New energy lithium battery surface defect detection method based on adaptive deep learning

A technology of deep learning and defect detection, applied in the fields of computer vision and deep learning, can solve problems such as inability to achieve optimal performance, inability to call light sources, and complex system parameters, so as to improve labeling efficiency and accuracy, improve defect detection efficiency, The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

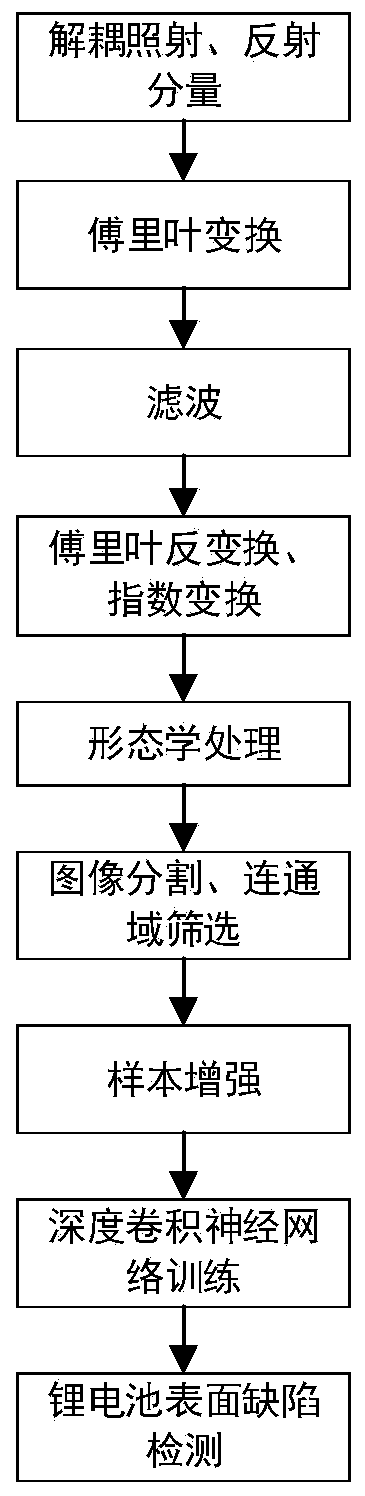

[0064] The new energy lithium battery surface defect detection method based on adaptive deep learning includes:

[0065] Step 1: Collect the grayscale image of the lithium battery surface, use a nonlinear operator to perform nonlinear mapping on the grayscale image of the lithium battery surface, and decouple the irradiation component and the reflection component:

[0066] ln(G(x,y)+1)=ln(I(x,y)+1)+ln(R(x,y)+1)

[0067] Among them, G is the grayscale image of the lithium battery surface, I is the irradiation component, R is the reflection component, and (x, y) are the pixel coordinates.

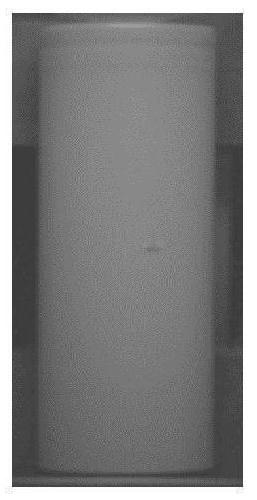

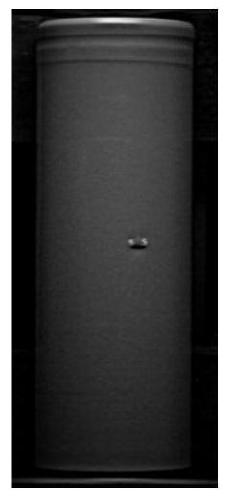

[0068] The grayscale image G of the lithium battery surface is acquired by an ordinary area scan camera. In the image acquisition, since the lithium battery is cylindrical, it is necessary to take images of the four directions of the lithium battery.

[0069] Fix the camera, drive the battery to rotate through the servo motor and the tray, and rotate 90 degrees each time, and obtain four im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com