Indoor inspection robot system for substation and inspection method for indoor inspection robot system

An inspection robot and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of equipment collision, less online monitoring and sampling signals of inspection robots, and high cost, so as to prevent accidental collisions or falls, and patrol inspections The effect of good data consistency and accurate and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

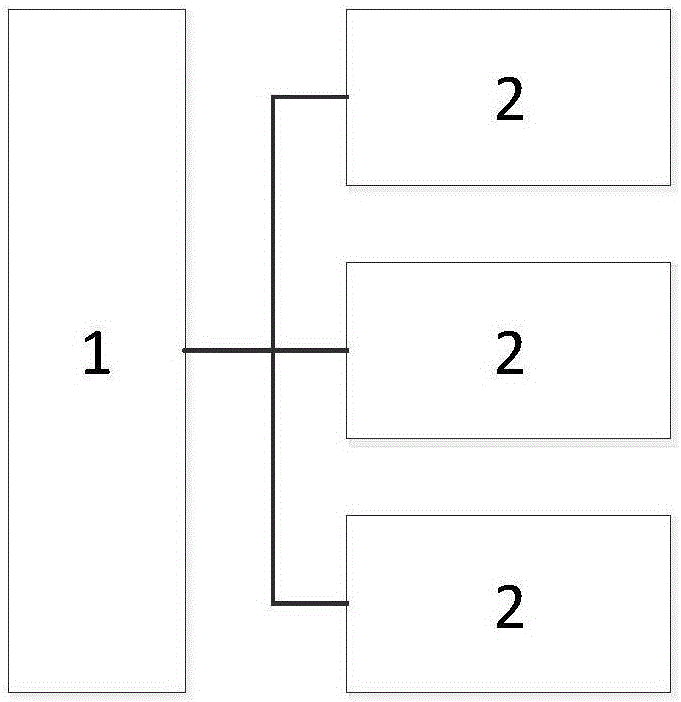

[0049] Such as figure 1 As shown, a substation indoor inspection robot system includes a remote control center 1 and a rail robot terminal system 2 .

[0050] The remote control control center 1 is connected to at least one rail robot terminal system 2 through a network;

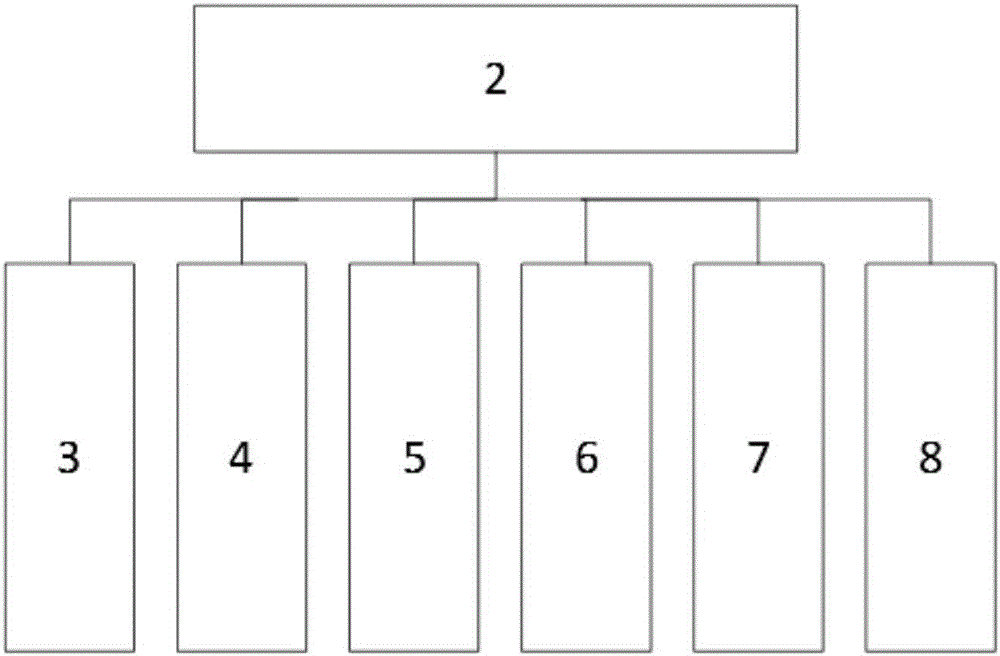

[0051] Such as figure 2 As shown, the rail robot terminal system 2 includes a robot motion module 3 , a control module 4 , a communication module 5 , a power supply module 6 , a detection module 7 and a safety protection module 8 .

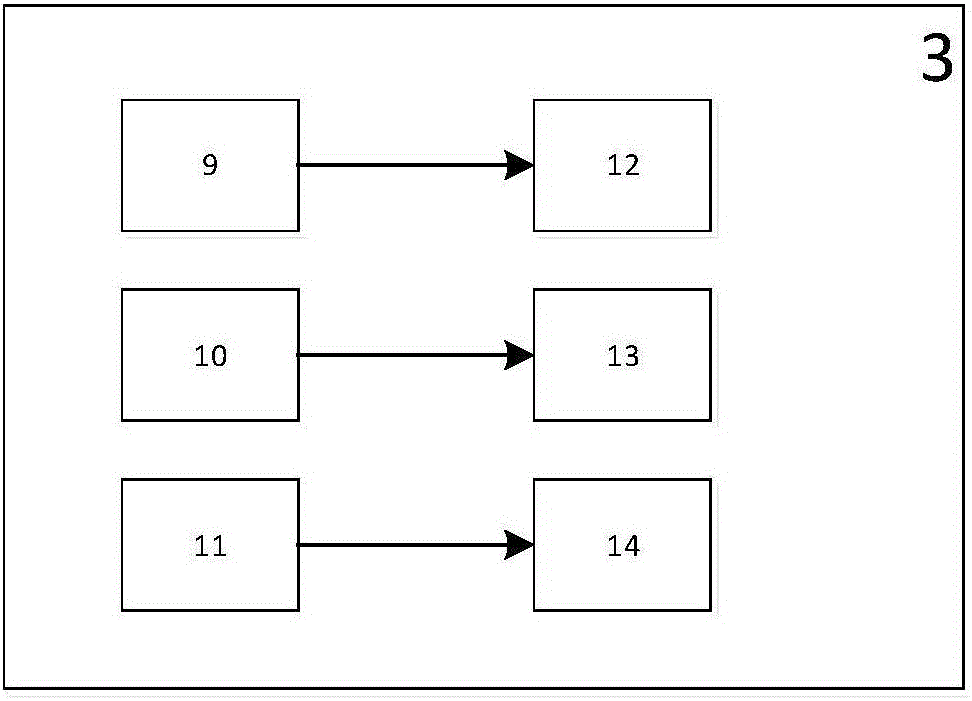

[0052] Such as image 3 and Figure 4 As shown, the motion module 3 includes an X-axis motor 9, a Y-axis motor 10, a Z-axis motor 11, an X-axis motion mechanism 12, a Y-axis motion mechanism 13, and a Z-axis motion mechanism. The three motors are respectively installed in three motion In terms of mechanism, the motor 9 on the X-axis motion mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com