Presswork defect detection method based on deep learning

A deep learning and defect detection technology, applied in optical testing defects/defects, measuring devices, scientific instruments, etc., can solve problems such as limited detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

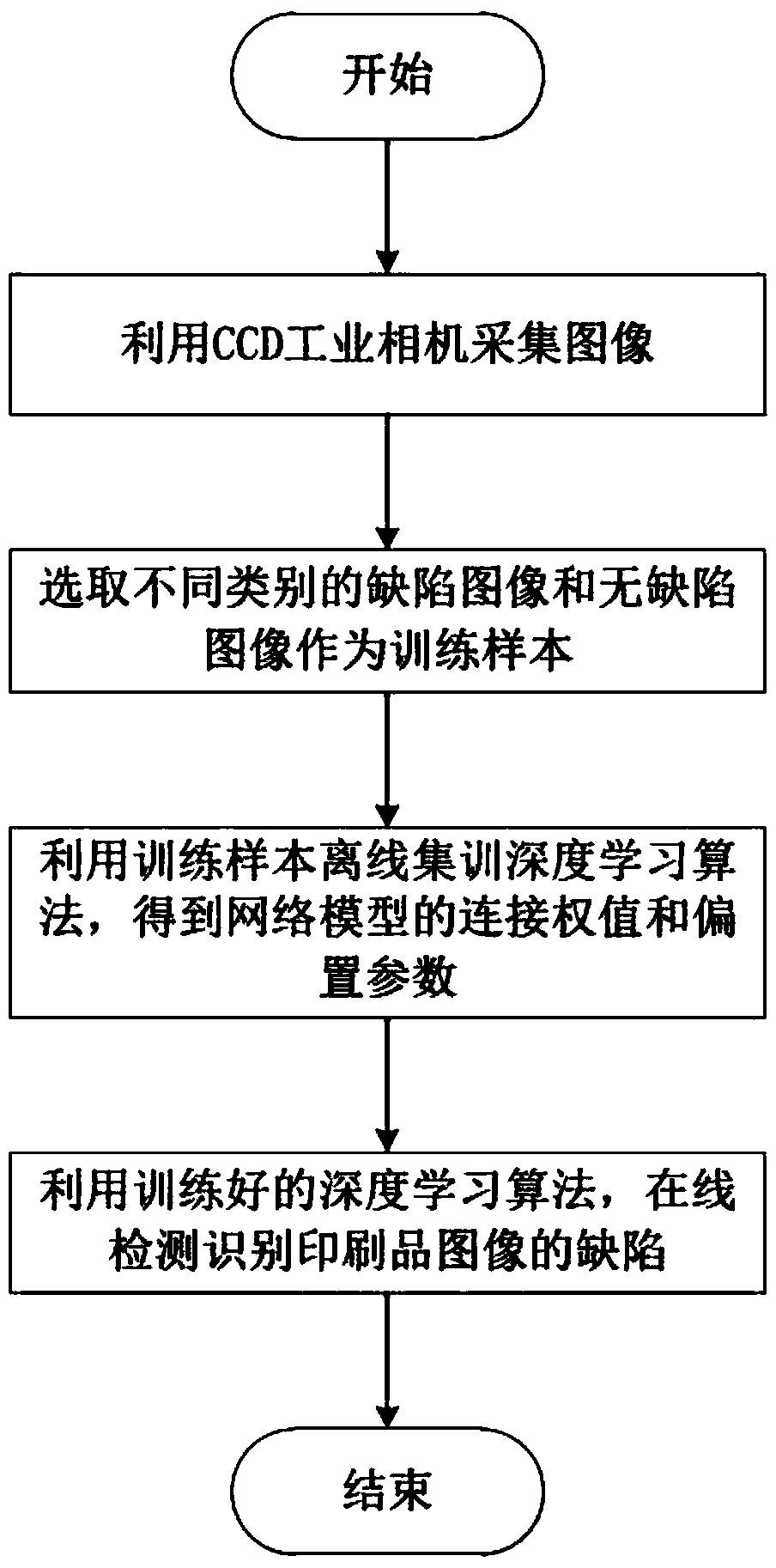

[0029] A kind of printing defect detection method based on deep learning of the present embodiment, such as figure 1 As shown, the steps include the following:

[0030] Step A: collecting images with a CCD industrial camera;

[0031] Step B: selecting defect images and non-defect images of different categories from the collected images as training samples;

[0032] Step C: use the training samples to train the deep learning algorithm offline, and obtain the connection weights and bias parameters of the network model;

[0033] Step D: Use the trained deep learning algorithm to detect and identify the defects of the printed matter image online.

[0034] Specifically, in step A, the image acquisition process is to select an industrial camera with a linear array CCD, and use a special light source fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com