Stay-cord sensor based roller spacing measurement system and method

A technology of roll spacing and measurement system, which is applied in mechanical gap measurement, program control in sequence/logic controller, electrical program control, etc. The effect of forming accuracy, reducing waste and idle, and saving hardware investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the content, features, and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

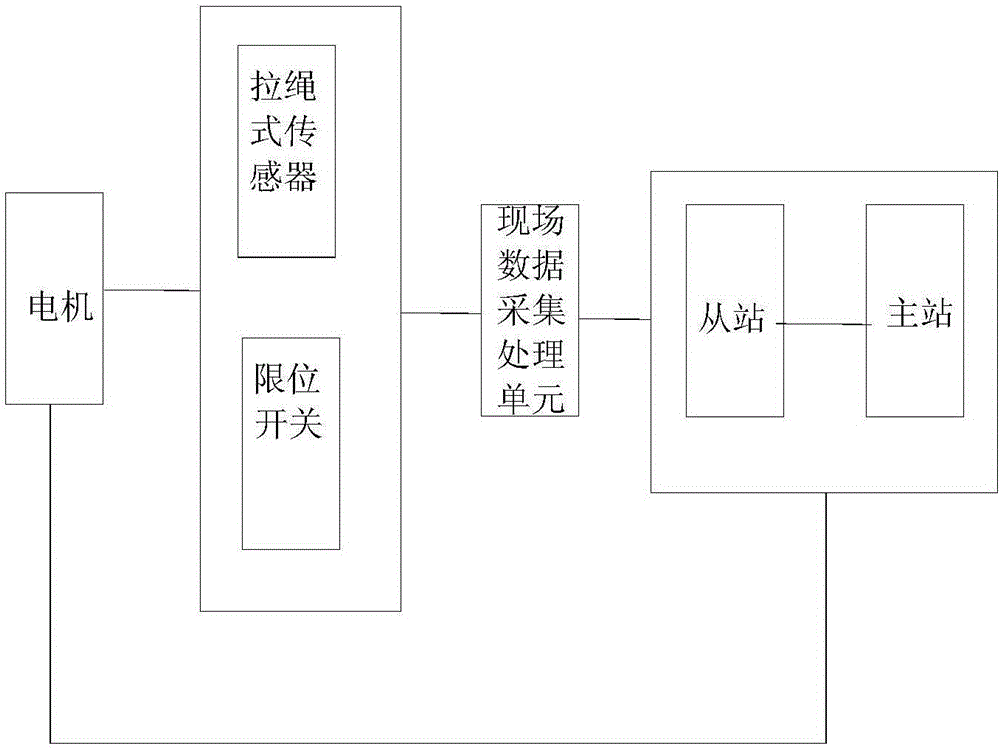

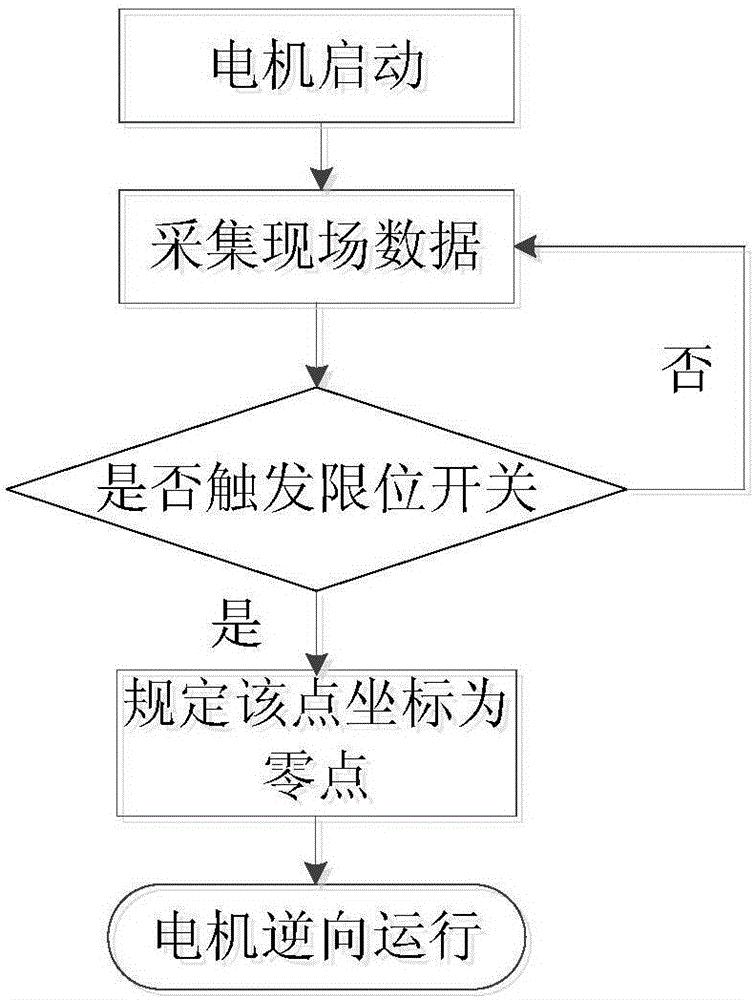

[0033] See Figure 1 to Figure 4 , A roll gap measurement system based on a drawstring sensor, including:

[0034] A limit switch for zero adjustment; the limit switch is located on the adjacent side of the mechanical arm and the roll;

[0035] A rope type sensor used to measure the distance between rolls; the rope type sensor is located between the roll and the mechanical arm; the rope type distance sensor, the wire rope is always tightened by the self-coiling spring, and is converted by the linear displacement of the wire rope Measurement of the amount of rotation; the wire rope is tightly wound on the multi-turn measuring wheel, and the stroke of each circle is the same, so the measurement is linear at all times during the whole measurement process; the wire rope measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com