Forging defect detection method based on deep learning

A defect detection and deep learning technology, applied in the field of visual inspection, can solve problems such as low contrast, high similarity between noise and defects, and lack of pertinence in diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below in conjunction with an embodiment using the solution of the present invention.

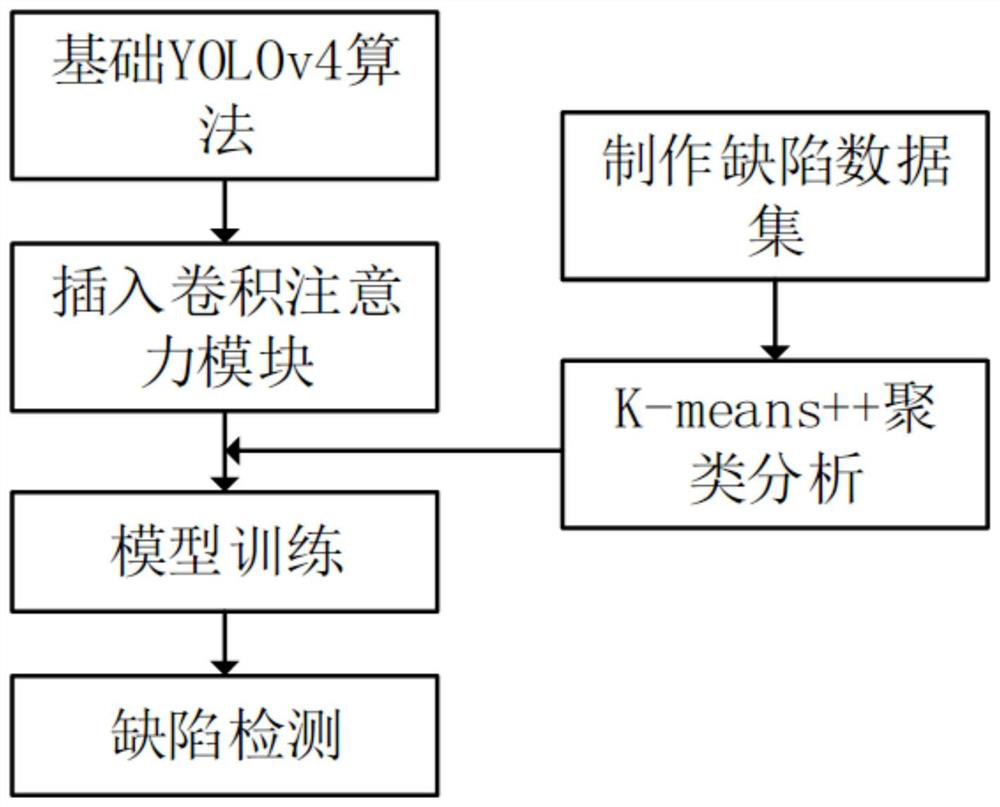

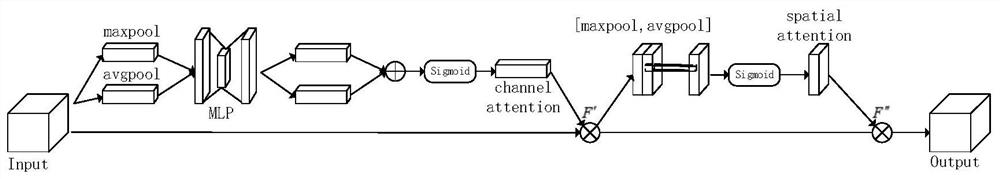

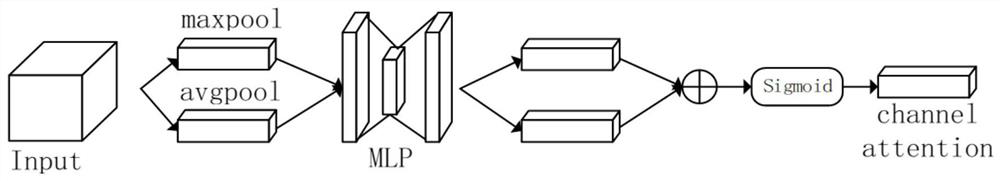

[0063] The development of deep learning target detection is relatively lagging behind in the detection of large-scale forging defects, mainly due to the variety of defect types and sizes in large-scale forging defects. It affects the judgment of the detection system, causes large errors in the detection results, and affects the effect of defect detection. Therefore, it is necessary to optimize the model to realize the detection of forging defects. In order to improve the detection effect, this embodiment proposes a YOLOv4 defect detection method based on convolutional attention based on the defect detection requirements and the characteristics of forging defects. The algorithm optimization process is as follows: figure 1 As shown, the YOLOv4 algorithm is used as the basic algorithm, and the attention mechanism is introduced, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com