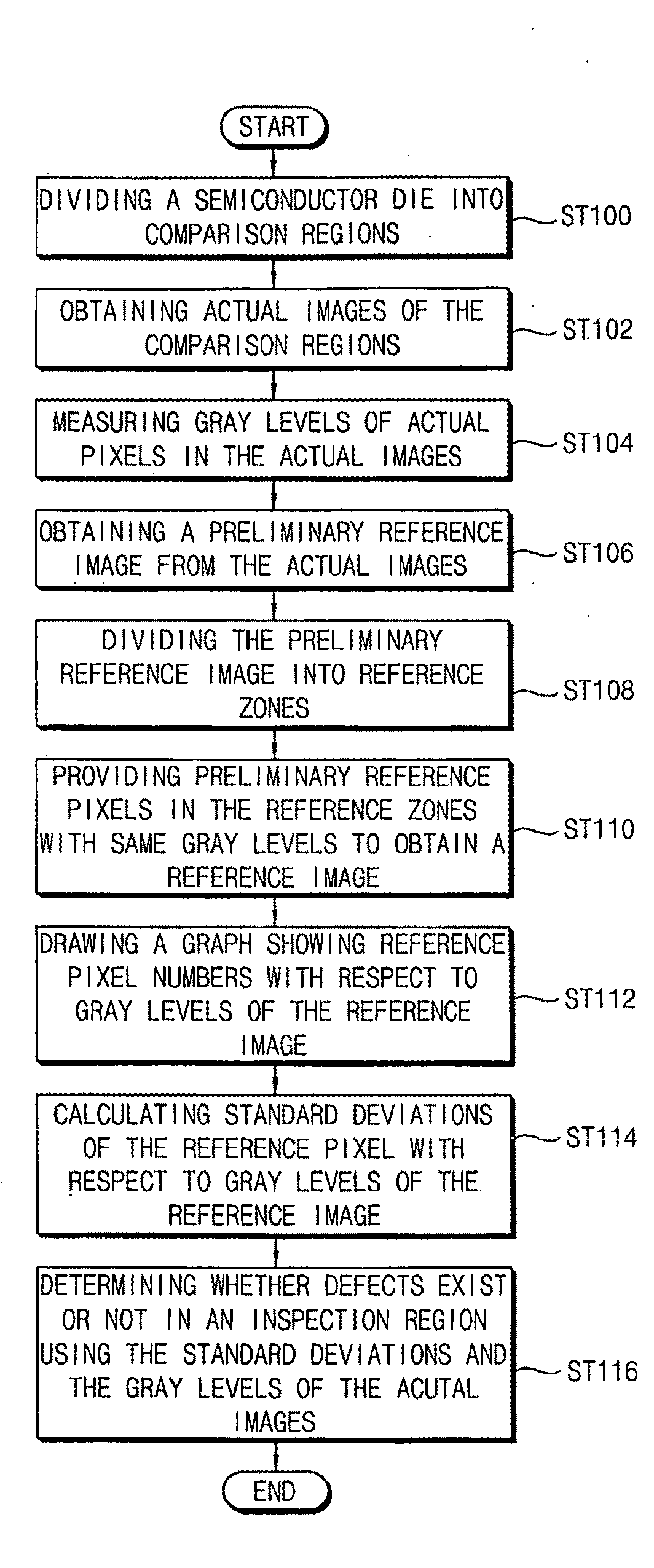

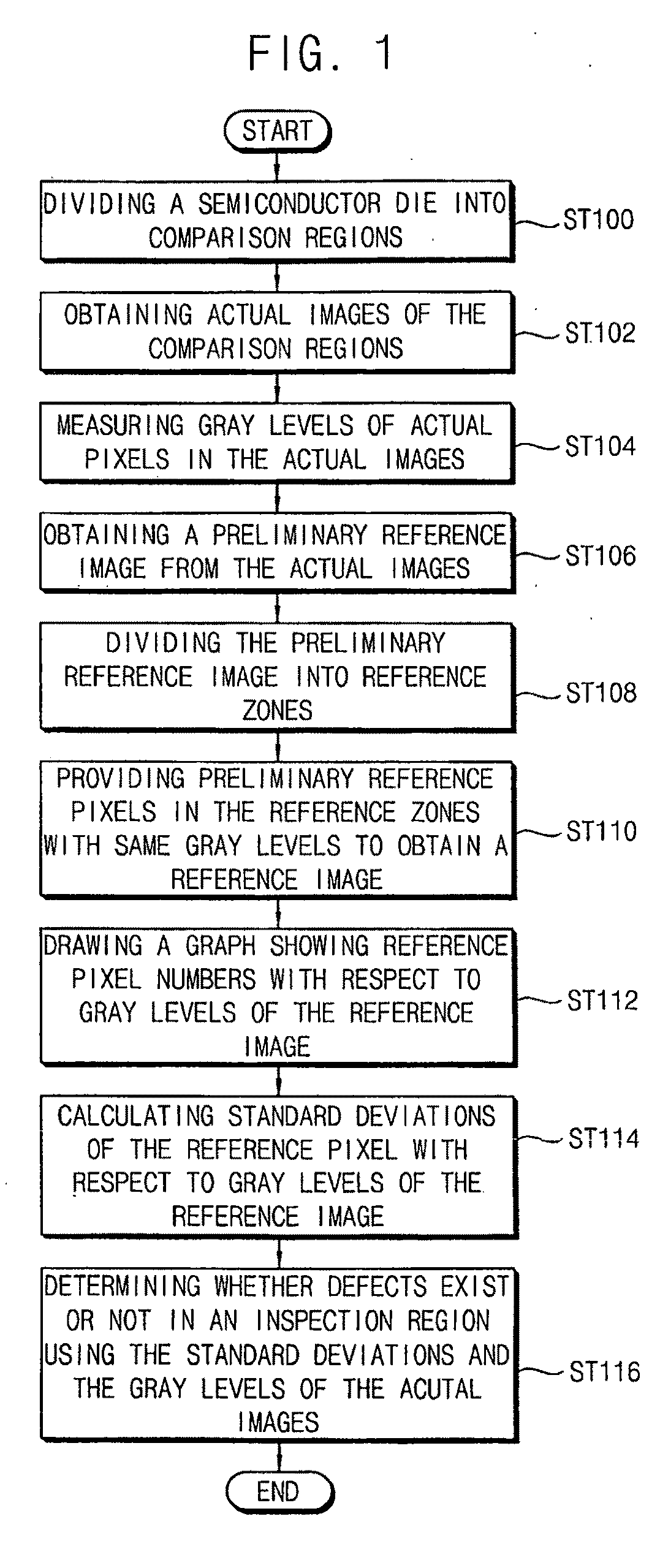

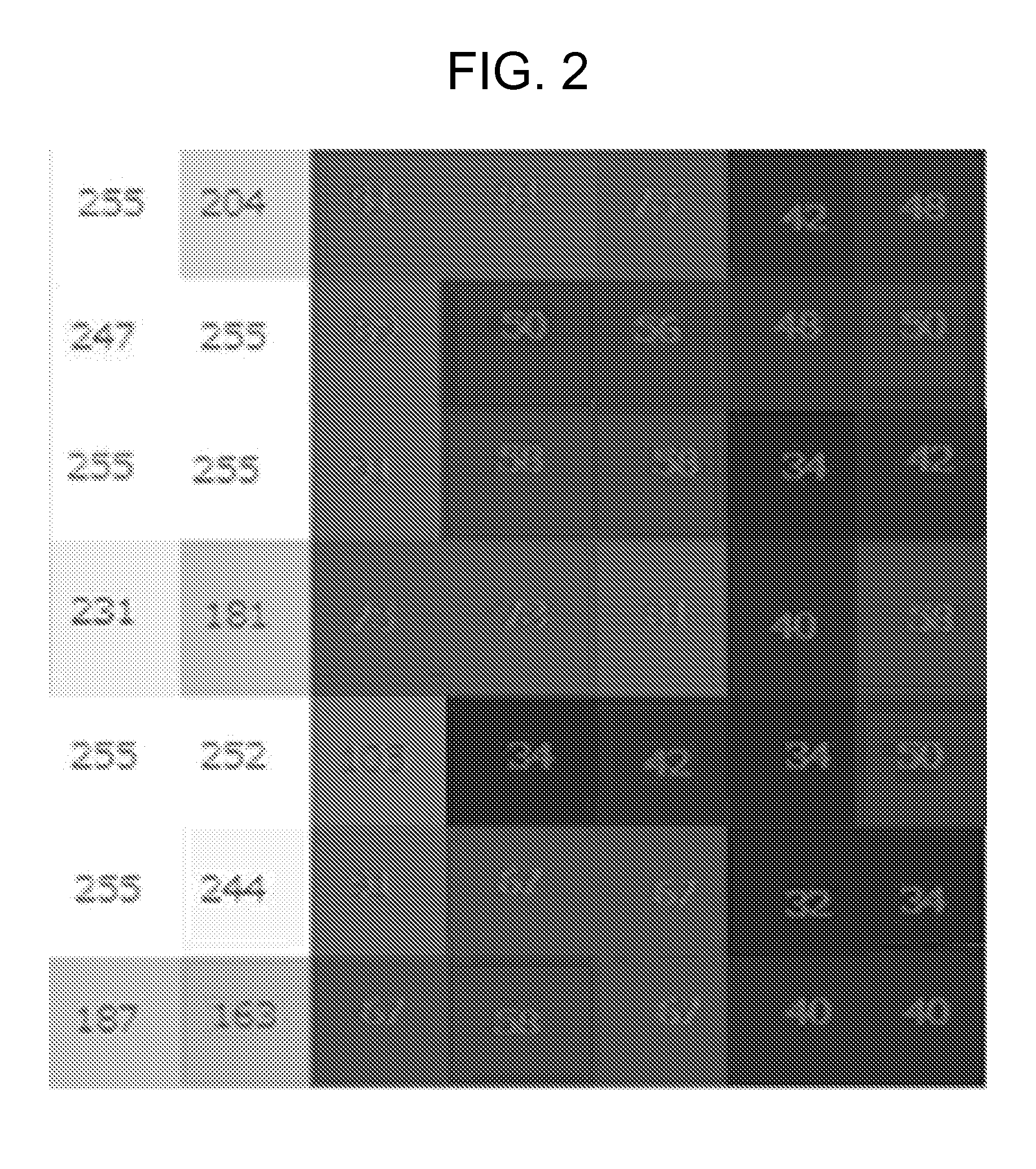

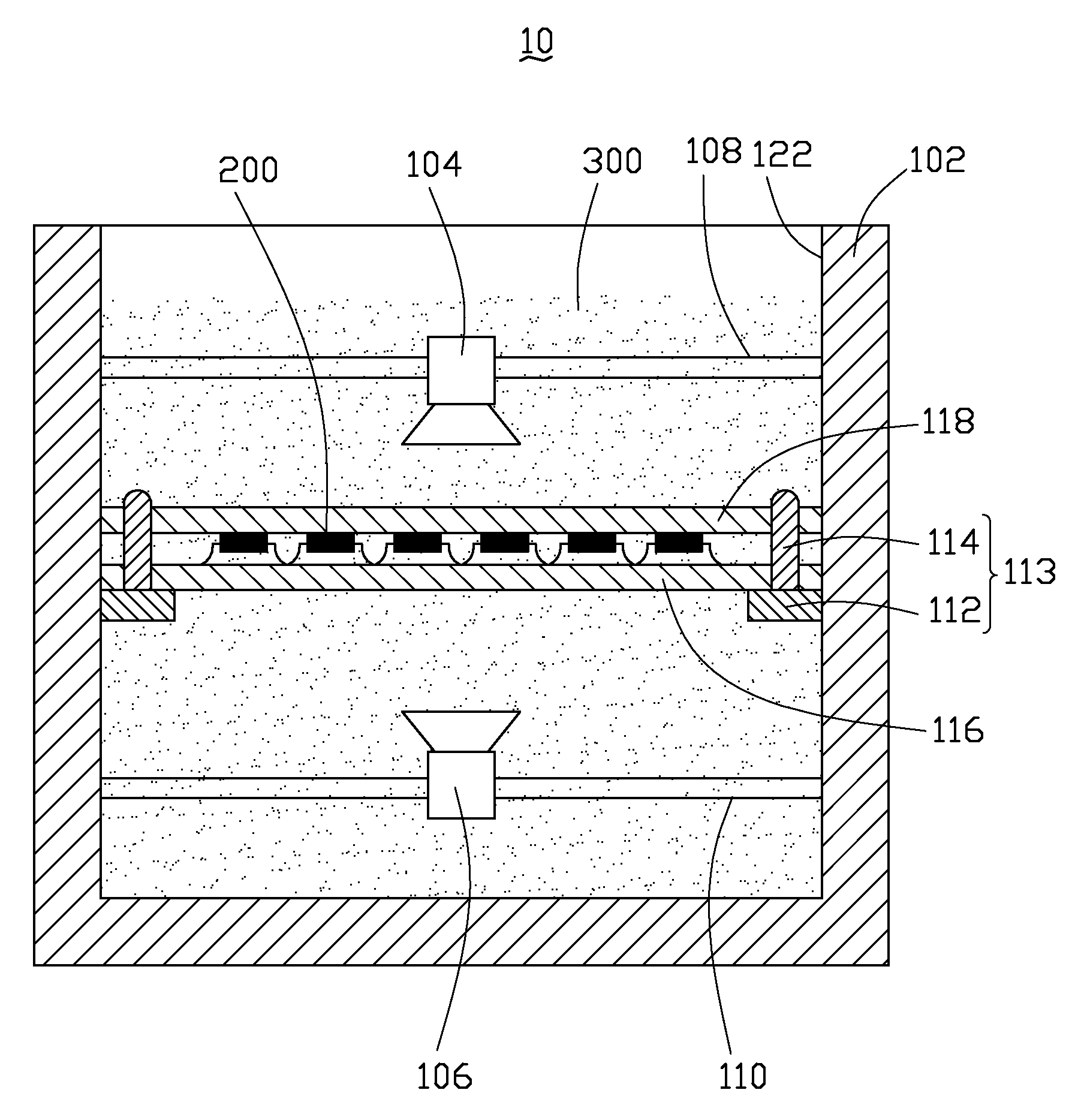

ActiveUS20090238445A1Accurate detectionDefect detectabilityImage enhancementImage analysisGray levelReference Region

In a method of detecting a defect on an object, a preliminary reference image can be obtained from a plurality of comparison regions defined on the object. The preliminary reference image is divided into reference zones by a similar brightness. Each of the reference zones is provided with substantially the same gray level, respectively, to obtain a reference image. Whether a defect exists in an inspection region in the comparison regions is determined using the reference image. Thus, defects in the inspection regions having different brightnesses can be detected using the properly obtained reference image.

Owner:SAMSUNG ELECTRONICS CO LTD

Ultrasonic inspection apparatus

InactiveUS7878065B2Accurate defect detectionFulfil requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansTransducerMechanical engineering

An ultrasonic inspection apparatus includes a container containing de-ionized water, at least one limiting member, a loading member, and a cover member. The at least one limiting member, the loading member, and the cover member are disposed in the de-ionized water and between the transmitting transducer and the receiving transducer. The limiting member is supported on the limiting member for loading the integrated circuits to be inspected. The cover member is detachably disposed on the loading member for holding the integrated circuits by a gravitational force of the cover member acting on the loading member.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Visual detection method for disc suspension type ceramic insulator

ActiveCN107179323AEasy to operateAccurate Defect DetectionOptically investigating flaws/contaminationPattern recognitionReference database

The invention discloses a visual detection method for a disc suspension type ceramic insulator. The method comprises the following steps: 1) establishing feature libraries of various defects; 2) confirming a numerical range of each type of defects in the feature library, and further refining the defects to establish a more detailed defect reference database to determine the type and specific state of a defect; 3) determining if a to-be-detected ceramic insulator is at a detection position; 4) performing image processing on collected image data; 5) utilizing a threshold segmentation principle to process and analyze the image processed and analyzed in the step 4), comparing the processing and analysis result with the defect reference database established in the step 2) one by one, if matching match is found, sending an unqualified signal of the ceramic insulator, and if not, sending a qualified signal of the ceramic insulator. The visual detection method is convenient in operation, is capable of greatly reducing labor intensity and increasing the detection working efficiency and is capable of accurately detecting the defects of the ceramic insulator.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

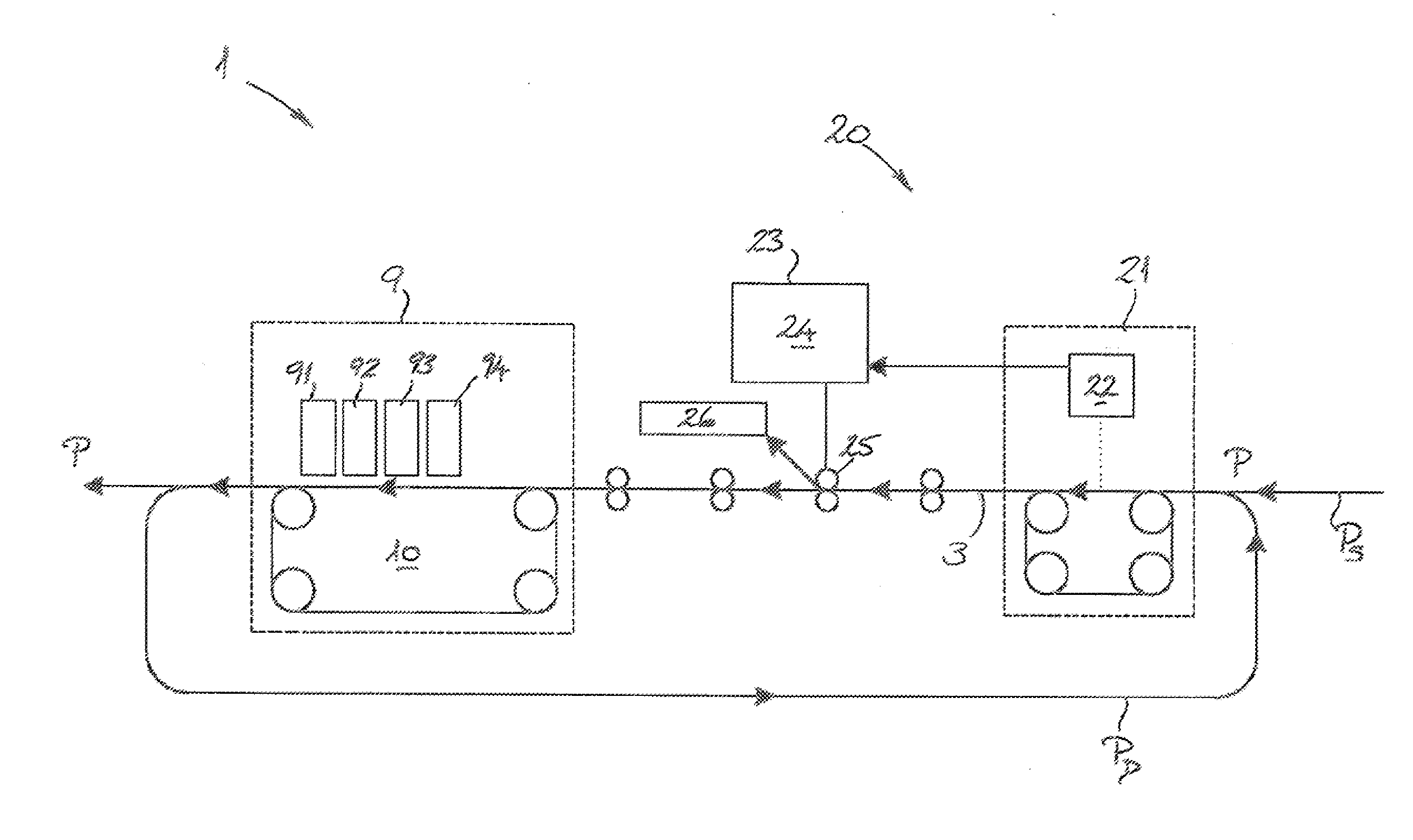

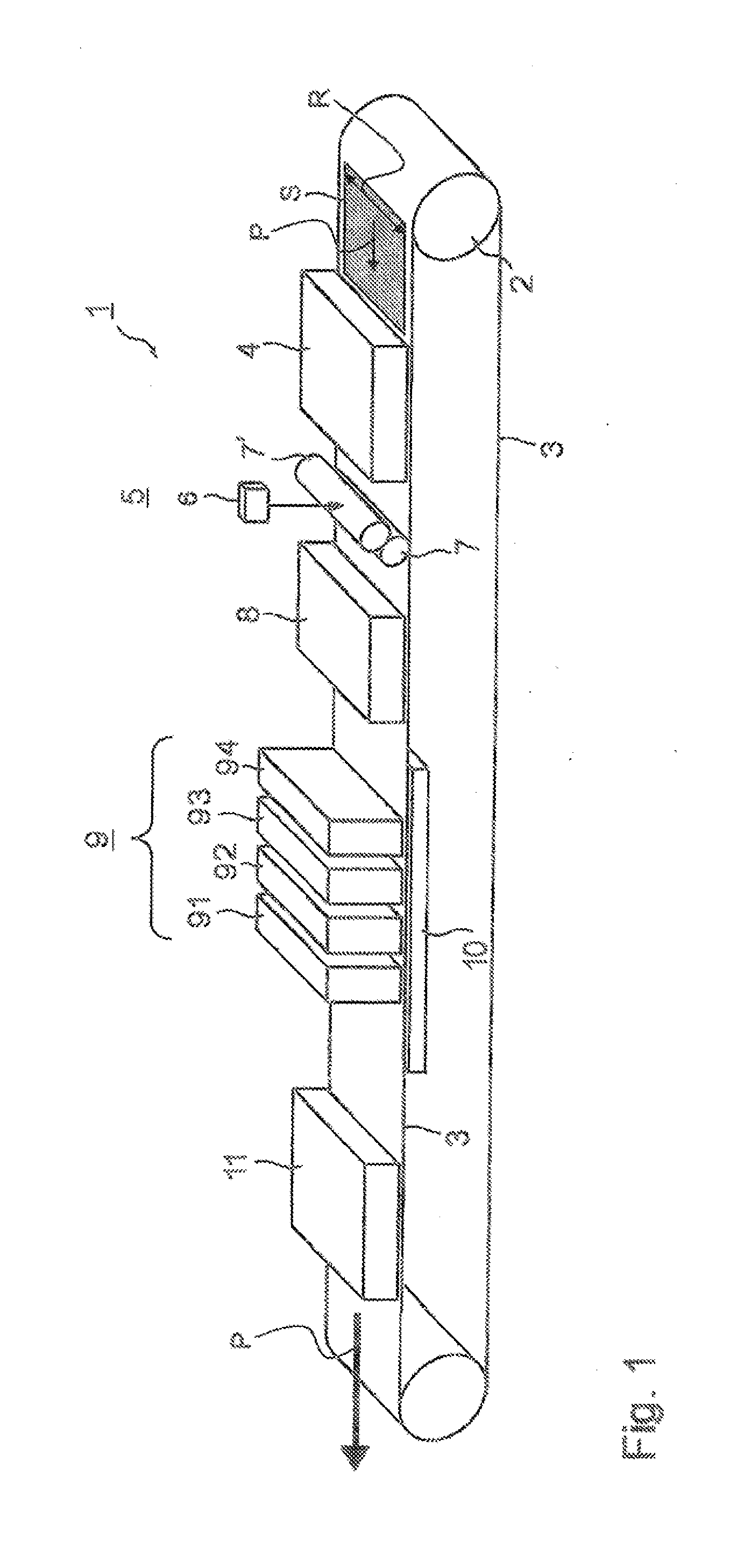

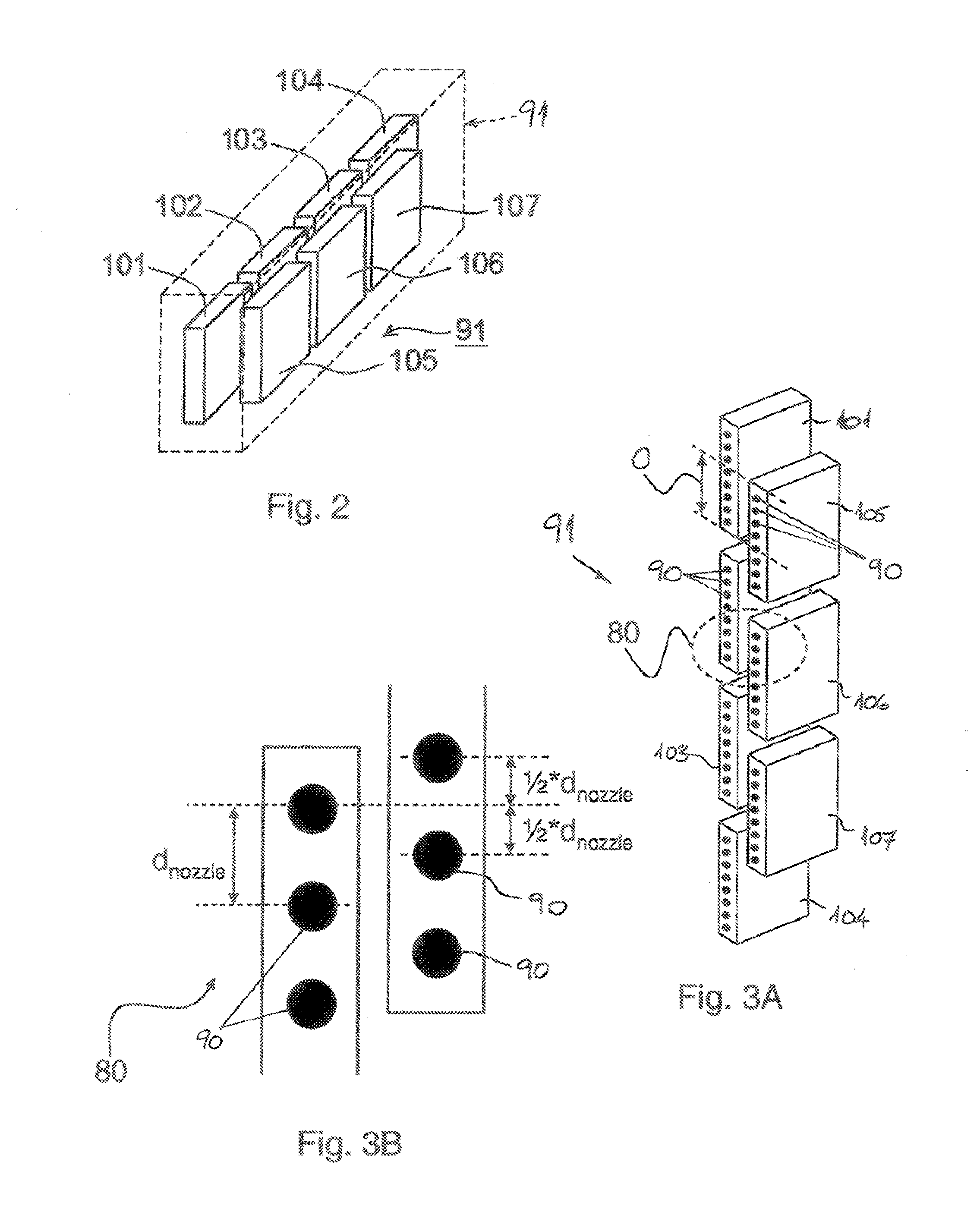

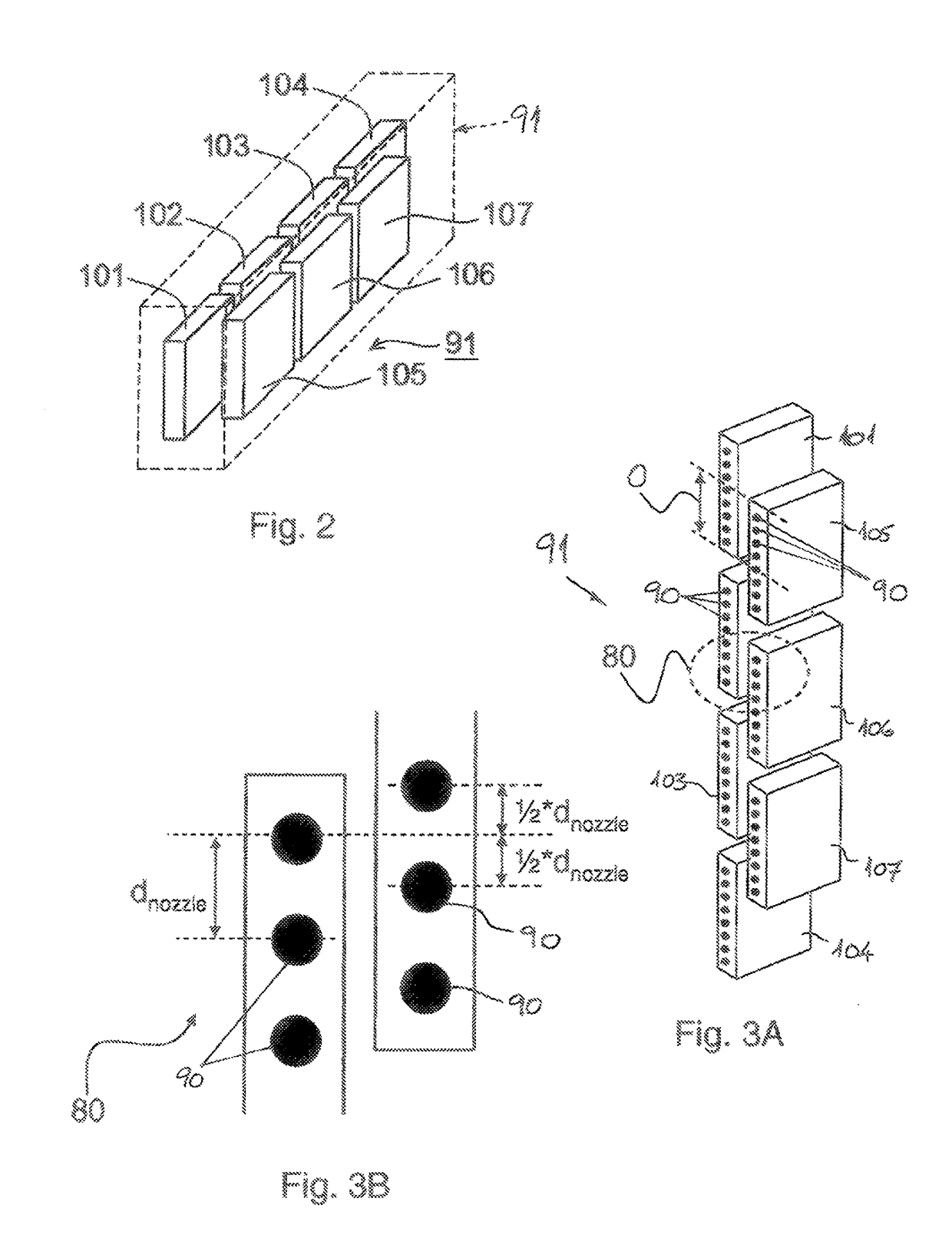

Apparatus and method for defect detection in a printing system

ActiveUS20160103634A1Accurate measurementAccurate and versatile methodImage enhancementImage analysisHeight mapEngineering

An apparatus for defect detection in a printing system, comprising a sensor device for sensing a surface of a sheet and for generating data representing a height map of the sheet, and a processor device for processing the data from the sensor device, wherein the processor device is configured to analyse the height map to detect a presence of a deformation in the sheet. The processor device is further configured to, when a deformation is detected, to determine at least one property of the deformation, to classify the deformation with respect to a plurality of deformation classes by means of the at least one property of the deformation, and to determine a suitability of the sheet for printing based on the deformation class wherein the deformation has been classified.

Owner:OCE TECH

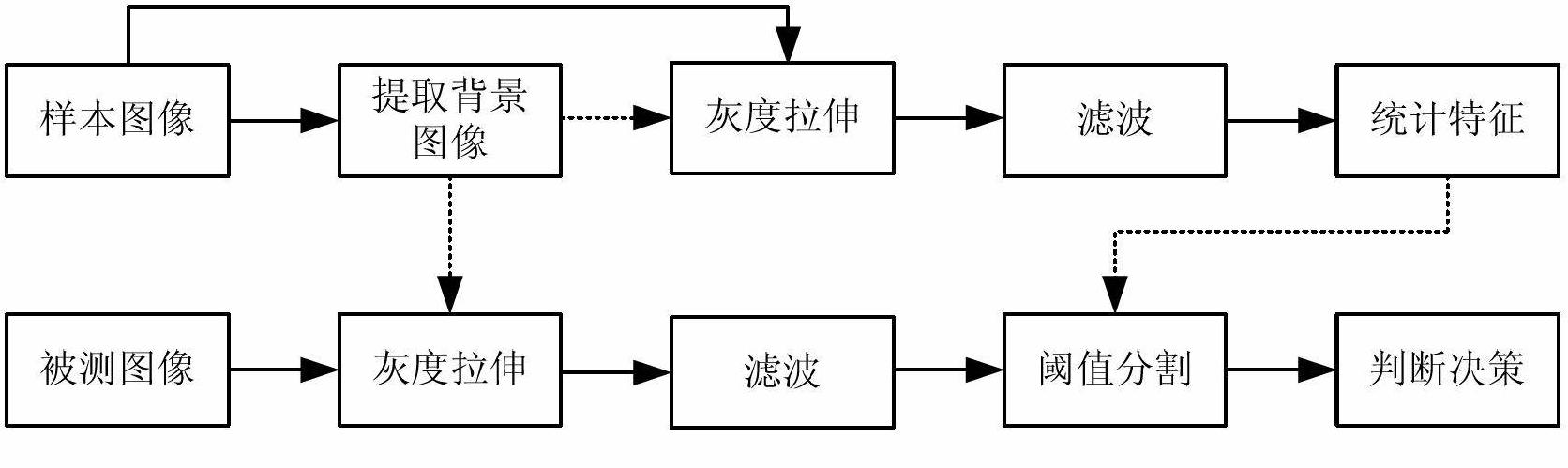

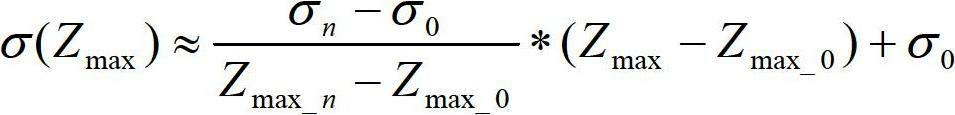

Real-time detecting method of metal arc plane flaw based on machine vision

ActiveCN102680494AEfficiently extract reflection componentsExtract reflection componentMaterial analysis by optical meansMachine visionLinear relationship

The invention relates to a real-time detecting method of metal arc plane flaws based on machine vision. The method comprises the following steps: step 1. obtaining N first sample images and M second sample images under the off-line condition, and carrying out data combination; step 2. establishing an image histogram after the combination so as to obtain a linear relationship equation between an image background and a corresponding gray value; step 3. calculating a refection component of a first sample image and a second sample image selected; step 4. establishing a corresponding relationship equation between a qualified working refection component standard difference and a corresponding gray value; step 5. on-line obtaining a detection image of a polished metal arc plane workpiece at real time, and calculating a first standard difference and a second standard difference; step 6. carrying out threshold partitioning so as to obtain a corresponding binary image; and step 7. comparing the connected region area of the binary image with a preset judgment threshold so as to judge the flaws of the polished metal arc plane. According to the method, the operation is convenient, the detection precision is high, the detection adaptability is good, and the stability and the reliability are realized.

Owner:JIANGSU LANCHAUNG INFORMATION TECH SERVICESCO LTD

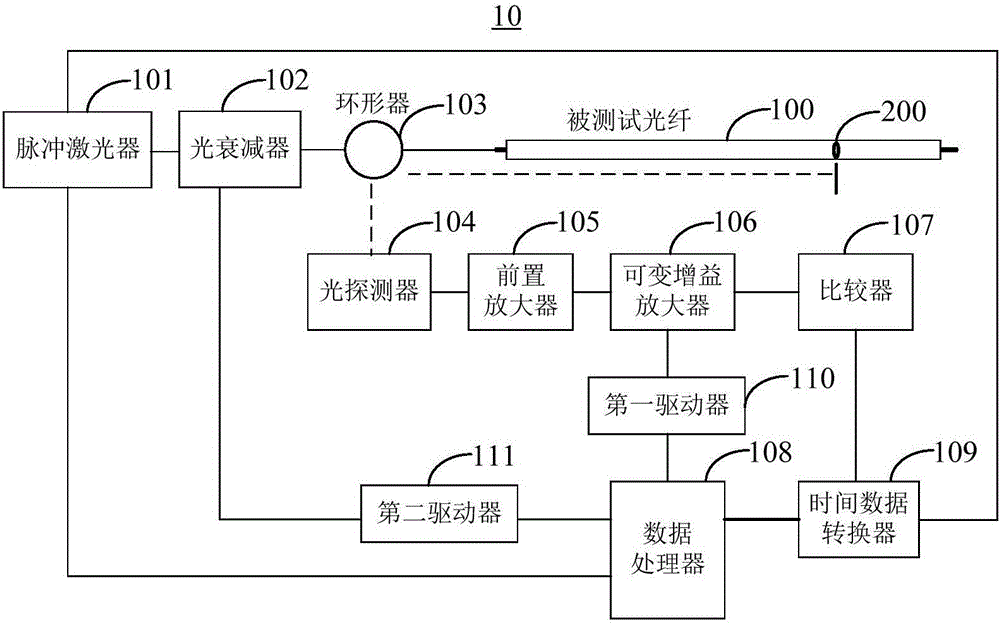

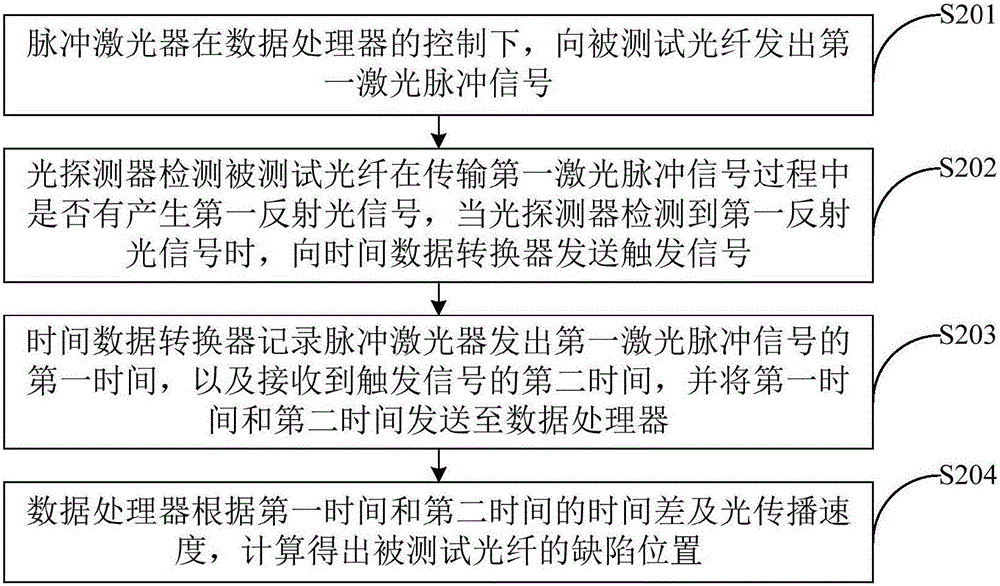

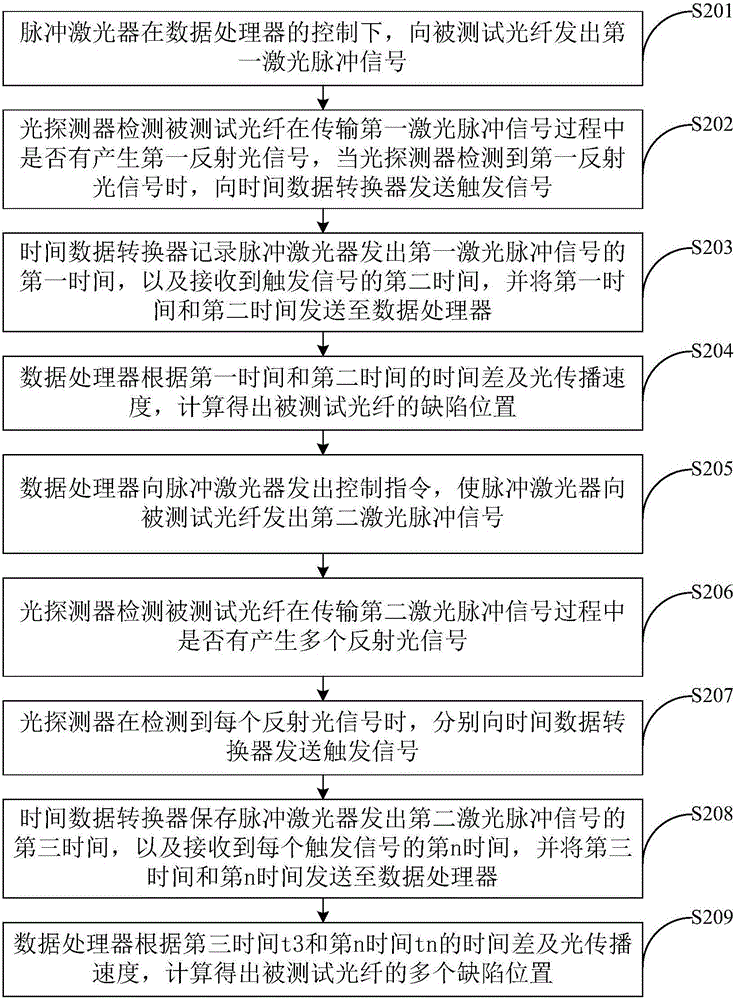

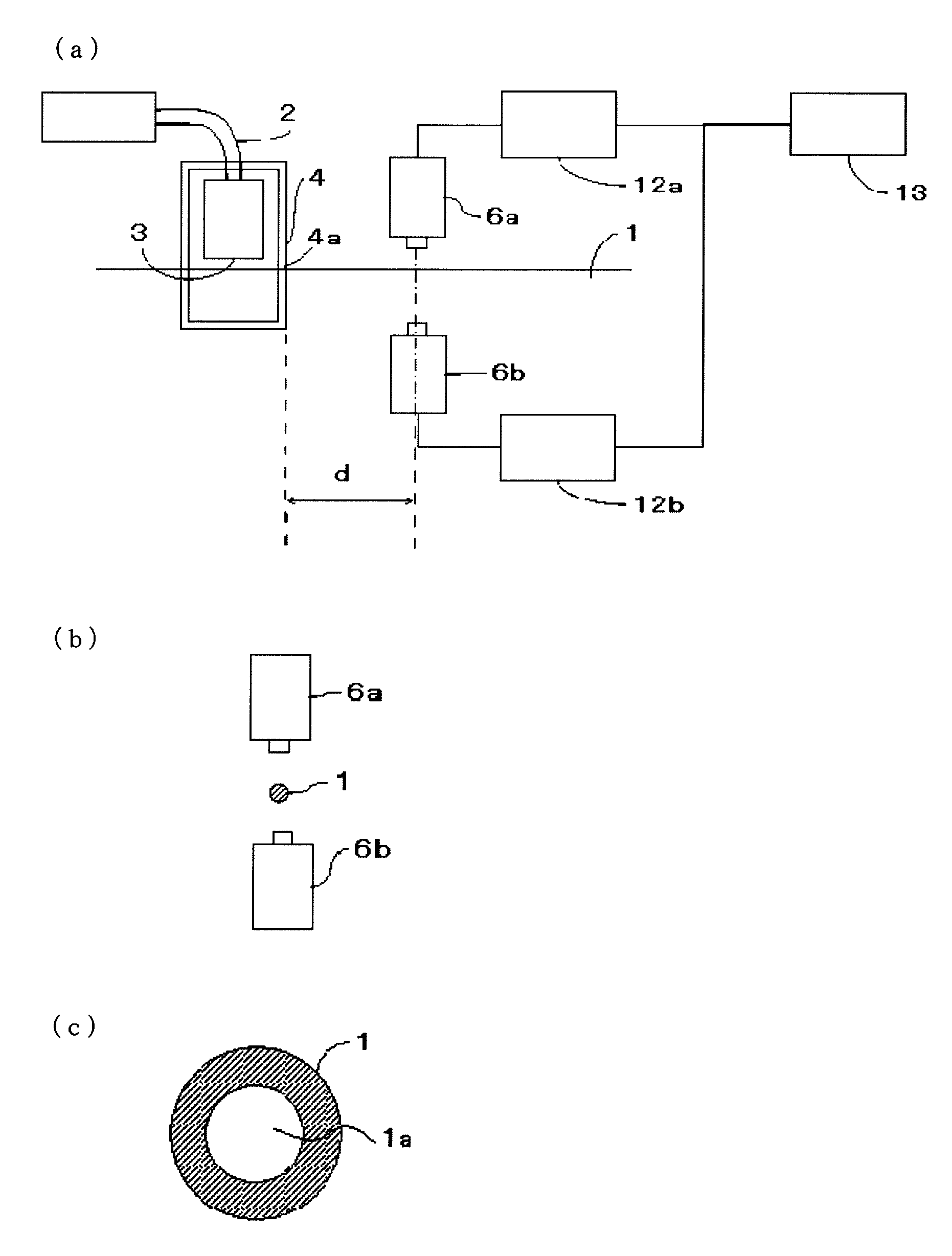

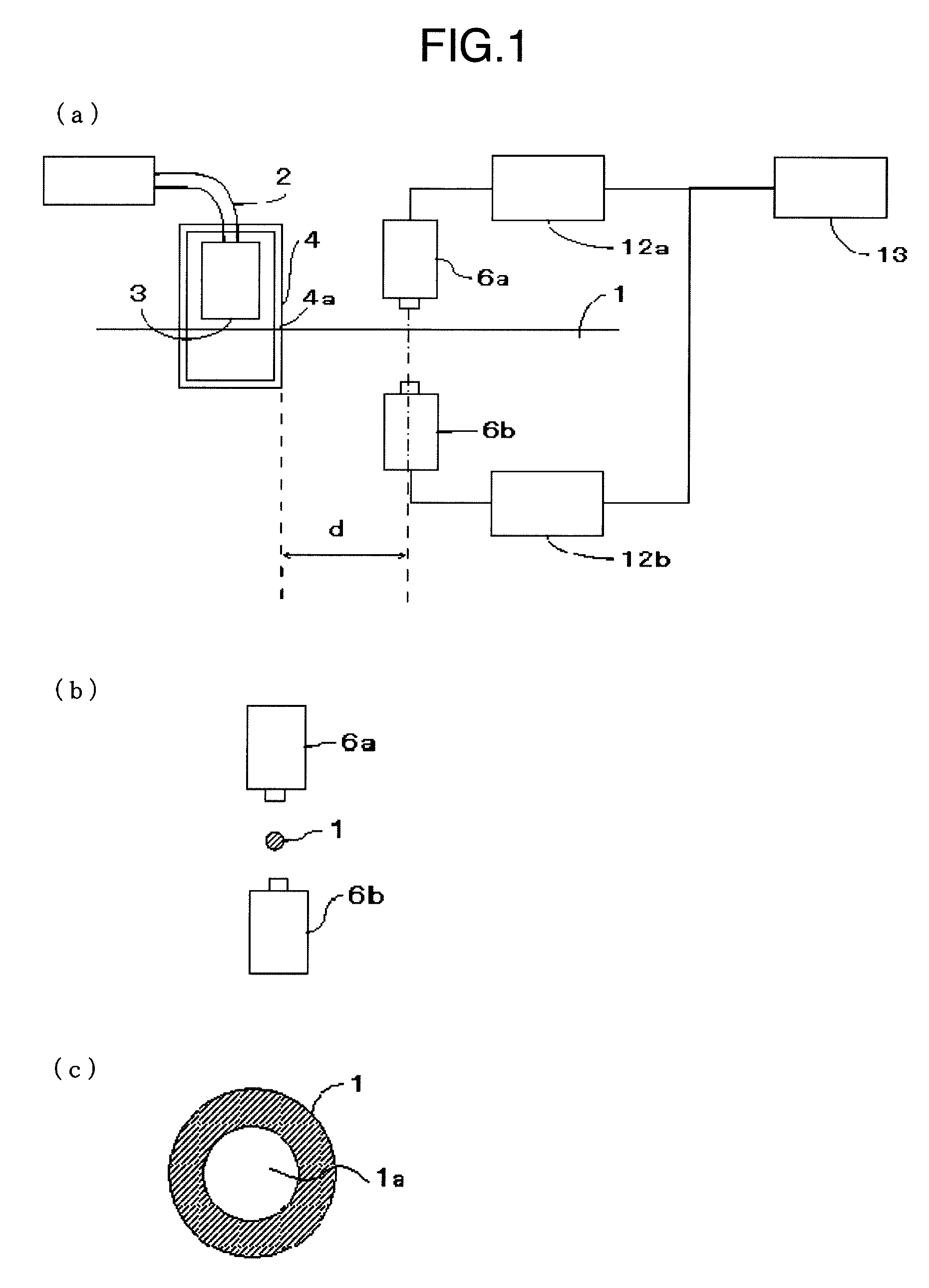

Optical fiber defect detecting method and device

ActiveCN105865750ARapid Defect DetectionAccurate Defect DetectionElectromagnetic wave reradiationReflectometers detecting back-scattered light in time-domainData translationErbium lasers

The invention provides an optical fiber defect detecting method and device. The optical fiber defect detecting device comprises a data processor, a pulse laser, a time data converter and an optical detector, wherein the pulse laser is used for emitting a laser pulse signal to a to-be-detected optical fiber under the control of the data processor; the optical detector is used for detecting whether the to-be-detected optical fiber generates a reflected light signal in the laser pulse signal transmission process and sends a trigger signal to the time data converter when detecting the reflected light signal; the time data converter is used for recording first time the pulse laser spent emitting the laser pulse signal and second time the pulse laser spent receiving the trigger signal and sends the first time and the second time to the data processor; the data processor is used for calculating positions of defects of the to-be-detected optical fiber according to the time difference between the first time and the second time as well as the light propagation speed. With the adoption of the optical fiber defect detecting method and device, the defects of the optical fiber can be detected conveniently and rapidly.

Owner:CHENGDU YINGXIN PHOTOELECTRIC TECH CO LTD

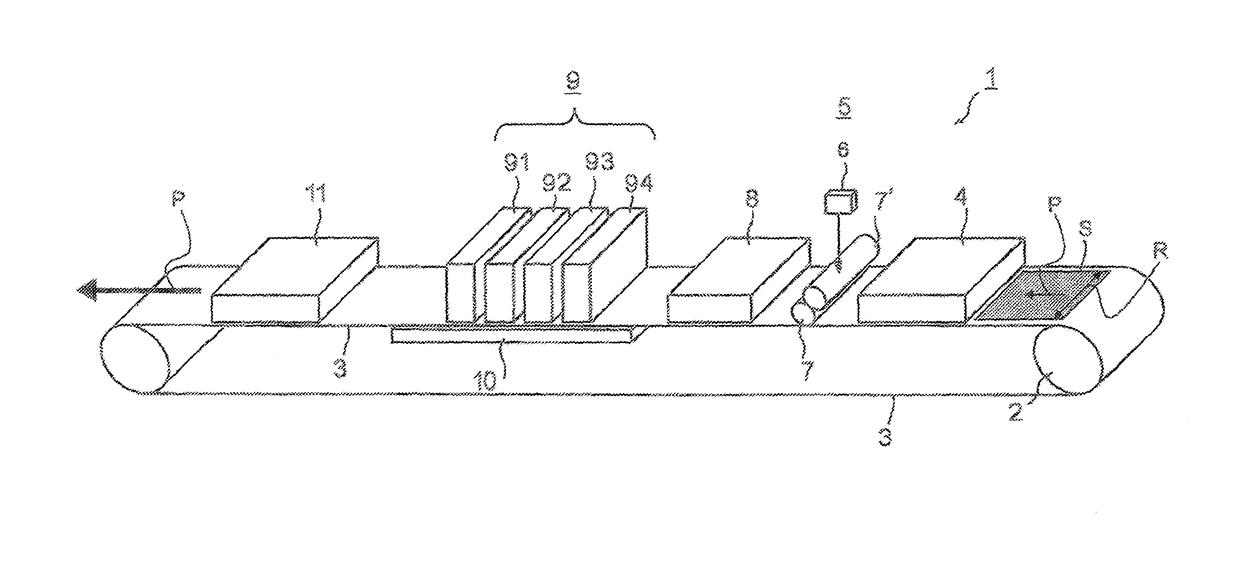

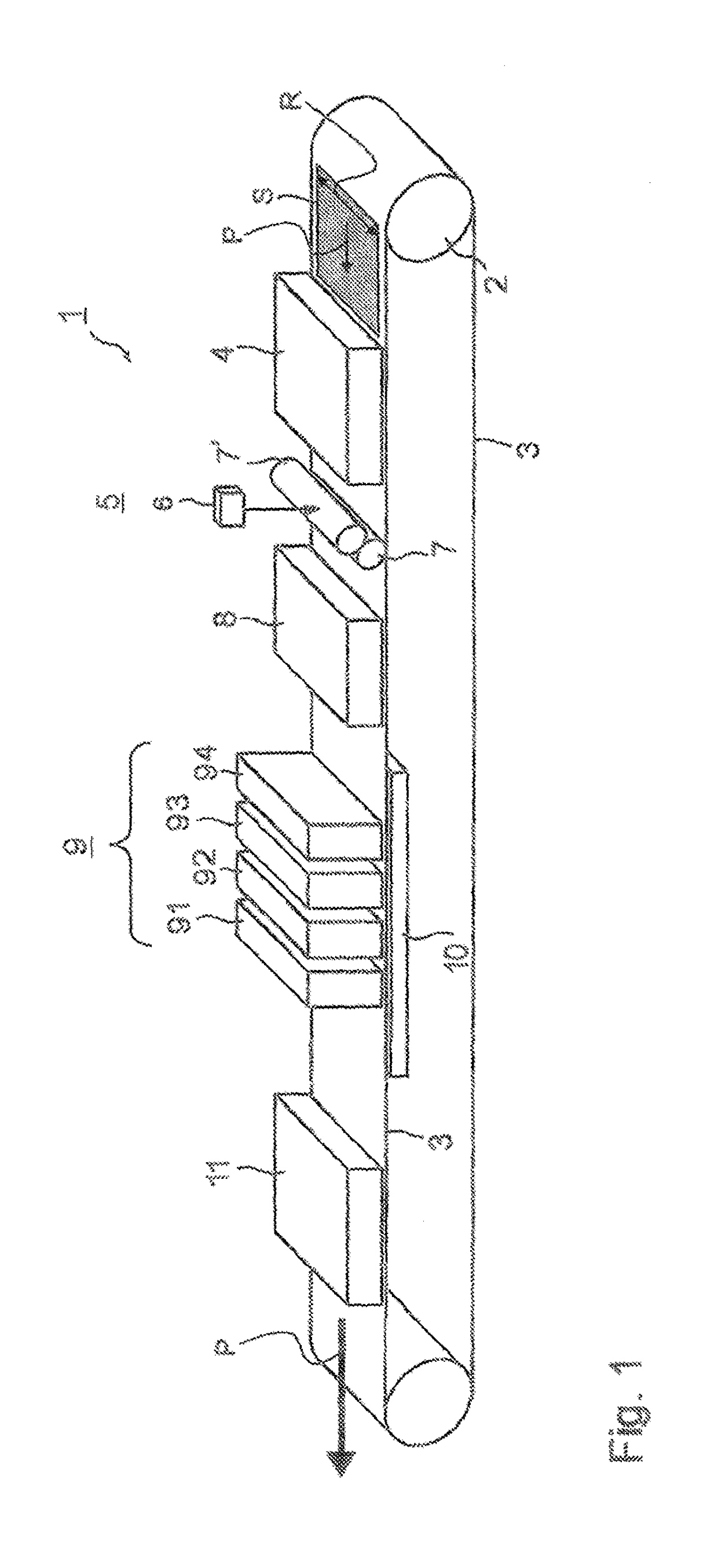

Apparatus and method for defect detection in a printing system

ActiveUS9710203B2Accurate measurementAccurate defect detectionImage enhancementImage analysisHeight mapEngineering

An apparatus for defect detection in a printing system, comprising a sensor device for sensing a surface of a sheet and for generating data representing a height map of the sheet, and a processor device for processing the data from the sensor device, wherein the processor device is configured to analyze the height map to detect a presence of a deformation in the sheet. The processor device is further configured to, when a deformation is detected, to determine at least one property of the deformation, to classify the deformation with respect to a plurality of deformation classes by means of the at least one property of the deformation, and to determine a suitability of the sheet for printing based on the deformation class wherein the deformation has been classified.

Owner:OCE TECH

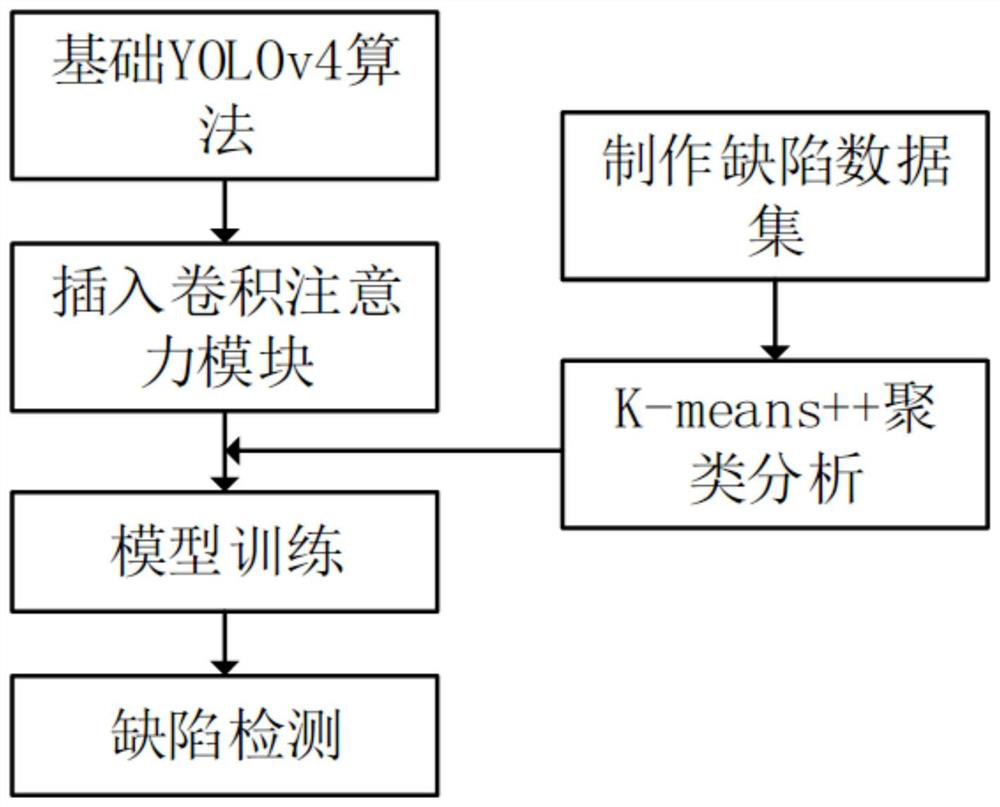

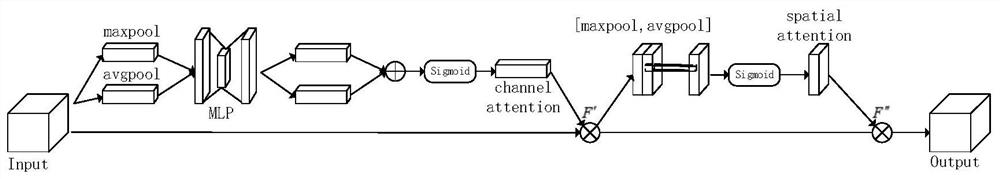

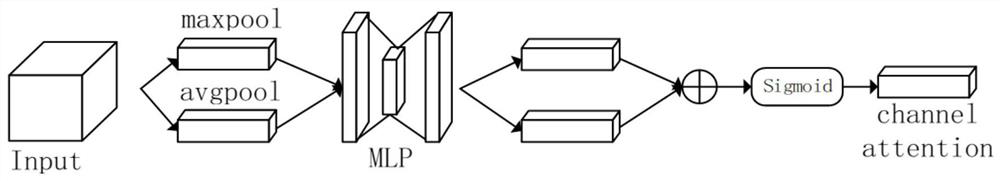

Forging defect detection method based on deep learning

PendingCN113393439AImprove robustnessEfficient defect detectionImage enhancementImage analysisFeature extractionAlgorithm

The invention discloses a forging defect detection method based on deep learning, which comprises the following steps: firstly, establishing a YOLOv4 algorithm model for detecting forging defects, then training the YOLOv4 algorithm model, and then carrying out defect detection on a picture of a to-be-detected forging by adopting the trained YOLOv4 algorithm model. The method is characterized in that after residual errors in a feature extraction network of a YOLOv4 algorithm model are connected, a CBAM attention module is inserted, and features are screened. The method has the advantages of being good in robustness, capable of efficiently and accurately conducting defect detection and the like.

Owner:CHONGQING UNIV OF TECH

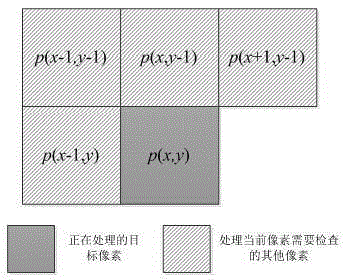

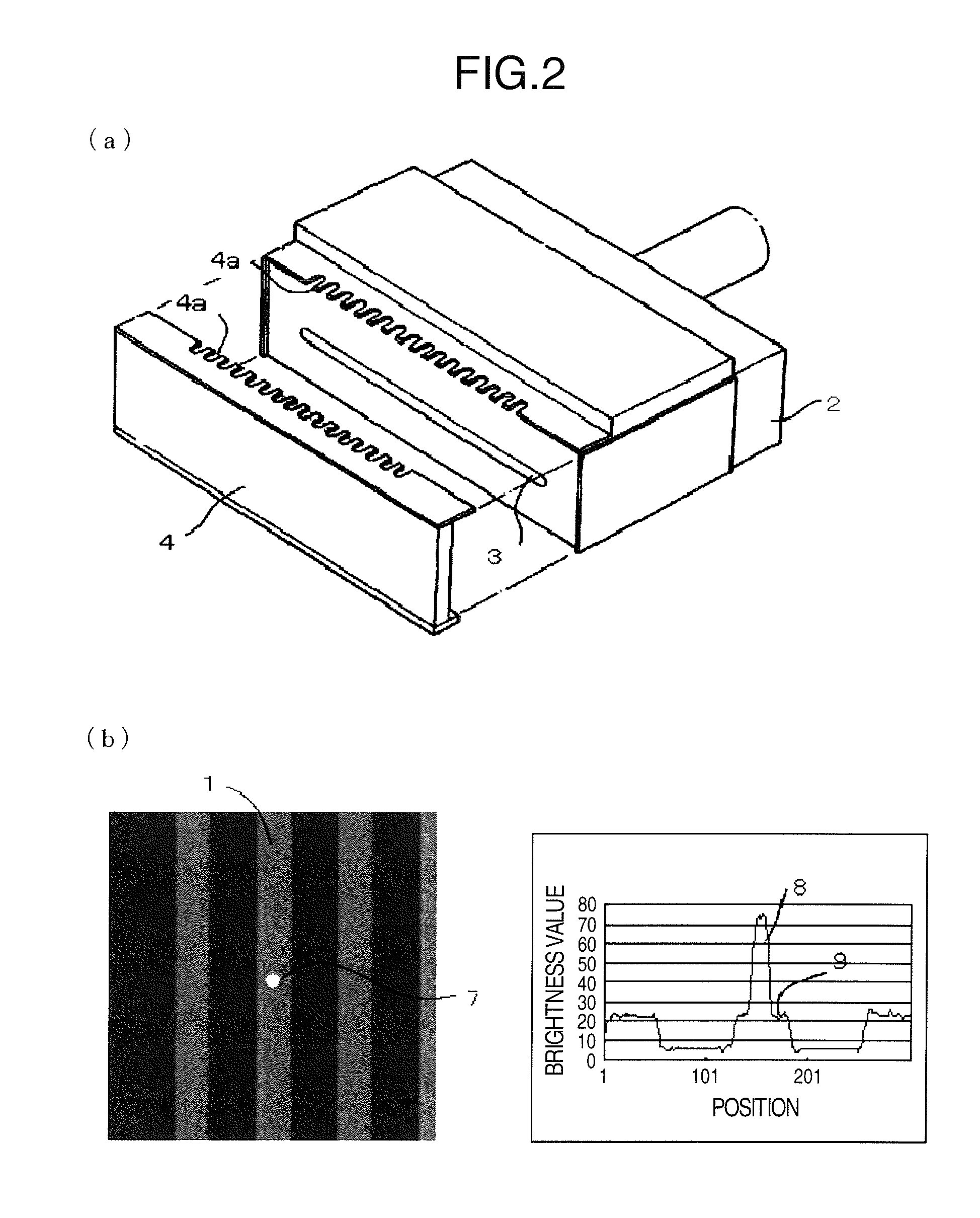

Defect detecting device, defect detecting method, image sensor device, image sensor module, defect detecting program, and computer-readable recording medium

InactiveUS8391585B2Accurate Defect DetectionReduce misjudgmentImage enhancementImage analysisPattern recognitionOutlier

A defect detecting device includes a pixel value correcting section, a block-division processing section, and a defective / non-defective determining section. The pixel value correcting section corrects a pixel value of an inspection-target image, on which detection of a defective area is to be carried out, in such a manner that the defective area of the inspection-target image is emphasized with respect to the other areas of the inspection-target image. The block-division processing section divides, into plural blocks, the inspection-target image with pixel values having been corrected, and obtains a block addition value or a block mean value. The defective / non-defective determining section determines whether or not the defective area is present by carrying out statistical processing to determine whether an outlier of the block addition value or an outlier of the block mean value is present or not.

Owner:SHARP KK

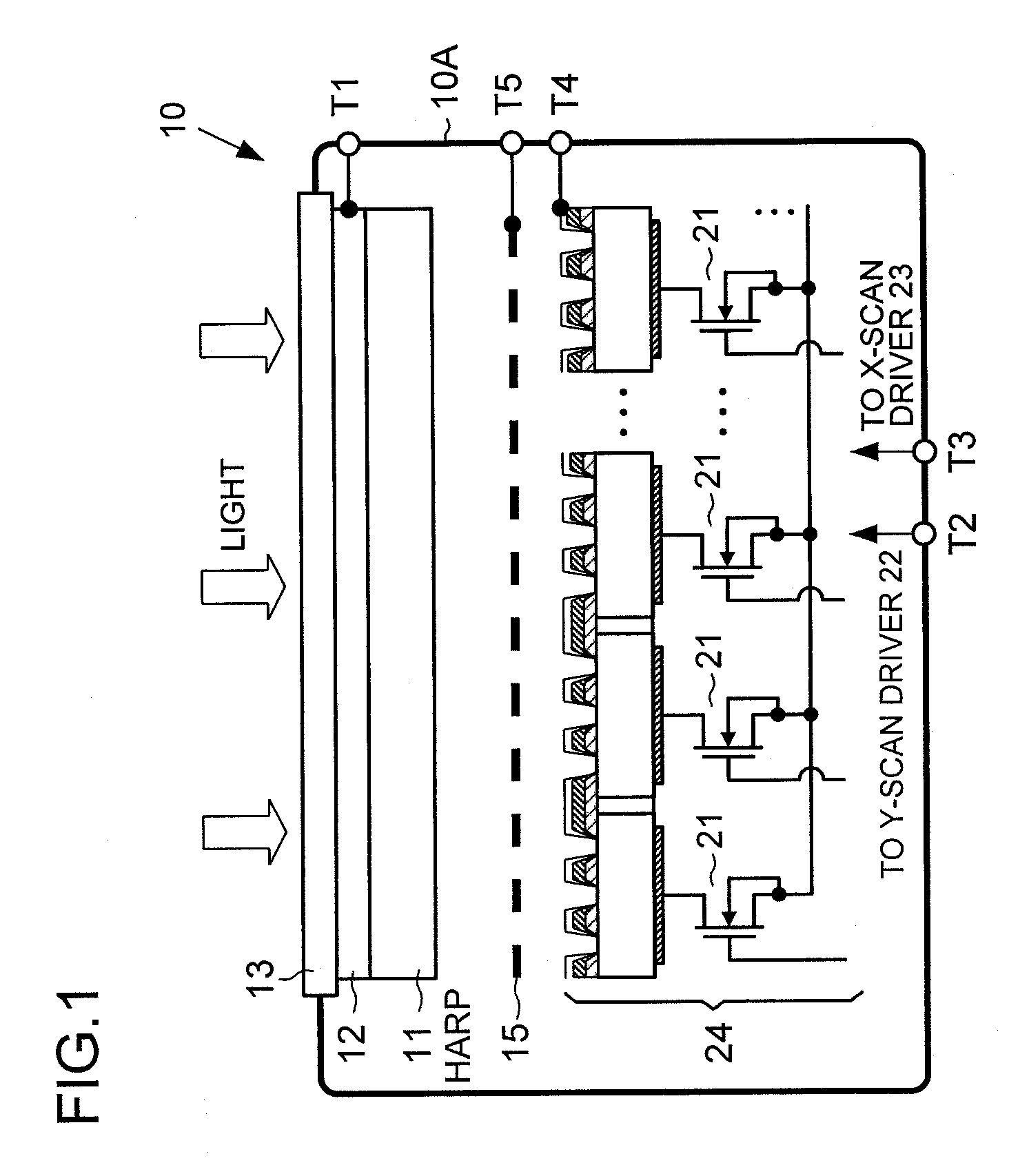

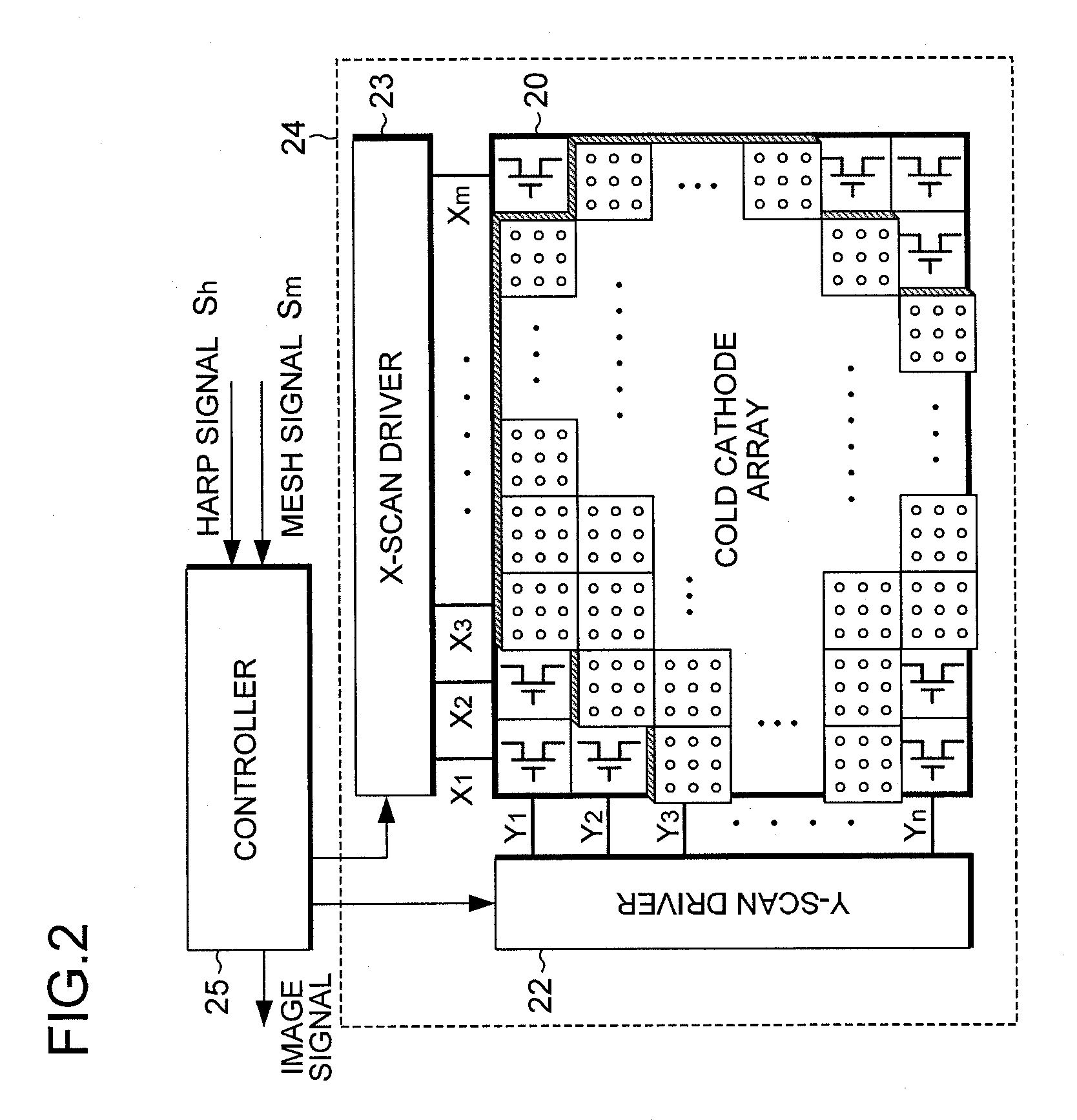

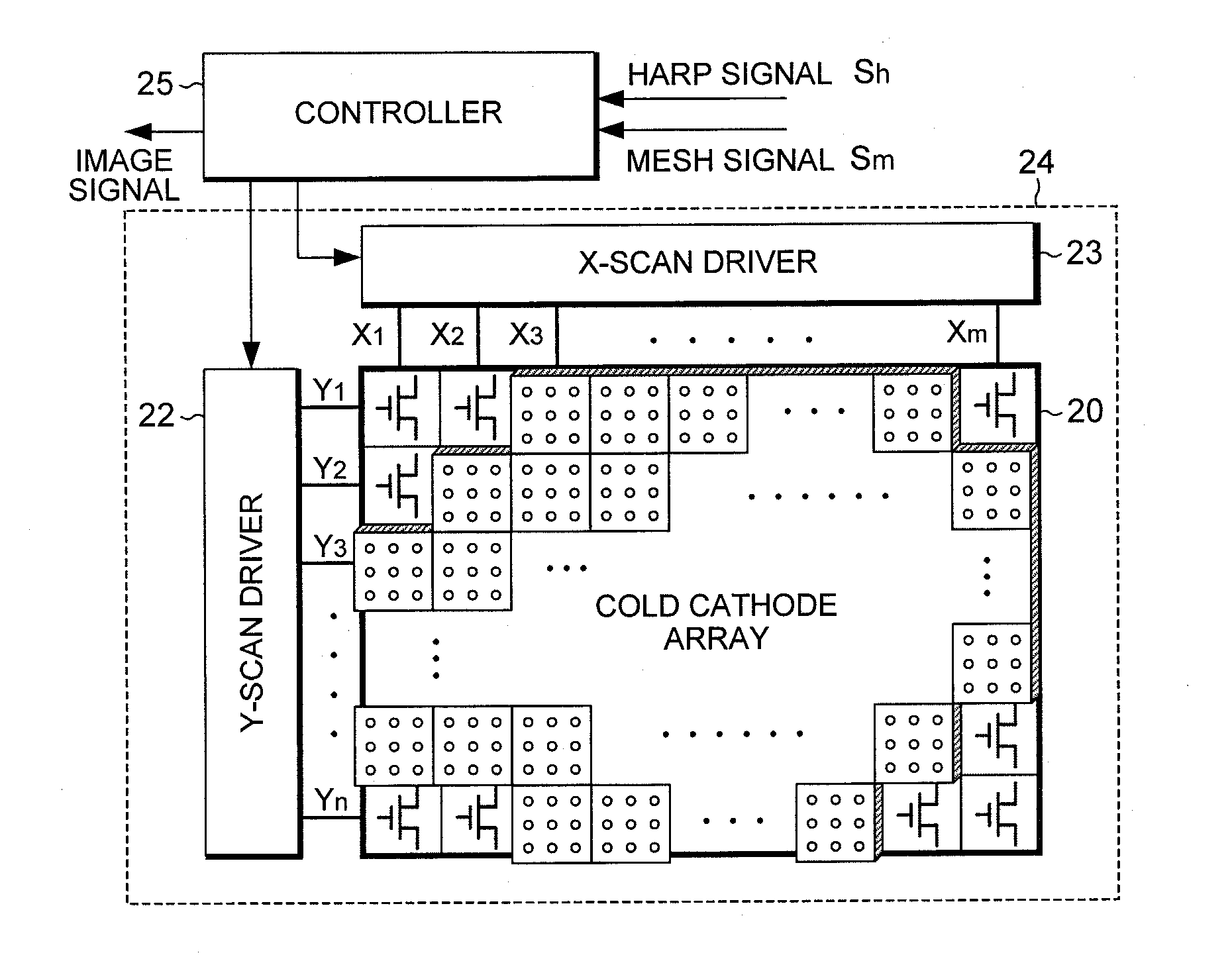

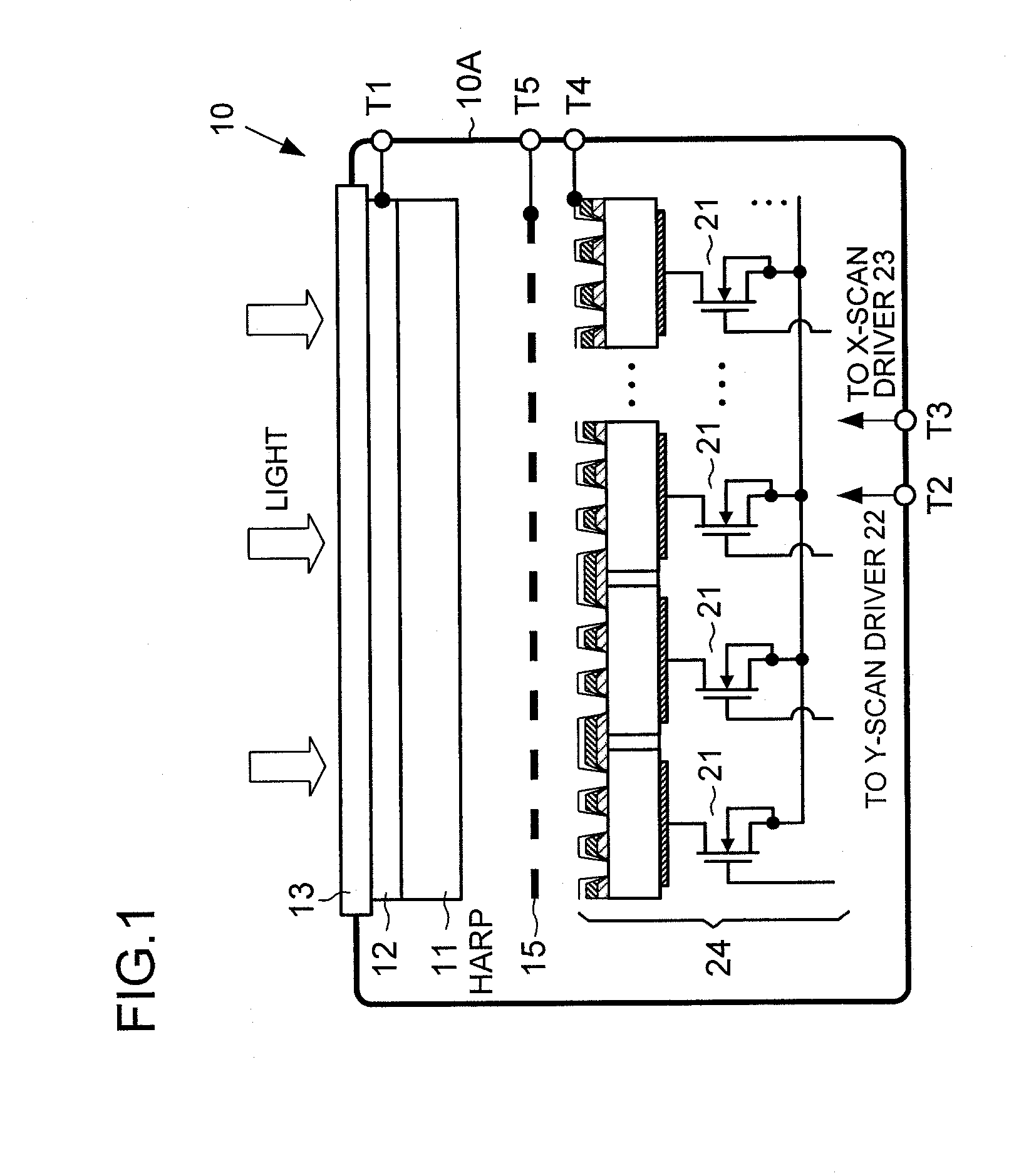

Image sensing device

InactiveUS8203112B2Accurate defect detectionTelevision system detailsSolid-state devicesPhotoelectric conversionElectron

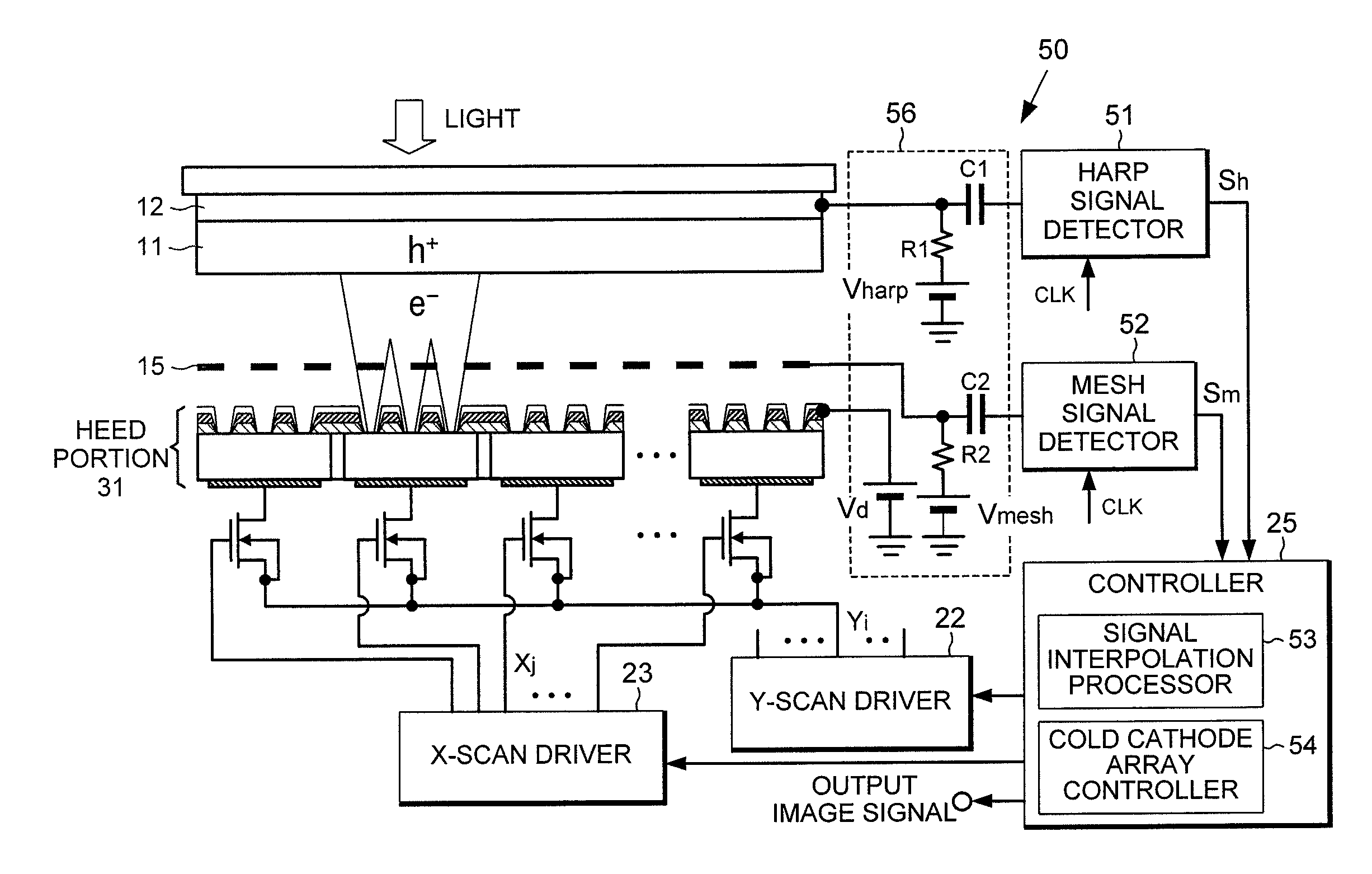

A device includes an electron emission source array including a plurality of electron emission sources, a photoelectric conversion film disposed to face the electron emission source array, and an intermediate electrode provided between the electron emission source array and the photoelectric conversion film, and an intermediate electrode current detector that applies a positive potential, relative to a potential of the electron emission source array, to the intermediate electrode and detects a current flowing in the intermediate electrode.

Owner:PIONEER CORP +3

Image sensing device

InactiveUS20100025568A1Accurate defect detectionTelevision system detailsSolid-state devicesPhotoelectric conversionElectron

A device includes an electron emission source array including a plurality of electron emission sources, a photoelectric conversion film disposed to face the electron emission source array, and an intermediate electrode provided between the electron emission source array and the photoelectric conversion film, and an intermediate electrode current detector that applies a positive potential, relative to a potential of the electron emission source array, to the intermediate electrode and detects a current flowing in the intermediate electrode.

Owner:PIONEER CORP +3

Method for inspecting defect of hollow fiber porous membrane, defect inspection equipment and production method

InactiveUS7940382B2Increase in absolute quantityImprove accuracySemi-permeable membranesCharacter and pattern recognitionFiberPorous membrane

Owner:ASAHI KASEI CHEM CORP

Method and Apparatus for Inspecting Defects

InactiveUS20100014075A1Accurate Defect DetectionOptically investigating flaws/contaminationReference imageOptical polarization

An apparatus for inspecting a substrate surface is provided, which includes illumination optics for irradiating the substrate surface linearly with rectilinearly polarized light from an oblique direction, detection optics for acquiring images of the substrate surface, each of the images being formed by the light scattered from the light-irradiated substrate surface, and means for comparing an image selected as an inspection image from the plurality of substrate surface images that the detection optics has acquired to detect defects, and another image selected from the plural images of the substrate surface as a reference image different from the inspection image; the illumination optics being formed with polarization control means for controlling a polarizing direction of the light according to a particular scanning direction of the substrate or a direction orthogonal to the scanning direction.

Owner:HITACHI HIGH-TECH CORP

Multifunction electromagnetic flaw detection device

ActiveCN101025406AAccurate detection of various defectsAccurate defect detectionMaterial magnetic variablesEngineeringScrew thread

The invention relates to a combination electromagnetism explore injure equipment, it includes sensor, its feature is that it also includes bearing installed on the pipe, bar straightener, supporting axle, supporting roller armed with envelope curve rolling curve and sensor supporting, of which supporting axle installed on the bearing, supporting roller installed on the supporting axle, bearing fixed on the dead plate, arc slot set on the bearing and dead plate relative position and dent into bolt fastening, one end of sensor supporting through the through hole of bearing center and connect with the screw-thread hole of the dead plate center, the other end of sensor supporting connect with the sensor which installed between the both sides supporting roller, supporting sleeve covered sensor supporting and dead connect with bearing, transverse hole installed on the supporting sleeve bottom, one end of supporting axle cantilever reeve through the hole. The invention characteristics is that it could improve measurement precision and accuracy, which integrates a entire with explore injure function and straightening function, the invention could be used on the pipe or bar or sheet or section steel straightening machine production line.

Owner:辽宁盛鸿科技股份有限公司

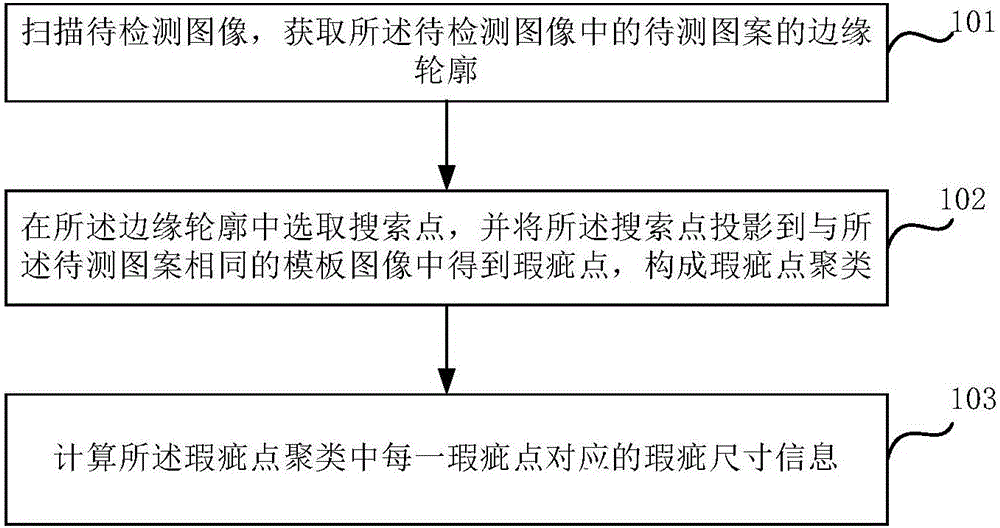

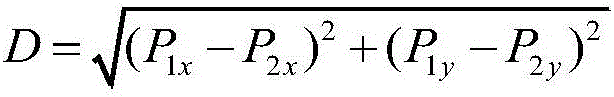

Image defect detection method

ActiveCN106815830AAccurate defect detectionLow costImage enhancementImage analysisDefect sizePoint cluster

The invention relates to an image defect detection method. The image defect detection method comprises steps that a to-be-detected image is scanned, and an edge contour of a to-be-detected pattern in the to-be-detected image is acquired; searching points in the edge contour are selected, and are projected in a template image, which is the same as the to-be-detected pattern, and defect points are acquired to form a defect point cluster; defect size information corresponding to every defect point in the defect point cluster is calculated. Under a cost reduction condition, the accurate detection of the image defect is realized.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com