Integrated coiled tubing defect detection device

An integrated technology for defect detection, applied in the direction of measuring devices, electromagnetic measuring devices, electrical devices, etc., can solve problems such as tubing cracks, reduce the service life of coiled tubing, increase the operating cost of coiled tubing service companies, etc., and achieve convenient use on site Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

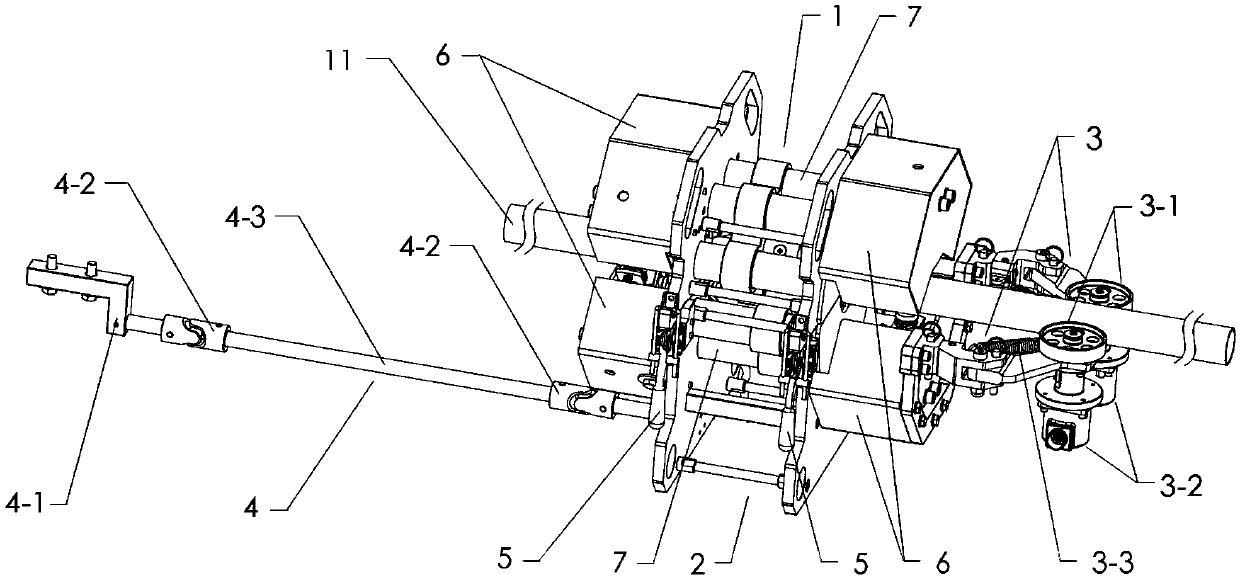

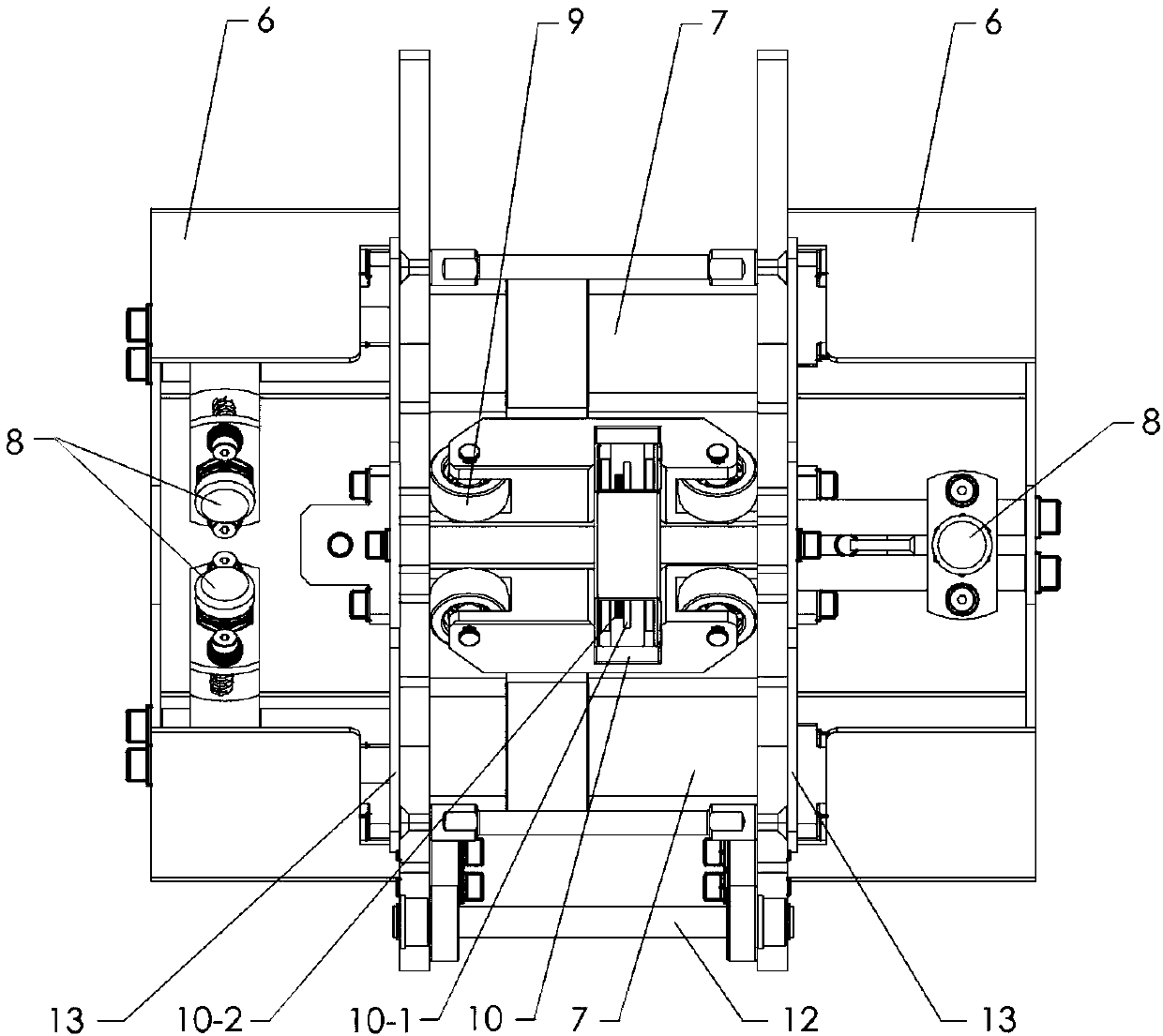

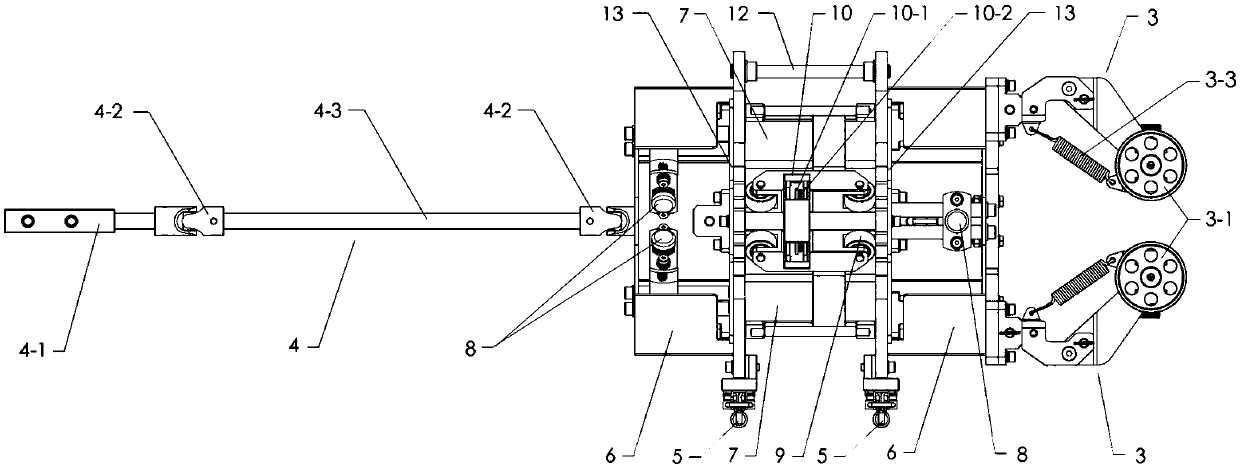

[0027] Such as figure 1 As shown, an integrated coiled tubing defect detection device includes two detection units, the upper half detection unit and the lower half detection unit. The two detection units are connected by two locking buckles. After the two detection units are assembled with each other, a channel through which the oil supply pipe passes is created between the two. In the channel, there are magnetic generation devices and magnetic flux leakage arranged on the two detection units. Detection probe, ellipticity detection probe and guide device, the detection unit is connected with a measuring arm assembly that guides the two detection units to move along the oil pipe, and the detection unit is also connected with a connecting rod assembly for connecting peripheral equipment.

[0028] Such as figure 1 As shown, the integrated coiled tubing defect detection device of the present invention adopts a clamshell design, and the overall structure is composed of an upper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com