Patents

Literature

135 results about "PROFINET" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Profinet (usually styled as PROFINET, as a portmanteau for Process Field Net) is an industry technical standard for data communication over Industrial Ethernet, designed for collecting data from, and controlling equipment in industrial systems, with a particular strength in delivering data under tight time constraints (on the order of 1ms or less). The standard is maintained and supported by PROFIBUS & PROFINET International (PI) , an umbrella organization headquartered in Karlsruhe, Germany.

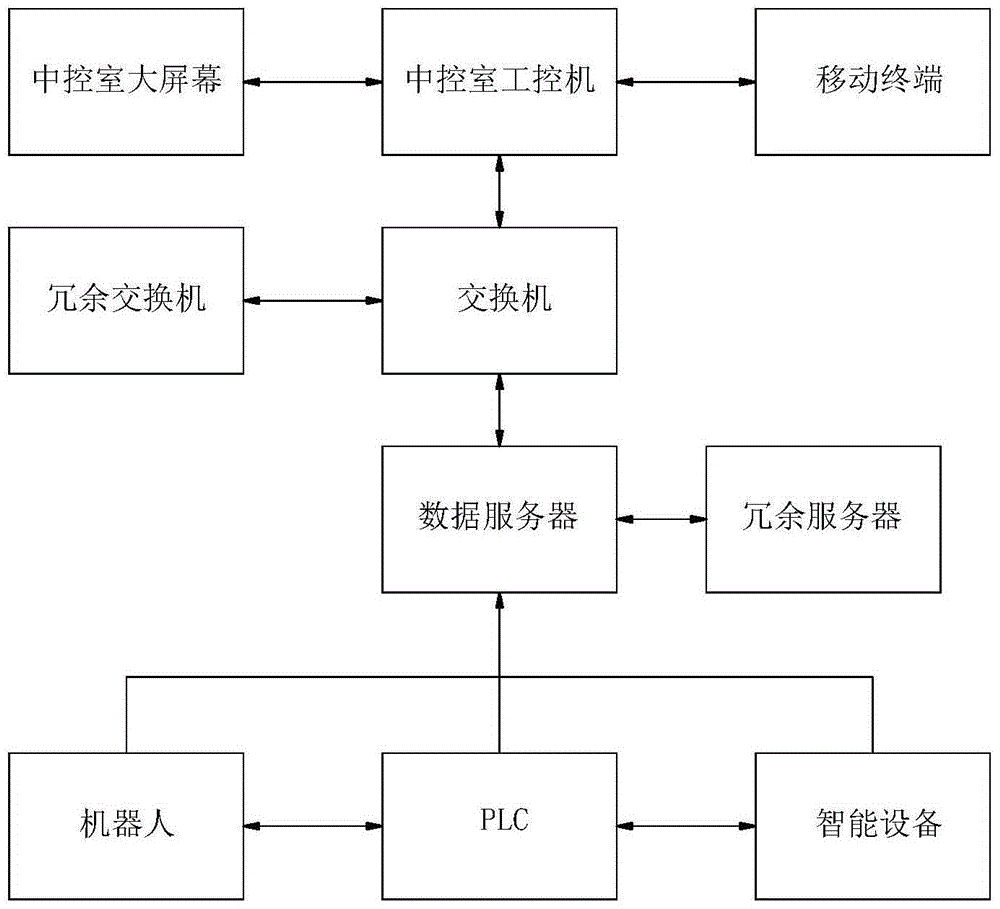

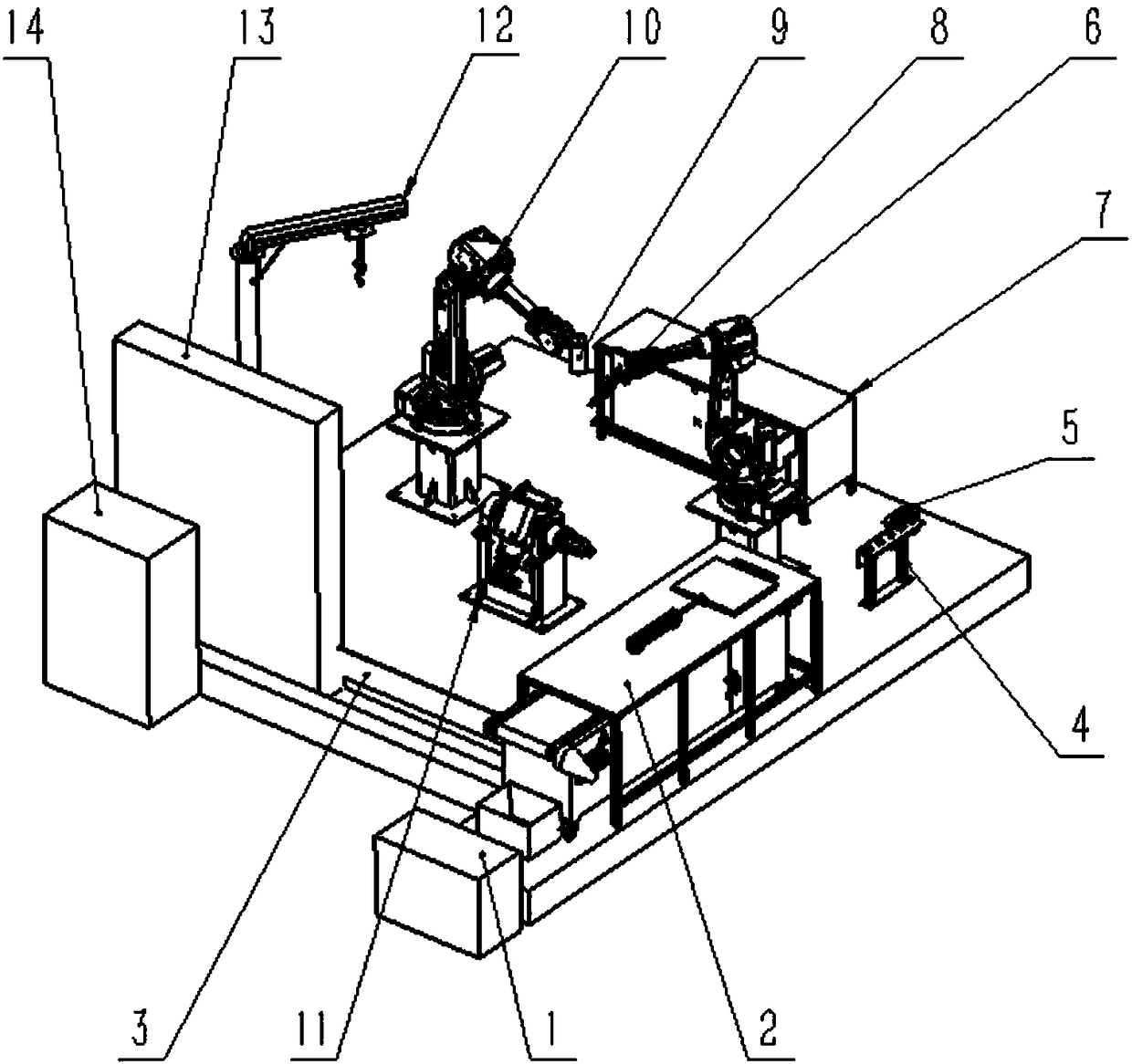

Remote state monitoring method and system for robots and robot production line equipment

InactiveCN105171748ARapid positioningAlarm in timeProgramme-controlled manipulatorPROFINETProgrammable logic controller

The invention relates to a remote state monitoring method and system for robots and robot production line equipment. The system comprises a central control room IPC (industrial personal computer), an exchanger and data servers, wherein the central control room IPC, the exchanger and the data servers are connected sequentially, the data servers are connected with robot controllers and all intelligent equipment provided with Ethernet interfaces in a production line through Ethernet, and all PLCs (programmable logic controllers) in the production line are connected with the data servers through PROFINET interfaces; furthermore, the central control room IPC is connected with a central control room large screen and a mobile terminal, and the exchanger and the data servers are in redundancy configuration. According to the method and the system, data acquisition, data mining, off-line analysis and wireless remote transmission are performed on operating states of the robots and key equipment in the production line, the operating states of the robots and the key equipment can be monitored on a remote platform and a mobile platform, possible potential faults of the robots and the key equipment are predicated, the current fault is positioned rapidly and accurately, and guidance and advices of experts are offered.

Owner:ANSHAN SONGYI ROBOT MFG

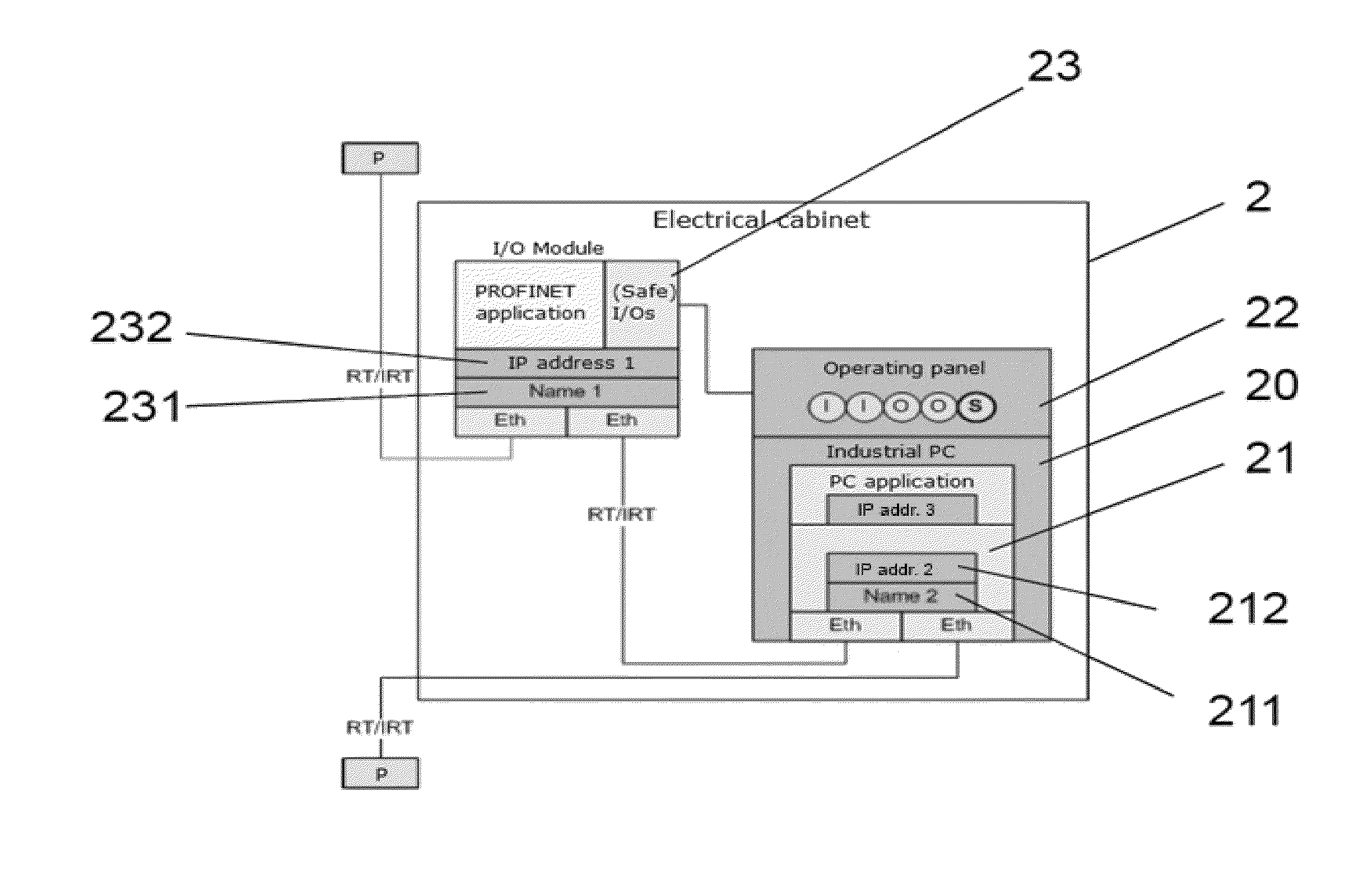

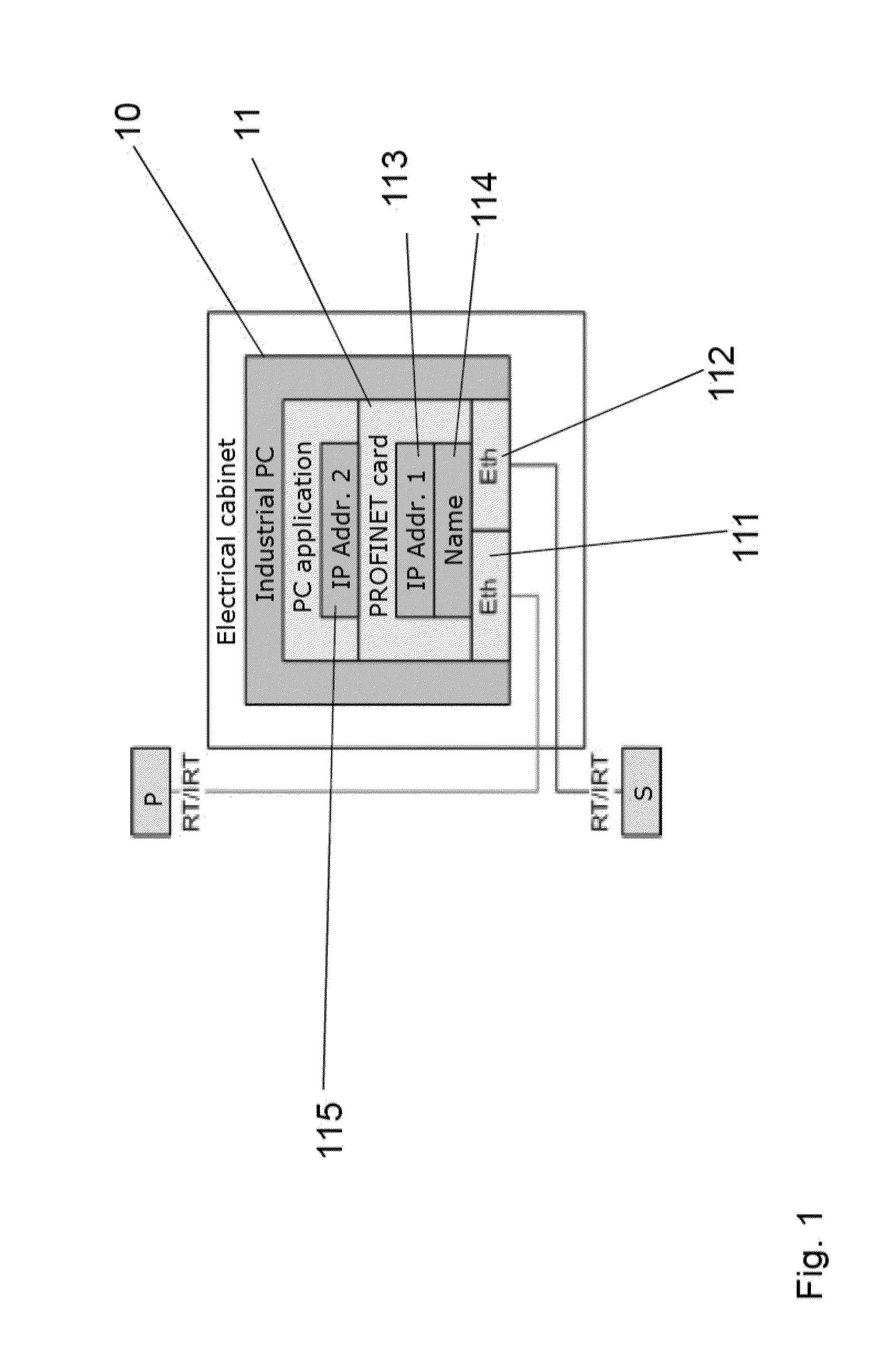

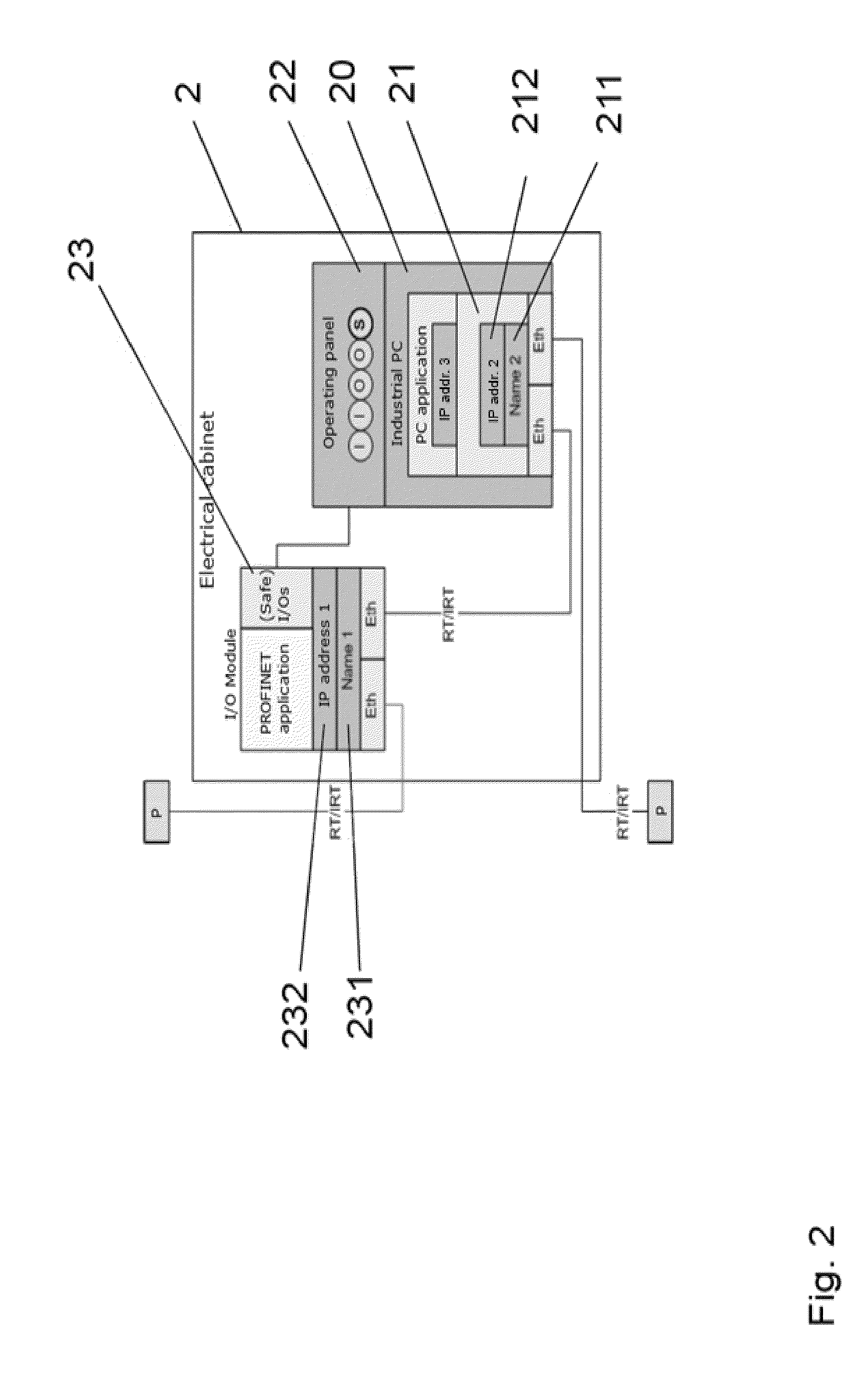

Profinet ethernet adapter

ActiveUS20140341220A1Simplifies connection of componentAvoid problemsData switching by path configurationReal-time dataNetwork packet

A PROFINET adapter having at least one first and one second Ethernet interface for coupling a subscriber to a PROFINET network. The PROFINET adapter comprises a third Ethernet interface, a number of at least one application interface and a splitter. The third Ethernet interface is designed at least for exchanging Ethernet-based data packets. The splitter is connected to the switch, the PROFINET protocol stack, the application interfaces and the third Ethernet interface, and is designed to divide real-time data packets and near real-time data packets according to a certain configuration and to transmit them between the switch and the application interface and / or the third Ethernet interface.

Owner:PHOENIX CONTACT GMBH & CO KG

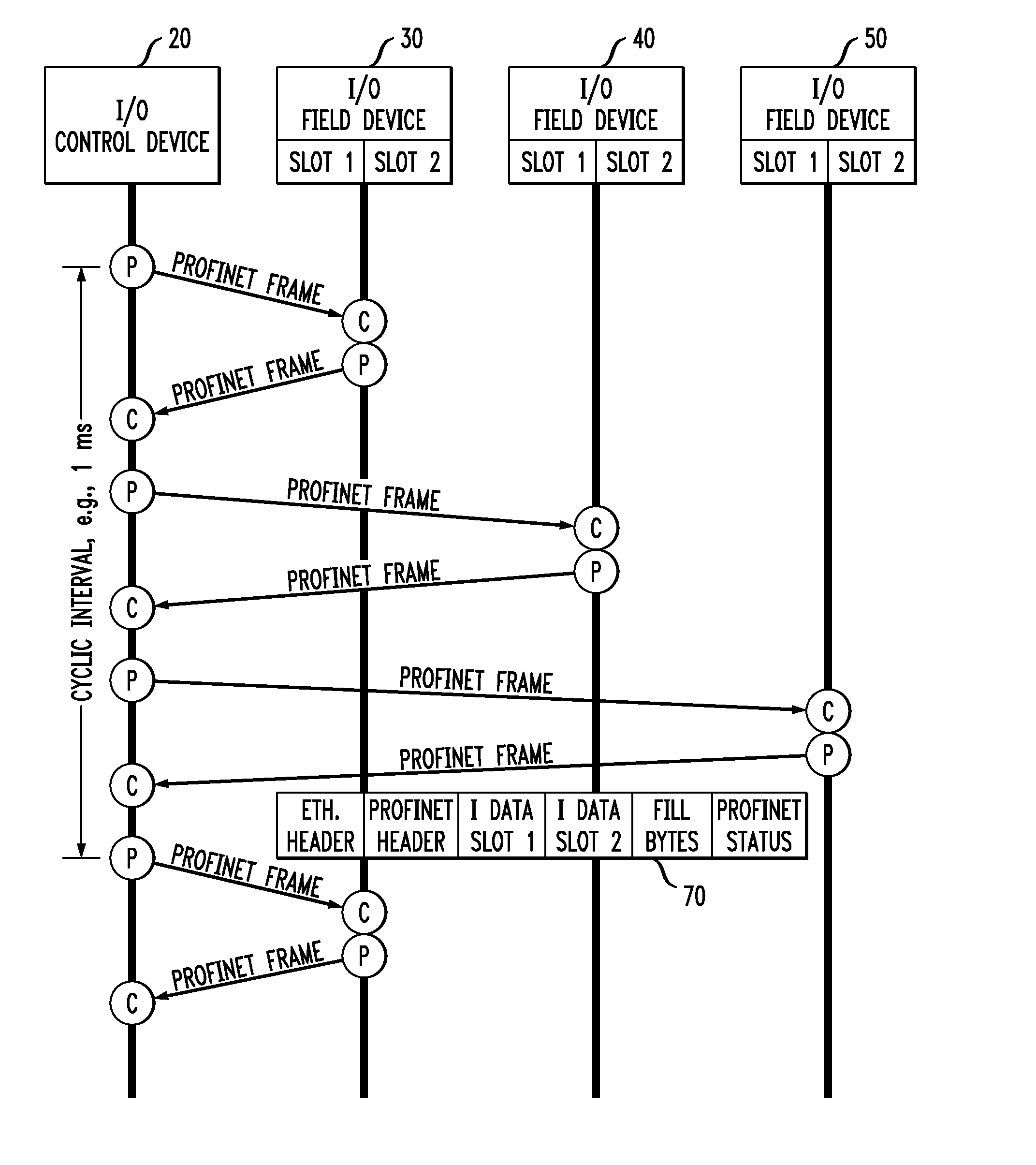

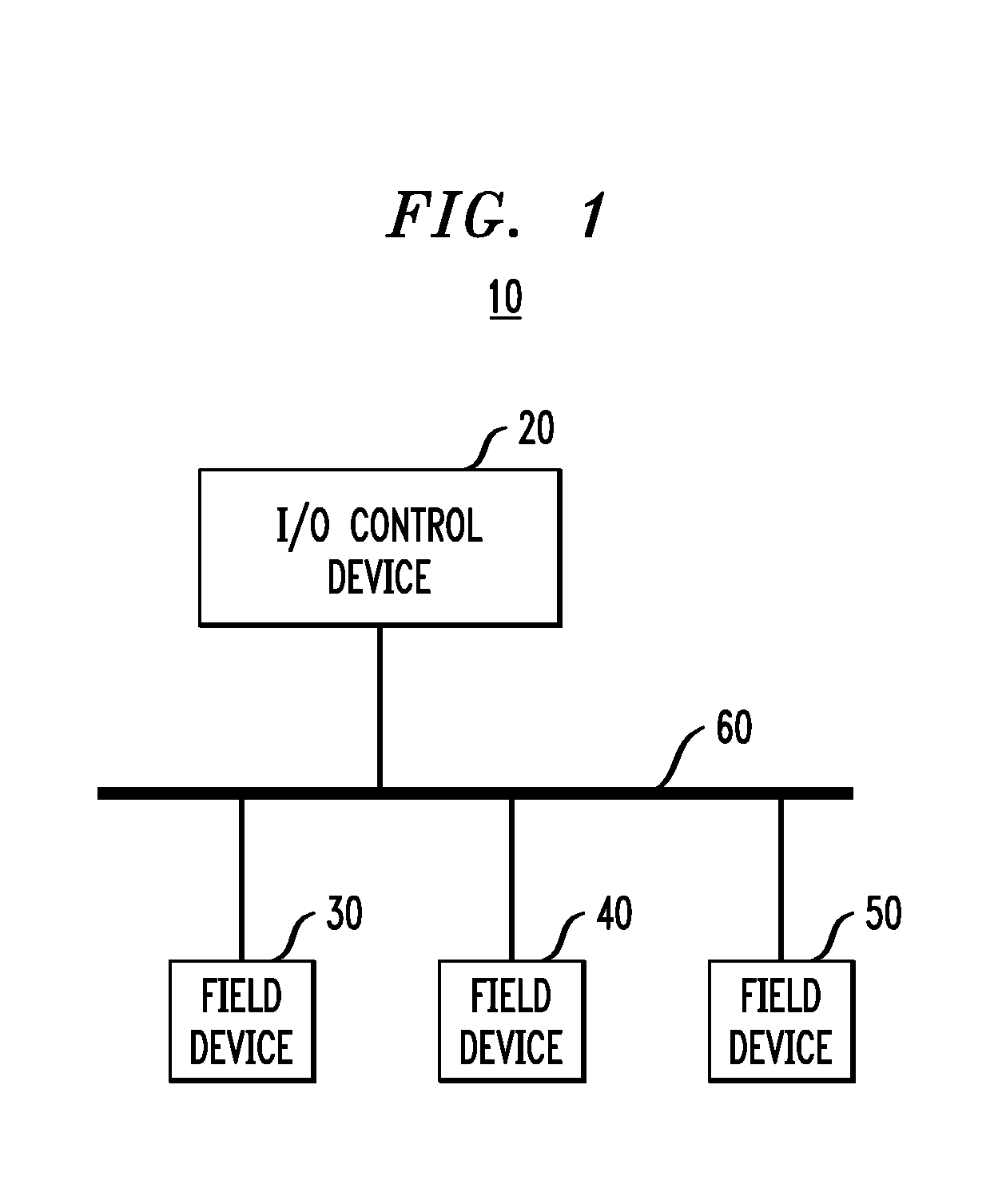

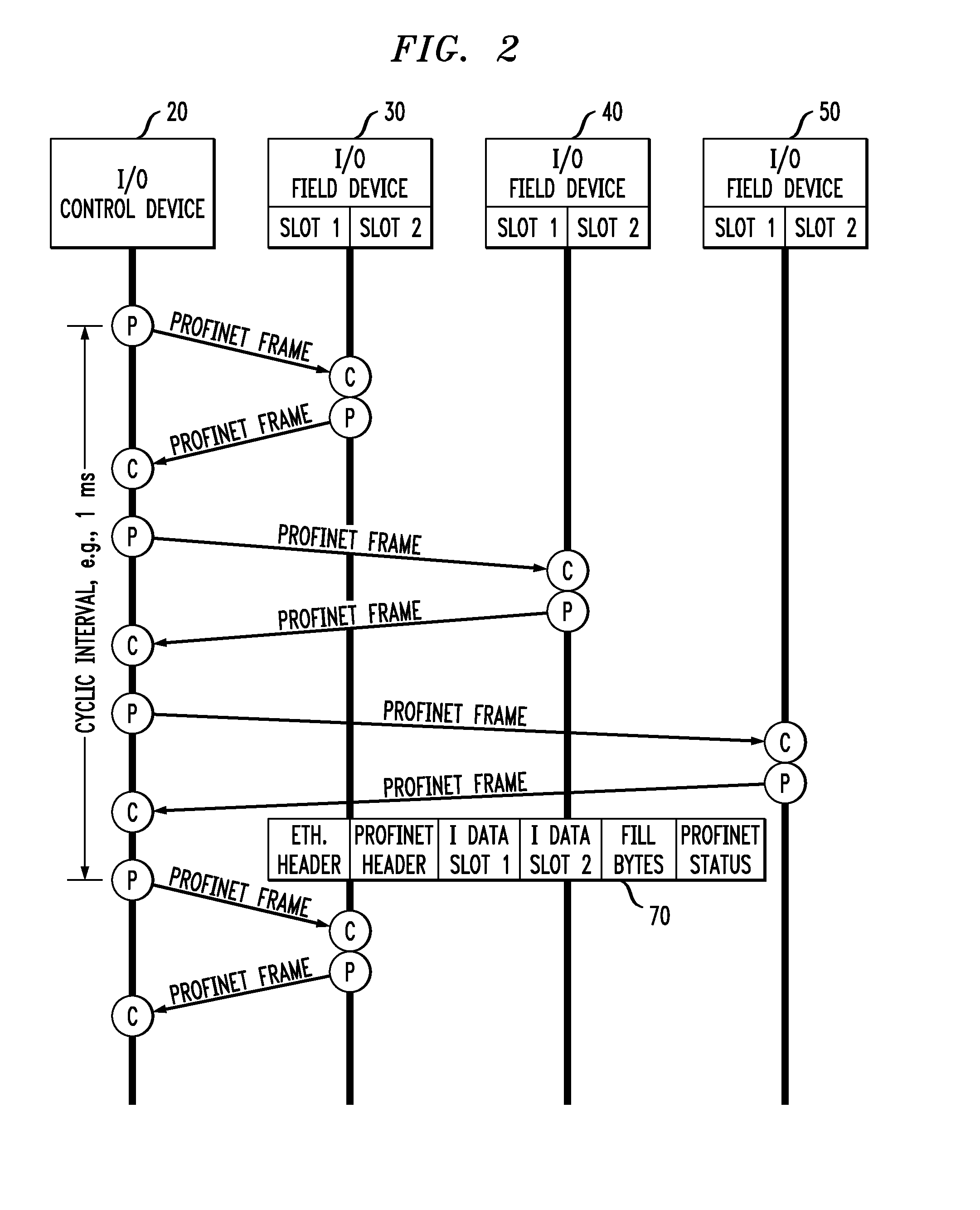

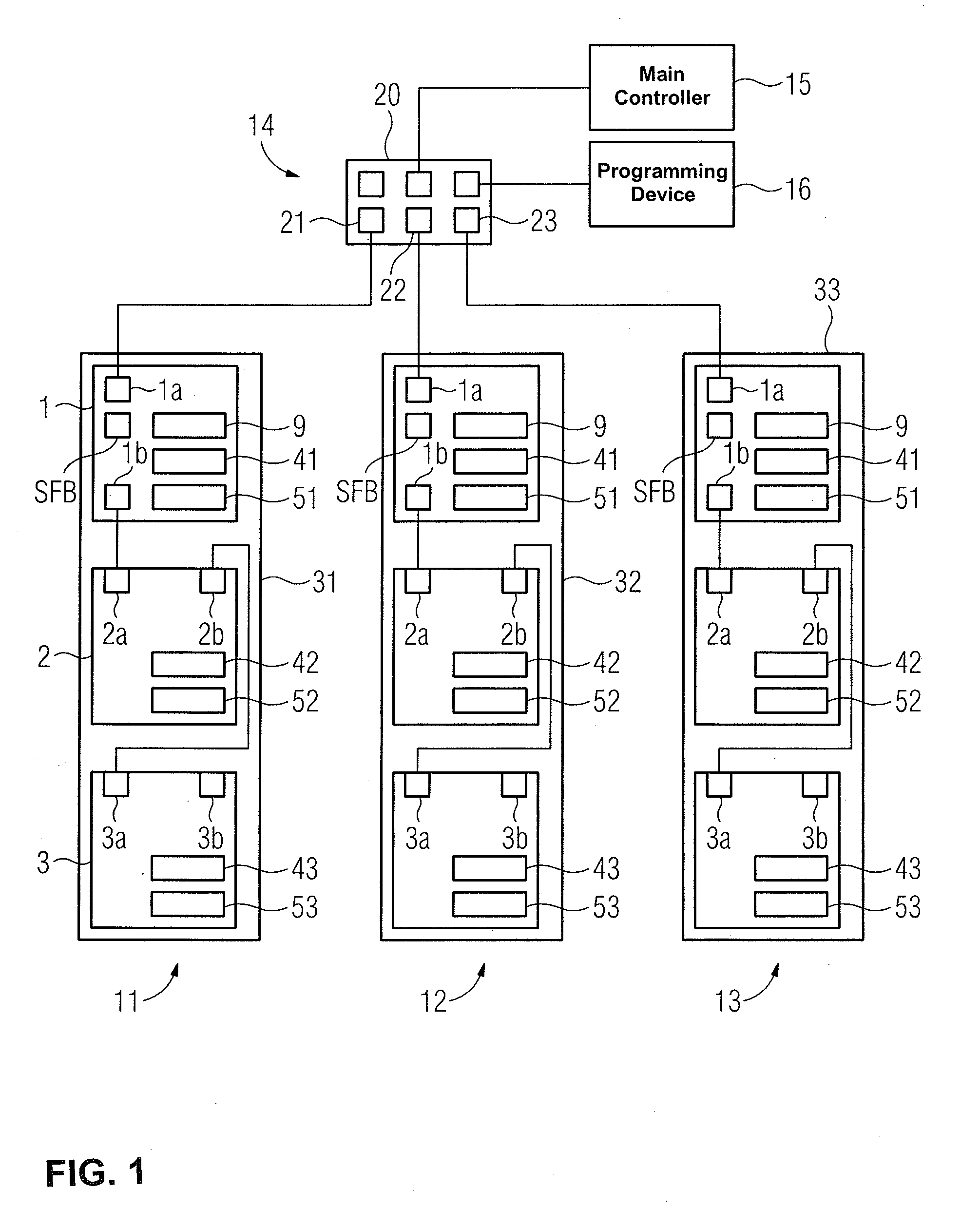

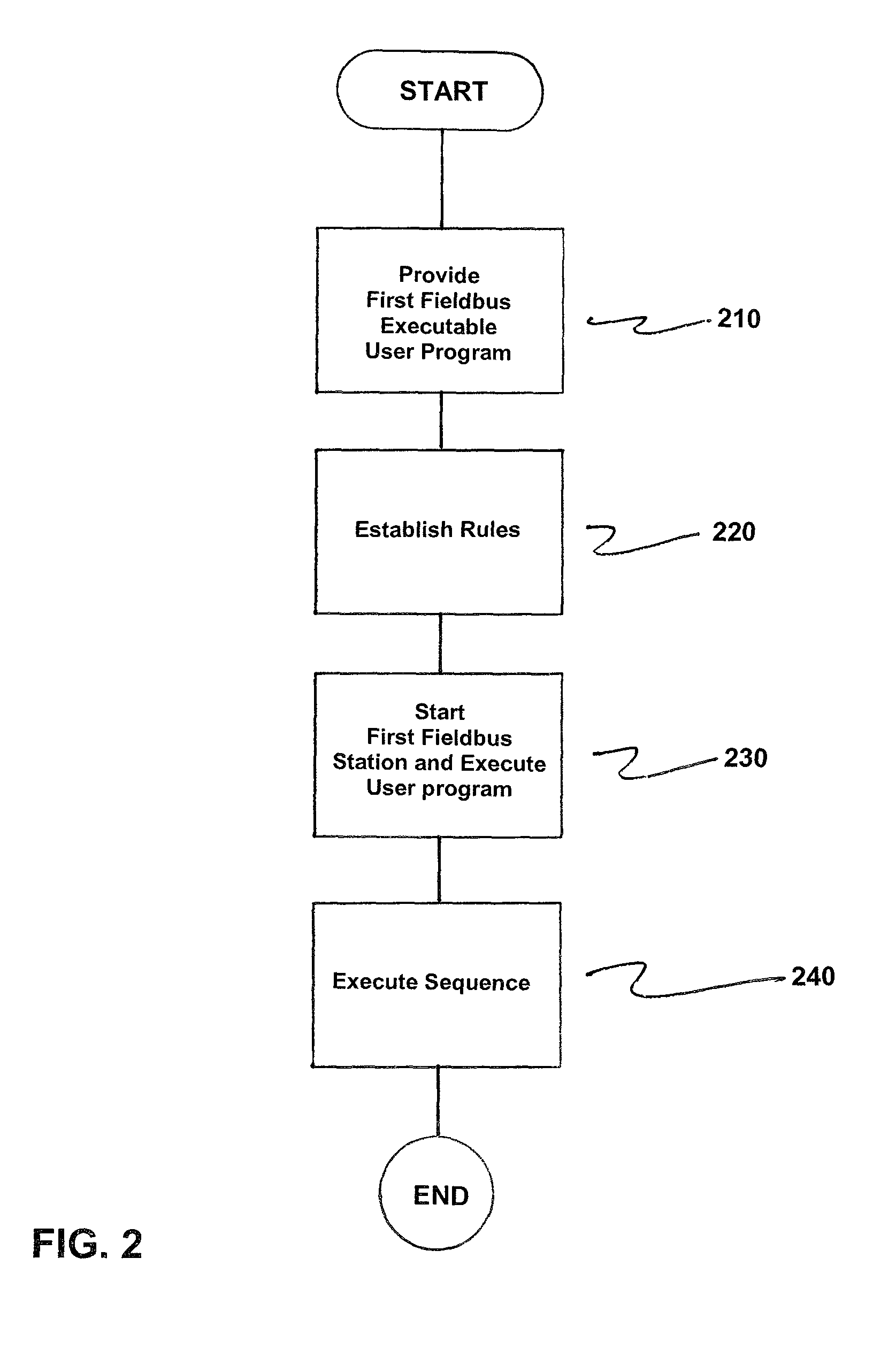

Method and Installation for Optimized Transmission of Data Between a Control Device and a Plurality of Field Devices

ActiveUS20100074262A1Improve transfer rateReduce in quantityData switching by path configurationData transmissionControl equipment

The invention relates to a method for optimized transmission of data between a control device and a plurality of field devices that are connected to one another via an IP-based communications network, wherein the data transmission is controlled using a Profinet protocol. The invention further relates to a control and data transmission installation (10) that is particularly suited to the performance of the method. With the control and data transmission installation (10), it is possible to transmit the data to be transmitted from a control device (20) to a group of field devices (30,40, 50) in a single sum frame subdivided into data fields, and to transmit the data to be transmitted from a plurality of field devices to a control device likewise in only one common sum frame subdivided into data fields. In this manner, the transmission rate can be optimized with respect to standard Profinet frames.

Owner:PHOENIX CONTACT GMBH & CO KG

Method for configuring fieldbus stations

A method for configuring fieldbus stations, wherein station names and addresses for the fieldbus stations are executed by reading in a parameter over a first network port of a coupling element, which acts as a topology anchor so as to assign a unique addressing in a subnetwork, i.e., a unique name and a unique IP address, in a PROFINET-IO, such as a fieldbus based on Ethernet.

Owner:SIEMENS AG

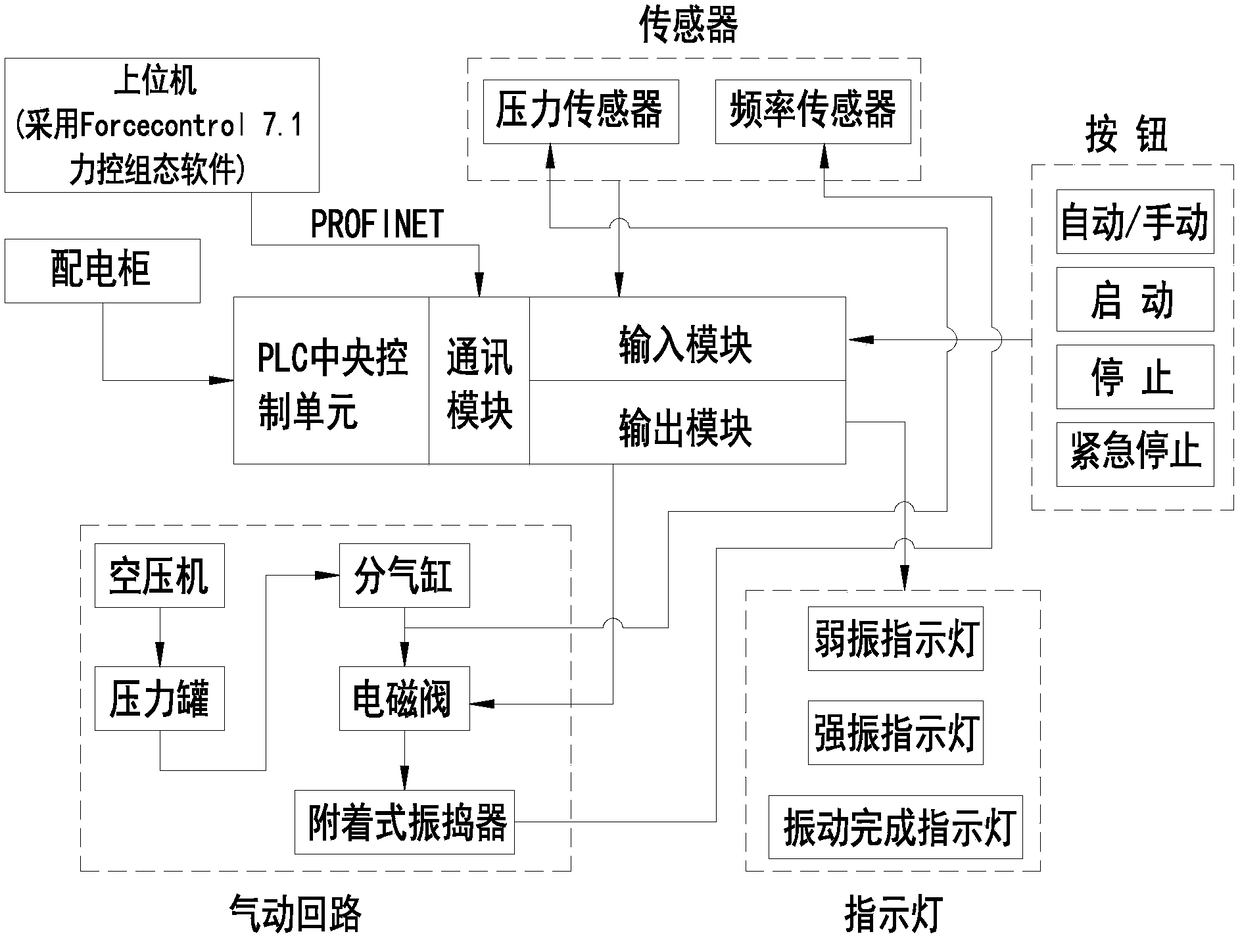

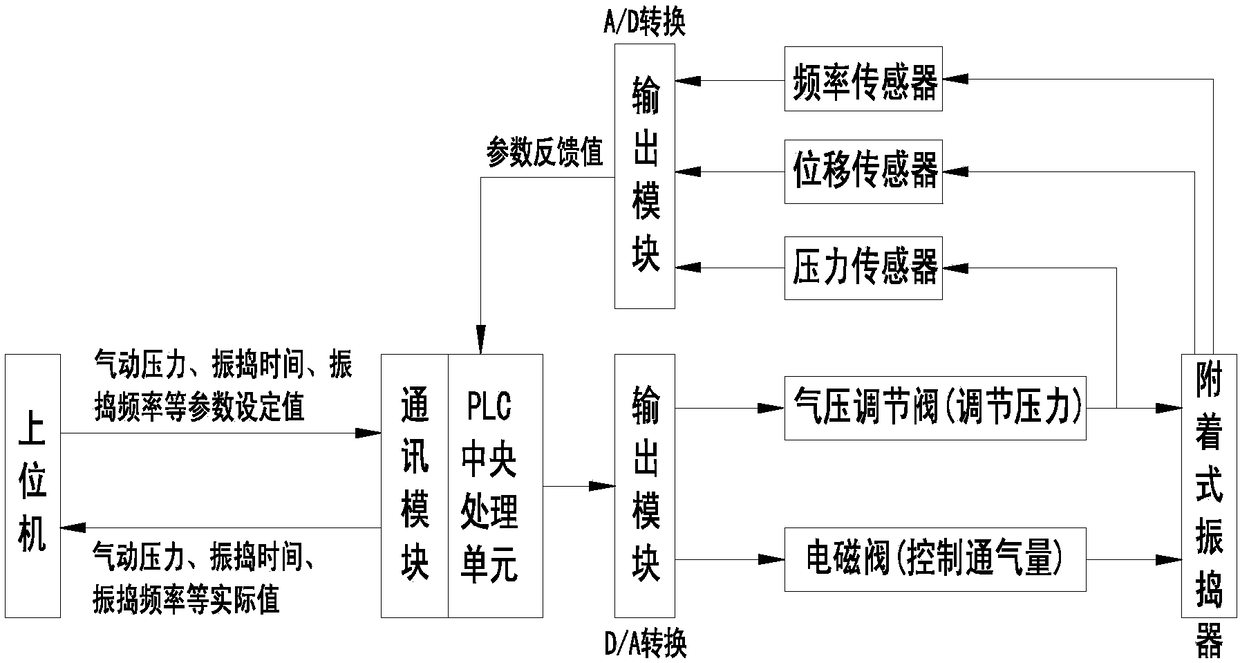

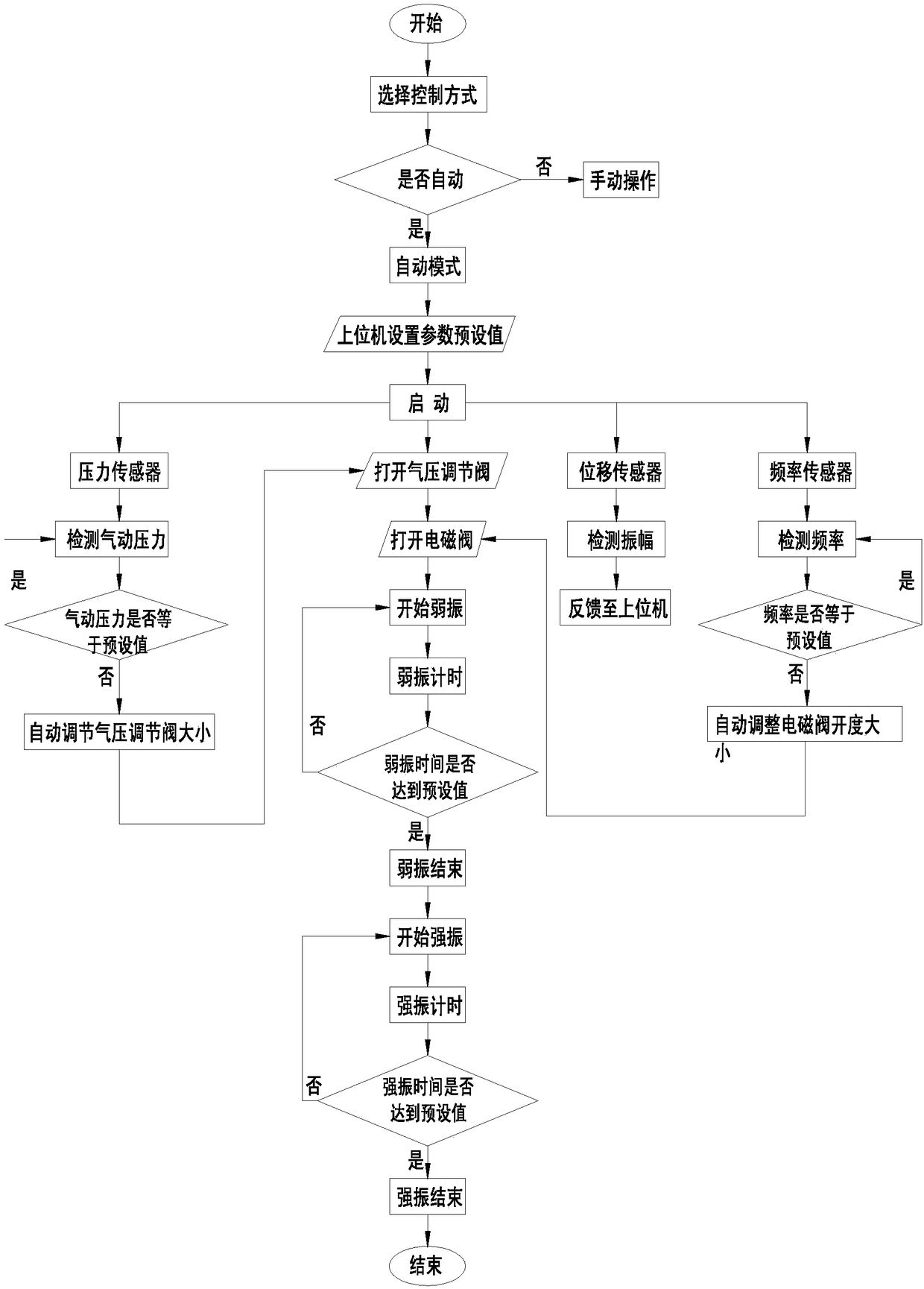

Control system for attached vibrator used for shield segment concrete vibration

InactiveCN108284507AGuarantee the construction qualitySimple structureAuxillary shaping apparatusPneumatic circuitControl system

The invention provides a control system for an attached vibrator used for shield segment concrete vibration. The control system for the attached vibrator used for shield segment concrete vibration comprises a power distribution cabinet, a PLC central processing unit, an input module, an output module, a communication module, an upper computer, a control button, a sensor, a signal indicator light and a pneumatic circuit. The input module provides a sensor signal and a button signal for the central processing unit. The output module executes an output signal of the central processing unit to drive all systems of the pneumatic circuit. Based on the PROFINET protocol, the upper computer interacts with the central processing unit through a communication module. According to the control system for the attached vibrator, parameters such as the vibration frequency, the vibration time, the amplitude and the pneumatic pressure can be monitored and controlled in real time, programmed control overthe attached vibrator is achieved, the labor intensity is relieved, the vibration process can be controlled, and excessive vibration and insufficient vibration are effectively avoided; and concrete quality problems such as bubbles, holes, honeycombs and pitted surfaces of shield segments are eliminated, and the concrete construction quality of the shield segments is ensured.

Owner:中国水利水电第七工程局有限公司

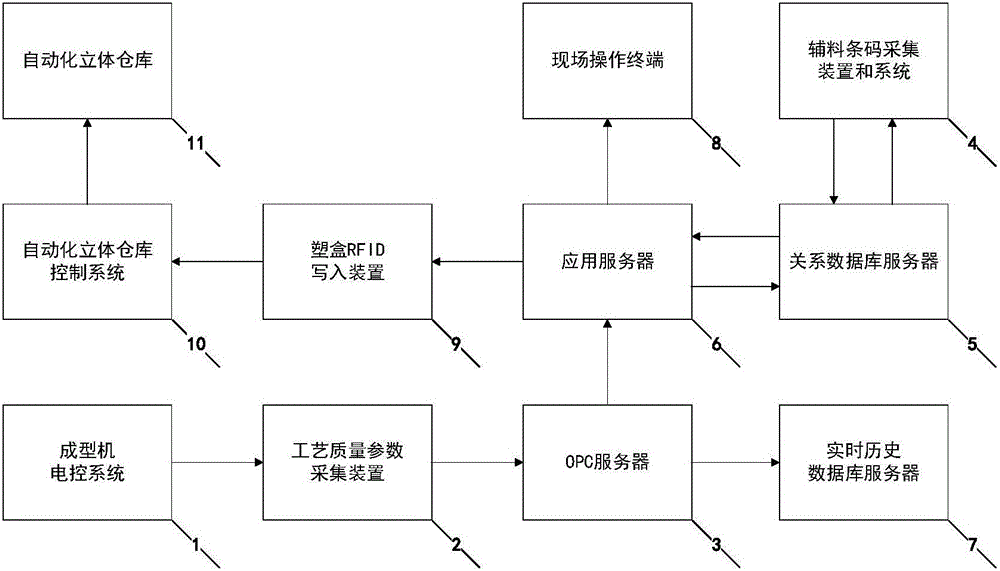

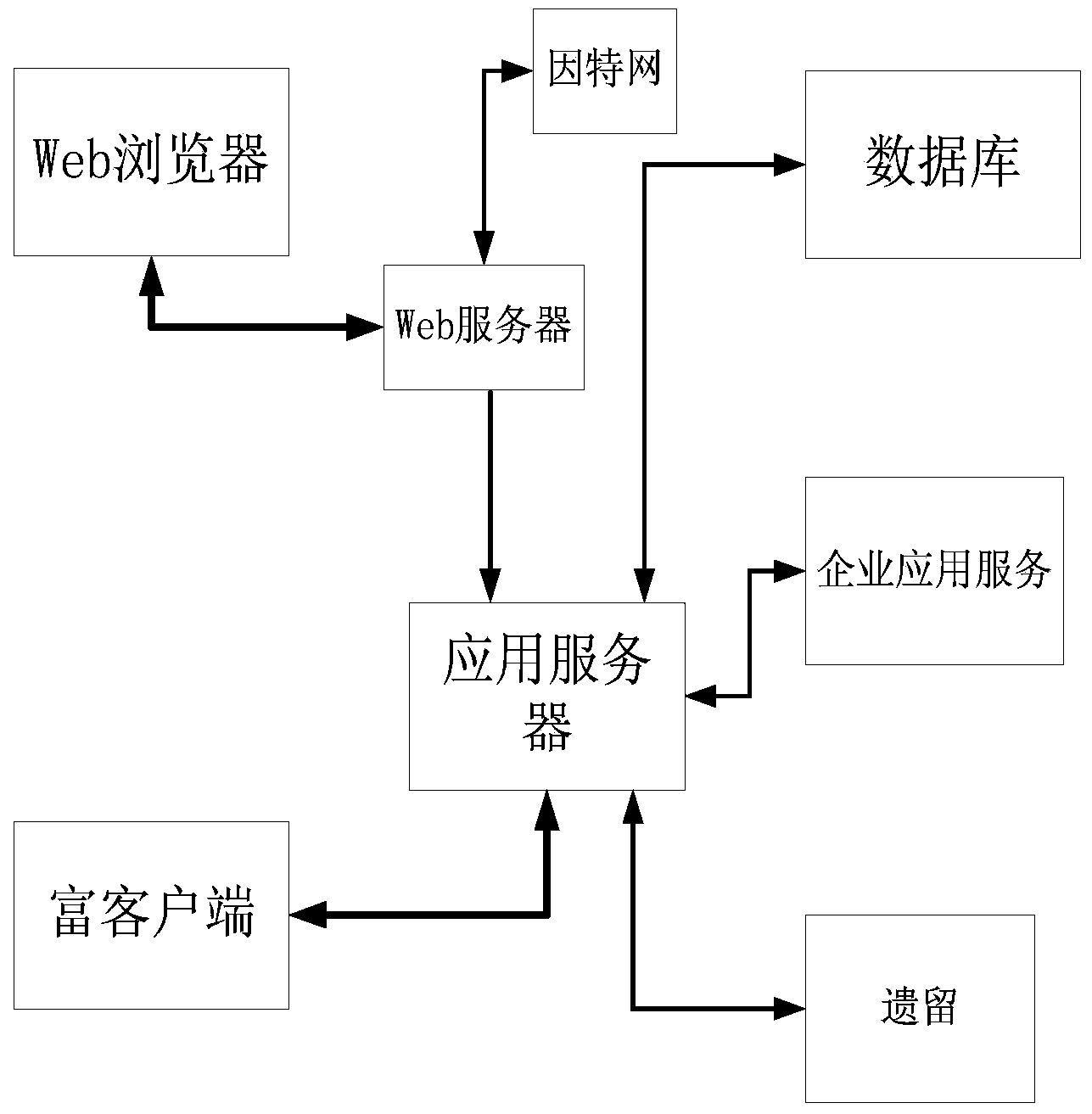

Filter stick forming process quality analyzing and tracing system

ActiveCN105760555AAvoid quality anomaliesReduce complexityRelational databasesCo-operative working arrangementsProcess qualityOLE for Process Control

The invention relates to a filter stick forming process quality analyzing and tracing system. The system consists of a forming machine electric control system, a process quality parameter acquisition device, an OPC (OLE for Process Control) server, an auxiliary material bar code acquisition device and system, a relationship database server, an application server, a real-time history database server, a field operation terminal, a plastic box RFID (Radio Frequency Identification Devices) writing device, an automation three-dimensional warehouse control system, an automation three-dimensional warehouse and PROFINET industrial Ethernet. According to the filter stick forming process quality analyzing and tracing system, process quality parameters in an equipment production process are acquired in real time through the process quality parameter acquisition device, and real-time monitoring and feedback of the change situations, adjustment situations and abnormal situations of the process quality parameters in a filter bar production process are realized according to a process quality standard of filter bars through an analysis model based on big data and a full-sample statistics technology. Recurrence of quality anomalies is avoided; a delivery command is sent to the automation three-dimensional warehouse control system specific to quality anomalies found through analysis, so that the manual tracing complexity is lowered greatly.

Owner:CHINA TOBACCO ZHEJIANG IND

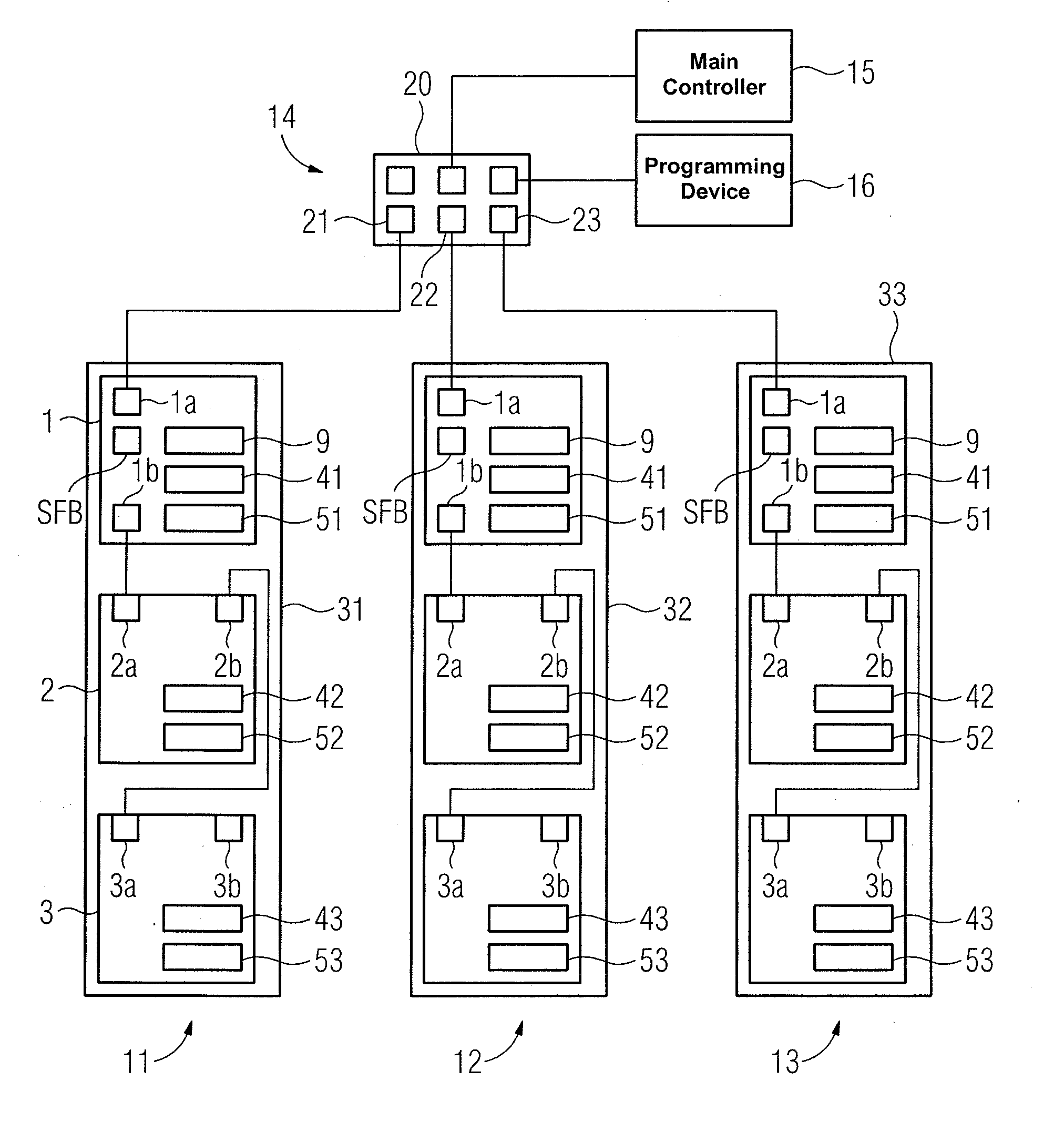

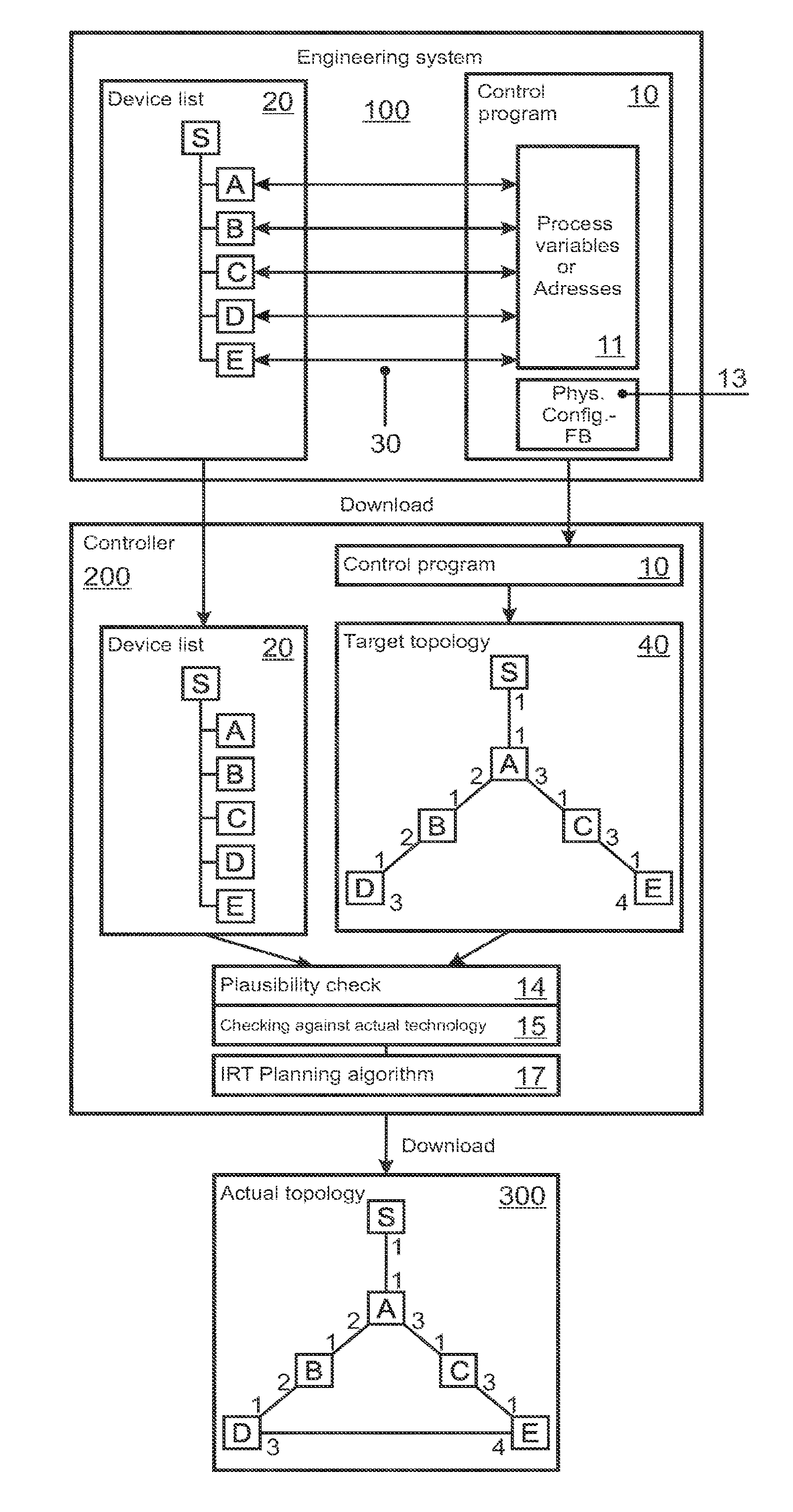

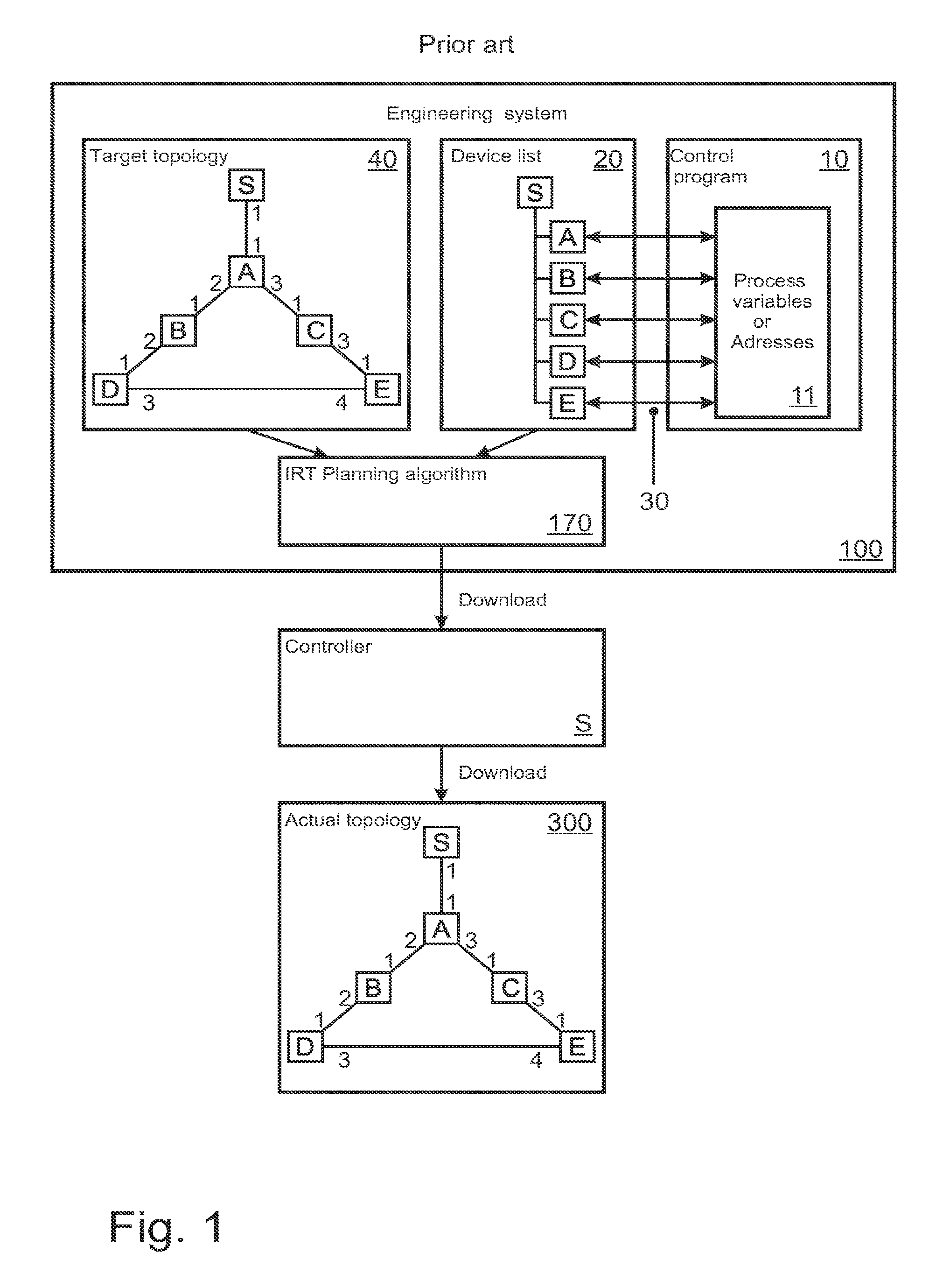

Port-independent topologically planned real-time network

ActiveUS20120215891A1Flexible mounting of the network linesSimple processDigital computer detailsTransmissionTime structureTime critical

For an industrial network, for example a PROFInet IRT net for a motion control or in general a network with an isochronous time structure for transmitting time-critical data, it is the object according to the invention to considerably simplify the handling during installation or during maintenance and device replacement. For this purpose, a port-independent, topologically predefined real time network is introduced which provides the compliance with the at least similar safety standard as the PROFInet IRT while dispensing with the (target) specification of a network interface being used. The apparatus according to the invention is illustrated.

Owner:PHOENIX CONTACT GMBH & CO KG

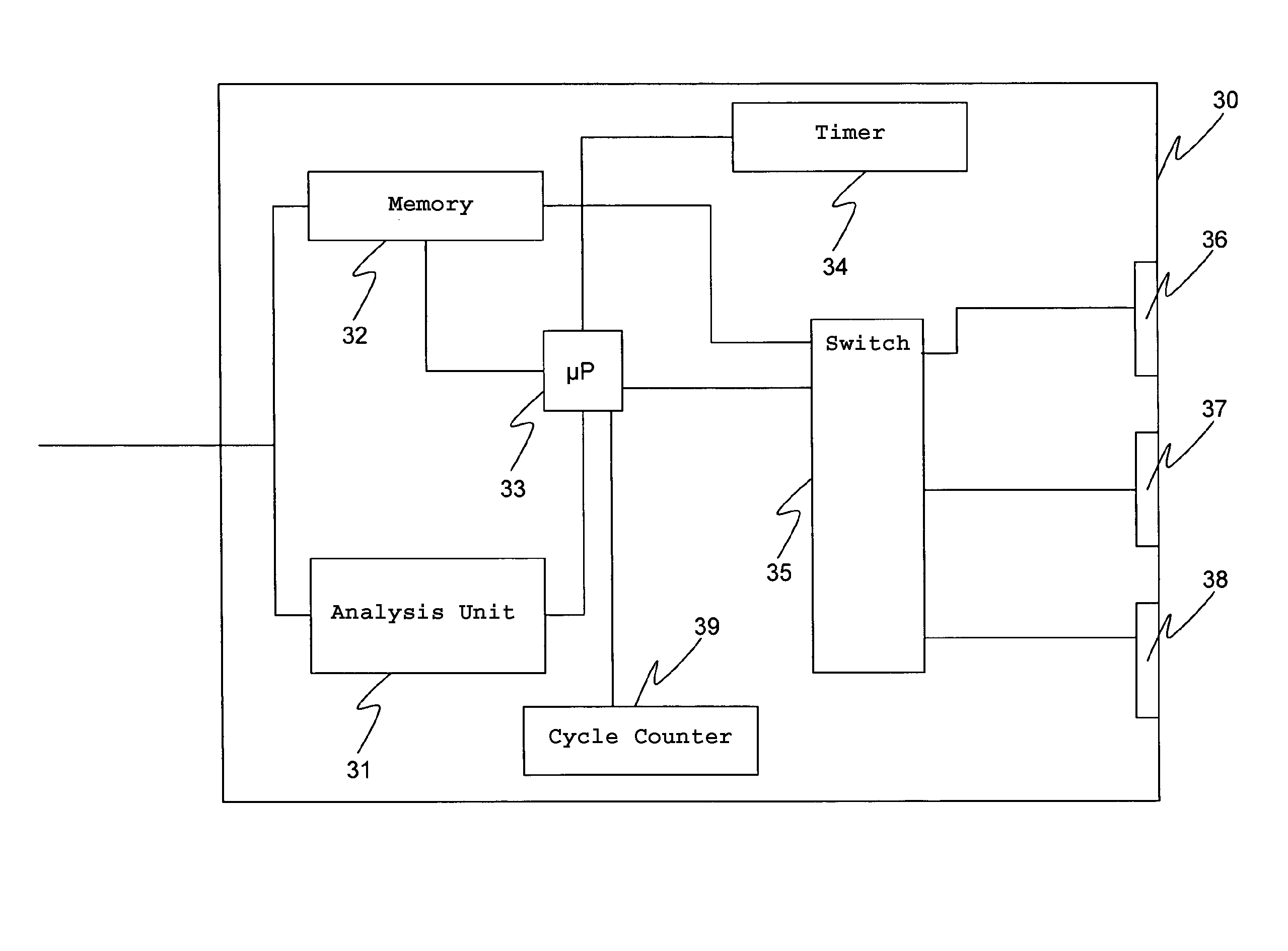

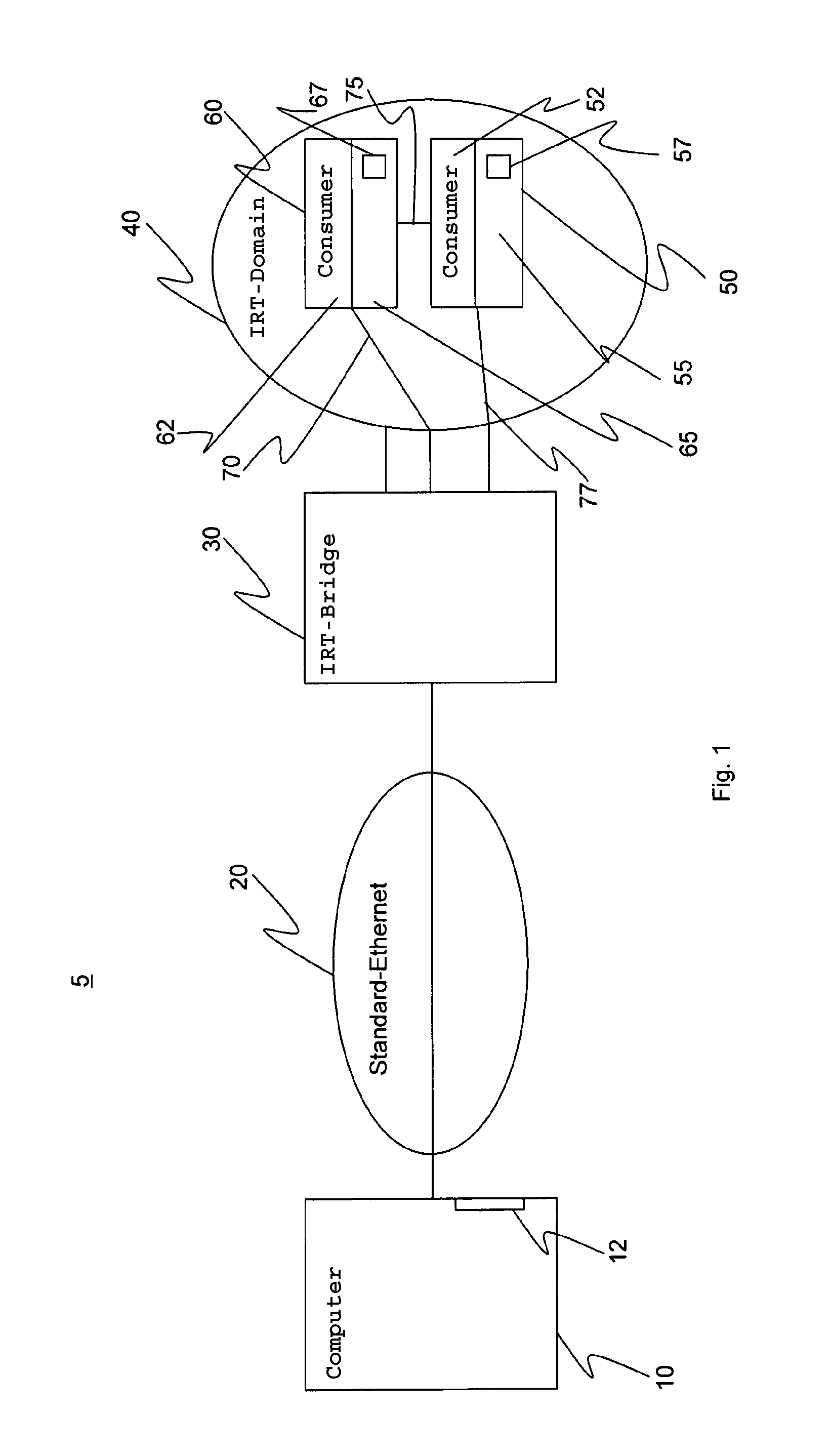

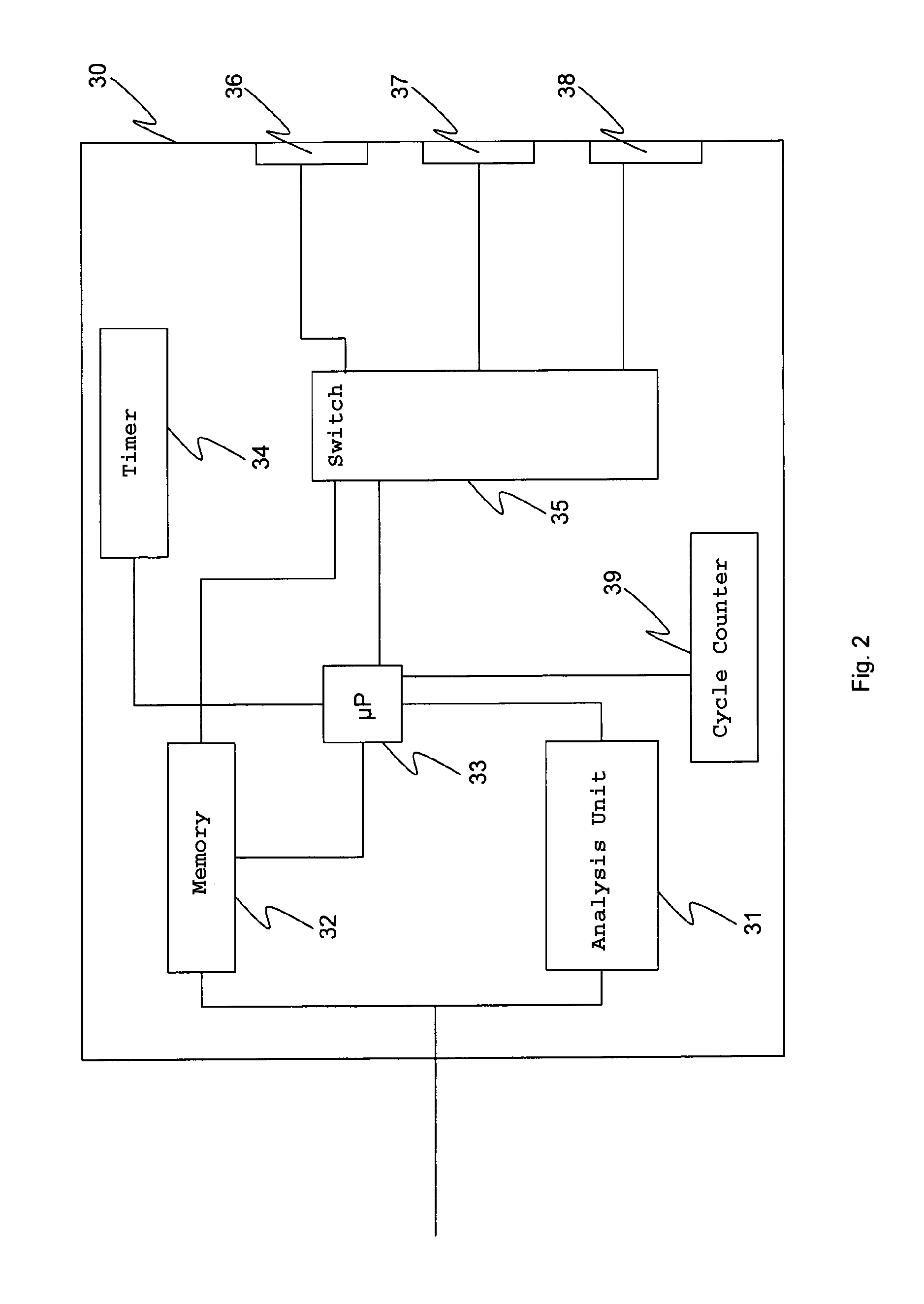

Communication system and method for isochronous data transmission in real time

A communication system which has a PROFINET IRT system with first communication devices for isochronous transmission. A special IRT bridge device is created, so that a traditional standard Ethernet communication device can also transmit real time-critical data over the PROFINET IRT system. The bridge device has a timer, which is synchronized in time with the timers of the first communication devices. In addition, a device for analysis of the transmission point in time of a real time-critical data telegram received by the communication device and a control unit are provided, such that the control unit controls the forwarding of the respective real time-critical data telegram to at least one second communication device as a function of the analyzed transmission point in time.

Owner:PHOENIX CONTACT GMBH & CO KG

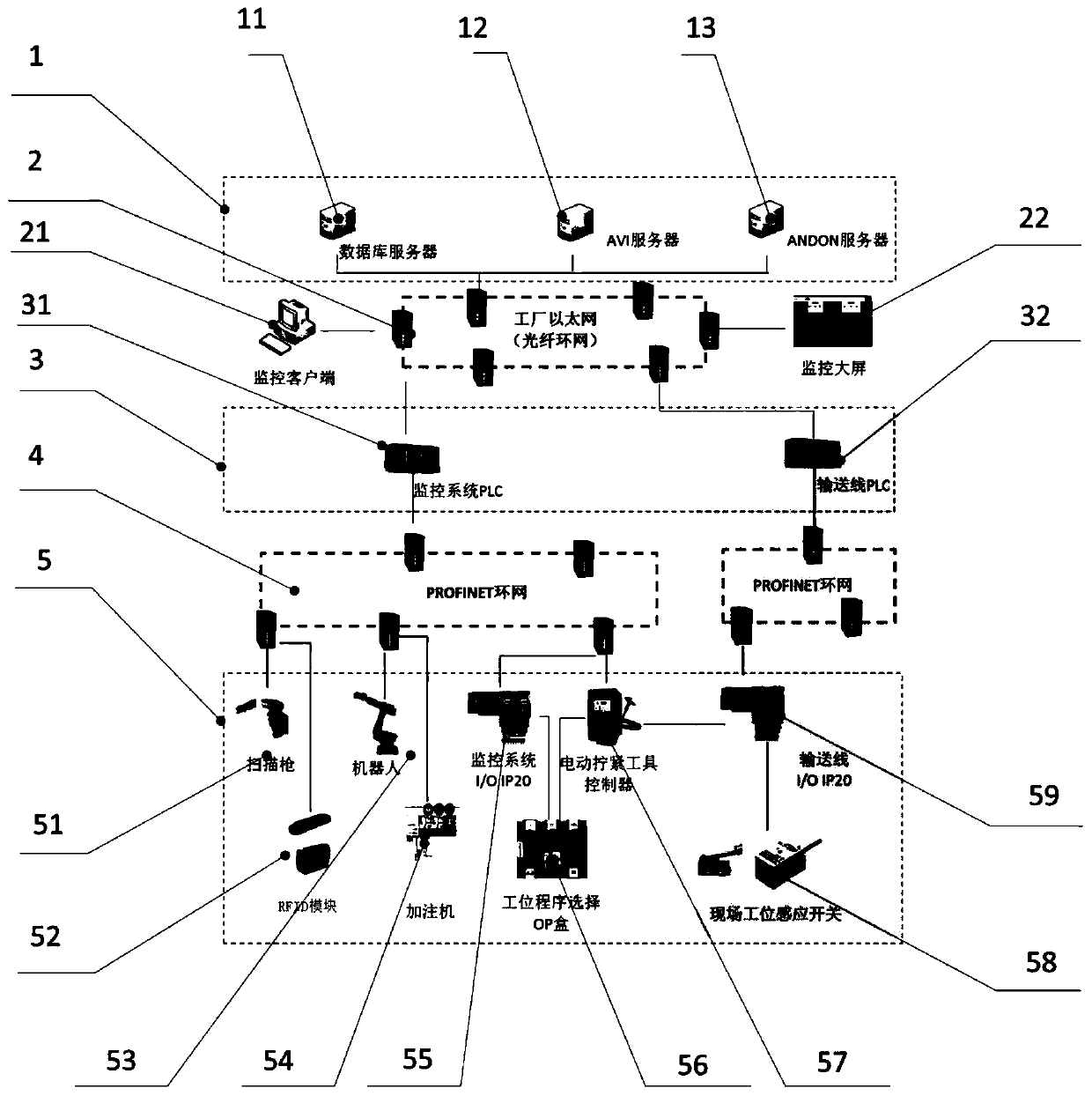

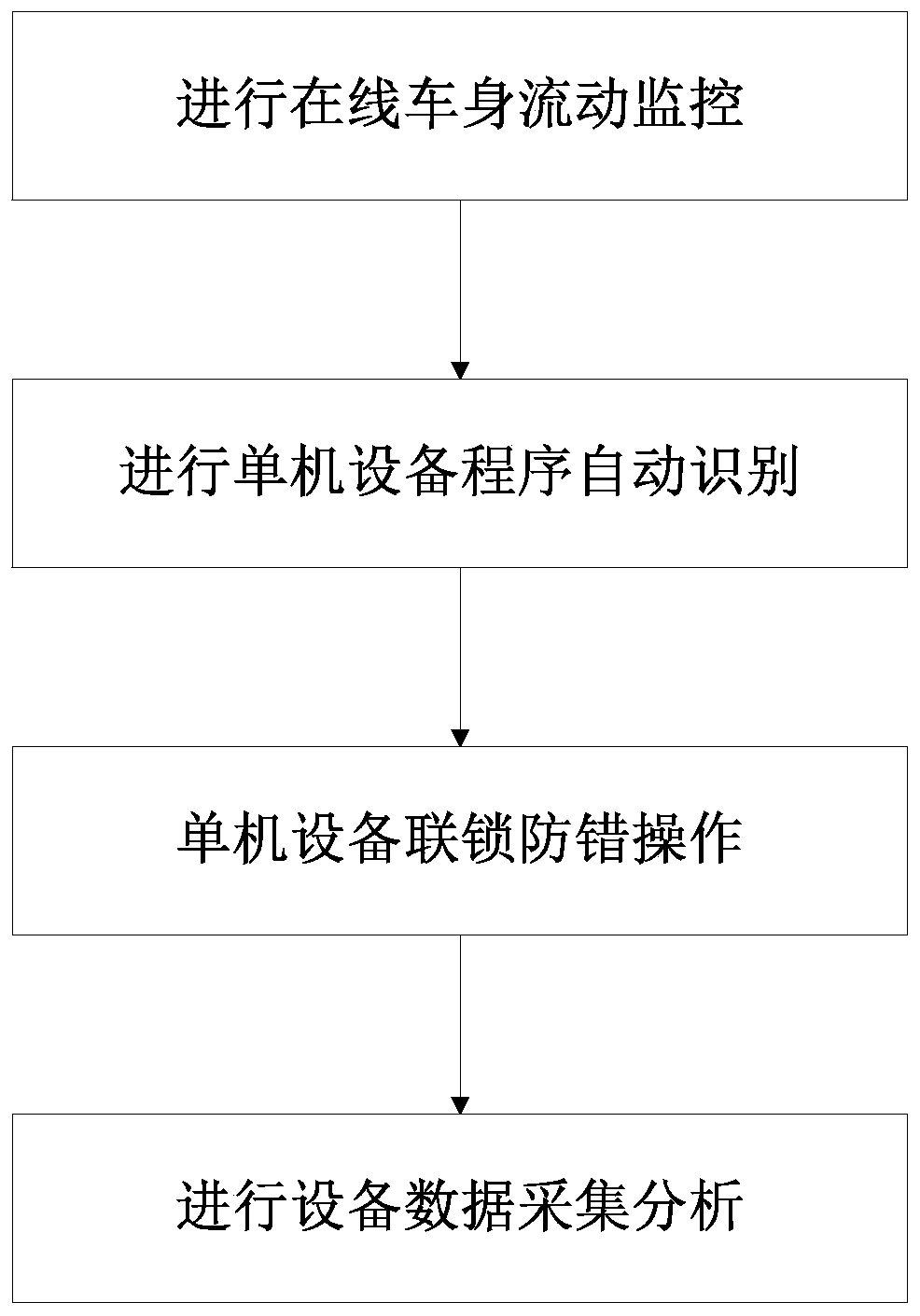

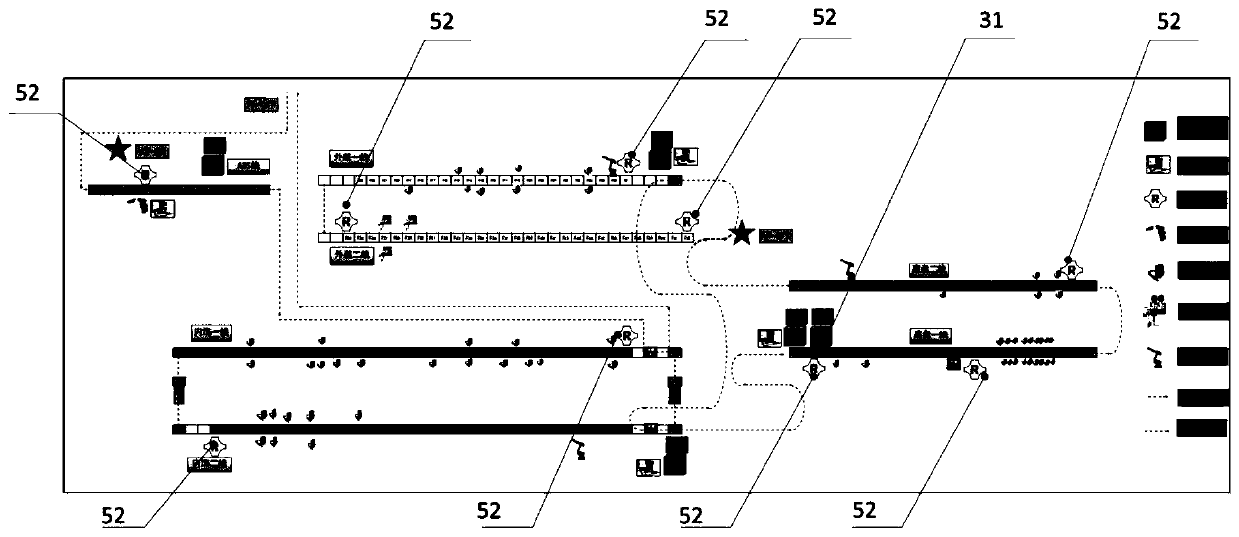

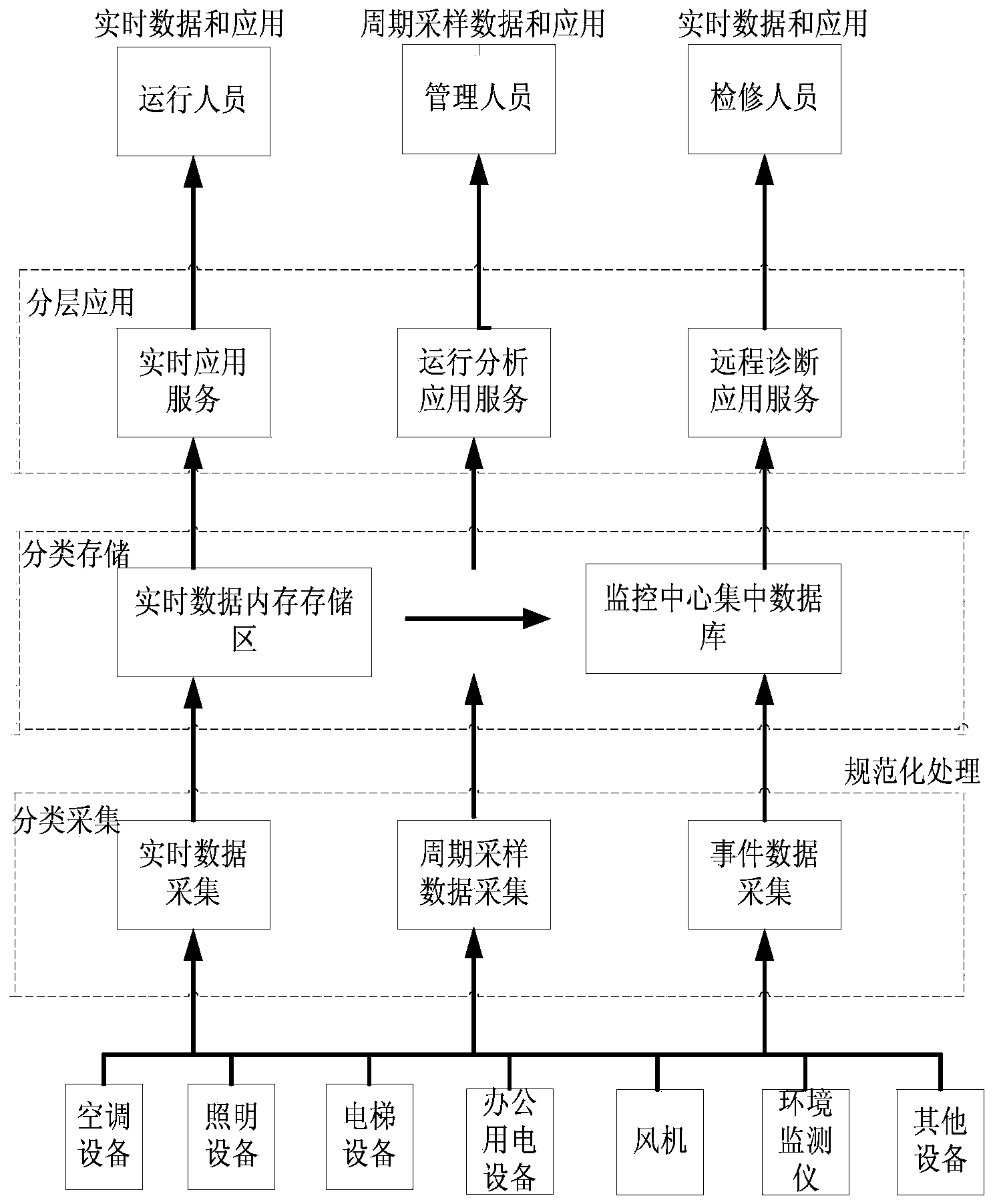

Workshop production monitoring system and method

InactiveCN111007808AAutomate the processLow costCo-operative working arrangementsTotal factory controlInformatizationMachine

The invention provides a workshop production monitoring system and method. A monitoring system PLC is used as a core, unified ultrahigh-frequency RFID is adopted for key points of all line bodies in awhole workshop, on-line monitoring of a whole-workshop vehicle queue is automatically achieved, on the basis of the queue, based on a stable and reliable PROFINET communication protocol, automatic program recognition of workshop equipment is achieved, a redundant scheme is adopted, assembly mistake-proofing interlocking of single-machine equipment and a conveying line is achieved, and it is guaranteed that no defective products flow out; through an optical fiber ring network, assembly process data and equipment state information are collected in real time and process analysis is performed soas to effectively guide production and manage equipment; and finally, automation and informatization of production in a final assembly workshop are achieved, and the efficiency of final assembly production and the assembly quality are improved.

Owner:GUANGZHOU AUTOMIBILE GRP MOTOR

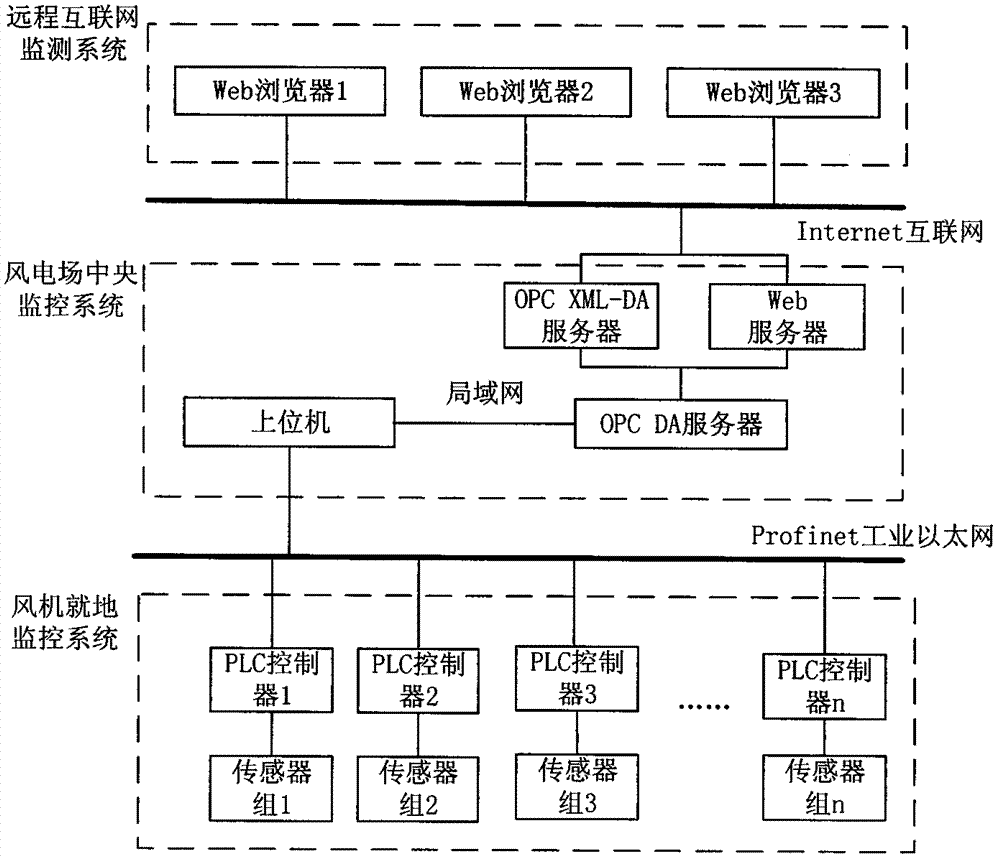

Intelligent wind power plant SCADA system in encrypted Profinet communication mode

InactiveCN107479524AAvoid major accidentsSolve the disadvantages of not being able to pass through the firewallTotal factory controlProgramme total factory controlSite monitoringInternet monitoring

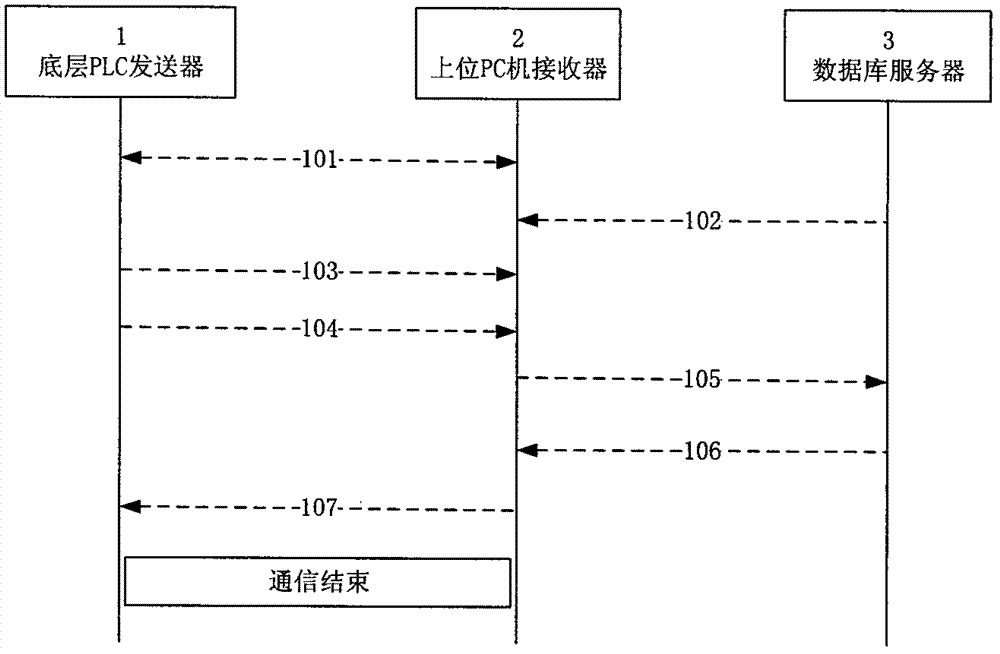

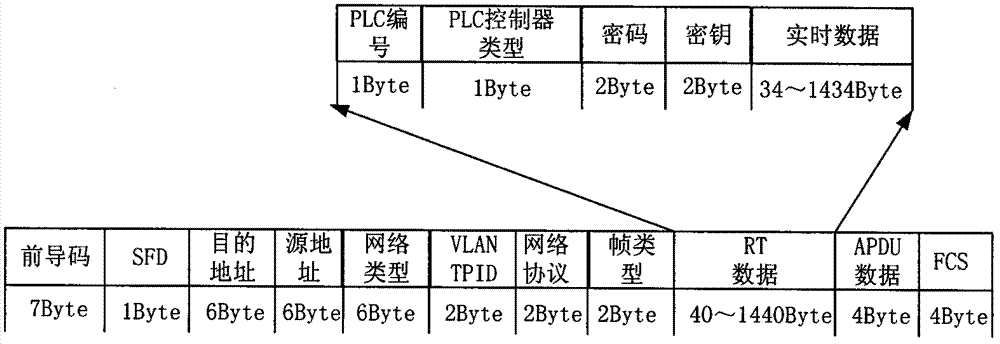

The invention discloses an intelligent wind power plant SCADA system in an encrypted Profinet communication mode. The system comprises an on-site monitoring system for fans, a central monitoring system for wind power plants and a remote Internet monitoring system. According to the system, an architecture development mode combining B / S and C / S is adopted and is different from a traditional single B / S or C / S architecture mode, and the problem of poor system architecture adaptability is effectively solved. An isochronous synchronization mechanism is adopted in Profinet industrial Ethernet communication, in a multi-cycle transmission process, RT and IRT communication characteristics are flexibly used, network resources are fully utilized, a network structure is optimized, and the real-time characteristic of the traditional Ethernet is further improved. A DES algorithm is adopted for encryption in the process of sending data to an upper PC receiver by a bottom-layer PLC transmitter, and the system safely transmits real-time data. A matching mode in a database server is utilized to determine whether or not the transmission data of a lower computer is received, and the reliability of the system is enhanced.

Owner:TIANJIN UNIV OF SCI & TECH

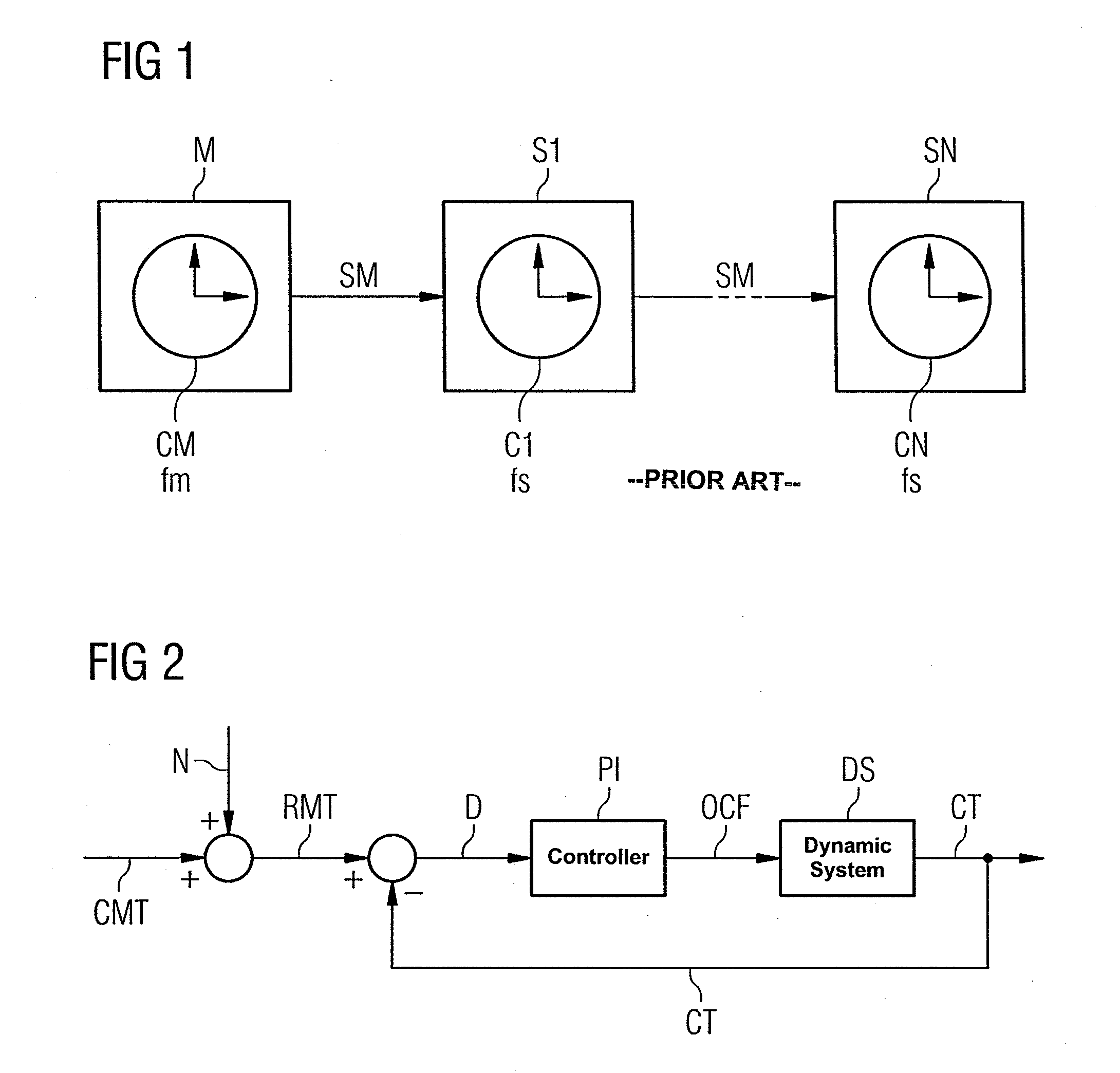

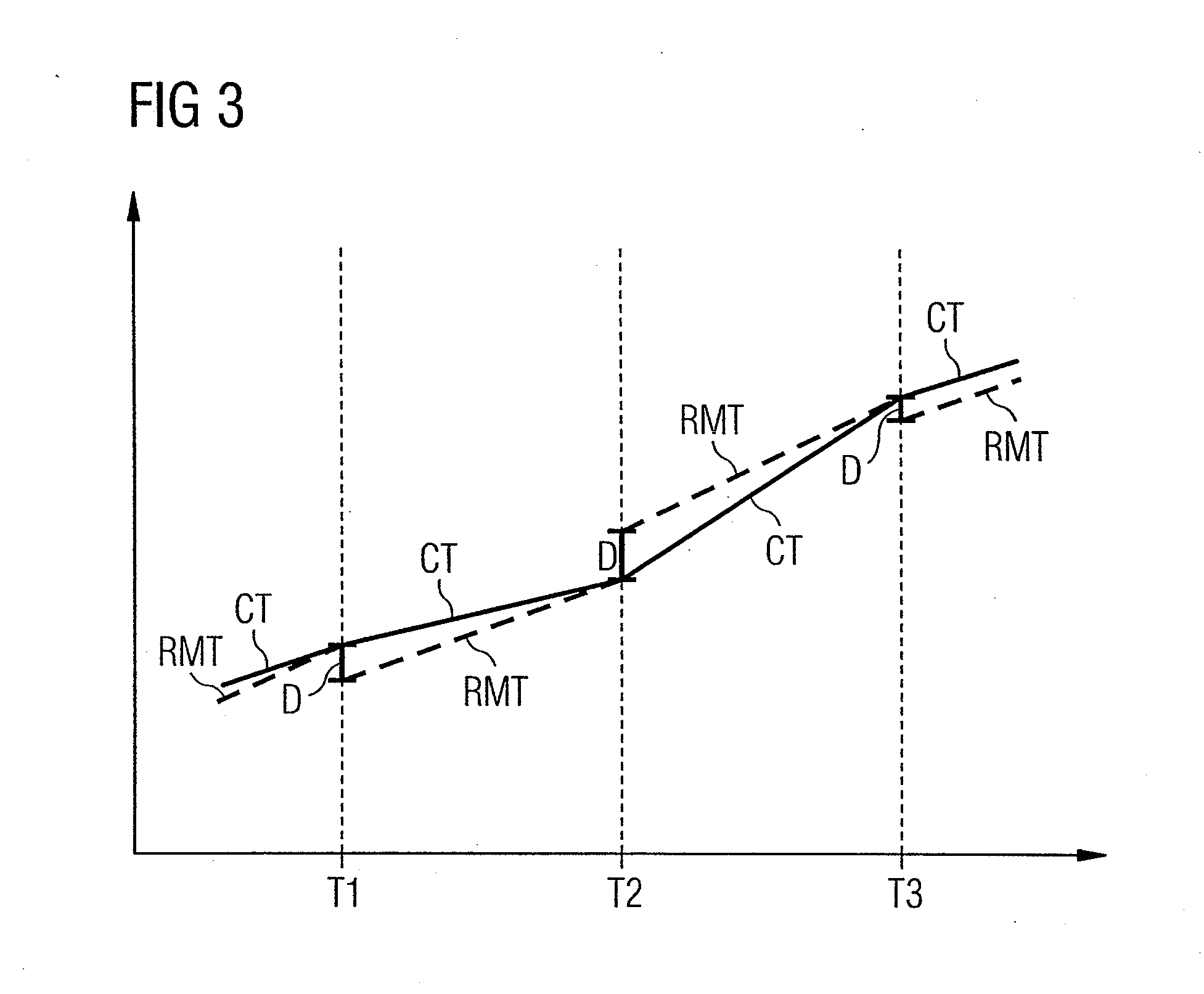

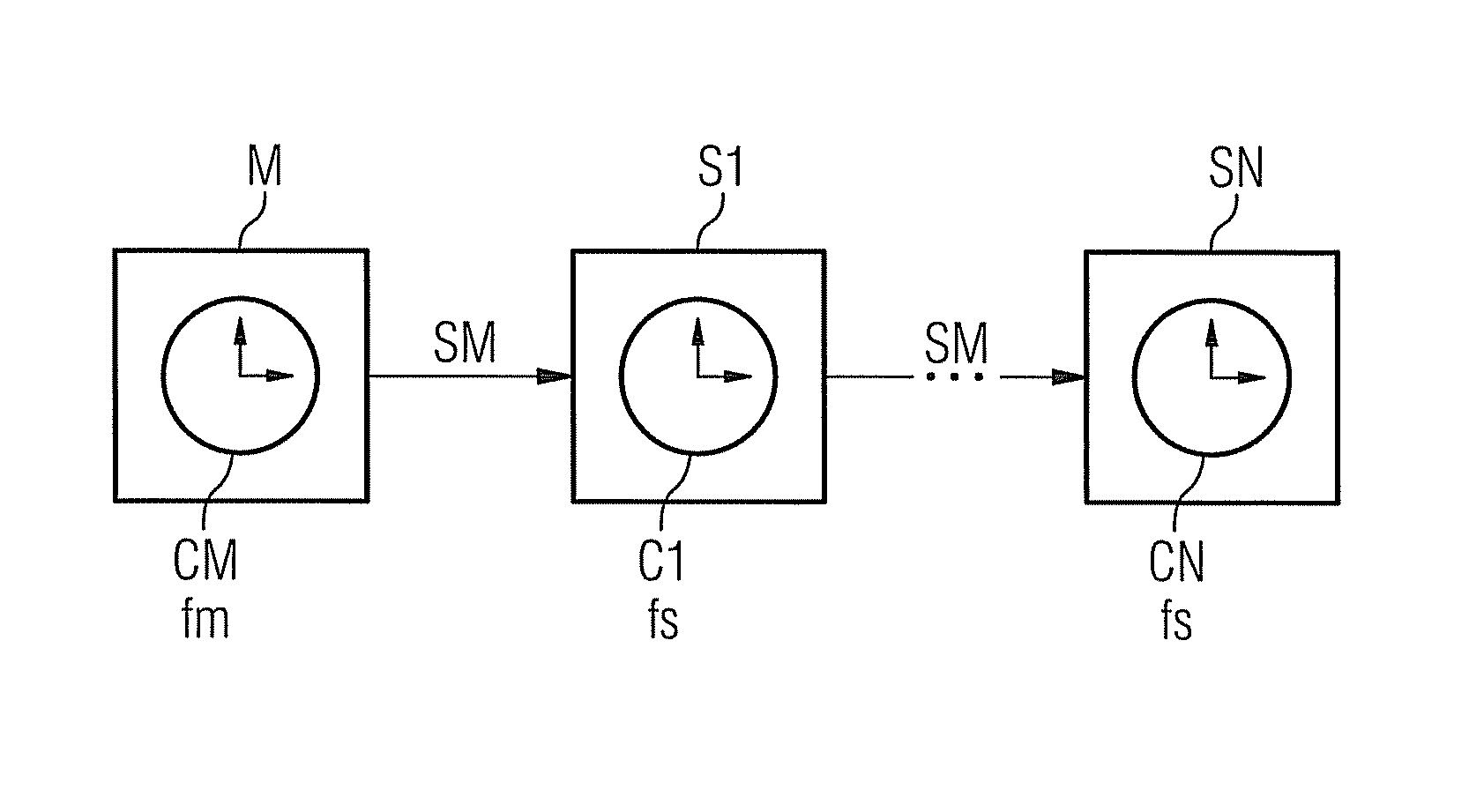

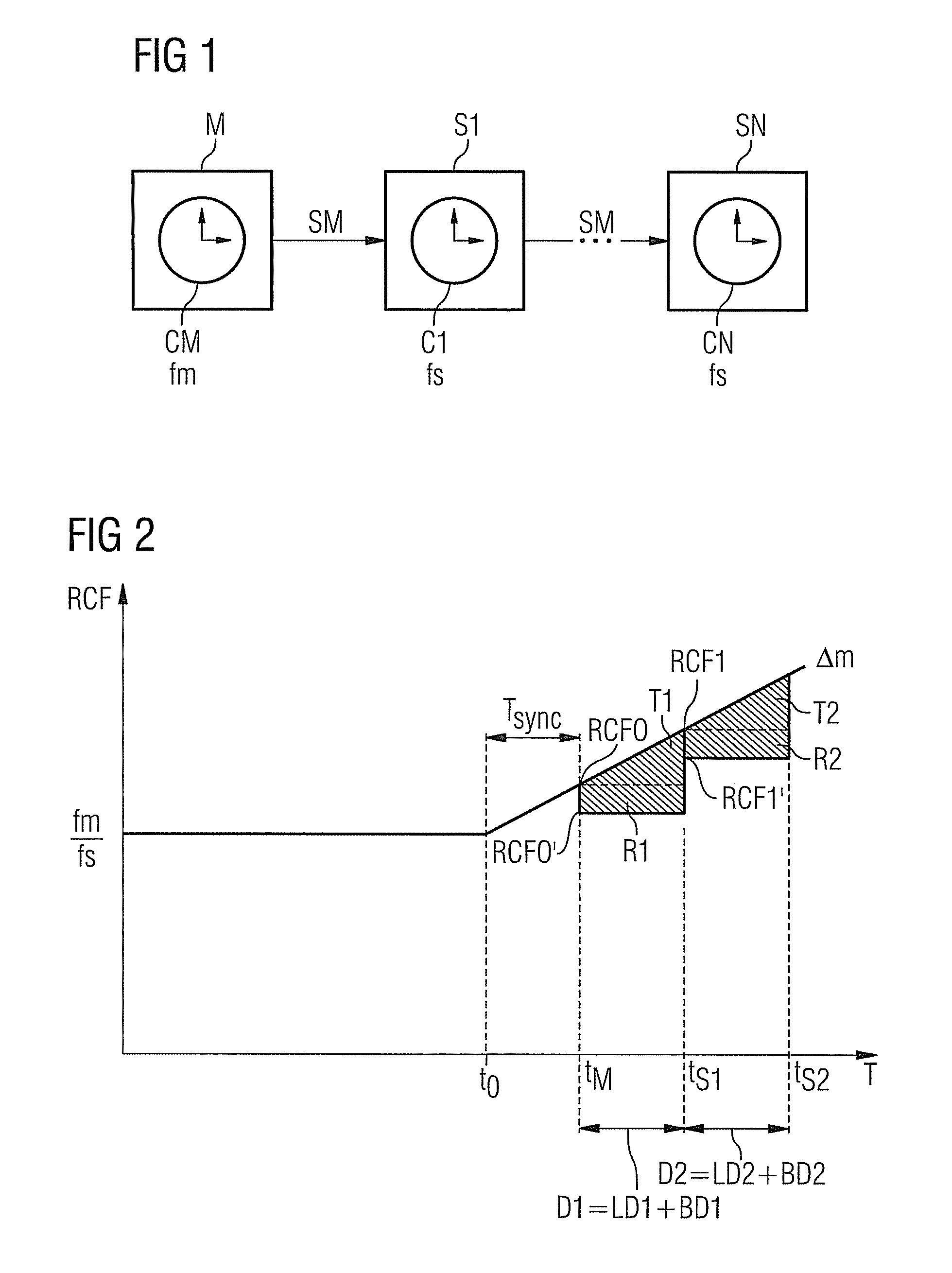

Method for transmitting synchronization messages in a communication network

ActiveUS20090086766A1Accurate synchronizationAccurate measurementTime-division multiplexSynchronization networksTime changes

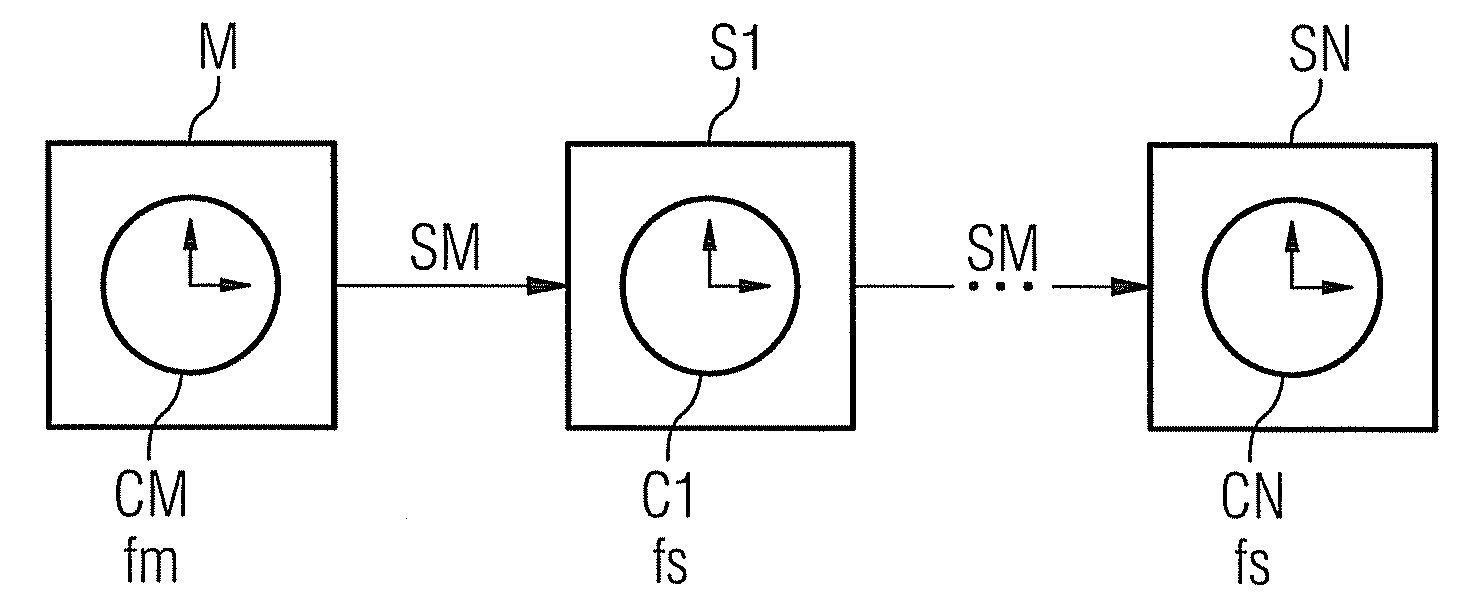

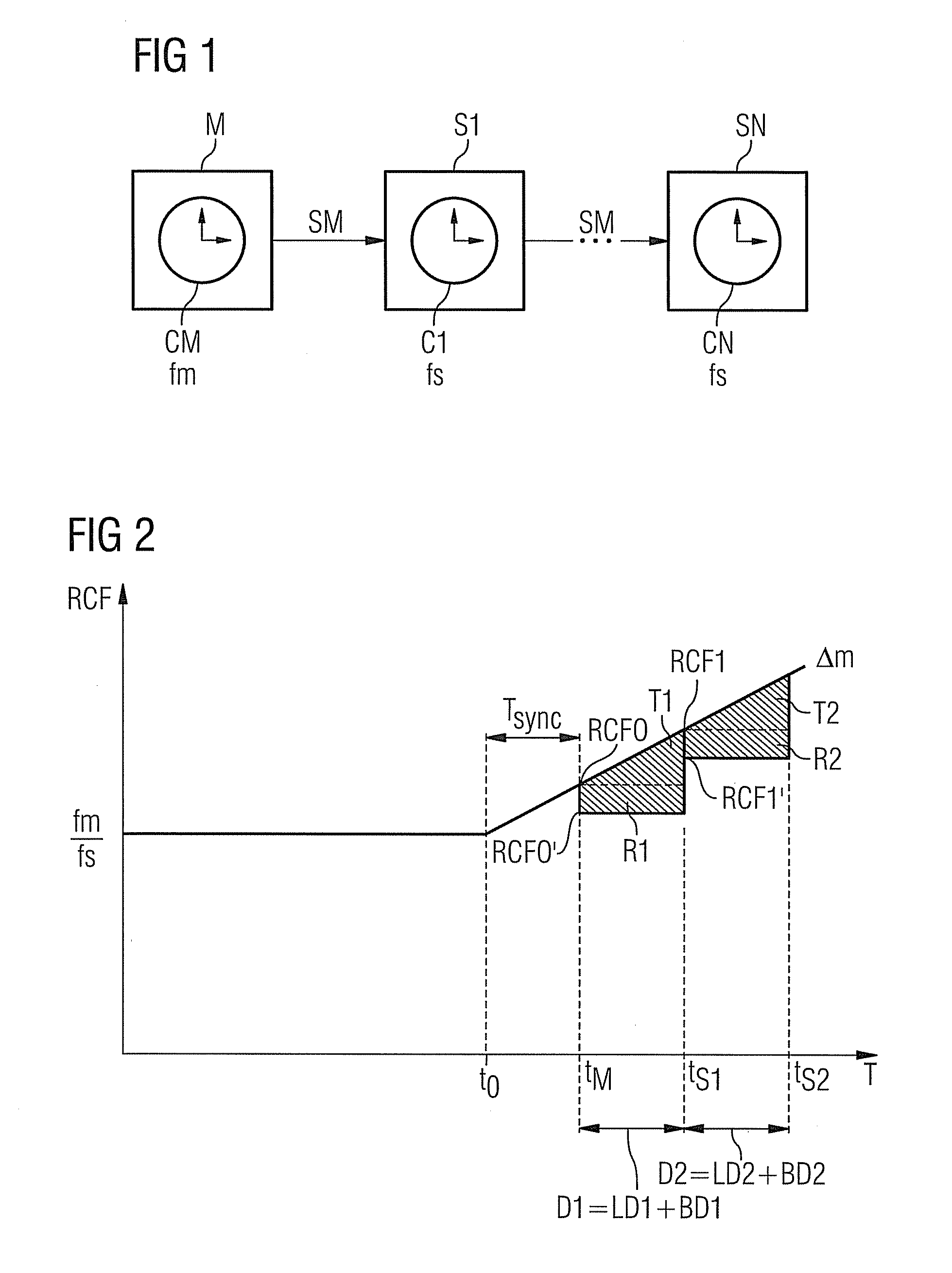

There is described a method for transmitting synchronization messages in a communication network, the communication network comprising a plurality of network nodes communicating with one another, each containing an internal clock, which is timed with a node clock frequency assigned to the respective network node. The synchronization messages transmitted in the communication network serve to synchronize the times of the internal clocks of the network nodes and contain the pulse counter status of a synchronization clock operating at a predefined synchronization clock frequency. The pulse counter status is estimated by each network node and updated in the synchronization message. Changes in the synchronization clock frequency are taken into account when estimating the pulse counter status. Precise determination of the pulse counter status is achieved with the aid of an approximation of the change over time in the pulse ratio between synchronization clock frequency and node clock frequency by means of a function, with the result that the pulse ratio on transmission of a new synchronization message can be predicted and a precise current pulse counter status can be determined on the basis of the predicted pulse ratio. The method is particularly suitable for use in a communication network of an industrial automation system, whose components communicate with one another for example according to the Profinet standard.

Owner:SIEMENS AG

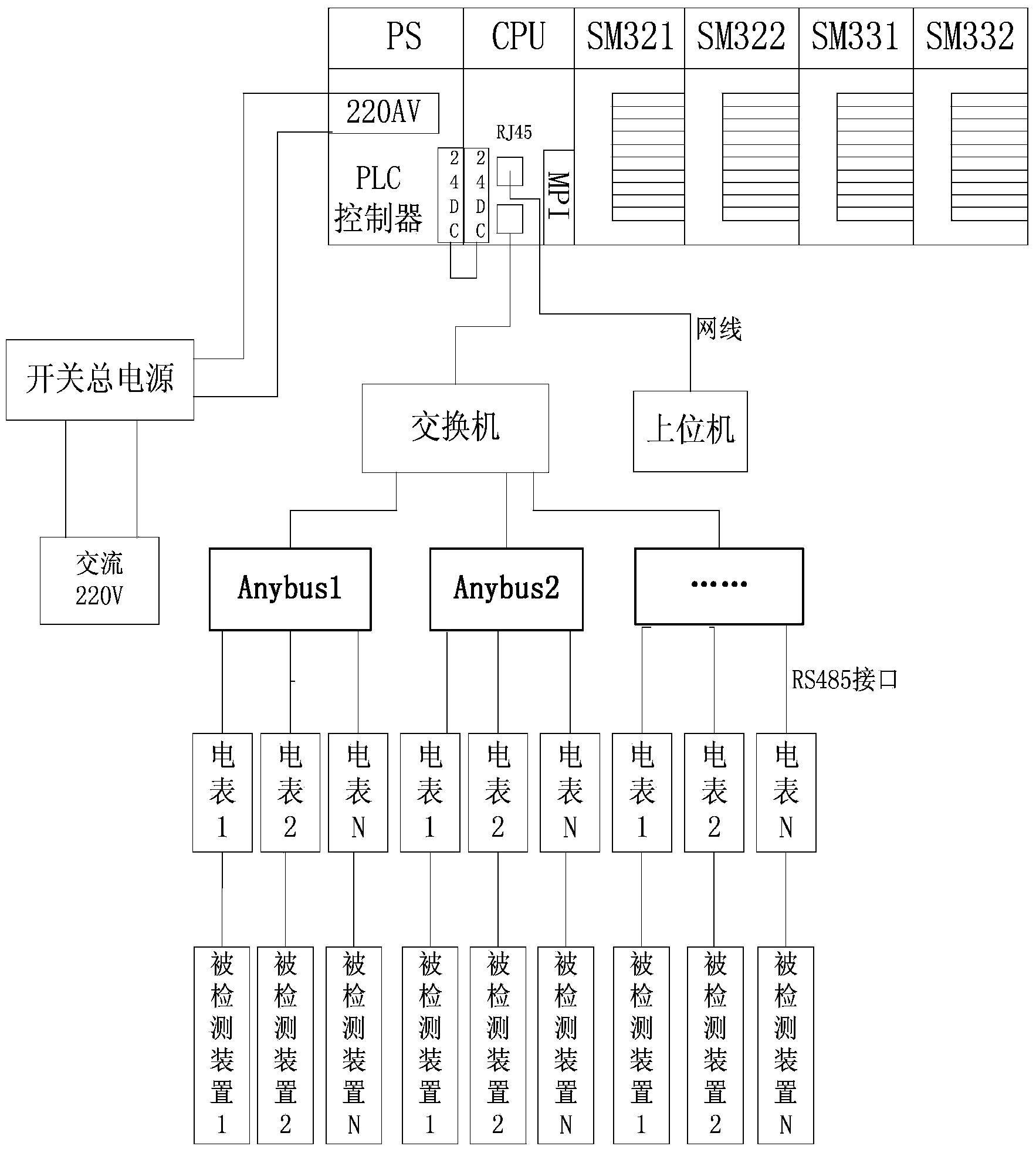

Interactive and smart electric energy distribution and consumption monitoring device and method

ActiveCN103944265AGood for regular checkingGuarantee energy saving and consumption reductionCircuit arrangementsElectrical engineering technologySmart data

The invention provides an interactive and smart electric energy distribution and consumption monitoring device and method, and belongs to the technical field of electric engineering. An Anybus Profinet AB7013 webmaster is used for breaking through limit of the line distribution length and the communication bottleneck that one through network is hard to realize, the operating condition of a detected device is flexibly detected, start and stop of an operating device are controlled, an electrical load for alarming is omitted, and the electric energy waste condition due to abnormal operation of the electrical load is avoided; for the detected device, different device types and different regional devices can be involved, and the requirement for distributed smart data collection can be met; by means of a terminal user energy-saving monitoring, analysis and optimization technology, comprehensive energy conservation of multiple building groups and multiple districts can be achieved, and energy efficiency is improved; collected user requirement data are stored in an upper computer in a report mode, mangers can conveniently check the data regularly, energy conservation and consumption reduction in the electrical industry are guaranteed, and operation is safe and efficient.

Owner:STATE GRID CORP OF CHINA +2

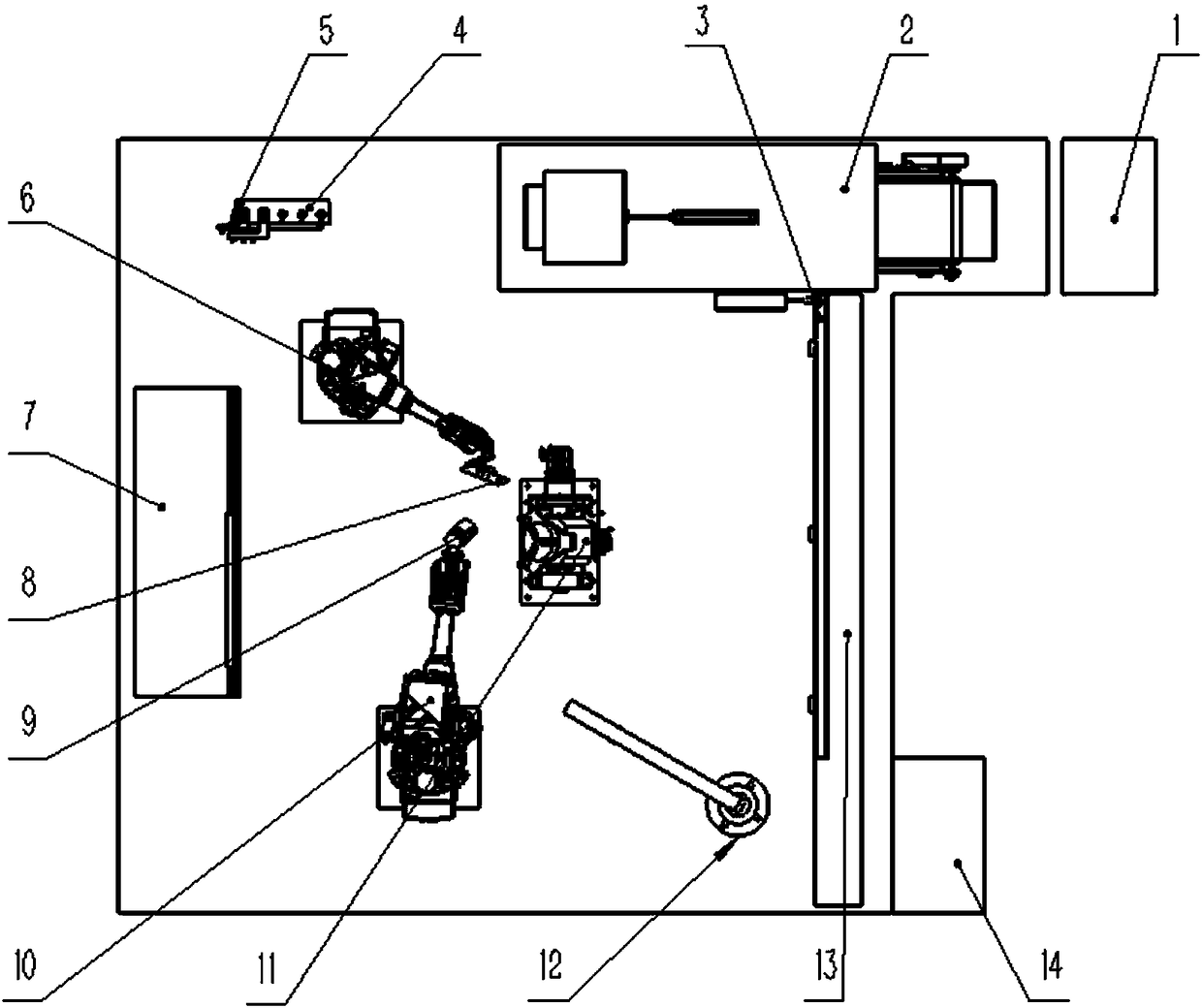

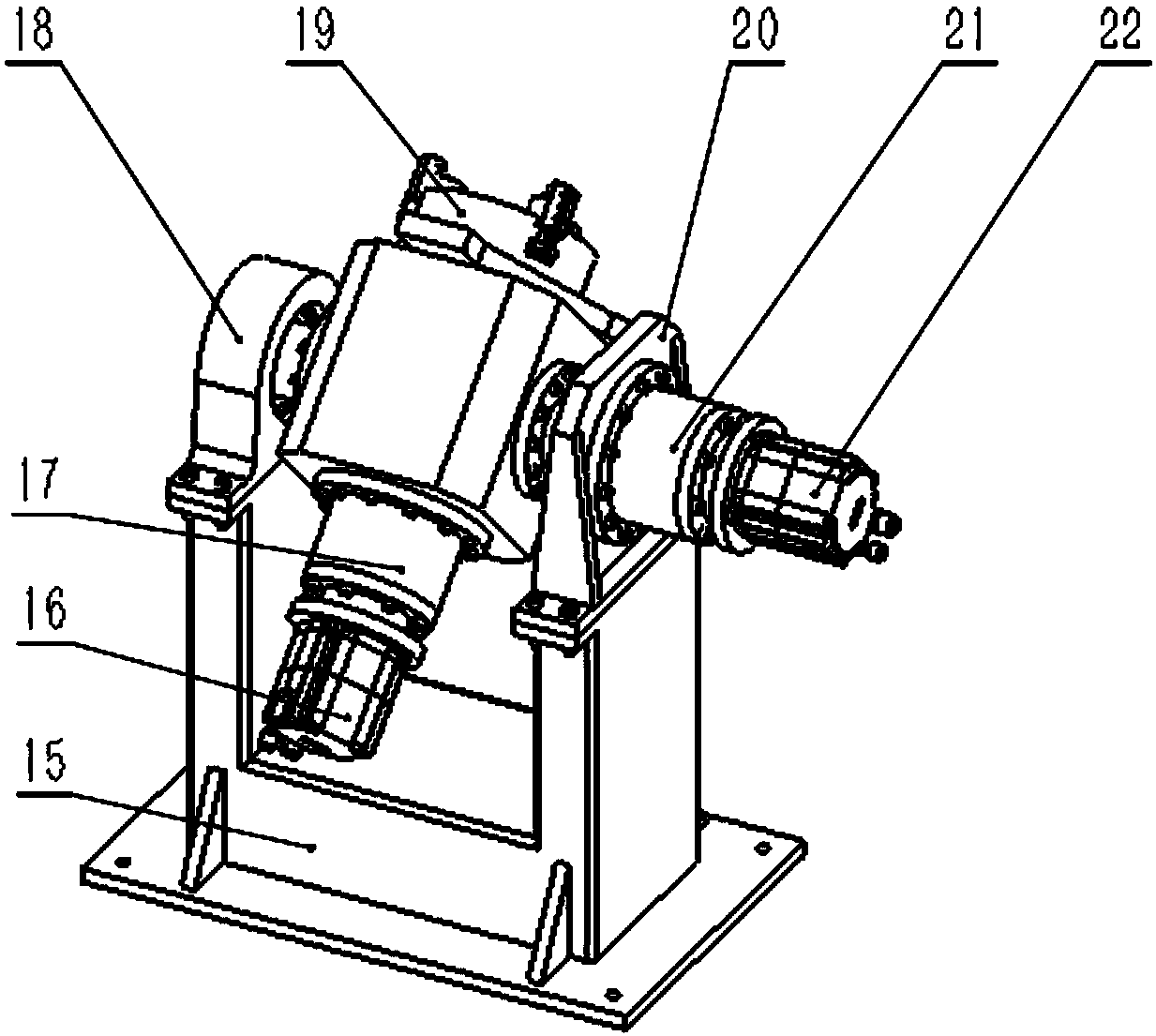

Digital ray automatic detecting system and method for detecting wheel parts

PendingCN108152306AGuaranteed postureShort processMaterial analysis by transmitting radiationDigital RayEngineering

The invention relates to a digital ray automatic detecting system and method for detecting wheel parts. The system comprises a PLC console, a CR imaging device, two industrial robots, an X-ray machine, a quick-change gripper frame, a quick-change gripper, a storage cabinet, a conveying device, a rotating worktable, a door groove cover plate, a small-sized cantilever crane and an automatic lead door; the PLC console and the CR imaging device are arranged outside a protective lead room; the two industrial robots, the X-ray machine, the quick-change gripper frame, the quick-change gripper, the storage cabinet, the conveying device, a rotating worktable, the door groove cover plate, the small-sized cantilever crane and the automatic lead door are arranged in the protective lead room. The X-raymachine is installed at the tail end of the large robot, and the PLC console controls the two industrial robots and the rotating worktable through Profinet buses, controls the X-ray machine through an RS-232 serial port and controls the quick-change gripper, the conveying device, the storage cabinet, the automatic lead door and the door groove cover plate through IO modules. The digital ray automatic detecting system and method have the advantages that 1, the detection efficiency is improved, and the time for manual placement and opening and closing of the lead door is saved; 2, the detectionaccuracy is improved; 3, the detection cost is reduced.

Owner:WUHAN UNIV OF TECH +1

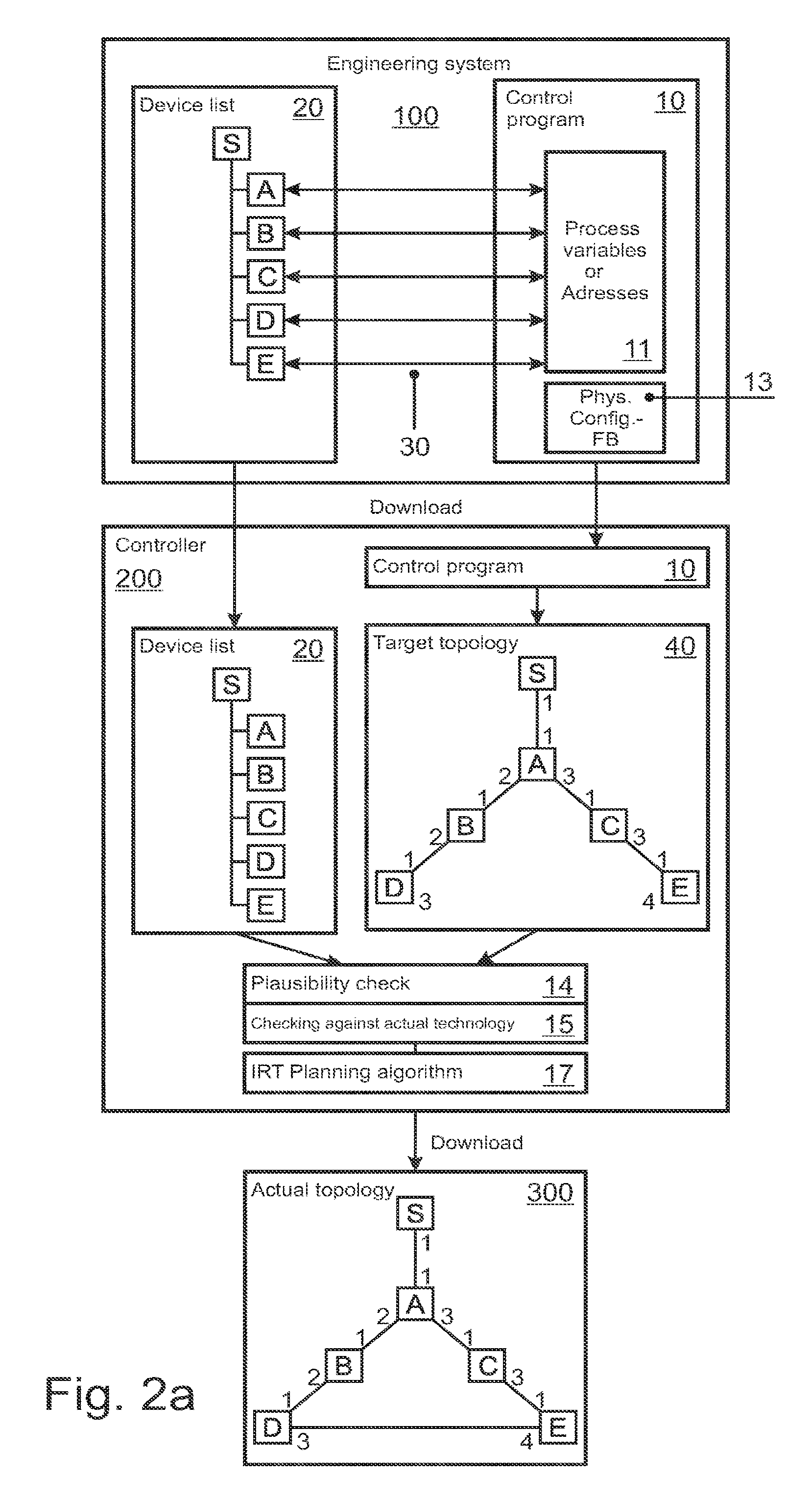

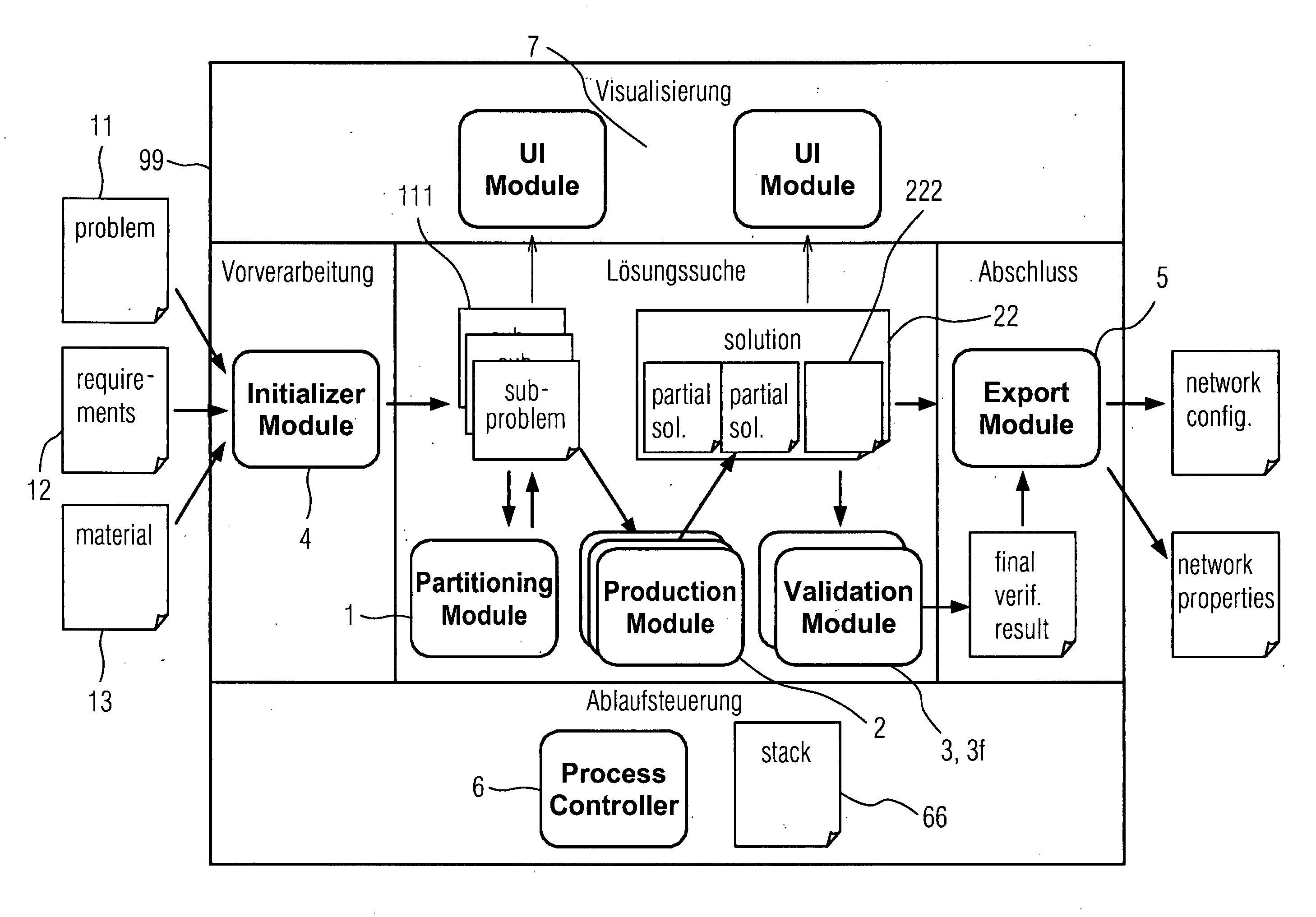

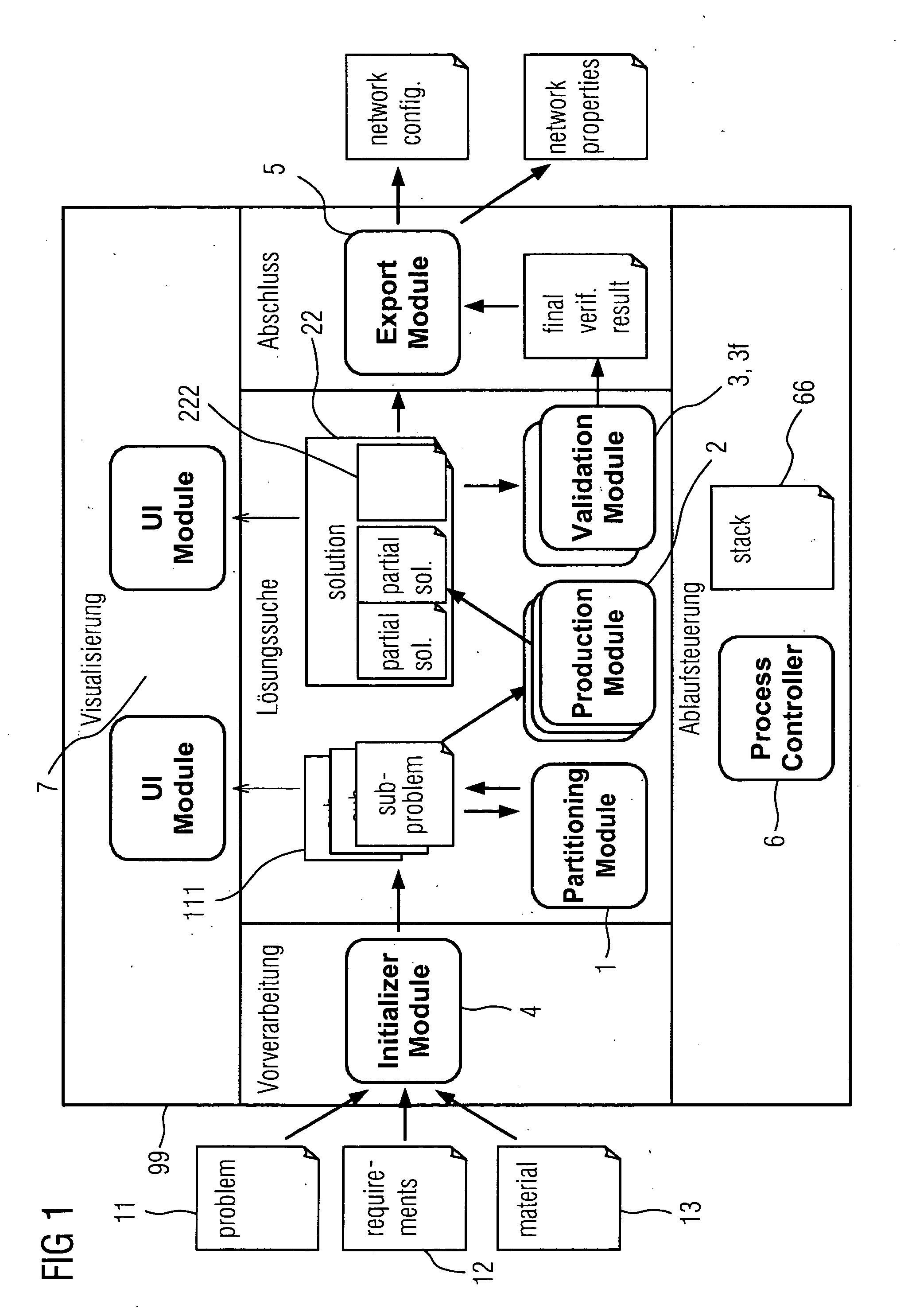

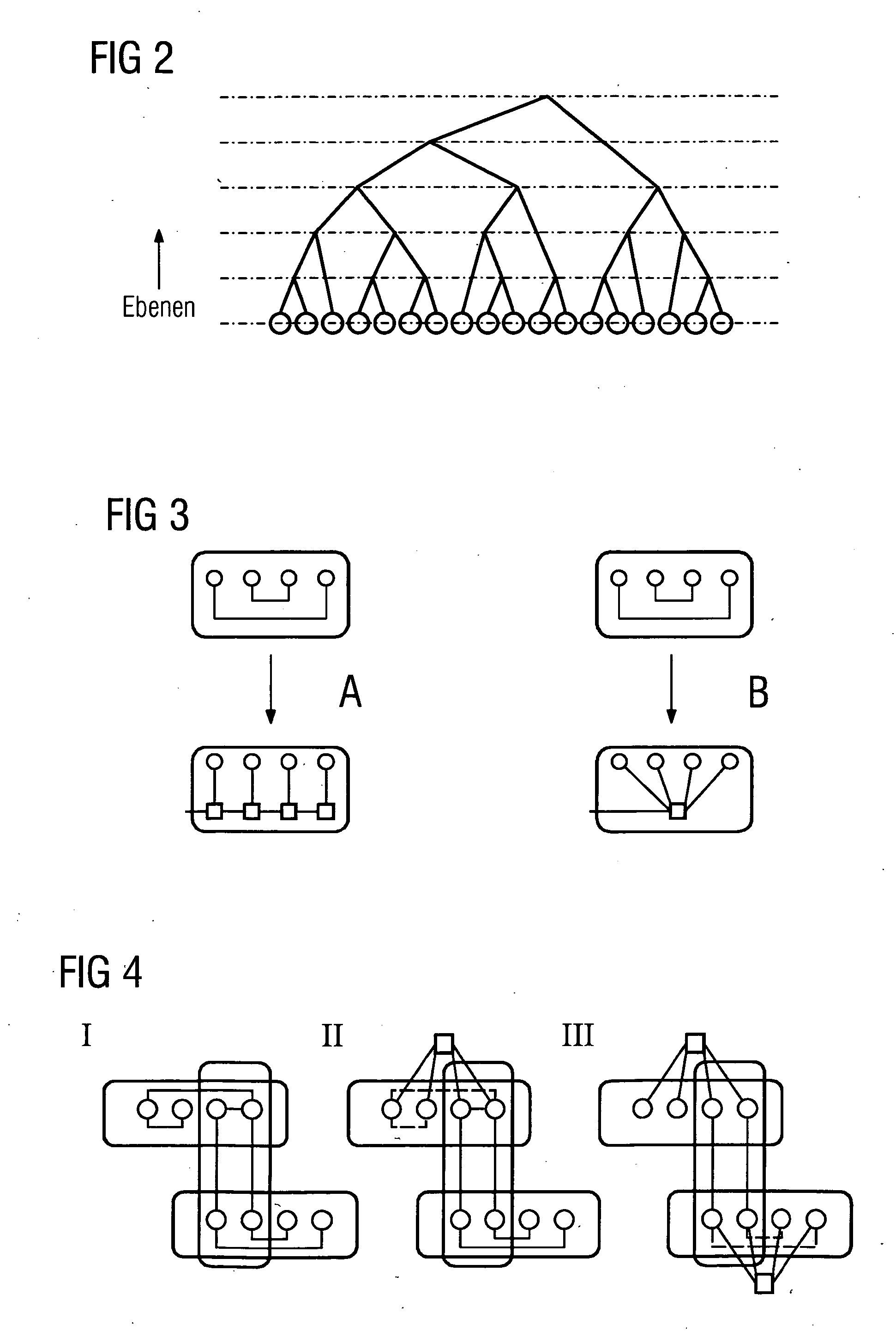

Automatic planning of network configurations

InactiveUS20060026276A1Easy to set upReduce spendingDigital computer detailsData switching networksNetwork structureEthernet lan

The invention relates to a device and a method, which reduce the outlay required when searching for a suitable network configuration, in particular in the field of automation. The device for the automatic planning of a network configuration, in particular for an automation system, comprises at least one partition module to break down at least one described network planning problem into sub-problems, at least one production module to generate at least one solution to each of the sub-problems of the at least one network planning problem based on predefinable rules and at least one validation module to verify the generated solutions to the sub-problems. The purpose of the device and the method according to the invention for automatic network planning is to support the planning process for network structures for major systems, in particular for systems with more than 1000 users, by supplying suitable methods and tools. One of the focal areas is switch-based Ethernet-LANs, as used for example in PROFInet environments.

Owner:SIEMENS AG

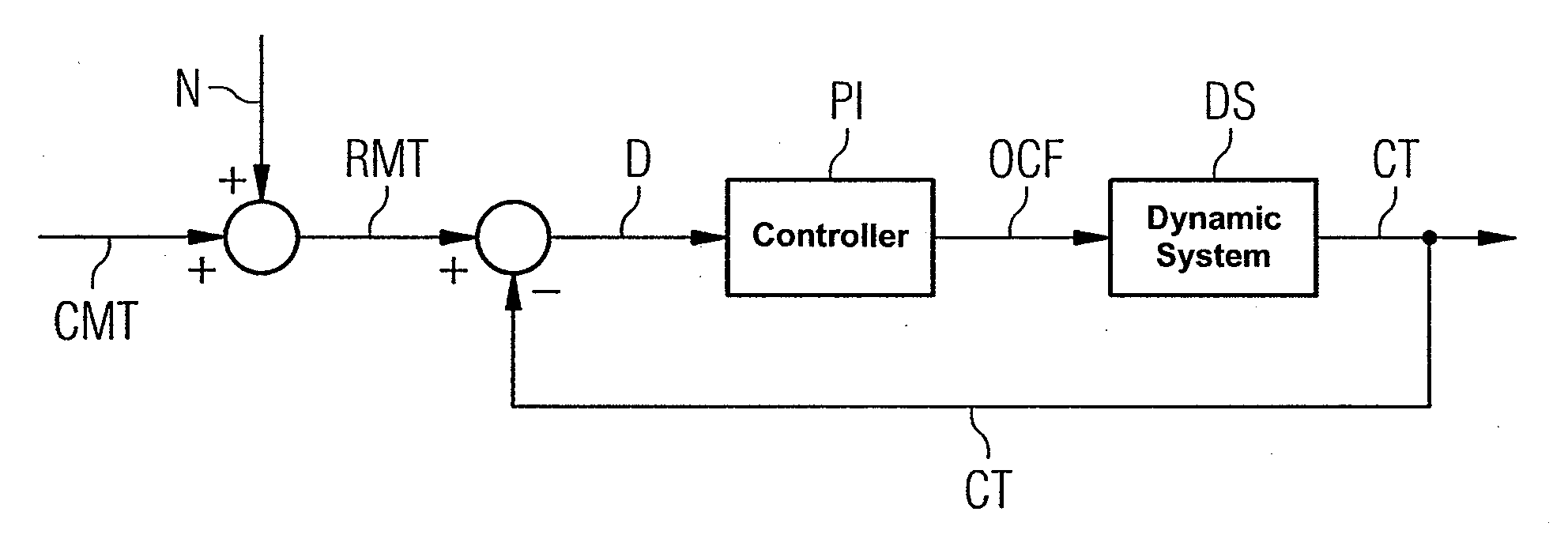

Device and Method for Time Synchronization in a Communication Network

ActiveUS20110064177A1Improve referenceGood estimateTime-division multiplexSynchronising arrangementTime criticalPROFINET

A device and method for time synchronization in a communication network, wherein a virtual clock is produced by a controller in each network node based on the PROFINET-Standard and / or the Precision Transparent Clock Protocol. In contrast to known methods for estimating the time, the time of the virtual clock does not undergo sudden changes. The virtual clock includes a controlled, continuous path. As a result, the virtual clock is particularly suitable for time-critical applications. Here, the estimation of the time of a reference clock is improved by 18-35%. Accordingly, a markedly greater number of network nodes may be synchronized with a predetermined level of accuracy for the time synchronization.

Owner:SIEMENS AG

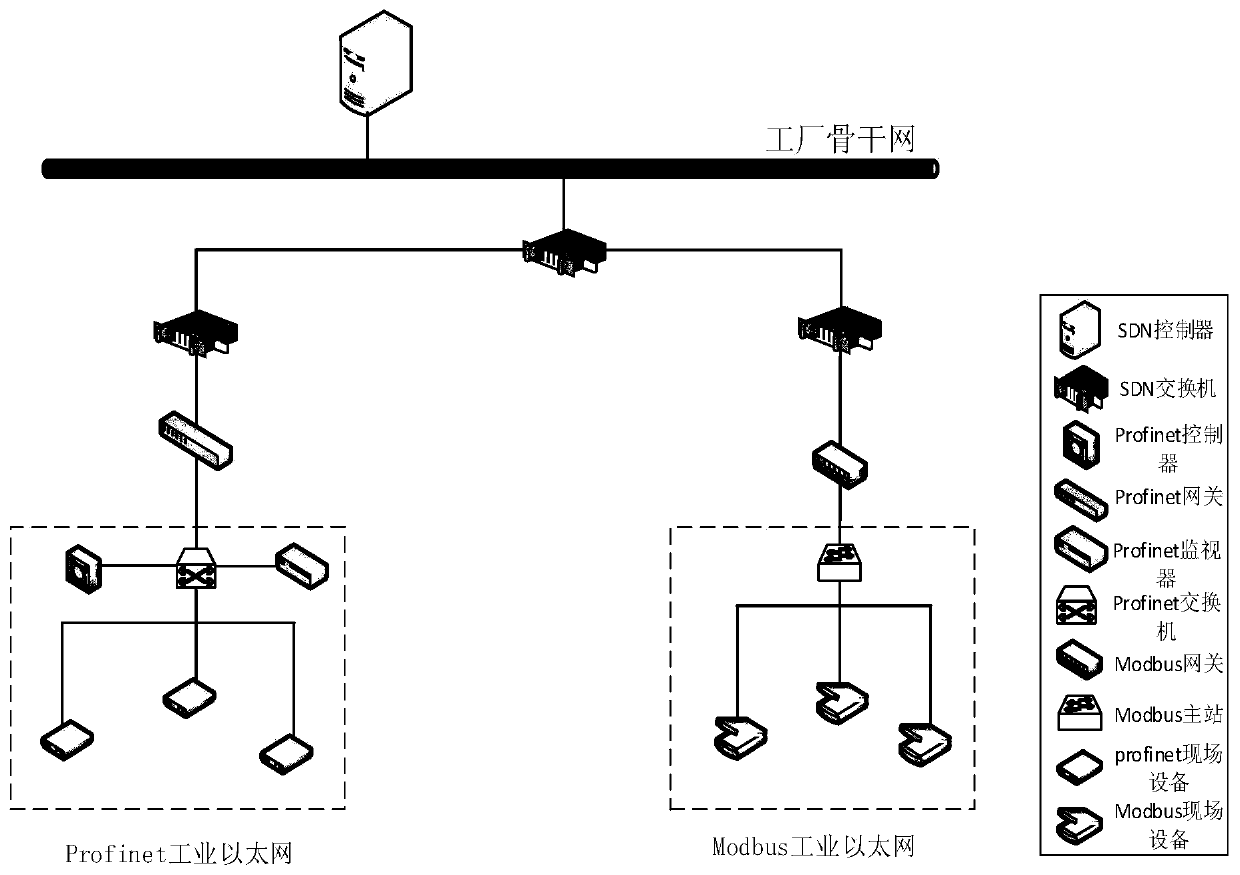

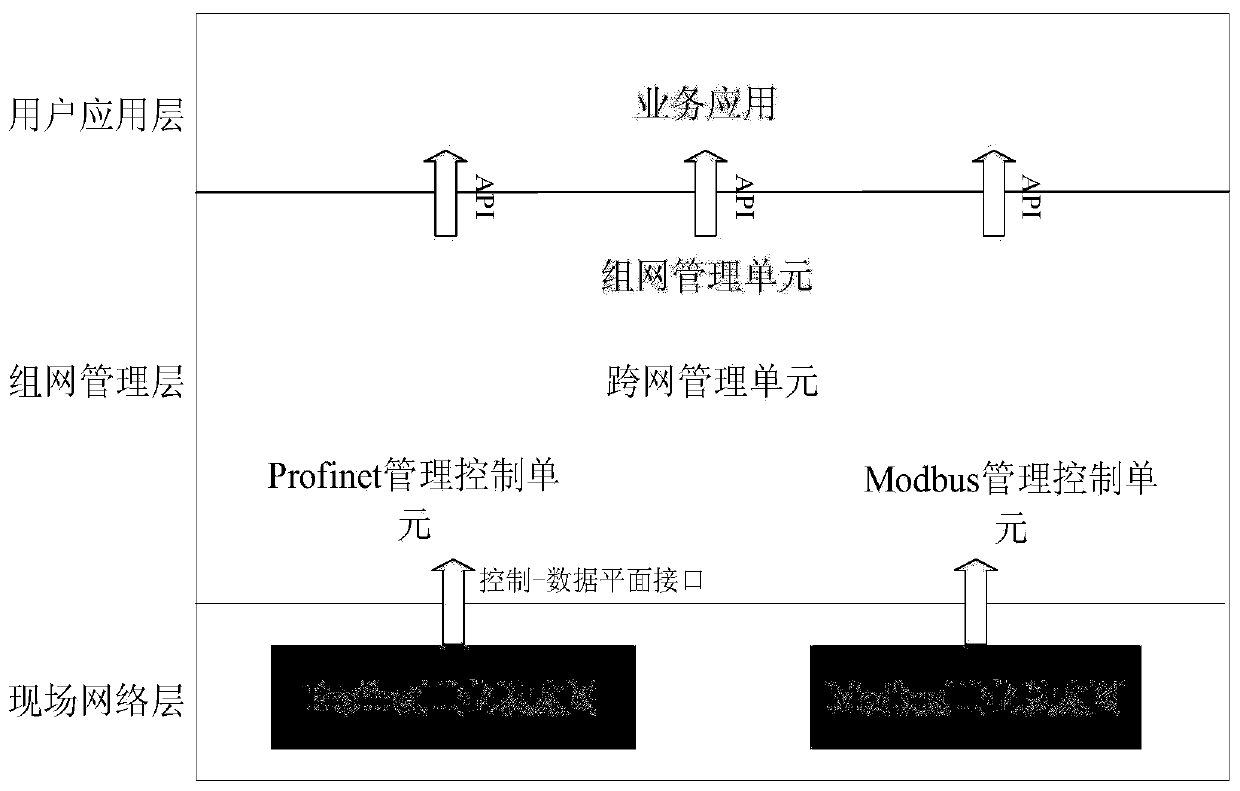

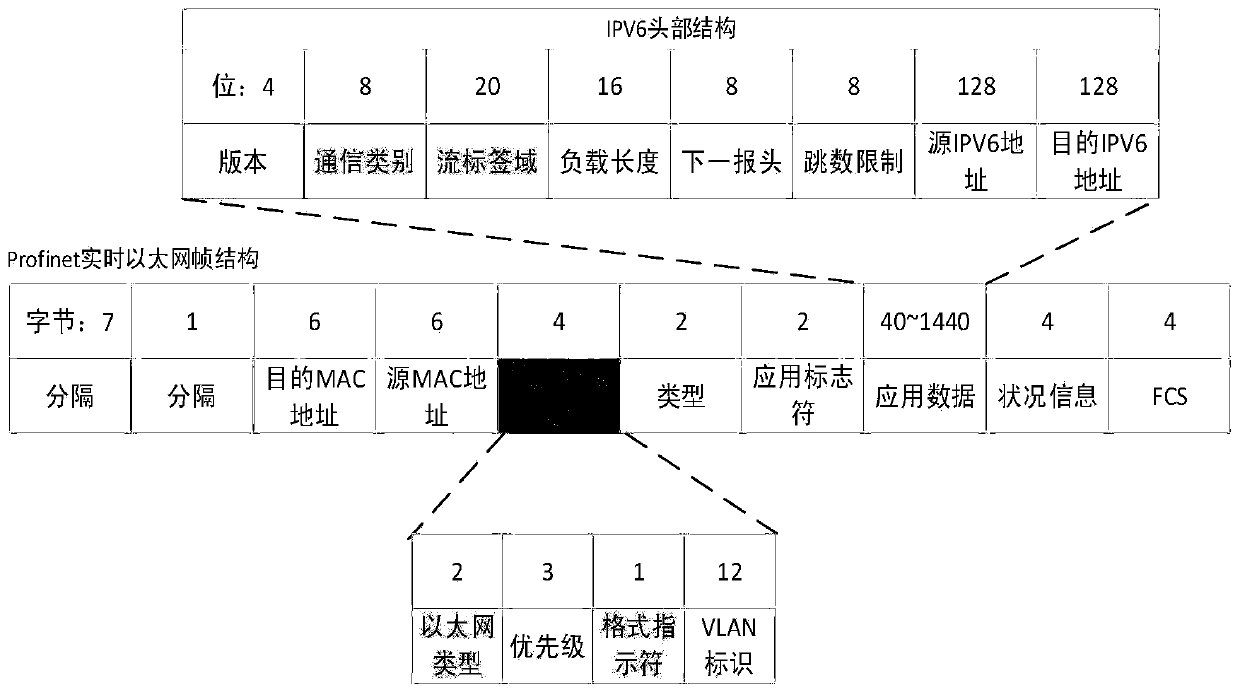

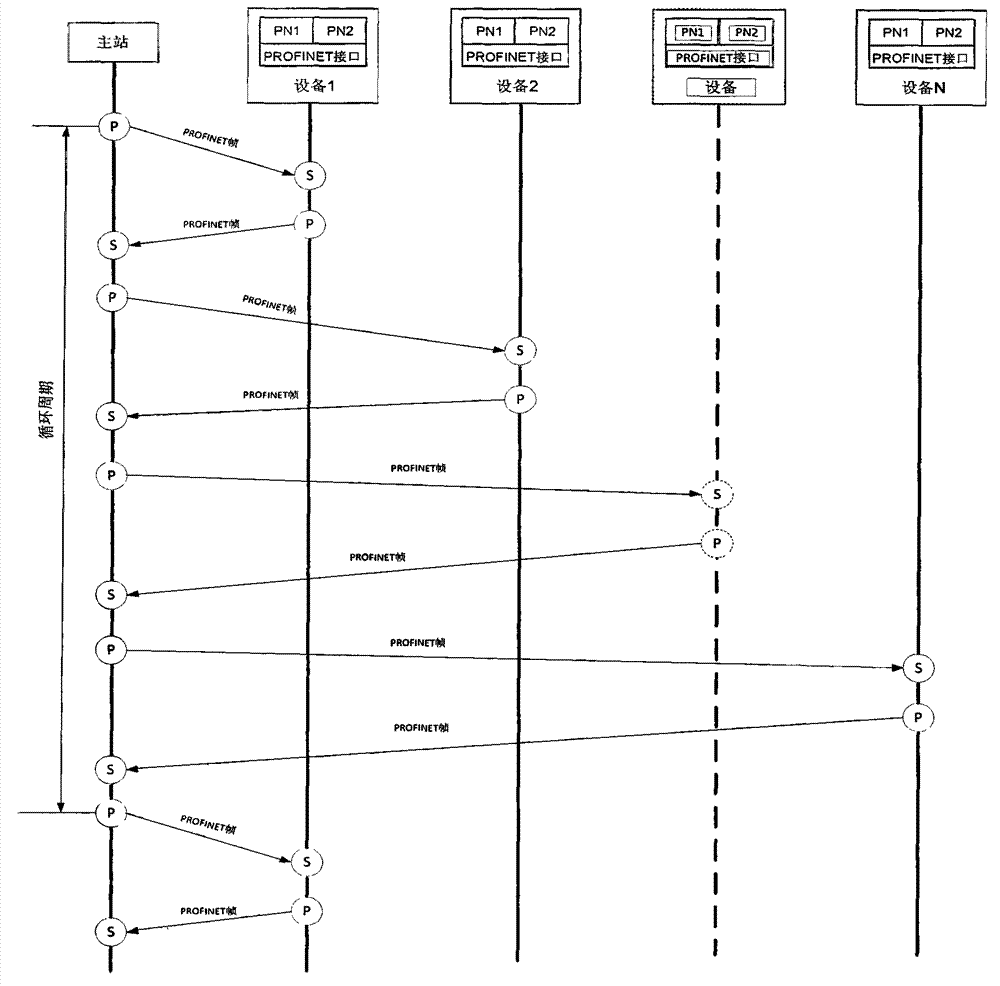

Profinet and Modbus equipment heterogeneous networking method based on SDN (Software Defined Network)

ActiveCN110460483ASolve communication problemsImprove efficiencyData switching networksModbusNetwork communication

The invention relates to a Profinet and Modbus equipment heterogeneous networking method based on an SDN, and belongs to the technical field of industrial networks. According to the method, an SDN (Software Defined Network) is applied to Profinet and Modbus heterogeneous industrial Ethernet networking; under the condition of unified identification flow based on Profinet and Modbus, networking topology establishment of heterogeneous industrial Ethernet Profinet and Modbus, equipment network access, cross-network communication application relationship establishment, cross-network communication data exchange completion and other functions are integrated, and networking management of Profinet / Modbus heterogeneous industrial Ethernet equipment is realized. According to the method, the problem of cross-network networking communication between Profinet equipment and Modbus equipment is solved, and the efficiency and flexibility of heterogeneous networking are improved through the SDN controller.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Data transmission system and method used between energy storage power station site equipment

ActiveCN104767598AGood effectReliable transmissionError preventionTotal factory controlPower stationDistributed control system

The invention relates to a data transmission system and method used between energy storage power station site equipment. The data transmission system is a distributed control system based on a PROFINET bus. The distributed control system comprises two or more sub units of the energy storage power station, an ethernet network ring framework is formed between the sub units of the energy storage power station through a PROFINET ethernet switch, and the PROFINET ethernet switch is connected with a monitor station of the energy storage power station. Each sub unit comprises a master station and two or more slave stations, and the master station is connected with the slave stations through the PROFINET bus. According to the technical scheme of the data transmission system and method used between energy storage power station site equipment, fast, synchronized and reliable data transmission can be realized.

Owner:STATE GRID CORP OF CHINA +3

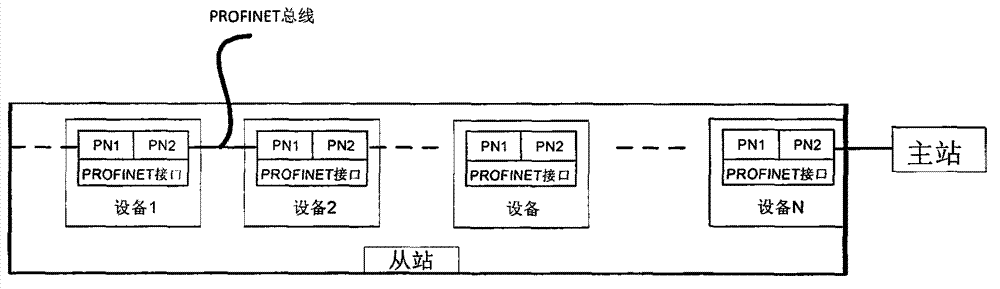

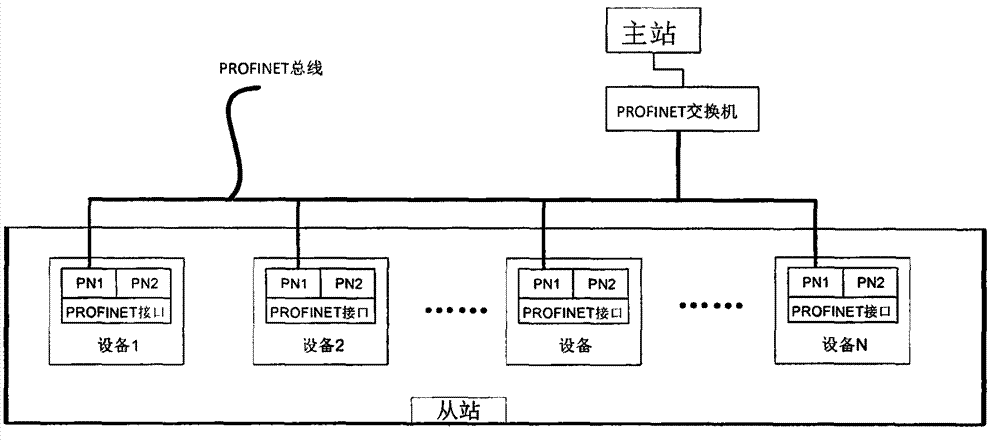

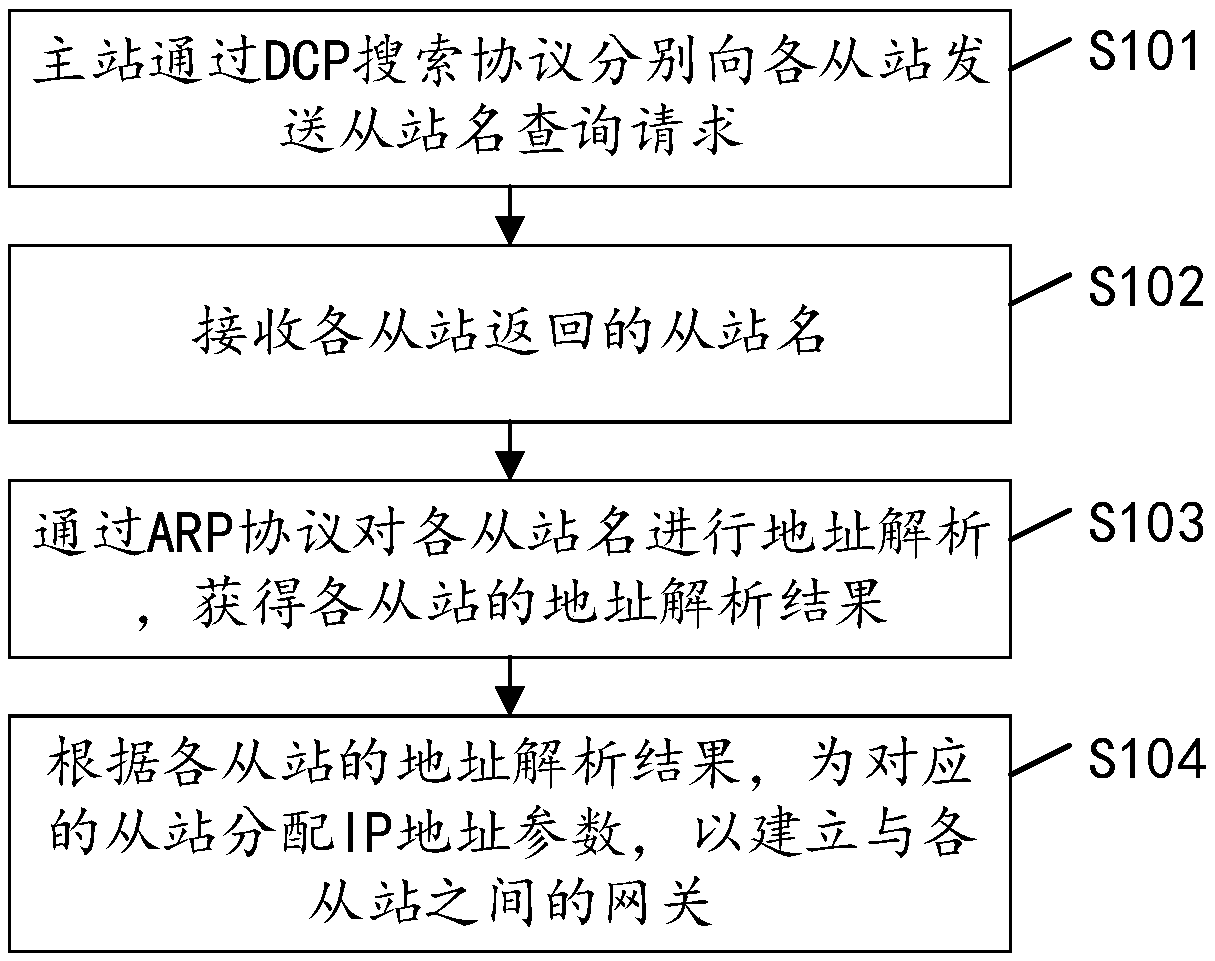

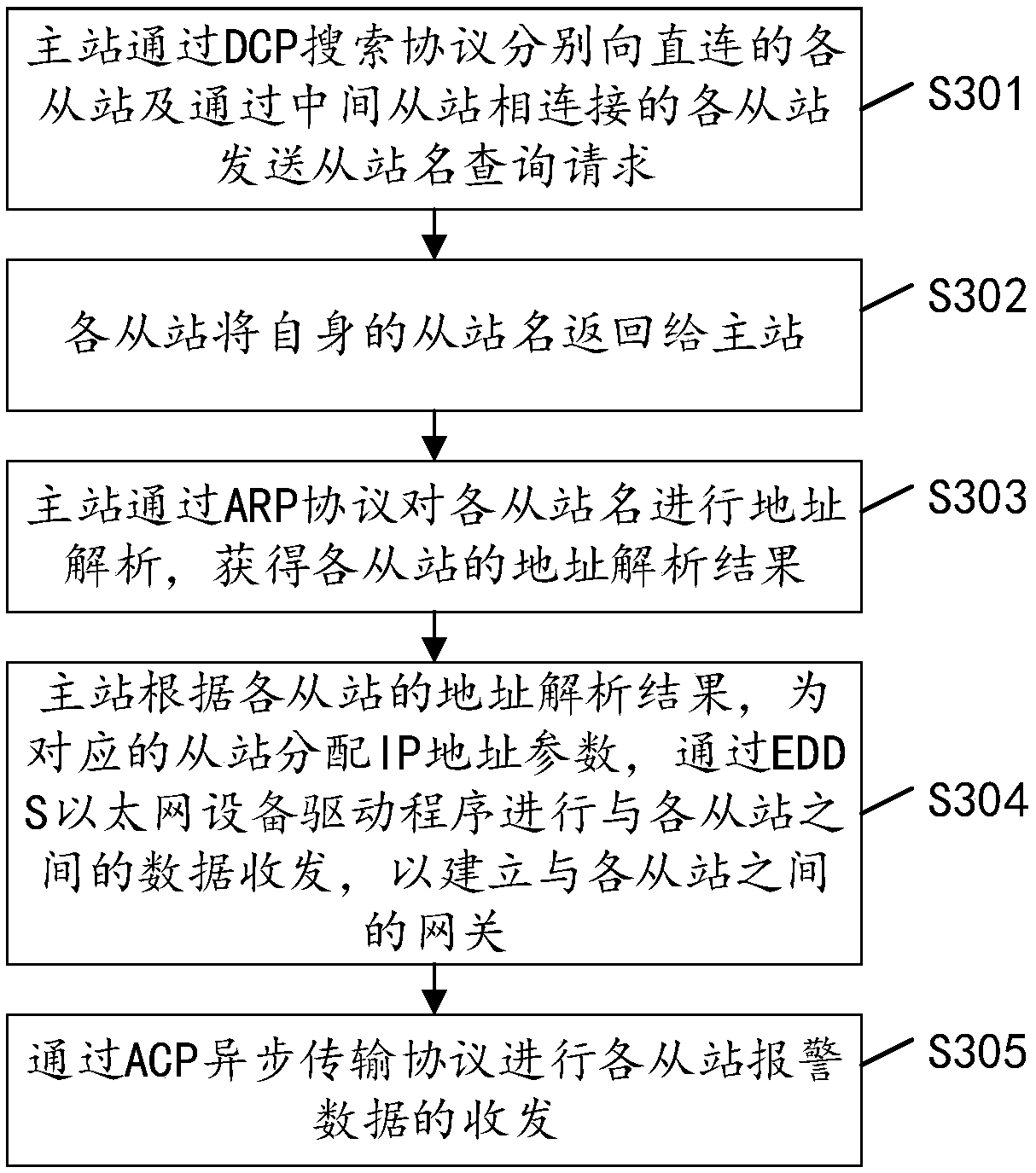

a method and a device for realizing a PROFINET industrial Ethernet gateway

ActiveCN109067644ASolve problemsSolve complexityProgramme controlComputer controlIp addressAddress resolution

The invention discloses a method for realizing PROFINET industrial Ethernet gateway. The method comprises the following steps: a master station respectively sends a slave station name inquiry requestto each slave station through a DCP search protocol; the master station sends the slave station name inquiry request to each slave station. Receiving a master station name returned by each slave station. The address resolution of each slave station is performed by ARP protocol, and the address resolution results of each slave station are obtained. According to the address resolution result of eachslave station, IP address parameters are assigned to the corresponding slave station to establish a gateway with each slave station. The technical proposal provided by the embodiment of the inventiondoes not require an external PROFINET protocol special chip, solves the problem of complex maintenance and replacement procedures of the PROFINET protocol special chip, and reduces the cost. The invention also discloses an implementation device, a device and a storage medium of a PROFINET industrial Ethernet gateway, which have corresponding technical effects.

Owner:HANGZHOU HOLLYSYS AUTOMATION

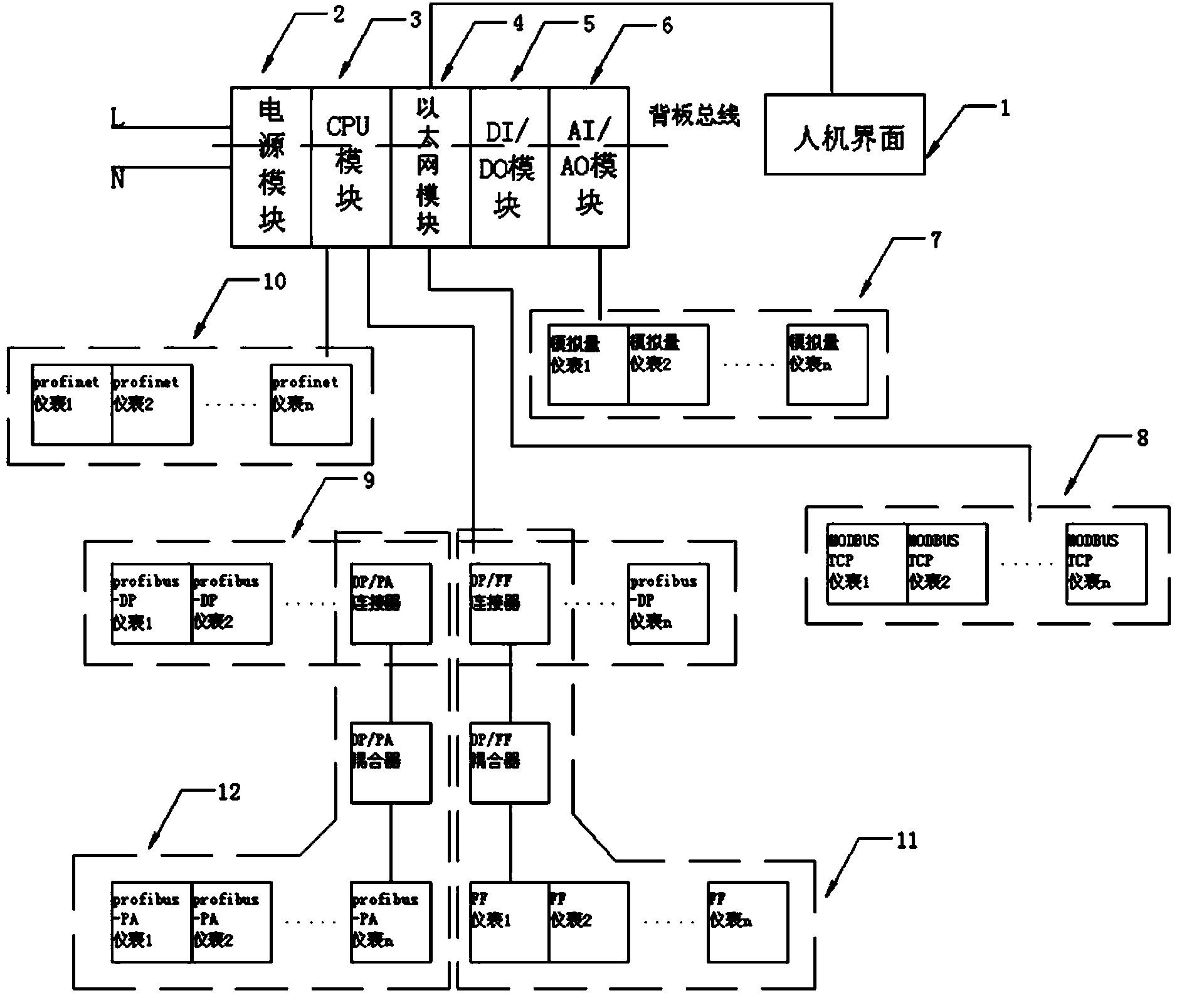

Multi-protocol reconfigurable bus-based instrument experiment system

InactiveCN103970100AImprove interchangeabilityAvoid reprogrammingTotal factory controlProgramme total factory controlHuman–machine interfaceMulti protocol

The invention relates to a multi-protocol reconfigurable bus-based instrument experiment system. The system comprises a human-computer interface, a PLC hardware system and a reconfigurable intelligent instrument system. The PLC hardware system comprises a power module, a CPU module, an Ethernet module, a DI / DO module and an AI / AO module. The human-computer interface is in communication connection with the PLC hardware system through the Ethernet module. The reconfigurable intelligent instrument system comprises an analog quantity instrument system, a MODBUSTCP instrument system, a Profibus-DP instrument system, a Profinet instrument system, an FF instrument system and a Profibus-PA instrument system. The multi-protocol reconfigurable bus-based instrument experiment system can achieve the purpose that software and hardware are reused to the largest extent and achieve interchange of bus-based instruments, so that the fact that the software is repeatedly programmed due to system upgrade or test demand changing is avoided, the flexibility of the system can be greatly improved, and development time is reduced.

Owner:CHINA TOBACCO ZHEJIANG IND

Method for transmitting synchronization messages in a communication network

ActiveUS7848360B2Accurate synchronizationAccurate measurementTime-division multiplexSynchronization networksTime changes

There is described a method for transmitting synchronization messages in a communication network, the communication network comprising a plurality of network nodes communicating with one another, each containing an internal clock, which is timed with a node clock frequency assigned to the respective network node. The synchronization messages transmitted in the communication network serve to synchronize the times of the internal clocks of the network nodes and contain the pulse counter status of a synchronization clock operating at a predefined synchronization clock frequency. The pulse counter status is estimated by each network node and updated in the synchronization message. Changes in the synchronization clock frequency are taken into account when estimating the pulse counter status. Precise determination of the pulse counter status is achieved with the aid of an approximation of the change over time in the pulse ratio between synchronization clock frequency and node clock frequency by means of a function, with the result that the pulse ratio on transmission of a new synchronization message can be predicted and a precise current pulse counter status can be determined on the basis of the predicted pulse ratio. The method is particularly suitable for use in a communication network of an industrial automation system, whose components communicate with one another for example according to the Profinet standard.

Owner:SIEMENS AG

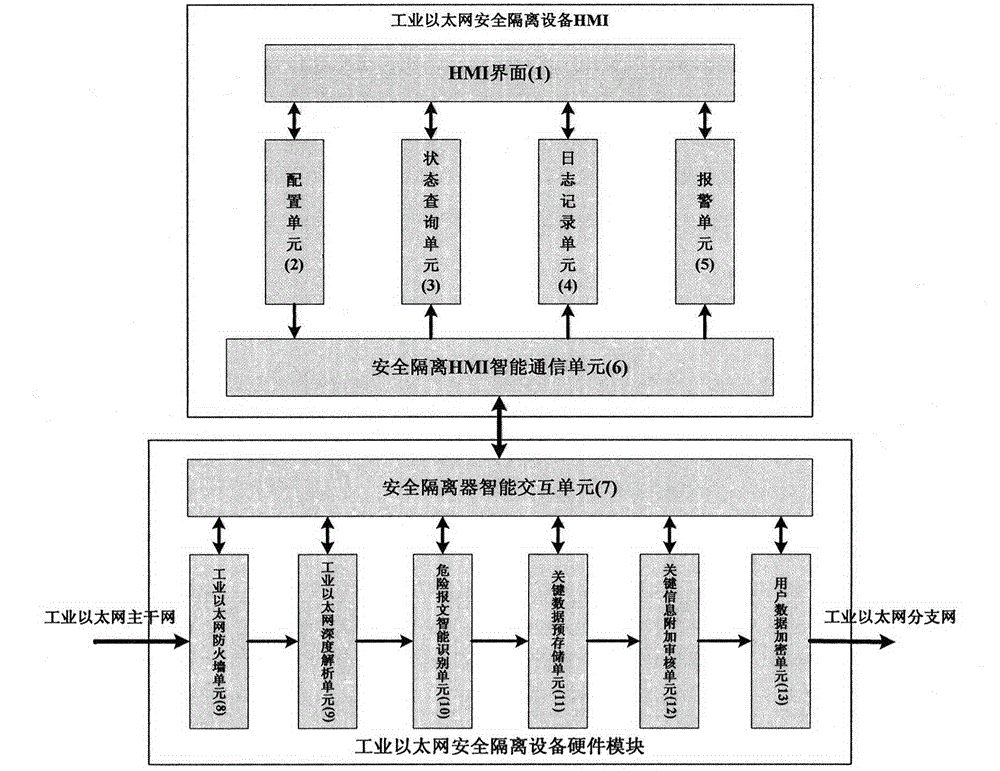

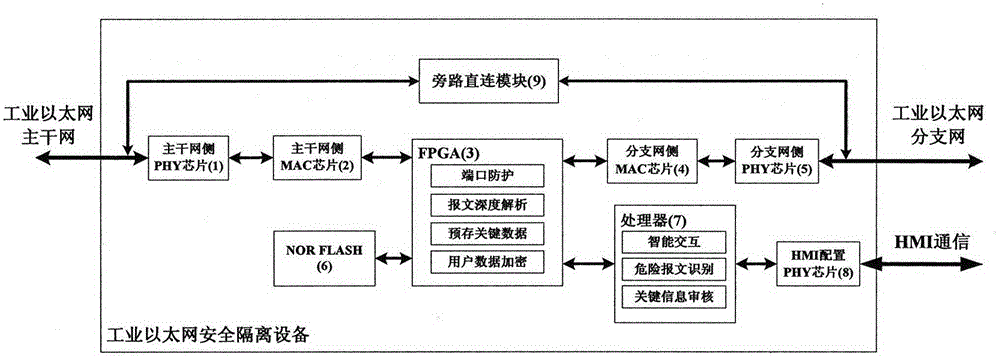

Secure isolation system applied to PROFINET industrial Ethernet

InactiveCN106161330APrevent unauthorized accessNot to be leakedTransmissionResearch ObjectNetwork communication

The invention discloses a secure isolation system applied to a PROFINET industrial Ethernet. Taking the PROFINET real-time Ethernet with wide application prospect as a research object, a PROFINET-based dedicated industrial information security device is developed by combining a PROFINET communication protocol depth detection function with a general industrial firewall function. Besides the functions of blocking network attack and defending viruses, preventing unauthorized access of a control network and field equipment and protecting general information security of data encryption, identity authentication and the like, the system also deeply analyzes the communication characteristic of the PROFINET network, and effectively recognizes abnormal communication situations on the network by predicting network communication behaviors according to configuration information and monitoring a communication relation, a real-time throughput and a non-real-time bandwidth at the initial networking stage, as well as deeply detecting data packets of a PROFINET application layer and the like. When a security threat appears, the contact between the PROFINET network and the external network is timely ''isolated'', and a hazard identification processing and alarm log is sent, so that security download can be performed on an out-of-control or fault main station.

Owner:INSTR TECH & ECONOMY INST P R CHINA

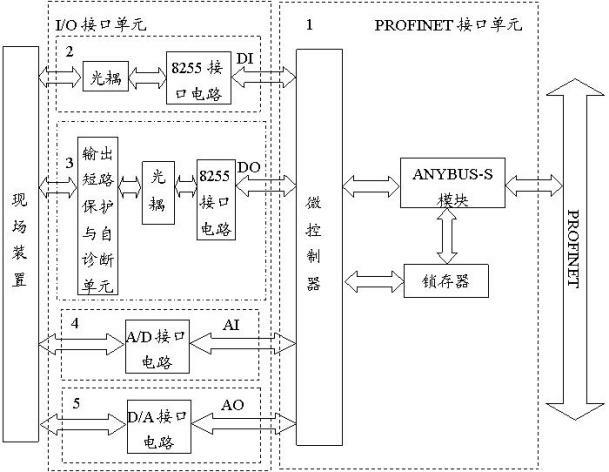

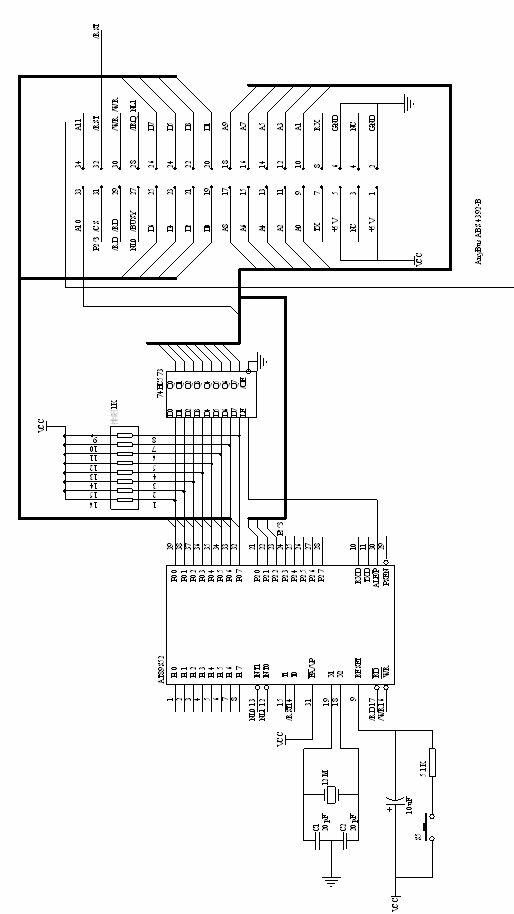

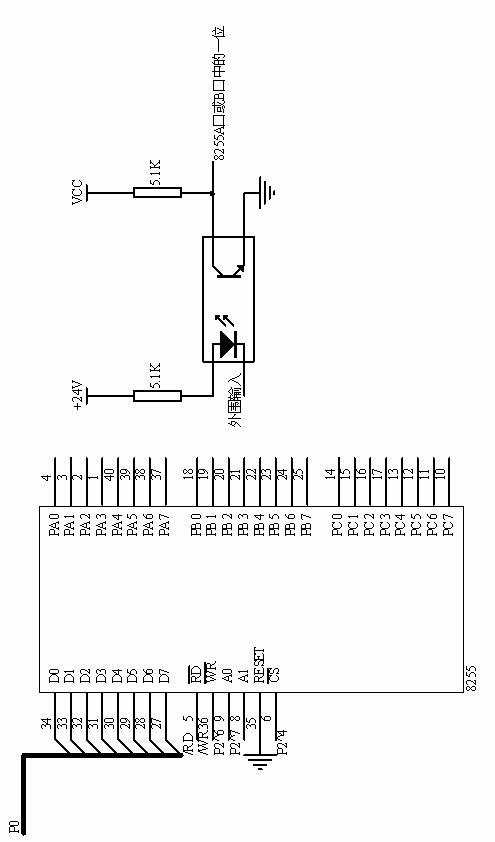

PROFINET remote I/O control device based on ANYBUS-S

InactiveCN102122167AAvoid burnsConvenient fault monitoringTotal factory controlProgramme total factory controlMicrocontrollerDiagnostic data

The invention discloses a PROFINET remote I / O control device with short-circuit protection and self-diagnosis functions based on ANYBUS-S, which comprises a PROFINET interface unit for finishing initialization of the ANYBUS-S by a microcontroller and performing data communication with the PROFINET, an I / O interface unit for expanding an I / O port of a singlechip through a 8255 interface and processing peripheral digital quantity and analogue quantity data through a photoelectric coupling isolation circuit and AD and DA conversion circuits, and a short-circuit protection and self-diagnosis unit for cutting off power to perform short-circuit protection when a short circuit occurs in the I / O interface unit circuit, and transmitting the diagnosis data of the short circuit process to the PROFINET interface unit. The remote I / O device provided by the invention has the short-circuit protection and self-diagnosis functions, can cut off power and provide self-diagnosis information when the short circuit occurs in an interface load, and can automatically back to work when the short circuit fault is eliminated.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

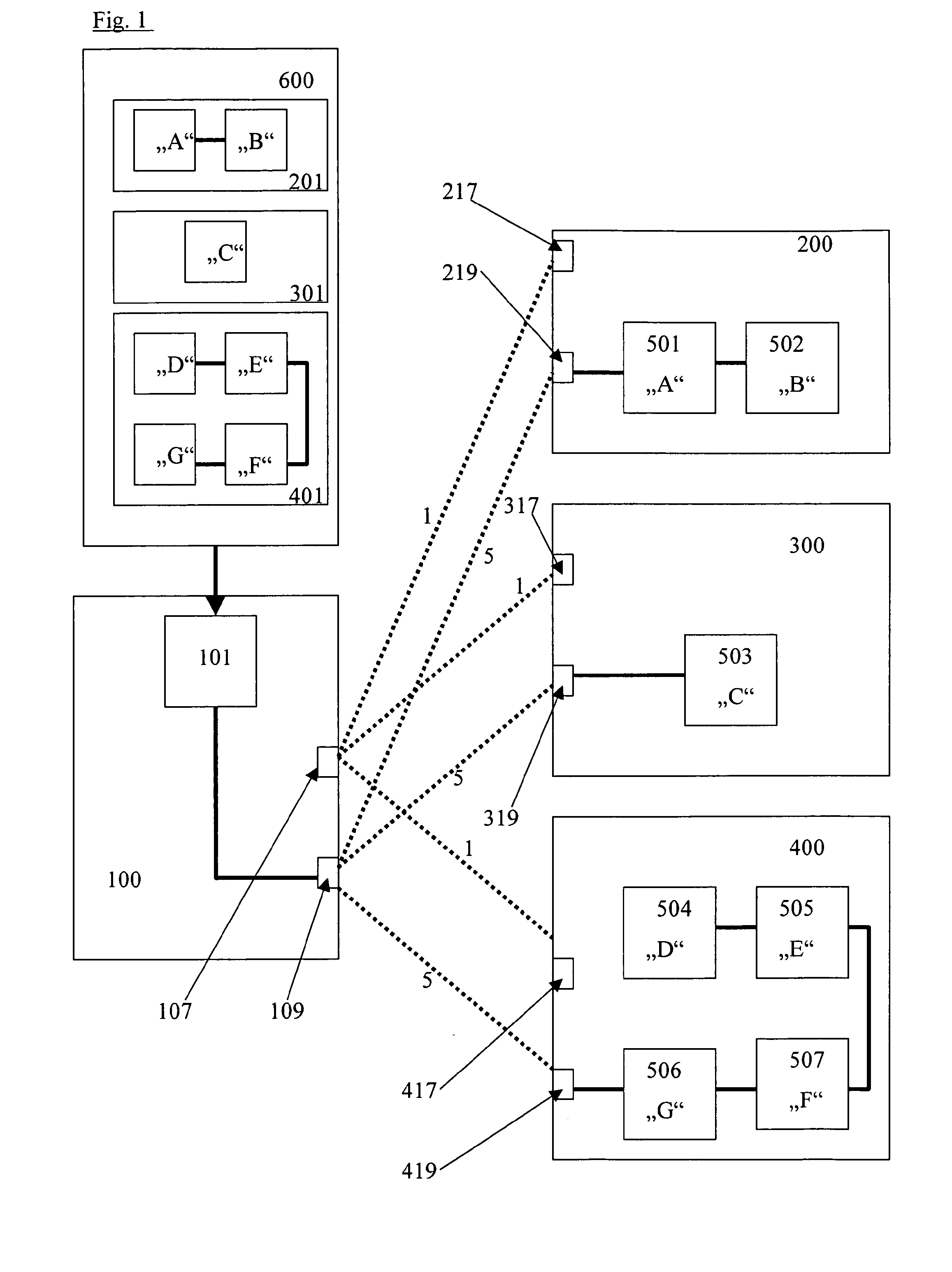

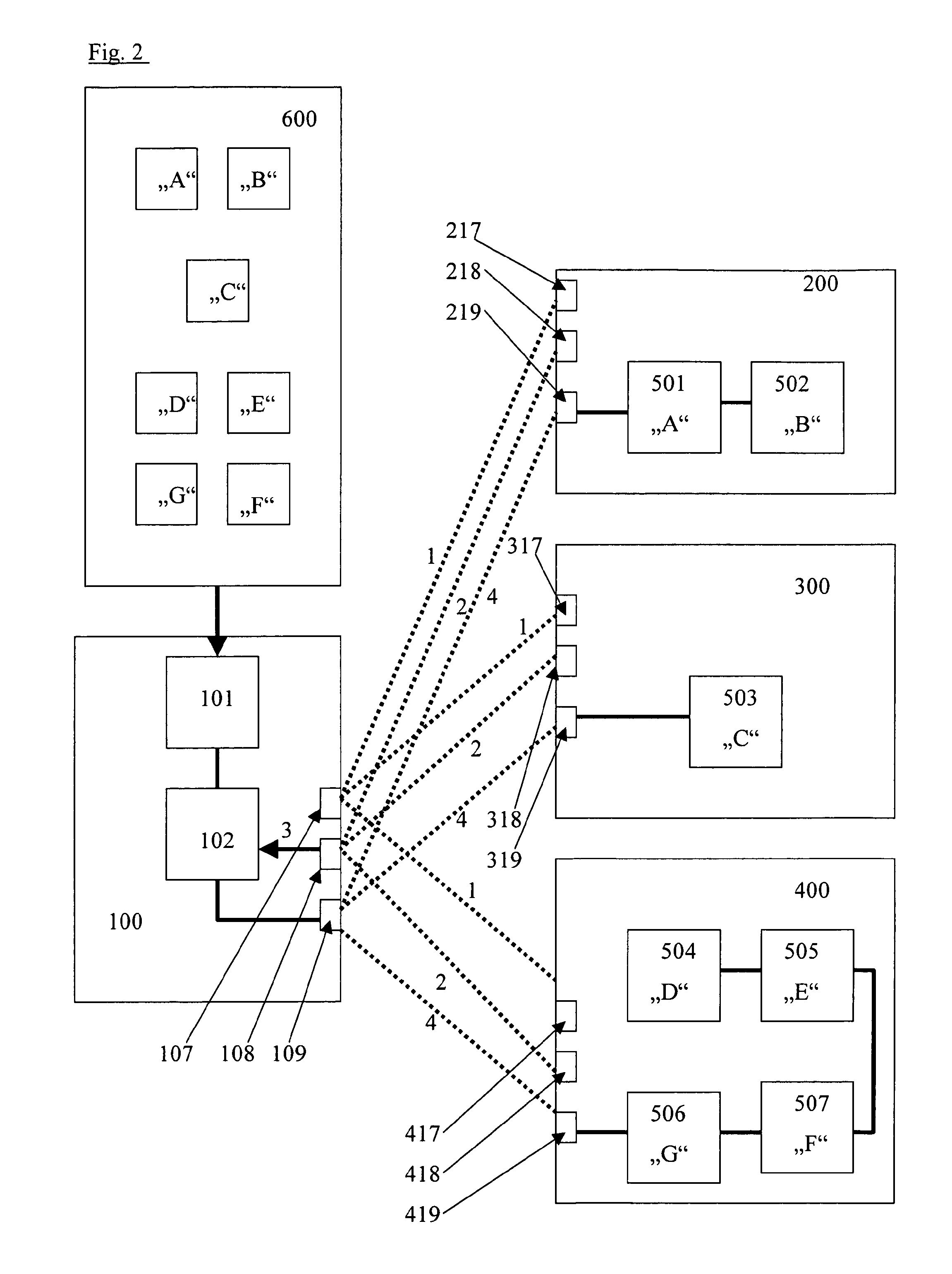

Tool recognition with profinet

The invention relates to a method for activating an automation station in the automation apparatus of an industrial application.The invention provides a method for activating an automation station (200, 300, 400) in the automation apparatus (100) of an industrial application, in which the automation station comprises a plurality of Profinet-compatible devices (501, . . . , 507) to which an unambiguous symbolic name is provided for identification, and wherein an identification of the automation station connected to the automation apparatus for operation is performed based on the symbolic names of the Profinet-compatible devices, and the Profinet-compatible devices are driven by the automation apparatus after connection of the automation station in functional dependence on the identified automation station.

Owner:PHOENIX CONTACT GMBH & CO KG

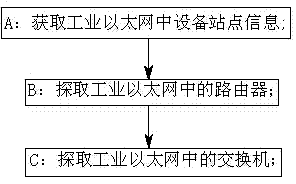

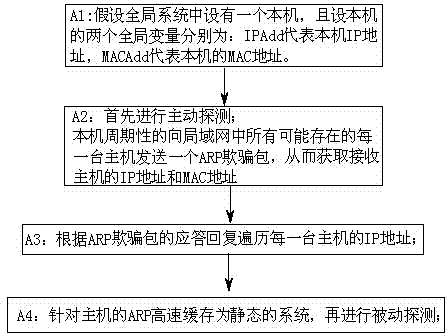

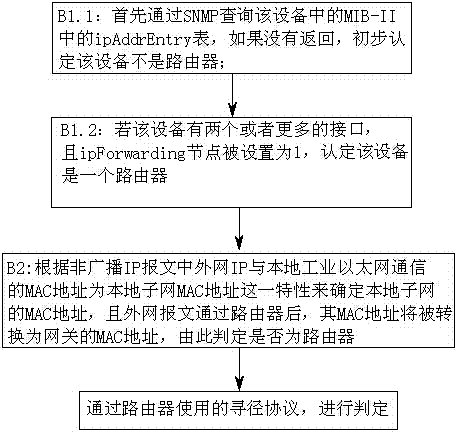

Industrial Ethernet network topology management implementation method based on PROFINET

InactiveCN104506339AImplement detectionRealize the network connection relationshipData switching networksNetwork connectionNetwork service

The invention discloses an industrial Ethernet network topology management implementation method based on PROFINET. Through Ethernet network topology management, detection of various equipment information in industrial Ethernet such as information of various network servers, routers, printers, switches and the like and network connection relations among equipment is mainly implemented, and a user knows equipment owned by a certain network in the form of a graph and detects whether various equipment can work normally or not. Equipment site information and equipment such as routers and switches are detected in order to detect whether various equipment can work normally or not.

Owner:CHINA TOBACCO HENAN IND

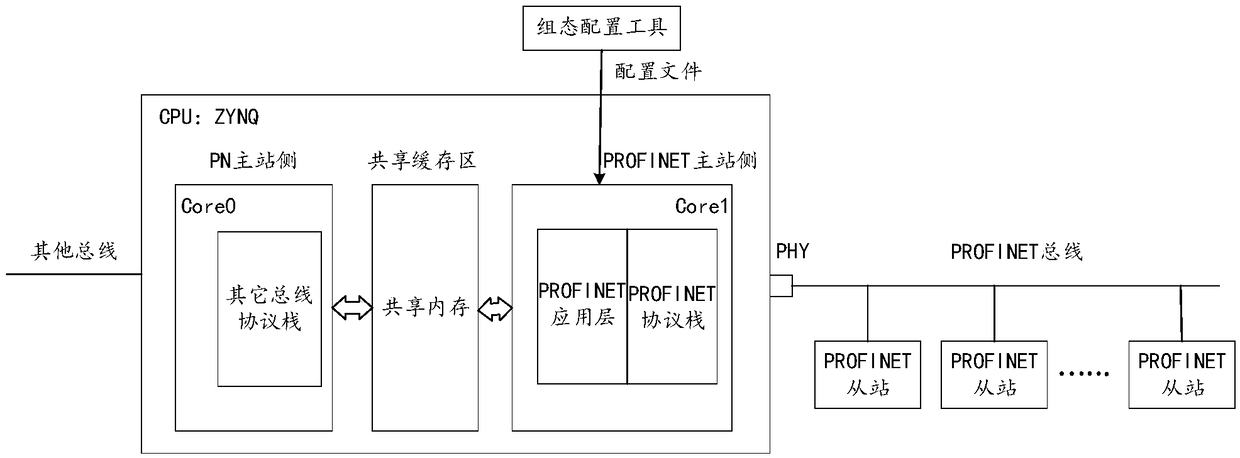

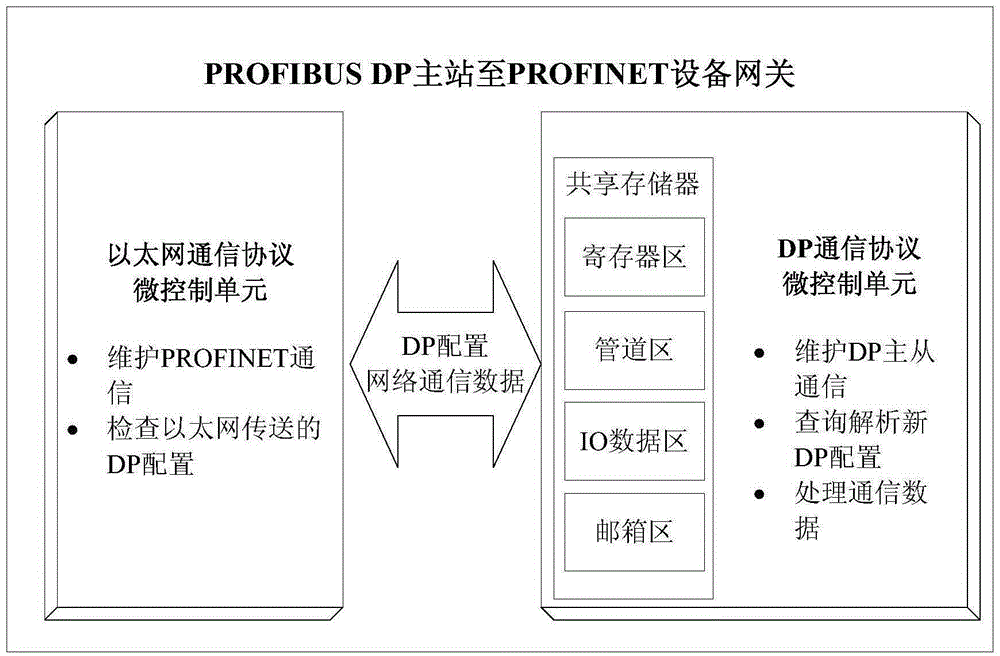

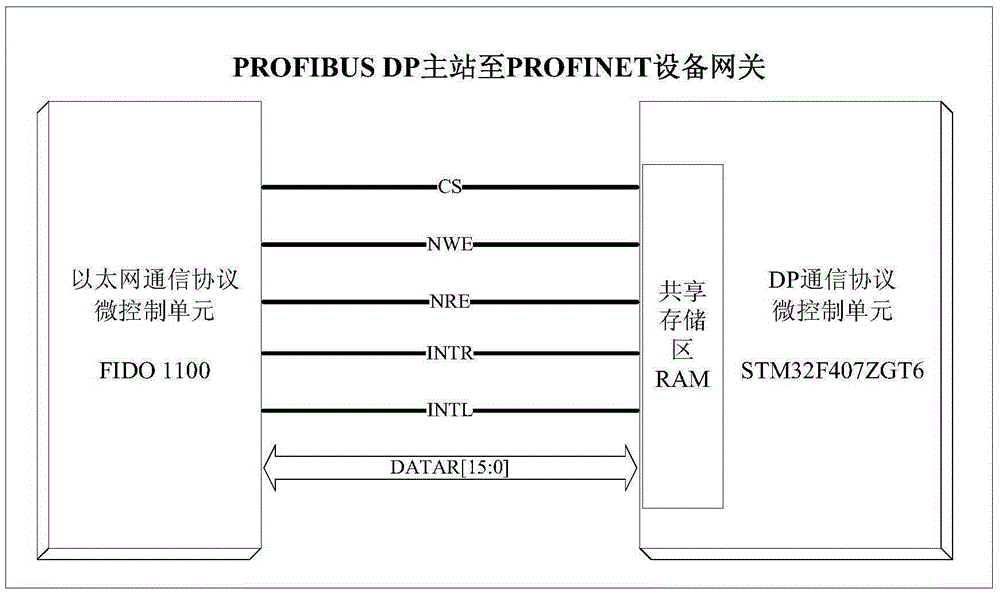

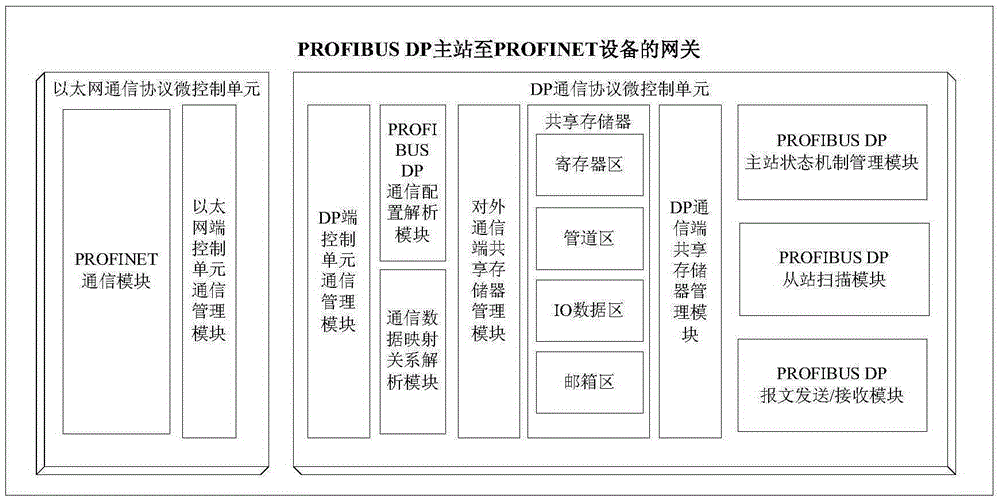

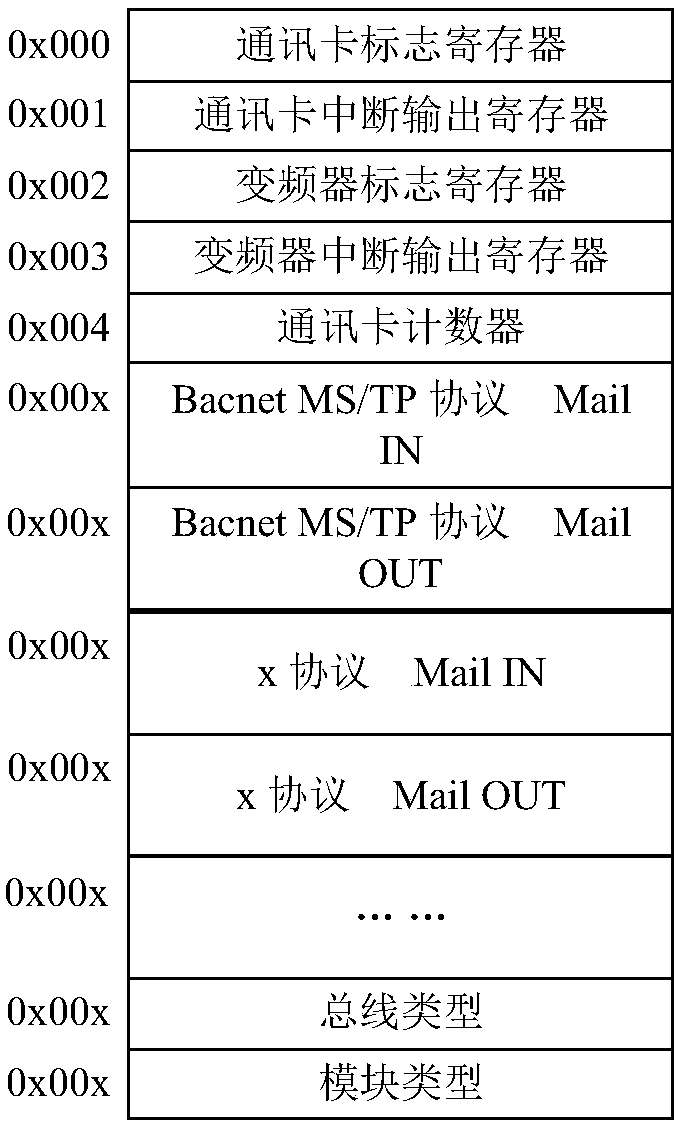

Interconnection method for PROFIBUS DP and PROFINET communication networks through sharing storage unit

ActiveCN105245424ARealize mutual transmissionReduce the burden onBus networksPrimary stationProcessor register

The invention discloses an interconnection method for PROFIBUS DP and PROFINET communication networks through a sharing storage unit, and the method comprises the steps: (1) the sharing storage unit is divided into a register region, a pipeline region, an IO data region, and a mail box region; (2) a DP communication protocol micro-control unit detects whether there is effective DP configuration locally or not after power-on; (3) the DP communication protocol micro-control unit periodically visits the sharing storage unit to search the effective DP configuration and carry out communication data inter-transmission which serves as the communication between a DP main station maintenance gateway and a slave station; (4) an Ethernet communication protocol micro-control unit maintains PROFINET communication and communication data inter-transmission; (5) the Ethernet communication protocol micro-control unit transmits the DP configuration obtained through an Ethernet to be transmitted to the DP communication protocol micro-control unit through the sharing storage unit; (6) DP bus scanning is started according to the current state of the main station and the DP configuration when the DP communication protocol micro-control unit finds DP configuration updating. The method achieves the protocol conversion and data transmission between a PROFIBUS DP communication network and a PROFINET communication network.

Owner:BEIJING D&S FIELDBUS TECH

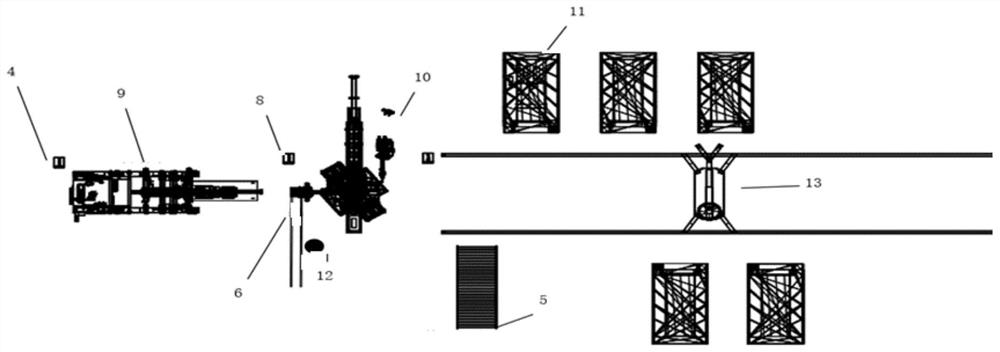

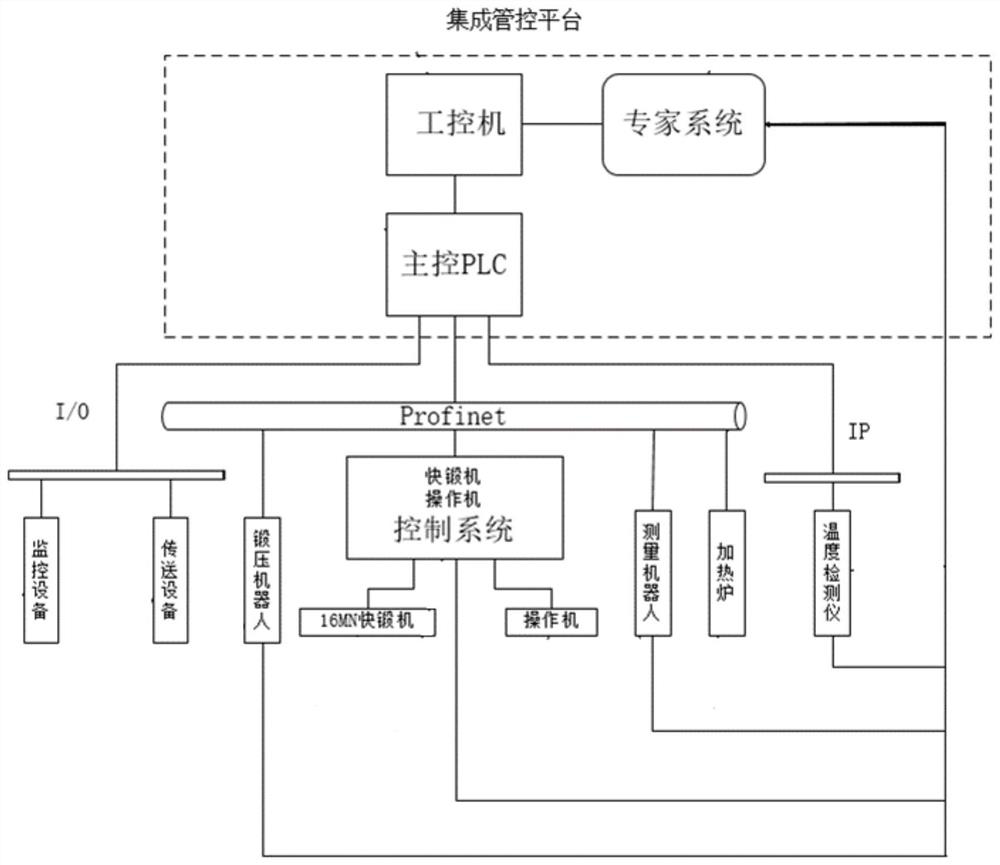

Free forging intelligent production system and method

PendingCN112275981AGuaranteed coaxialityImprove assembly accuracyForging press drivesEngine componentsPROFINETMachining process

The invention belongs to the technical field of free forging production line control, and discloses a free forging intelligent production system and method. The free forging intelligent production system comprises a main station programmable logic controller (PLC), an industrial control computer, an expert system, a remote I / O, a heating furnace, a fast forging machine, a manipulator, a forging and pressing robot, a measuring robot, a conveying device, a monitoring device, and a temperature detector. The main station PLC is connected with an upper computer, namely the industrial control computer, through a TCP / IP protocol, and is connected with the heating furnace, the fast forging machine, the manipulator, the forging and pressing robot, the measuring robot, the conveying device, the monitoring device and the temperature detector through a Profinet Ethernet technology, the remote I / O and an IP. By constructing the expert system, the hitting force can be optimally adjusted according todifferent initial forging temperatures in the machining process, so that the machining quality consistency is improved. Data-based fact monitoring and decision-making intelligent control are realizedthrough an integrated management and control platform.

Owner:AVIC BEIJING CHANGCHENG AVIATION MEASUREMENT & CONTROL TECH INST +2

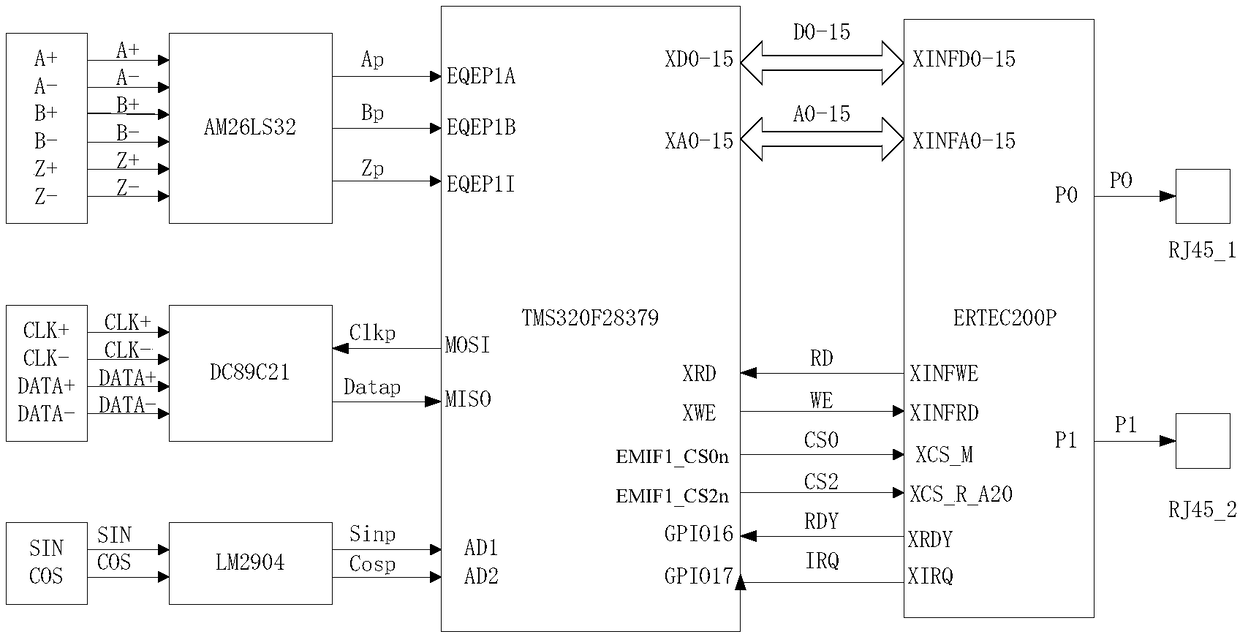

Universal synchronous motor speed and position detection system based on PROFINET protocol

ActiveCN109347370AAchieve sharingElectric motor controlElectronic commutatorsInformation sharingSynchronous motor

The invention discloses a universal synchronous motor speed and position detection system based on a PROFINET protocol. The system comprises a motor side speed position encoder interface part, an MCUreal-time control part and a PROFINET network interface part, and is compatible with an analog quantity encoder, an absolute photoelectric encoder and an incremental photoelectric encoder of a currentuniversal synchronous motor. The system adopts TMS320F28379 and ERTEC200P as main chips, and speed, direction and position signals of the motor are obtained through a speed measuring program. The speed and the rotor position are calculated out through the microprocessor TMS320F28379, and are connected into the industrial Ethernet through the PROFINET, so that information sharing is realized.

Owner:BEIJING ARITIME INTELLIGENT CONTROL

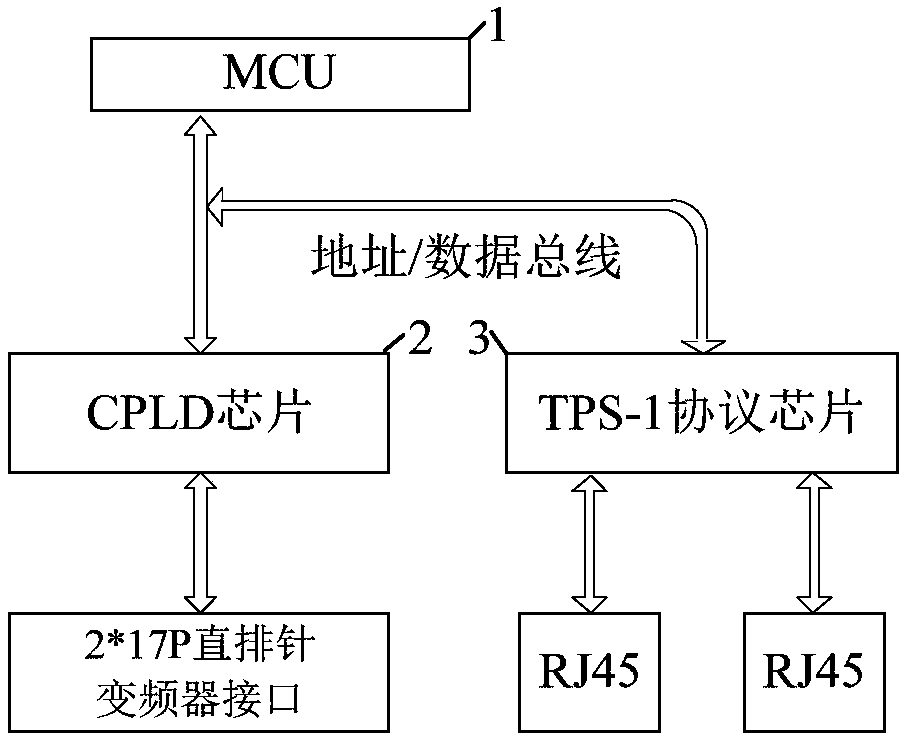

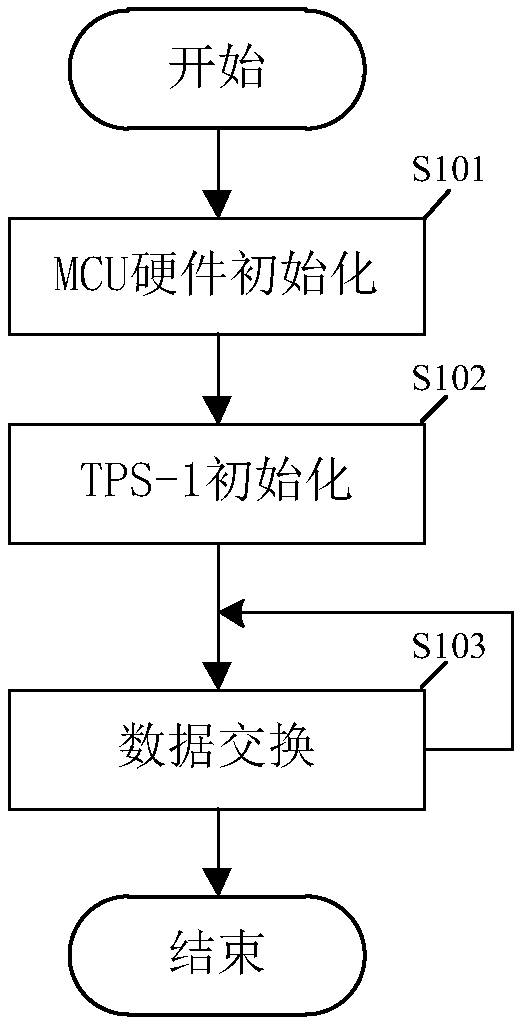

Profinet communication protocol conversion card and conversion method

InactiveCN108173723ASave pinsDevelopment is easy to implementBus networksWide area networks16-bitMaster station

The invention discloses a Profinet communication protocol conversion card and a conversion method. The Profinet communication protocol conversion card comprises an MCU, a CPLD chip and a TPS-1 protocol chip, wherein the MCU is respectively connected to the CPLD chip and the TPS-1 protocol chip; the MCU is used for reading a control instruction of a Profinet master station through the TPS-1 protocol chip and writing data into a frequency converter through the CPLD chip after protocol data processing, and acquiring state data of the frequency converter through the CPLD chip, writing the state data into the TPS-1 protocol chip after protocol data processing and sending the state data to the Profinet master station in order to realize data exchange. The Profinet communication protocol conversion card supports a 8 / 16-bit parallel bus and is compatible with a hardware interface of an existing 8-bit bus, the software development is easy to realize, the number of chip pins is small, the designis simple, and the development period is short.

Owner:SHENZHEN INVT ELECTRIC

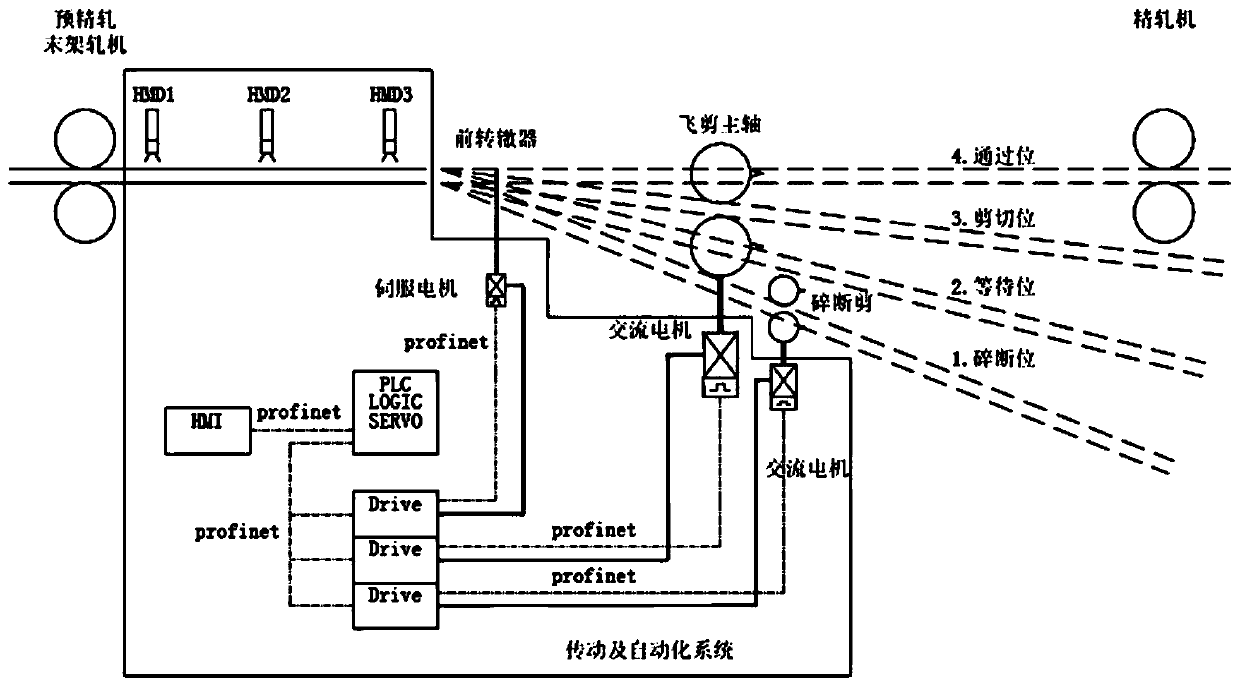

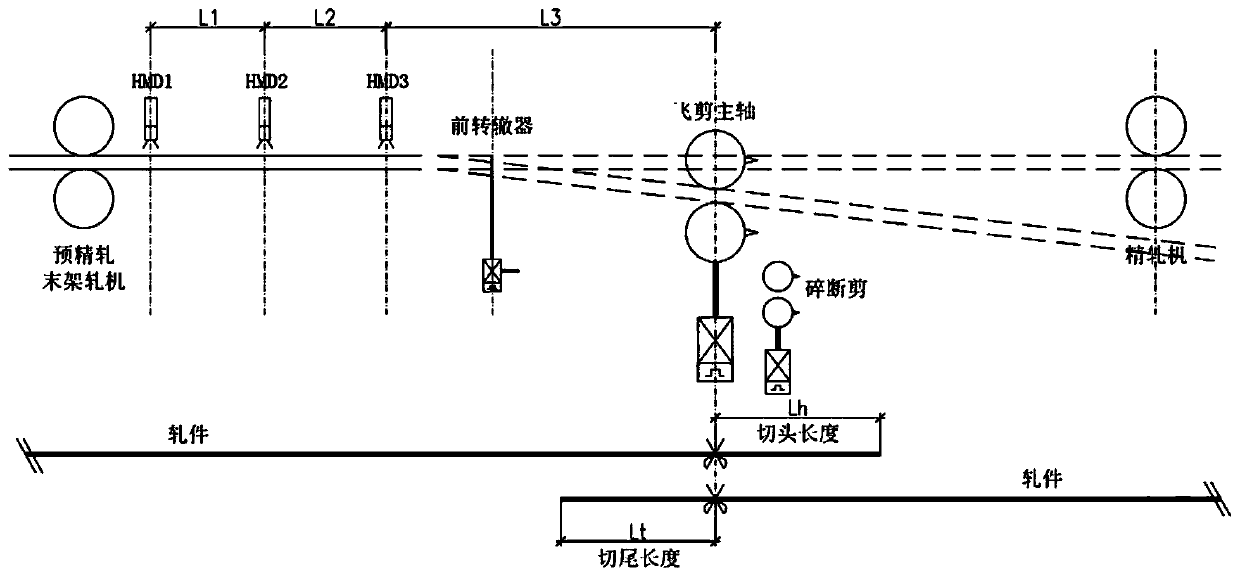

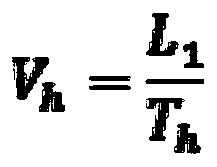

Servo fly-shear control method based on novel control platform

InactiveCN109940218AChange the way of communicationImprove stabilityMeasurement/indication equipmentsStock shearing machinesControl theoryData transmission

The invention discloses a servo fly-shear control method based on a novel control platform. The method comprises a hardware part and a software part, firstly, a novel-generation high-performance PLC is configured to be responsible for the logic control of the whole set of devices, the PLC servo control process is used for the servo control, and a servo controller in an old system is replaced; secondly, the Profinet network is adopted between the hardware equipment, all the servo electrical encoders and main transmission motor encoders also adopt the Profinet network, the TCP / IP protocol is implemented, the data transmission rate is increased, and the inherent scanning cycle is shortened; and finally, a novel detecting measure is established to optimize the software, the calculation date can be more accurate, and the shear accuracy is improved.

Owner:MCC HUATIAN NANJING AUTOMATION ENG

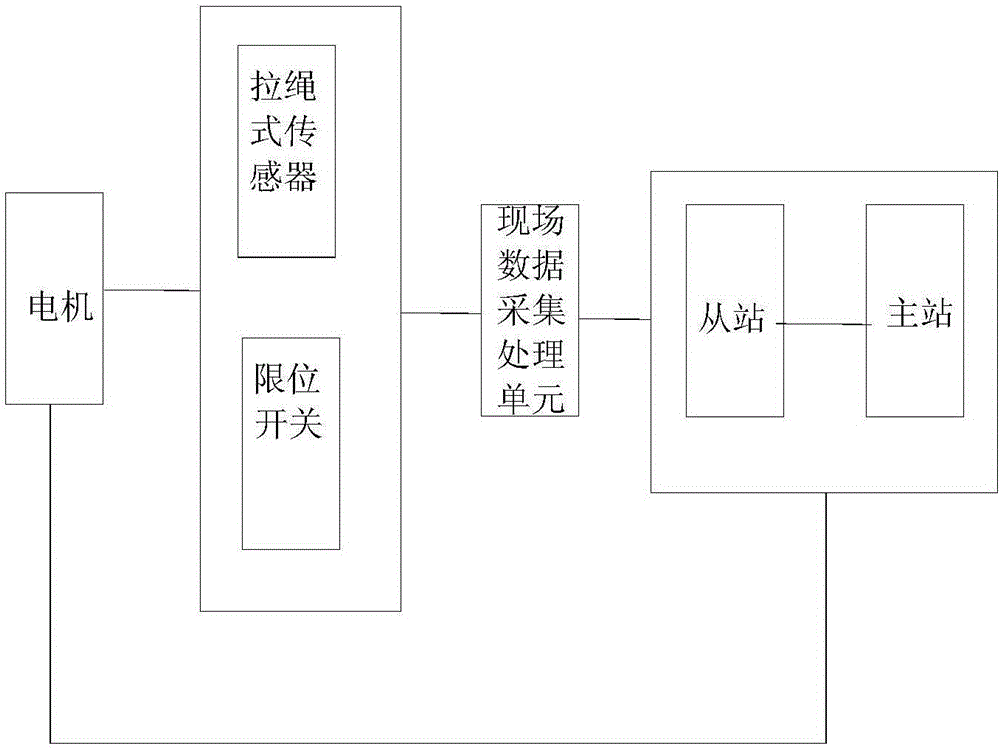

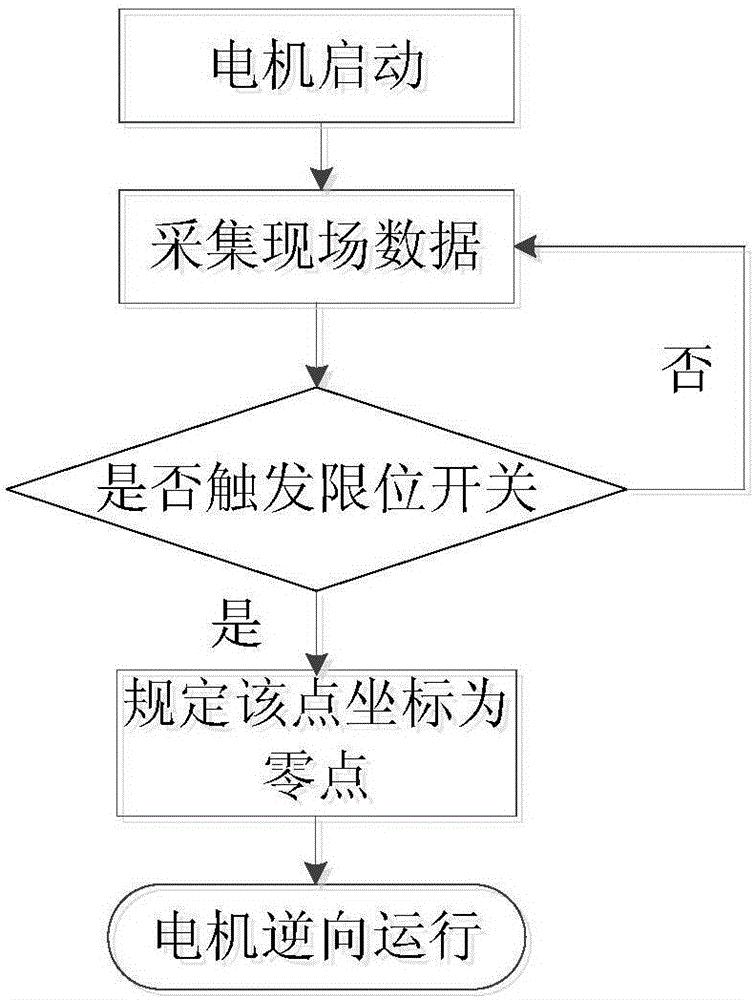

Stay-cord sensor based roller spacing measurement system and method

ActiveCN106547247ARealize automated detectionReduce wasteMechanical clearance measurementsProgramme control in sequence/logic controllersControl systemElectric machinery

The invention discloses a stay-cord sensor based roller spacing measurement system and method. The stay-cord sensor based roller spacing measurement system comprises a limit switch used for performing zero setting, a stay-cord sensor used for measuring the roller spacing, a field data acquisition and processing unit and a control system, and is characterized in that the limit switch is located at the side, which is adjacent to a roller, of a mechanical arm; the stay-cord sensor is located between the roller and the mechanical arm; the field data acquisition and processing unit is used for receiving output signals of the limit switch and the stay-cord sensor and performing data processing on the received signals; the control system is used for performing data interaction with the field data acquisition and processing unit and controlling a motor to operate; signal output terminals of the limit switch and the stay-cord sensor are respectively connected with an I / O port of the field data acquisition and processing unit; the control system comprises a salve station controller and a master station controller; the field data acquisition and processing unit performs data interaction with the master station controller through a PROFINET bus; and the slave station controller performs data interaction with the master station controller through the Ethernet / IP.

Owner:天津市友发德众钢管有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com