Digital ray automatic detecting system and method for detecting wheel parts

A digital ray, automatic detection technology, applied in measurement devices, material analysis using radiation, material analysis using wave/particle radiation, etc., can solve the problems of reduced detection efficiency, low detection efficiency, low detection accuracy, etc. The effect of detection efficiency, reduction of detection cost, and improvement of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the patent of the present invention, the patent of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

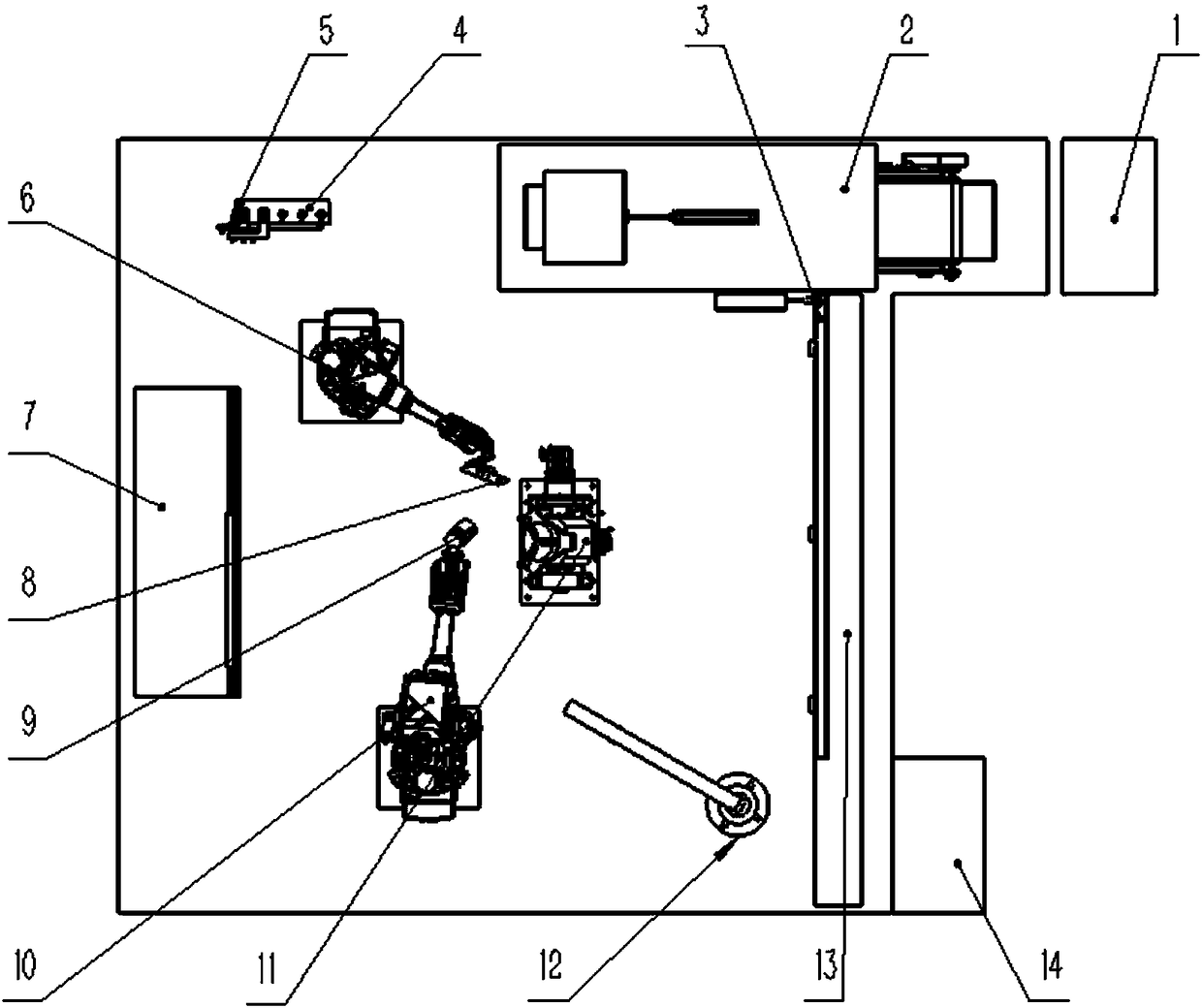

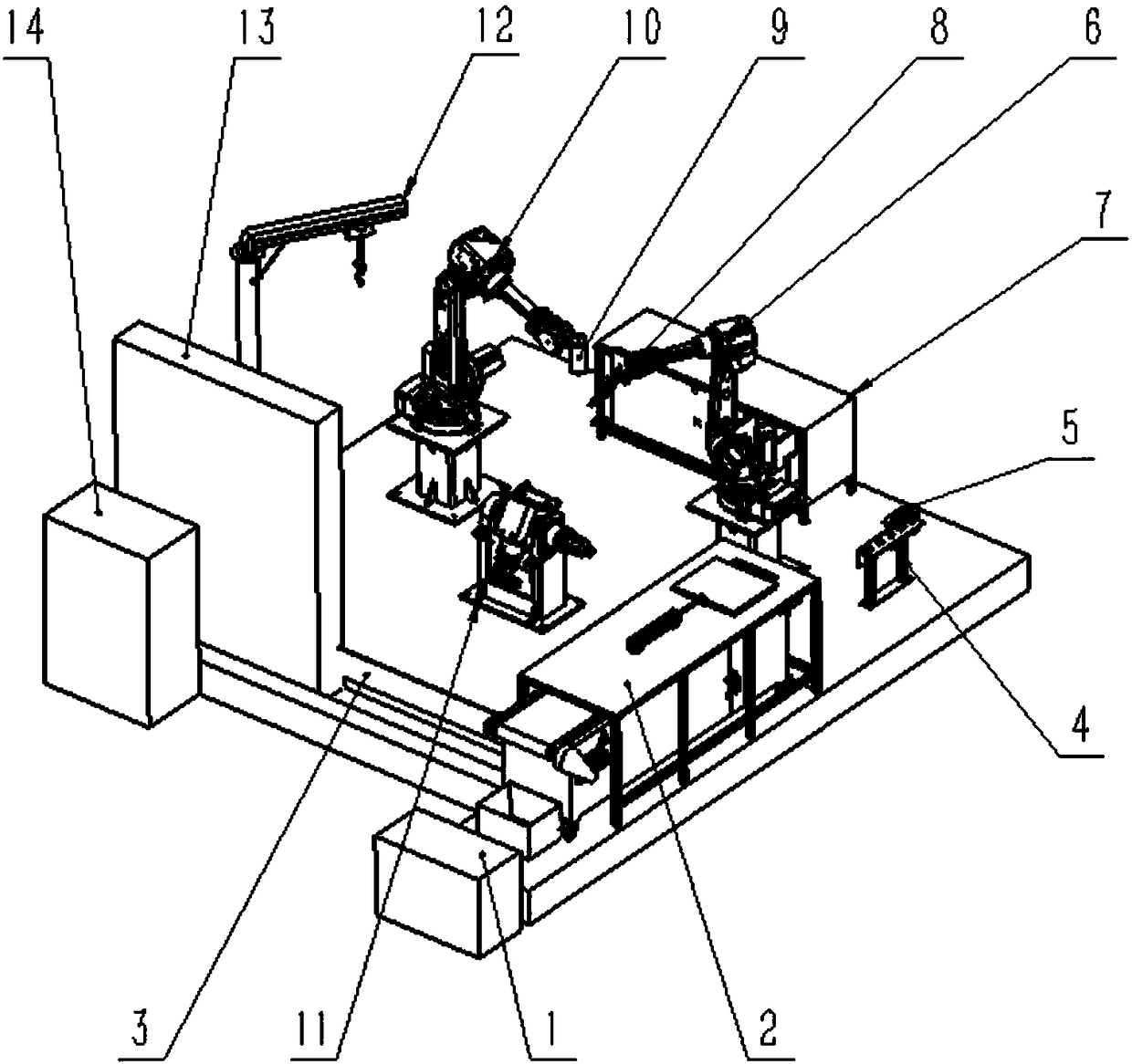

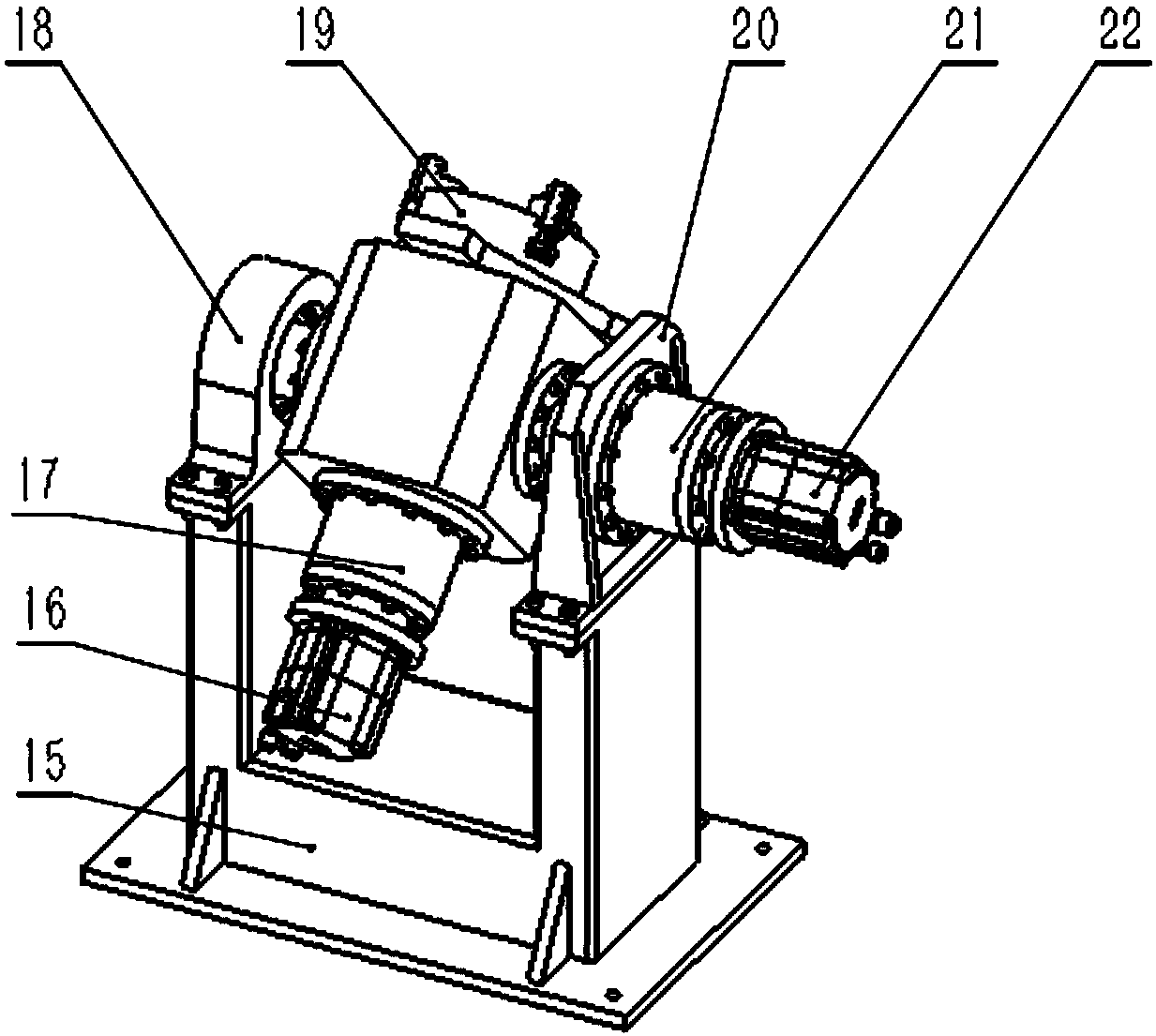

[0032] Such as figure 1 figure 2 As shown, a digital ray automatic detection system for detecting wheel parts includes: a PLC console 14 and a CR imaging device 1 arranged outside the protective lead room; a large robot 10, a small robot 6, and an IP Plate 8, X-ray machine 9, quick-change grip frame 4, quick-change grip 5, storage cabinet 7, transmission device 2, rotary table 11, door slot cover plate 3, small cantilever crane 12, automatic jaw 13. The model of the large robot 10 is the IRB4600 series of ABB Company, the model of the small robot 6 is the IRB2600 series of the ABB Company, and the small cantilever crane 12 is a 12V complete set of 500 kg produced by Lestar. The quick-change grippers are all produced by ATI Company, and the models are not limited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com