Real-time detecting method of metal arc plane flaw based on machine vision

A technology for polishing metal and real-time detection, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of background image extraction errors, narrow effective area, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with specific drawings and embodiments.

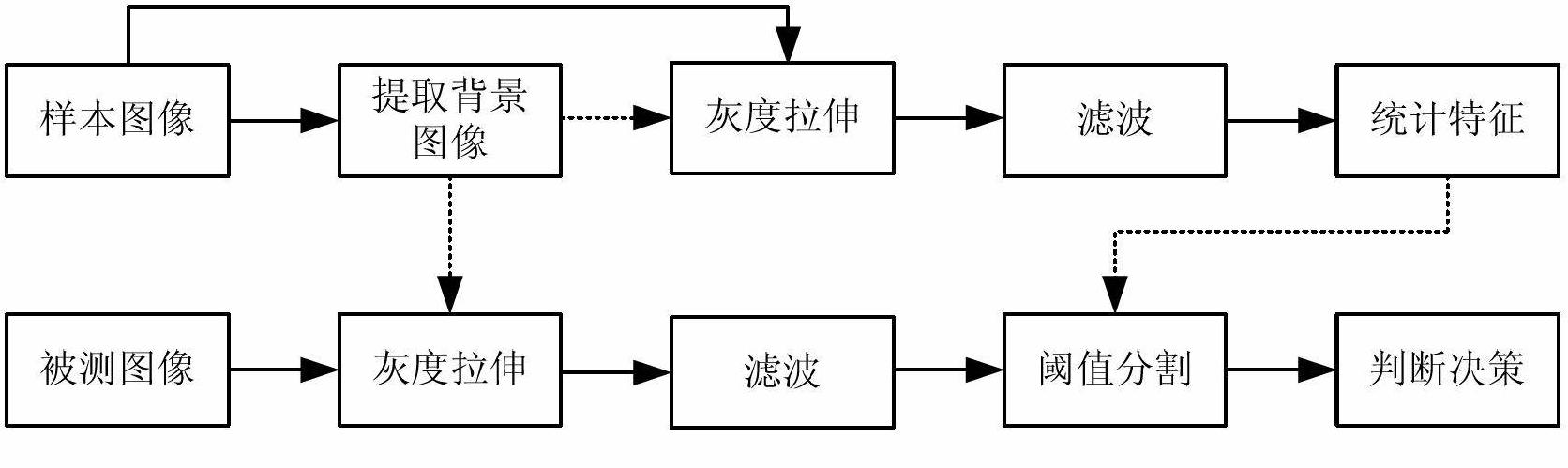

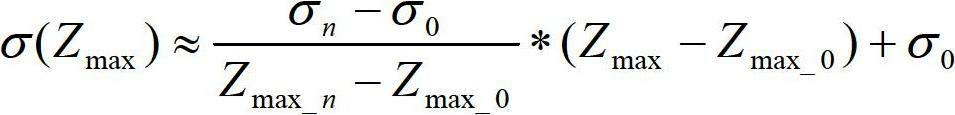

[0072] The purpose of the present invention is to carry out real-time detection of flaws on polished metal arc-shaped surfaces. Since the surface of polished metal arc-shaped surfaces is smooth, the diffuse reflectance is low, and the surface is arc-shaped, the intensity of light emitted by surfaces at different spatial positions is different, so it is difficult to obtain Wide image with uniform brightness. According to this problem, a method based on offline learning knowledge for real-time detection of polished metal arc-shaped surfaces and online real-time detection of defects is proposed.

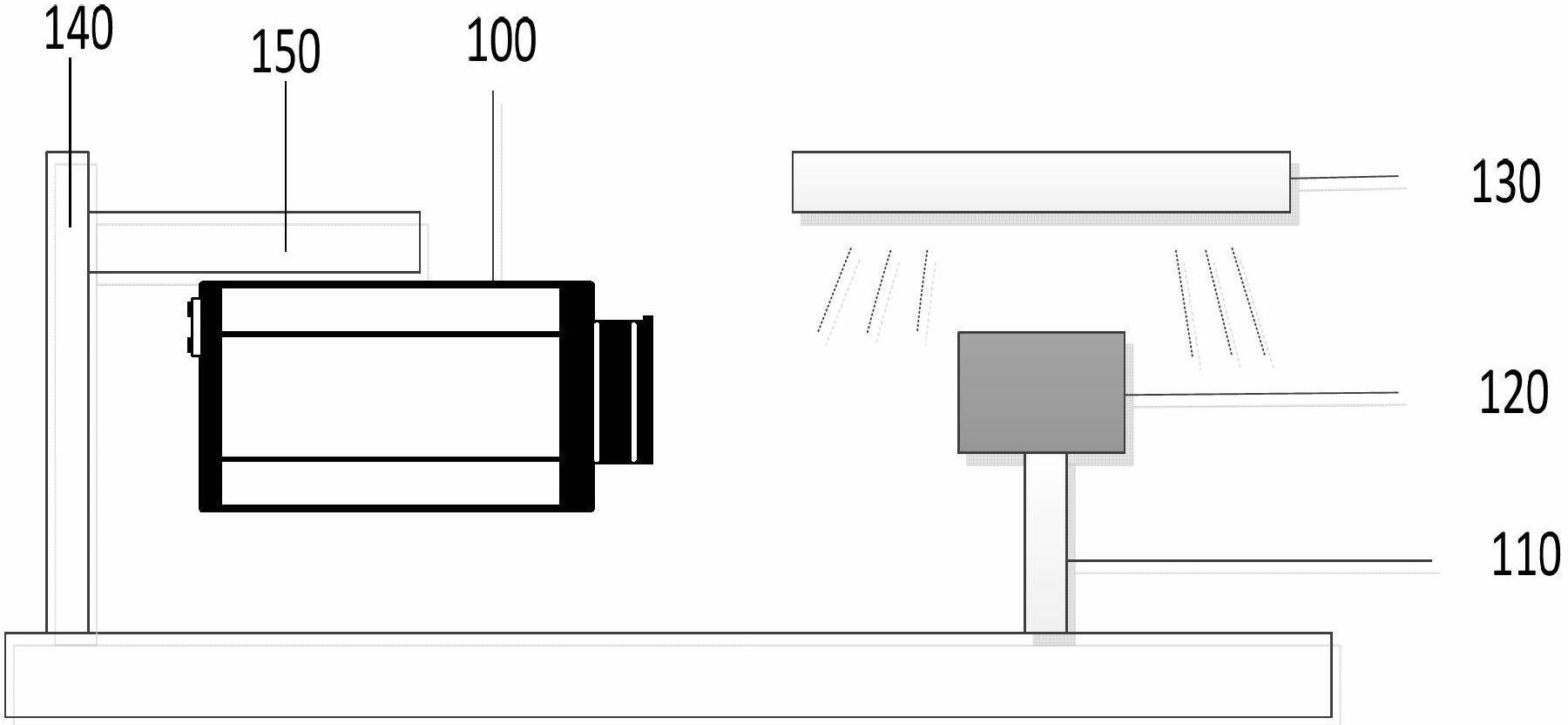

[0073] Such as figure 1 As shown, when collecting images, the present invention includes a base 140, the base 140 is provided with a vertically distributed support frame 110, and the metal arc-shaped surface can be supported by the support frame 110; the base 140 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com