Patents

Literature

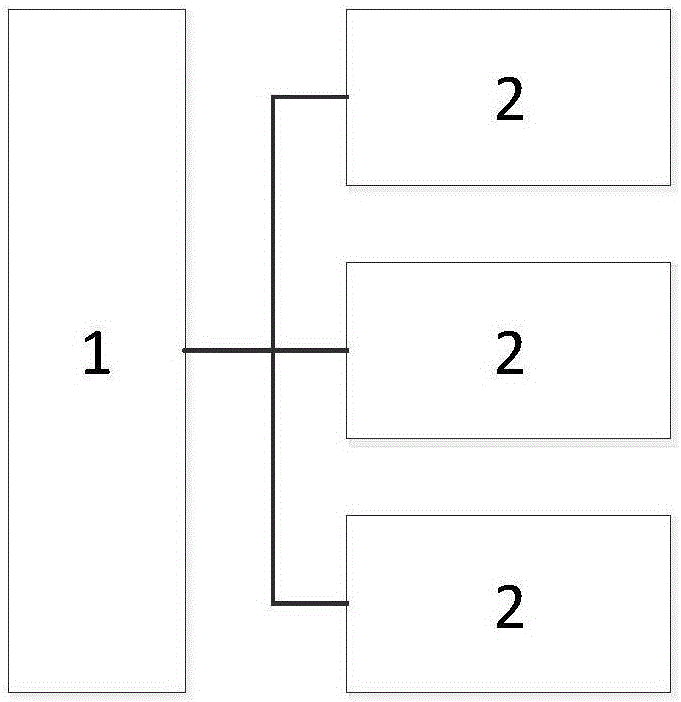

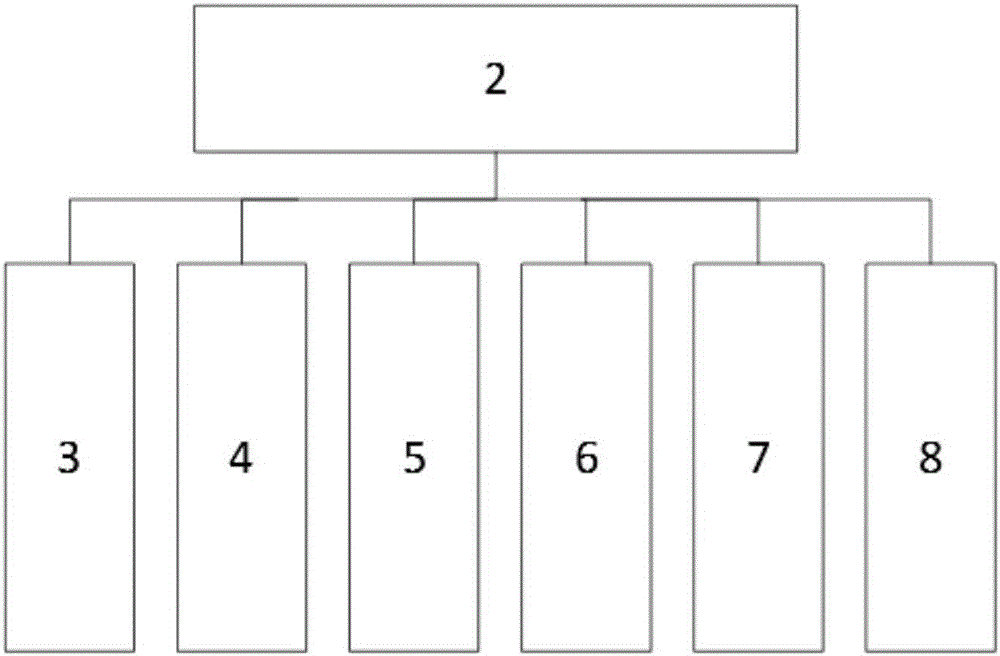

158results about How to "Improve defect detection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

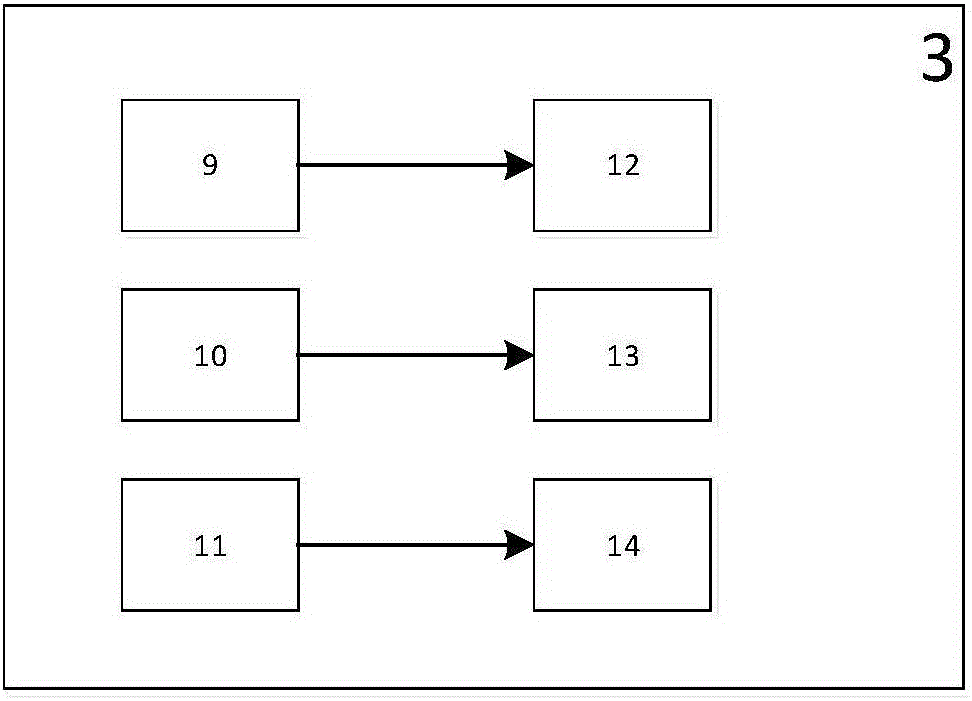

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indoor inspection robot system for substation and inspection method for indoor inspection robot system

ActiveCN105835063AShort driving routeShort detection timeProgramme-controlled manipulatorData transmissionRobotic systems

The invention discloses an indoor inspection robot system for a substation and an inspection method for the indoor inspection robot system. The indoor inspection robot system comprises a remote monitoring center and multiple robot terminals communicating with the remote monitoring center. Each robot terminal comprises a control module for controlling a robot to move in a three-dimensional space. The control modules drive movement modules so as to drive the robot to move in the X-axis direction, the Y-axis direction and the Z-axis direction and walk to the target detection position. Detection modules monitor the environment of the position and transmit monitoring data to the remote monitoring center. In the running and monitoring processes of the robot, safety protection modules keep detecting barriers and prevent the robot from moving out of the track. The remote monitoring center dispatches the robot terminals. By the adoption of the indoor inspection robot system for the substation and the inspection method for the indoor inspection robot system, the working labor intensity is lowered effectively, the substation operation and maintenance cost is lowered, the intelligent level and the automated level of normal inspection work and management are increased, and a detection means and an all-around safety guarantee are provided for intelligent substations and unmanned substations.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

Texture-based insulator fault diagnostic method

InactiveCN102508110AOutstanding FeaturesProminenceImage analysisFault locationHigh pressureFeature fusion

The invention relates to a texture-based insulator fault diagnostic method. According to the invention, a visible light image collected in the inspection process of a high voltage transmission line by a helicopter is used as an object to be processed, and the diagnosis can be carried out based on an insulator fault of the visible light image. The method comprises the following steps of: inputting an insulator image, carrying out gray processing, obtaining a bounding rectangle and rotating, carrying out a GLCM (gray level co occurrence matrix) method, blocking, obtaining textural features, carrying out Gabor filtering, blocking, calculating block-mean value and variance, performing feature fusion, and determining whether to have a string-drop phenomenon based on a threshold value. The method provided by the invention diagnoses the insulator string-drop characteristic by texture, integrates the thoughts of the most classical GLCM texture diagnostic method in the texture diagnosis and the recent research focus Gabor filter texture diagnosis, adjusts the parameter settings of the GLCM and the Gabor filter and efficiently and accurately finds out the string-drop insulators. The method can effectively improve the efficiency of the thermal defect detection of the power transmission line and can be effectively applied to the inspection business of the vehicle-mounted or helicopter power transmission line.

Owner:SHANGHAI UNIV

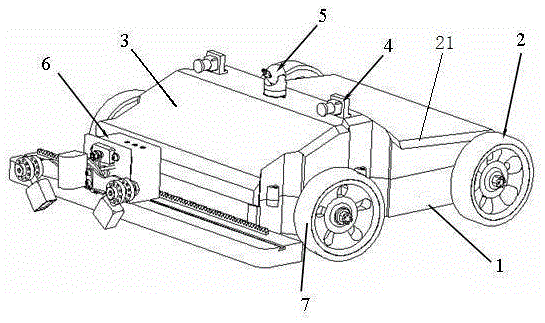

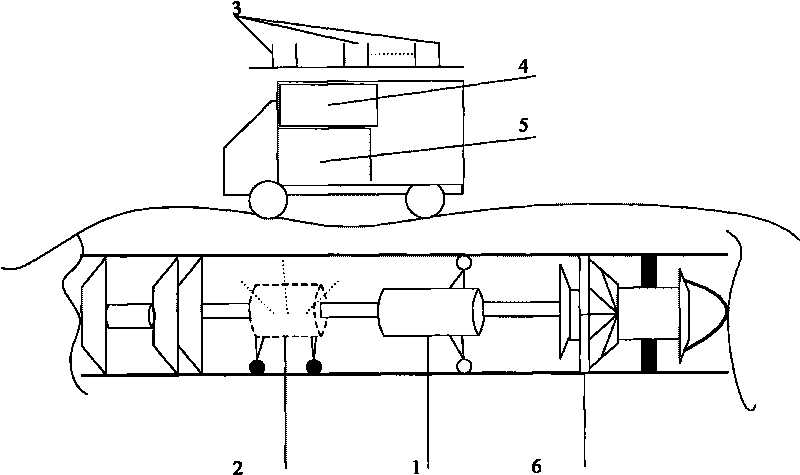

Automatic detector for welding line of storage tank bottom plate based on wireless transmission

ActiveCN105158337ARealize non-destructive testingAchieve horizontal movementAnalysing solids using sonic/ultrasonic/infrasonic wavesWireless transmissionComputer module

The invention relates to an automatic detector for a welding line of a storage tank bottom plate based on wireless transmission. The automatic detector comprises a machine body, a synchronous positioning and map construction module, a wireless data communication module and a control mechanism, wherein front wheels capable of controlling steering are mounted on the two sides of the machine body; driving rear wheels are mounted on the two sides of the rack; a bottom plate is arranged at the front end of the machine body in a manner of stretching frontwards; a lossless detection mechanism is mounted on the bottom plate; the lossless detection mechanism is provided with two air coupling ultrasonic probes with adjustable positions; the two air coupling ultrasonic probes are obliquely arranged in a V shape; a laser welding line tracking device is arranged between the two probes; an infrared camera and an infrared sensor are mounted at the top of the machine body; the control mechanism is connected with the front wheels and the driving rear wheels respectively; and the synchronous positioning and map construction module, the wireless data communication module, the laser welding line tracking device, the infrared camera and the infrared sensor are connected with the control mechanism respectively. With the adoption of the automatic detector, intelligent detection and evaluation of the welding line of the bottom plate are realized, and the manual detection cost is greatly reduced.

Owner:桐乡金橙云智科技有限公司

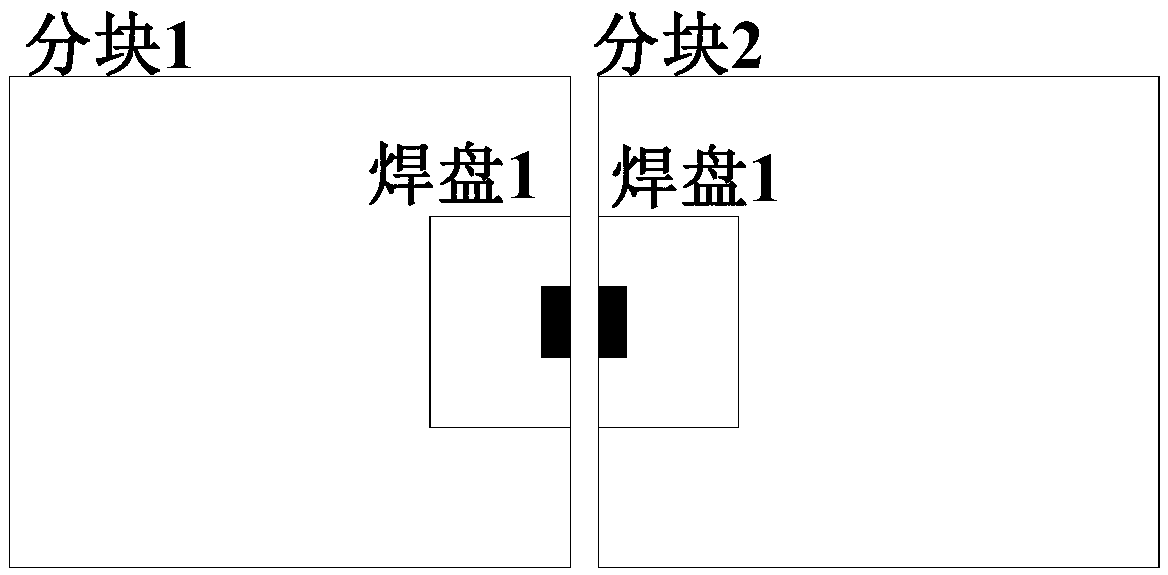

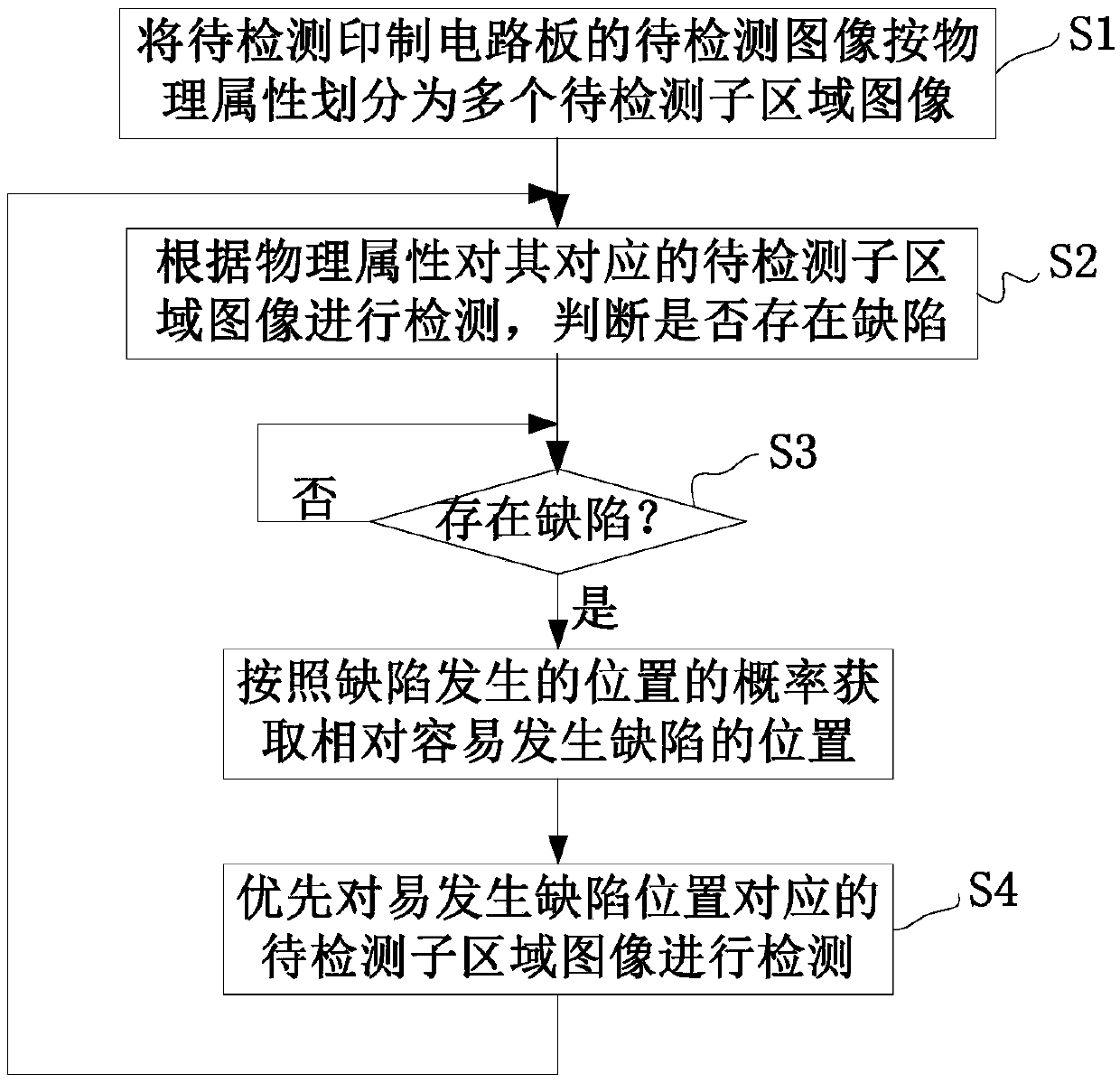

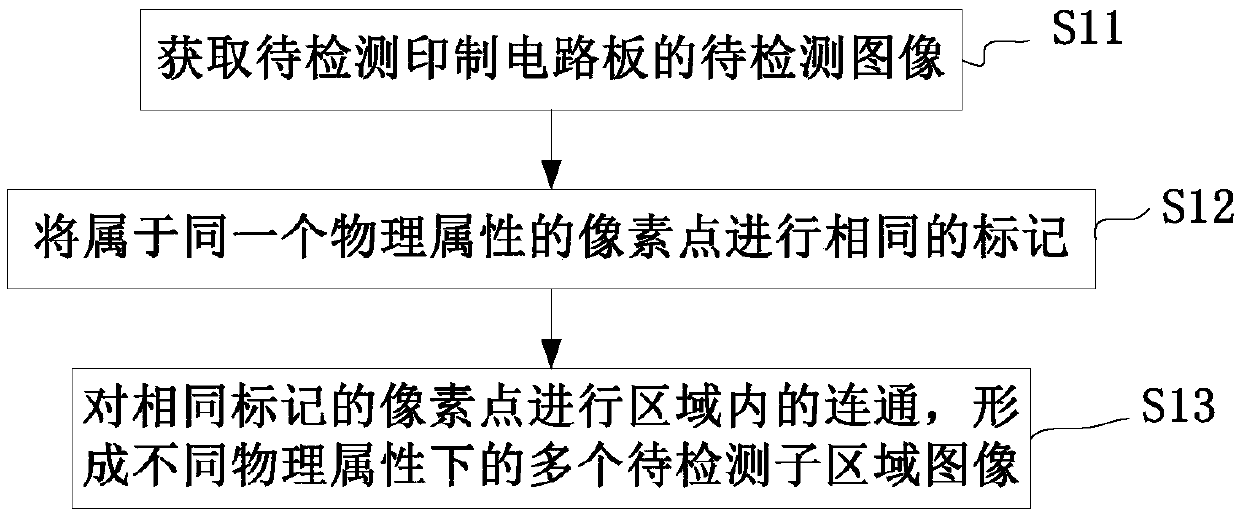

Flaw detection method and device of printed circuit board and detection equipment

InactiveCN105510348AAccurate Defect DetectionGuaranteed uniformityOptically investigating flaws/contaminationEdge effectsPrinted circuit board

The invention provides a flaw detection method and device of a printed circuit board and detection equipment. The flaw detection method of the printed circuit board comprises the following steps: dividing an image to be detected of a printed circuit board to be detected into a plurality of sub-region images to be detected according to physical properties; detecting the sub-region images to be detected corresponding to the physical properties according to the physical properties; and judging whether the printed circuit board to be detected has flaws or not. By dividing the image to be detected of the printed circuit board to be detected into the plurality of sub-region images to be detected according to the physical properties, the images corresponding to the same physical property in the printed circuit board to be detected can be located in the same sub-region image to be detected and a phenomenon that the images are divided into the two different sub-region images to be detected to cause leaked detection by a partitioning edge effect is avoided, so that the flaw detection is relatively accurate.

Owner:JOINT STARS TECH

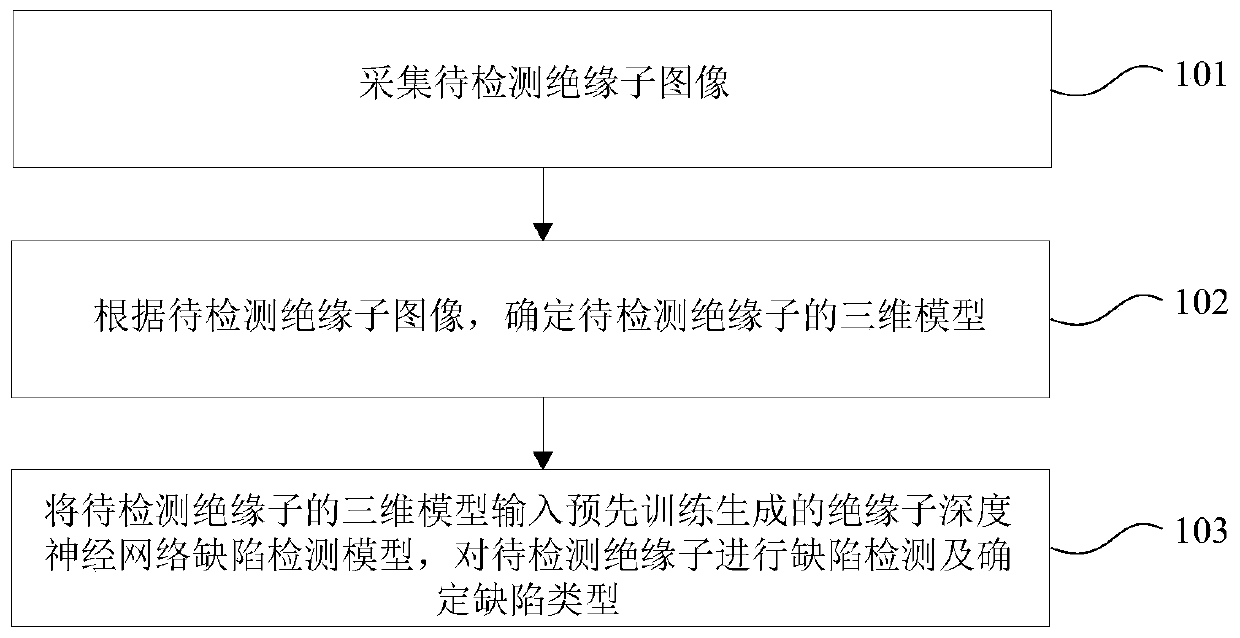

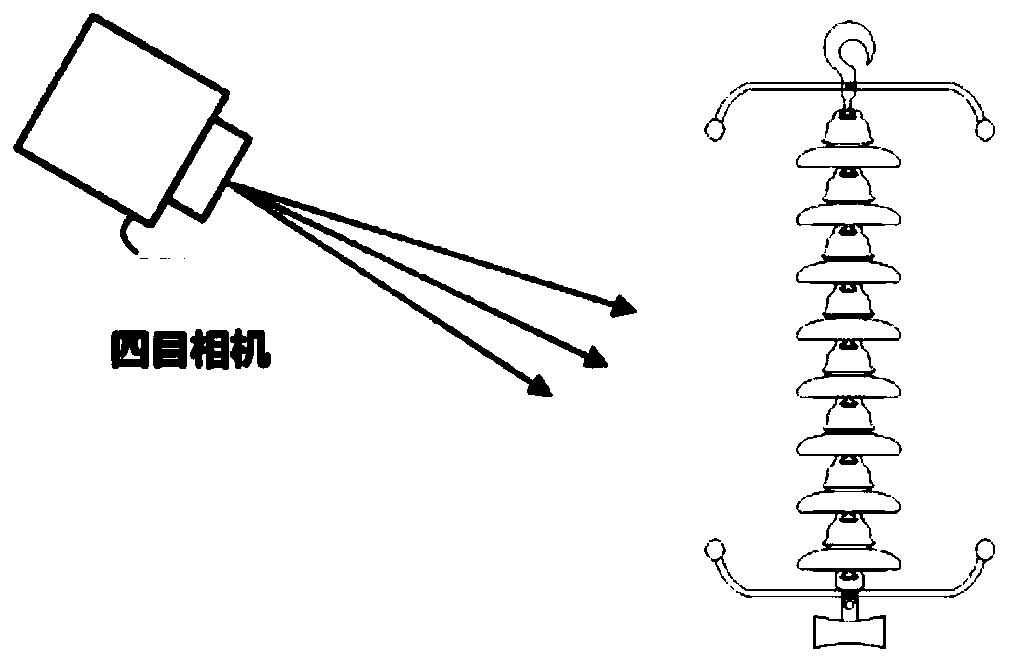

Insulator defect detection method and device for a power transmission line

InactiveCN109872323AImprove efficiencyLow costImage analysisMaterial analysis by optical meansThree dimensional modelDeep neural networks

The invention provides a power transmission line insulator defect detection method and device, and the method comprises the steps: collecting a to-be-detected insulator image; determining a three-dimensional model of the to-be-detected insulator according to the to-be-detected insulator image; inputting the three-dimensional model of the to-be-detected insulator into an insulator deep neural network defect detection model generated by pre-training, performing defect detection on the to-be-detected insulator, and determining a defect type; wherein the insulator deep neural network defect detection model is generated by pre-training a plurality of insulator image samples. According to the technical scheme, the efficiency, accuracy and safety of insulator defect detection are improved, the cost of insulator defect detection is reduced, and the method can be widely applied to an electric power system.

Owner:BEIJING GUOWANG FUDA SCI & TECH DEV

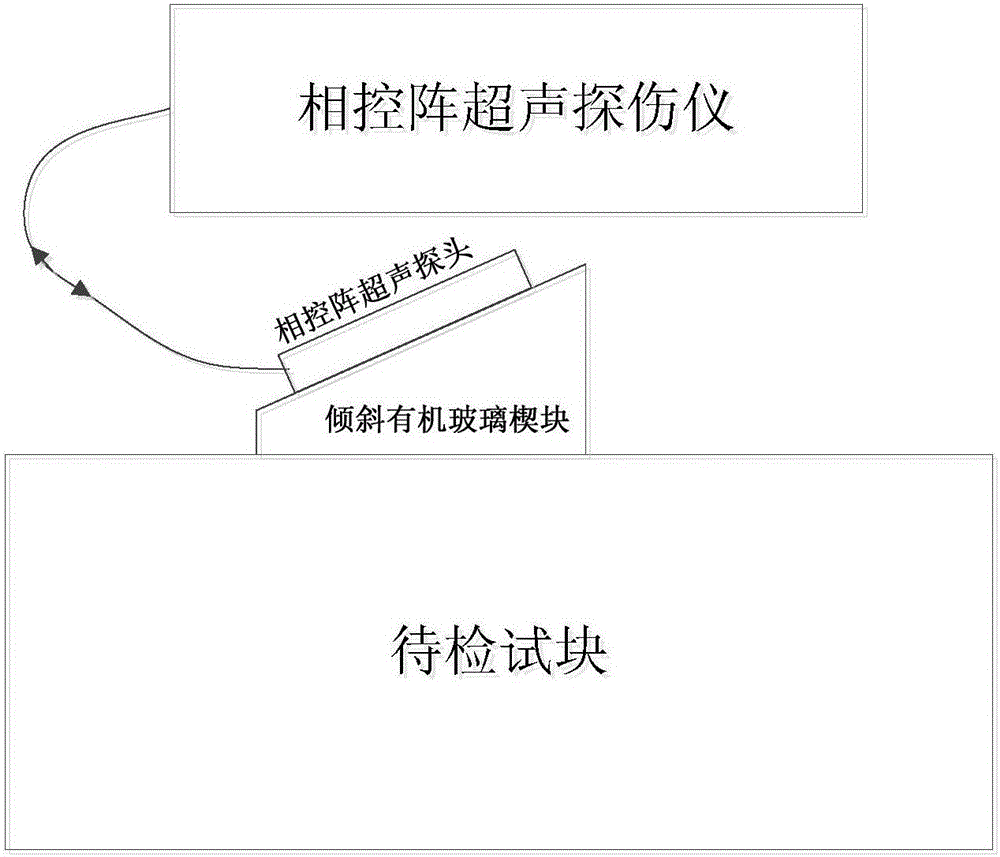

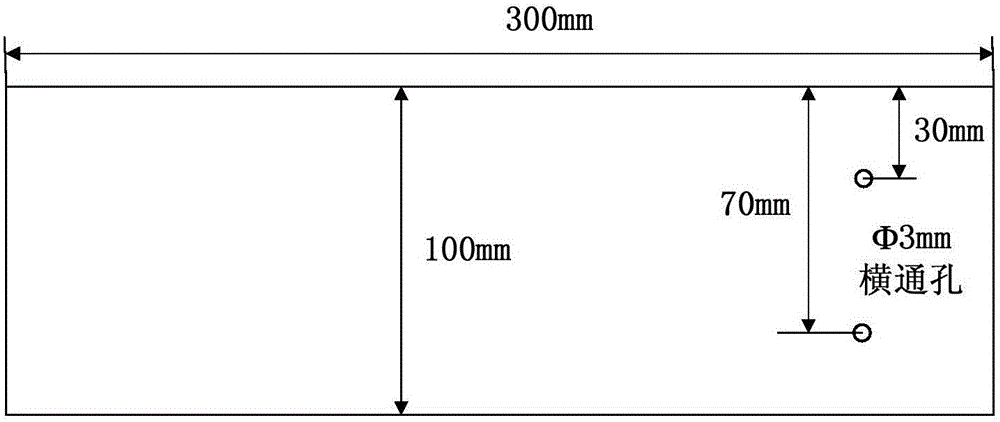

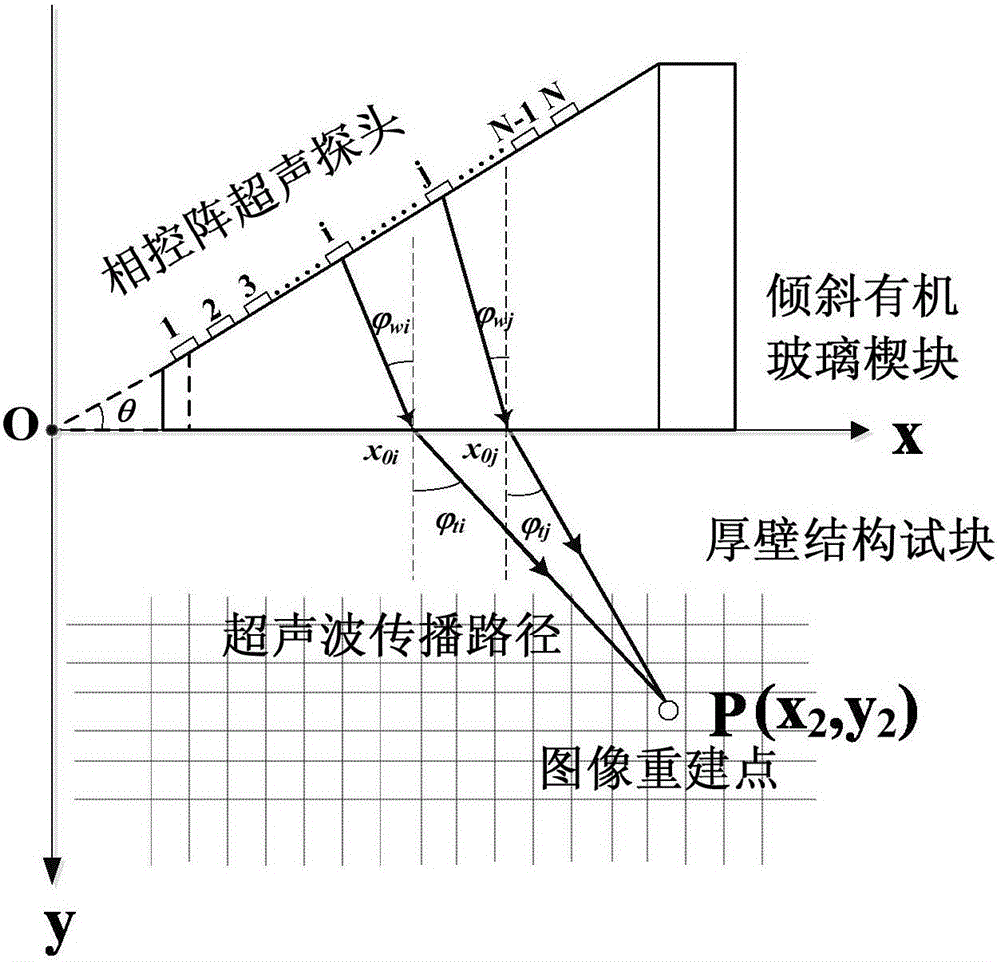

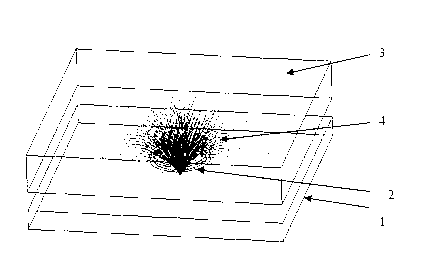

Oblique incident ultrasonic synthetic aperture focusing-based thick wall structure defect detection method

ActiveCN106093205ALarge energy coverageImprove defect detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic attenuationThick wall

The invention discloses an oblique incident ultrasonic synthetic aperture focusing-based thick wall structure defect detection method, and belongs to the technical field of nondestructive detection. The method comprises the following steps: a thick wall structure test block is detected through using a phased array electron scanning function by using an ultrasonic detection system comprising a phased array ultrasonic flaw detector, a phased array ultrasonic probe and an oblique organic glass wedge in order to obtain the A scanning signal set of all phased array elements; the Fermat's theorem is used to solve the emission point positions of all the phased array elements and image reconstruction points in the wedge / test block interface, and all A scanning signals undergo time delaying and amplitude superposing processing; and the processed A scanning signals undergo Hilbert transformation, and a difference function is used to obtain a reconstructed ultrasonic detection B scanning image. The method has the advantages of high defect detection resolution, large detection range, detection efficiency increase, and provision of an effective solving technology for the nondestructive detection problem of the defect of a thick wall structure. The method also can be embedded to the flaw detector to realize automatic real-time imaging, and has high engineering application values.

Owner:DALIAN UNIV OF TECH

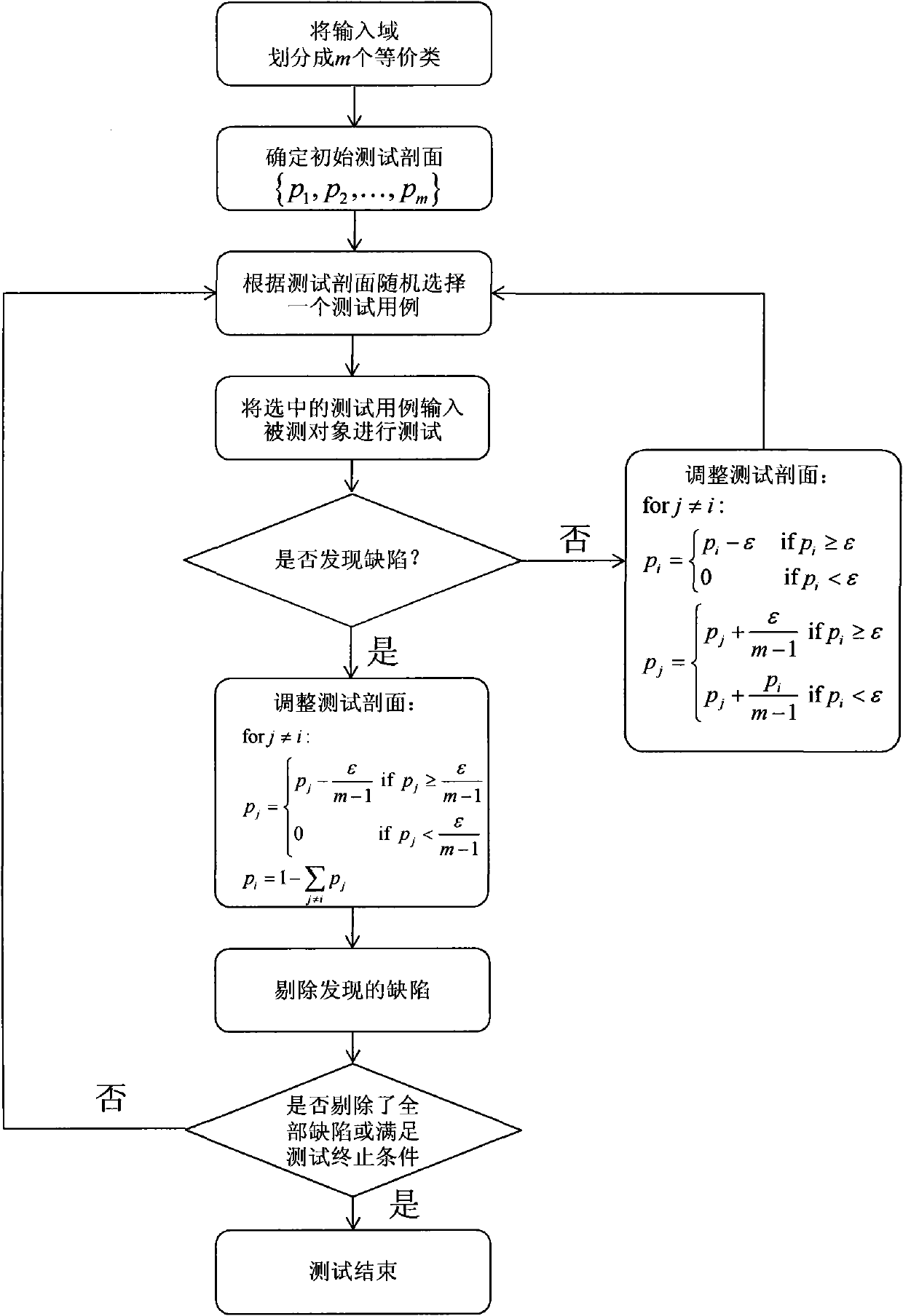

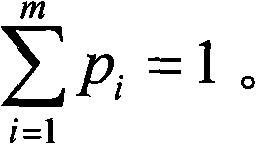

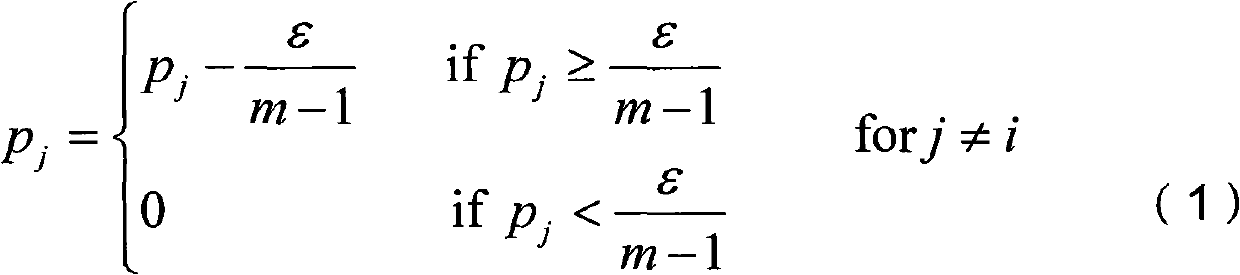

Dynamic random testing method

InactiveCN101620566AThe principle is simpleImprove defect detection efficiencySoftware testing/debuggingProgramming languageGreek letter epsilon

The invention relates to a dynamic random testing method. The method comprises the following steps: (1), a test case or test object input domain is divided into a plurality of equivalence classes {C1, C2, etc., Cm-1, Cm}; (2), an initial test profile {p1, p2, etc., pm-1, pm} is determined, a test case set Ci is selected at random according to the profile and a test case is selected from the Ci at random for testing; (3), the test profile is adjusted according to the test result, if a defect exists, pi is equal to pi + Epsilon, and the found defect is eliminated at the same time; and if no defect exists, pi is equal to pi-Epsilon, Epsilon is a given parameter before test, and meanwhile, other elements of the test profile are correspondingly corrected so that pi is equal to or more than 0, I is equal to 1, 2, etc., m and *pi is equal to 1; (4), a test case set is selected according to the adjusted test profile, and a test case is selected from the test case set at random for testing; (5), the test profile is adjusted according to the test result and the adjustment rule is same as the step (3); and (6), and so forth, the operation is continued until all defects are found and eliminated or the other test completion conditions are met. The method is simple in principle and convenient in application.

Owner:BEIHANG UNIV

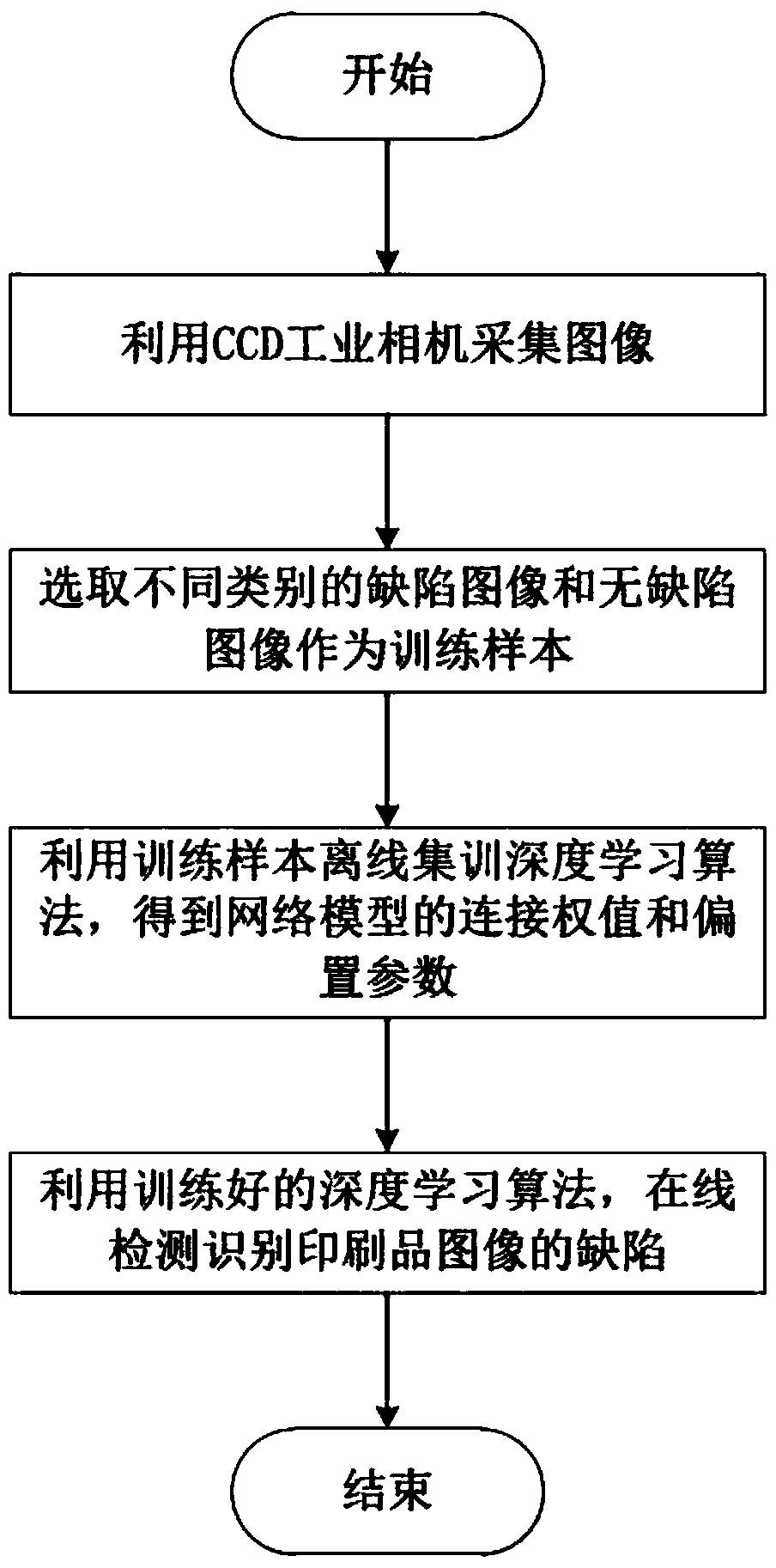

Presswork defect detection method based on deep learning

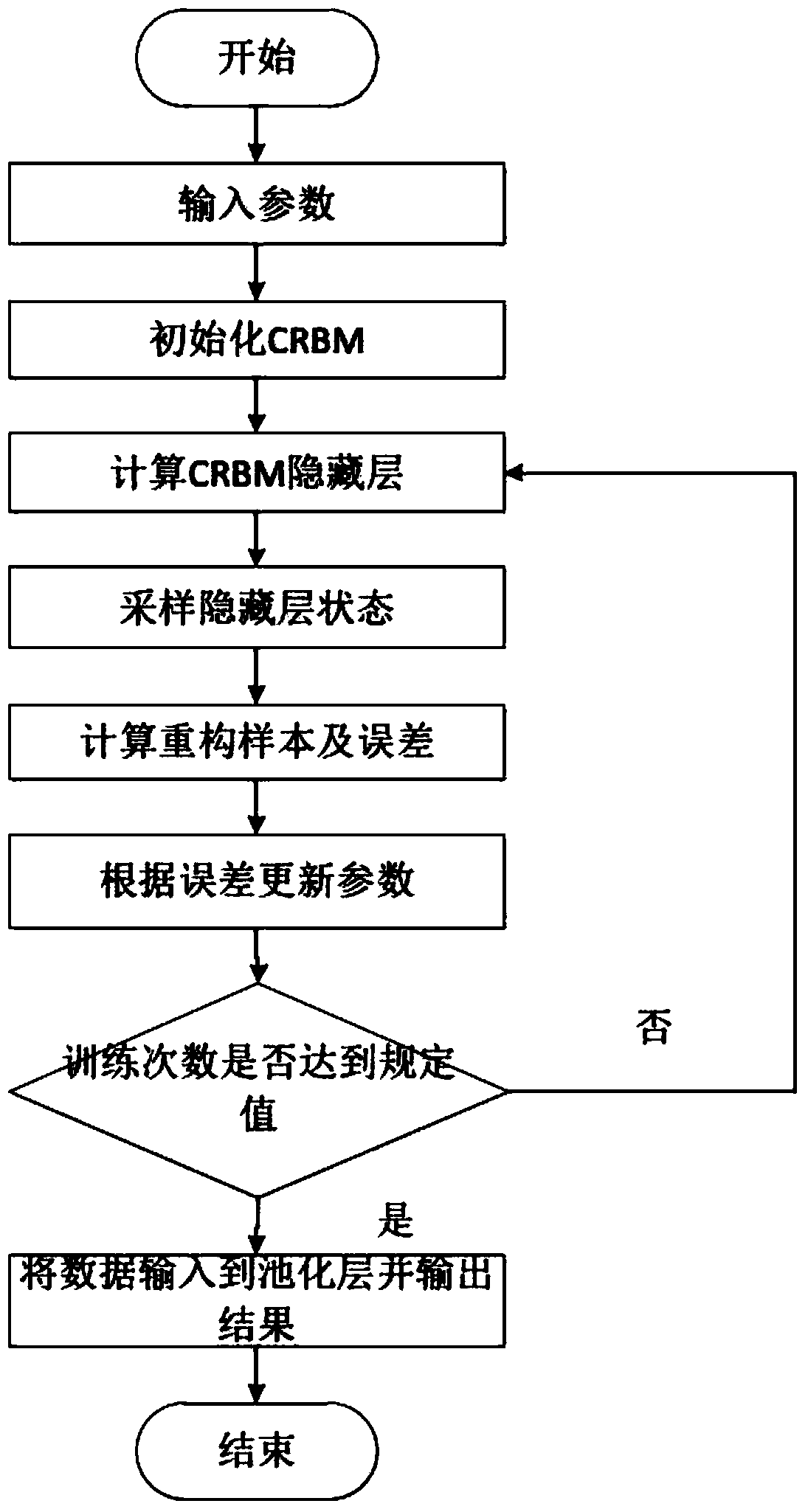

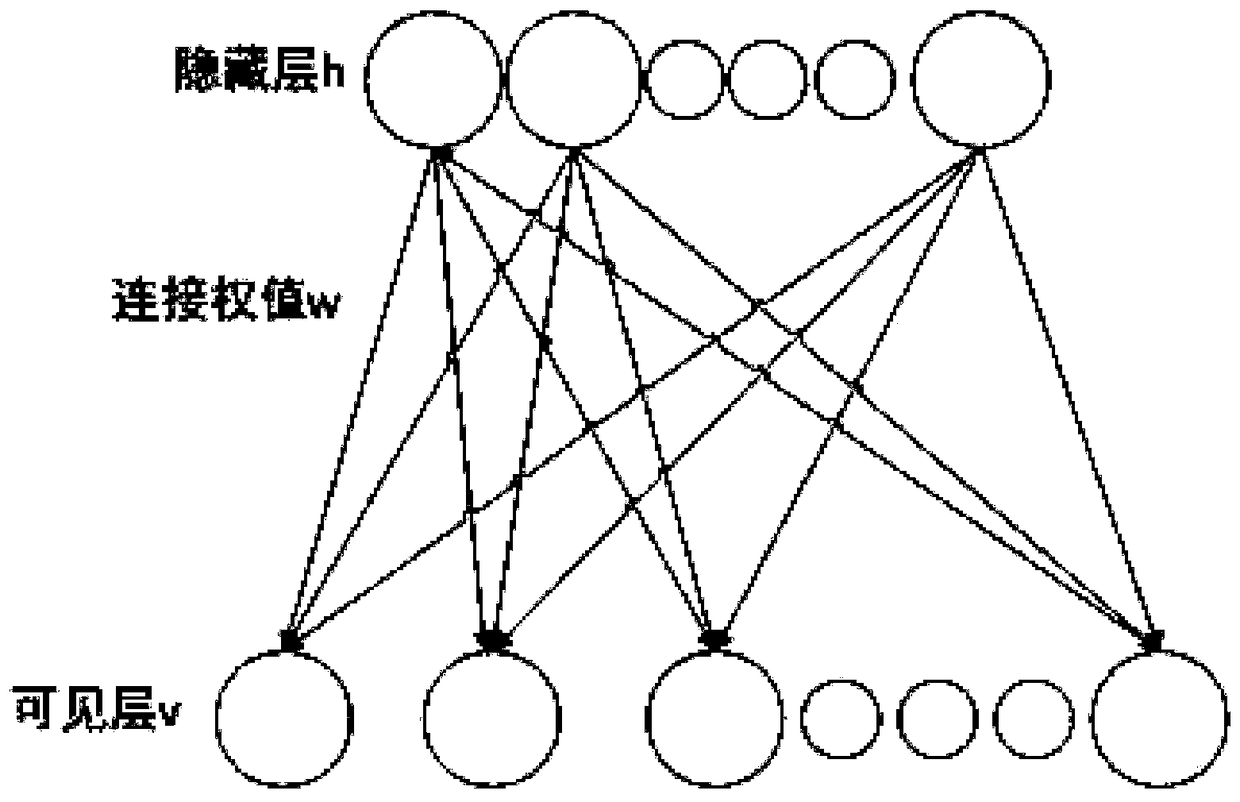

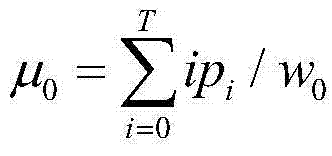

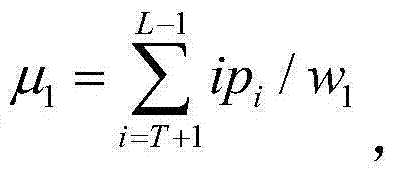

InactiveCN108918527AImprove defect detection efficiencyOptically investigating flaws/contaminationPattern recognitionNetwork model

The invention discloses a presswork defect detection method based on deep learning. The presswork defect detection method based on deep learning comprises following steps: A, a CCD industrial camera is used for image acquisition; B, defect images and defect-free images of different kinds are selected from the collected images as training samples; C, the training samples are adopted for off-line training of deep learning algorithm, so as to obtain connection weight values and offset parameters of a network model; D, the trained deep learning algorithm is adopted for on-line detection and identification of presswork image defects. According to the presswork defect detection method based on deep learning, presswork images are collected in printing process, the obtained images are subjected topre-treatment, and after pre-treatment, the images are input into the pre-trained defect detection model for defect detection, so that the presswork defect detection efficiency in production is increased.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

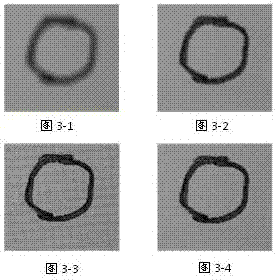

Automated optical inspection (AOI)-based bullet apparent defect detection method

InactiveCN104122271AAchieve complete detectionAccurate and comprehensive image acquisitionImage analysisOptically investigating flaws/contaminationImaging processingFeature extraction

The invention discloses an automated optical inspection (AOI)-based bullet apparent defect detection method including (1) using a CCD (charge coupled device) linear array camera to shoot the bullet surface to obtain a bullet surface initial gray level image; (2) sequentially denoising, enhancing and segmenting the initial gray level image for pretreatment to obtain a binaryzation image; (3) performing connected domain labeling processing on the binaryzation image to obtain a pixel dot set of all defects on the bullet surface; (4) respectively extracting the characteristics of each defective area; and (5) comparing the extracted characteristic values with preset defect standard features to determine the type of each defect. The method is based on the automatic optical inspection, designs a whole set of bullet apparent defect detection programs, and through the precision comprehensive image acquisition, fast image processing algorithm and convenient and accurate feature extraction and recognition, complete bullet apparent defect detection can be efficiently and accurately implemented.

Owner:NINGBO MOSHI OPTOELECTRONICS TECH

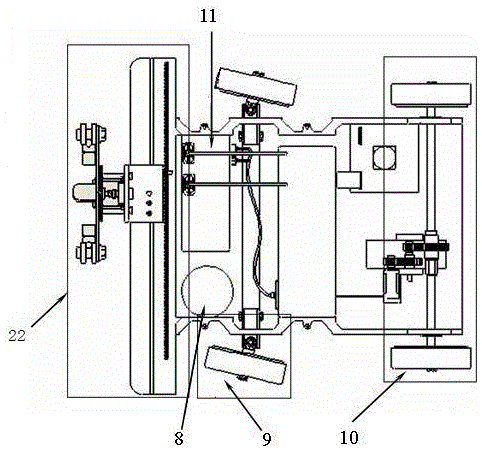

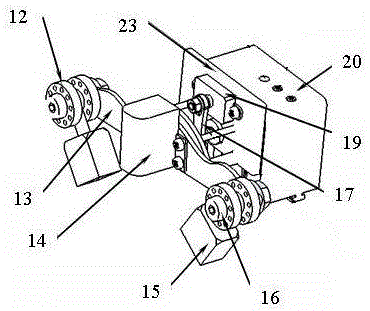

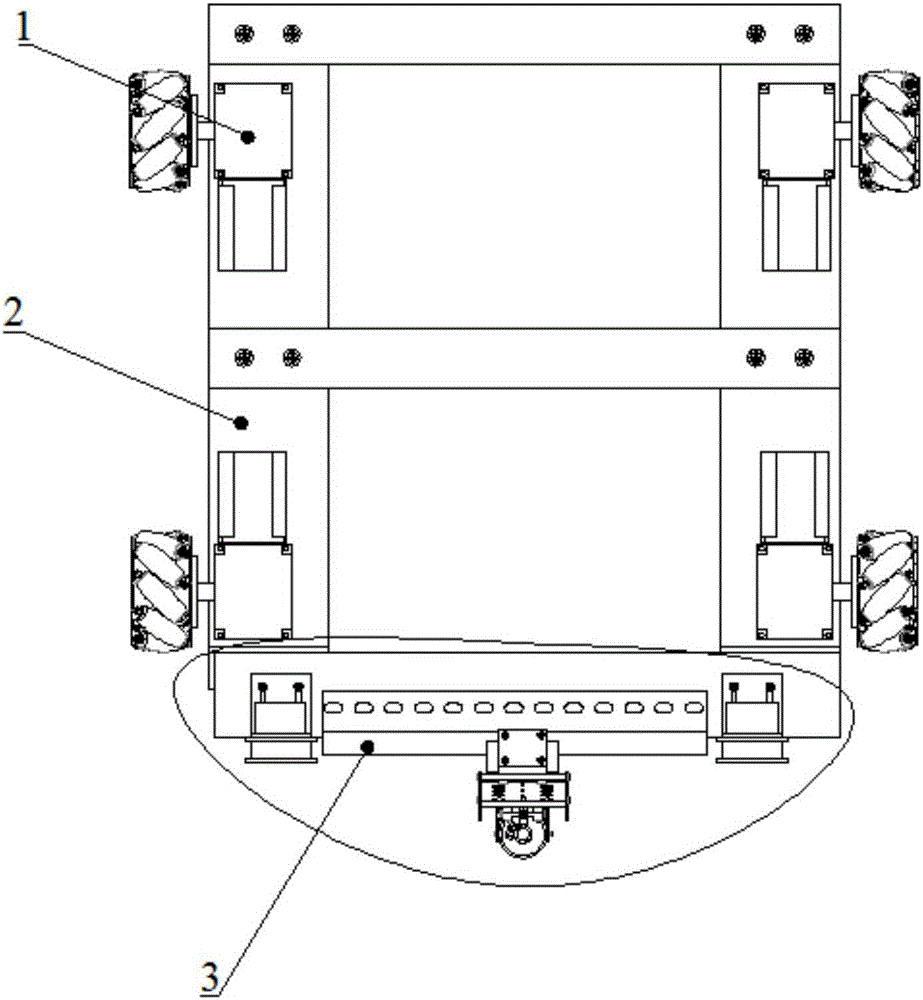

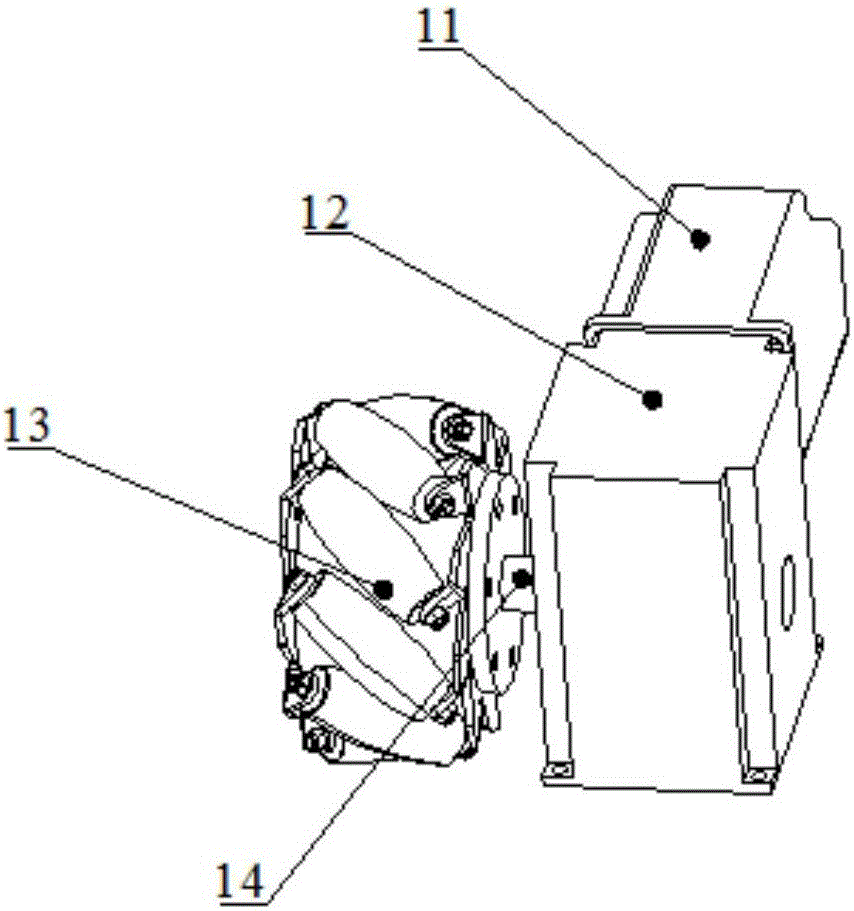

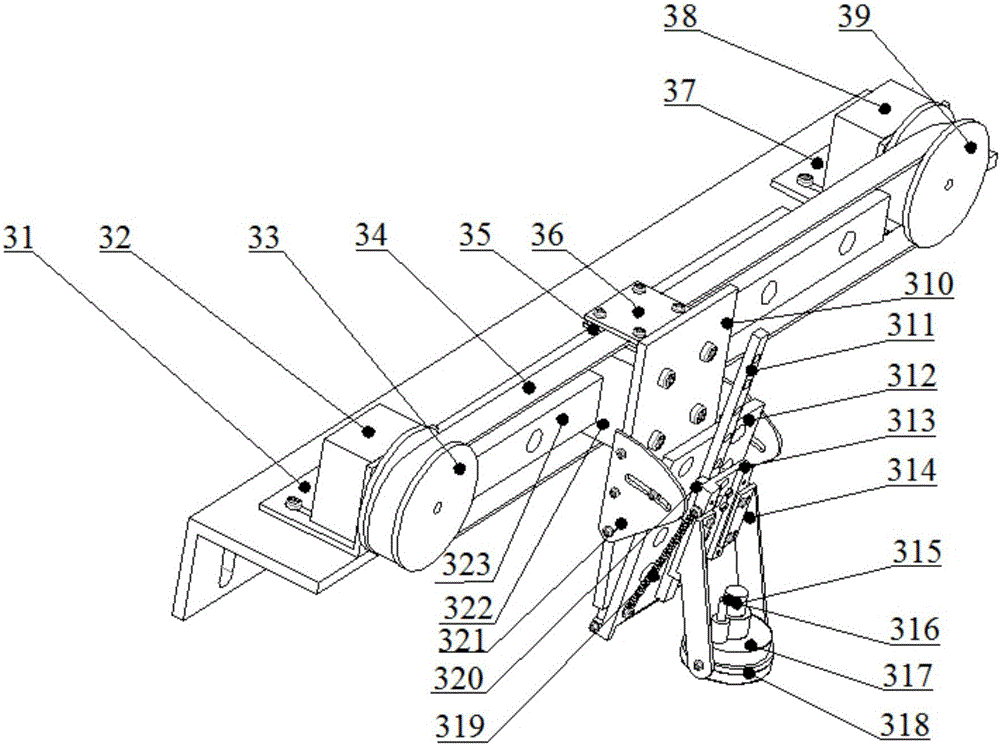

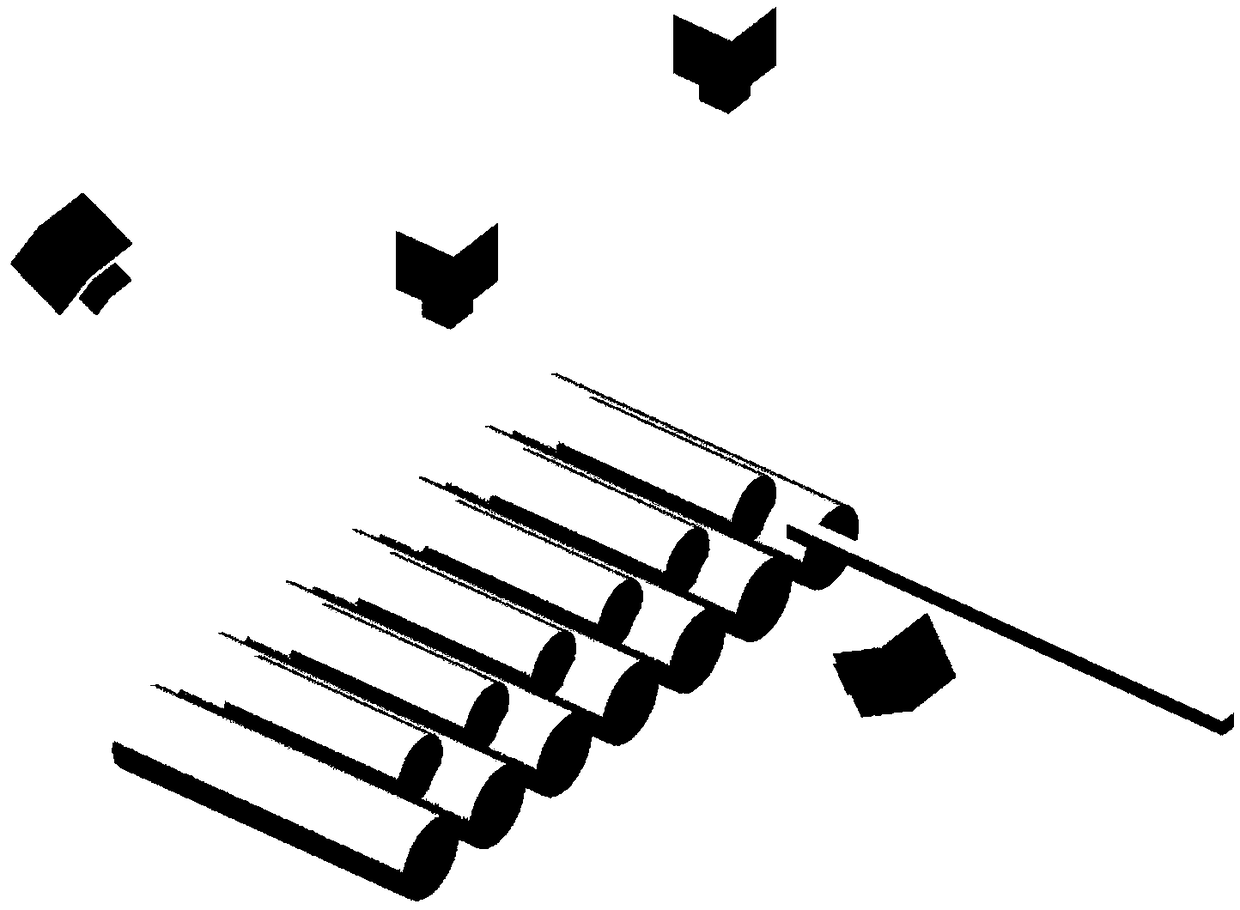

Robot for all-bearing defect detection of large-capacity flat-bottom container bottom plate and detection method

InactiveCN105973986AFacilitate all-round defect location detectionEasy to detect all-round defect position detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesIndependent motionLocation detection

The invention discloses a robot for all-bearing defect detection of a large-capacity flat-bottom container bottom plate and a detection method. The robot comprises a robot body, wherein a walking device and a detection device are arranged under the robot body, and the detection device is arranged at one end of the robot body; the walking device consists of four independent Mecanum wheel mechanisms which are arranged on the robot body; the detection device mainly consists of an ultrasonic probe and an ultrasonic probe adjusting mechanism, and the ultrasonic probe is connected with an ultrasonic generator; the ultrasonic probe adjusting mechanism comprises a first adjusting mechanism and a second adjusting mechanism; the first adjusting mechanism is used for driving the ultrasonic probe to move left and right along the horizontal direction; the second adjusting mechanism is used for adjusting the height of the ultrasonic probe, so that the ultrasonic probe is attached with the surface of the to-be-detected container bottom plate to be detected. The robot has the advantages that the all-bearing defect position detection can be performed on the detected container, the missed detection due to low feedback signal intensity caused by inverticality between ultrasonic direction and defect direction is avoided, and the detection accuracy is improved.

Owner:SICHUAN UNIV

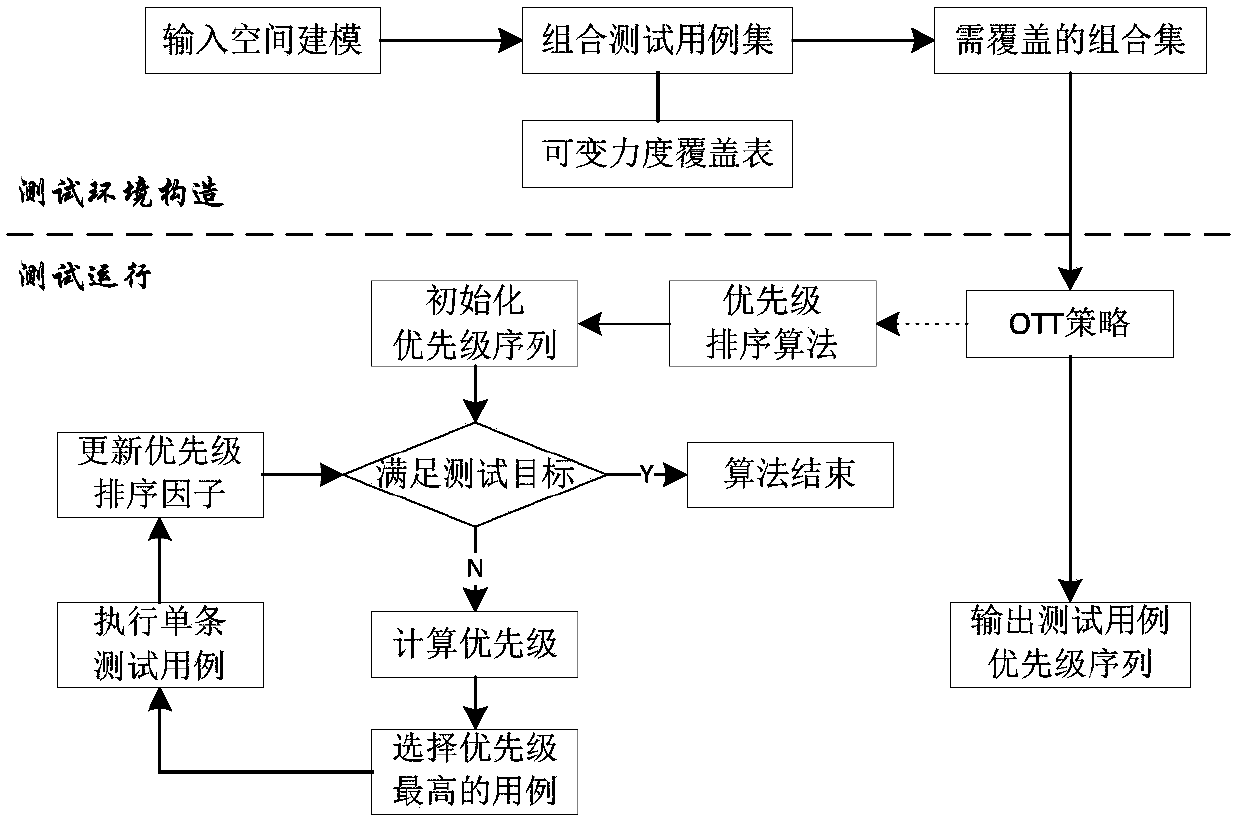

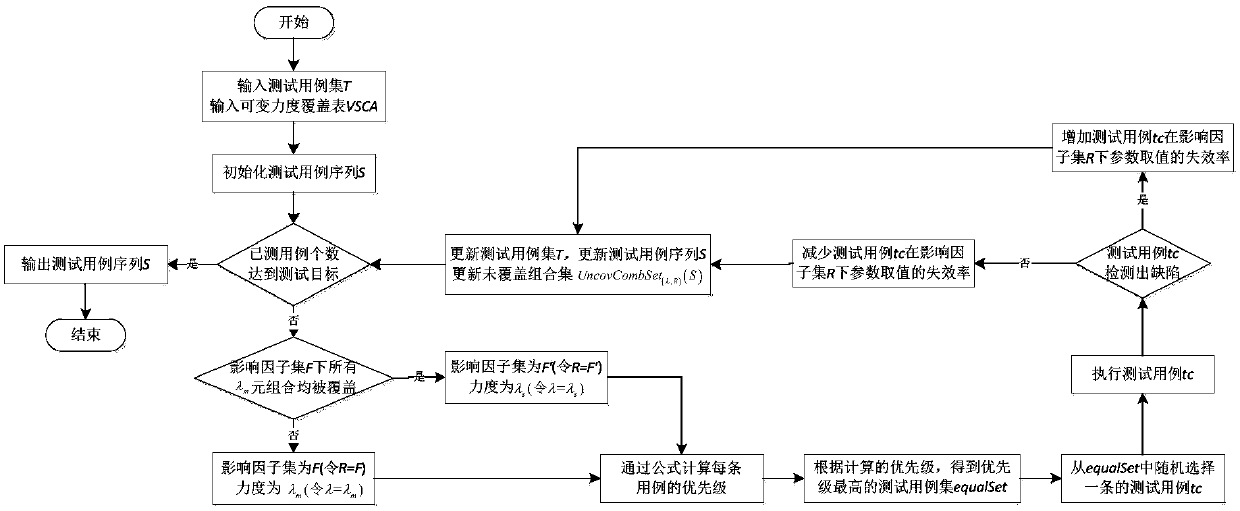

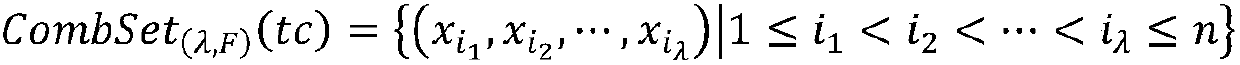

OTT policy-based variable intensity combination test case priority online sorting method

ActiveCN107766245AImprove defect detection efficiencySoftware testing/debuggingFailure rateVariable intensity

The invention discloses an OTT policy-based variable intensity combination test case priority online sorting method and belongs to the field of software testing. The method comprises the steps of adjusting an influence factor set according to a current test case sequence coverage combination condition; through an OTT policy thought, selecting a test case with a highest priority to be executed froma combination test case set each time; calculating and ranking test case priorities by using three influence factors including a local combination coverage rate, a test case failure rate and test case importance; according to test results of test cases, adjusting parameter values of the influence factors in real time, and updating a test case sequence, the test case set and a non-covered combination set of the test case sequence; and re-calculating the priorities, and repeating the process until a test goal is achieved. The method can be used for ranking the test case priorities generated bydifferent combination coverage intensities; and more defects can be effectively detected out under the condition of using the same test case quantity, so that the defect detection efficiency is improved.

Owner:ZHEJIANG SCI-TECH UNIV

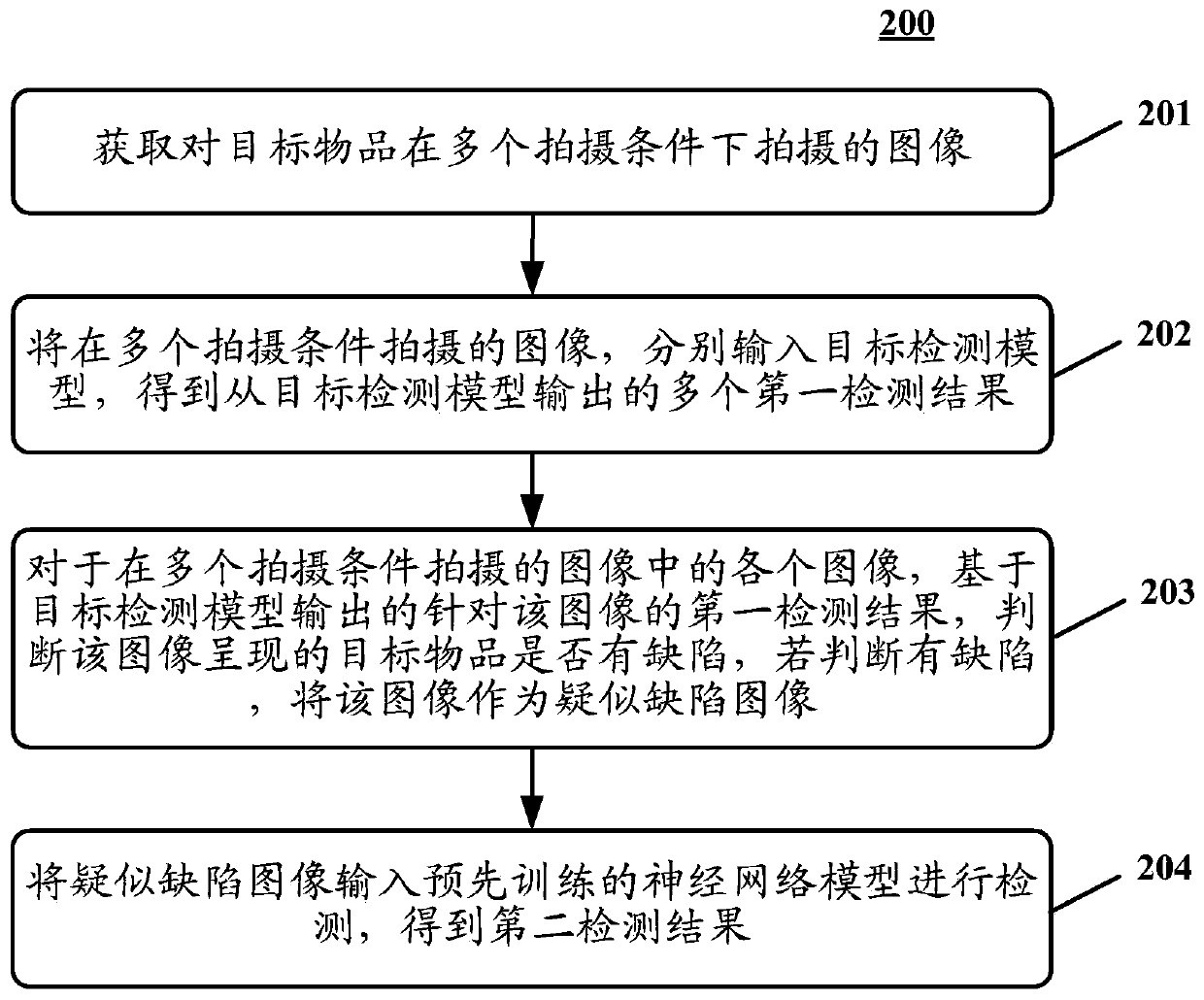

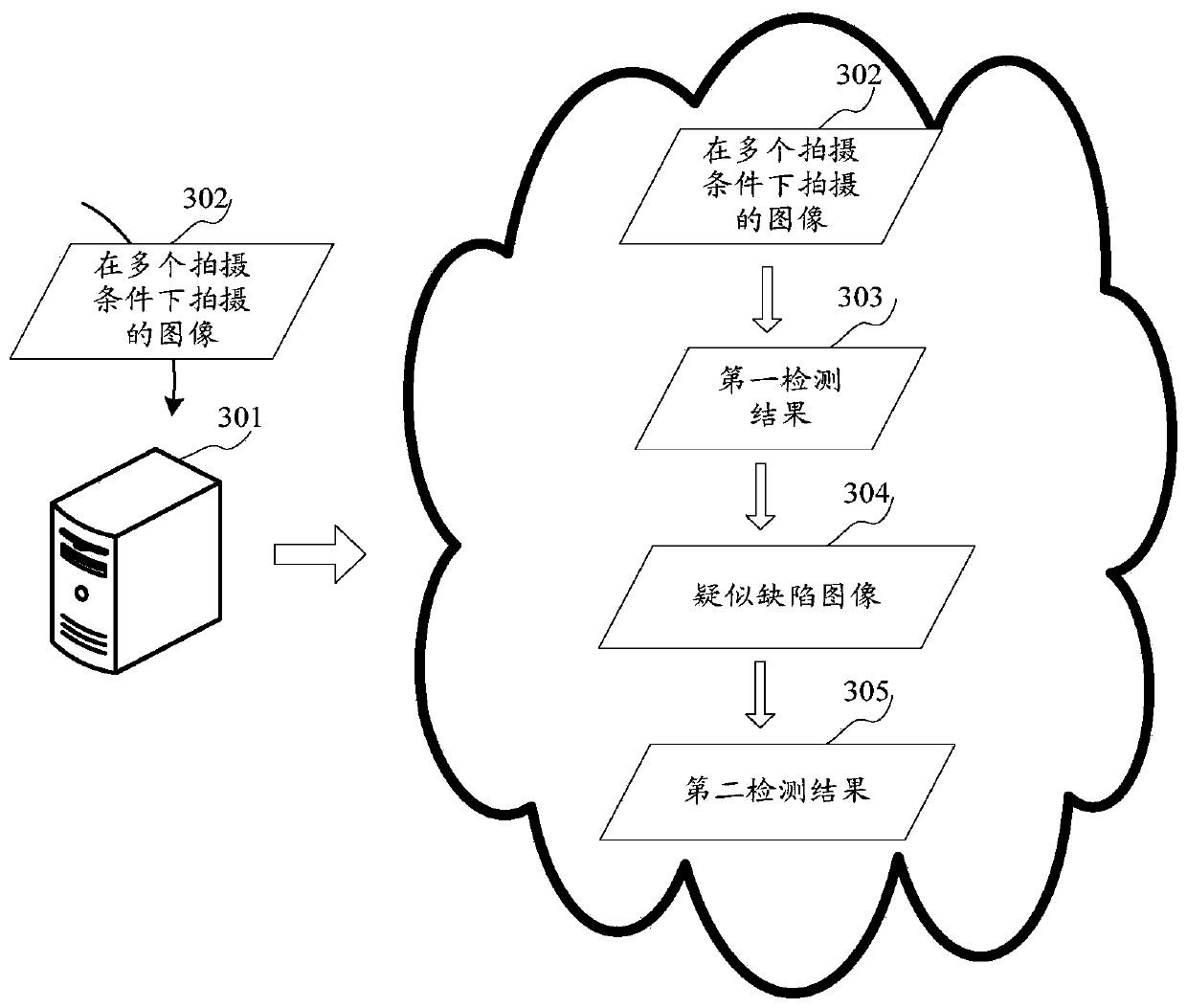

Defect detection method, system, and apparatus

PendingCN110726724AAccurate judgmentReduce the number of imagesImage enhancementImage analysisRadiologyNetwork model

Embodiments of the application disclose a defect detection method, system, and apparatus. The method can be applied to the field of cloud computing. Specifically, a specific embodiment of the method includes: separately inputting images captured under multiple photographing conditions to a target detection model, to obtain multiple first detection results output by the target detection model; foreach of the images captured under the multiple photographing conditions, determining, based on a first detection result output by the target detection model for the image, whether a target object presented in the image has a defect, and if it is determined that there is the defect, using the image as a suspected defect image; and inputting the suspected defect image to a pre-trained neural networkmodel for detection, to obtain a second detection result. The embodiments of the application can filter out the suspected defect image through a fast unsupervised model, thereby reducing a quantity of images input to the neural network model and improving efficiency of defect detection.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

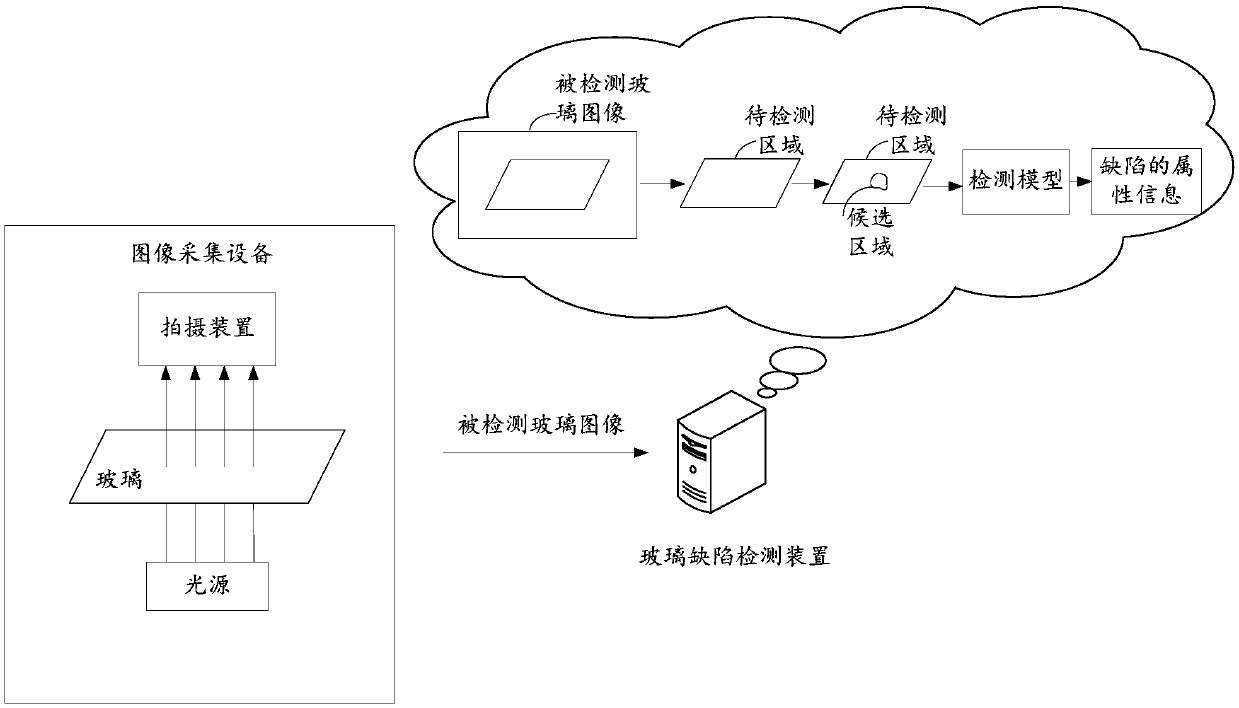

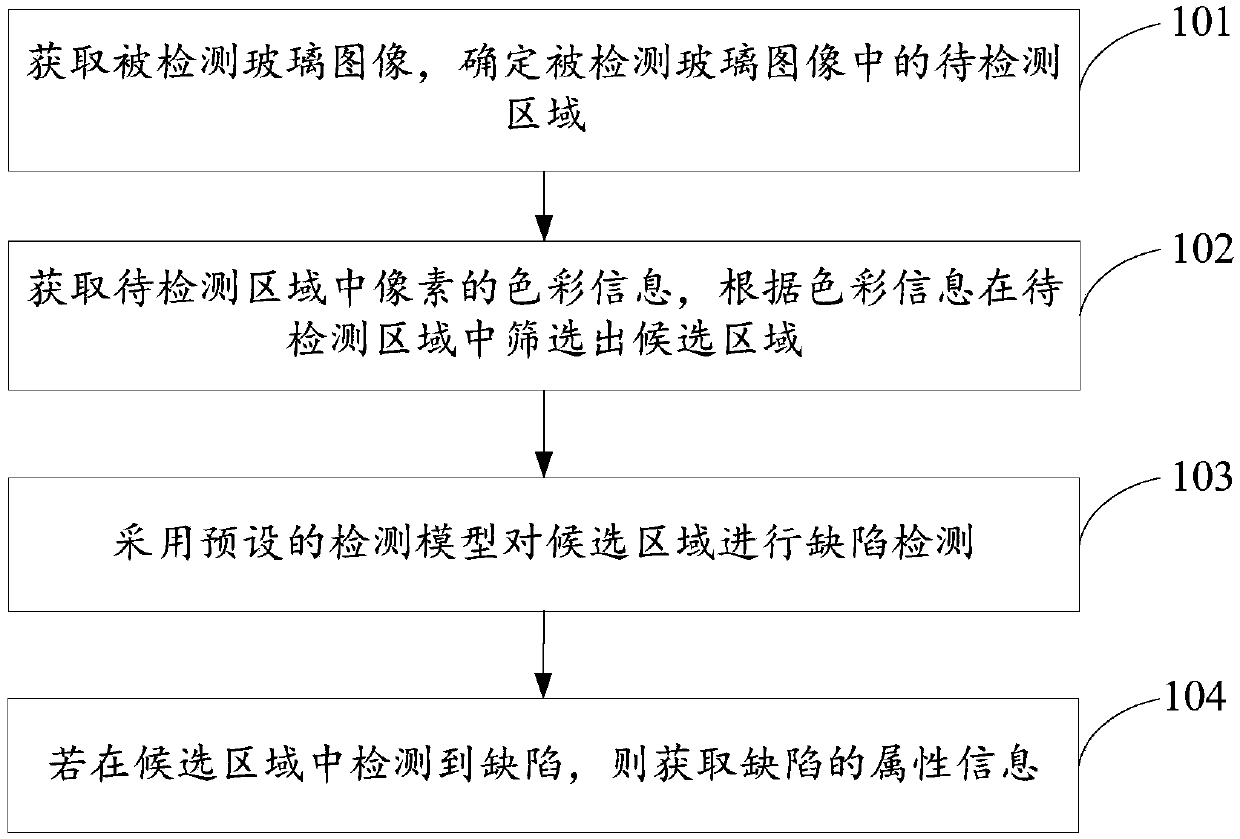

Glass defect detection method and device and storage medium

ActiveCN109613002AImprove efficiencyReduce the probability of missed or false detectionOptically investigating flaws/contaminationFalse detectionPattern recognition

The embodiment of the invention discloses a glass defect detection method and device and a storage medium. According to the embodiment of the invention, a glass image to be detected can be acquired and a region to be detected in the glass image to be detected is determined; color information of pixels in the region to be detected is acquired, and candidate regions are screened in the region to bedetected according to the color information; a preset detection model is used to perform defect detection on the candidate regions; and if a defect is detected in the candidate regions, attribute information of the defect is acquired. Therefore, compared with the existing manual detection, the scheme realizes the automatic detection of glass defects, greatly improves the efficiency of glass defectdetection, and reduces the probability of missed detection and false detection.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

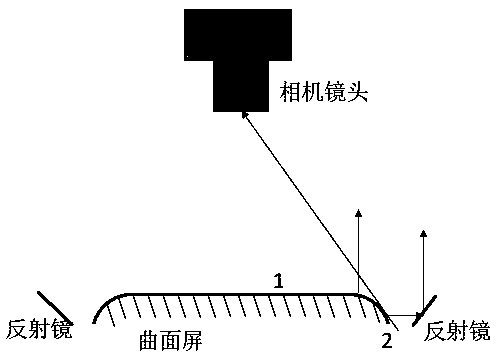

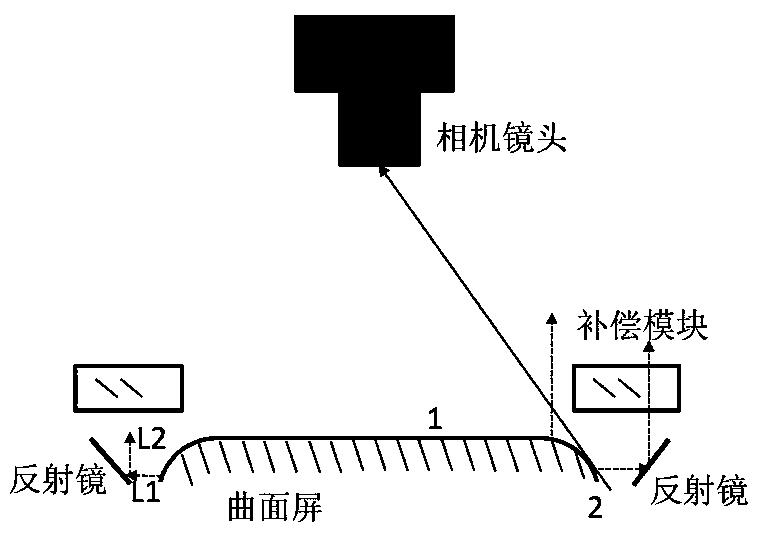

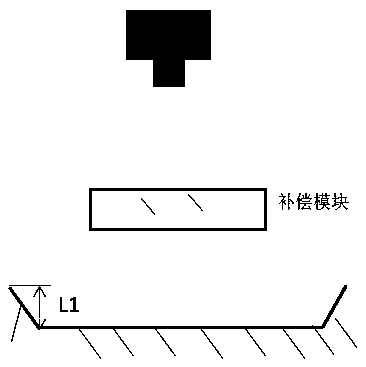

Defect detection device applied to curved screen

PendingCN111157542AEasy to operateGood imaging consistencyOptically investigating flaws/contaminationEngineeringOptical pathlength

The invention discloses a defect detection device applied to a curved screen, and the curved screen comprises a plane and a curved surface, and the defect detection device is characterized by comprising a camera, a detection module and an optical path extension compensation module; the camera is used for imaging the plane and the curved surface of the curved screen to obtain an image; the detection module is used for outputting a defect detection result according to the image; the optical path extension compensation module is installed on an optical path where the curved surface of the curvedscreen or the plane of the curved screen is imaged on the camera so that the curved surface of the curved screen or the plane of the curved screen is imaged on the camera through the optical path extension compensation module, and the imaging optical path of the curved surface of the curved screen on the camera and the imaging equivalent imaging distance of the plane of the curved screen on the camera to be the same or the difference of the equivalent imaging distances is within a preset threshold range. Sngle focusing imaging of the curved surface and the plane can be realized.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

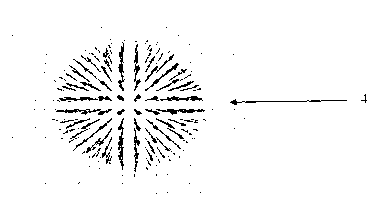

Eddy current detecting device used for performing metal defect detection and eddy current probe thereof

ActiveCN103196996AReduce measurementReduce distractionsMaterial magnetic variablesHemt circuitsEddy current

The invention discloses an eddy current detecting device used for performing metal defect detection and an eddy current probe thereof. The eddy current probe comprises more than one orthogonal combination probe, wherein each orthogonal combination probe comprises one exciting coil and two induction coils, the geometric centers of the two induction coils are overlapped, the central cross sections of the two induction coils pass by the geometric center of the exciting coil, and the central cross sections of the exciting coil and the two induction coils are pairwise vertical. If more than two orthogonal combination probes are arranged, the central cross sections of the exciting coils of all the orthogonal combination probes are located on the same plane, and the geometric centers of all exciting coils are located on the same straight line. The eddy current detecting device comprises a controller, a signal generating circuit, a wave filtering and amplifying circuit, a phase-sensitive wave detecting circuit, a signal collecting card, a host computer, a first high-speed analogue switch, a second high-speed analogue switch and the eddy current probe. According to the eddy current detecting device and the eddy current, the detection sensitivity is high and the detection speed is fast.

Owner:ZHEJIANG UNIV

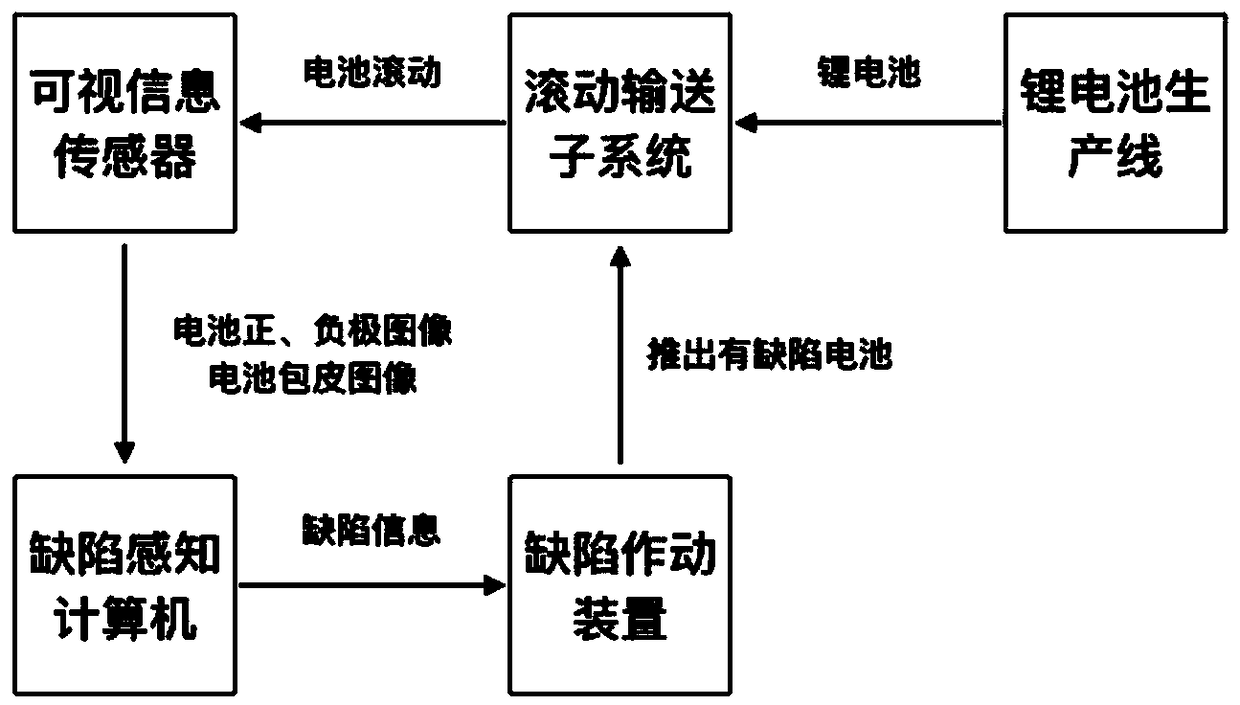

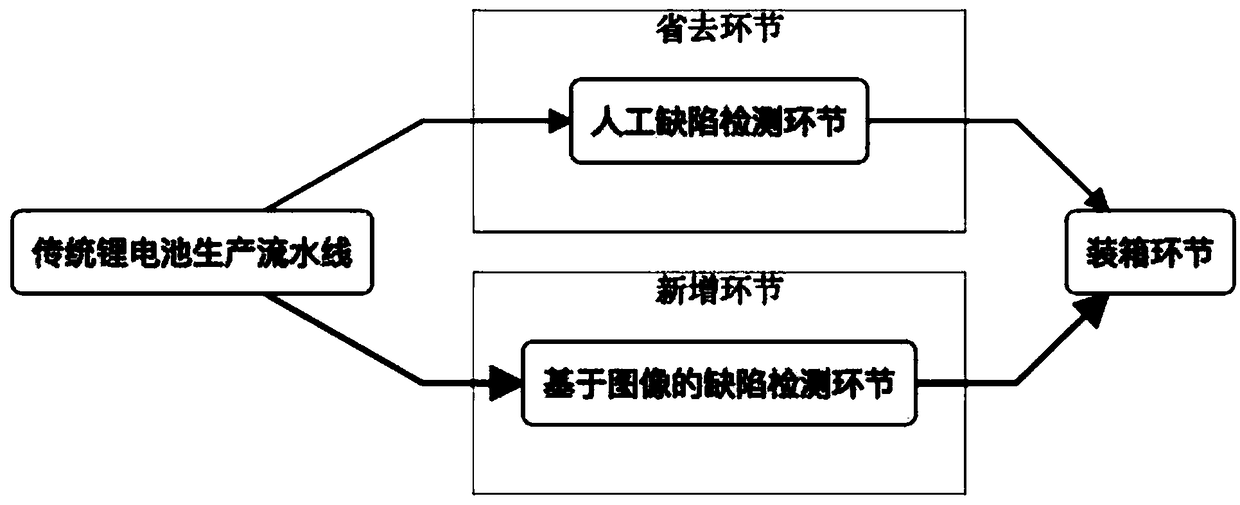

Lithium battery defect detection device based on battery temperature field and visible light image

PendingCN108732507AImprove signal-to-noise ratioDynamic panorama informationElectrical testingMaterial defectEngineering

The invention discloses a lithium battery defect detection device based on a battery temperature field and a visible light image. The appearance information of a lithium battery of the infrared thermal image, the temperature field distribution and the visible spectrum section image can be measured in different states (charging, discharging, processing and transportation), different directions (positive side view, negative side view and shell top view)), different time (continuous observation on a production line) and different complex backgrounds (the production line is complex in thermal noise environment). A double-waveband defect detection algorithm is used, and when the defect is detected, the influence of the production process and the production line environment on the detection canbe corrected in real time, the sensitivity of the system is improved, and finally the defective lithium battery is removed from the production line. The invention is advantageous in that the externalpackaging defect detection and internal material defect detection method are integrated; the defect detection integrity and accuracy can be guaranteed, and the reliability and the efficiency of lithium battery defect detection are greatly improved, and the automation degree of the lithium battery production line is improved.

Owner:UNIV OF SCI & TECH OF CHINA

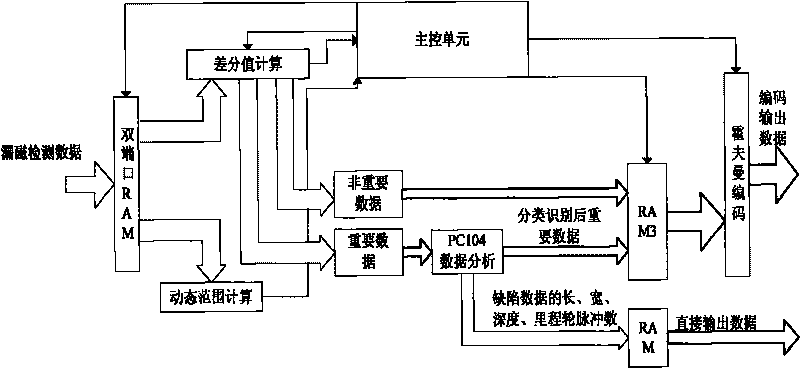

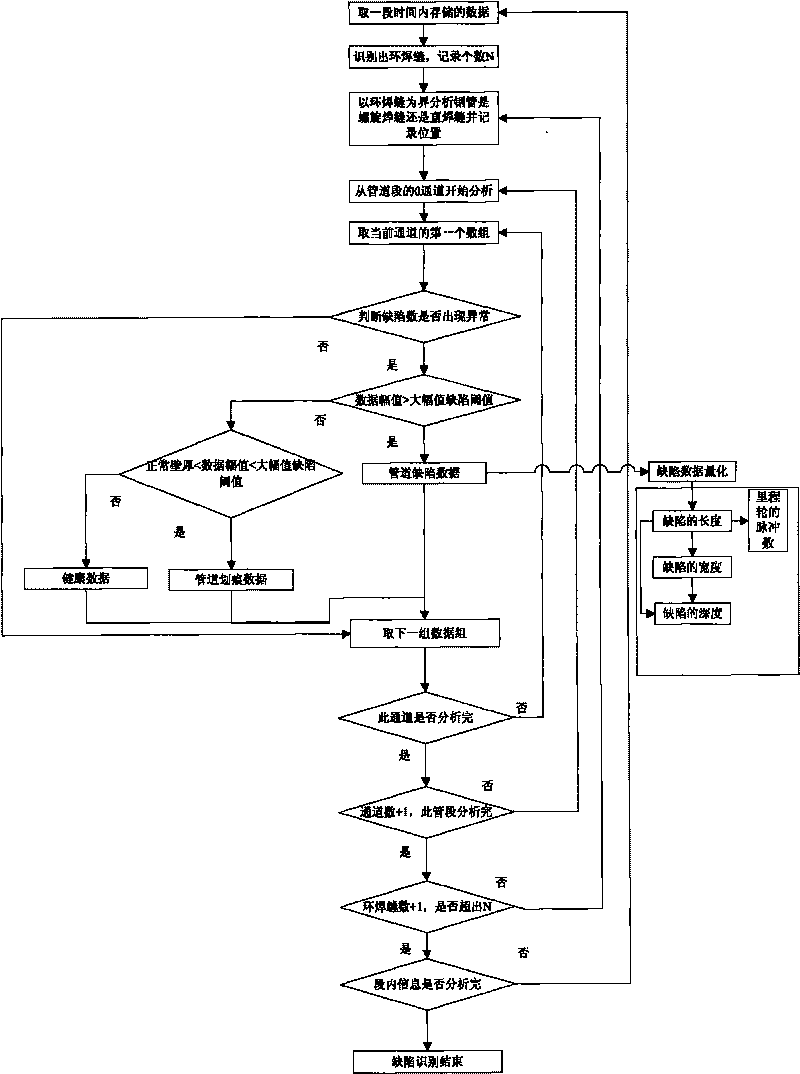

Method for transmitting very low frequency signal of oil-vapor pipe magnet leakage detector

InactiveCN101692301ATimely analysis and determinationImprove defect detection efficiencyTransmission systemsPipeline systemsMicrocontrollerElectromagnetic pulse

The invention provides a method for transmitting the very low frequency signal of an oil-vapor pipe magnet leakage detector. A pipe inner part is driven by a driving device to move at constant speed in an oil-vapor pipe; the magnet leakage data detected by a magnetic sensor detecting unit is sent to a data processing unit to be subjected to classification, compression and defect quantification and then is stored temporarily; the magnet leakage data which is stored temporarily and the mileage wheel count are transmitted to a microcontroller in a SCM at set intervals; after being subjected to power amplification and DA conversion, the magnet leakage data and the mileage wheel count are transmitted into a transmitting coil, and different types of data in the oil-vapor pipe is outputted; the electromagnetic pulse is received by a magnetic-induction receiving antenna set, after the voltage of the electromagnetic pulse is extracted and is sent to a data decompressing unit, the data in the oil-vapor pipe is restored in the time interval, and the condition and the position of the defect in the oil-vapor pipe are further determined. The compressed data stored for some time, the defect quantification data and the mileage wheel information can be transmitted into a receiving device on the ground, the information on the defect in the oil-vapor pipe can be analyzed and determined in time, and the efficiency of detecting the defect in the oil-vapor pipe can be improved.

Owner:HARBIN ENG UNIV

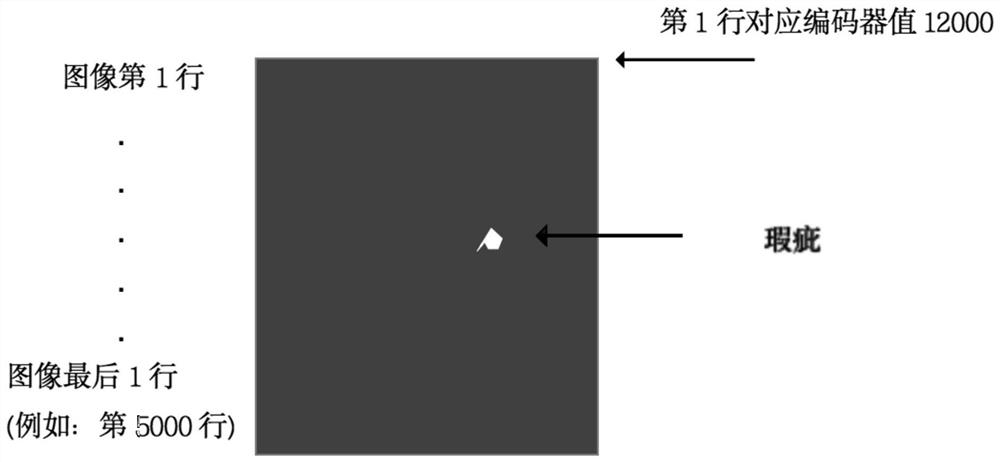

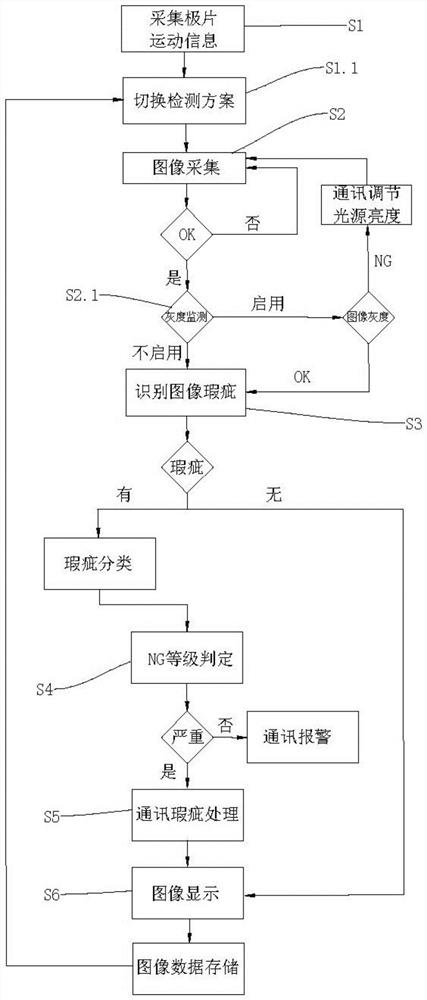

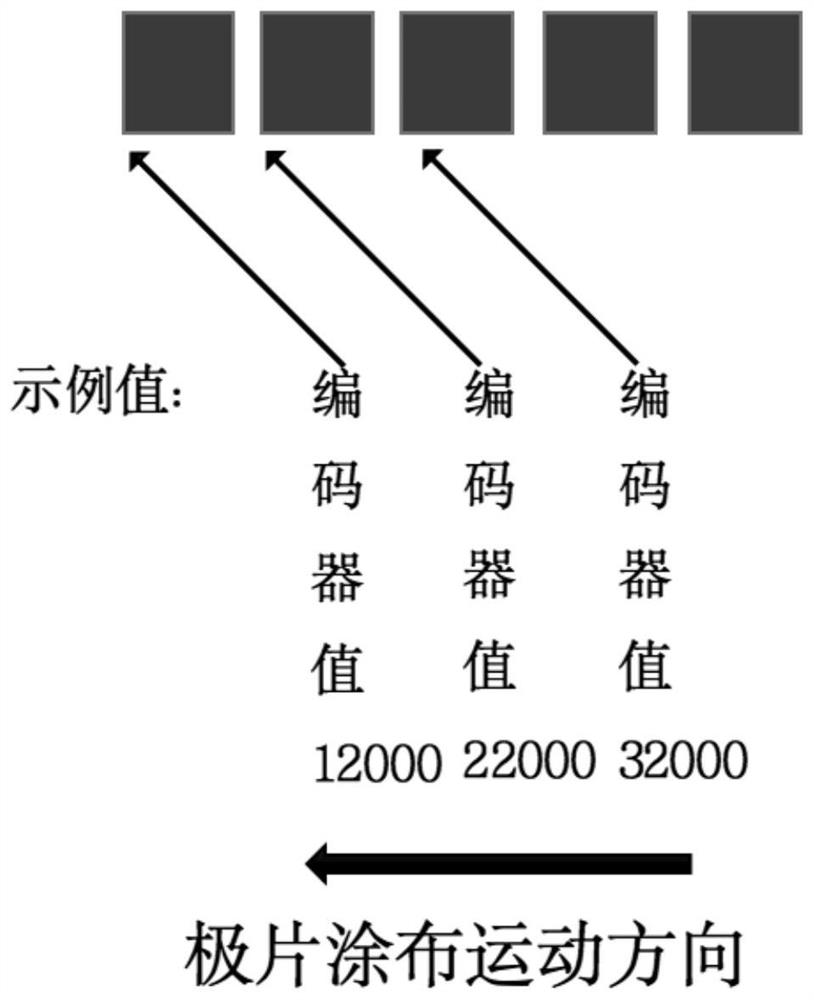

Real-time detection processing method and system for detects of lithium battery pole piece

ActiveCN112179910AMeet the real-time detection needs of high-speed productionEliminate Response LagOptically investigating flaws/contaminationEngineeringPole piece

The invention discloses a real-time detection processing method for defects of a lithium battery pole piece. The method comprises the steps of S1, acquiring motion information of the pole piece transmitted at a high speed by adopting an encoder; S2, triggering a linear array camera to acquire a pole piece image by using the encoder; S3, identifying defects of the pole piece according to the imagefeatures; S4, carrying out NG grade judgment on the defects, and recording position information of the defects; and S5, performing defect processing operation on the serious defects by a defect processing device. The invention further discloses a real-time detection processing system for defects of the lithium battery pole piece, which adopts the method. According to the invention, defects can beautomatically classified and processed, response delay of images and a processing device is eliminated, the detection precision is high, the efficiency is good, and the requirements of high-speed production and real-time detection of battery pole pieces can be met.

Owner:GUANGDONG AOPUTE TECH CO LTD

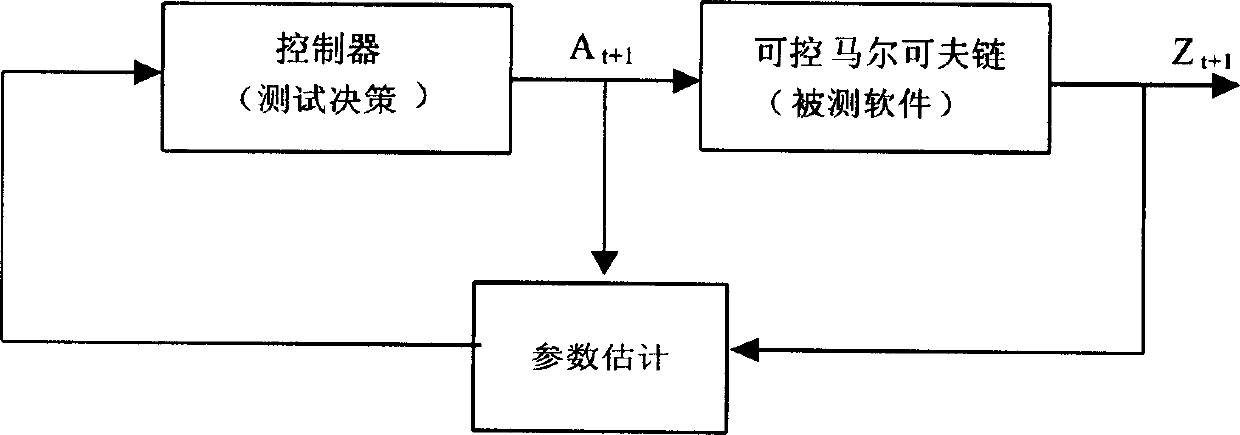

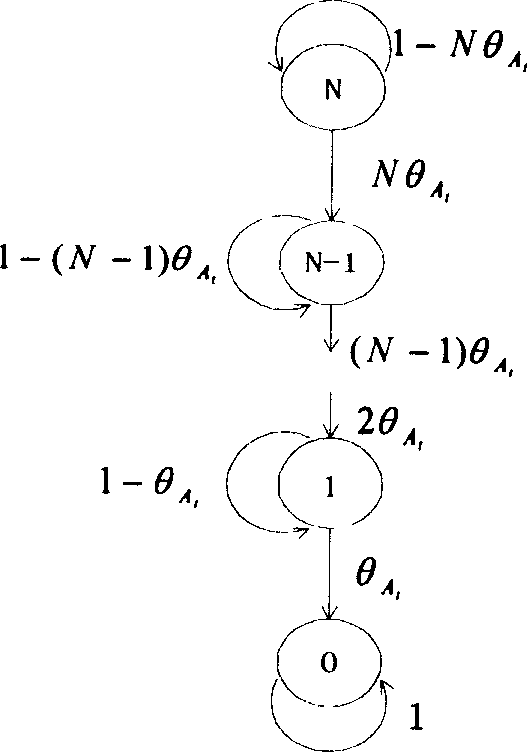

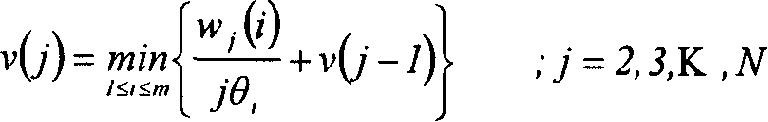

Adaptive test method for software

InactiveCN1770118AImprove defect detection efficiencyImprove stabilitySoftware testing/debuggingMarkov chainOptimal test

Disclosed is a software self-adapting test method which comprises: 1. according to controllable Markov chain mode to get equation: v(j)ú¢min{wj(i) / jª’i+v(j-1ú”jú¢2ú¼3ú¼Kú¼N; 2. according to controller equation, in the process of software test, each selected test decision should meet the need: Atú¢argmin{w(i) / ª’i}; 3. if parameter N and ª’i is known for tested software, getting test decision from the equation and going on testing software; 4. employing self-adaptive test to evaluate parameter (N andª’i) online in each test; 5. employing evaluated value to get optimal test decision to test until remove all bugs.

Owner:BEIHANG UNIV

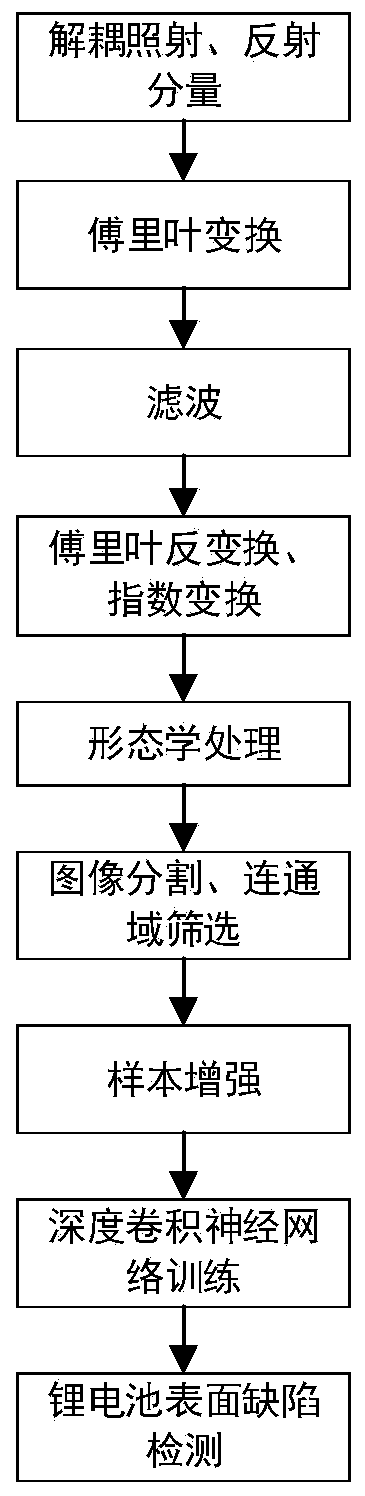

New energy lithium battery surface defect detection method based on adaptive deep learning

ActiveCN111105405AAccurate defect locationNo need for manual labelingImage enhancementImage analysisImage segmentationSample image

The invention discloses a new energy lithium battery surface defect detection method based on adaptive deep learning. The method comprises the following steps: carrying out nonlinear mapping on a lithium battery surface grayscale image; transforming the decoupled irradiation component and reflection component to a frequency domain; performing filtering, inverse Fourier transform and exponential transform on the frequency domain data to obtain a reconstructed lithium battery image; based on morphological processing and background differencing, enhancing gray scale response at the defect; carrying out image segmentation and connected domain analysis and screening processing, and taking a result as a labeled image; designing an operator to simulate illumination details, and carrying out sample enhancement operation on the surface grayscale image of the lithium battery; training a deep convolutional neural network based on the enhanced sample image set and the labeled image; and achievinglithium battery surface defect detection based on the trained network. By utilizing the method, the detection efficiency can be improved and the false detection rate can be reduced in a lithium battery surface defect detection scene.

Owner:芜湖楚睿智能科技有限公司

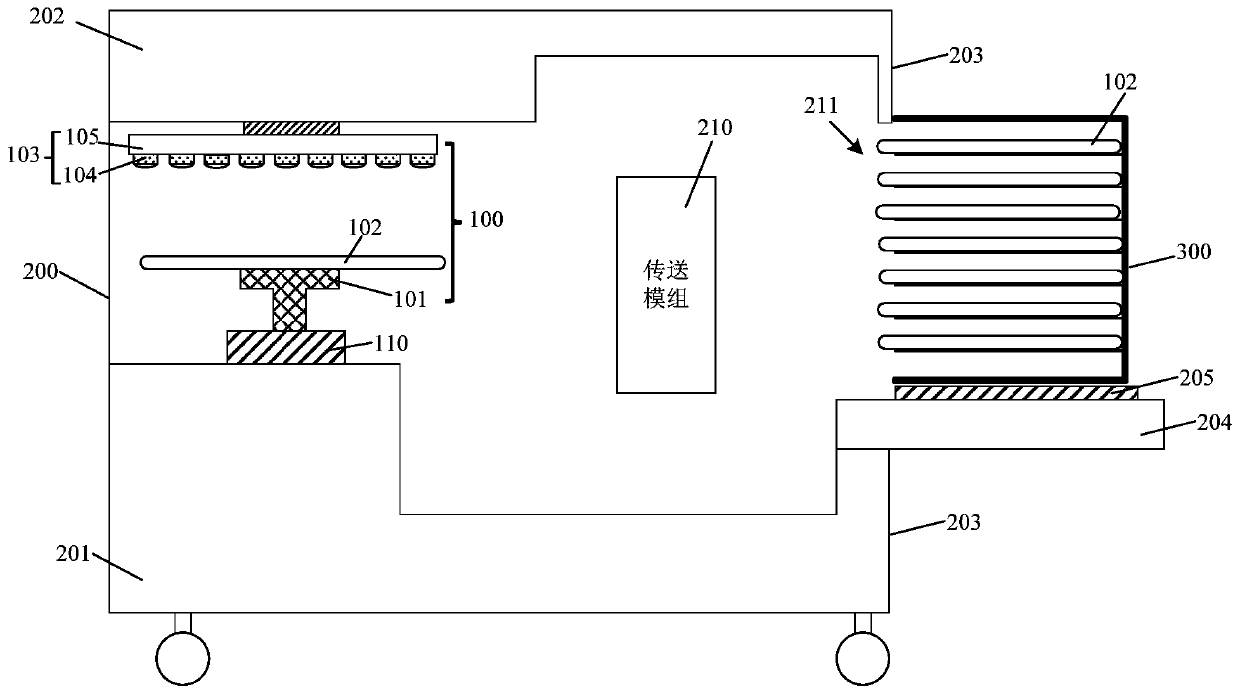

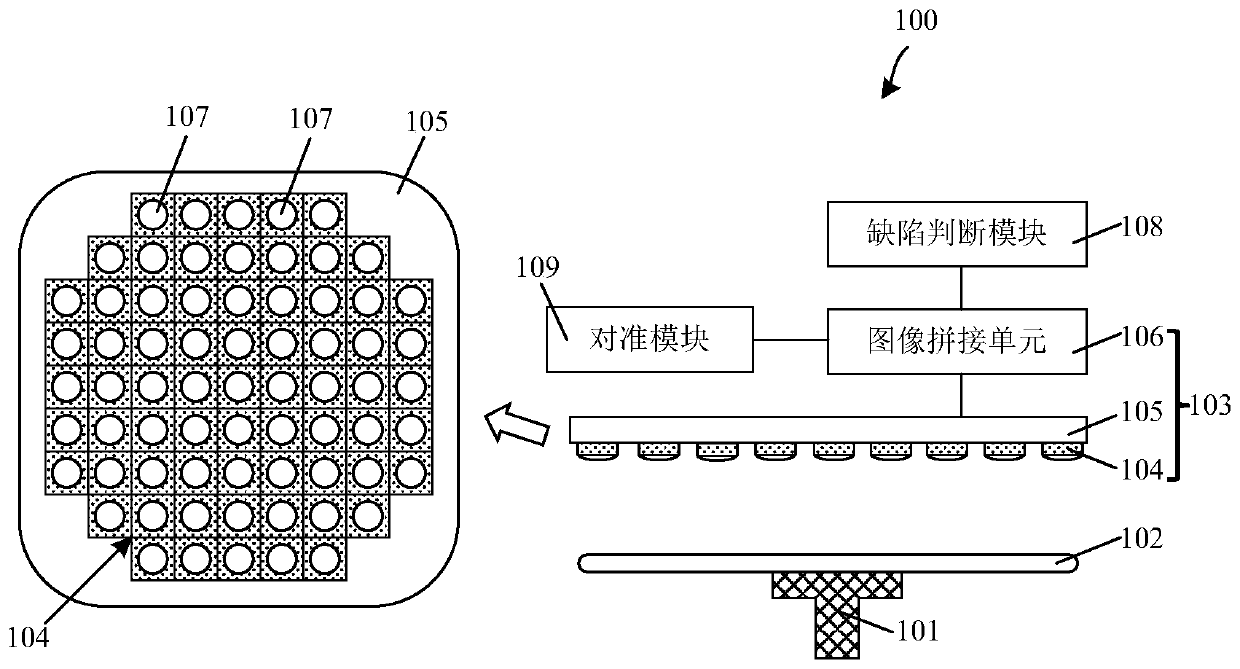

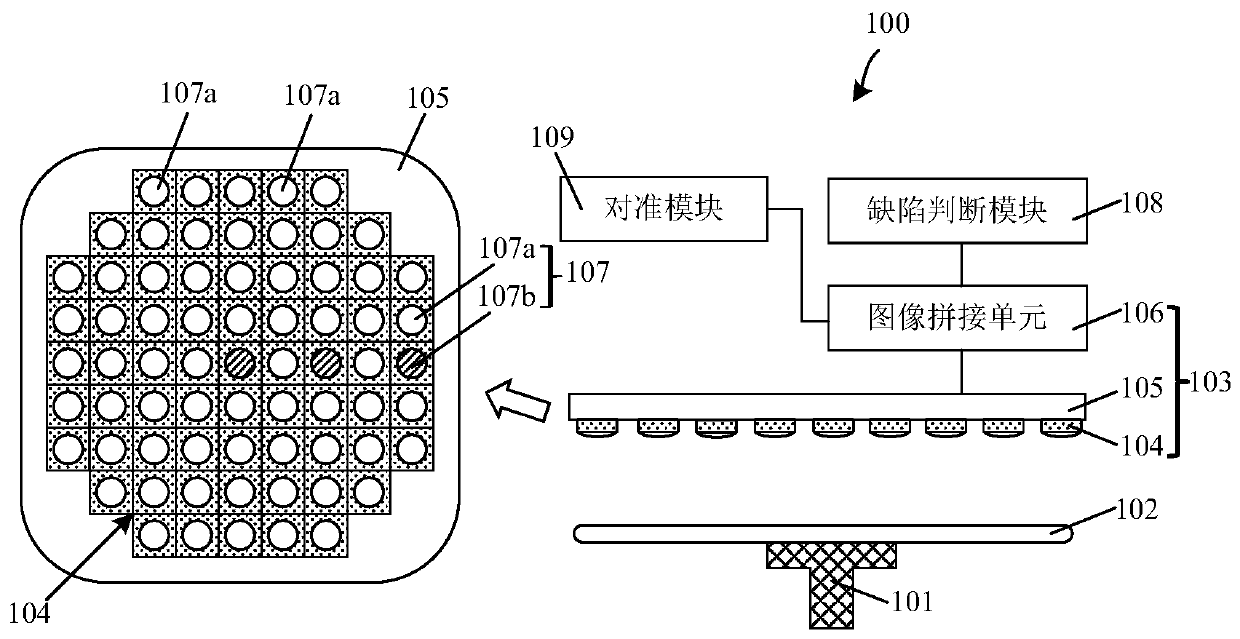

Wafer front-end conveying system

ActiveCN111554601AShorten the timeReduce volumeSemiconductor/solid-state device manufacturingConveyor partsWaferEngineering

A wafer front-end conveying system comprises a loading table and a defect detection module, and the defect detection module is used for detecting defects of a wafer and aligning the wafer before the wafer enters an equipment end and comprises a wafer carrying table used for fixing the wafer needing defect detection; an image acquisition module which comprises a camera array, and obtains a first detection image corresponding to the whole surface of the wafer on the wafer carrying table through one-time shooting of the camera array or obtains a circle of alignment detection image corresponding to the edge of the wafer through one-time shooting of the camera array; a defect judging module which is used for judging whether defects exist on the surface of the wafer or not according to the firstdetection image obtained by the image obtaining module; and an alignment module which is used for obtaining the position of the wafer on the wafer carrying table according to the position of the notch in the alignment detection image. The wafer front-end conveying system has both the functions of defect detection and alignment.

Owner:SHANGHAI GUONA SEMICON TECH CO LTD

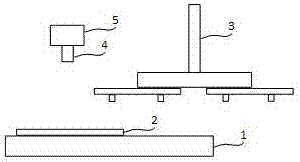

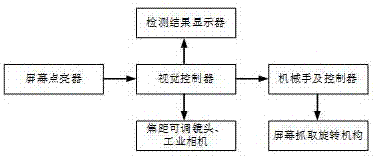

Optical automatic detection system for TFT-LCD defects

PendingCN107966836AImprove detection accuracyImprove efficiencyNon-linear opticsManipulatorScreen capture

An optical automatic detection system for TFT-LCD defects comprises an automatic focal length adjustable lens, an industrial camera, a screen capture rotating mechanism, a screen lightening device, avision controller, a detection result displayer, a mechanical hand and a controller. When TFT-LCD defects are automatically detected, the screen lightening device firstly drives the TFT-LCD to displaya first detection picture, meanwhile, an instruction is transmitted to the vision controller, the vision controller receives the instruction and then controls the industrial camera to take a picture,and a picture processing procedure of the corresponding detection picture is operated. Then, a second detection picture is detected, and circular operation is sequentially performed till all the TFT-LCD detection pictures are displayed and detection is completed. Finally, the result is sent to the detection result displayer. In order to improve the detection accuracy, the vision controller controls the focal length adjustable lens to perform automatic focusing. In order to improve the detection efficiency, the screen capture rotating mechanism at the tail end of the mechanical hand performs rapid picking and placing. The system has the advantages of being high in detection accuracy rate and detection efficiency.

Owner:NANCHANG INST OF TECH

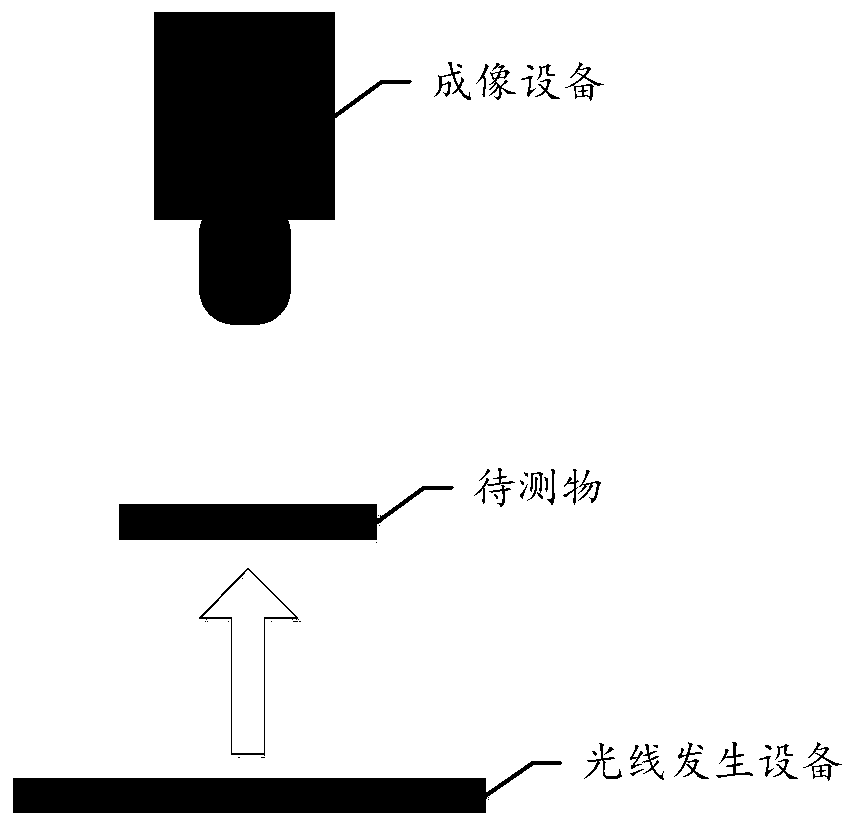

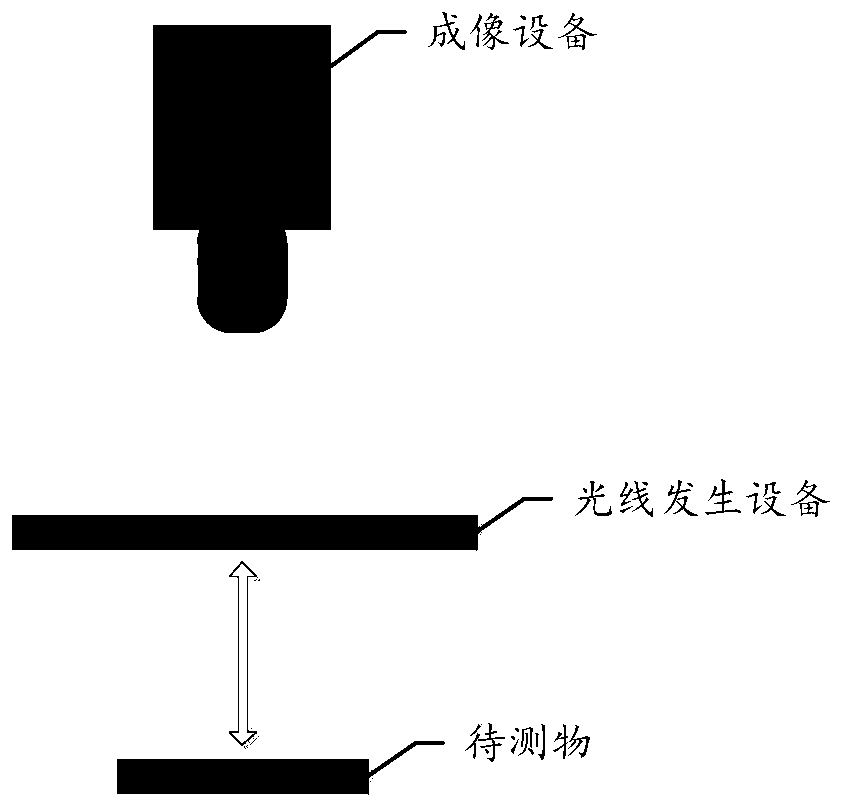

Detection device and detection method

PendingCN110057835AImprove the detection rateReduce false positivesOptically investigating flaws/contaminationLight beamImaging equipment

The invention discloses a detection device and a detection method. The device comprises a light ray generating device and an imaging device. The light ray generating device comprises a stripe pattern,the device is used for emitting light beams and projecting the stripe pattern to the object to be detected through the light beams, and the stripe pattern comprises a plurality of separated straightstrips which are arranged in parallel; the imaging device is used for obtaining the light beam transmitted or reflected by the object to be detected to form a detection image, and the detection imagecomprises a plurality of stripes; and the detection image is used for acquiring the defect information of the object to be detected according to the stripes. If the surface of the object to be detected is processed ideally and without defects, the detection image obtained by the imaging device should demonstrate straight stripes similar to the stripe pattern. However, if the surface of the objectto be detected has defects, such as orange lines, die scratches, indentations, and the like, the stripes in the detection image are distorted. The detection device can be used for automatically detecting the surface defects of the object to be detected, and compared with the manual detection method in the prior art, the detection efficiency is significantly improved.

Owner:SKYVERSE TECH CO LTD

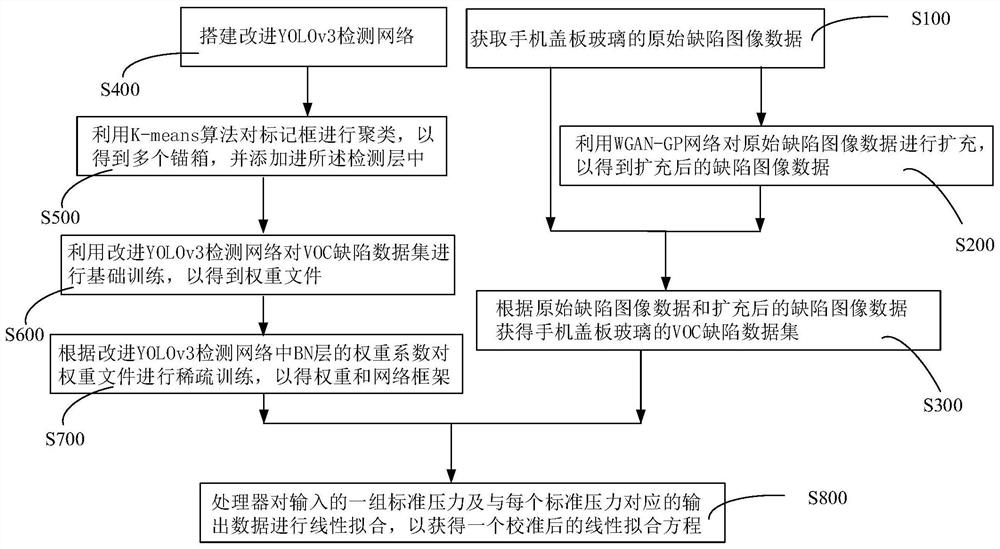

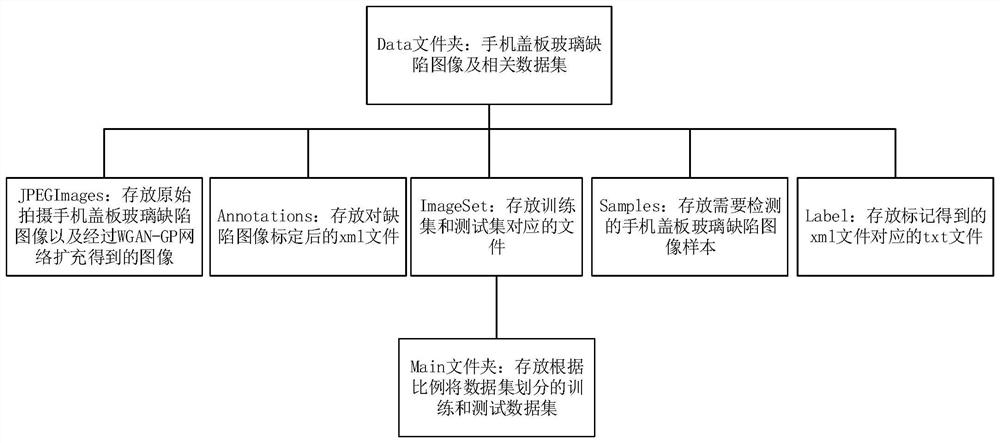

Mobile phone glass defect detection method and device, computer equipment and storage medium

PendingCN112614125AImplement defect detectionImprove accuracyImage analysisCharacter and pattern recognitionData setAlgorithm

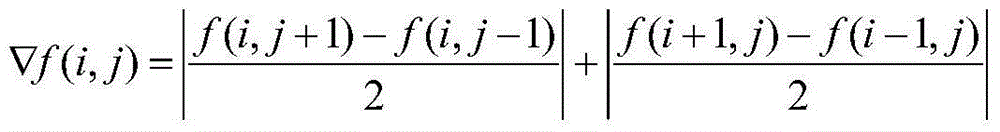

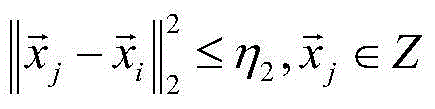

The invention relates to a mobile phone glass defect detection method and device, computer equipment and a storage medium. The mobile phone glass defect detection method comprises the following steps: acquiring original defect image data of mobile phone cover plate glass; expanding the original defect image data by using a WGAN-GP network to obtain expanded defect image data; obtaining a VOC defect data set of the mobile phone cover plate glass; building an improved YOLOv3 detection network; clustering the mark box by using a K-means algorithm to obtain a plurality of anchor boxes, and adding the anchor boxes into a detection layer; performing basic training on the VOC defect data set by using an improved YOLOv3 detection network to obtain a weight file; performing sparse training on the weight file according to the weight coefficient of the BN layer in the improved YOLOv3 detection network to obtain a weight and a network framework; and testing the detection data set for the weight and the network framework to obtain category information, position information and confidence information of the detection target. The method has high defect detection efficiency and high defect detection precision at the same time.

Owner:HUNAN UNIV OF SCI & TECH

Electronic component surface defect detection method based on sample library dictionary

ActiveCN103954627AImprove defect detection efficiencyOvercoming the shortcomings of manual visual inspection methodsOptically investigating flaws/contaminationVisual inspectionElectronic component

The invention relates to an electronic component surface defect detection method based on a sample library dictionary. At present, since finished product defect detection in a process of producing electronic components is mainly manually finished, time and labor are consumed, the workload is high, the production process is easily influenced by subjective factors of detecting workers, error detection and detection leakage are easily caused, the detection efficiency is low, and the labor intensity is high. If careless manipulation is caused during detection, the electronic components are subjected to secondary damage. According to the method, the defect detection efficiency of the electronic components is improved by utilizing a non-contact digital image detection technology, and the electronic component surface defect detection method based on the sample library dictionary is provided. In the method, the surface defects of the electronic components are self-adaptively and automatically detected by constructing a qualified sample library dictionary base for various defects, the defect types are automatically determined, and the defects in a manual visual inspection detection method can be well overcome.

Owner:HANGZHOU DIANZI UNIV

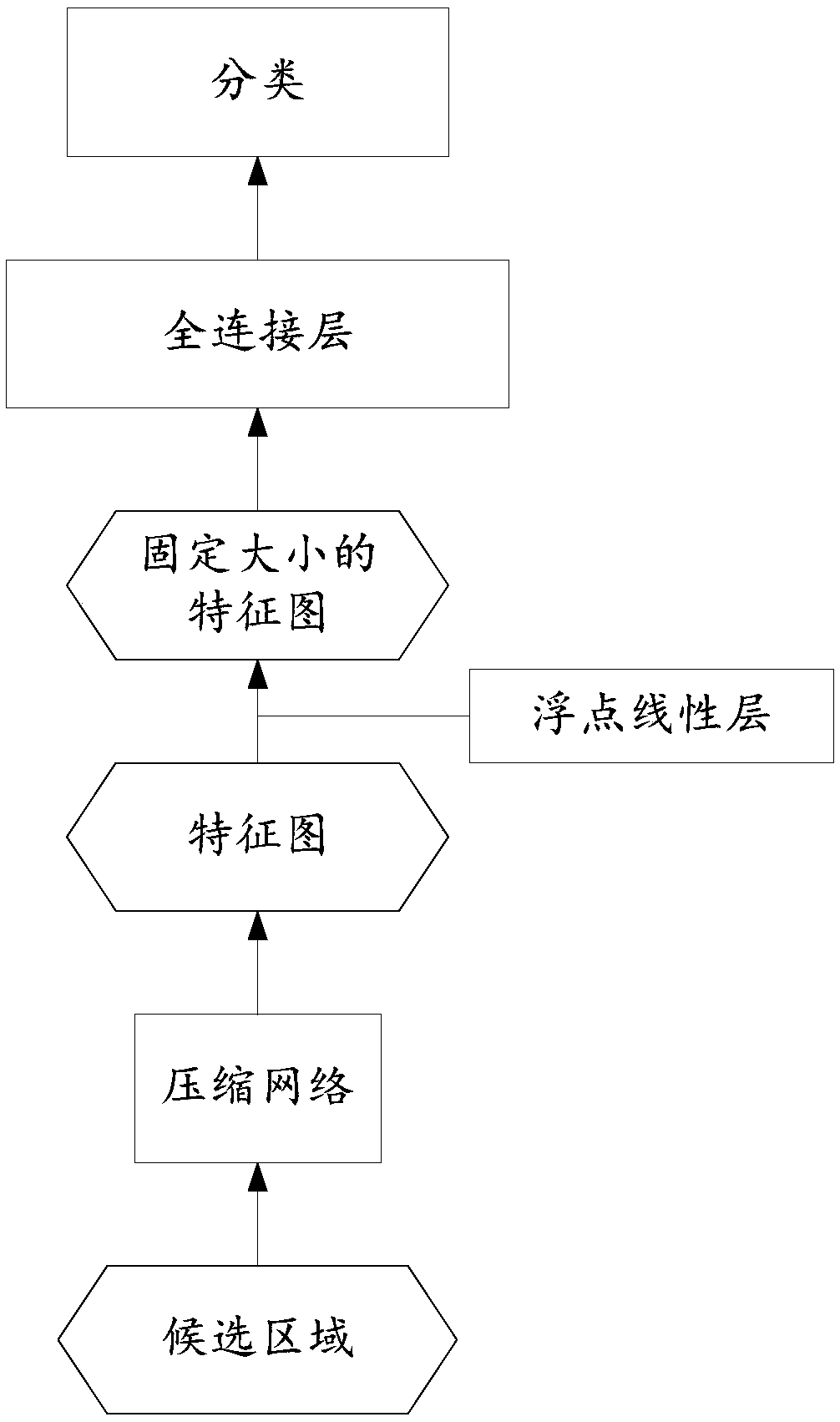

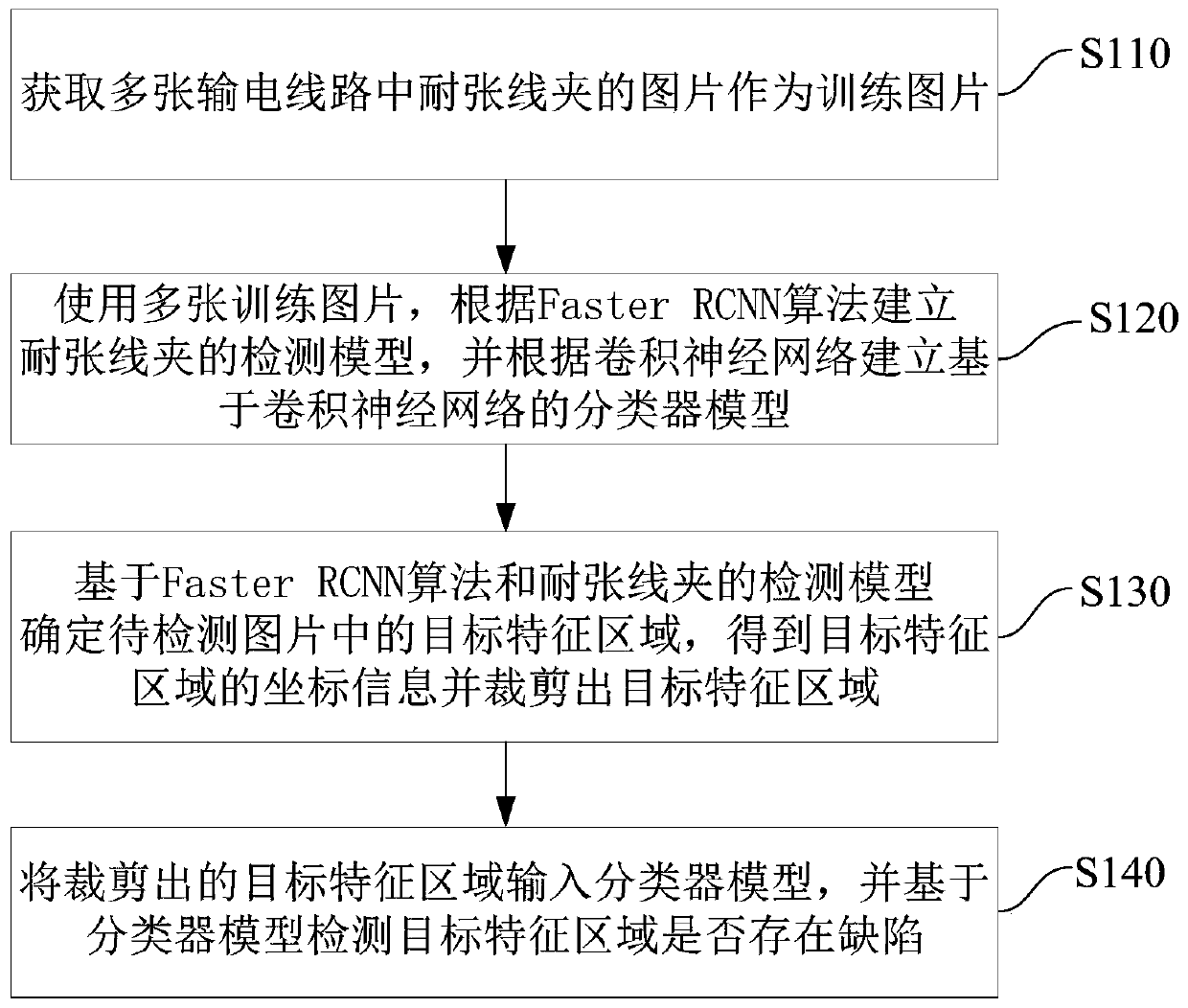

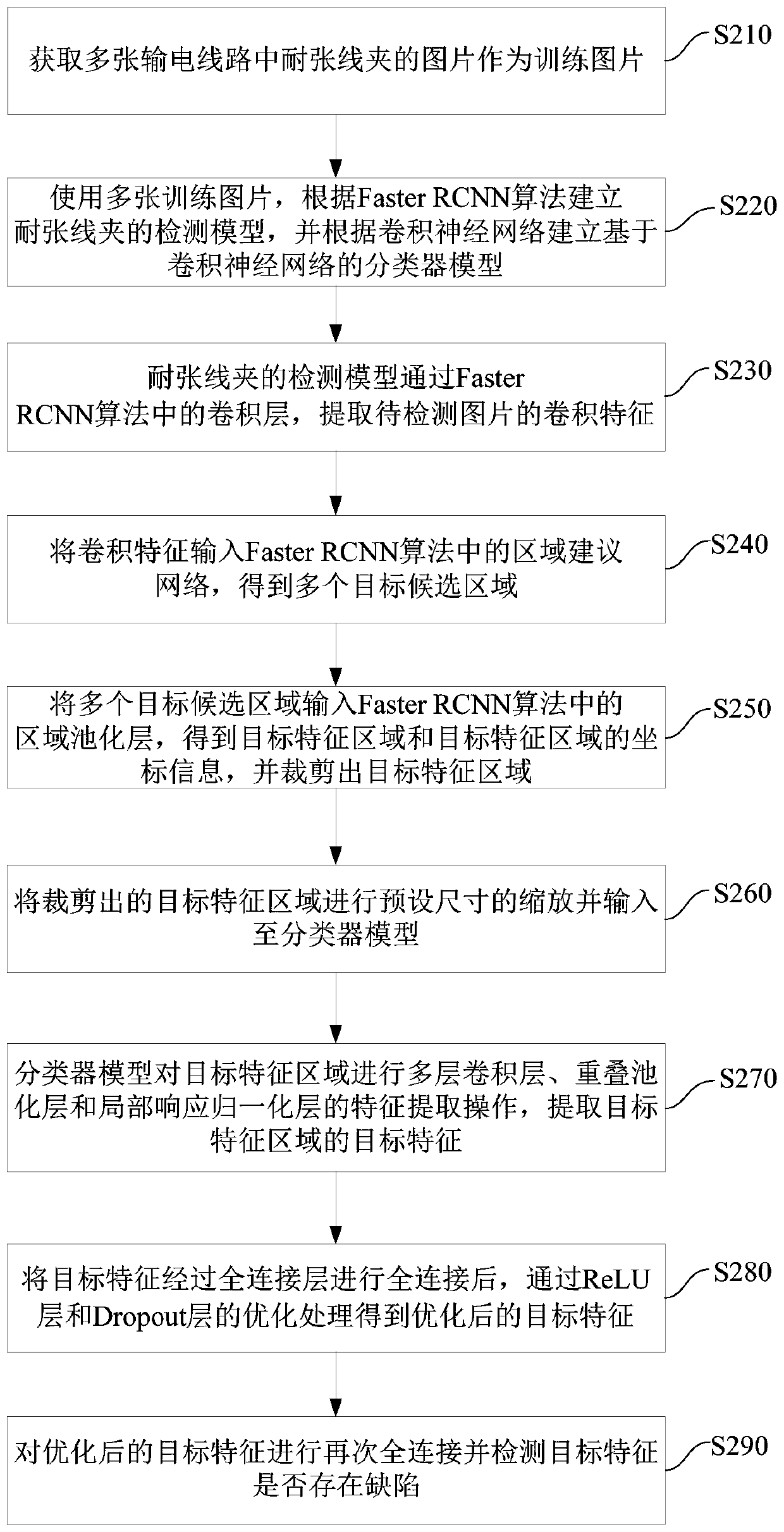

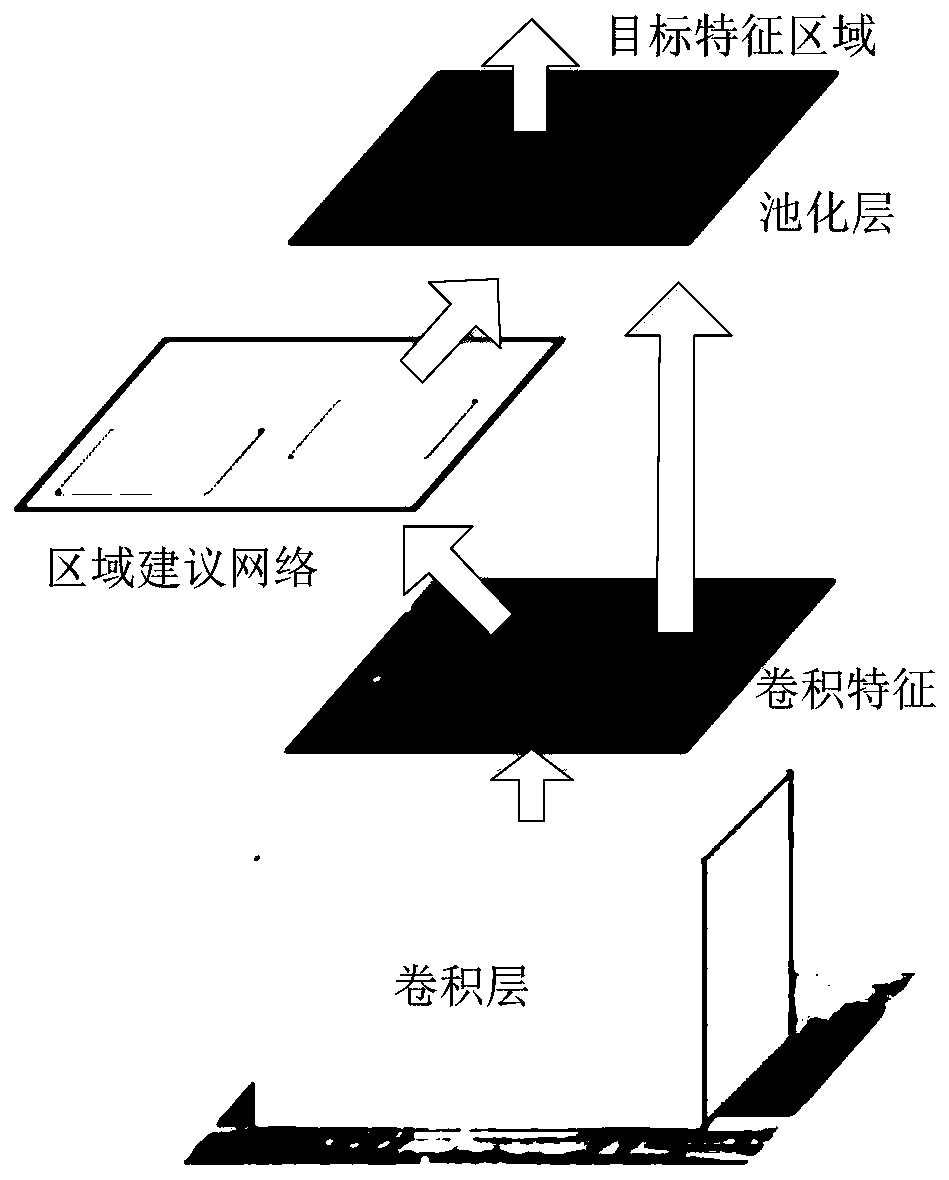

Defect detection method, device and equipment for strain clamp and storage medium

PendingCN111462109AImprove convenienceImprove defect detection efficiencyImage enhancementImage analysisAlgorithmEngineering

The embodiment of the invention discloses a defect detection method, device and equipment for a strain clamp, and a storage medium. The defect detection method comprises the steps: obtaining picturesof the strain clamp in a plurality of power transmission lines as training pictures; using the plurality of training pictures, establishing a detection model of the strain clamp according to a FasterRCNN algorithm, and establishing a classifier model based on a convolutional neural network according to the convolutional neural network; determining a target feature region in the to-be-detected picture based on a Faster RCNN algorithm and a detection model of the strain clamp, obtaining coordinate information of the target feature region, and cutting out the target feature region; and inputtingthe cut target feature region into a classifier model, and detecting whether the target feature region has defects or not based on the classifier model. According to the defect detection method, device and equipment for the strain clamp and the storage medium provided by the embodiment of the invention, the convenience of defect detection of the strain clamp can be realized, and the defect detection efficiency is improved.

Owner:GUANGDONG POWER GRID CO LTD +1

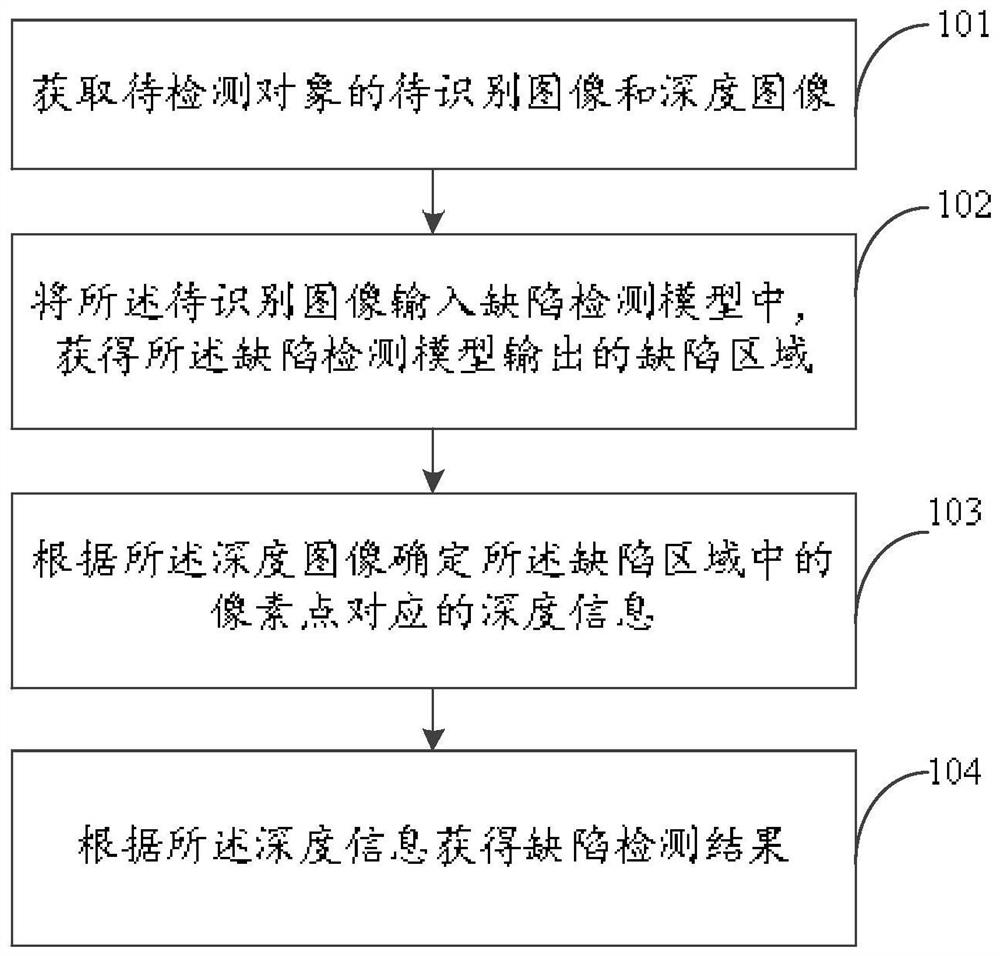

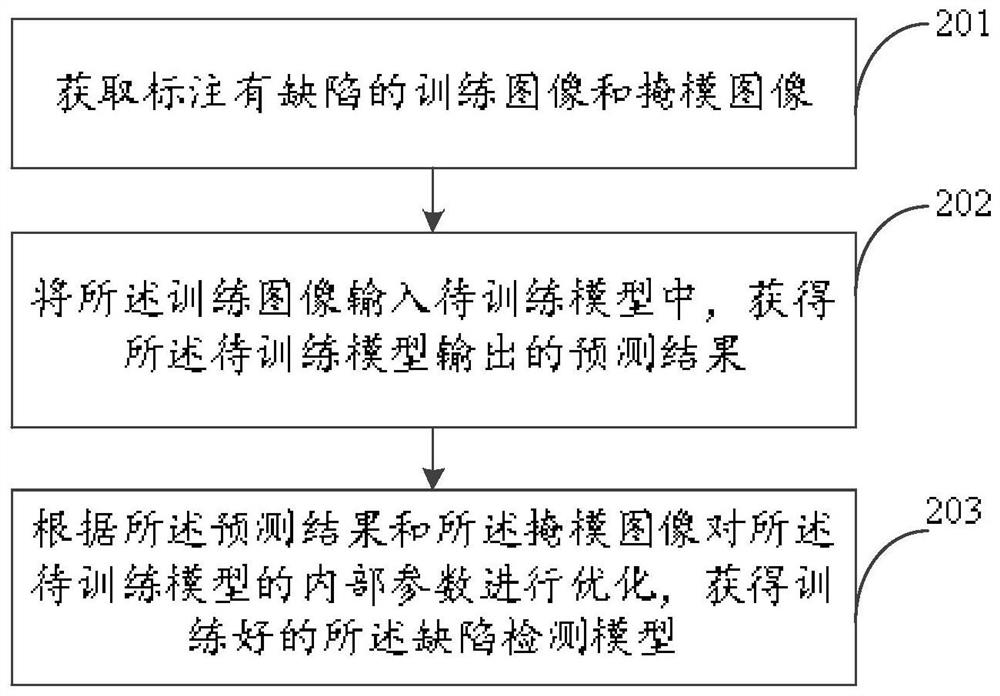

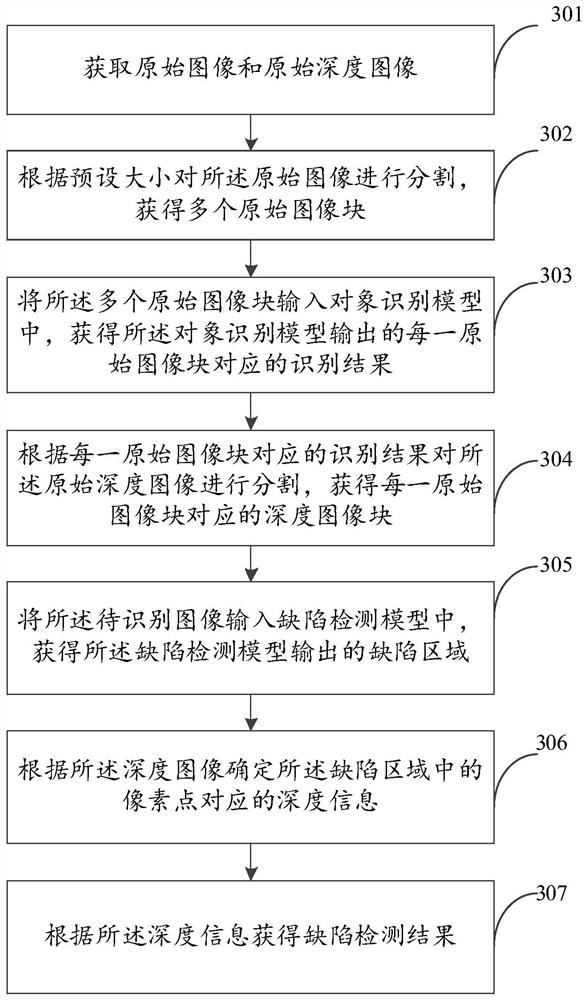

Defect detection method and device, electronic equipment and storage medium

PendingCN113763355AImprove accuracyImprove defect detection efficiencyImage enhancementImage analysisEngineeringComputer science

The invention provides a defect detection method and device, electronic equipment and a storage medium. The method comprises the steps of obtaining a to-be-recognized image and a depth image of a to-be-detected object, the pixel positions occupied by the to-be-detected object in the to-be-recognized image and the depth image being the same; inputting the to-be-recognized image into a defect detection model to obtain a defect area output by the defect detection model; determining depth information corresponding to pixel points in the defect area according to the depth image; and obtaining a defect detection result according to the depth information. According to the embodiment of the invention, image acquisition is carried out on the to-be-detected object, defect identification is carried out on the image, after the defect area is determined, the depth information is obtained by using the depth map corresponding to the defect area, and finally whether the defect is the target defect is determined according to the depth information. According to the embodiment of the invention, the defect detection is realized by processing the image, and the target defect is determined in combination with the depth information, so that the defect detection efficiency is improved.

Owner:创新奇智(青岛)科技有限公司

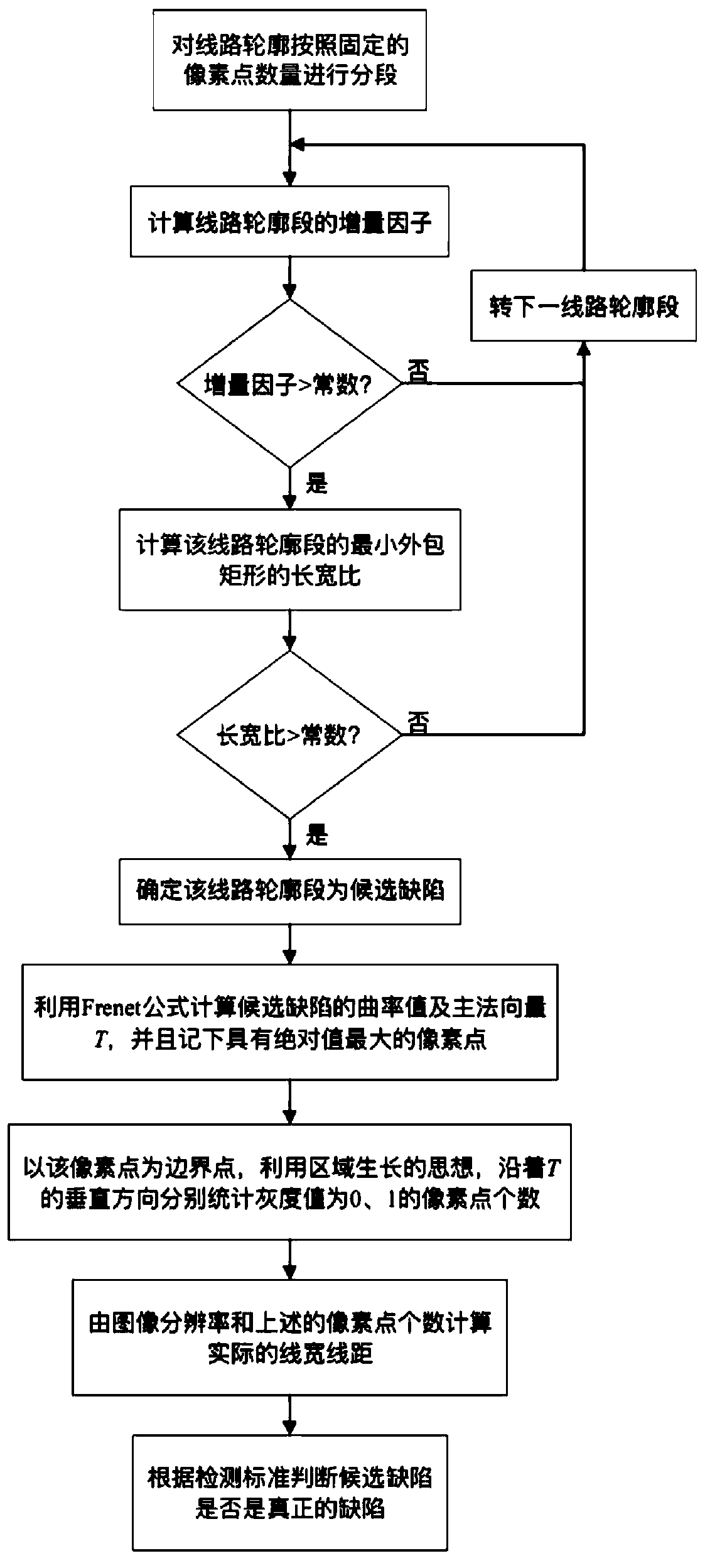

Geometric positioning-based flexible circuit board line defect identification method

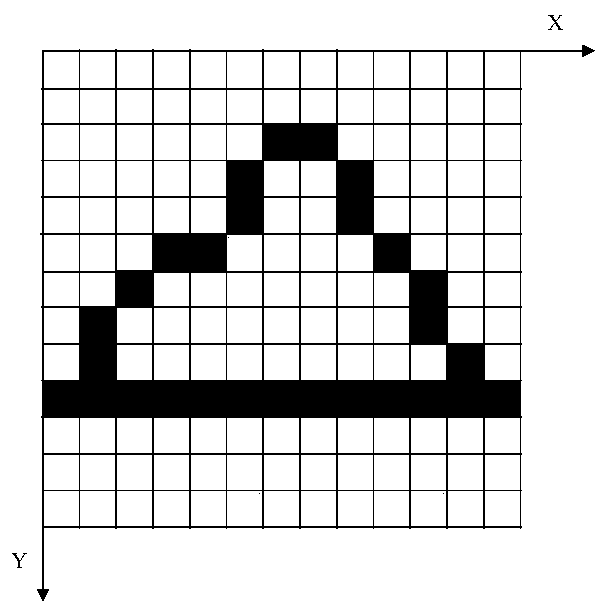

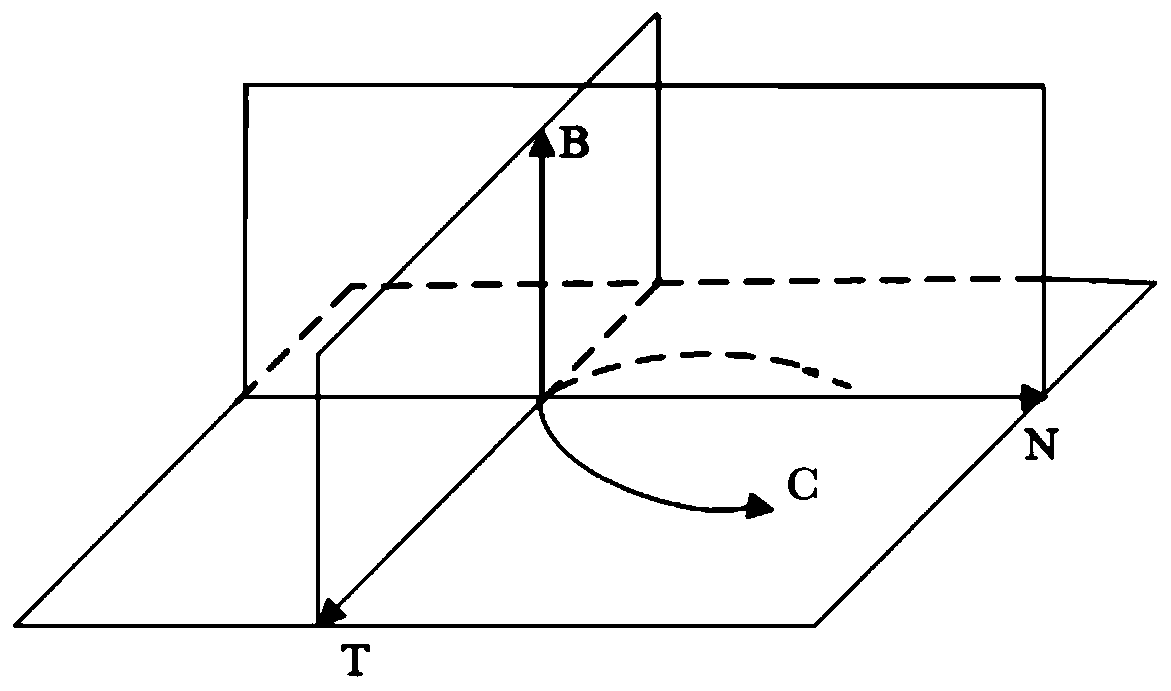

ActiveCN110544238AAchieve sagAchieving identifiabilityImage enhancementImage analysisMinimum bounding rectangleSize measurement

The invention discloses a geometric positioning-based flexible circuit board line defect identification method. The geometric positioning-based flexible circuit board line defect identification methodcomprises the following steps: S1, segmenting a line contour according to a preset number of pixel points; S2, calculating an increment factor of each contour section in the X direction or the Y direction, and roughly positioning candidate defect positions; S3, determining a minimum bounding rectangle of the contour section according to the increment factor; S4, determining candidate line defectpositions according to the length-width ratio of the minimum bounding rectangle; S5, measuring the defect positions of the candidate lines on the basis of a Frenet frame; and S6, judging the defect type according to the measurement result. According to the invention, the defects of the recesses and the projections of the FPC circuit part are identified and the sizes of the recesses and the projections are measured, so that the quality of finished products in FPC actual production is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

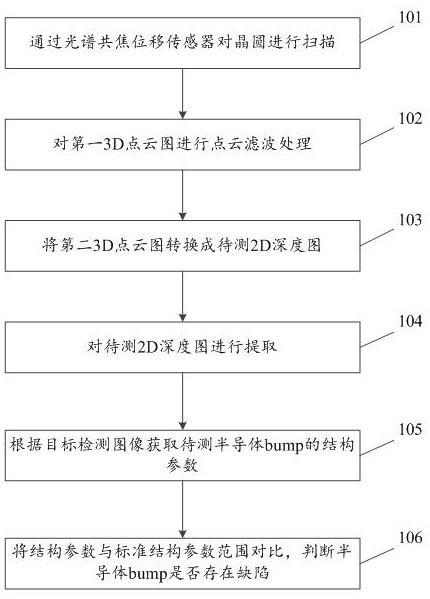

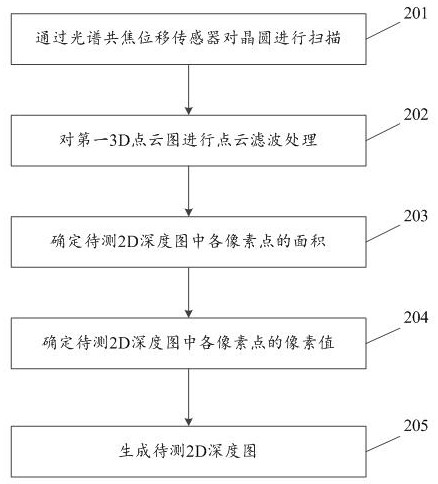

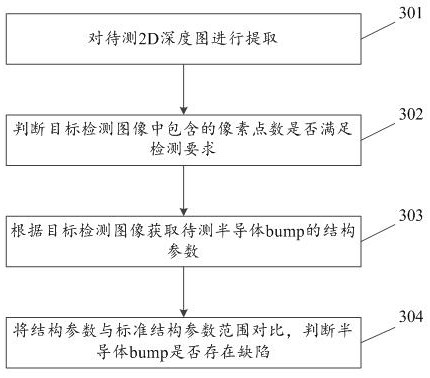

Semiconductor bump defect detection method, electronic equipment and storage medium

ActiveCN112734760AImprove defect detection efficiencyQuality improvementImage enhancementImage analysisPoint cloudWafer

The invention relates to a semiconductor bump defect detection method. The method comprises the steps of scanning a wafer by a spectral confocal displacement sensor, wherein the wafer comprises N semiconductor bumps, a first 3D point cloud picture is obtained, and N is an integer larger than 1; performing point cloud filtering on the first 3D point cloud image to obtain a second 3D point cloud image; converting the second 3D point cloud image into a to-be-measured 2D depth image, wherein pixel values of pixel points in the to-be-measured 2D depth image correspondingly represent depth information of the pixel points; extracting the to-be-measured 2D depth map to obtain a target detection image of the to-be-measured semiconductor bump; and acquiring structural parameters of the to-be-measured semiconductor bump according to the target detection image, comparing the structural parameters with a standard structural parameter range, and if the structural parameters are not matched with the standard structural parameter range, judging that the to-be-measured semiconductor bump has defects. According to the scheme provided by the invention, the defects of the semiconductor bump can be effectively detected, the detection accuracy is improved, and the quality of the semiconductor bump process is improved.

Owner:高视科技(苏州)股份有限公司

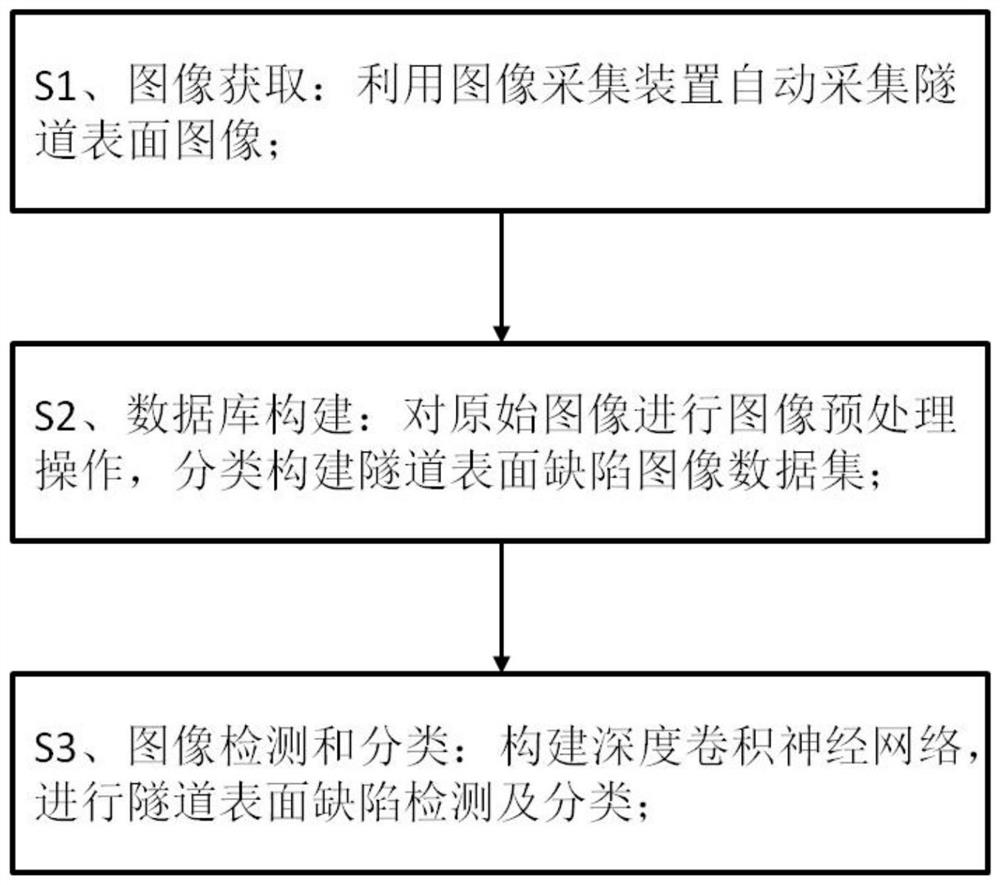

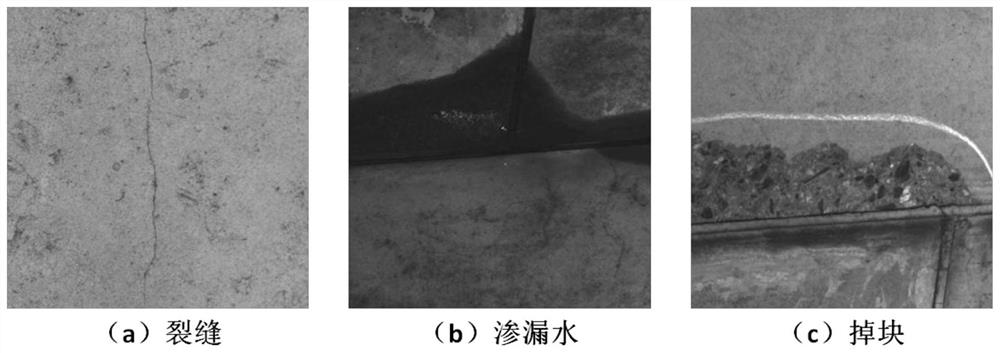

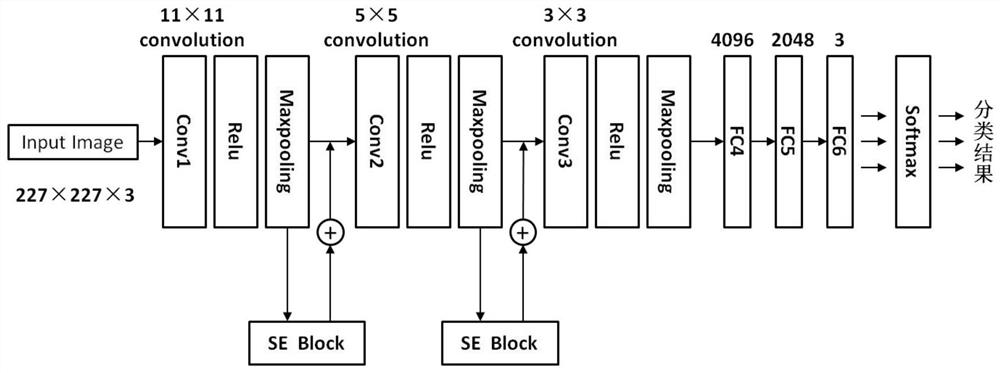

Tunnel surface defect classification method based on deep convolutional neural network

ActiveCN111931800AEasy to identifyImprove classification accuracyCharacter and pattern recognitionNeural architecturesImage detectionClassification methods

The invention relates to a tunnel surface defect classification method based on a deep convolutional neural network. The tunnel surface defect classification method comprises the following specific steps of S1, image acquisition, automatically acquiring a tunnel surface image by utilizing an image acquisition device; S2, database construction, performing image preprocessing operation on the original image, and constructing a tunnel surface defect database in a classified manner; S3, image detection and classification, constructing a deep convolutional neural network, and carrying out tunnel surface defect detection and classification. Compared with a traditional method, automatic recognition and classification of tunnel surface defects can be achieved, labor cost is greatly reduced, and defect detection efficiency and classification accuracy are effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com