Geometric positioning-based flexible circuit board line defect identification method

A technology for flexible circuit boards and circuit defects, which is applied in image data processing, instruments, calculations, etc., can solve the problems of insufficient industrial application and low accuracy of detection results, and achieve the effect of reducing the amount of calculation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

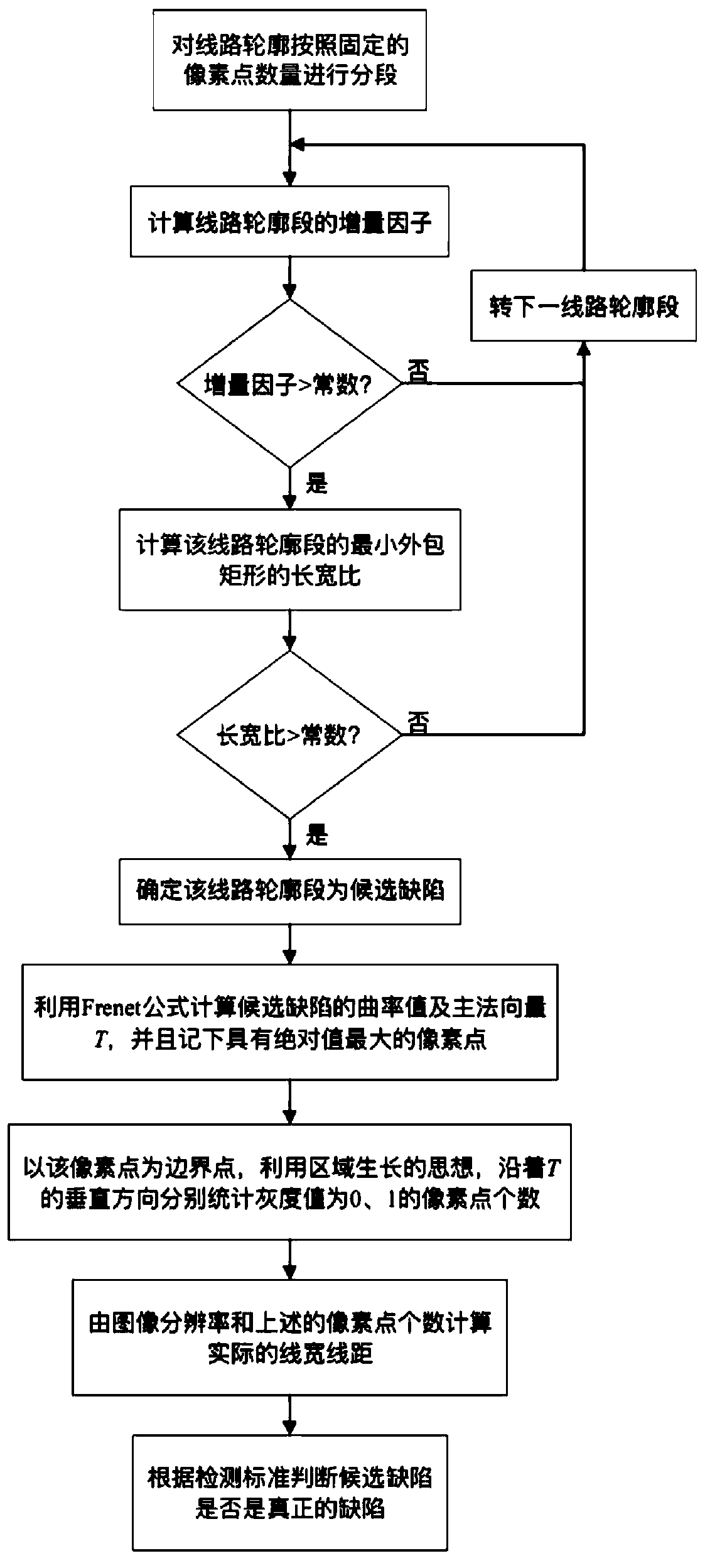

[0050] Such as figure 1 As shown, a method for identifying defects of flexible printed circuit boards based on geometric positioning includes:

[0051] S1 segments the outline of the line according to the preset number of pixels;

[0052] In general, defects appear on a line outline at intervals, so the line outline needs to be segmented according to a certain number of pixels according to the actual situation.

[0053] S2 calculates the increment factor of each contour segment in the X direction or the Y direction, and roughly locates the candidate defect position;

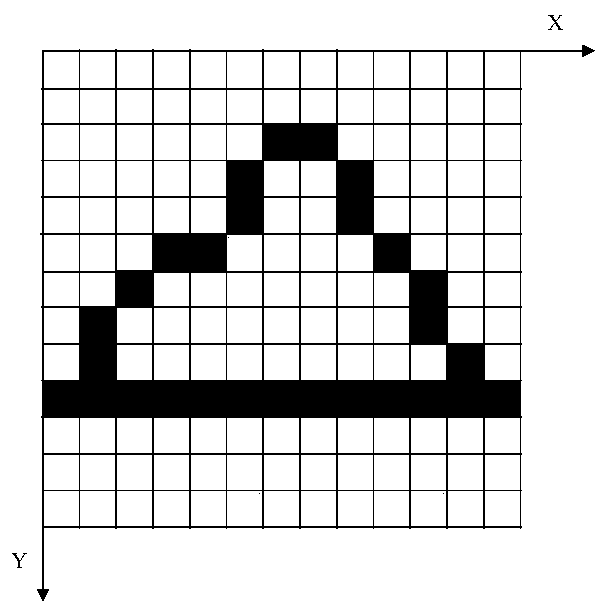

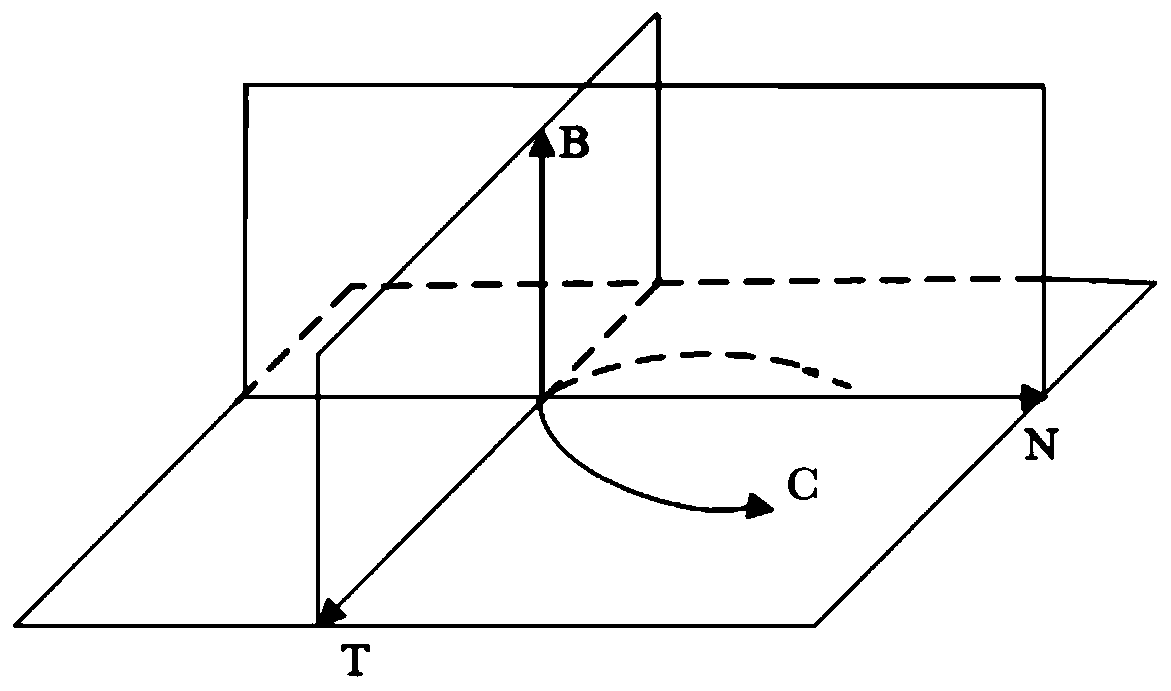

[0054] Such as figure 2 As shown, when the defect of the line part is suddenly deviated from the direction of the original regular and uniform line, not only the change in the curvature, but also the position of the pixel point on the line outline in the X and Y directions changes greatly. Therefore, when there is a large difference in the cumulative change of the pixel position of the line outline in the X a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com