Defect detection method and device, electronic equipment and storage medium

A defect detection and defect technology, applied in the field of image processing, can solve the problems of high labor cost, time-consuming and laborious, etc., and achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

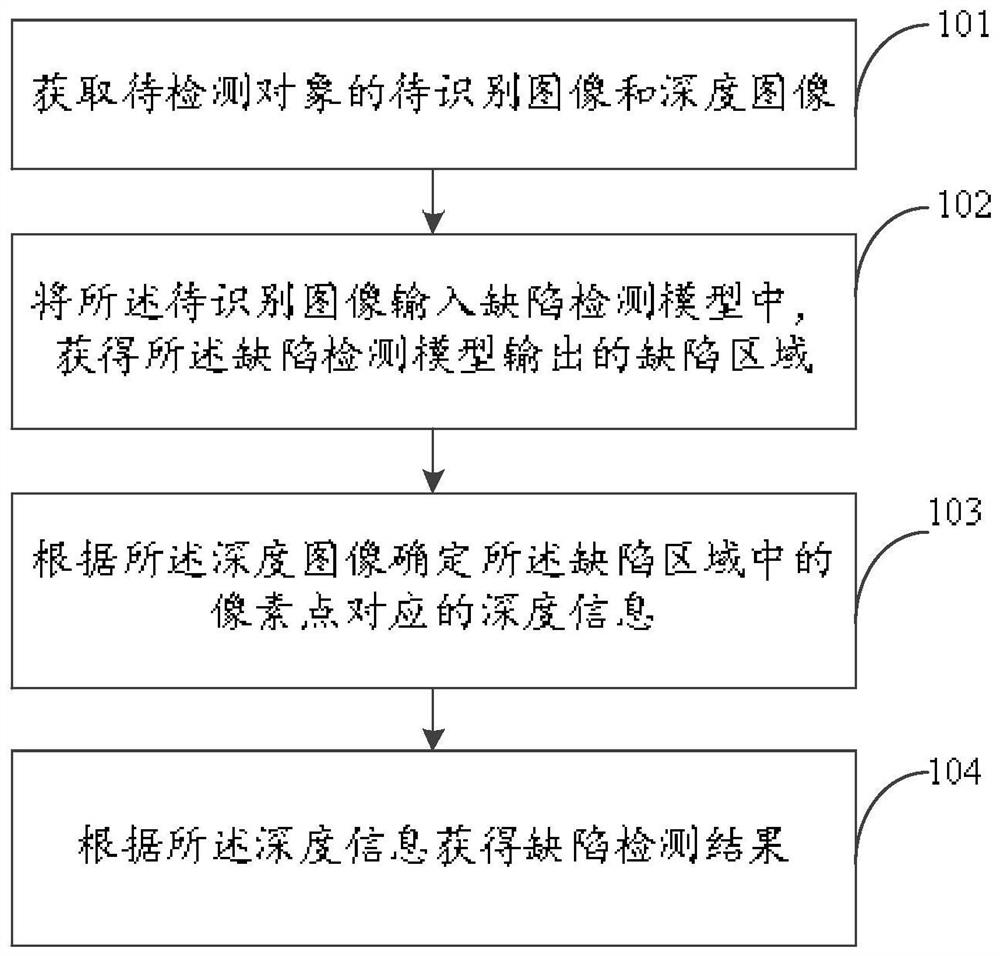

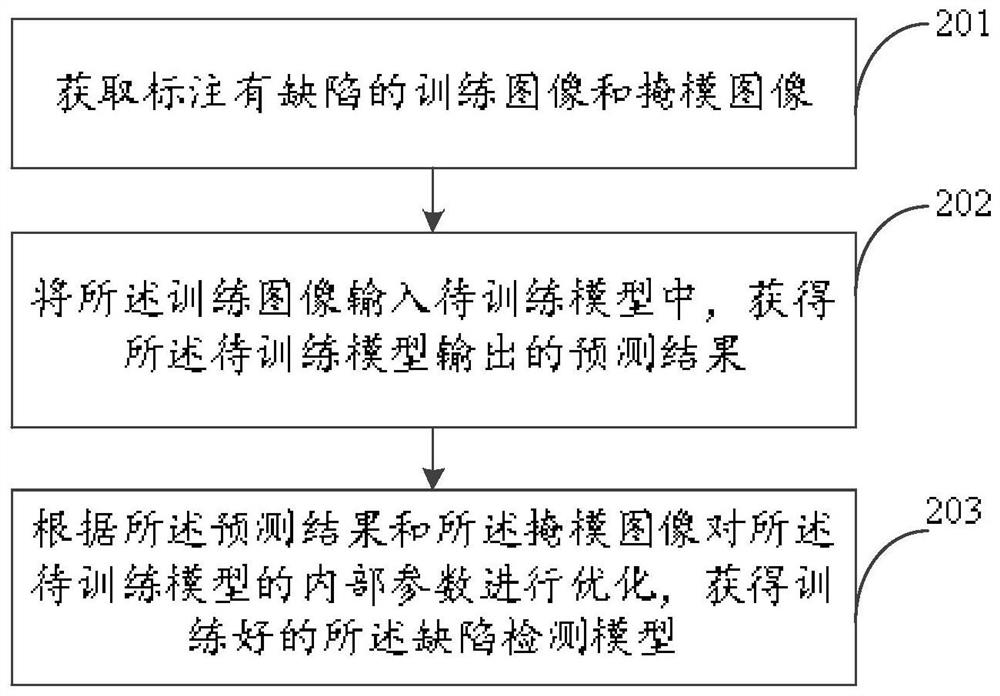

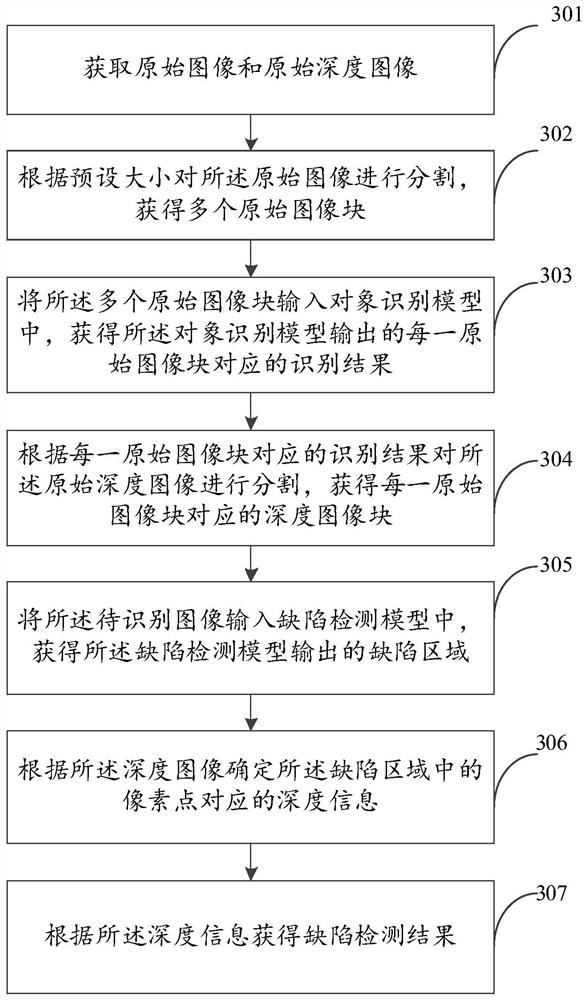

[0029] The inventors have found that by brushing soapy water on the casing of the electronic device to be tested and judging whether there are bubbles to determine whether the appearance defect is a functional defect, the efficiency of this method is low. Therefore, in order to solve this technical problem, the embodiment of the present application provides a defect detection method, which uses the defect detection model to determine the defect area from the image to be recognized, and combines the depth image to obtain the defect detection result. The result can be obtained by processing the collected images, and there is no need to brush soapy water on the casing, which greatly improves the efficiency of defect detection.

[0030] The defect detection method provided by the embodiment of the present application can be applied to the defect detection of the shell of electronic products, for example: the defect detection of the middle frame of the mobile phone, the defect detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com