Multifunction electromagnetic flaw detection device

A flaw detection device and multi-functional technology, applied in the direction of material magnetic variables, etc., can solve the problems of constant detection elements, smaller signal lift-off distance, shortened sensor service life, etc., to achieve convenient operation, simple structure, improve detection accuracy and The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

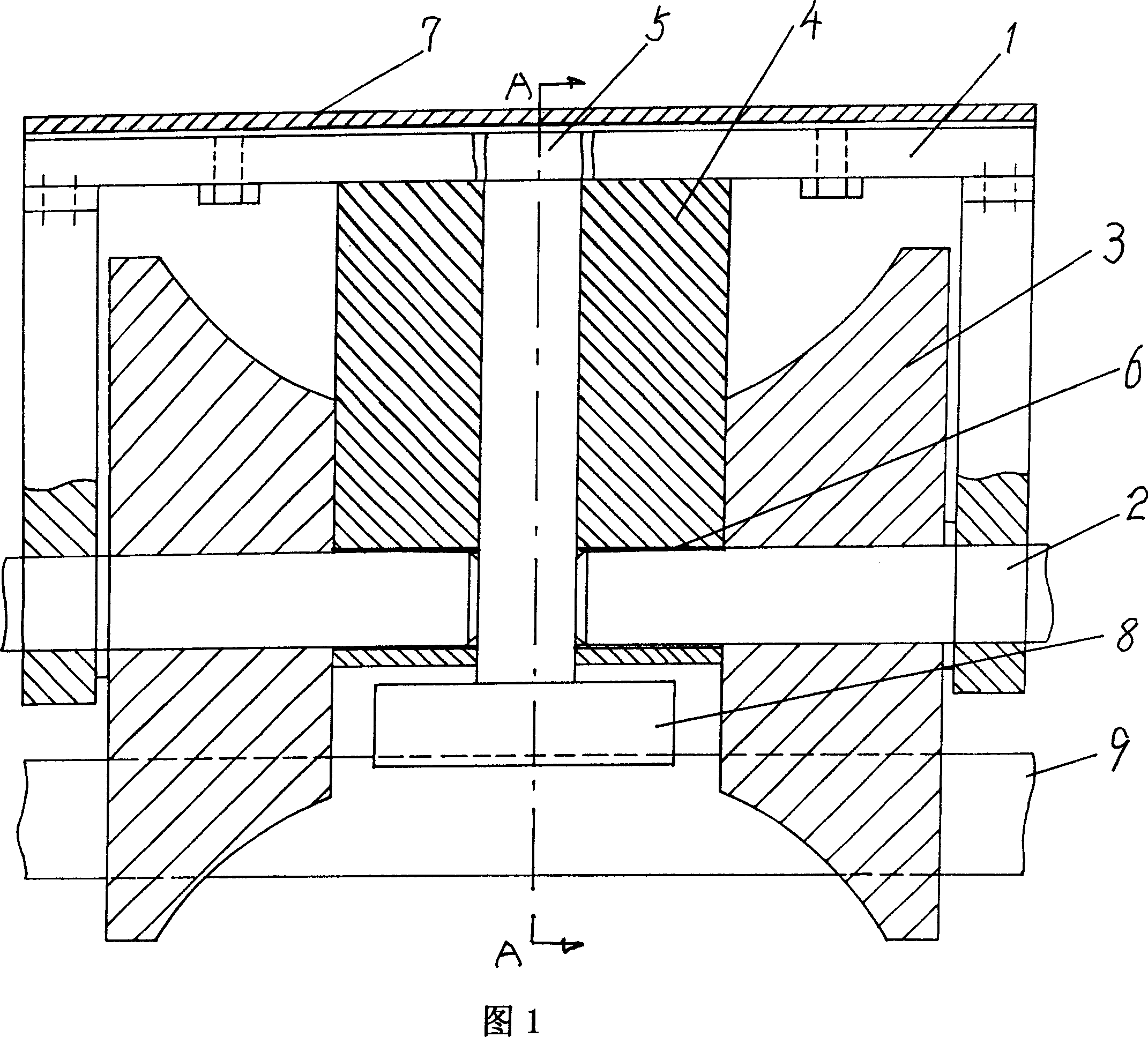

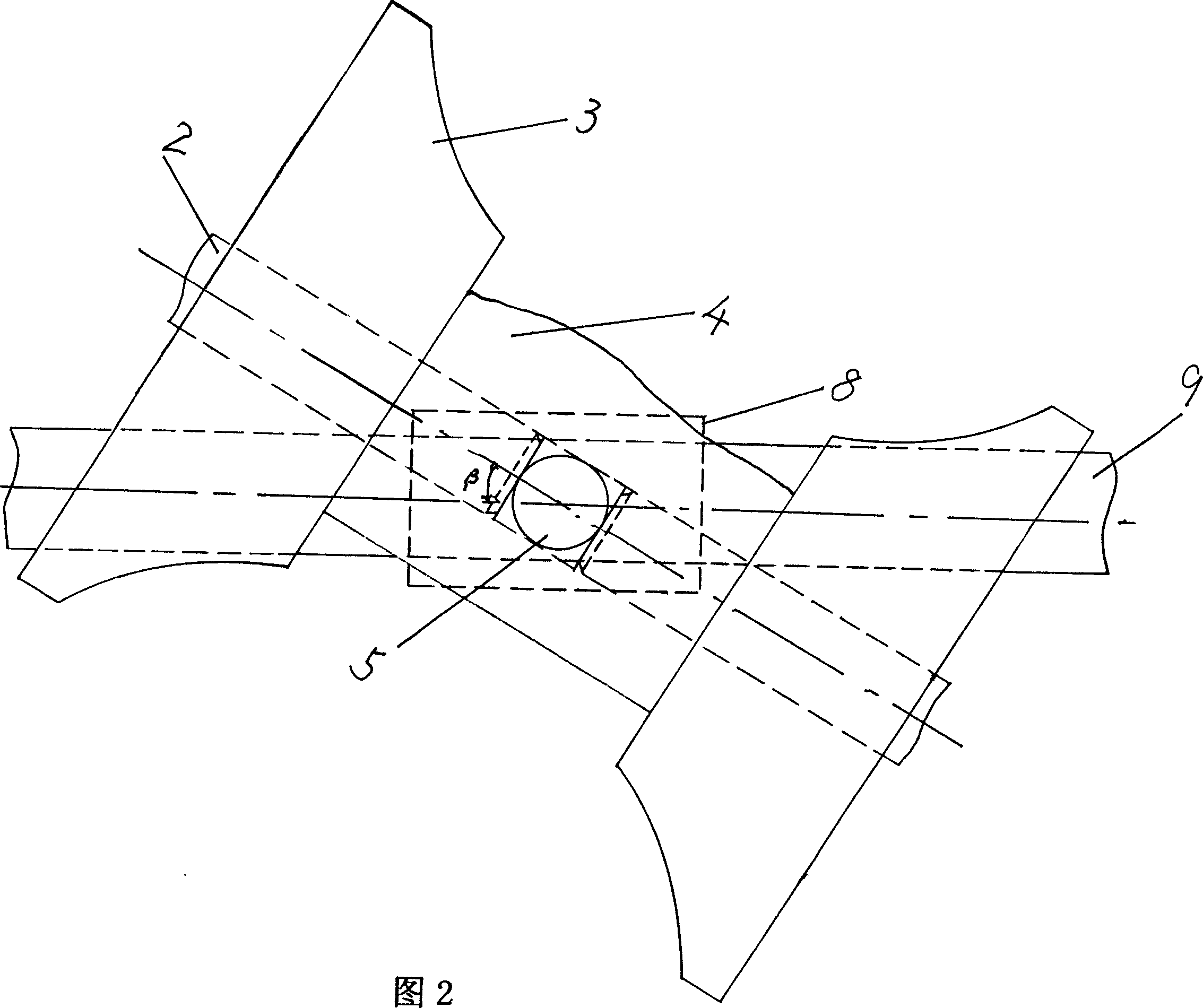

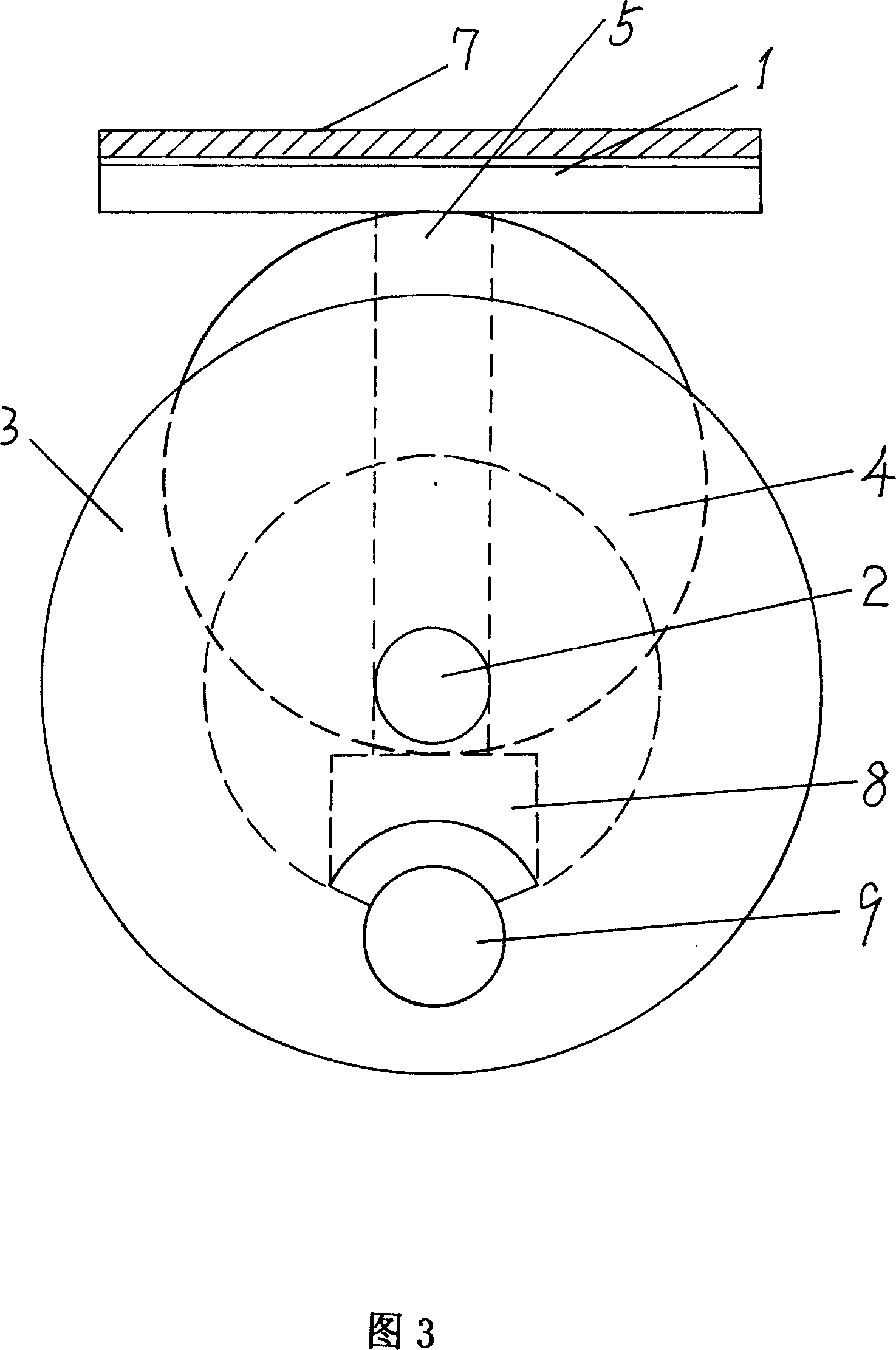

[0016] As shown in Figures 1 to 3, this multifunctional electromagnetic flaw detection device includes a sensor 8, a support 1 installed on a tube and bar straightening machine, a support shaft 2, and a support roll with an envelope roll curve. 3 and the sensor bracket 5, wherein the support shaft 2 is provided on the support shaft 2, the support roller 3 is installed on the support shaft 2, the support 1 is installed on the fixed plate 7, and the support 1 is on the corresponding position of the fixed plate 7 All are provided with arc grooves and penetrate bolts for fastening. One end of the sensor bracket 5 passes through the through hole in the center of the support 1 and connects with the threaded hole in the center of the fixing plate 7. The other end of the sensor bracket 5 is connected to the set The sensor 8 between the support rollers 3 on both sides is connected, and the support sleeve 4 is also sleeved on the sensor bracket 5. The support sleeve 4 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com