Defect detection method, device and equipment for strain clamp and storage medium

A strain clamp and defect detection technology, applied in the field of defect detection, can solve the problems of heavy workload, manpower consumption, and slow detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

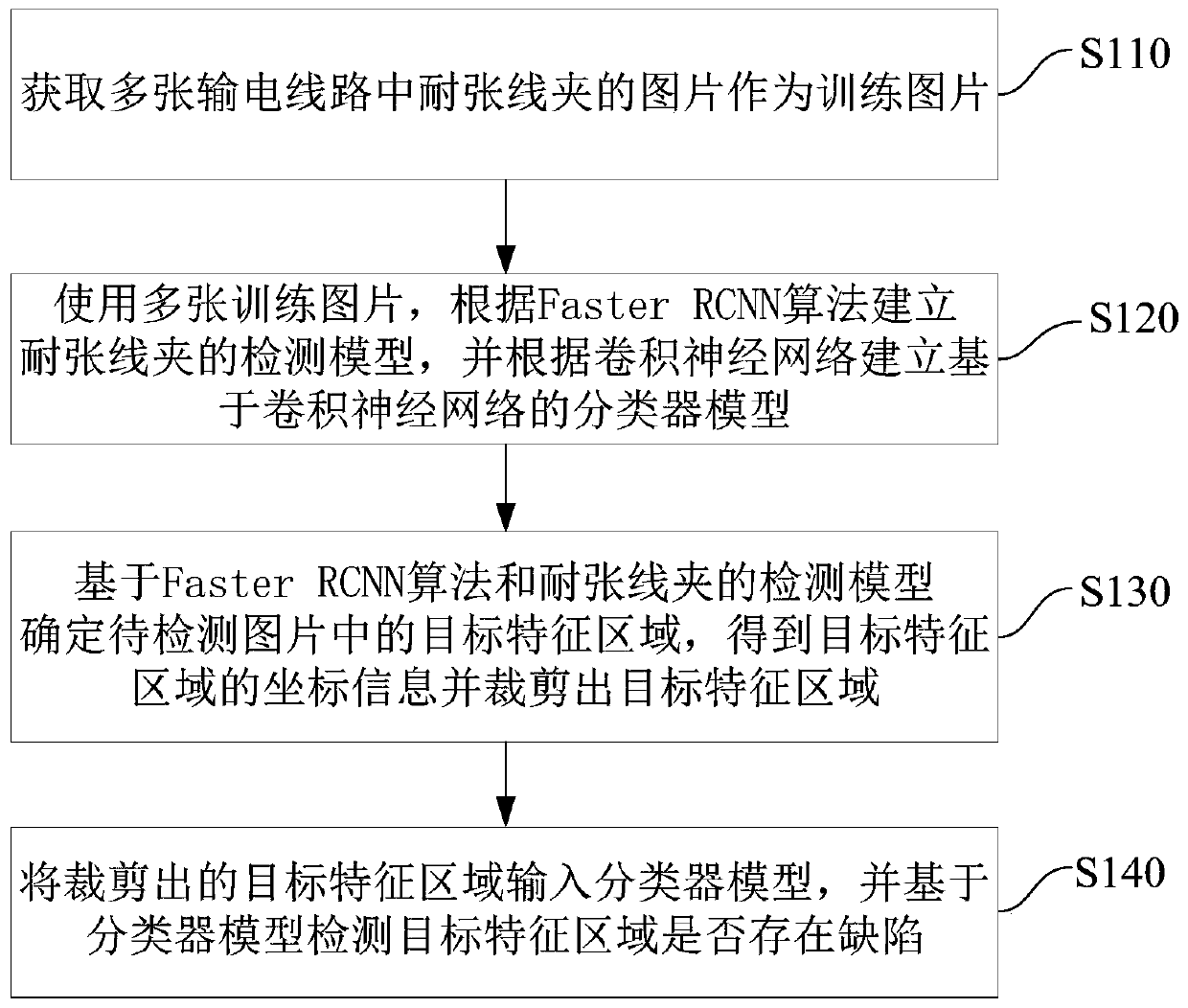

[0042] figure 1 It is a flow chart of a defect detection method for tension clamps provided by Embodiment 1 of the present invention. This embodiment is applicable to the detection of defects in tension clamps in power transmission lines, etc. The defect detection device can be implemented by means of software and / or hardware, and the device can be integrated in an electronic device such as a computer with a defect detection function of the tension clamp, and the method specifically includes the following steps:

[0043] Step 110, acquiring a plurality of pictures of the strain clamps in the transmission line as training pictures.

[0044] Among them, the pictures of the tension clamps in the transmission line can be the pictures of defects such as bending deformation and cracks in the transmission lines and the pictures of the tension clamps without defects. The pictures of strain-resistant clamps in transmission lines can be 5,000 pictures of strain-resistant clamps in tran...

Embodiment 2

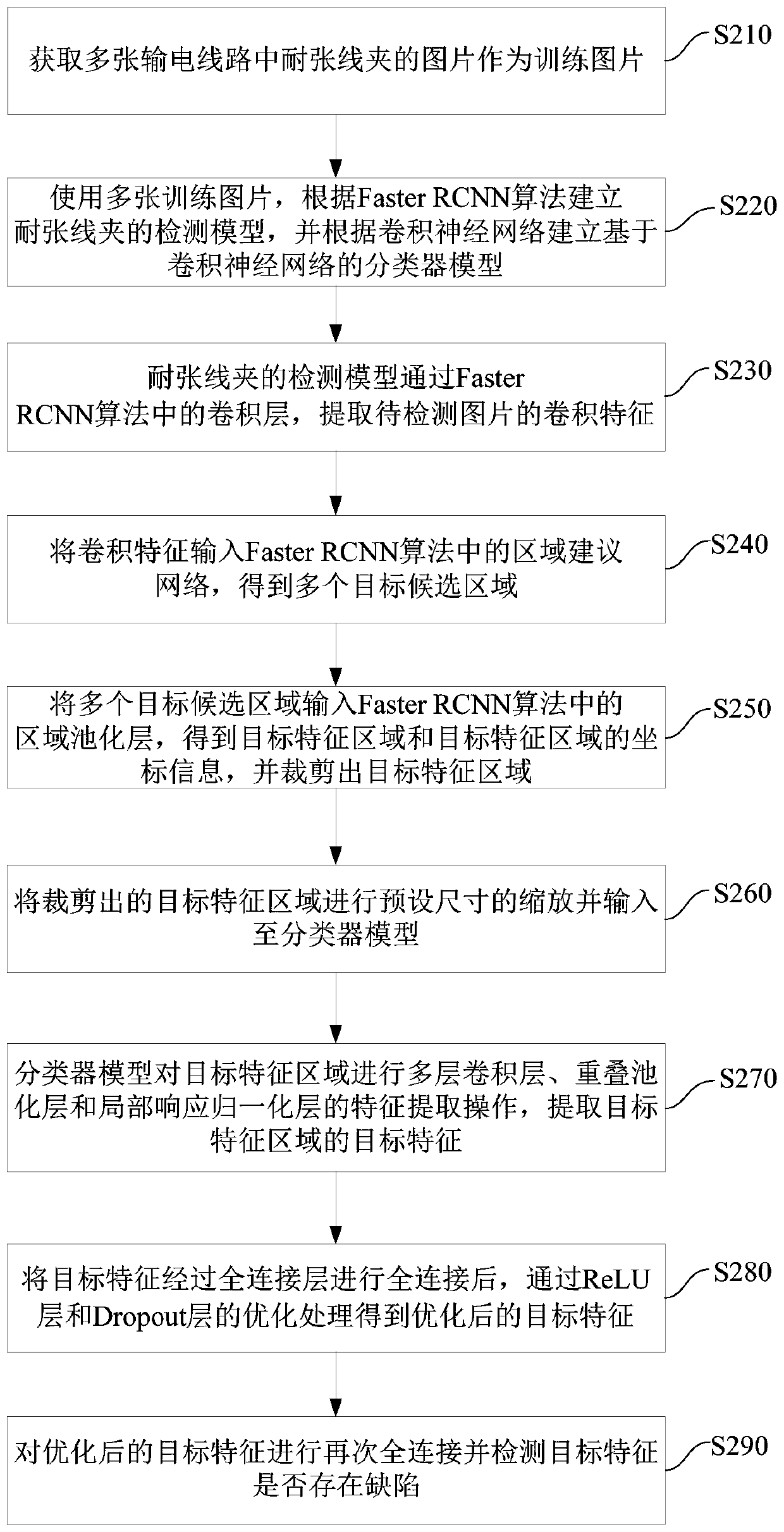

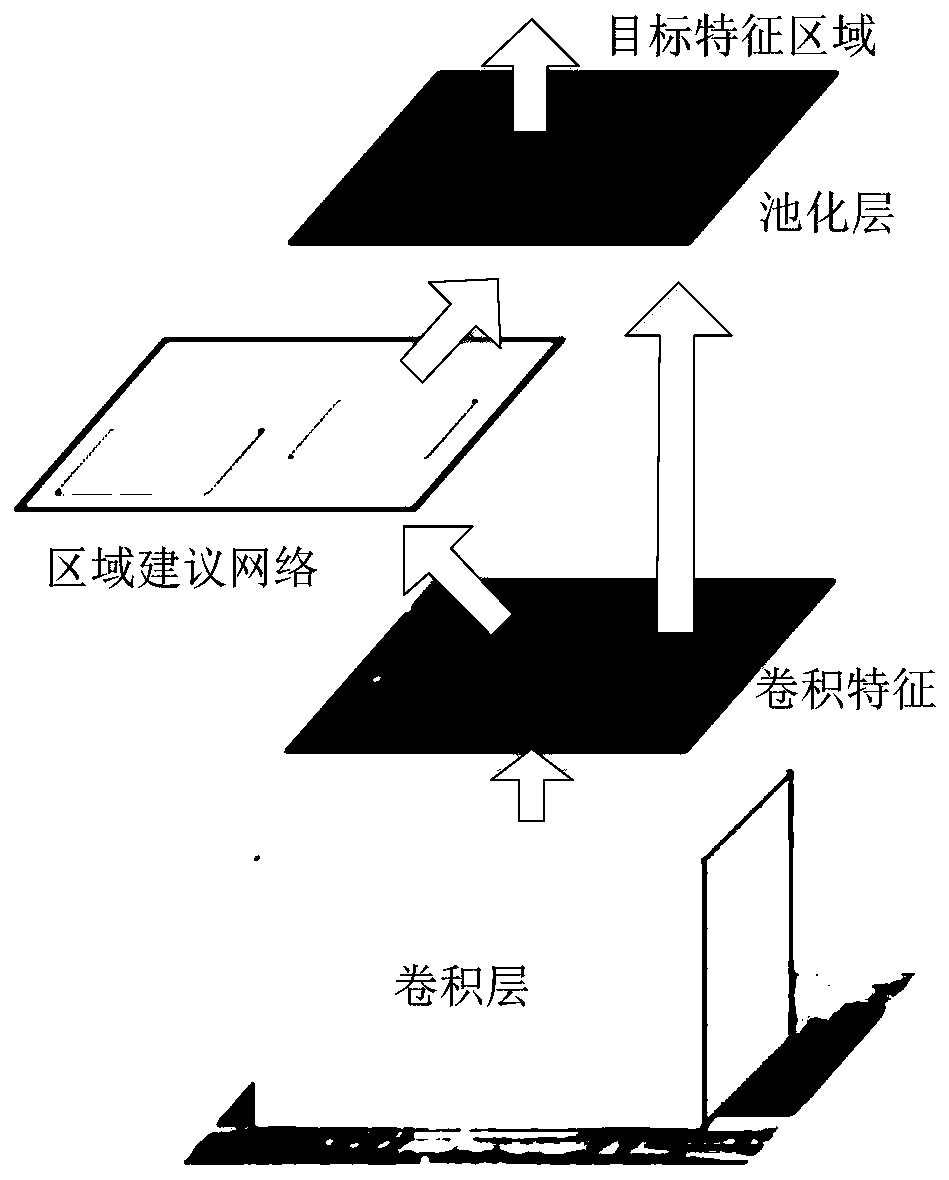

[0053] figure 2 It is a flow chart of a defect detection method for tension clamps provided in Embodiment 2 of the present invention. The method can be executed by a defect detection device for tension clamps, and the device can be implemented by software and / or hardware. The device can be integrated in an electronic device such as a computer with a defect detection function of the tension clamp, and the method specifically includes the following steps:

[0054] Step 210, acquiring a plurality of pictures of the strain clamps in the transmission line as training pictures.

[0055] Wherein, the training pictures may be pictures of defects such as bending deformation and cracks in the transmission lines including strain clamps and pictures of no defects in the strain clamps. After obtaining multiple pictures of strain clamps in the transmission line as training pictures, the corresponding strain clamps in the training pictures can also be marked, so as to distinguish the pictu...

Embodiment 3

[0087] Figure 7 It is a structural block diagram of a defect detection device for strain clamps provided in Embodiment 3 of the present invention, the device includes a picture acquisition module 310, a model building module 320, an area determination module 330 and a defect detection module 340; wherein, the picture acquisition module 310 is used to obtain the pictures of the strain clamps in multiple transmission lines as the training pictures; the model building module 320 is used to use multiple training pictures, and establishes the detection model of the strain clamps according to the Faster RCNN algorithm, and according to the convolutional neural network Establish a classifier model based on a convolutional neural network; the area determination module 330 is used to determine the target feature area in the picture to be detected based on the Faster RCNN algorithm and the detection model of the tension clamp, obtain the coordinate information of the target feature area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com