Patents

Literature

51 results about "Digital Ray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Condensed mesenchymal tissue on the embryonic hand and footplates that is the future site of the formation of the digits, which appear approximately during the sixth week of development in the hand plates and approximately during the seventh week for the footplates.

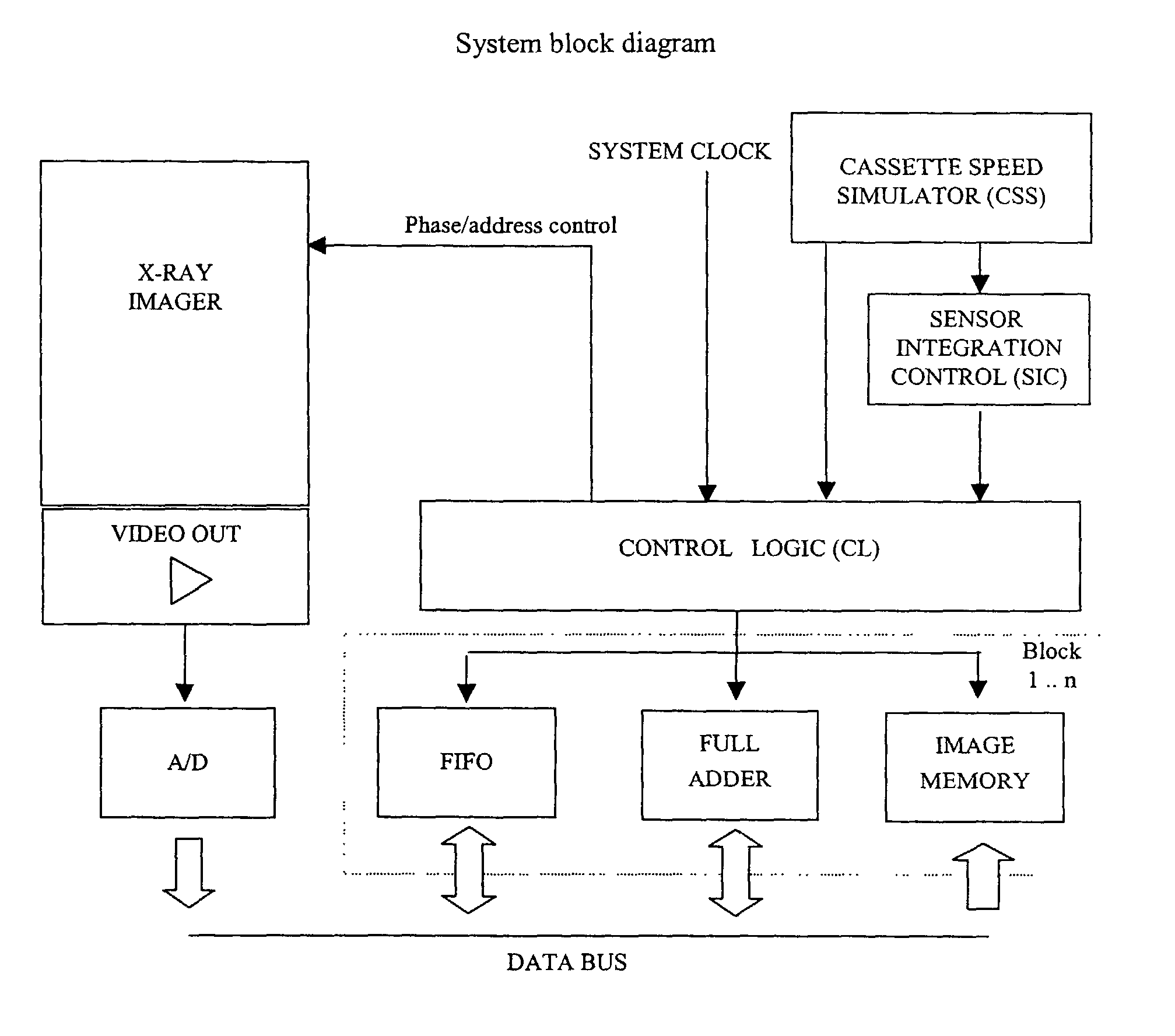

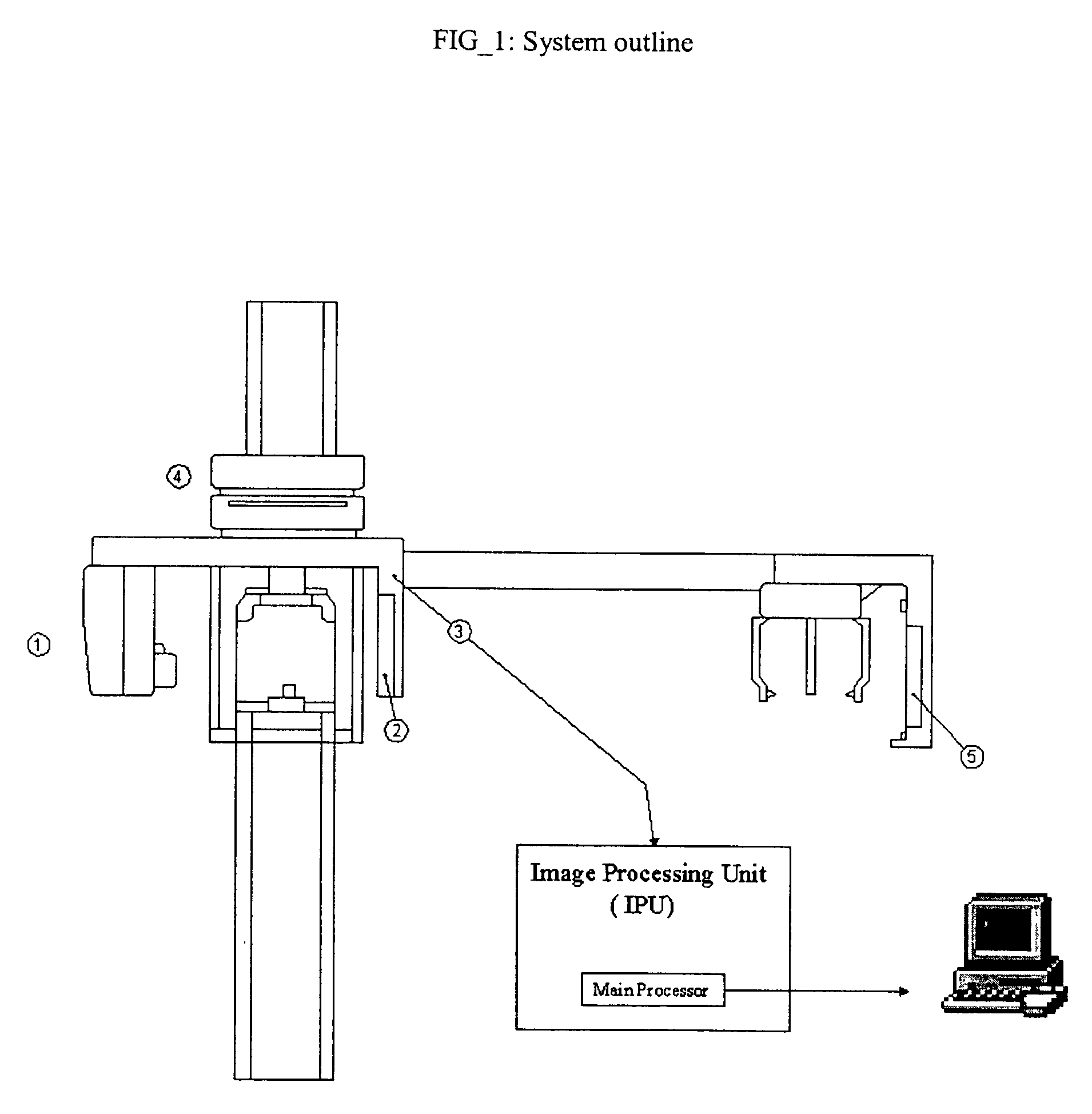

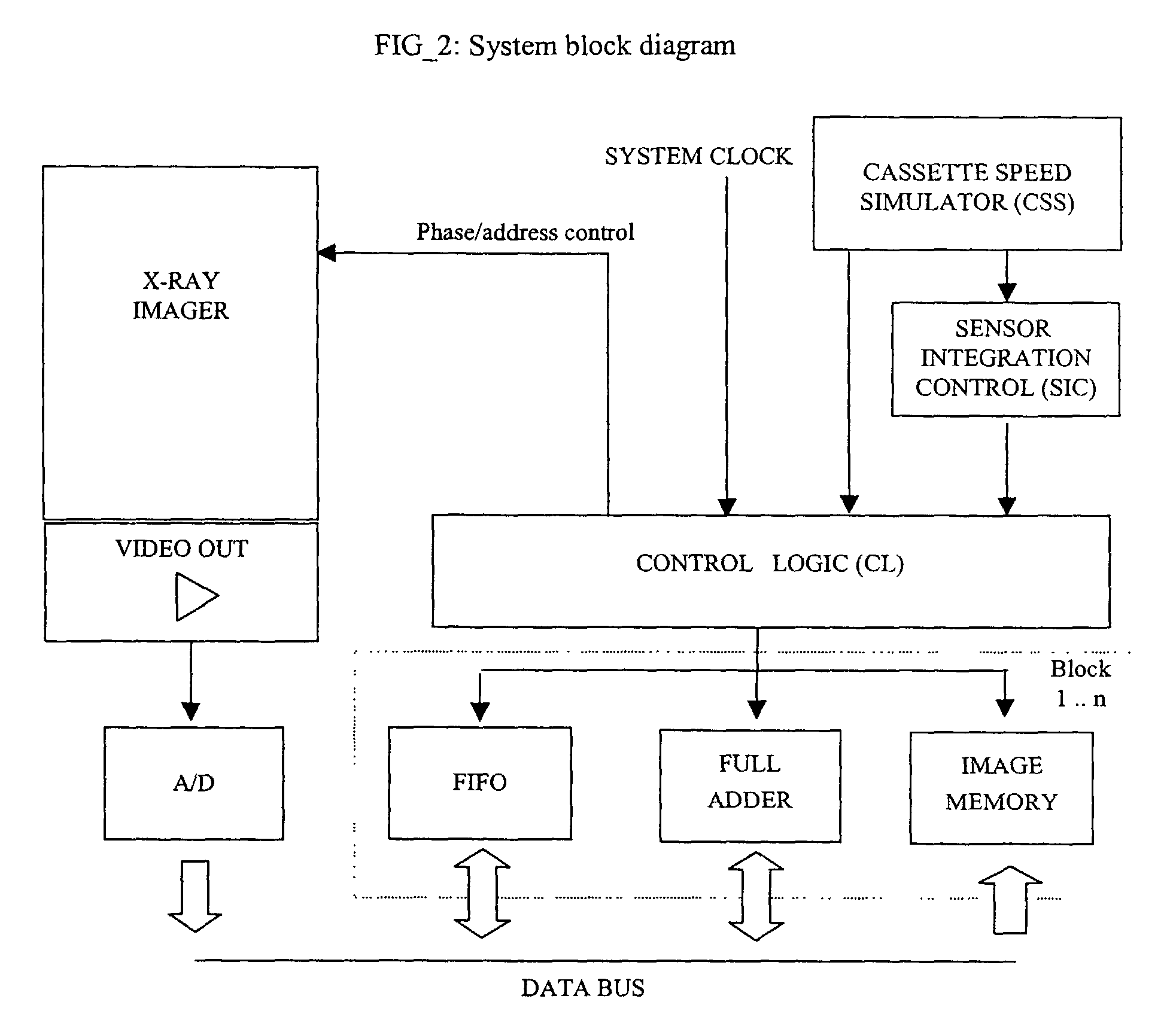

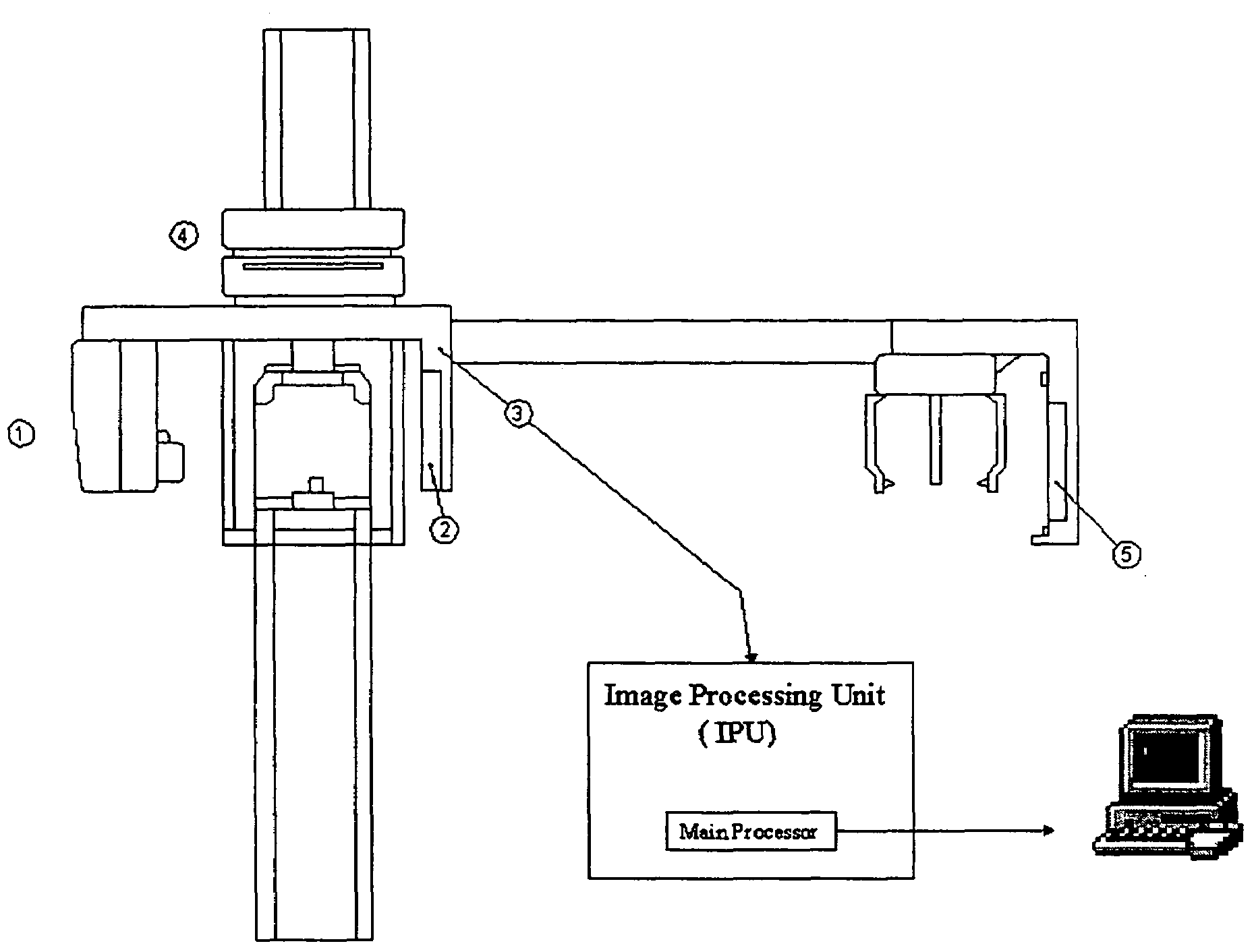

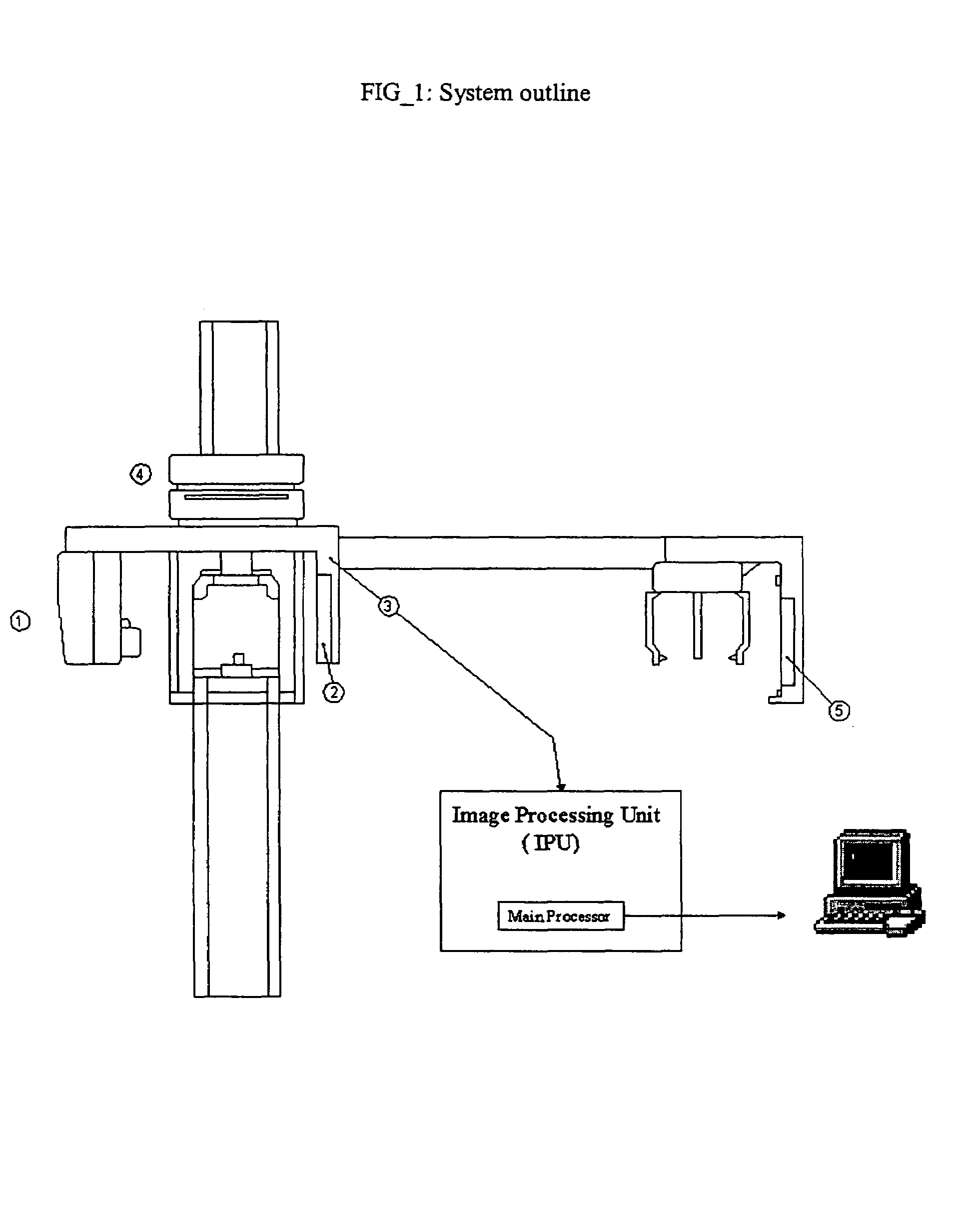

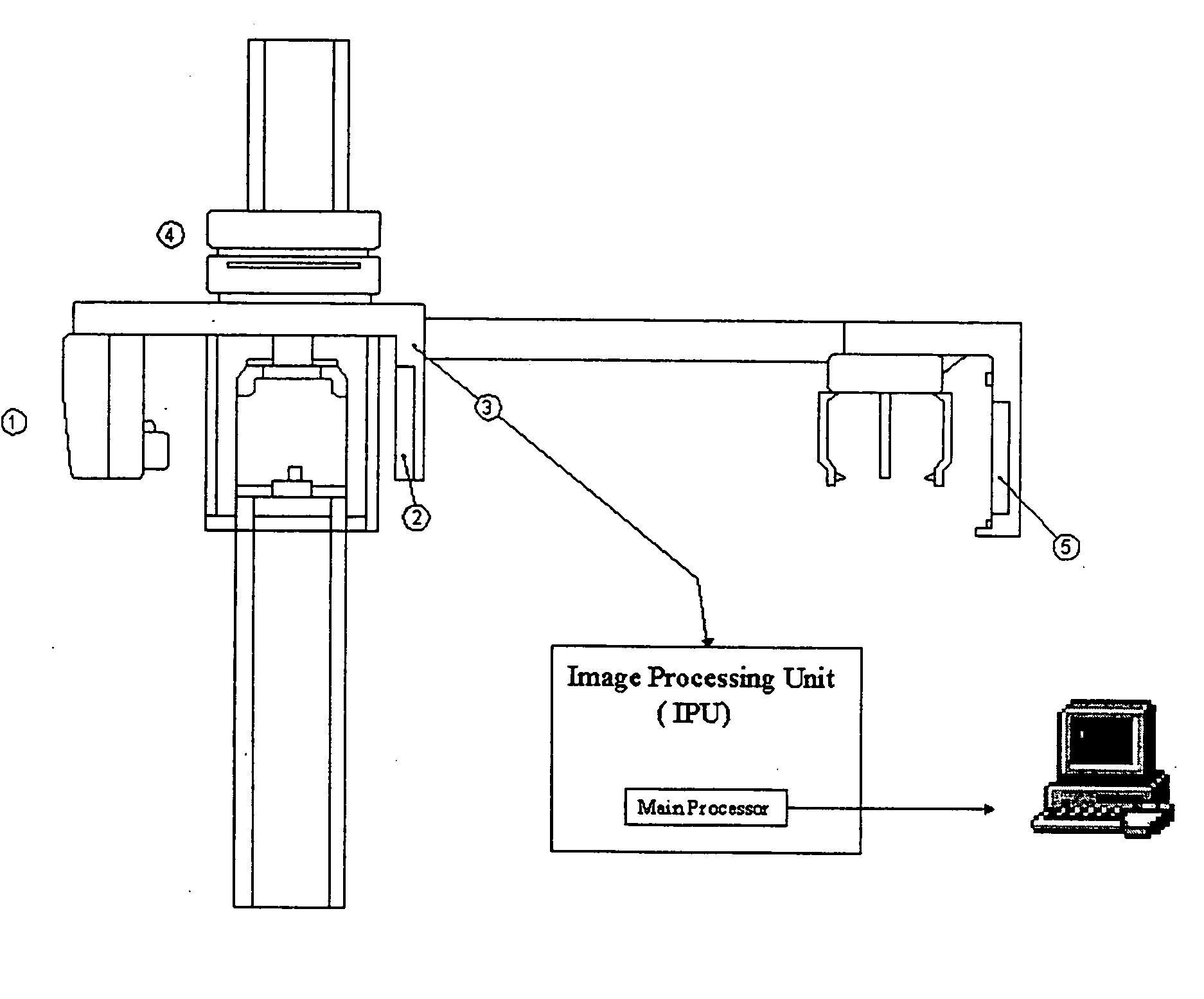

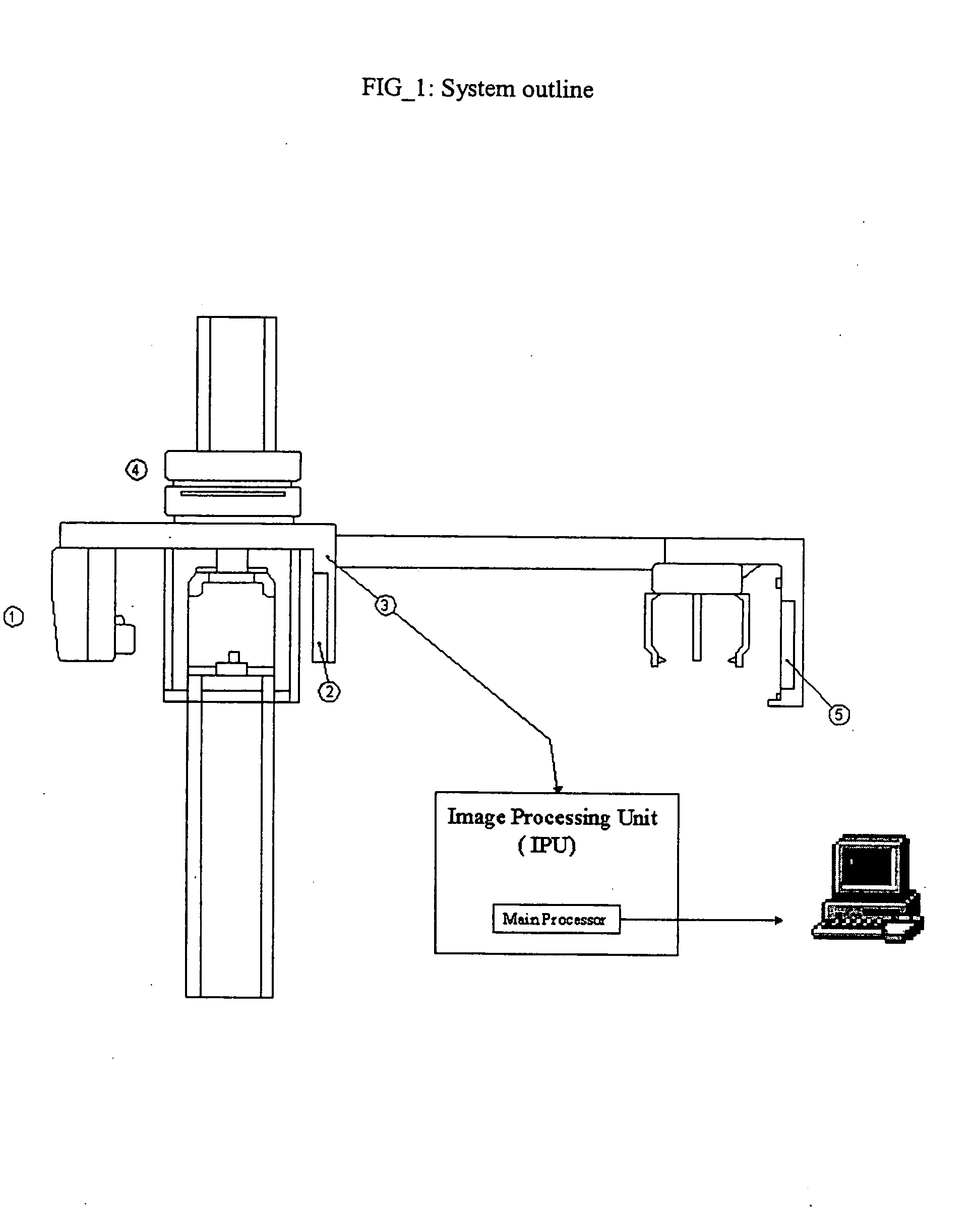

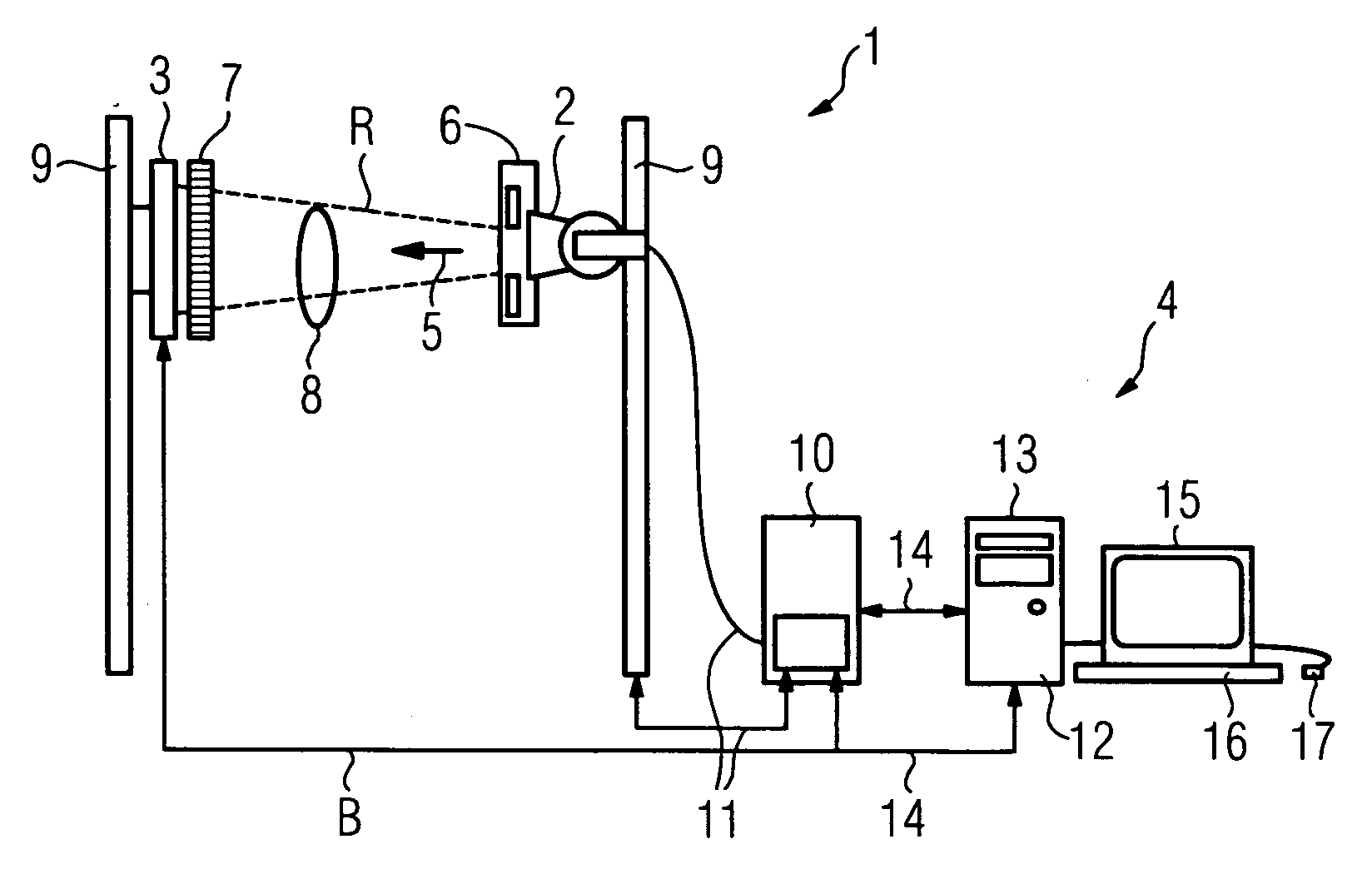

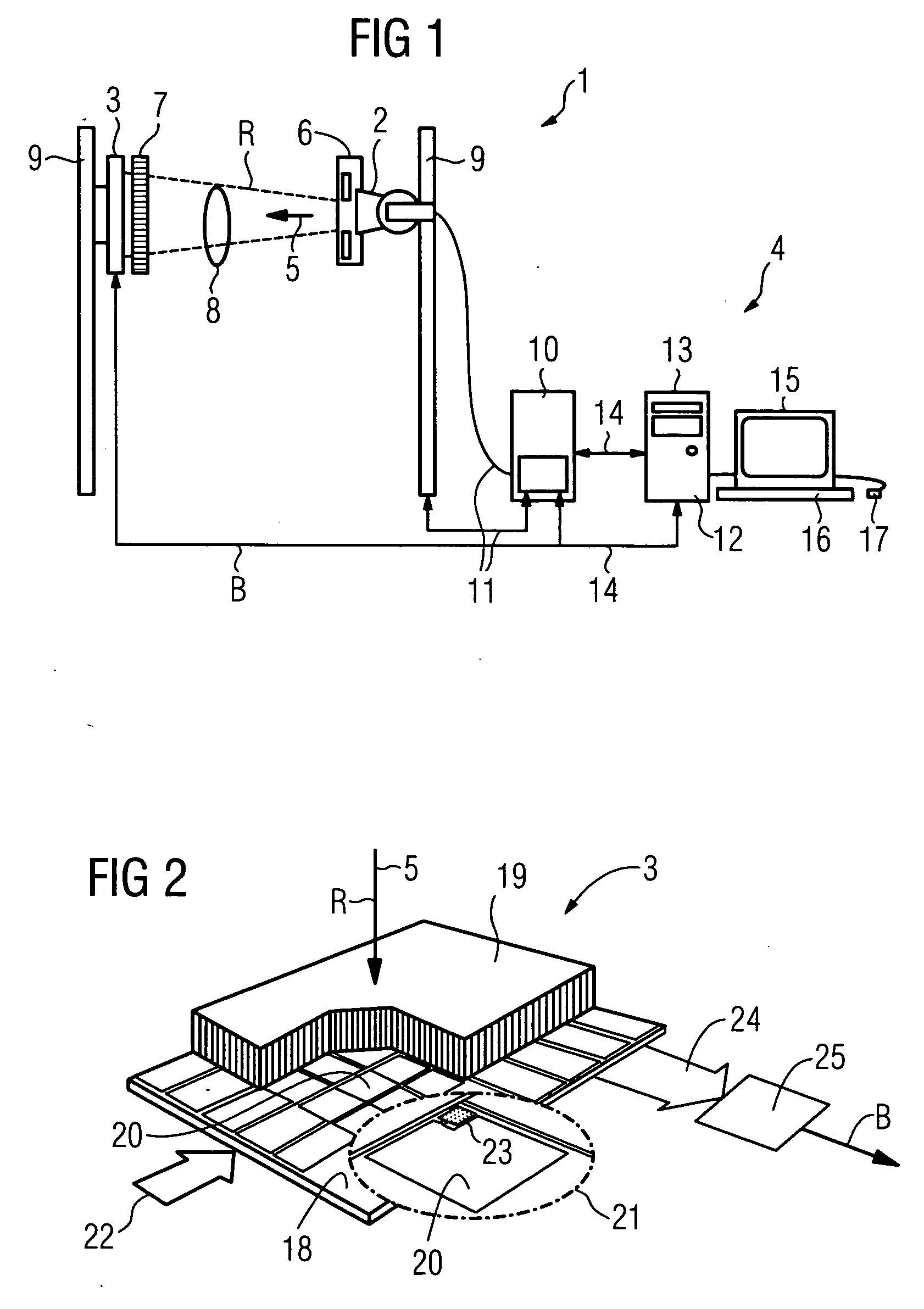

Real-time digital x-ray imaging apparatus

InactiveUS7016461B2Easy to optimizeReduce exposureTomosynthesisRadiation measurementAcquisition rateElectron

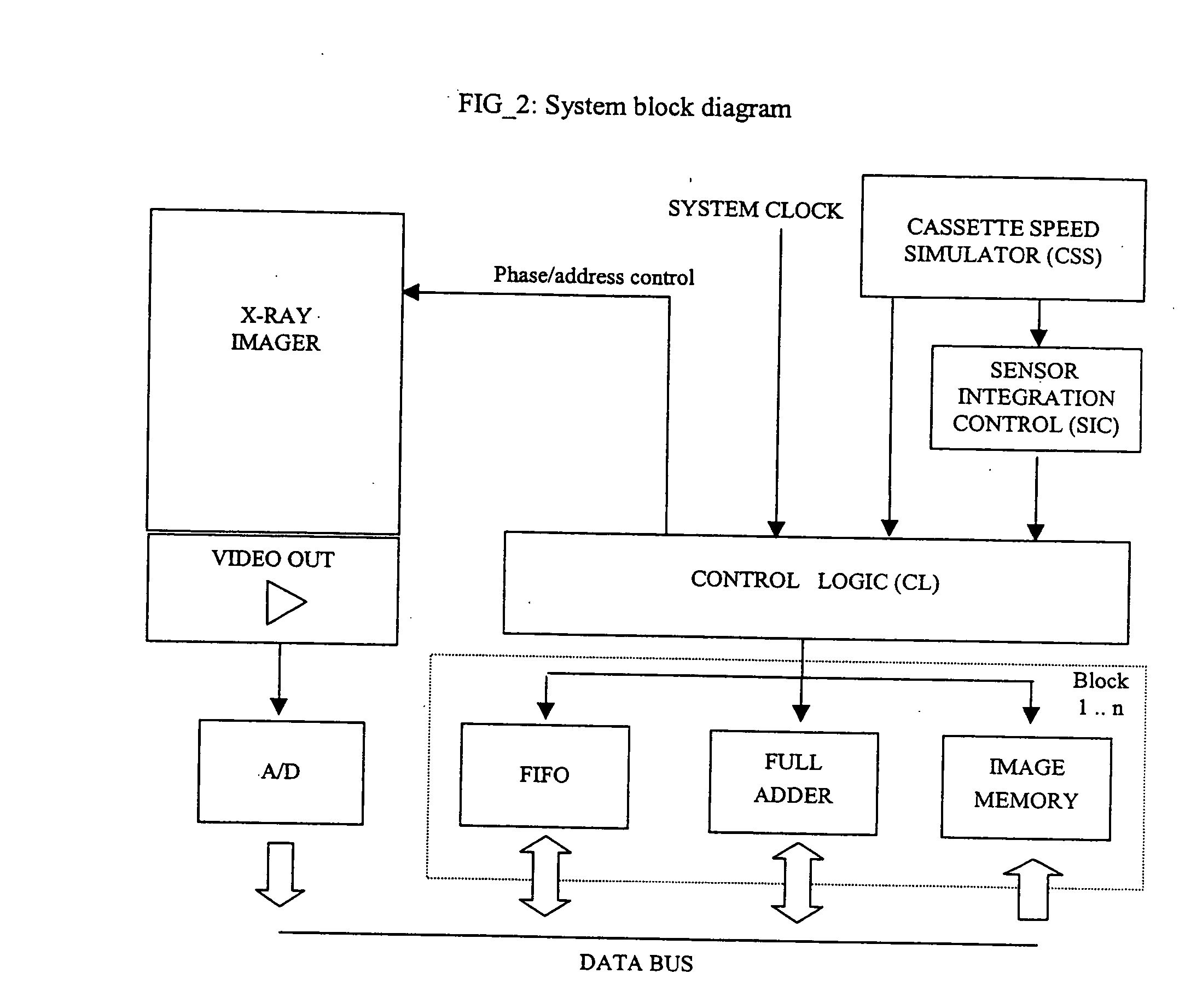

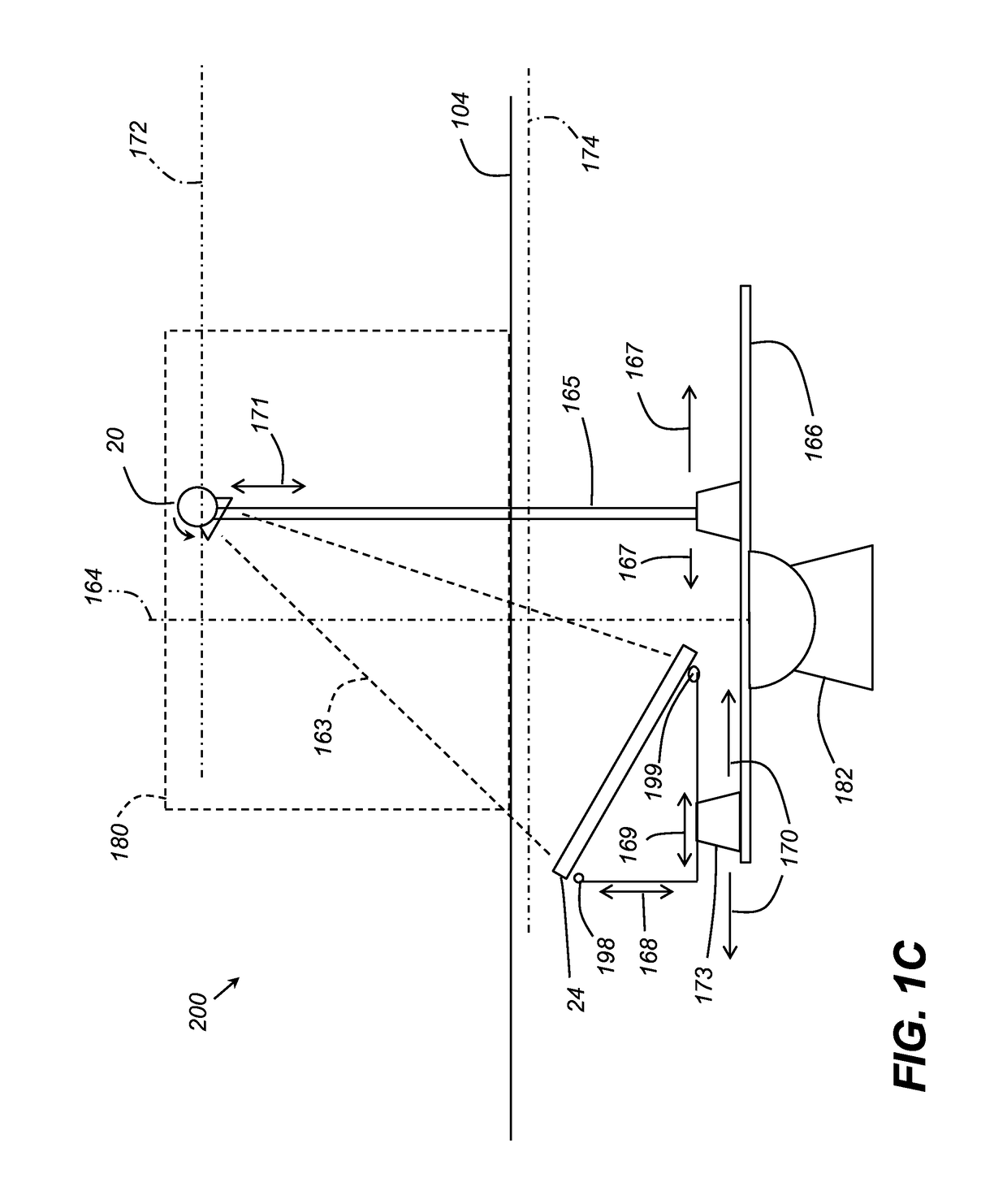

An x-ray diagnostic apparatus and methods performs Real-Time Digital Radiography with particular application in dental x-ray imaging modalities, such as Orthopantomography, Scannography, Linear Tomography and Cephalography, by using a versatile and modular electronic unit, featuring ultra fast computation capability to serve diversified image sensor typology and scanning modality.In Digital Orthopantomography and Scannography, a plurality of tomographic images at different depths of the jaw can be generated, based on the pre-selection made by the user interface.The image processing unit utilizes for the tomo-synthesis of the diagnostic image an accurate and economic digital simulator of the radiographic film speed, including a digital frequency synthesizer fed with film cassette speed digital input and high resolution clock signal, ensuring accurate and reproducible phase continuity of the output frequency signal.It also introduces an automatic adaptation of the frame acquisition rate in frame transfer mode, based on the actual speed of the cassette unit. By this method the dynamic of the exposure signal is reduced, and a better optimization of the signal response of the x-ray detector is achieved.

Owner:GENDEX

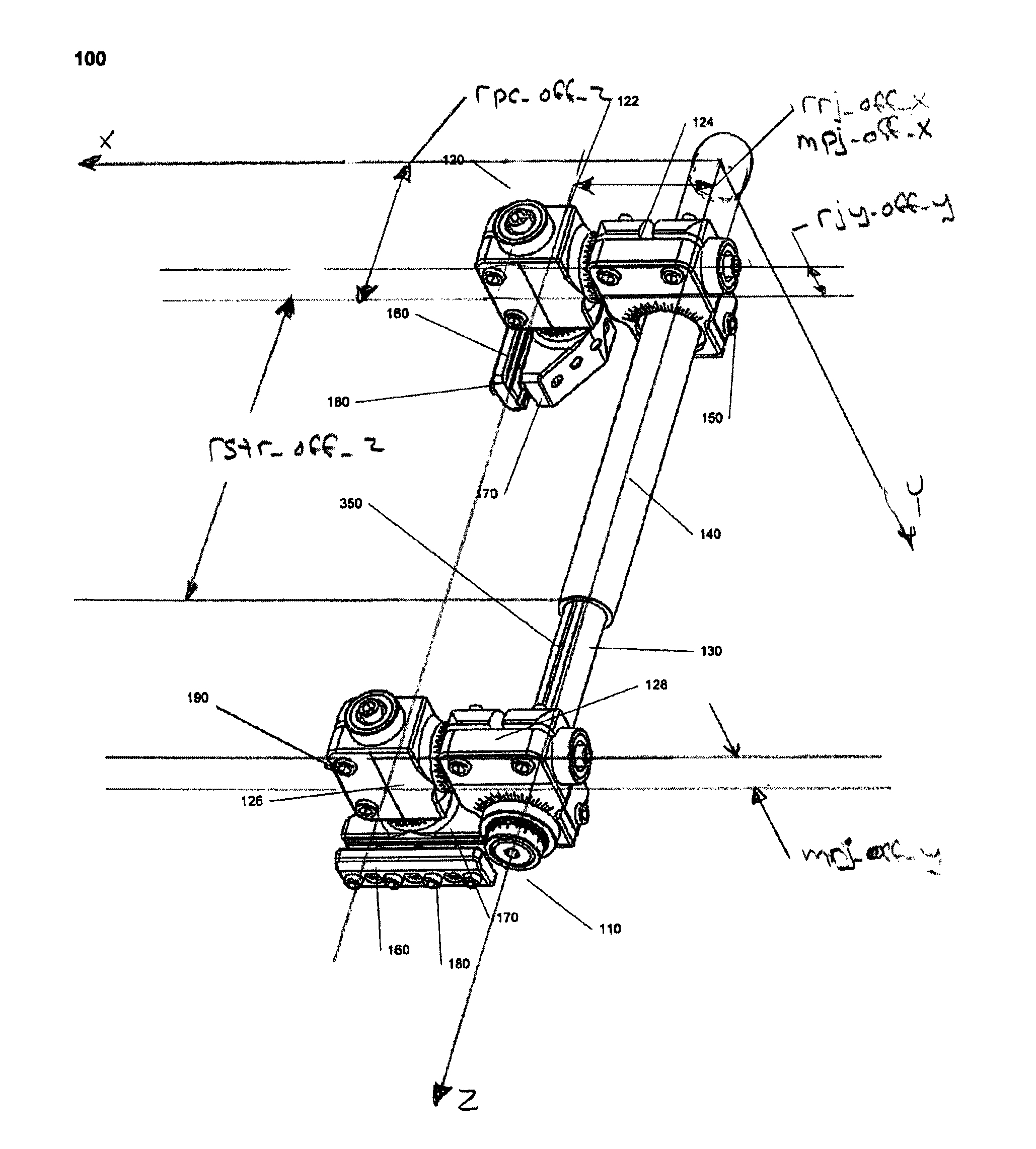

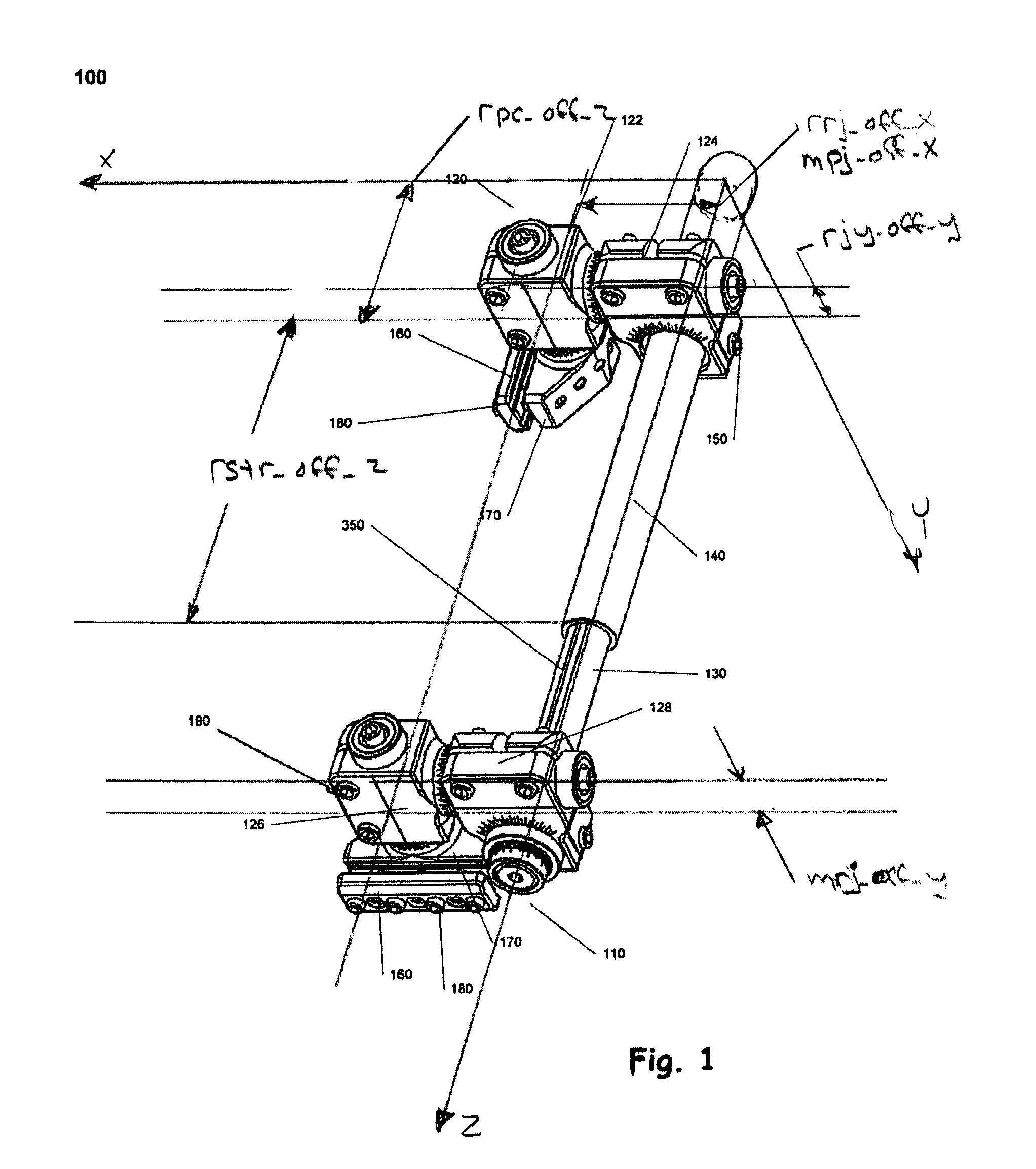

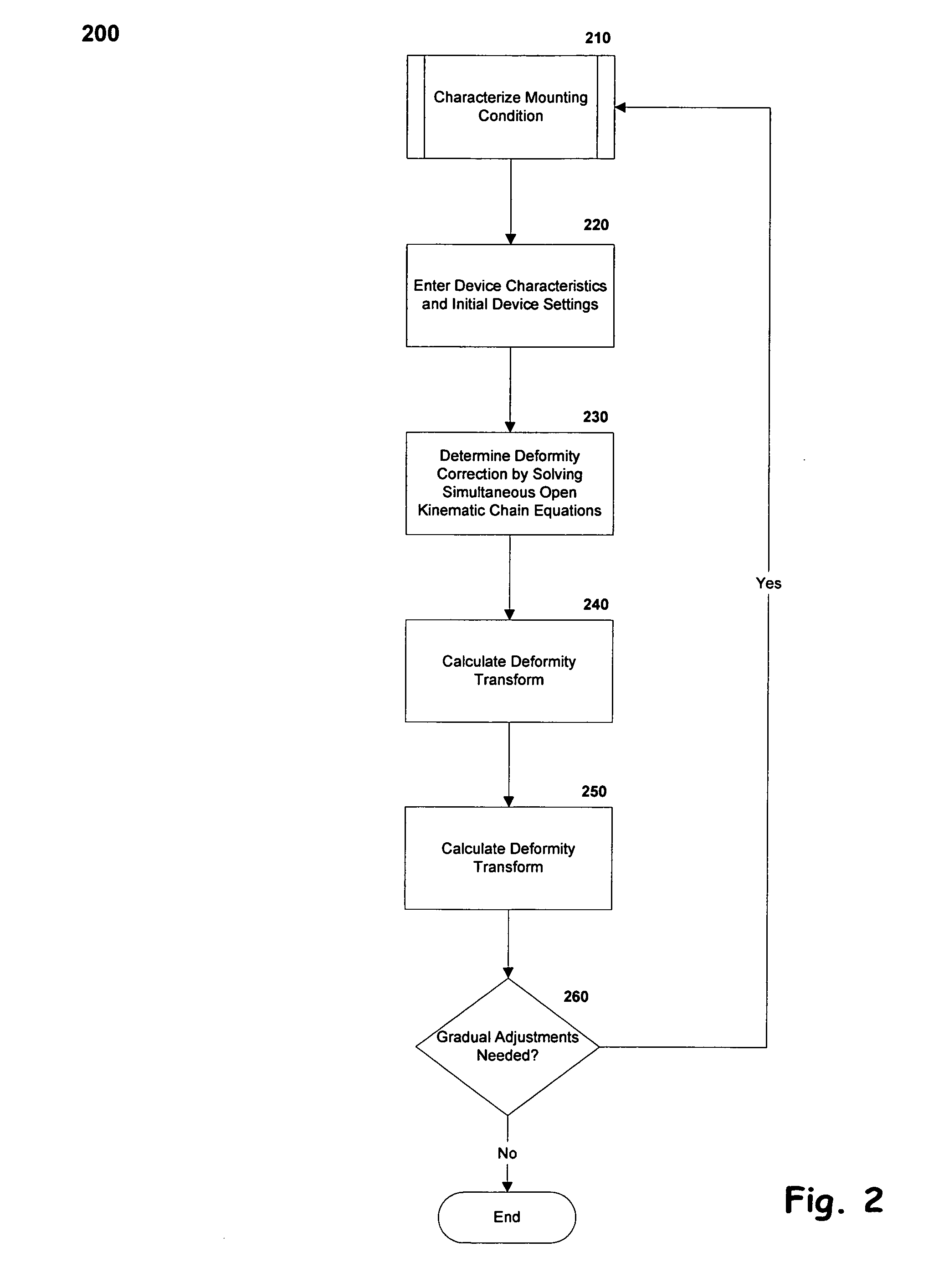

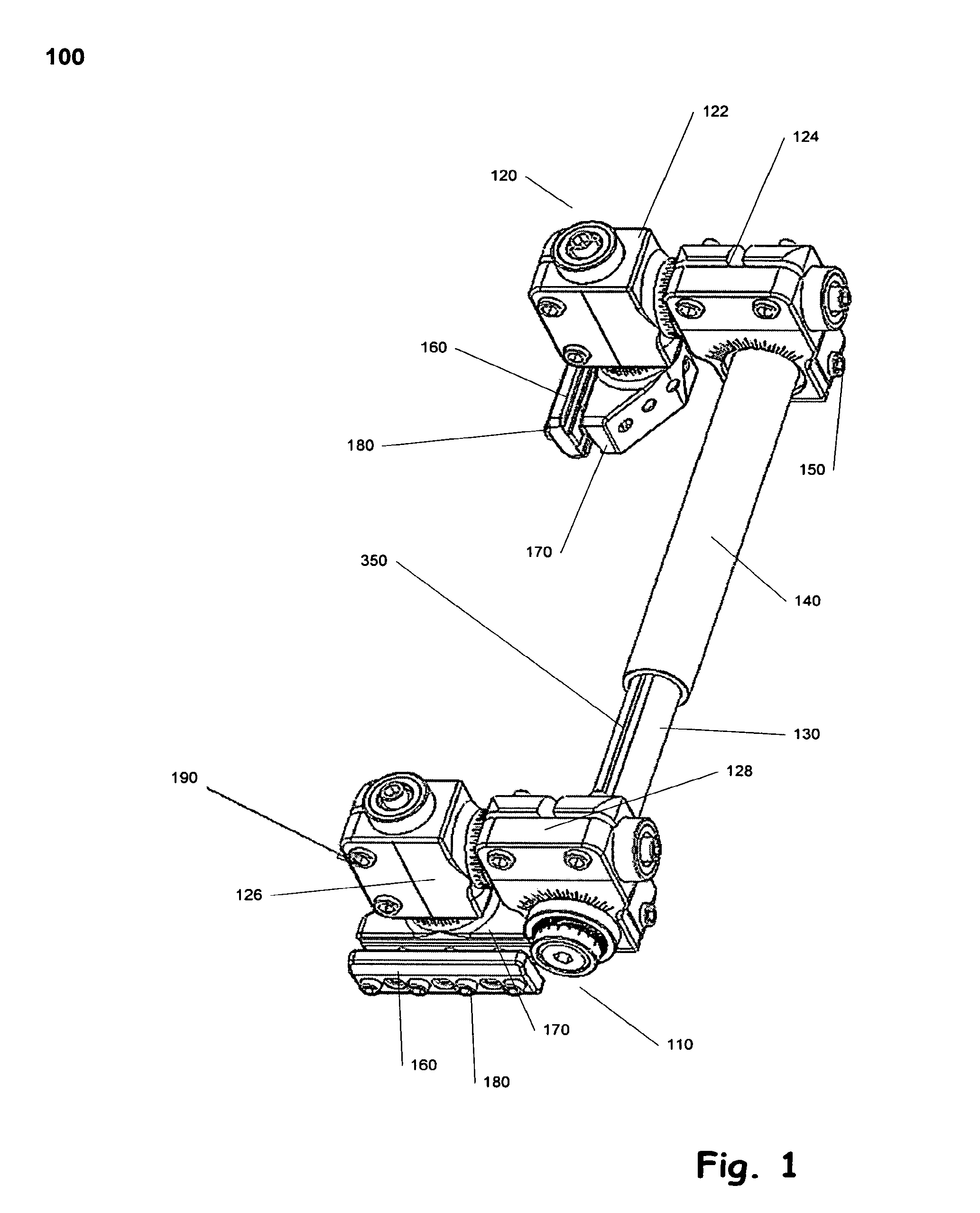

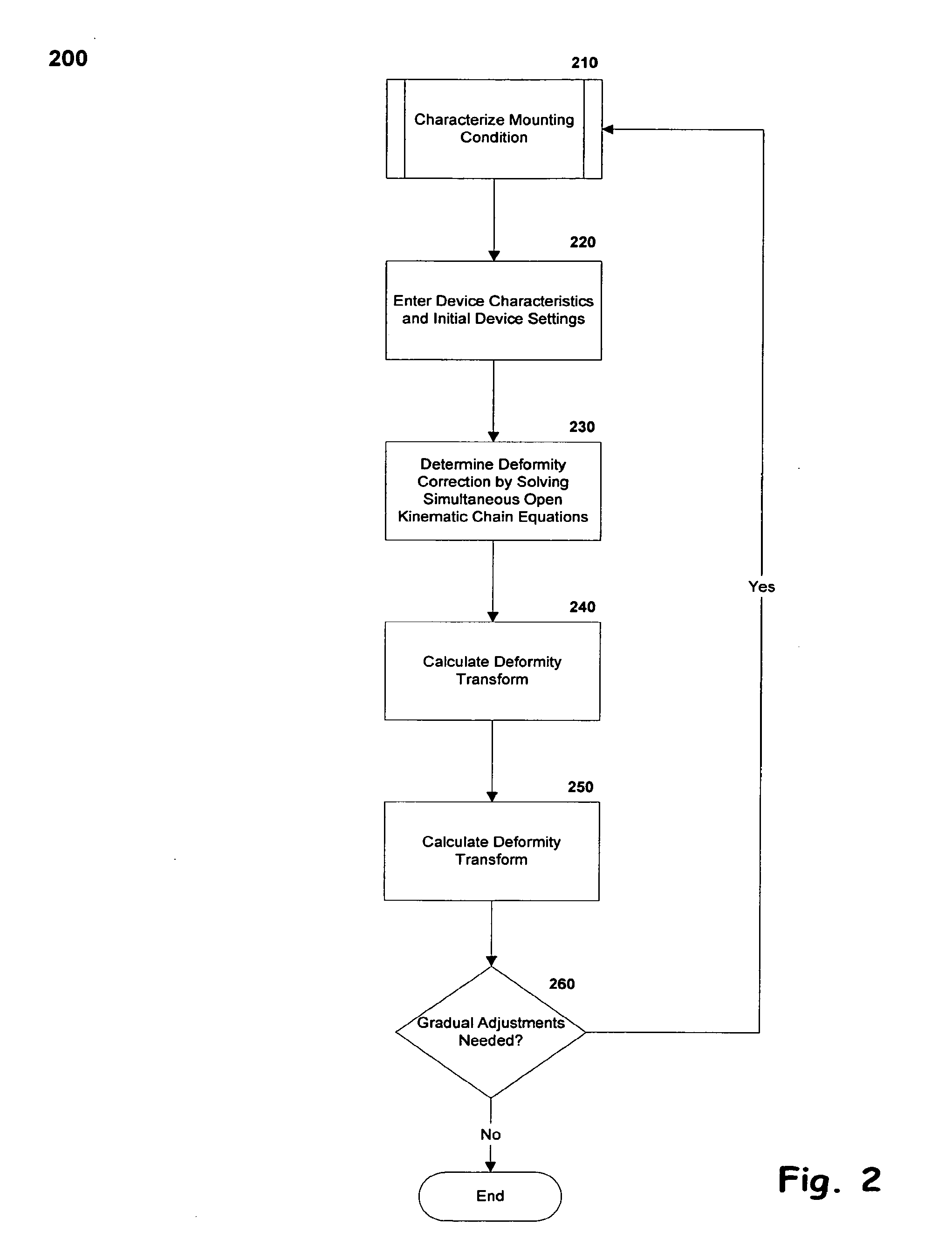

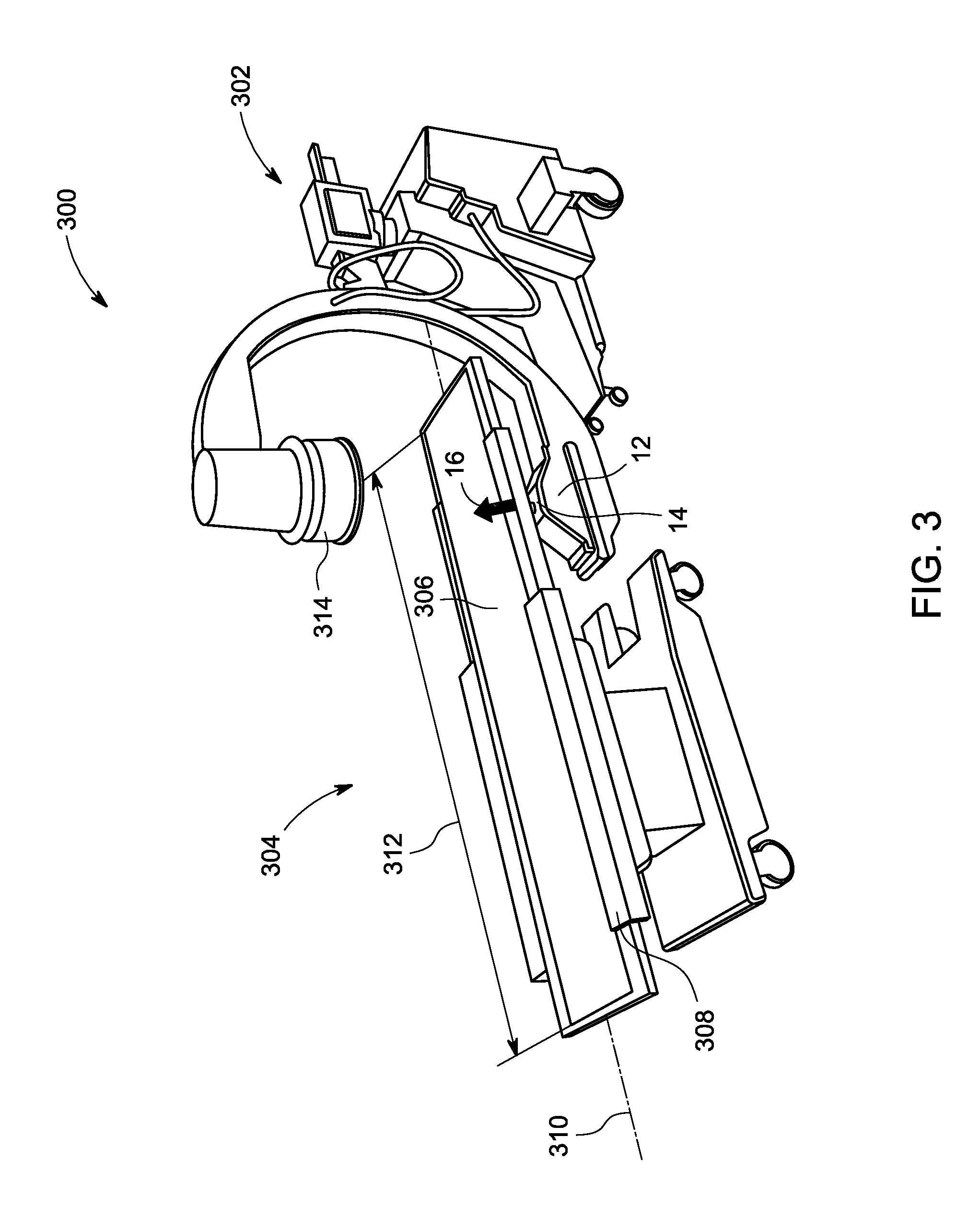

Method for using a fixator device

ActiveUS8419732B2Reduce eliminateDiagnosticsComputer-aided planning/modellingMedicineSimultaneous equations

A method for determining the proper configuration of a fixator or other medical device to correct a given deformity by solving the simultaneous equations representing the kinematic chain for the device. One skilled in the art would appreciate that x-rays, clinical evaluations, or a combination of both may be used to determine the distal and proximal mounting characteristics, including the use of digital x-rays with images from an imaging device to reduce or eliminate the needs for a physician to take measurements. The technique can be expanded to other medical evaluations. Additionally, one skilled in the art would appreciate that the method of the present invention could be written as one or more sets of instructions stored on a computer-readable medium that could be executed by a computer.

Owner:AMDT HLDG INC

Method for using a fixator device

InactiveUS20110103676A1Reduce eliminateCorrection of deformitiesDiagnosticsCharacter and pattern recognitionMedicineSimultaneous equations

A method for determining the proper configuration of a fixator or other medical device to correct a given deformity by solving the simultaneous equations representing the kinematic chain for the device. One skilled in the art would appreciate that x-rays, clinical evaluations, or a combination of both may be used to determine the distal and proximal mounting characteristics, including the use of digital x-rays with images from an imaging device to reduce or eliminate the needs for a physician to take measurements. The technique can be expanded to other medical evaluations. Additionally, one skilled in the art would appreciate that the method of the present invention could be written as one or more sets of instructions stored on a computer-readable medium that could be executed by a computer.

Owner:SIXFIX

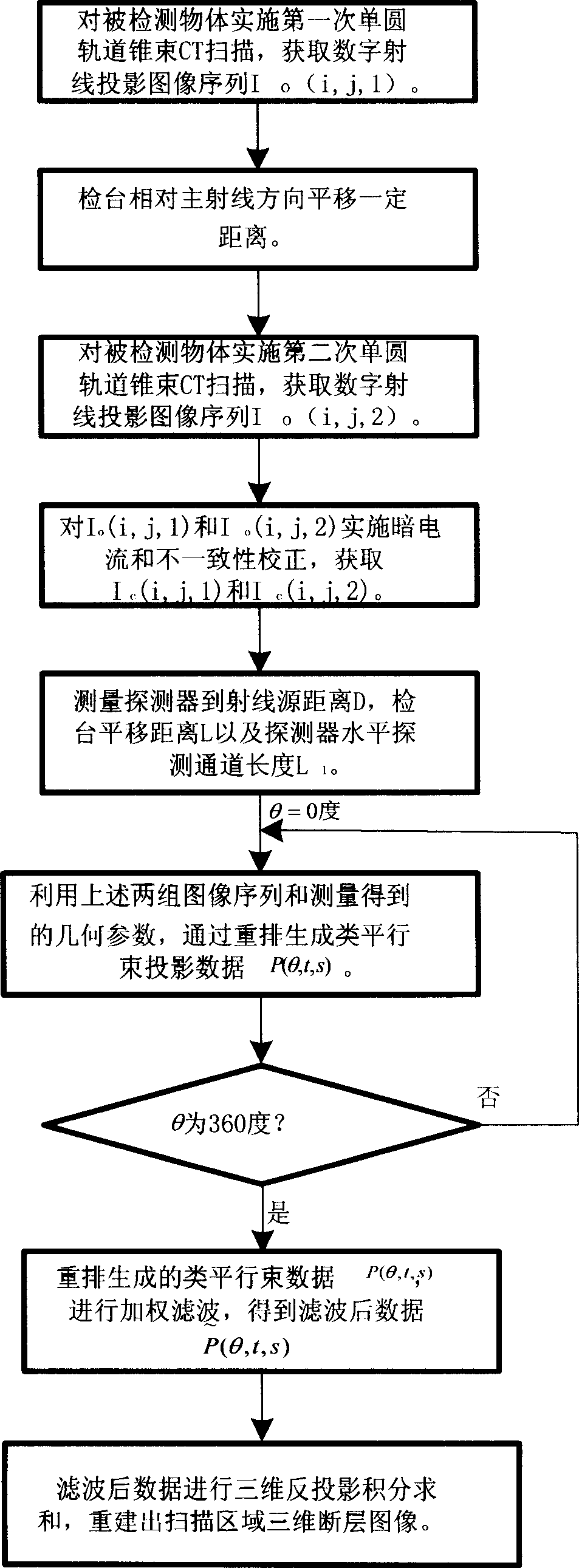

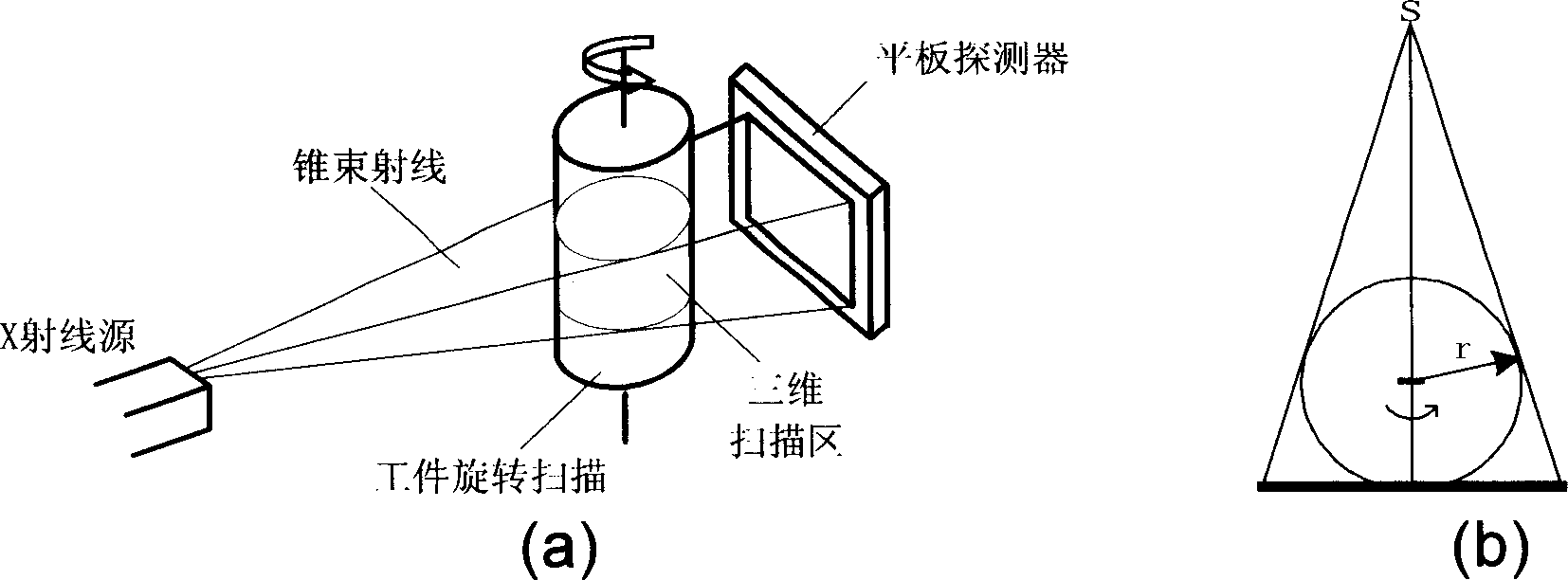

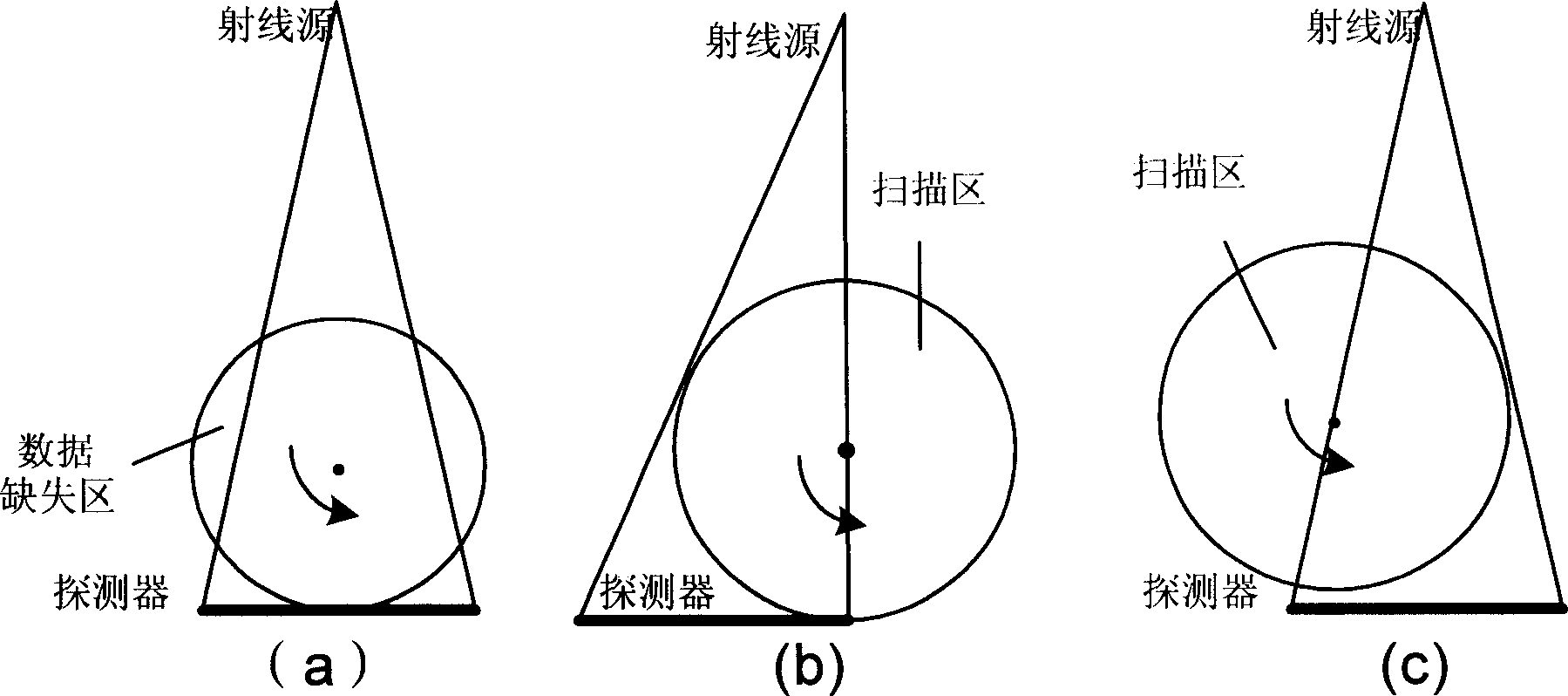

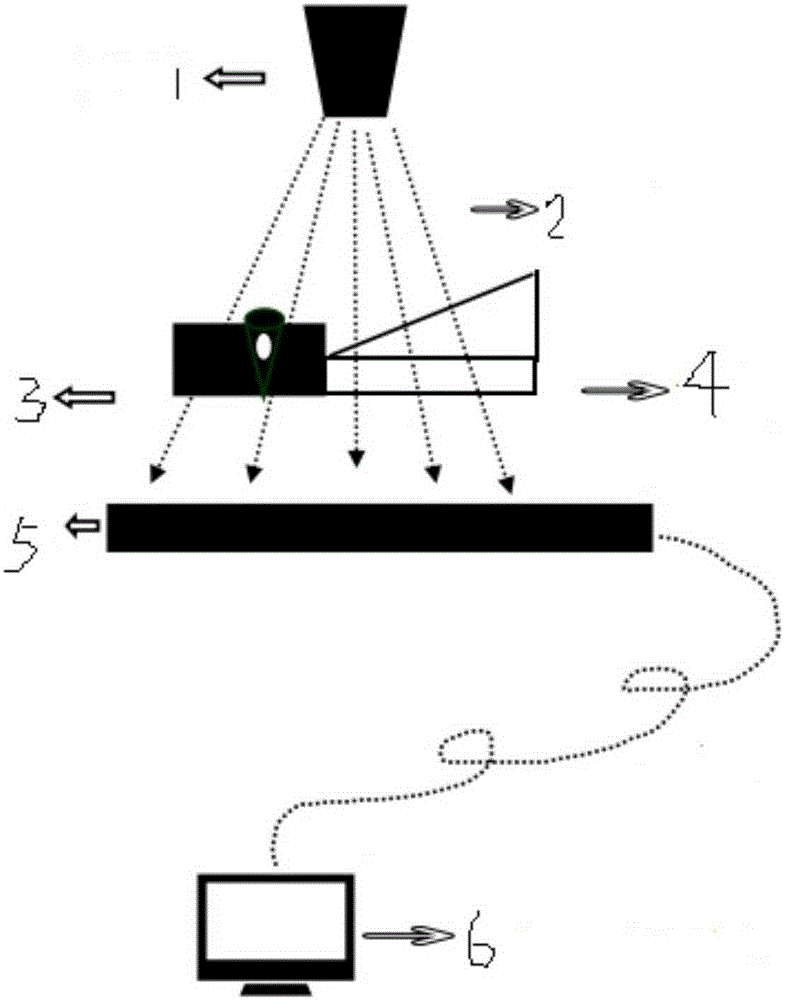

Wide view-field three-D CT imaging method

InactiveCN1865954AScan structure is simpleCompatibleComputerised tomographsTomographyDigital RayVisual field loss

The 3D CT imaging method for large view field comprises: (1) taking first single-circular orbit cone-beam CT scanning to obtain the first digital ray projection image sequence; (2) removing the platform vertical the main ray with some distance to take the second CT scanning and obtain the second image sequence; (3) correcting former two images for dark current and inconsistency; (4) recording distance from ray source to detector, former moved distance and detector level channel number; (5) with the projection rearrangement algorithm in this invention, rearranging former two images into self-contained quasi-parallel image sequence; (6) with the quasi-parallel ray reconstructing algorithm in this invention, reconstructing the 3D CT image. This invention can enlarge the view area more than 3 times with high efficiency.

Owner:BEIHANG UNIV

Real-time digital x-ray imaging apparatus

InactiveUS7319736B2Exact reproductionBetter optimizedTomosynthesisRadiation measurementAcquisition rateElectron

An x-ray diagnostic apparatus and methods performs Real-Time Digital Radiography with particular application in dental x-ray imaging modalities, such as Orthopantomography, Scannography, Linear Tomography and Cephalography, by using a versatile and modular electronic unit, featuring ultra fast computation capability to serve diversified image sensor typology and scanning modality. In Digital Orthopantomography and Scannography, a plurality of tomographic images at different depths of the jaw can be generated, based on the pre-selection made by the user interface. The image processing unit utilizes for the tomo-synthesis of the diagnostic image an accurate and economic digital simulator of the radiographic film speed, including a digital frequency synthesizer fed with film cassette speed digital input and high resolution clock signal, ensuring accurate and reproducible phase continuity of the output frequency signal. It also introduces an automatic adaptation of the frame acquisition rate in frame transfer mode, based on the actual speed of the cassette unit. By this method the dynamic of the exposure signal is reduced, and a better optimization of the signal response of the x-ray detector is achieved.

Owner:GENDEX

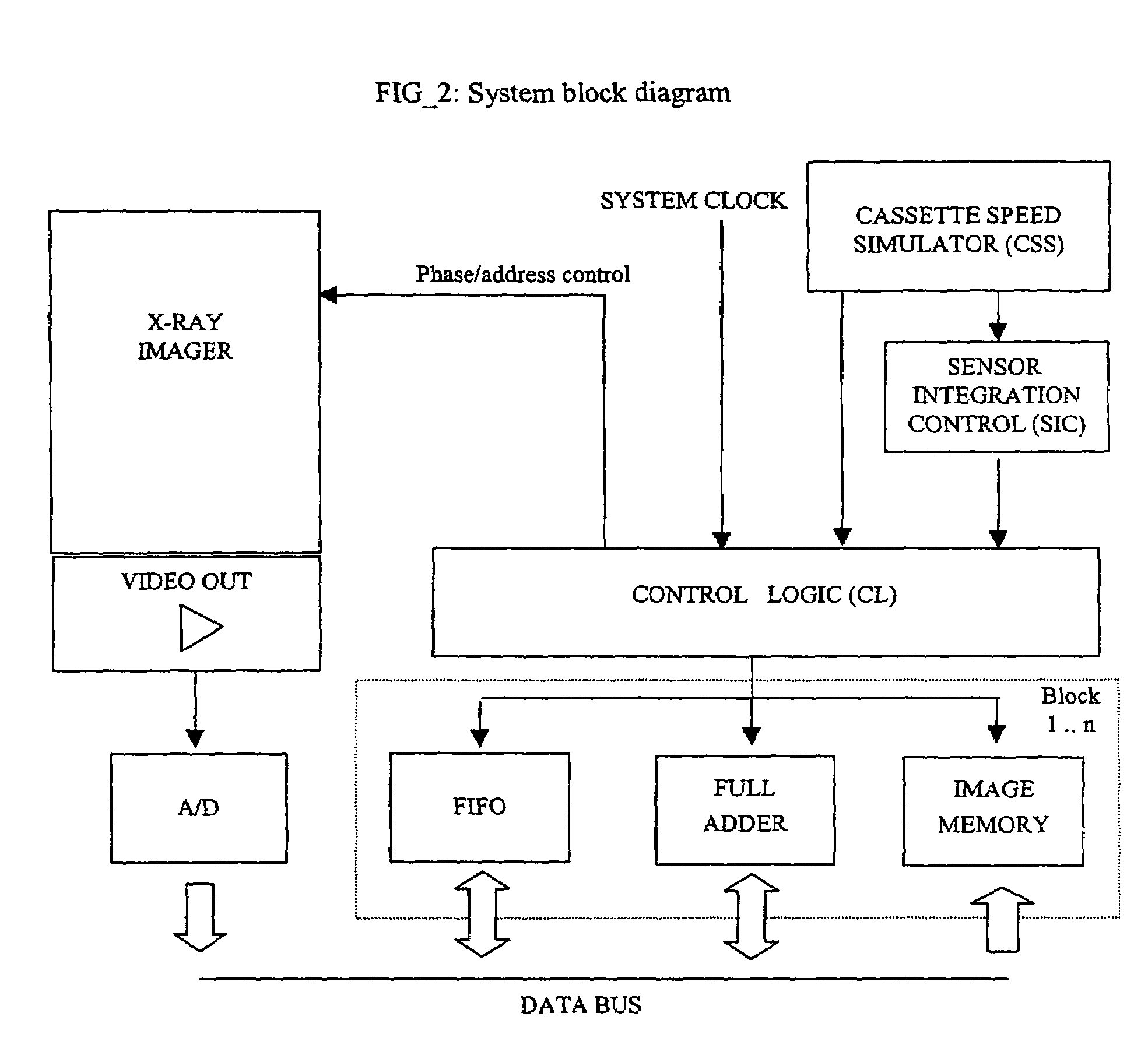

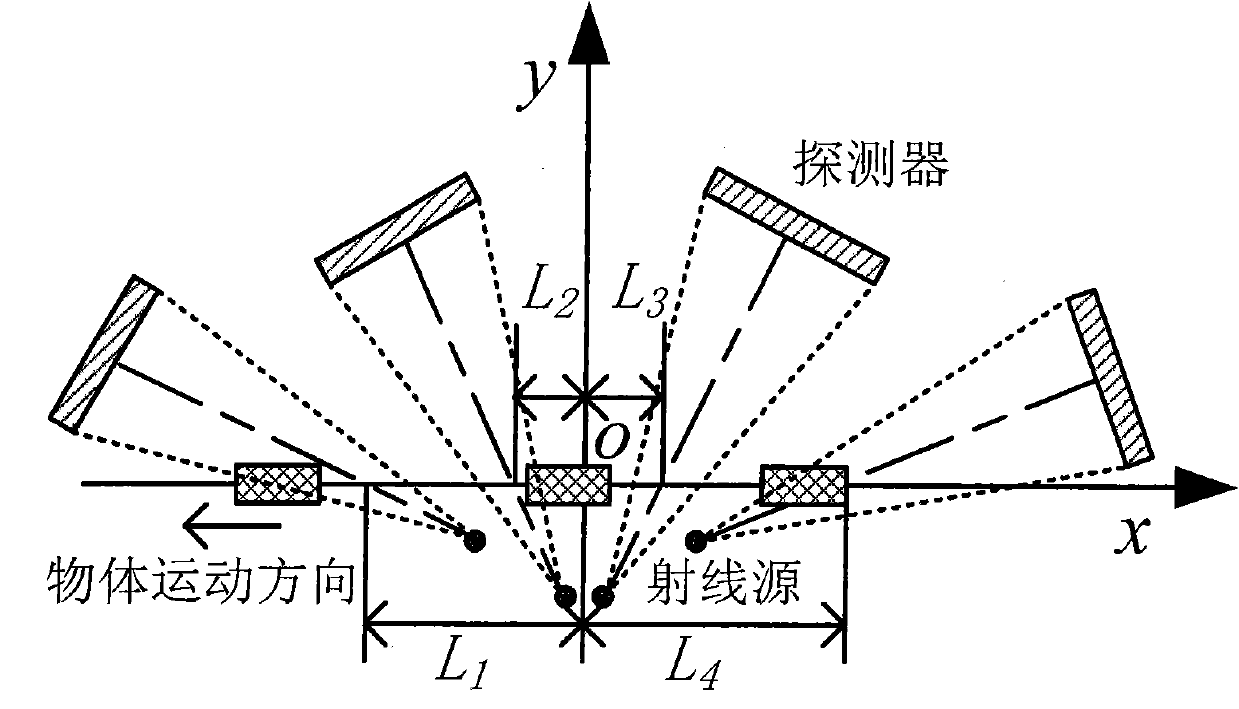

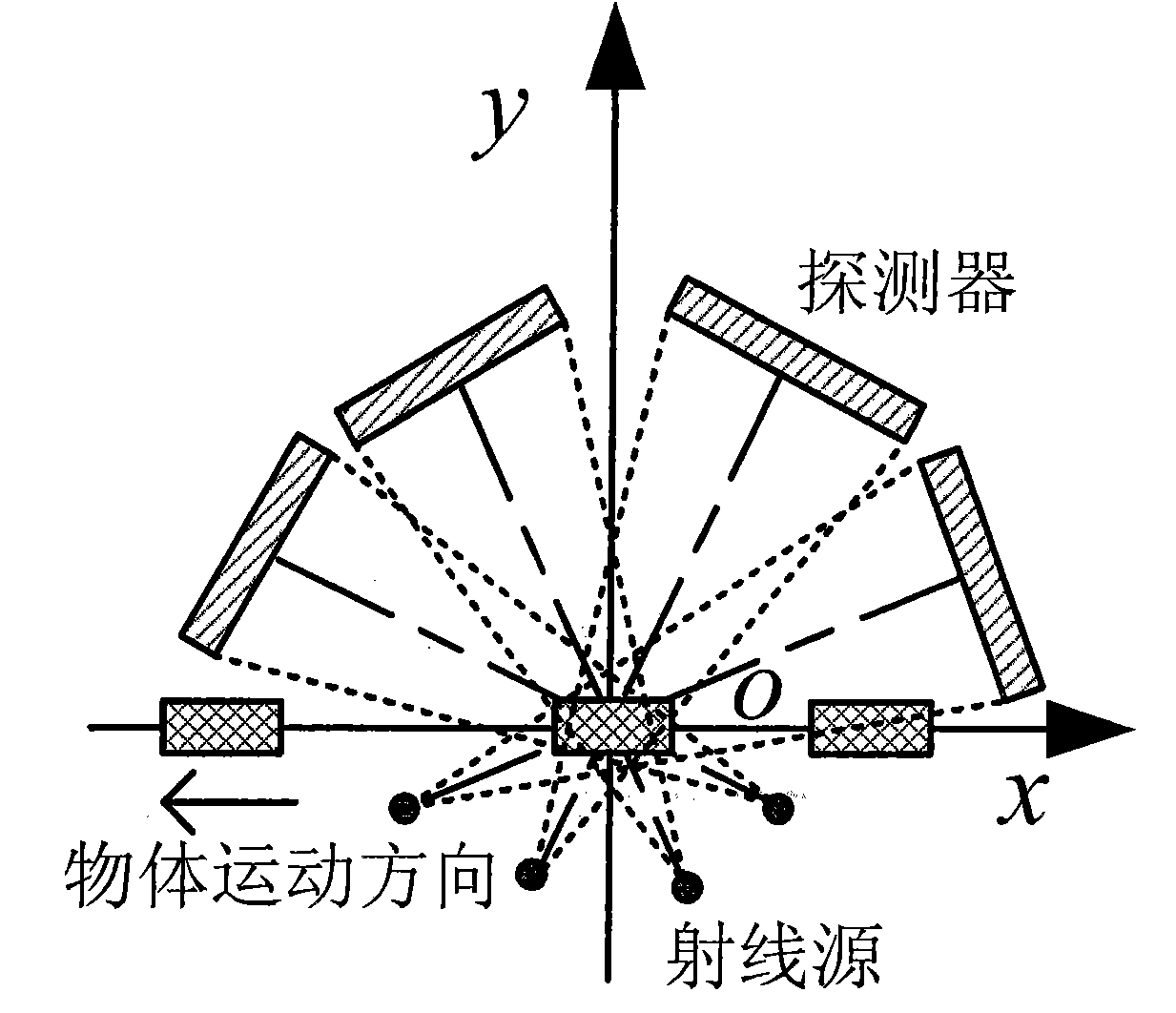

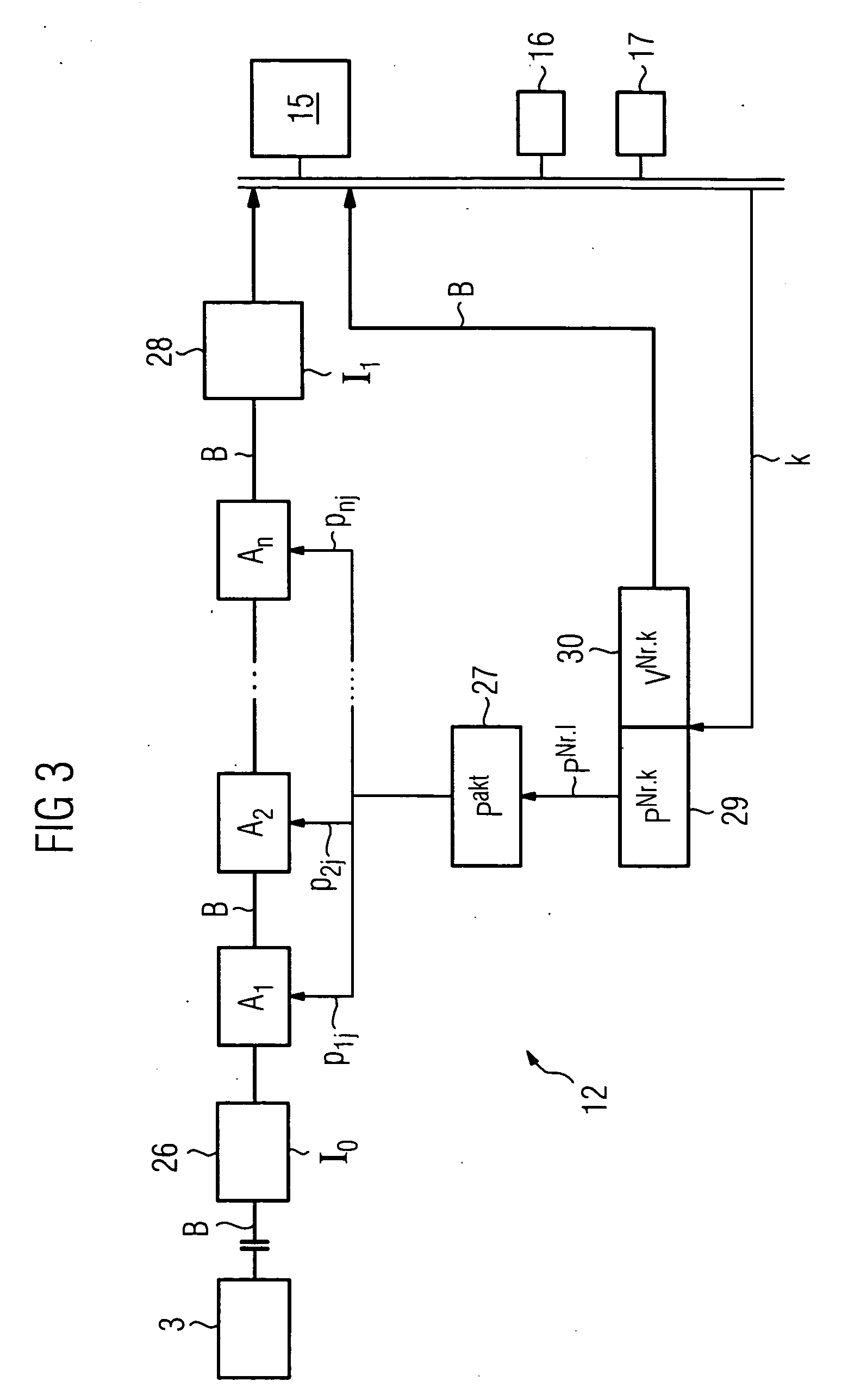

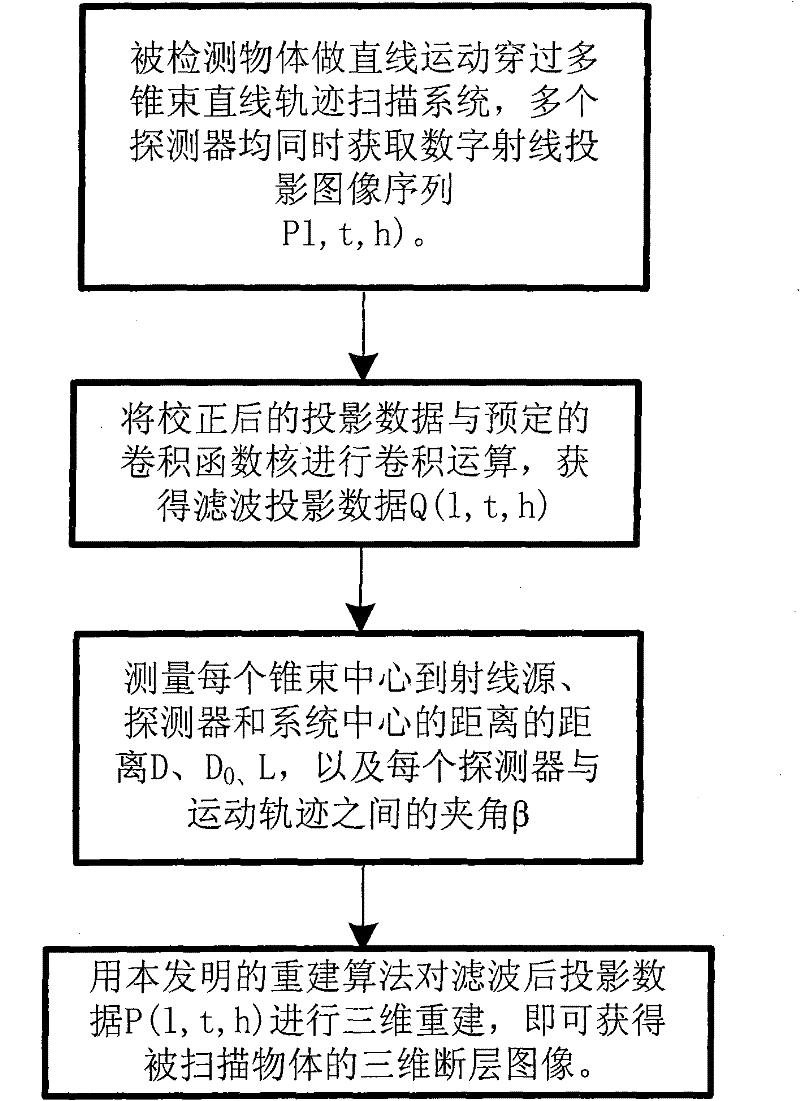

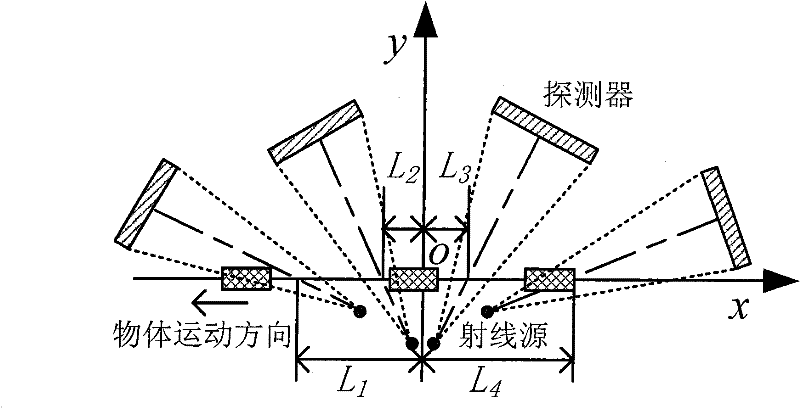

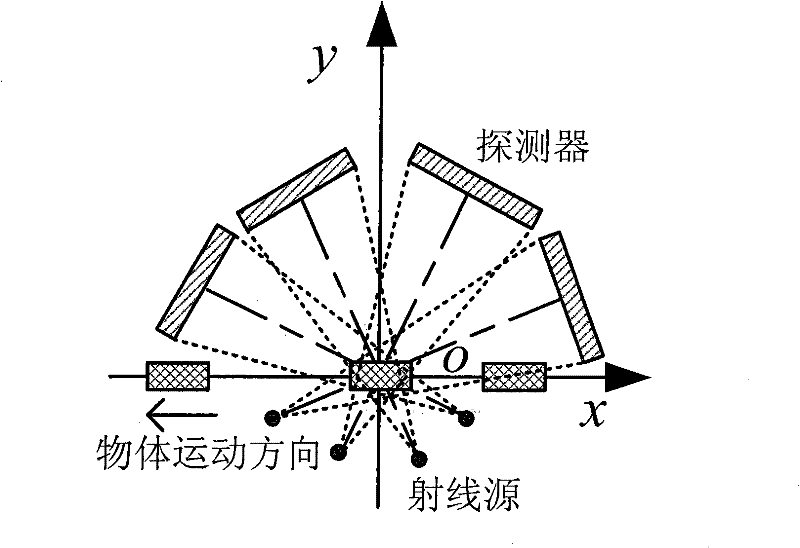

CT imaging method using tilted multi-cone-beam linear track

InactiveCN102004111AScan structure is simpleDetection speedMaterial analysis by transmitting radiation3D modellingLinear motionDigital Ray

The invention relates to the technical field of X-ray CT imaging testing, which discloses a CT imaging method using a tilted multi-cone-beam linear track. The imaging method comprises the steps of: projection acquisition, wave filtering and back-projection reconstruction, wherein during the projection acquisition, a detector receives rays from a ray source so as to obtain the sequence of digital ray projective images; during the wave filtering, specified filter function and ray projection are subjected to convolution operation to obtain the data of the filtered projection; and during back-projection reconstruction, the weighted back-projection reconstruction of the data of the filtered projection is conducted according to the system parameters. In the method of the invention, a scanning mode using the tilted multi-cone-beam linear track is adopted, multiple cone beams are aslant installed in different places, an object to be tested passes through all the cone beams in linear motion, the detector collects the rays which pass through the object in different directions, and thus the scanning process is simple, and the scanning rate is high; because of the back-projection reconstruction method, the reconstruction rate is high, and the problems of low detecting rate and large object volume are solved.

Owner:BEIHANG UNIV

Real-time digital x-ray imaging apparatus

InactiveUS20060126780A1Exact reproductionBetter optimizedMaterial analysis using wave/particle radiationRadiation/particle handlingAcquisition rateElectron

An x-ray diagnostic apparatus and methods performs Real-Time Digital Radiography with particular application in dental x-ray imaging modalities, such as Orthopantomography, Scannography, Linear Tomography and Cephalography, by using a versatile and modular electronic unit, featuring ultra fast computation capability to serve diversified image sensor typology and scanning modality. In Digital Orthopantomography and Scannography, a plurality of tomographic images at different depths of the jaw can be generated, based on the pre-selection made by the user interface. The image processing unit utilizes for the tomo-synthesis of the diagnostic image an accurate and economic digital simulator of the radiographic film speed, including a digital frequency synthesizer fed with film cassette speed digital input and high resolution clock signal, ensuring accurate and reproducible phase continuity of the output frequency signal. It also introduces an automatic adaptation of the frame acquisition rate in frame transfer mode, based on the actual speed of the cassette unit. By this method the dynamic of the exposure signal is reduced, and a better optimization of the signal response of the x-ray detector is achieved.

Owner:GENDEX

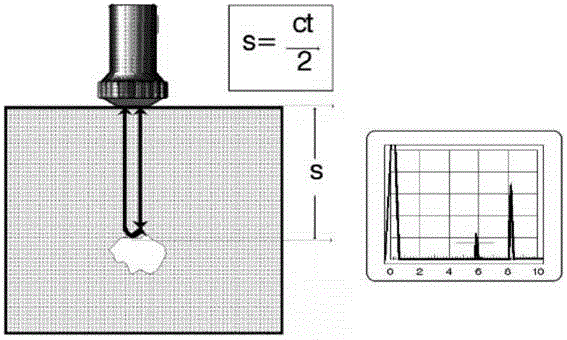

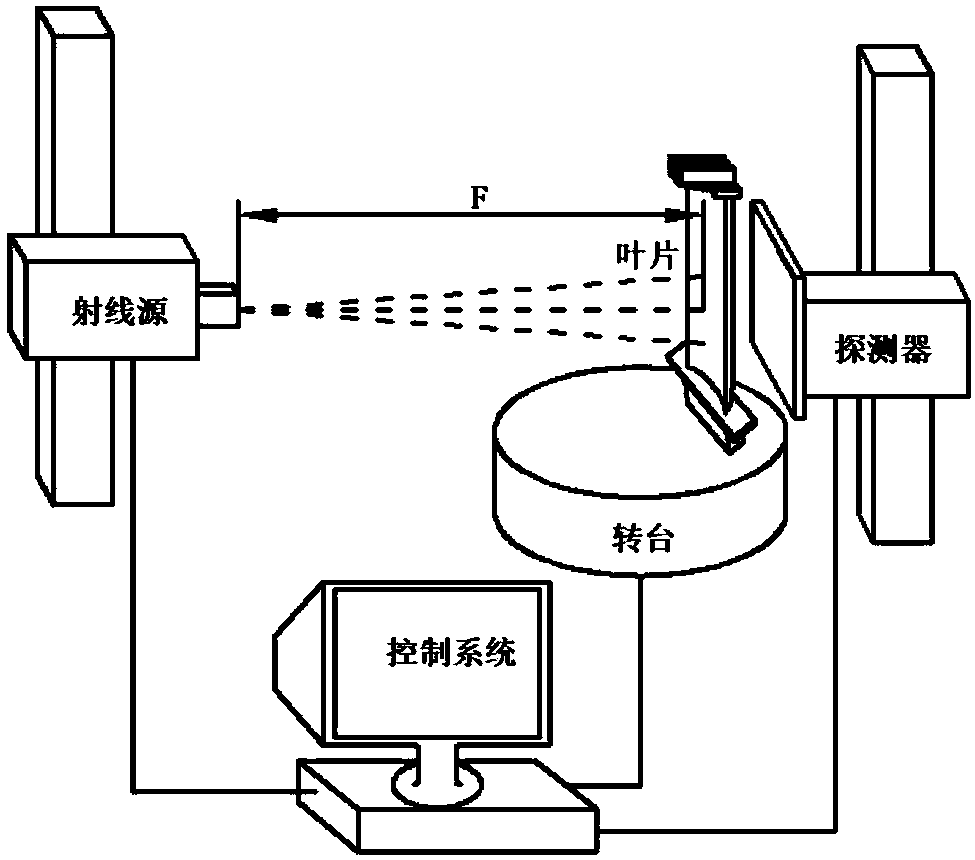

Large-sized high-temperature blade internal defect three-dimensional nondestructive detection method

InactiveCN104655658AMake up detectionMake up the priceMaterial analysis using wave/particle radiationAnalysing solids using sonic/ultrasonic/infrasonic wavesDigital RayEngineering

The invention relates to a large-sized high-temperature blade internal defect three-dimensional nondestructive detection method. The method comprises the steps of carrying out the internal defect detection for a front surface of a gas turbine blade to obtain a two-dimensional grayscale image by utilizing a digital ray device, processing the two-dimensional grayscale image to obtain a two-dimensional size and a two-dimensional position of a defect, carrying out the three-dimensional location for an internal defect of the blade, locating the depth of the defect by utilizing a water dipping ultrasonic method, and judging the existence of the defect by virtue of a defect echo signal; determining a distance from the defect to a detection surface by virtue of the position of the echo signal so as to realize the location of the defect. By integrating the advantages of a digital ray device and a water dipping ultrasonic device, the three-dimensional nondestructive detection of the internal defect can be realized, and the deficiencies that the three-dimensional information cannot be detected by the traditional ray film photographing method and an industrial CT is expensive in price can be overcome.

Owner:XI AN JIAOTONG UNIV

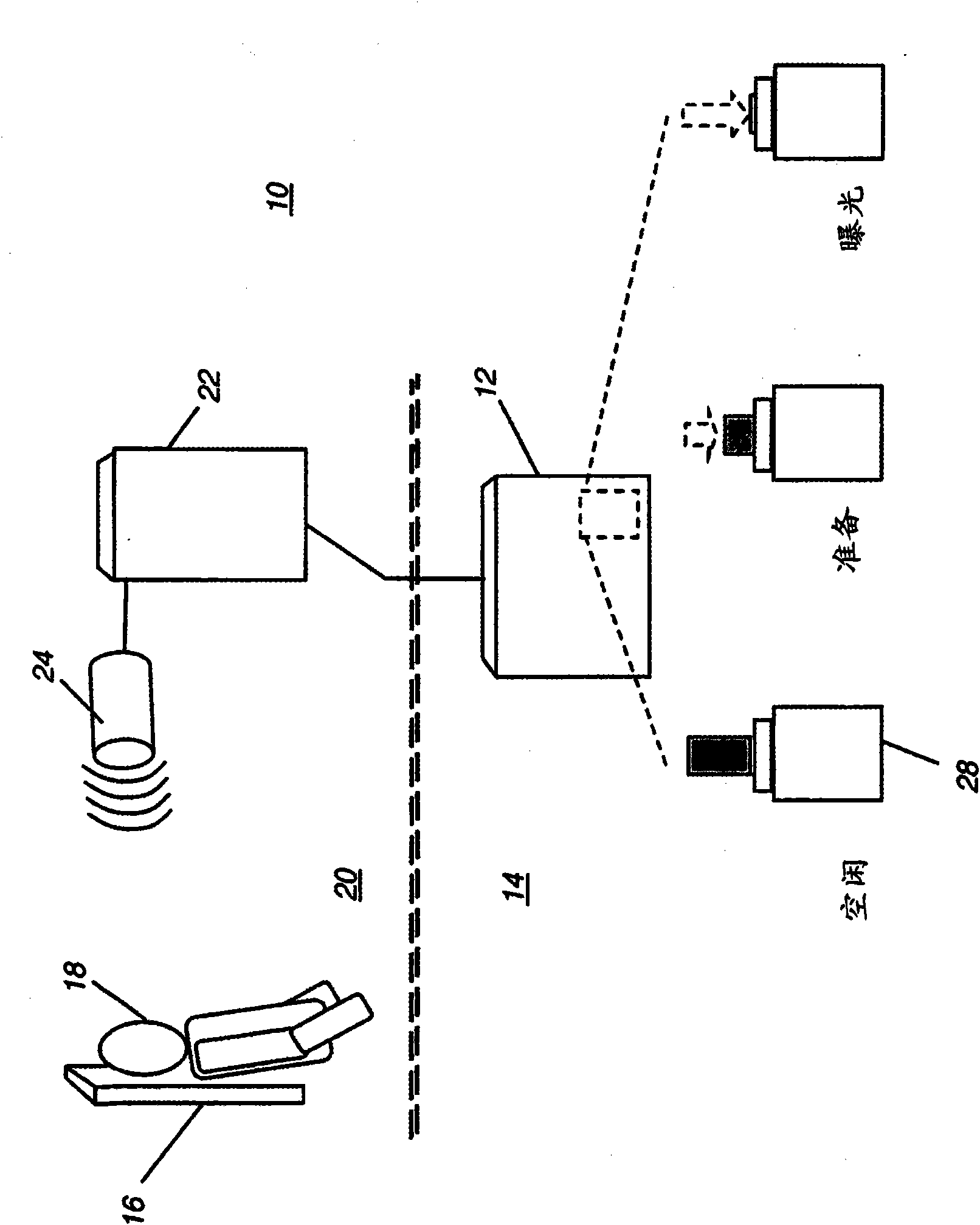

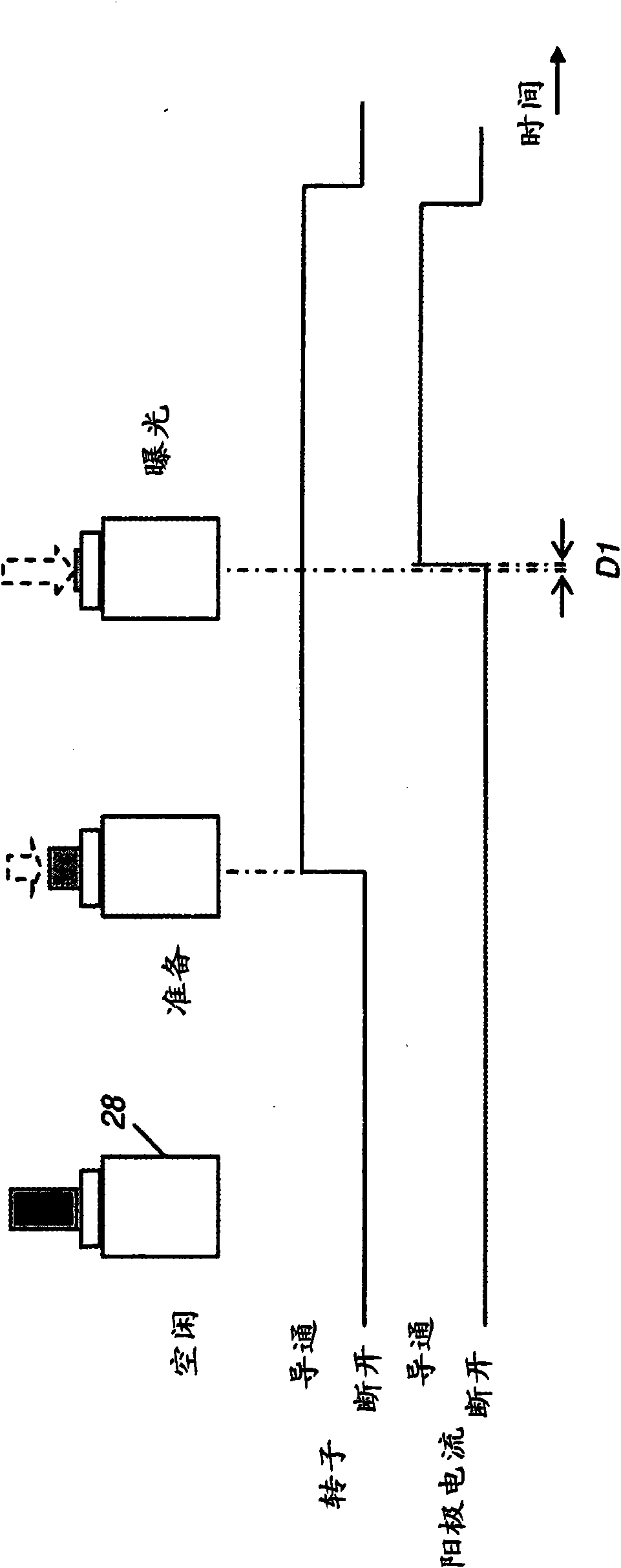

Firing delay for retrofit digital x-ray detector

A method and apparatus are disclosed for obtaining an x-ray image from an x-ray imaging apparatus using a digital radiography receiver installs a retrofit connection apparatus that adapts the x-ray imaging apparatus for use with the digital radiography receiver by forming a receiver interface channel for communicating signals to and from the digital radiography receiver, forming an operator interface channel for routing at least an input expose signal from an operator control to the connection apparatus and forming a generator interface channel for transmitting at least an output expose signal from the retrofit connection apparatus to an x-ray generator of the x-ray imaging apparatus. An input expose signal over the operator interface channel initiates a reset of the digital radiography receiver over the receiver interface channel before the output expose signal to the x-ray generator is transmitted over the generator interface channel.

Owner:CARESTREAM HEALTH INC

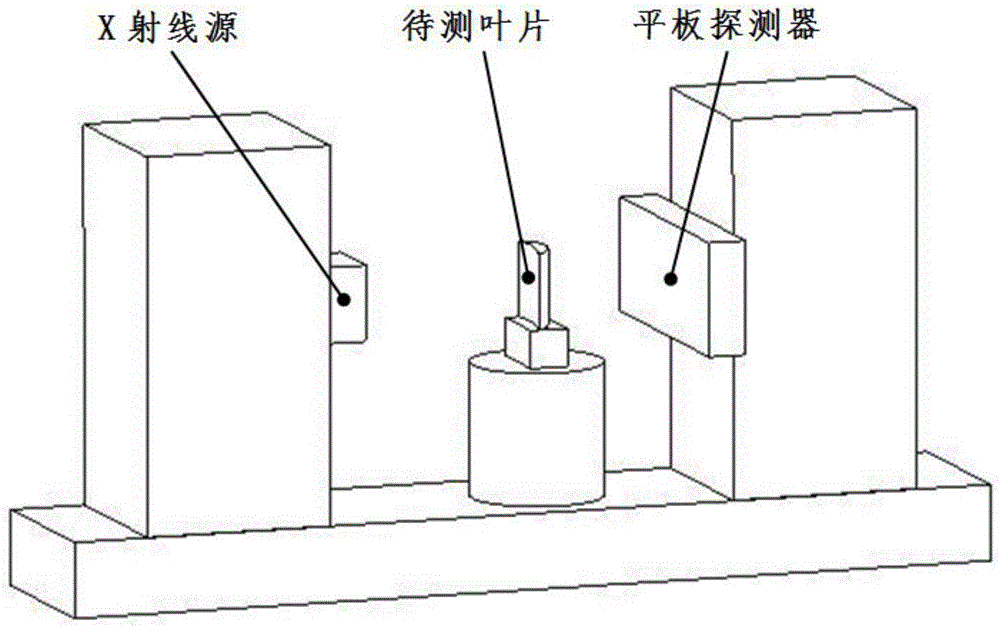

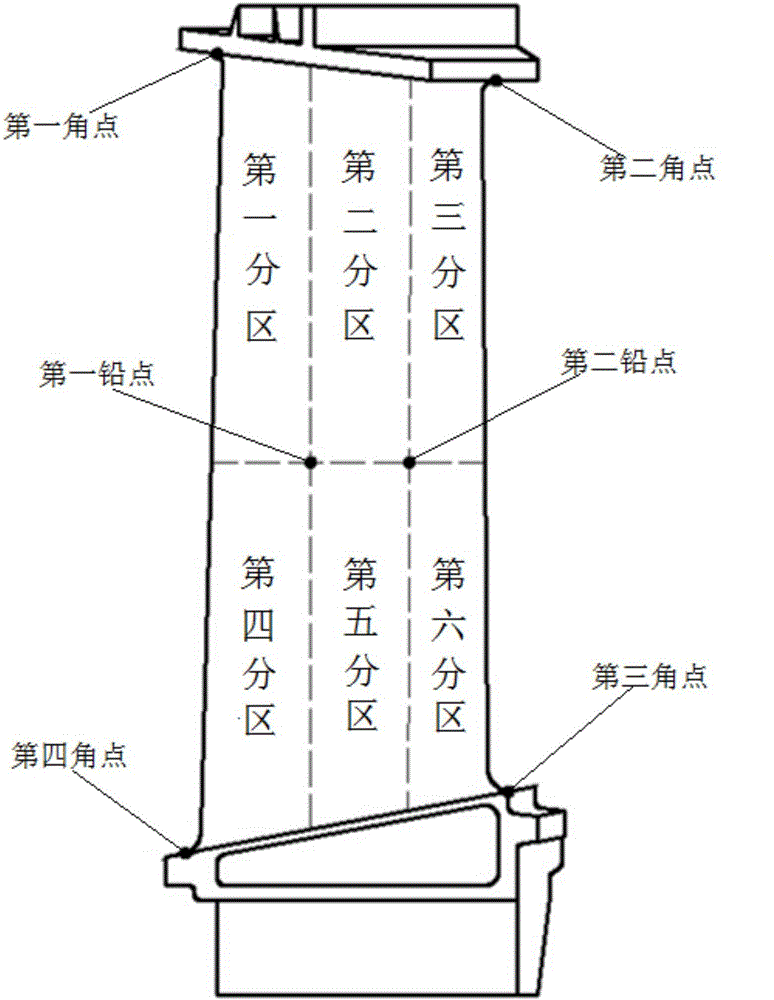

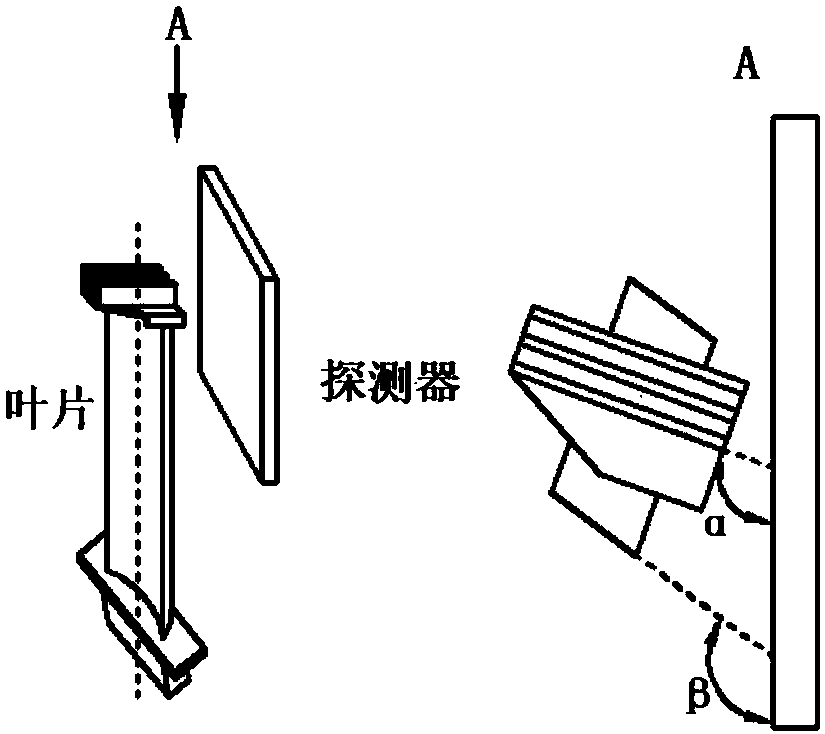

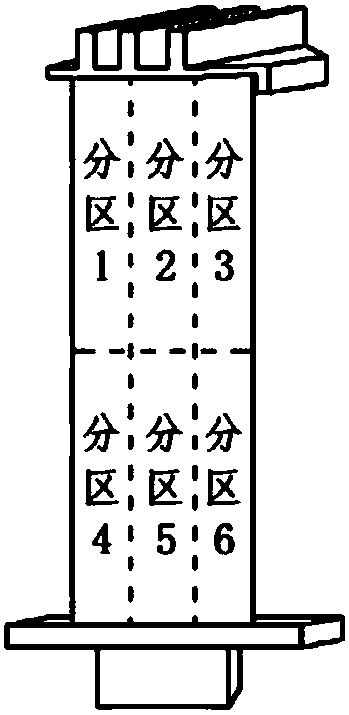

Method for blade digital ray partition detection of large gas turbine

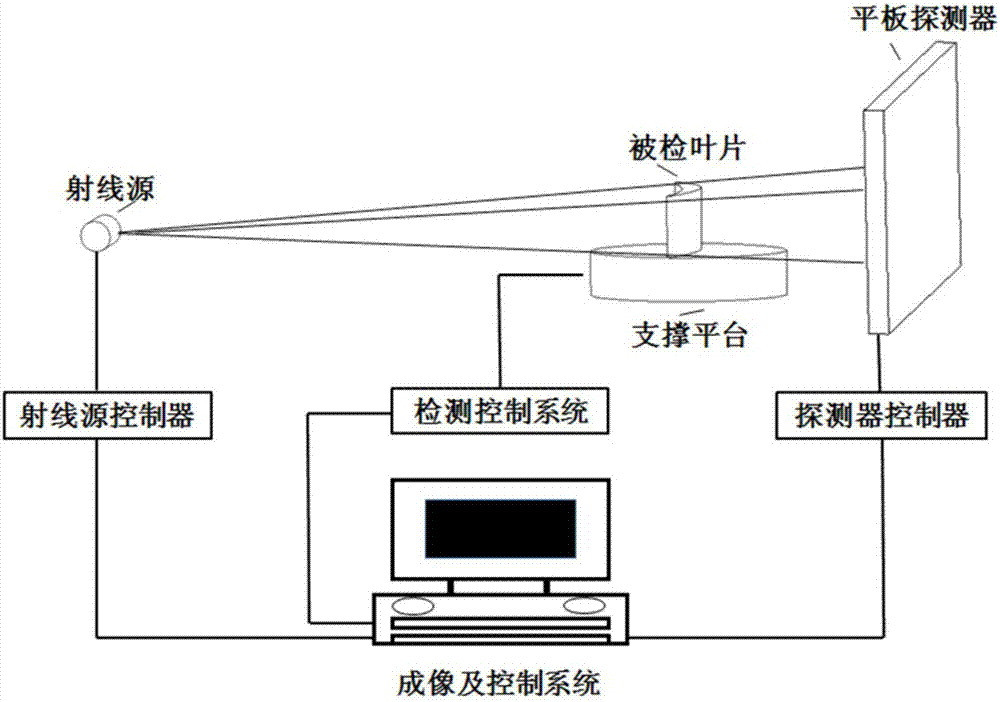

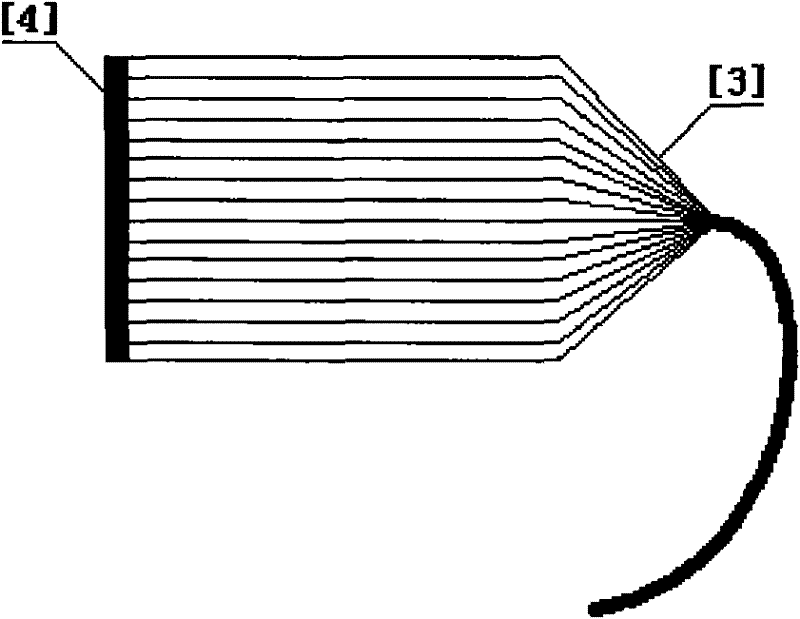

ActiveCN106845011AImprove defect detection efficiencyHelp identifyImage enhancementReconstruction from projectionDigital RayFlat panel detector

The invention discloses a method for blade digital ray partition detection of a large gas turbine. An X ray source and a flat panel detector are adopted to form a digital ray detection system. The X ray source performs transillumination on a to-be-measured blade through six groups of transillumination parameters, image gray undergoing transition from highlight all white to all black is formed on the flat panel detector, thickness change in each partition is determined, each transillumination partition is divided, an effective coverage is obtained through cutting, and finally splicing of a partition image is finished. According to the method, a ray transillumination area can be enlarged, operation is simplified, detection efficiency is improved, the method for blade digital ray partition detection of the gas turbine is standardized, internal defects of the gas turbine blade are extracted quickly, and the method is simple to operate, low in requirements for workers' technical level, high in efficiency during large-scale factory detection and high in practicality.

Owner:XI AN JIAOTONG UNIV

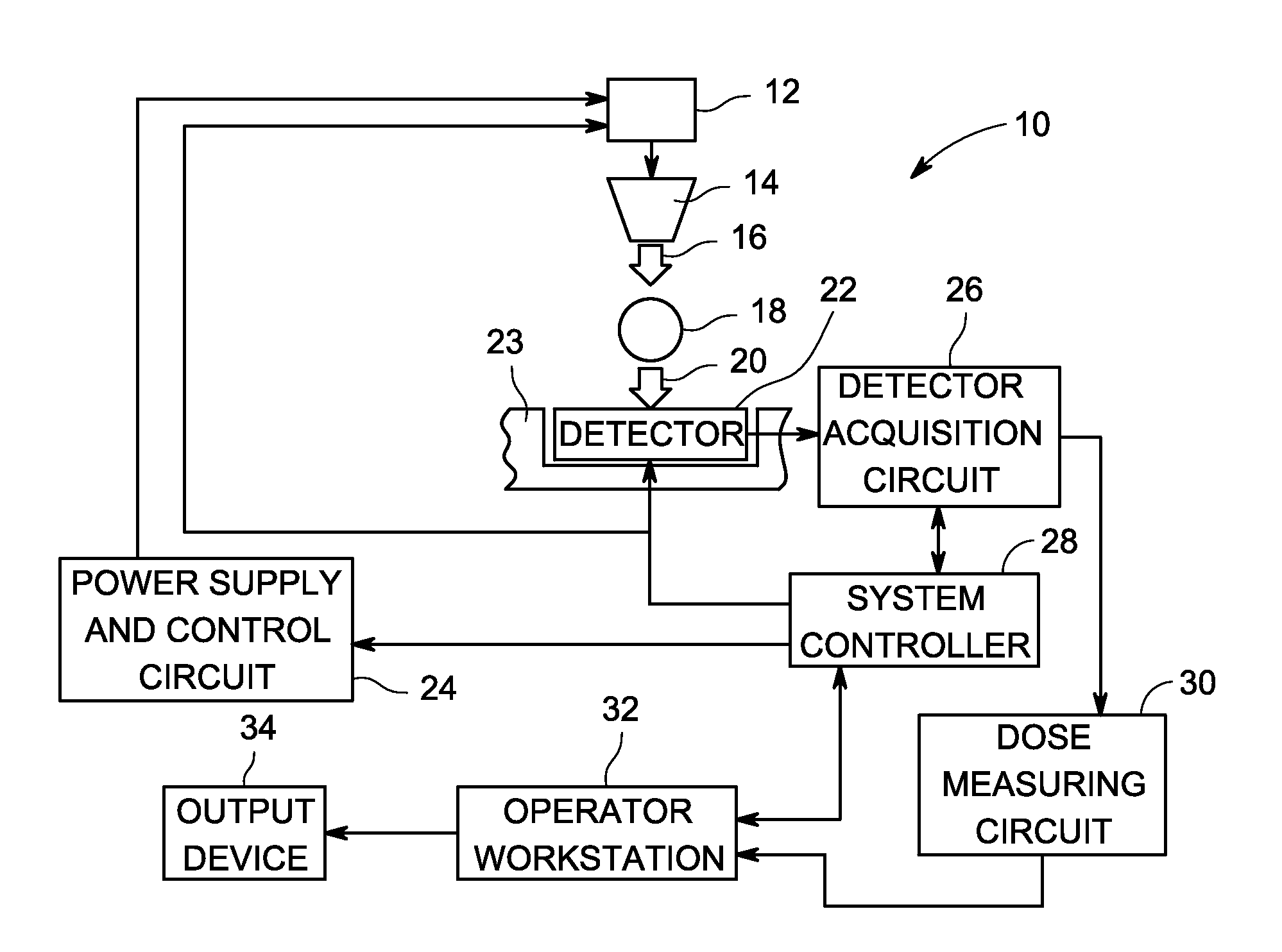

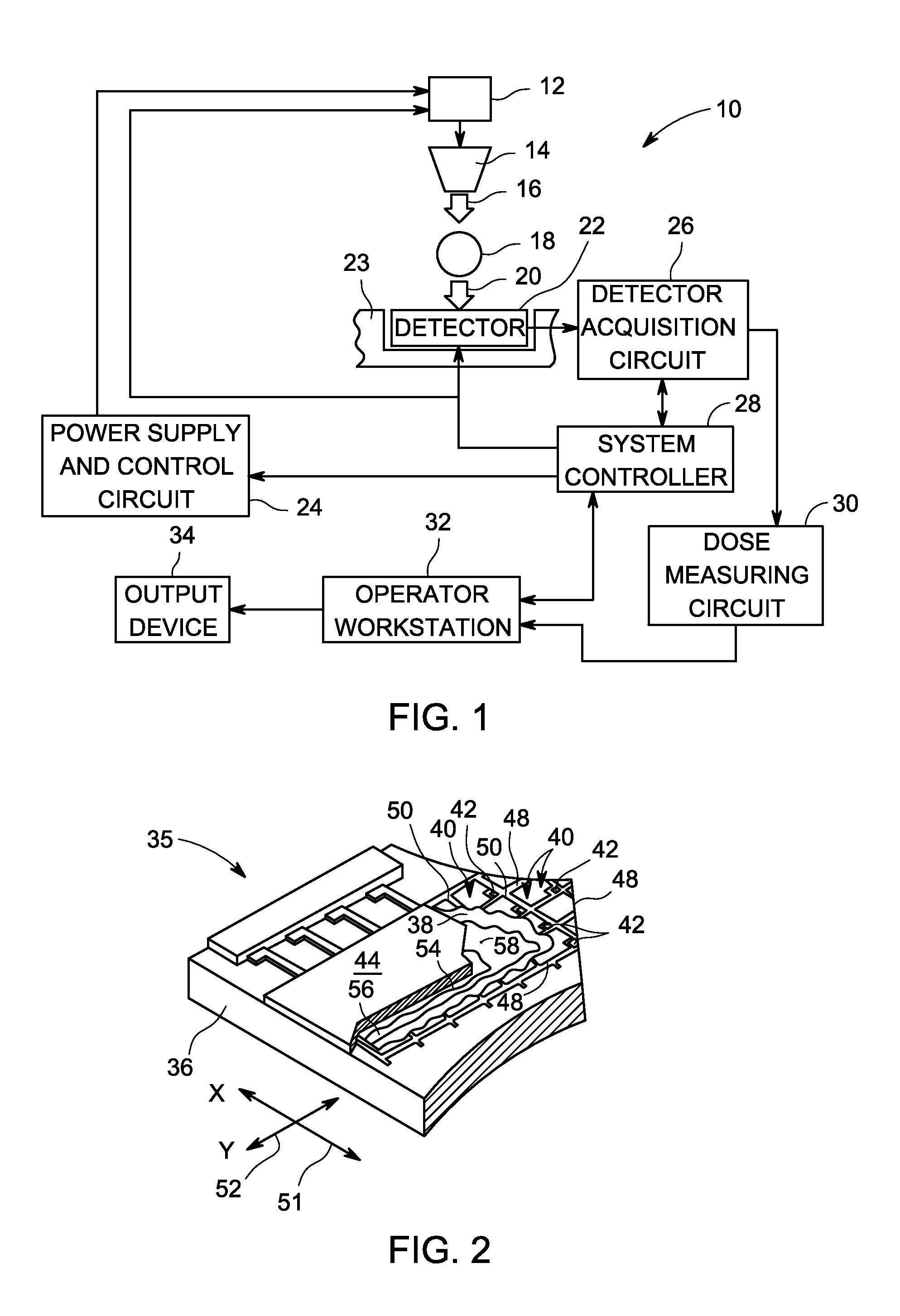

Method and system for integrated patient table digital x-ray dosimeter

A method of imaging a patient and an X-ray dosimetry system are provided. The X-ray dosimetry system includes a support platform configured to support an object to be imaged and a digital X-ray dosimeter mounted on a surface of the support platform, the X-ray dosimeter configured to receive incident radiation prior to the incident radiation having passed through the object to be imaged, the X-ray dosimeter comprising a thickness of less than about four millimeters.

Owner:GENERAL ELECTRIC CO

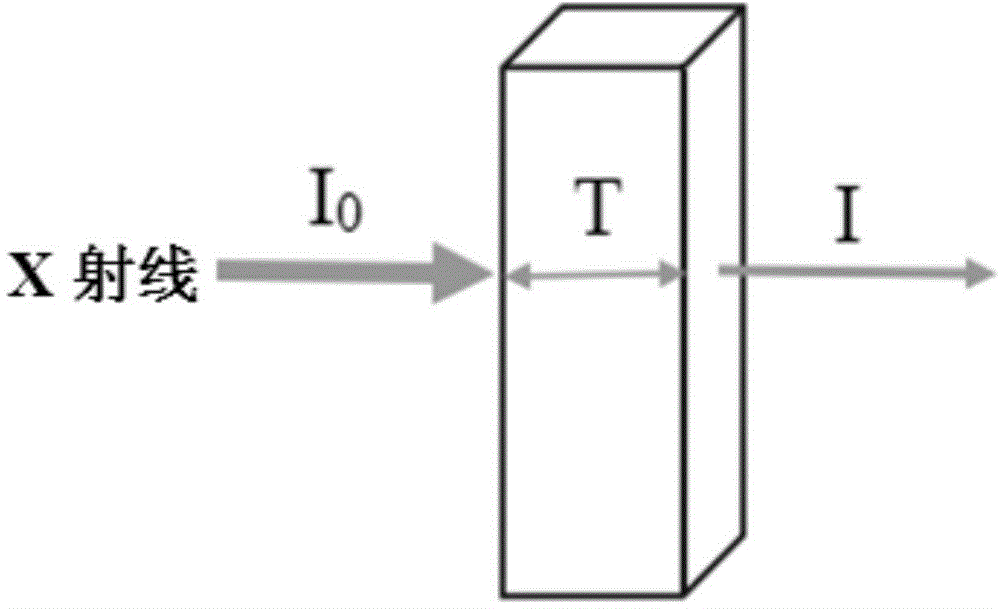

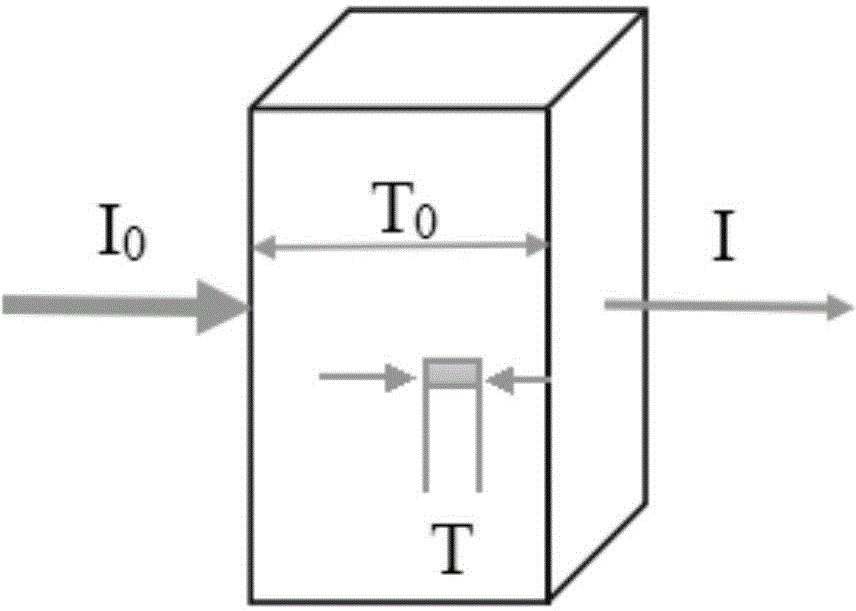

Method for accurate detection of material defect and thickness by using digital radiography transillumination technology

ActiveCN105158280ANon-destructive testingUsing wave/particle radiation meansMaterial analysis by transmitting radiationDigital RayMaterial defect

The invention provides a method for accurate detection of material defect and thickness by using a technology of digital radiography transillumination, and belongs to the field of nondestructive test. A test block with fixed gradient is placed on a material to be detected, a radiation field from top to bottom passes through a workpiece to be detected and the test block with fixed gradient at the same time, a digital ray reception plate receives attenuated ray, and the ray is converted into a two-dimensional image by a data displaying and processing unit. According to a flat weld detection, the test block with fixed gradient is placed beside the workpiece to be detected; the cross section of the test block is a right trapezoid, wherein a right-angle side is horizontally placed on the horizontal plane same to that of the workpiece; according to a small diameter tube detection, a test block with gradient is used, and the cross section of the test block along the axial direction of the test block is semi-toroidal, and the cross section of the test block along the circumferential direction is right trapezoid; internal diameter of the test block with gradient is equal to the external diameter of the small diameter tube, and the cross section of the test block with gradient is semi-toroidal, the test block is tightly wrapped outside the workpiece to be detected and is placed beside the weld. The method can be used for accurately measuring height of the defect and weld reinforcement or the like without misjudgement.

Owner:赵建江

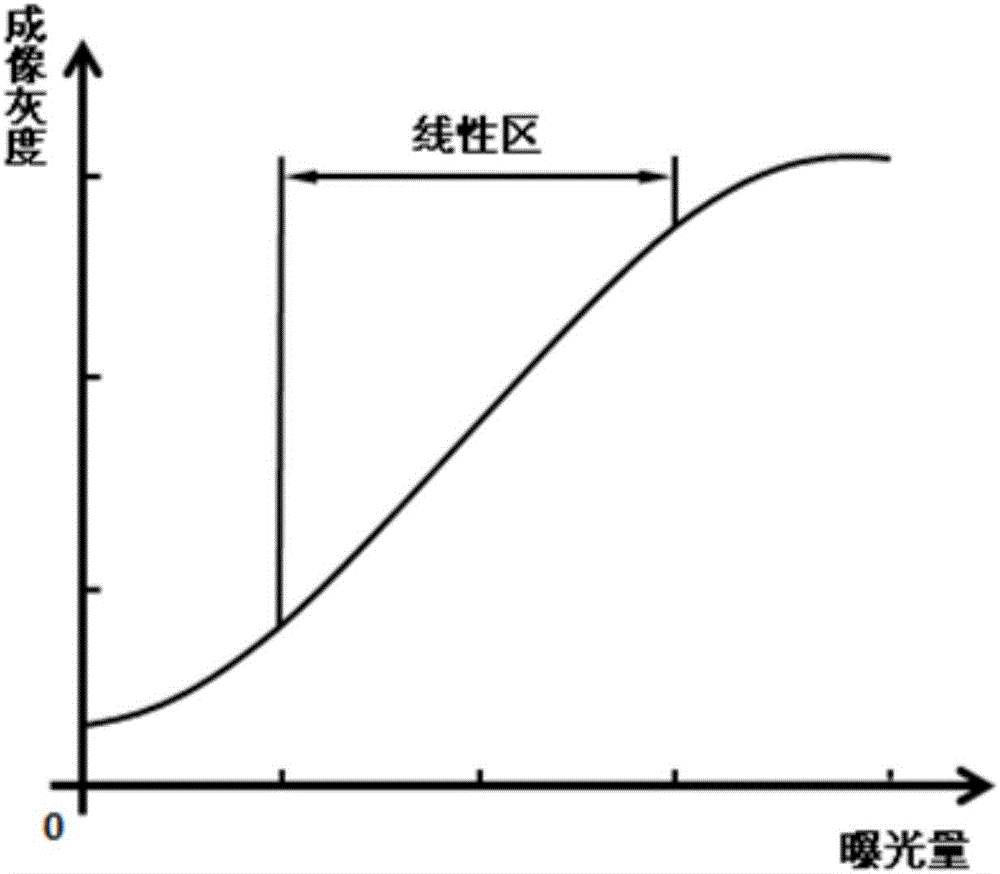

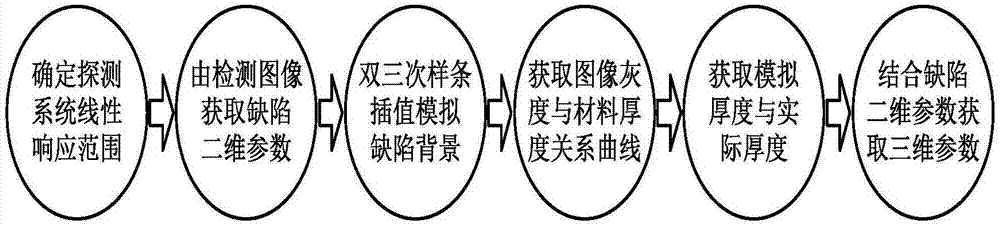

Three-dimensional parameter extraction method of internal defect of gas turbine blade based on digital ray

InactiveCN106932416AImplement extractionImprove efficiencyMaterial analysis by transmitting radiationDigital RayTurbine blade

The invention discloses a three-dimensional parameter extraction method of an internal defect of a gas turbine blade based on a digital ray. The method comprises the steps of arranging two-dimensional detection images of the defect according to pixels for primary finite element division, then performing discrete quantification on thickness of each pixel according to gray-scale values, determining a corresponding relation between grey-scale and the thickness, accumulating finite elements of all the pixels, and extracting a three-dimensional parameter of a defect area.The method is based on a finite element concept; the two-dimensional detection images of the defect are arranged according to the pixel for the primary finite element division; the discrete quantification is performed on the thickness of each pixel according to the gray-scale value; and further, the corresponding relation between the grey-scale and the thickness is determined.The three-dimensional parameter of the defect is extracted by accumulating finite element areas of all the pixels; the deficiency of the traditional radiographic detection method in three-dimensional parameter extraction of the defect can be effectively made up for; and the extraction of the three-dimensional parameter of the internal defect of the gas turbine blade can be achieved more efficiently at lower cost.

Owner:XI AN JIAOTONG UNIV

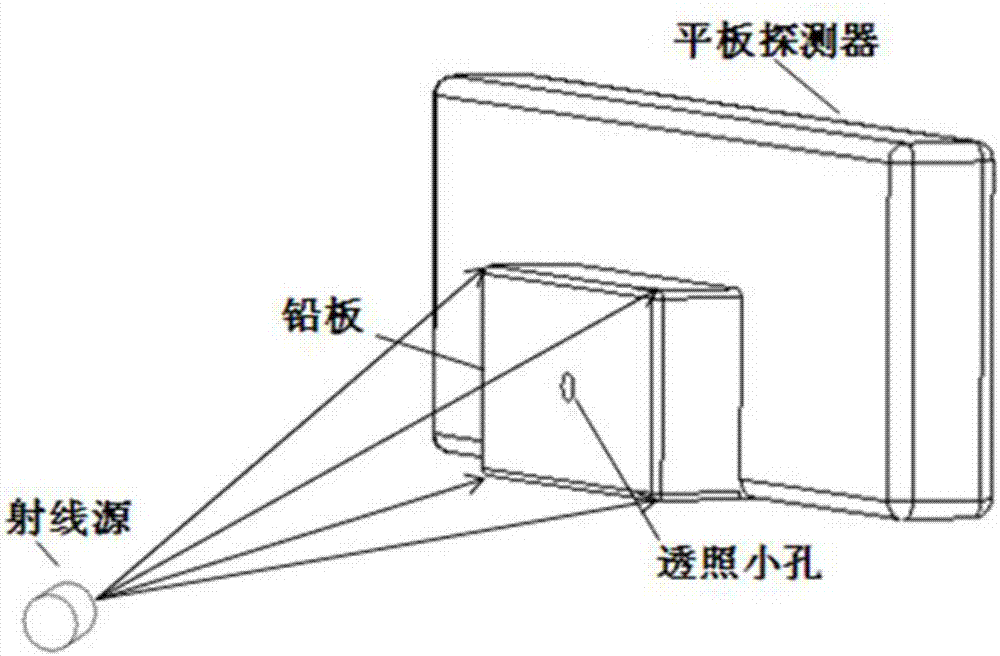

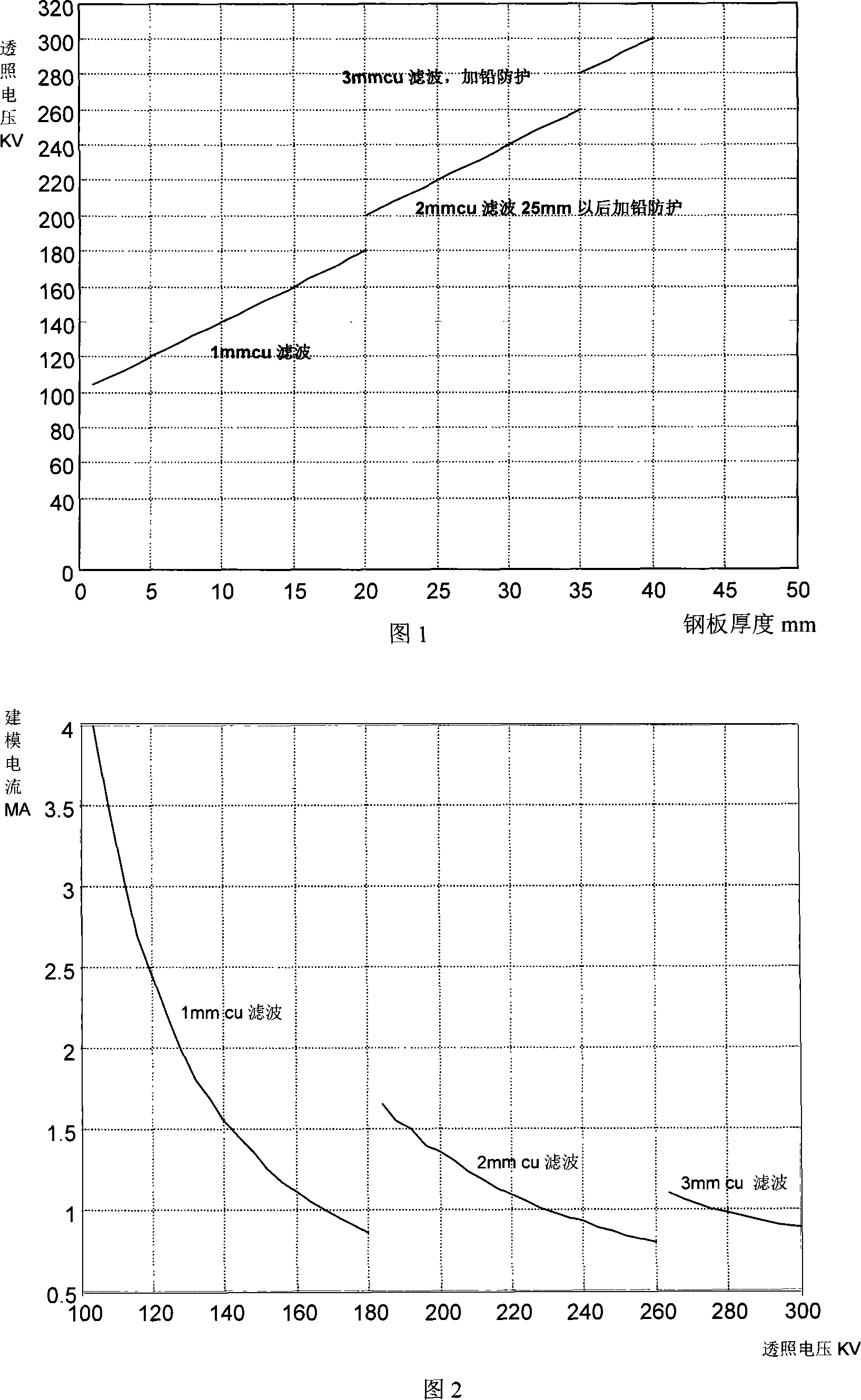

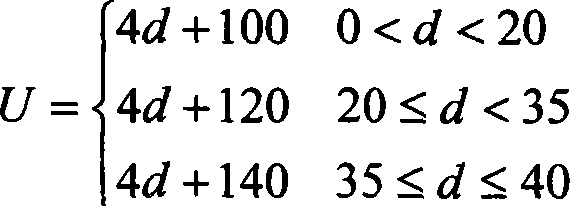

Method for establishing optimum transillumination parameter system of industry digital radial imaging detecting

ActiveCN101109627AEasy programmingFamiliar quicklyUsing wave/particle radiation meansX/gamma/cosmic radiation measurmentDigital RayDigital imaging

The invention discloses a method for establishing an optimal perspective parameter system for industrial digital ray image test, which solves the problem associated with prior X-ray digital image test that no correct industrial digital ray image test can be carried out due to lack of the method for establishing an optimal perspective parameter system, and provides a reliable and effective optimal parameter-selecting system for the industrial digital ray image test. The method is: (1) determining the thickness of the work piece to be tested; (2) establishing the curve of U(Kv) swung dash d(mm) on the imaging system; (3) forming the reference curve for U(Kv) swung dash Im(mA) selecting the perspective parameters for modeling the imaging system; (4) fitting the curve from (2) and (3), obtaining the corresponding optimal perspective parameters and the mathematic expression of the modeling parameters; (5) establishing the optimal perspective parameter based on (2) and (3); (6) obtaining the digital image of the work piece meeting class B test.

Owner:AOTAI ELECTRIC

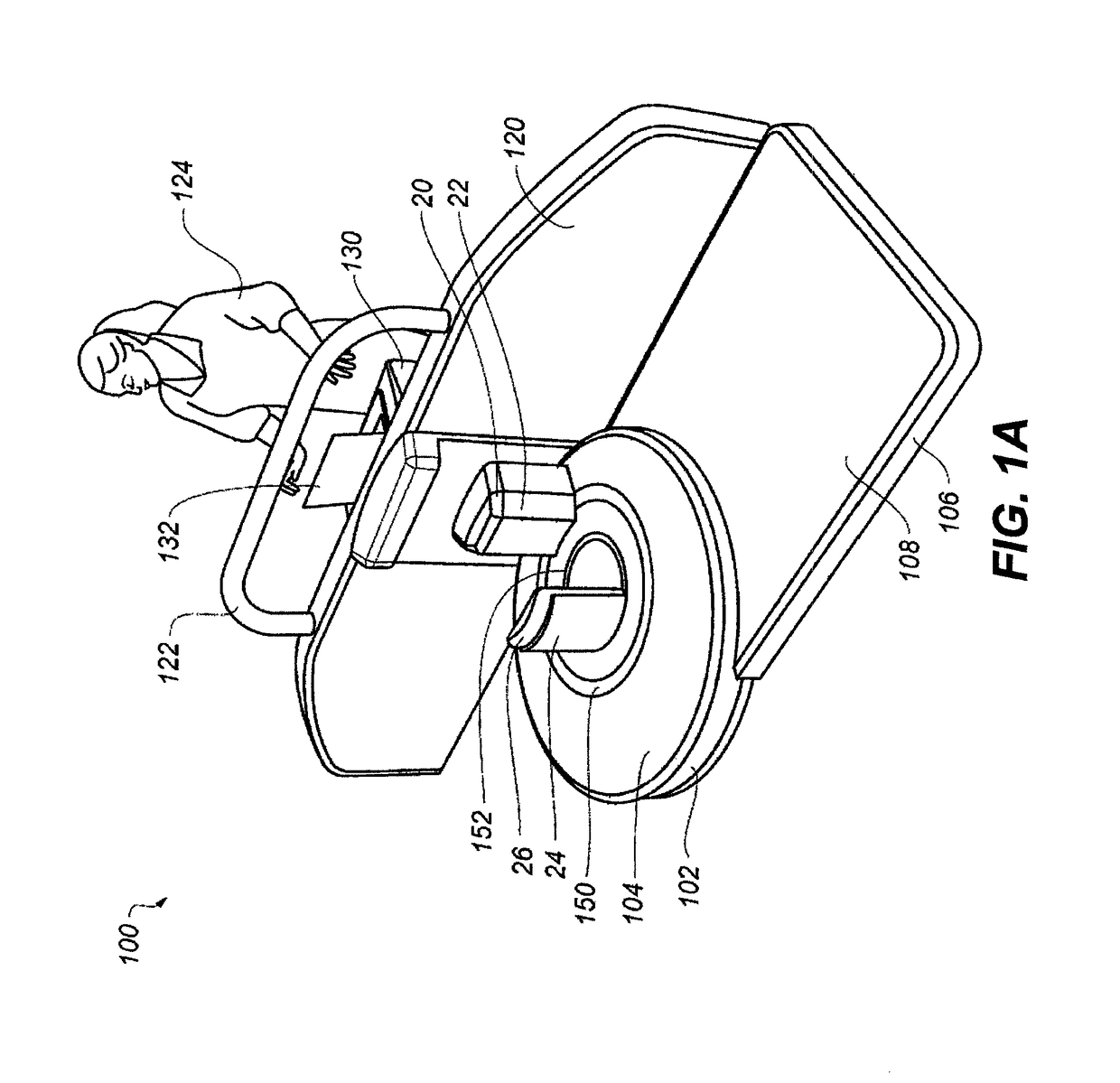

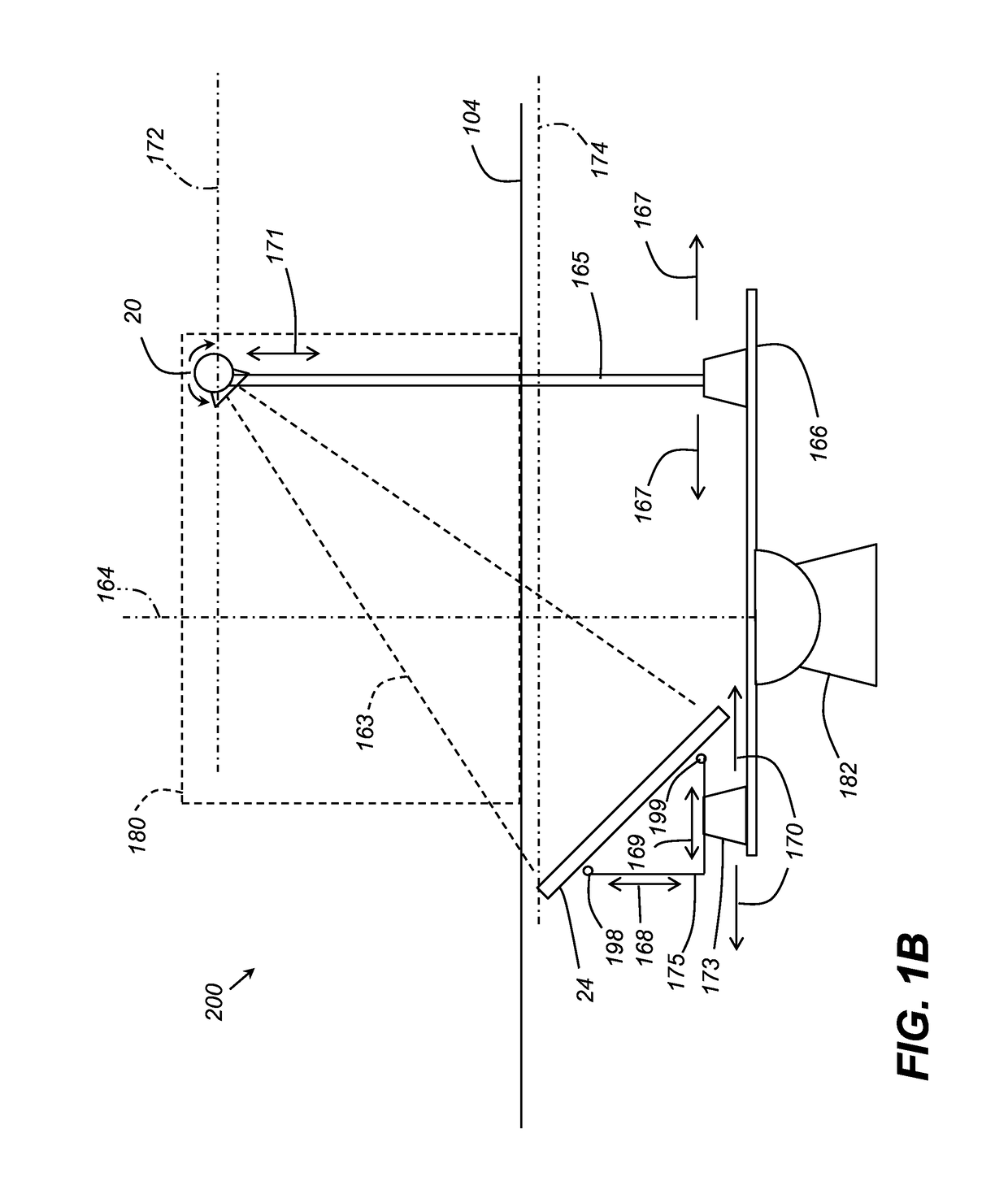

Extremity imaging for animals

InactiveUS10136870B2Reduce chanceSafer imagingPatient positioning for diagnosticsComputerised tomographsDigital RayProximate

An apparatus captures radiographic images of an animal standing proximate the apparatus. A moveable x-ray source and a digital radiographic detector are hidden from view of the animal and are revolved about a portion of the animal's body to capture one or a sequence of radiographic images of the animal's body.

Owner:CARESTREAM HEALTH INC

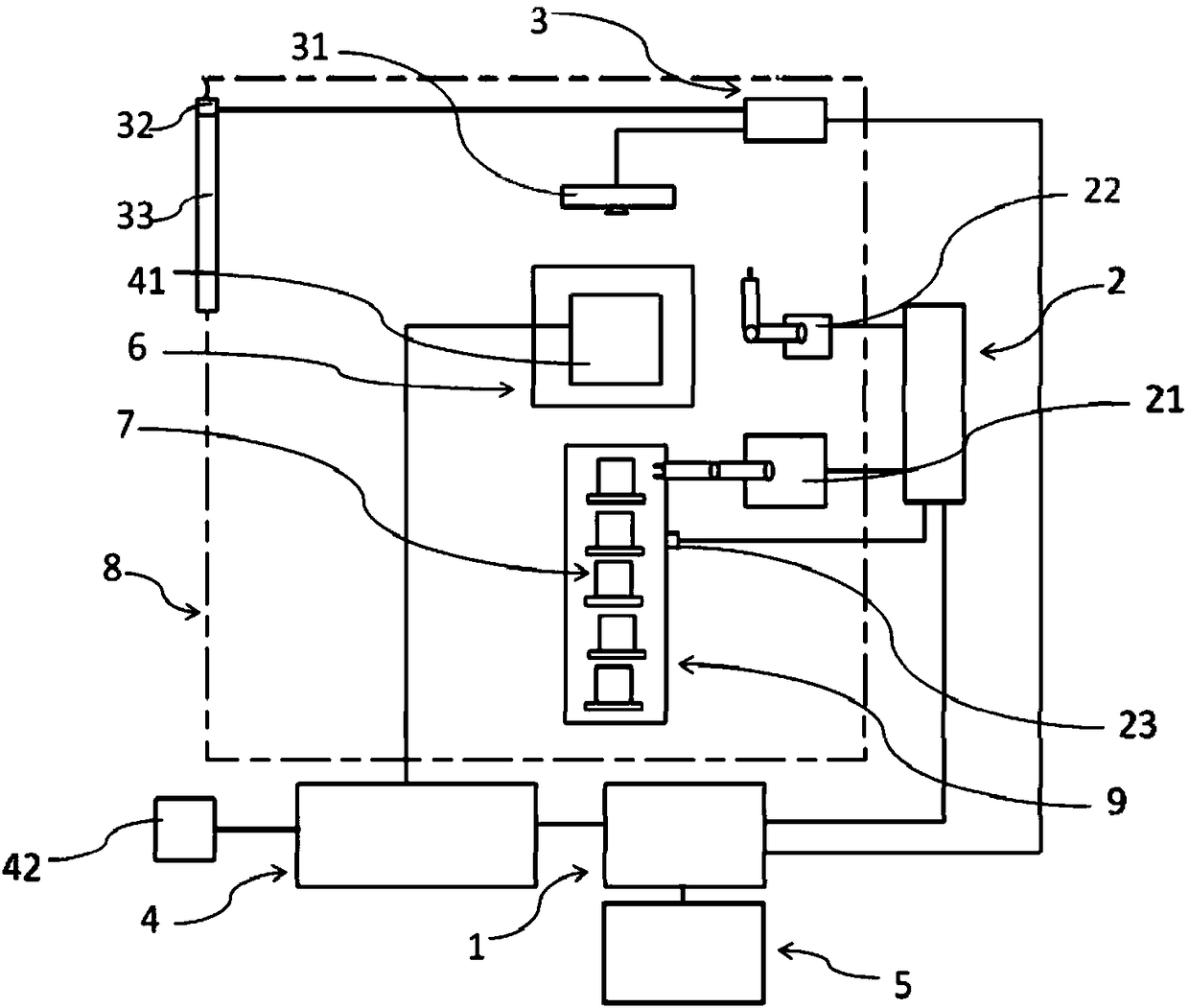

Digital ray automatic detecting system and method for detecting wheel parts

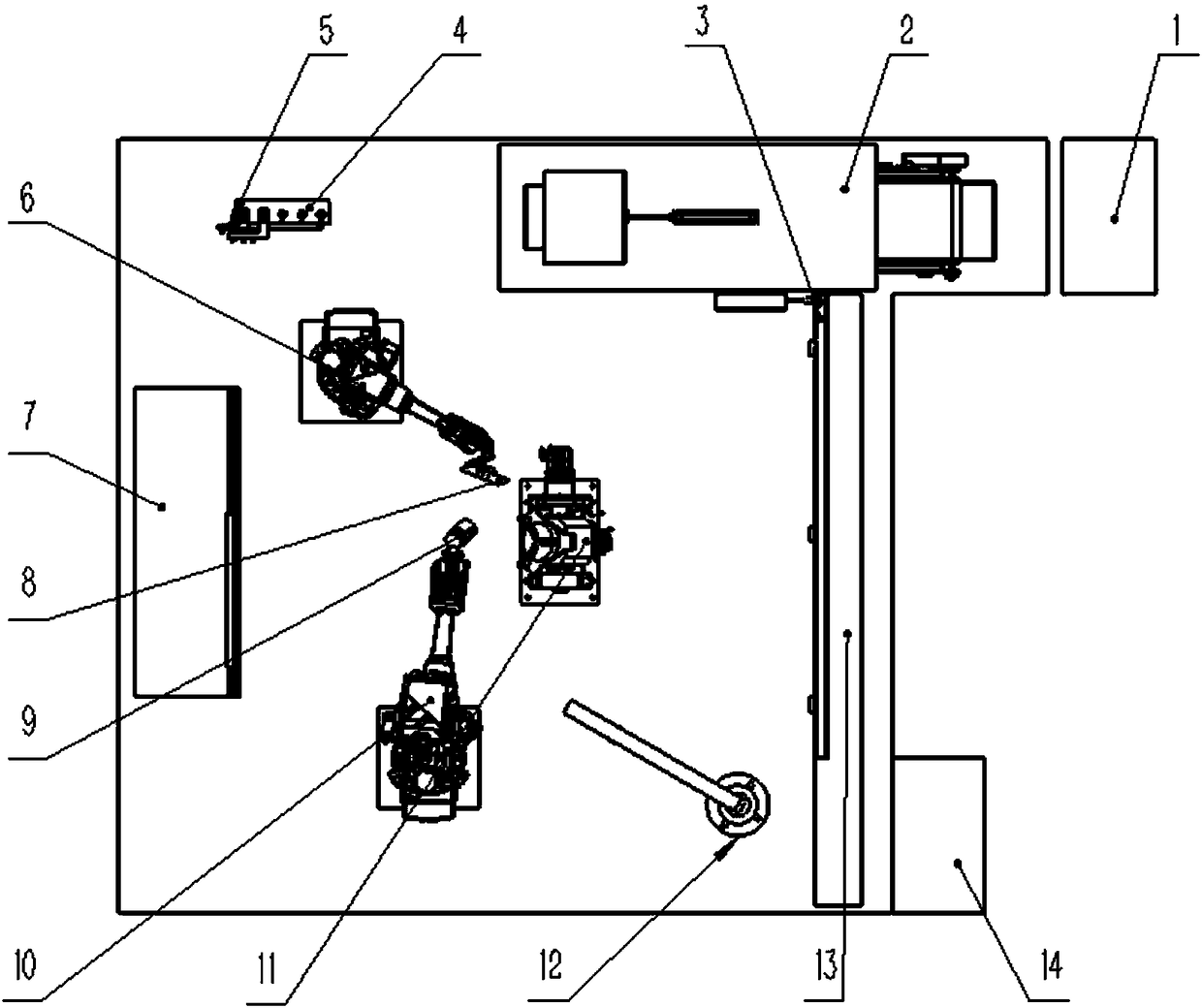

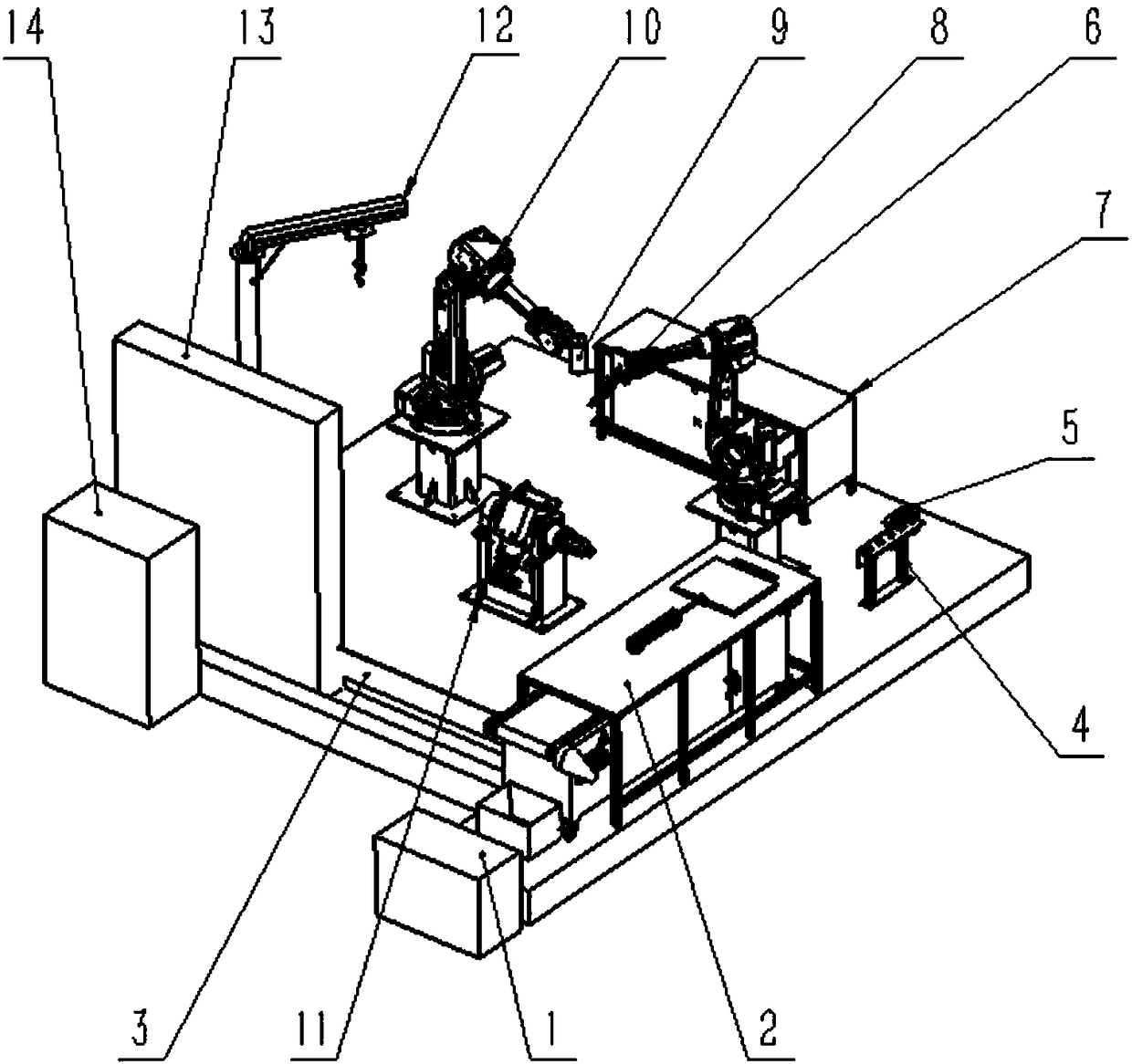

PendingCN108152306AGuaranteed postureShort processMaterial analysis by transmitting radiationDigital RayEngineering

The invention relates to a digital ray automatic detecting system and method for detecting wheel parts. The system comprises a PLC console, a CR imaging device, two industrial robots, an X-ray machine, a quick-change gripper frame, a quick-change gripper, a storage cabinet, a conveying device, a rotating worktable, a door groove cover plate, a small-sized cantilever crane and an automatic lead door; the PLC console and the CR imaging device are arranged outside a protective lead room; the two industrial robots, the X-ray machine, the quick-change gripper frame, the quick-change gripper, the storage cabinet, the conveying device, a rotating worktable, the door groove cover plate, the small-sized cantilever crane and the automatic lead door are arranged in the protective lead room. The X-raymachine is installed at the tail end of the large robot, and the PLC console controls the two industrial robots and the rotating worktable through Profinet buses, controls the X-ray machine through an RS-232 serial port and controls the quick-change gripper, the conveying device, the storage cabinet, the automatic lead door and the door groove cover plate through IO modules. The digital ray automatic detecting system and method have the advantages that 1, the detection efficiency is improved, and the time for manual placement and opening and closing of the lead door is saved; 2, the detectionaccuracy is improved; 3, the detection cost is reduced.

Owner:WUHAN UNIV OF TECH +1

Optimization method of model-unknown gas turbine blade digital ray partition transillumination direction

ActiveCN108229080AAvoid designImprove detection efficiencyDesign optimisation/simulationSpecial data processing applicationsDigital RayFlat panel detector

The invention discloses an optimization method of a model-unknown gas turbine blade digital ray partition transillumination direction. The method comprises the following steps: transilluminating a flat panel detector, and determining the gray scale linear response interval of the flat panel detector; transilluminating each partition of the blade from different angles; drawing a relation curve about the gray scale minimum and angle change of each partition of the blade, and determining the optimal transillumination direction of each partition; splicing the transformed transillumination images of all partitions to obtain a transillumination image of the blade; processing the overlap region image of each partition; calculating the cross-partition defect overlap volume by an approximation algorithm; subtracting the defect volume of the overlap region from the total defect volume obtained from each partition, to obtain the real volume of the blade defect and realize optimization of the transillumination direction. In the invention, the detection efficiency of tiny defects is increased, the design of complicated furniture is avoided, and the detection cost is lowered; and moreover, the universality is high, and a foundation is laid for the locating and qualitative and quantitative analysis of the defect.

Owner:XI AN JIAOTONG UNIV

Method and unit for refining digital x-ray images

InactiveUS20070140542A1Simplify image processingEasy to adjustUltrasonic/sonic/infrasonic diagnosticsPatient positioning for diagnosticsDigital RayImaging processing

Method for simplifying the adjustment of a digital x-ray device for the refinement of the x-ray images, and to an image refining unit for carrying out said method. According to the invention, a pre-determined modification is performed on the image data of the x-ray image by at least one image processing module according to at least one parameter: the or each parameter is supplied to the image processing module from a current set of parameters; the current set of parameters is selected from a plurality of stored standard sets of parameters; an associated model image can be displayed for each standard set of parameters using stored image data; and the standard group of parameters selected by selecting the associated model image.

Owner:SIEMENS HEATHCARE GMBH

CT imaging method using tilted multi-cone-beam linear track

InactiveCN102004111BScan structure is simpleDetection speedMaterial analysis by transmitting radiation3D modellingLinear motionDigital Ray

The invention relates to the technical field of X-ray CT imaging testing, which discloses a CT imaging method using a tilted multi-cone-beam linear track. The imaging method comprises the steps of: projection acquisition, wave filtering and back-projection reconstruction, wherein during the projection acquisition, a detector receives rays from a ray source so as to obtain the sequence of digital ray projective images; during the wave filtering, specified filter function and ray projection are subjected to convolution operation to obtain the data of the filtered projection; and during back-projection reconstruction, the weighted back-projection reconstruction of the data of the filtered projection is conducted according to the system parameters. In the method of the invention, a scanning mode using the tilted multi-cone-beam linear track is adopted, multiple cone beams are aslant installed in different places, an object to be tested passes through all the cone beams in linear motion, the detector collects the rays which pass through the object in different directions, and thus the scanning process is simple, and the scanning rate is high; because of the back-projection reconstruction method, the reconstruction rate is high, and the problems of low detecting rate and large object volume are solved.

Owner:BEIHANG UNIV

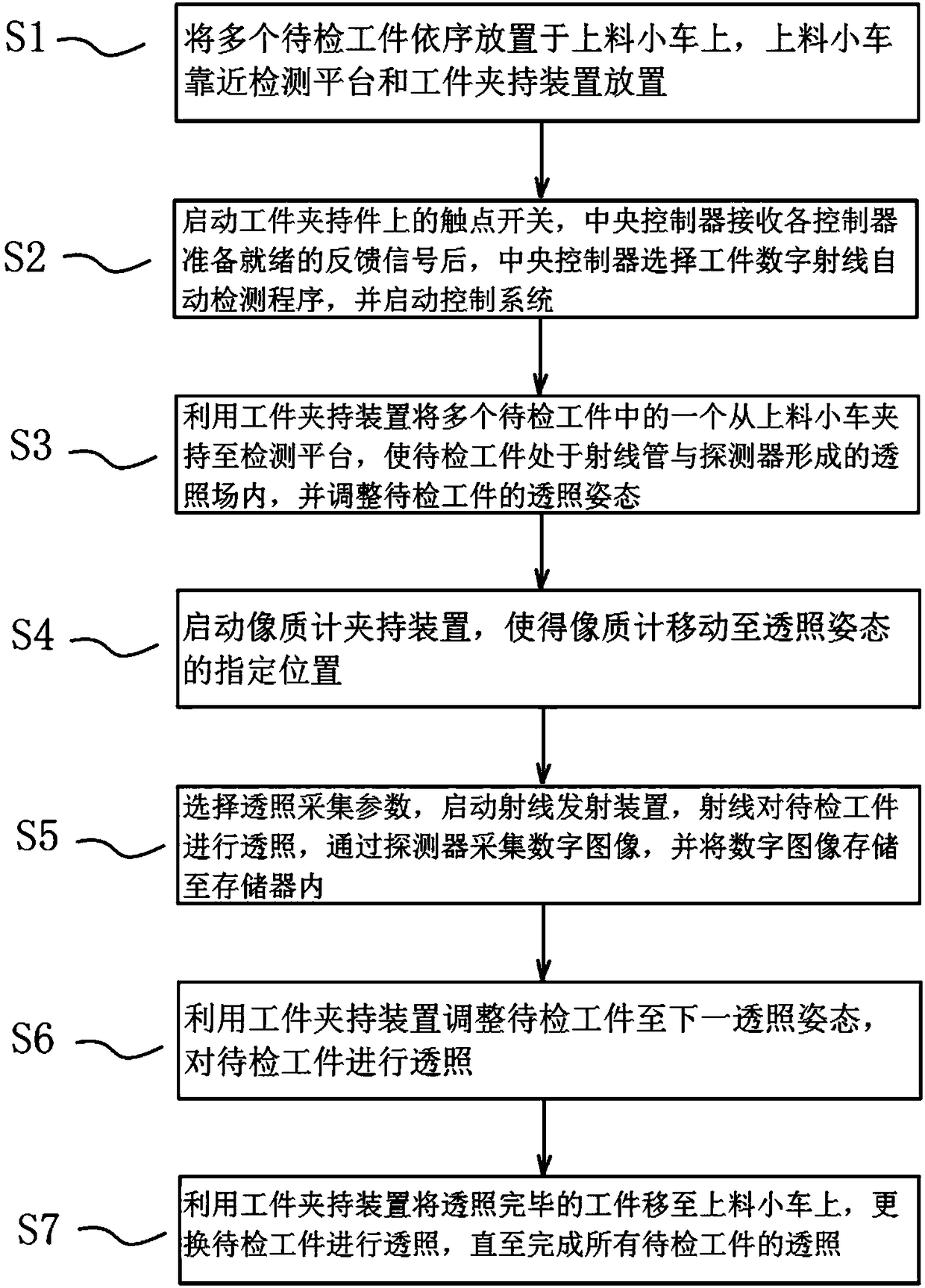

Digital ray automatic detection device, and detection method thereof

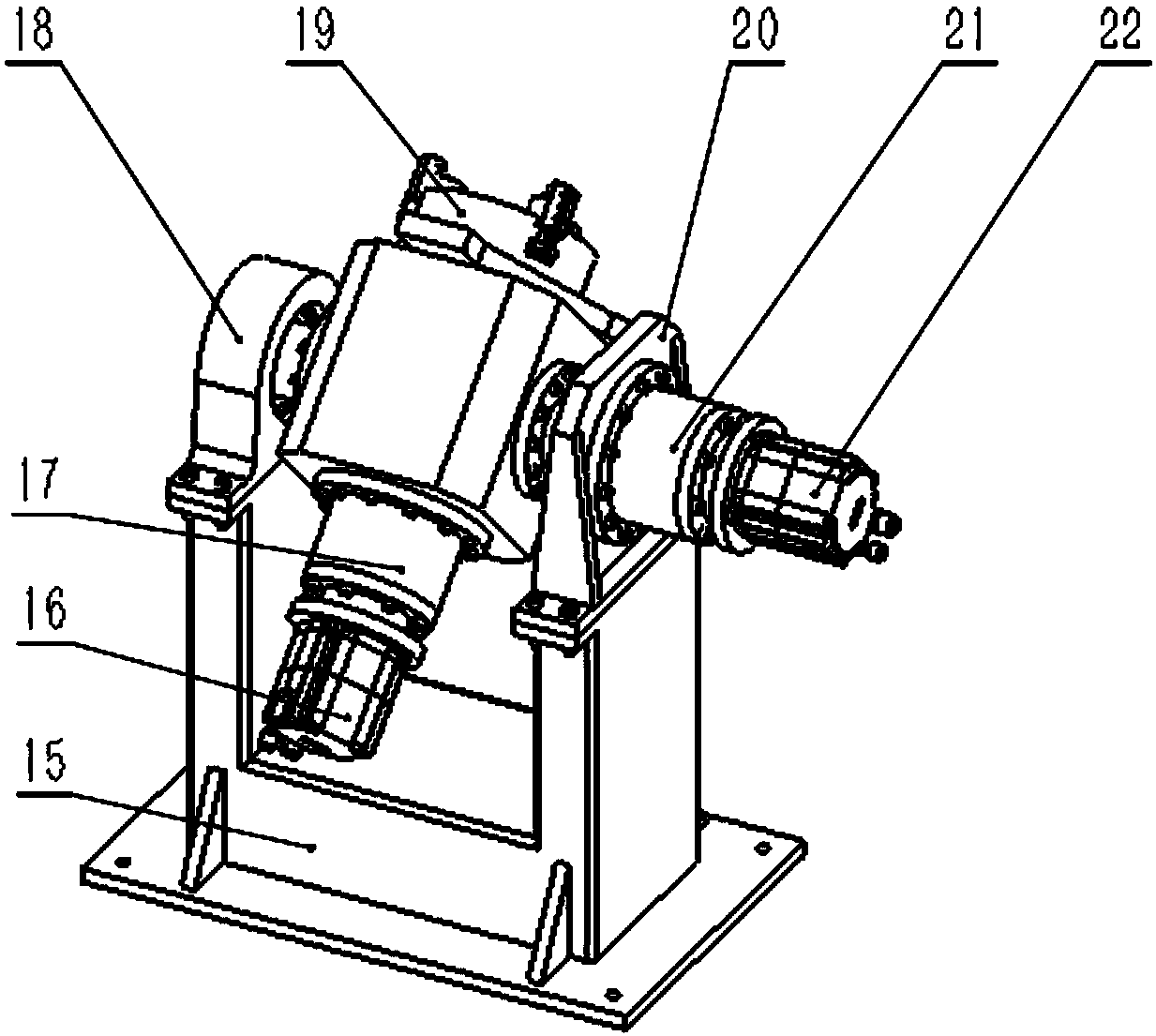

InactiveCN108593685ARealize digital radiography inspectionTo achieve effective detectionMaterial analysis by transmitting radiationElectricityDigital Ray

The invention discloses a digital ray automatic detection device, and a detection method thereof. The digital ray automatic detection device comprises a control system; the control system is connectedwith an execution system through electric connection; the execution system comprises a workpiece clamping device; the control system comprises a central controller; the central controller is connected with a mobile controller through electric connection; the mobile controller is provided with a contact switch; the mobile controller is connected with the workpiece clamping device through electricconnection; the mobile controller is used for controlling alternative loading and unloading of a plurality of workpieces to be tested by the workpiece clamping device; the mobile controller is used for controlling adjusting of the transillumination attitudes of workpieces to be tested by the workpiece clamping device. Detection process automation is achieved; detection efficiency is increased; when the workpiece clamping device is used for loading, in transillumination, the workpieces to be testes are ensured to be at the same transillumination attitude, workpiece transillumination consistencyis improved; the workpiece clamping device is used for adjusting the transillumination attitude of the workpieces to be tested, so that multi transillumination angle or heterogeneous structure detection requirements of the workpieces to be tested are satisfied; the detection cover range of the workpieces to be tested is widened; and transillumination blind area is reduced.

Owner:BAIMTEC MATERIAL CO LTD +1

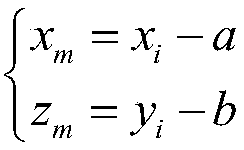

Gas turbine blade defect three-dimensional space positioning method based on digital rays

ActiveCN108072674AMake up for deficienciesRealization of 3D space positioningMaterial analysis by transmitting radiationDigital RaySpatial positioning

The invention discloses a gas turbine blade defect three-dimensional space positioning method based on digital rays. A machine coordinate system, an image coordinate system and a workpiece coordinatesystem of a system are established separately; the machine coordinate system determines transformation relations between the machine coordinate system and the image coordinate system and between the machine coordinate system and the workpiece coordinate system through Cartesian coordinate system expression to achieve unification of the coordinate systems; by conducting transillumination on bladesat two different angles, two-dimensional projection detection images of the blades and other defect features are obtained, and three-dimensional space positioning of the defects relative to the bladesis achieved by analyzing the defect features, the position relation of the project, on an imaging plane, of the rotation center line of a rotary table and the change rule of the defect features alongwith the transillumination angles. The method is simple in step, three-dimensional space positioning of all the defects of a certain type of blades can be achieved through one-time coordinate systemestablishment and unification, the detection efficiency is effectively improved, and the detection cost is reduced.

Owner:XI AN JIAOTONG UNIV

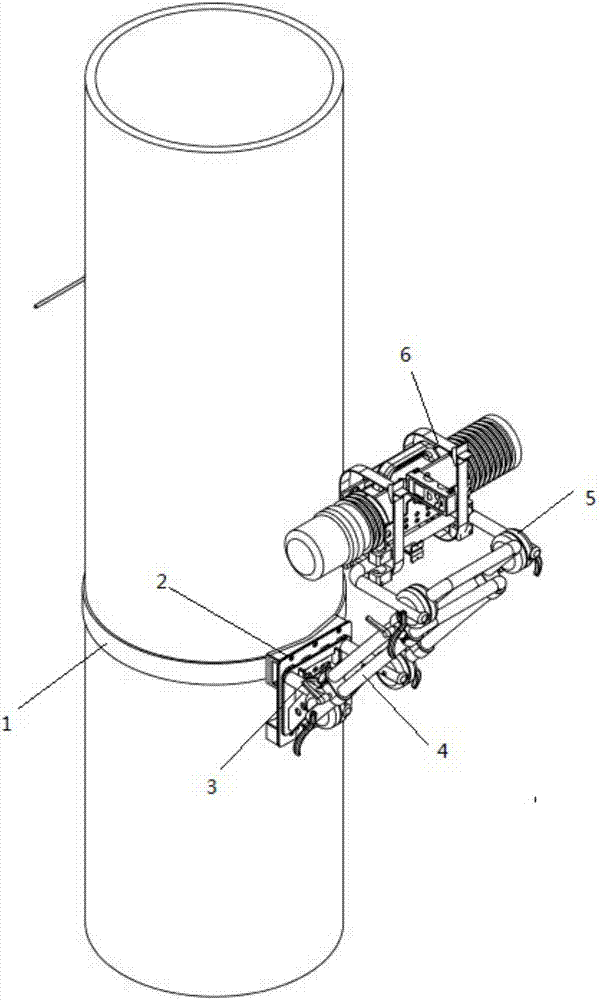

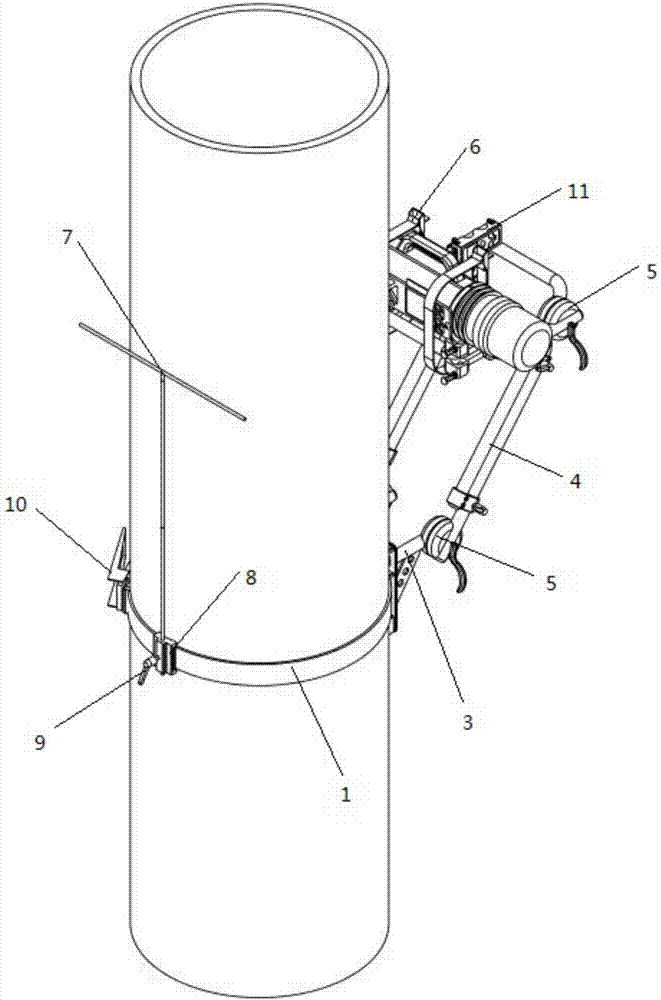

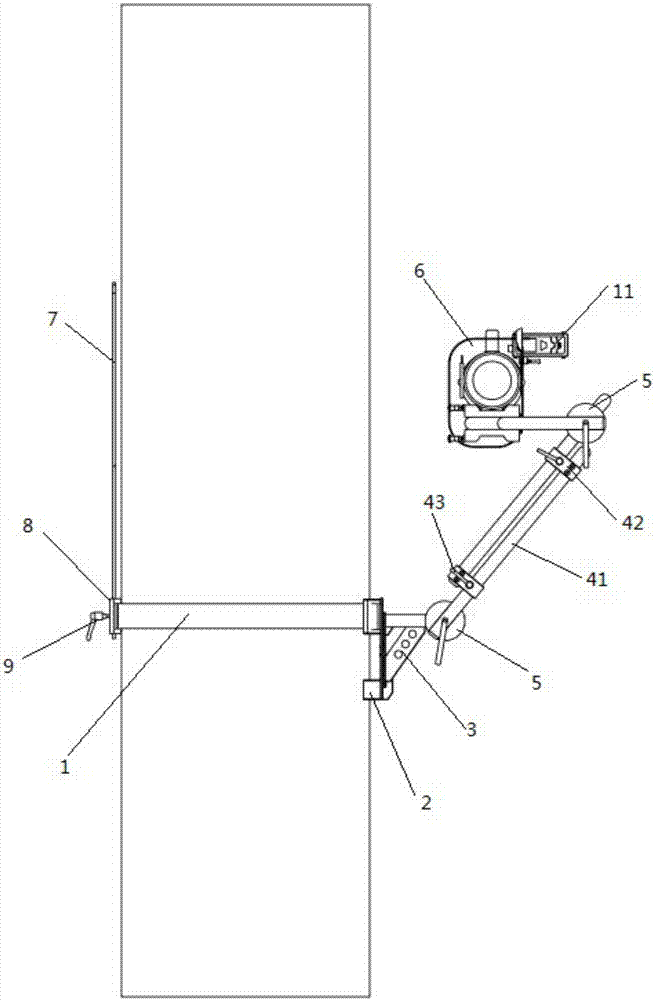

Digital ray detection bracket system supported by GIS cylinder

ActiveCN107367517AThe overall structure is simple and reliableAdjustable focal lengthMeasurement apparatus componentsMaterial analysis by transmitting radiationHoopingDigital Ray

The present invention discloses a digital ray detection bracket system supported by a GIS cylinder. The digital ray detection bracket system comprises a hooping belt around a GIS cylinder, wherein one surface of the hooping belt is provided with a dark bag bracket mechanism capable of being adjusted up and down along the axial direction of the GIS cylinder, the dark bag bracket mechanism is used for installing a CR dark bag, the other opposite surface of the hooping belt is provided with a pad block contacting the surface of the GIS cylinder, the pad block is connected to a support frame, the support frame is connected to a stretching rod through an angle adjustment mechanism, and the stretching rod is connected to a frame type rack for placing a ray machine. According to the present invention, through the ingenious combination of various parts, the ray detection bracket system with characteristics of convenient installation, simple operation, small occupation space, ray machine focal distance adjusting, stability, reliability, no shaking and strong applicability is designed, and is especially suitable for the ray detection of the GIS cylinder.

Owner:AMET WELDING AUTOMATION TECH BEIJING

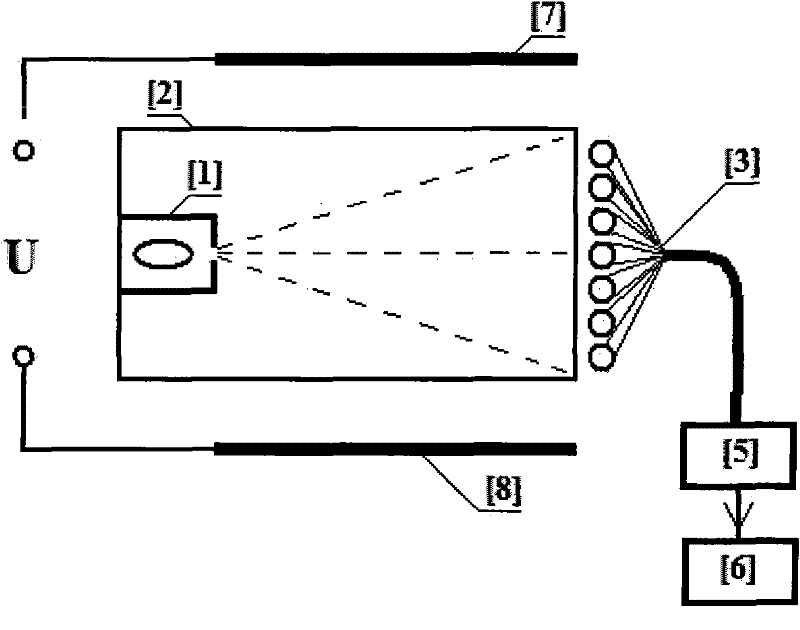

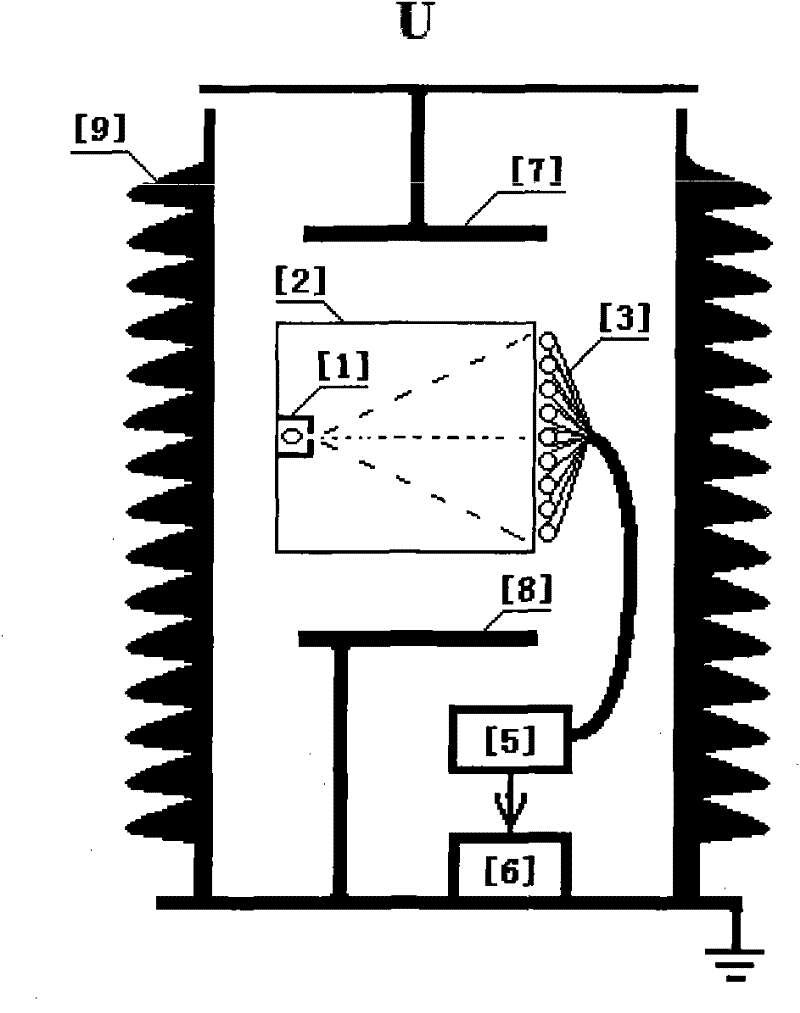

Digital ray imaging voltage sensor

InactiveCN102128974AVoltage/current isolationMeasurement using digital techniquesDigital RayElectric power system

The invention relates to a digital ray imaging voltage sensor based on the principle and the ray imaging technique of the electric field force (voltage) upon the charged particles. A vacuum glass is arranged between voltage polar plates; an isotope ray source positioned in the vacuum glass emits an alpha or beta charged particles to bombard scintillation optical fibers to flash; the scintillation optical fibers are uniformly and horizontally arranged from up to down and from left to right, wherein the upper end of the scintillation optical fibers is fixedly provided with a reflecting film for reflecting photons; the lower end is connected with an image intensifier. The photons emitted by the scintillation optical fibers are transmitted to the image intensifier for amplifying through the same optical fiber, and then are subjected with signal processing photo through the image sensor. The voltage to be measured is connected with the voltage polar plate; and the driving force of the electric field force between the polar plates upon the charged particles can change the moving track of the particles. When bombarding the scintillation optical fibers at different positions, the corresponding lighting positions can be changed; the changing amount is in proportion to the amplitude of the electric field force (voltage); and the change of the lighting position is detected by adopting a digital image processing method to obtain the real time digital voltage signal. The measuring method of the invention is linear, high in level without power, so the method is suitable for the measurement of the alternating and direct current voltage of a power system.

Owner:FUZHOU UNIV

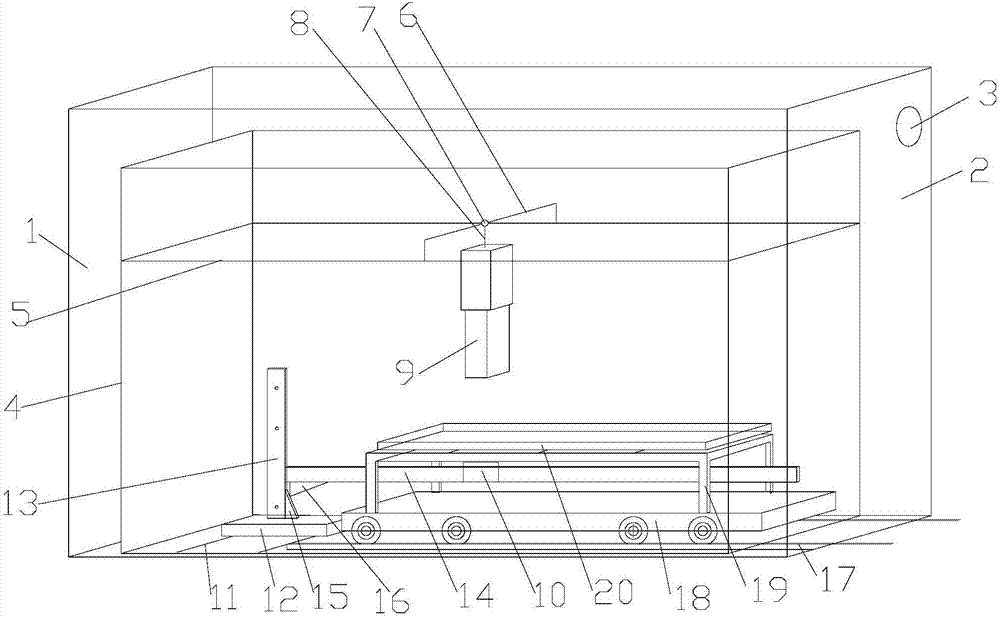

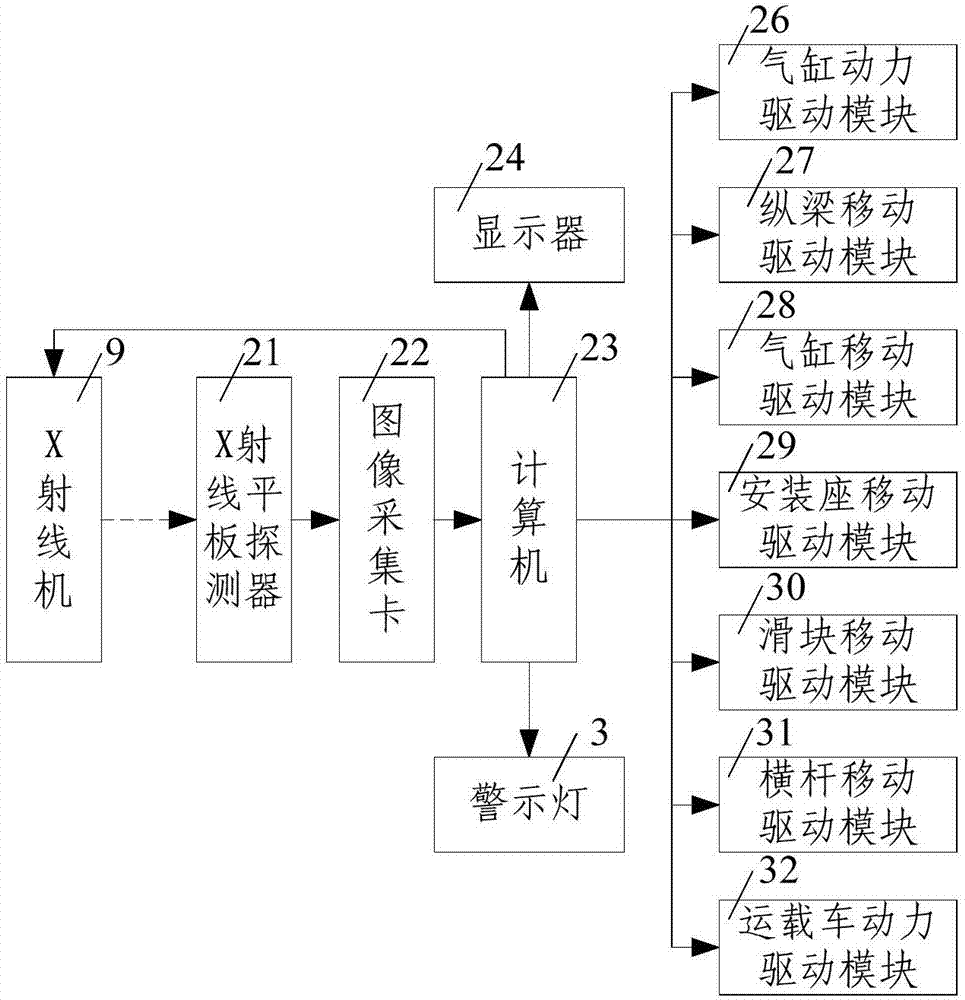

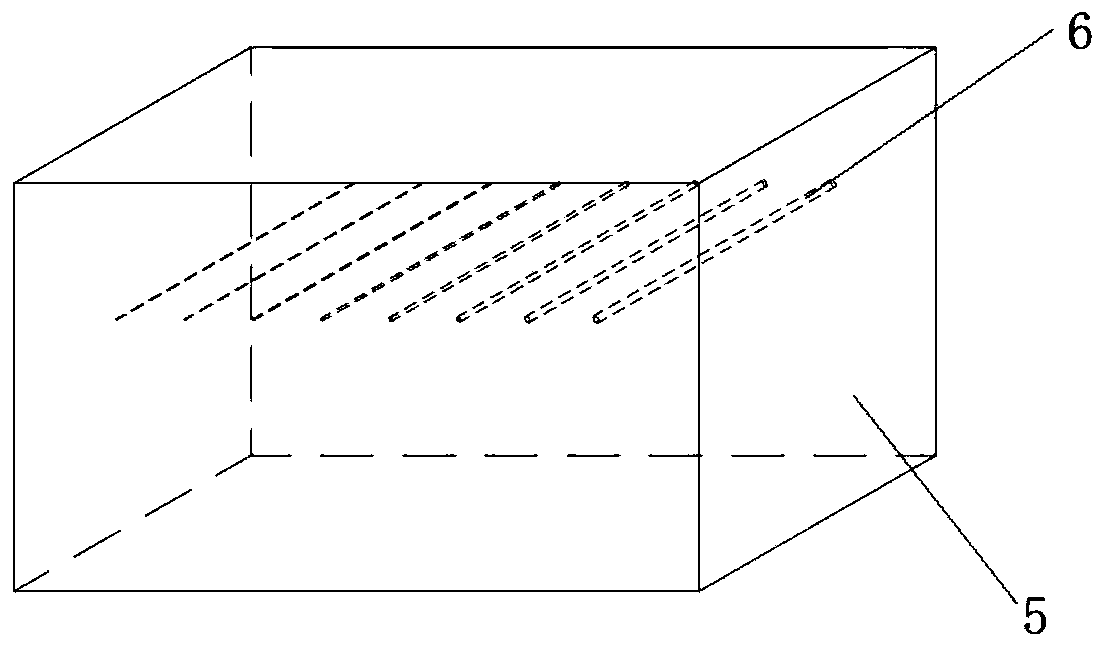

Digital-ray-direct-imaging interface morphology detection system for composite material and method

InactiveCN106959310ARealize detectionEasy to useMaterial analysis by transmitting radiationDigital RayFlat panel detector

The invention discloses a digital-ray-direct-imaging interface morphology detection system for a composite material and a method. The system comprises a detection chamber, a direct imaging device, cross rails and a processor, wherein the cross rails extend into an imaging area and are used for moving carrier loaders, and the processor is used for controlling the direct imaging device to automatically complete image acquisition and carrying out image processing on acquired images. The method comprises the steps: (1) mounting a composite plate, and feeding the composite plate to the imaging area; (2) determining a relative distance of an X-ray machine and an X-ray flat panel detector; (3) adjusting projection superposition of the X-ray flat panel detector and a ray radiation window of the X-ray machine; (4) controlling the X-ray machine and the X-ray flat panel detector to move synchronously, and carrying out digital-ray-direct-imaging detection on an interface of the composite plate; (5) carrying out image processing, and viewing corrugated morphology of an interface bonded area of the composite plate. According to the system and the method, digital-ray images of the interface of the composite plate can be acquired rapidly, clearly and visually, and corrugated morphologies of weak bonded areas of the interface of the composite plate are rapidly discriminated.

Owner:XIAN TIANLI CLAD METAL MATERIALS

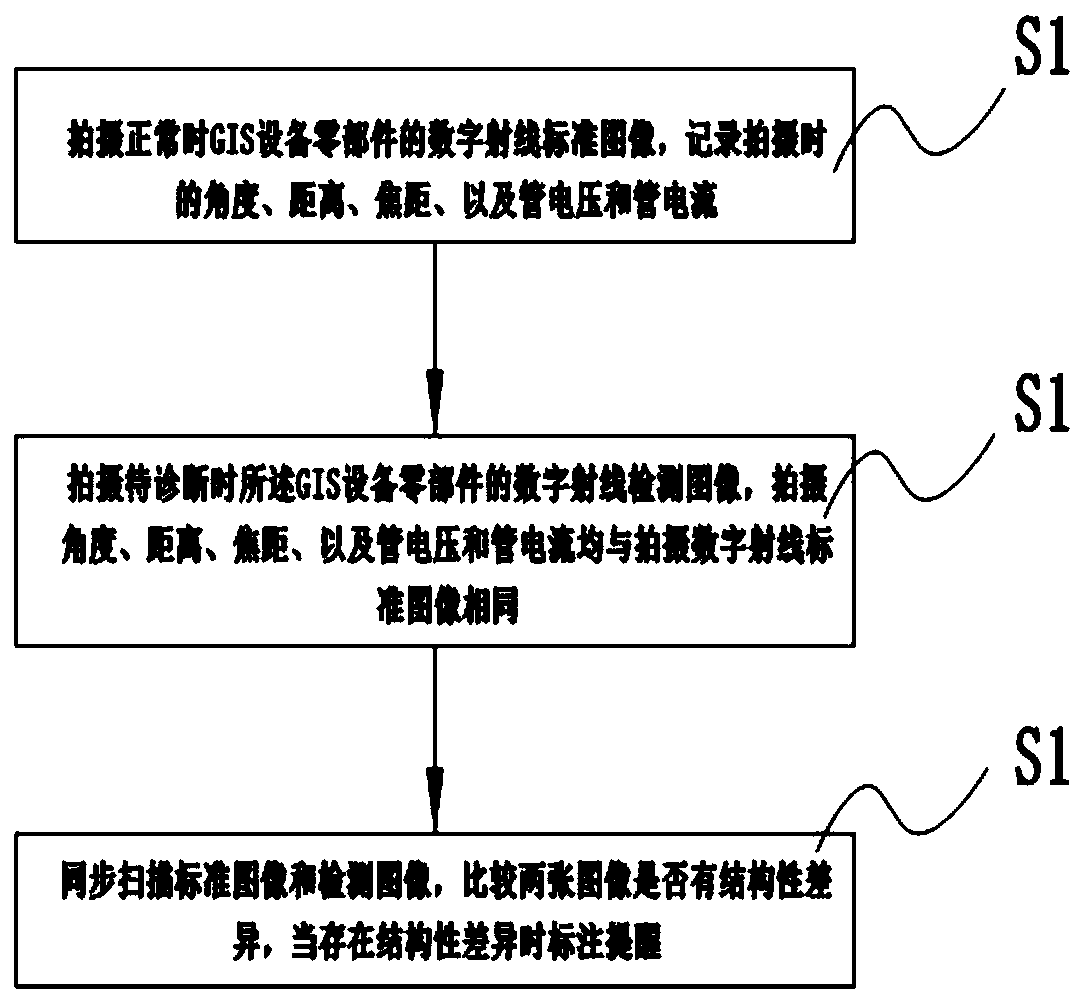

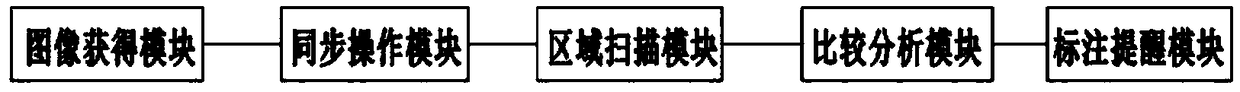

Method and device for intelligently diagnosing image through fixed-point, fixed-focus and fixed-parameter detection of GIS equipment through digital rays

InactiveCN109490337AEasy to operateAccurate comparisonMaterial analysis by transmitting radiationDigital RayComputer vision

The invention discloses a method and device for intelligently diagnosing an image through fixed-point, fixed-focus and fixed-parameter detection of GIS equipment through digital rays. The method comprises the following steps: (S1) photographing a digital ray standard image of a part of the GIS equipment in a normal state, and recording the angle, the distance, the focal length, the pipe voltage and the pipe current during the photographing; (S2) photographing s digital ray detection image of the part of the GIS equipment in a to-be-diagnosed state, wherein the photographing angle, distance, focal length, pipe voltage and pipe current are same as the photographing angle, distance, focal length, pipe voltage and pipe current of the digital ray standard image; and (S3) synchronously scanningthe standard image and the detection image, determining whether the two images have structural differences through comparison, and if yes, marking for warning. According to the method, the standard image and detection image of the part of the GIS equipment are photographed in fixed-point, fixed-focus and fixed-parameter manners and are subjected to synchronous correlation, scanning and contrastiveanalysis, so that compared with an existing manual diagnostic method, the method has the advantages of convenience in operation, precision in comparison and high detection efficiency.

Owner:GUIZHOU POWER GRID CO LTD

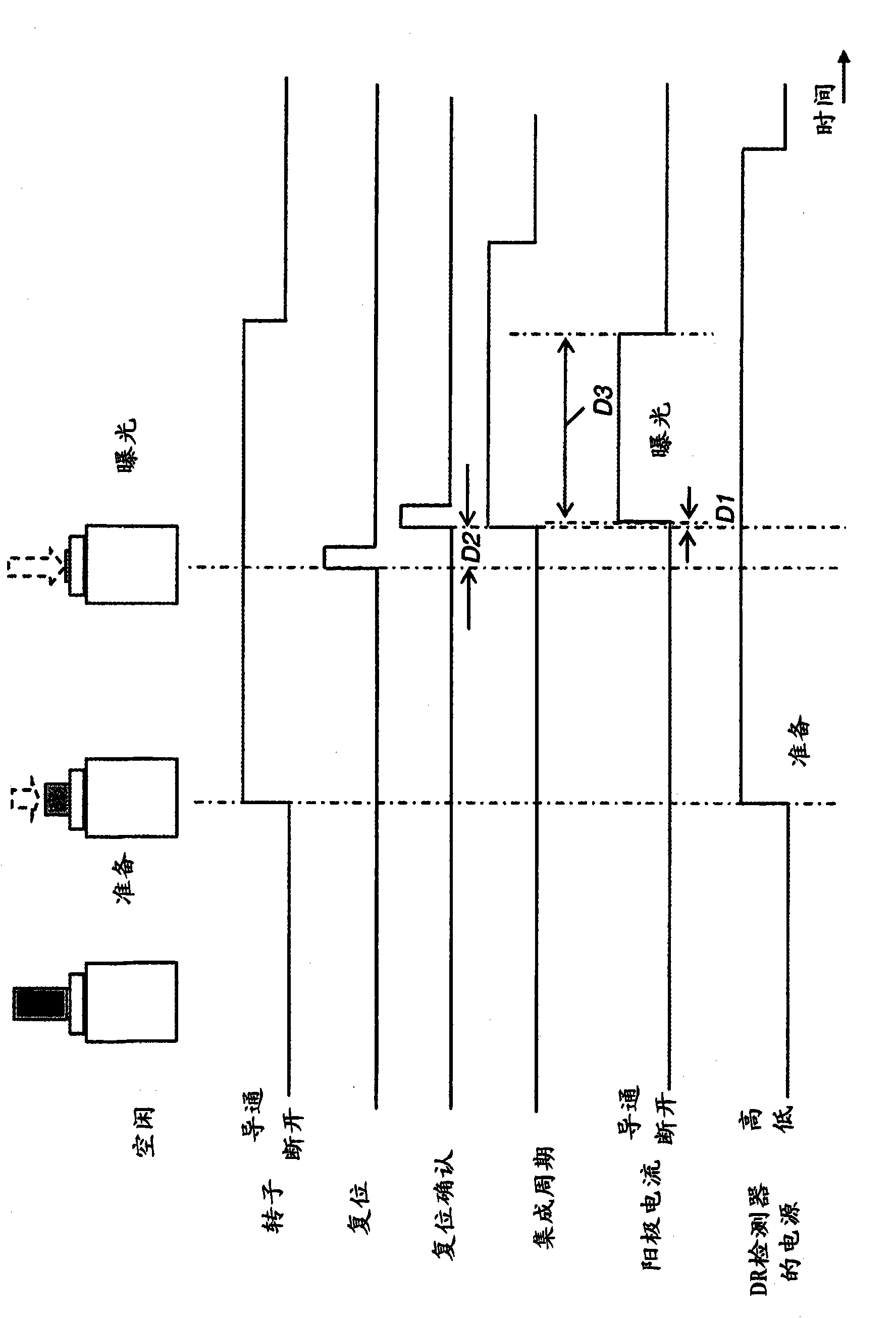

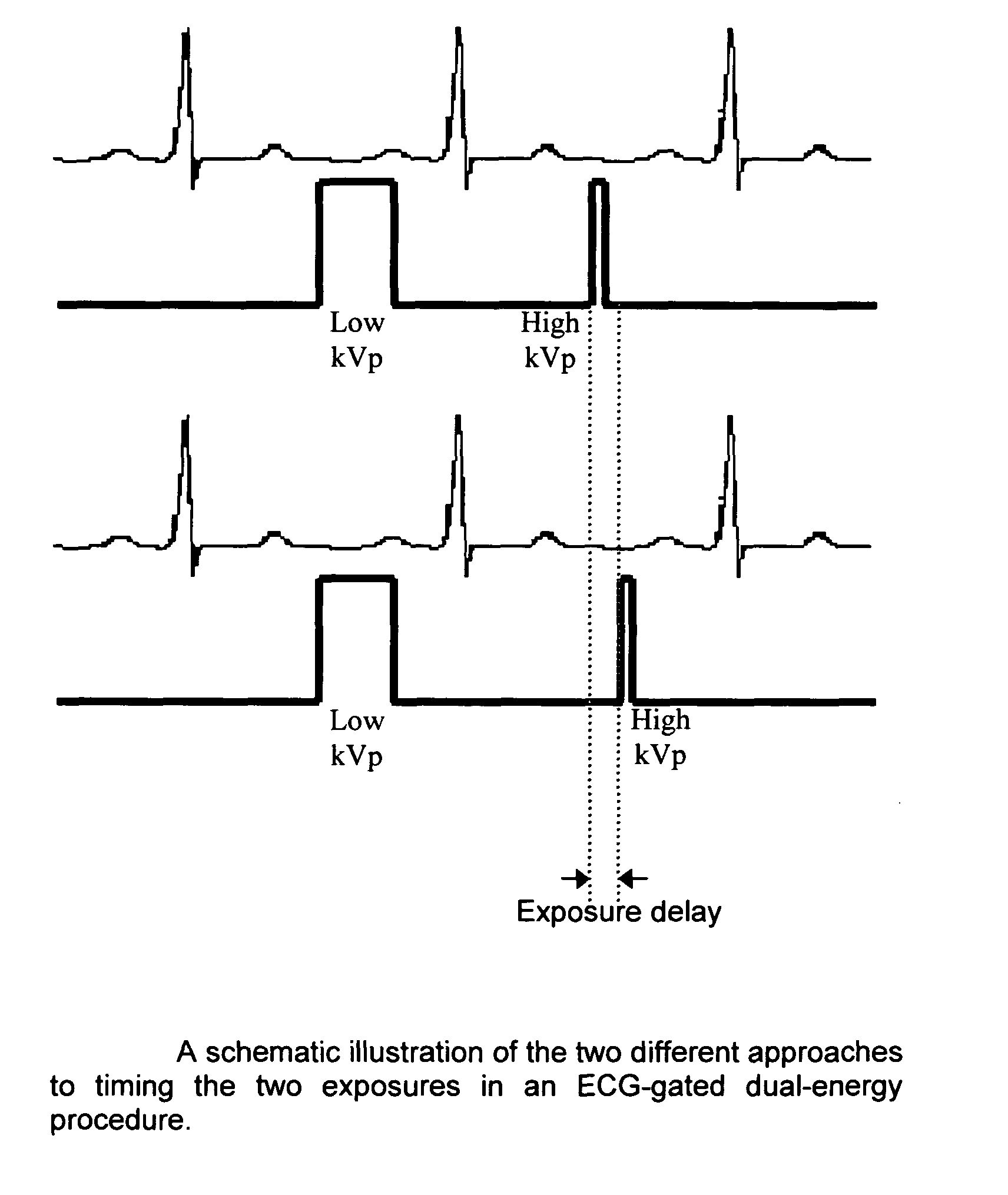

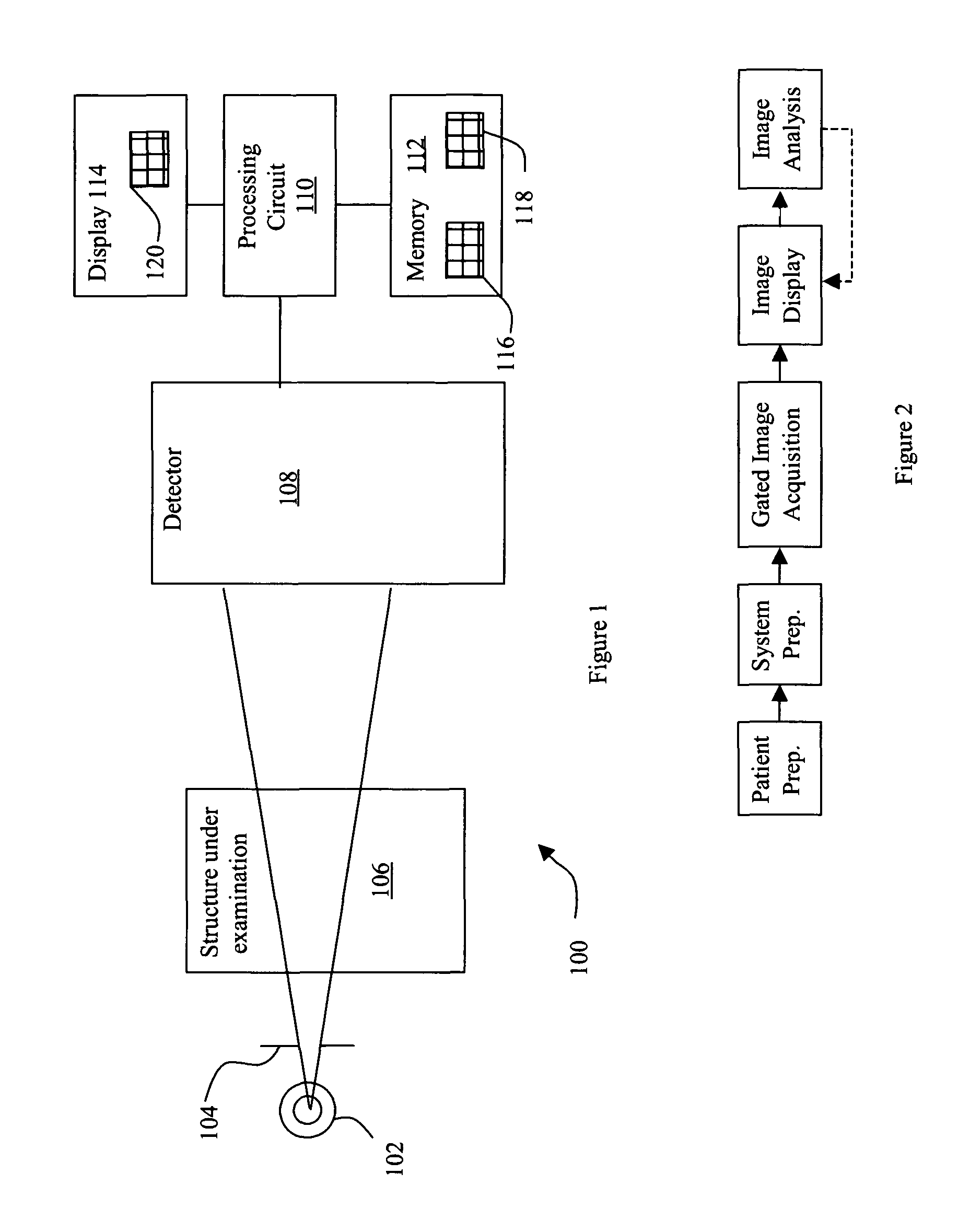

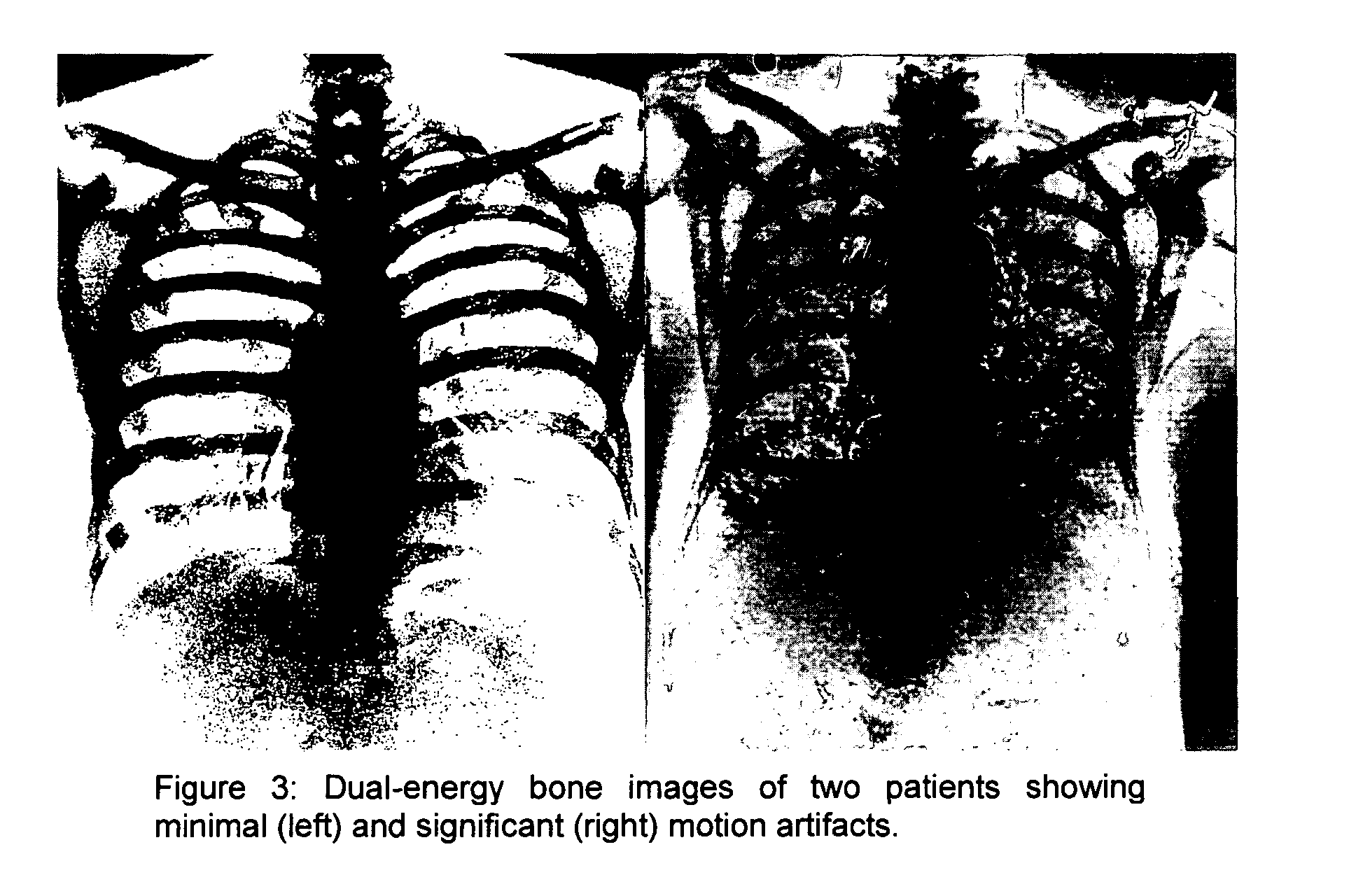

Methods and apparatus for gated acquisitions in digital radiography

ActiveUS8761864B2Material analysis using wave/particle radiationElectrocardiographyDigital RayDigital radiography

A method includes automatically determining at least one gating signal based on a physiological signal from a subject being imaged by an imaging system, automatically determining, based upon prior analysis and knowledge of the imaging system's capabilities, a timing of each of a plurality of exposures within a single or multiple cycles of the physiologic signal, and performing the multiple acquisitions.

Owner:GENERAL ELECTRIC CO

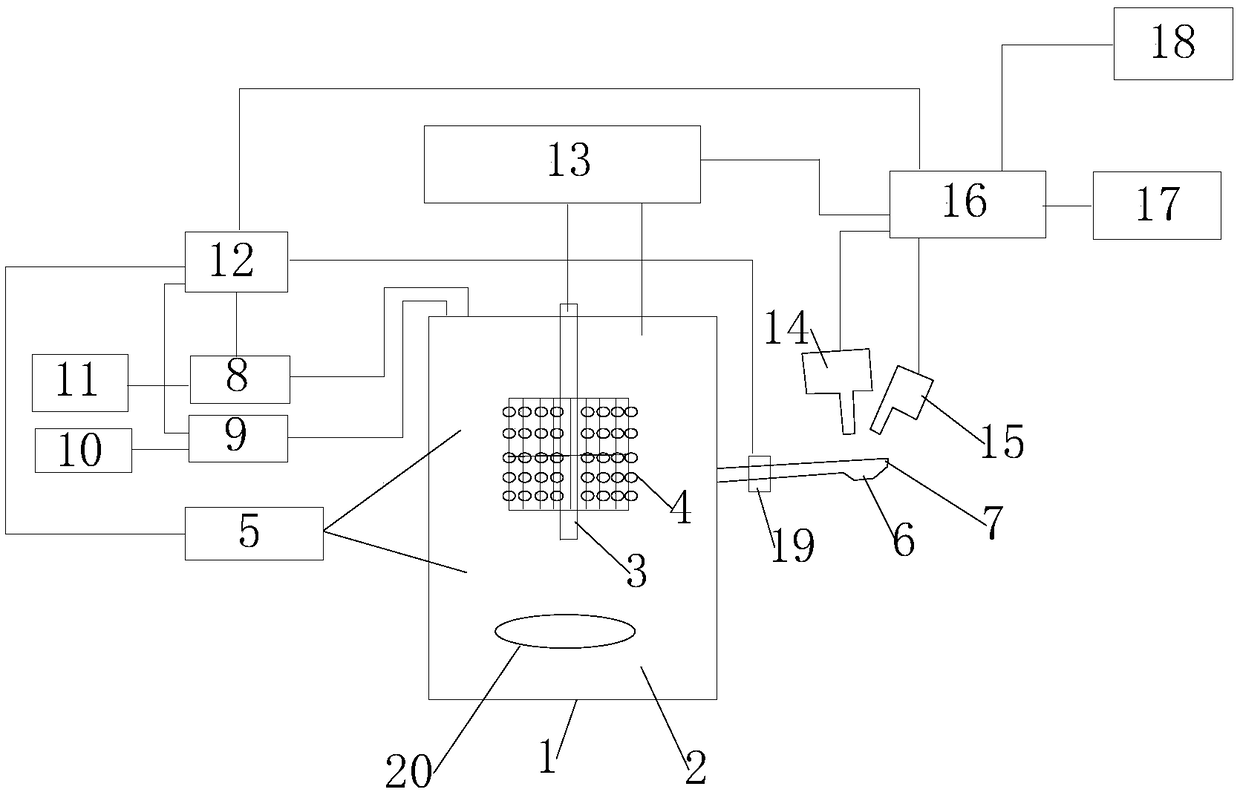

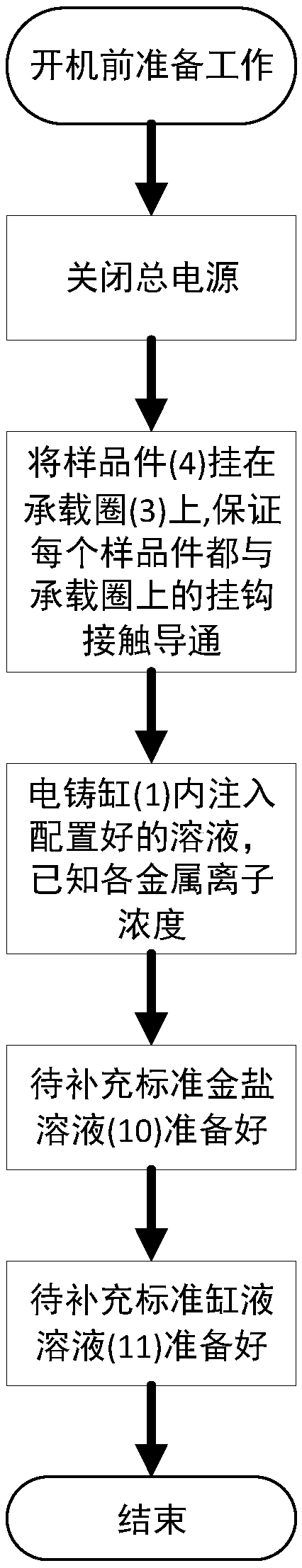

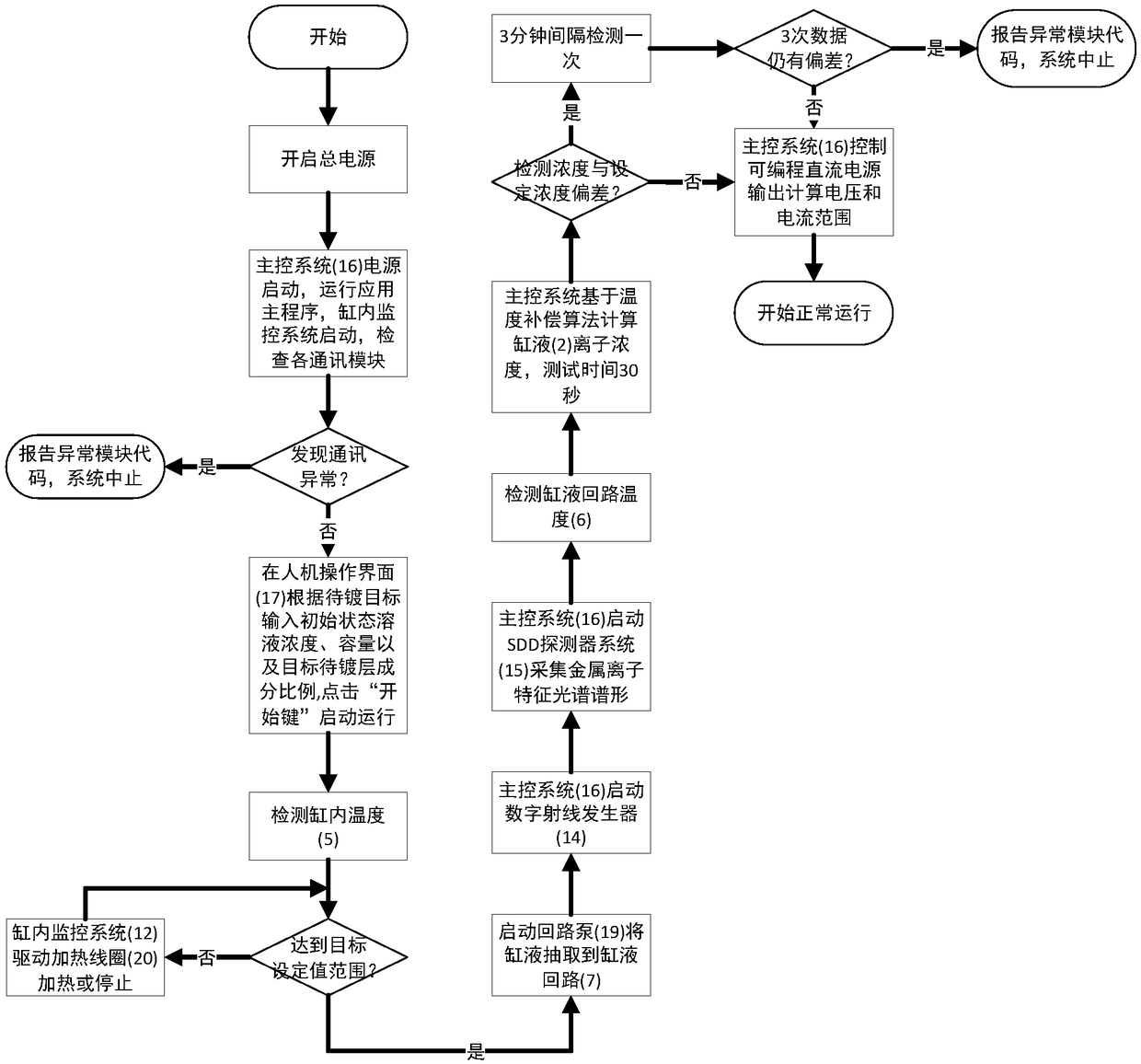

Fully-automatic control device for coating ingredients of K gold electrocasting and system

ActiveCN108827992AControl ratioImprove efficiencyMaterial analysis using wave/particle radiationControlling ratio of multiple fluid flowsDigital RayAnalysis data

The invention provides a fully-automatic control device for coating ingredients of K gold electrocasting. The fully-automatic control device comprises a charge pump, a loop pump, a digital ray generator, an SDD detector, a controller and a heating coil, wherein the controller controls the digital ray generator to generate soft X-rays so as to irradiate a solution in the loop pump, the SDD detectoracquires an X-fluorescence characteristic spectrum generated by metal ions in the solution, and the controller acquires the count strength of various metal ions in the solution according to the X-fluorescence characteristic spectrum and then performs quantitative calculation on the basis of a matrix corrected polynomial fitting algorithm and a solution temperature compensation algorithm so as toobtain final ion concentrations; a set of experience curves is established on the basis of variation parameters of all metal ion concentrations in the solution, ingredient analysis data of measured sample coatings and different electroplating voltages and temperatures, then, the controller controls and adjusts the work of the charge pump and the heating coil on the basis of the available experience curves and current data during system operation so as to control ion concentration in a cylinder solution and a cylinder interior temperature, and thus, the alloy proportion of the coatings is controlled. According to the device the efficiency and quality control of online production of K gold electrocasting can be greatly improved.

Owner:SHENZHEN CFANJD TECH CO LTD

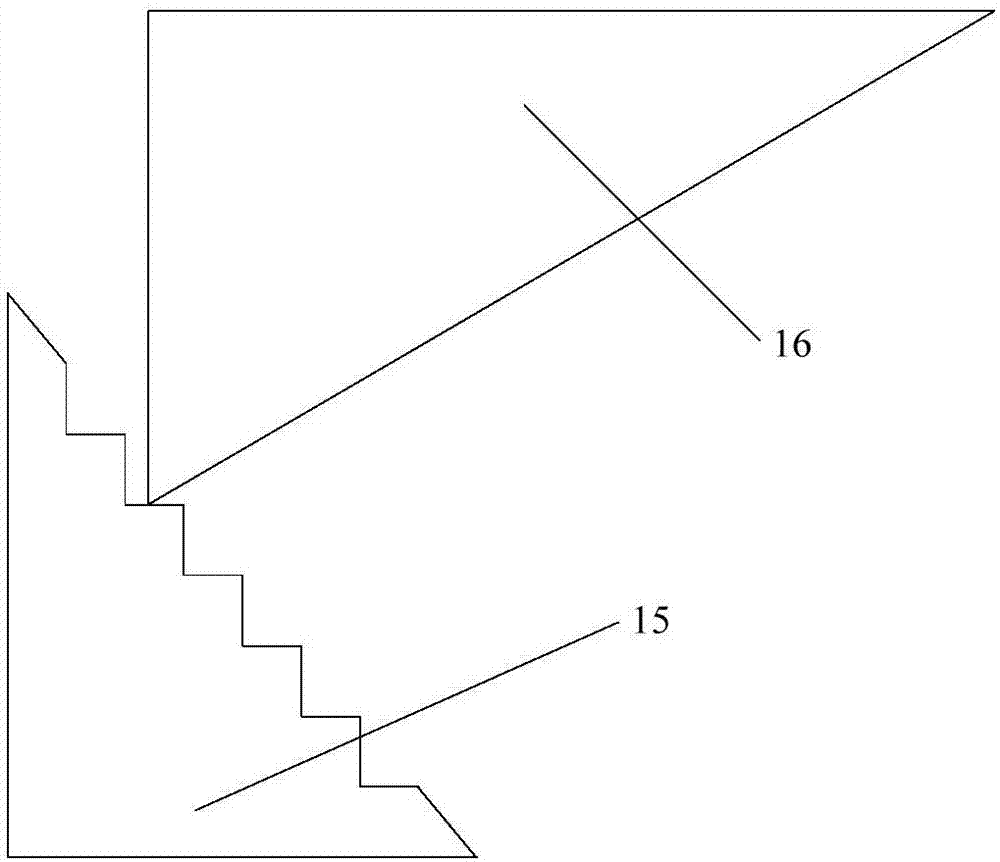

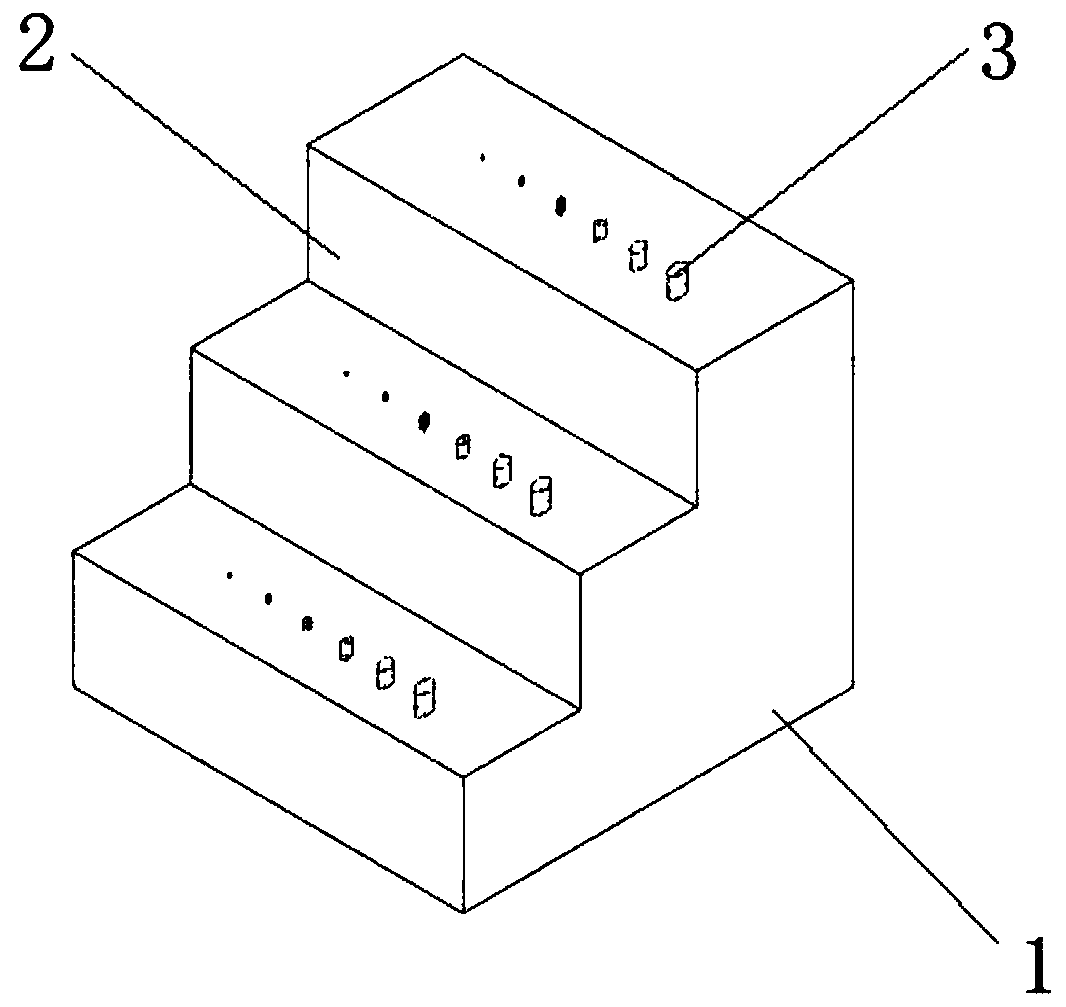

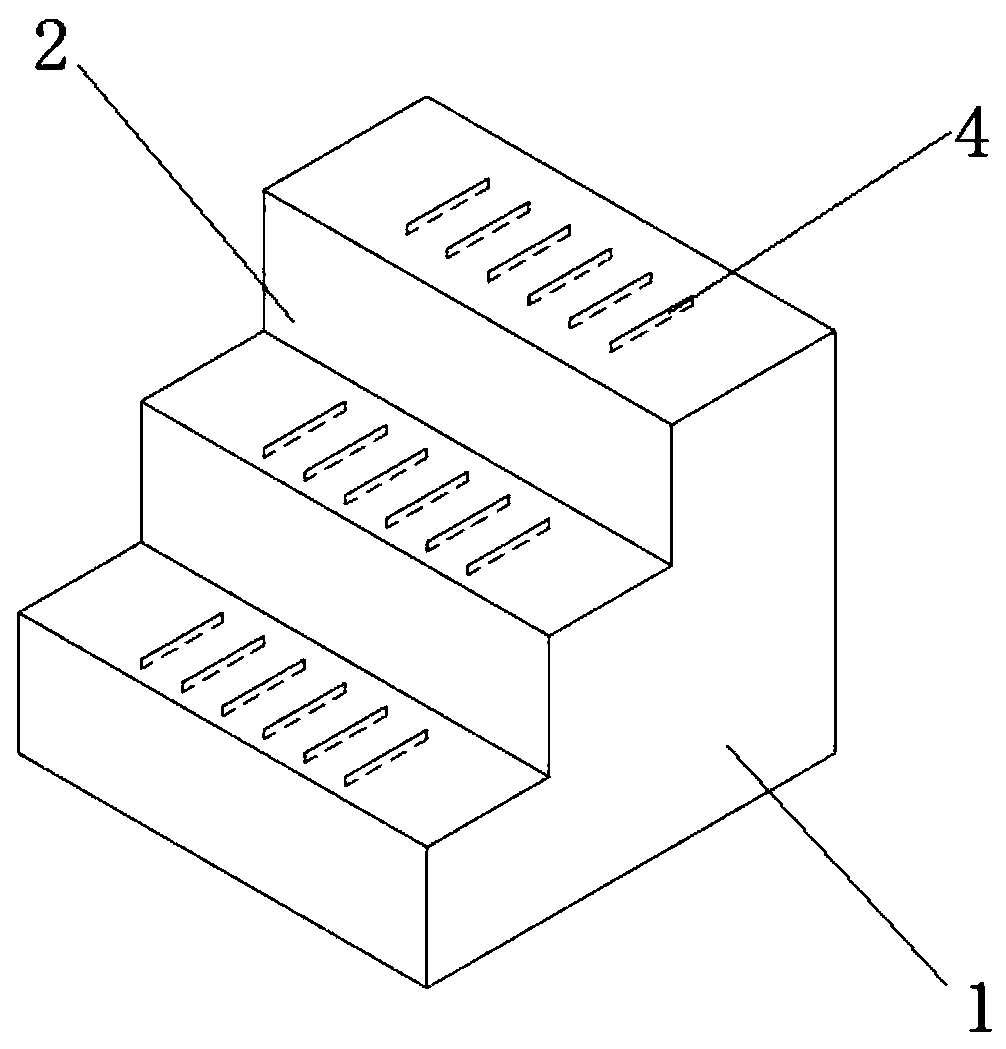

Basin-type insulator digital ray detection test block and detection method

InactiveCN109855938ASimple structureIngenious designPreparing sample for investigationMaterial analysis by transmitting radiationEpoxyDigital Ray

The application relates to a basin-type insulator digital ray detection test block and a detection method. The basin-type insulator digital ray detection test block comprises a massive main body (1) made of epoxy resin and aluminum powder, the main body is stair-stepped, the width of each step (2) of the main body is 35-45mm, and the length is 90-110mm; a plurality of concaves is arranged on eachstep of the main body, and the space between the concaves is 8-12mm. The test block disclosed by the invention has the advantages of being simple in structure and smart in design; the designed digitalray dedicated reference block can be used for formulating and evaluating the digital ray detection sensitivity of the basin-type insulator manufacturing process, the different defect types and sizescan be tested, the digital ray detection sensitivity can be evaluated, the manufacturing defect can be effectively discovered, the production process is improved, and the product safety performance isimproved.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

GIS equipment digital ray image double-screen same-area synchronous amplification diagnosis method and device

PendingCN109659027AAvoid switching,Avoid operabilityMedical automated diagnosisMedical imagesDigital RayDiagnosis methods

The invention discloses a GIS equipment digital ray image double-screen same-area synchronous amplification diagnosis method. The method comprises the steps that S1, a digital ray detection image of aGIS equipment part and a digital ray standard image of the GIS equipment part are acquired; S2, standard points in the standard image, and corresponding points are selected at the same position in the detection image; And S3, window-based synchronous display is performed on the detection image and the standard image of the GIS equipment part. synchronous association is established between the standard image and the detection image according to the selected standard point and the corresponding point, the window where the real mouse pointer is located as a target window, the corresponding position of the other window is calcuated, and the virtual mouse pointer is displayed at the position; According to the invention, the problems of inconvenient operation, asynchronous observation area andamplification factor and low detection efficiency in the existing manual diagnosis are effectively solved.

Owner:GUIZHOU POWER GRID CO LTD

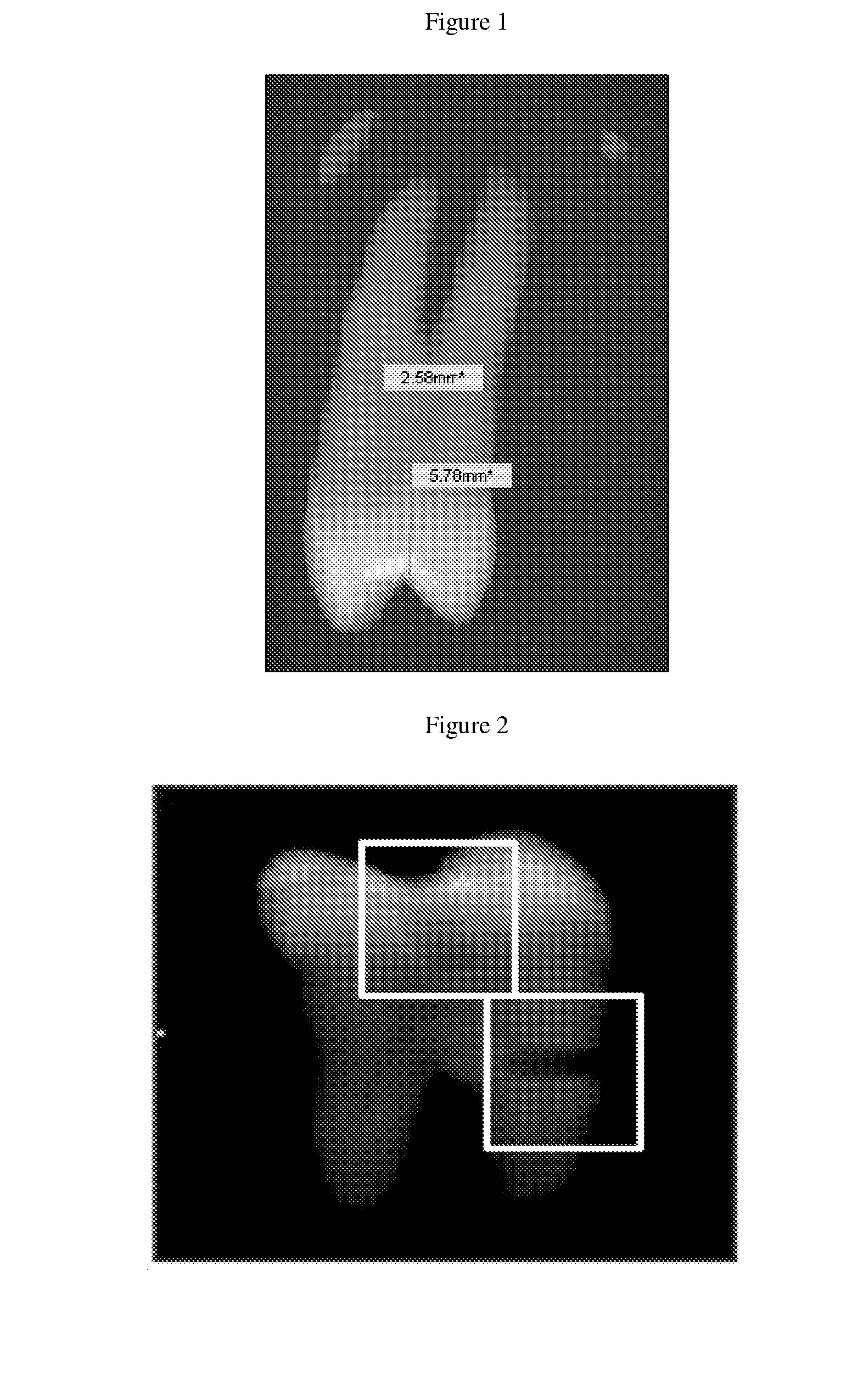

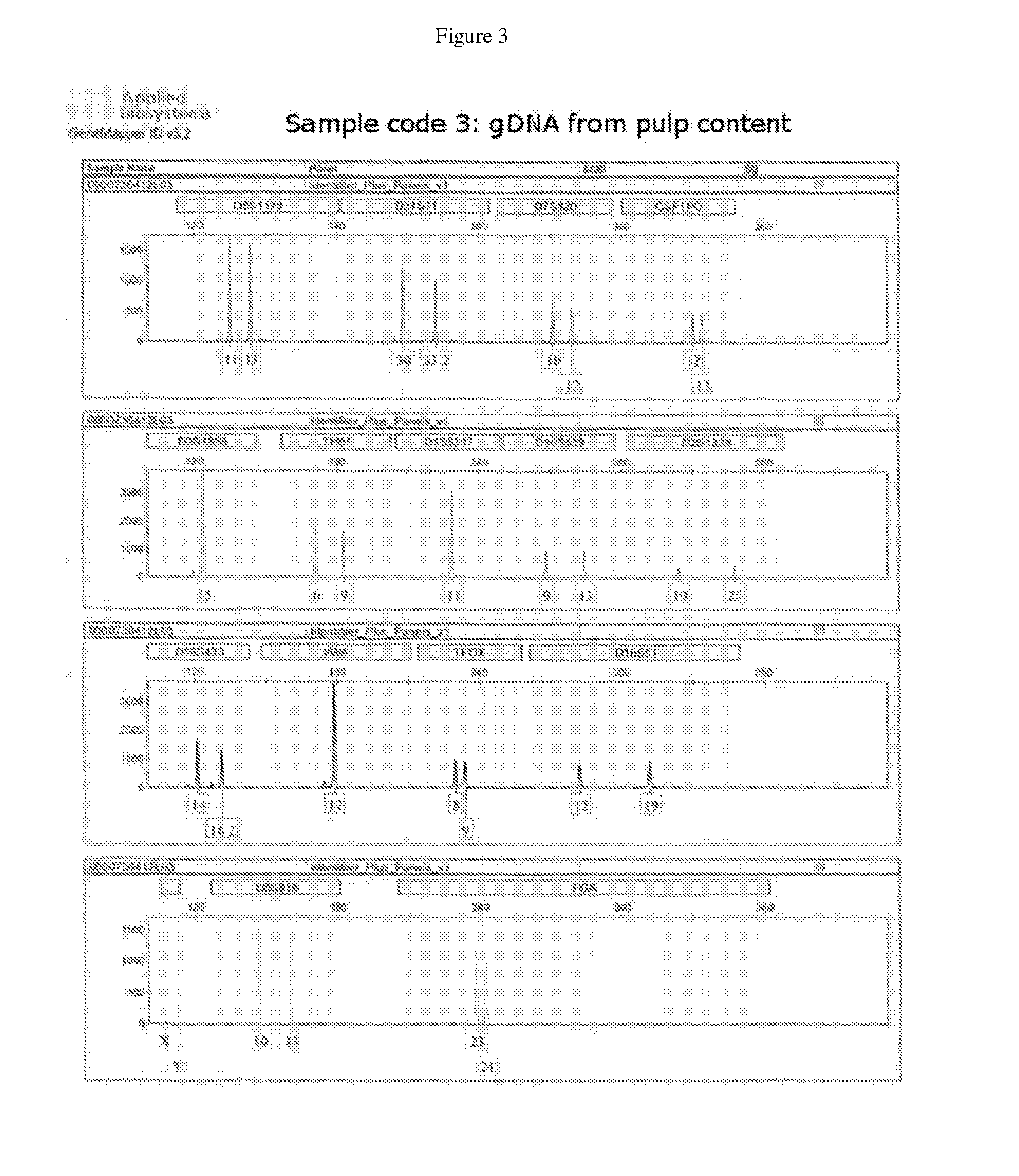

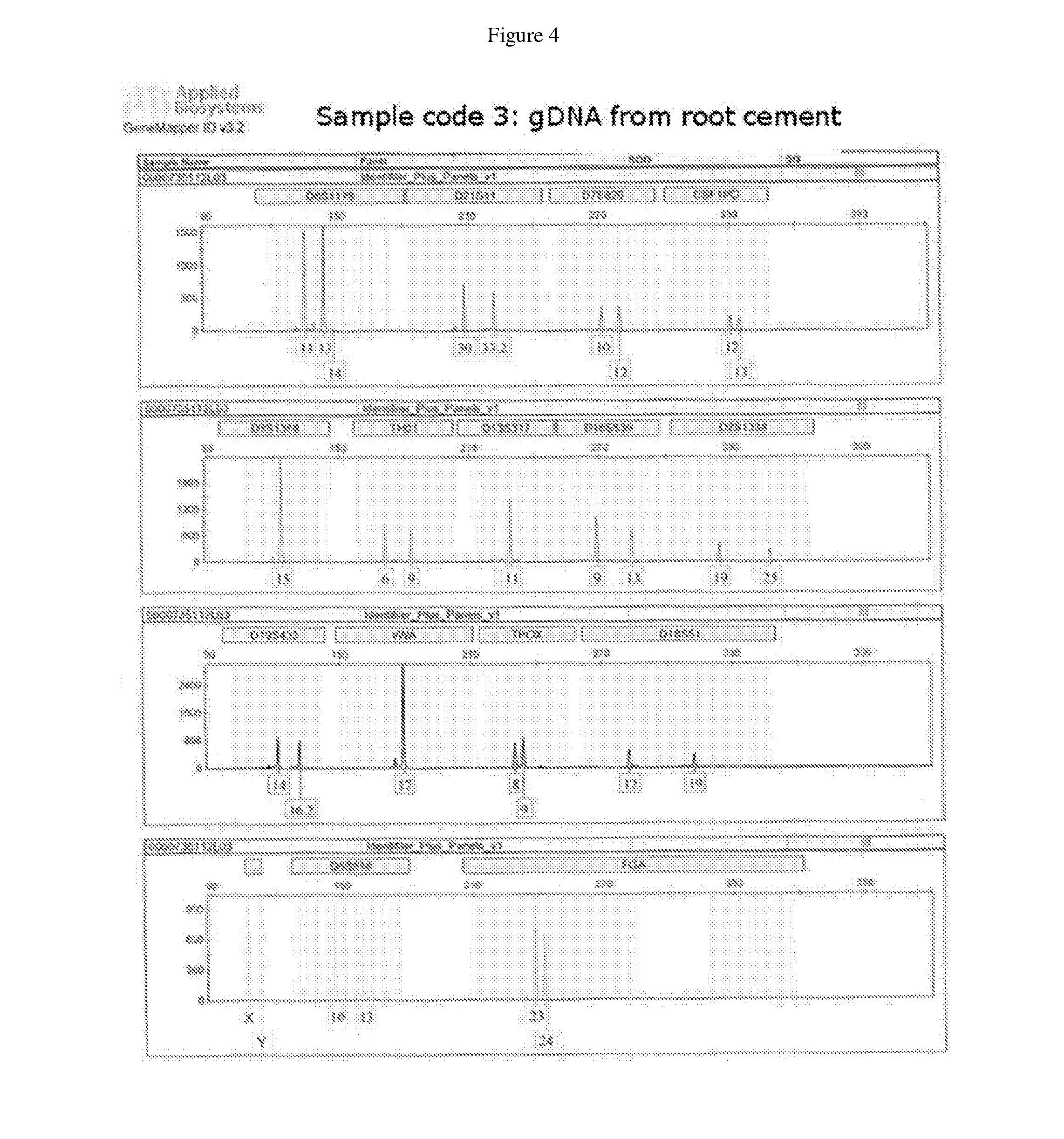

Method, systems and kit for forensic identification, post mortem interval estimation and cause of death determination by recovery of dental tissue in physiological conditions

ActiveUS20160123853A1Avoid pollutionPreserve integrityMicrobiological testing/measurementWithdrawing sample devicesForensic dentistryDentin

The present invention is related to a method for obtaining dental pulp and root cement in the forensic dentistry field, wherein the method comprises the steps of: (a) obtaining a tooth; (b) taking a digital radiography to the tooth; (c) external rehydrating of the tooth; (d) perforating the rehydrated tooth; (e) internal rehydrating of dentin pulp complex (f) obtaining rehydrated root cement; (g) obtaining rehydrated dental pulp content with a low speed rotation tool; and (h) storing, preservation, processing and / or analyses of the rehydrated dental pulp content and rehydrated root cement, and the use of this method and kits thereof for forensic identification, estimation of post mortem interval (early and late) and determination of possible causes of death.

Owner:UNIV DE LOS ANDES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com