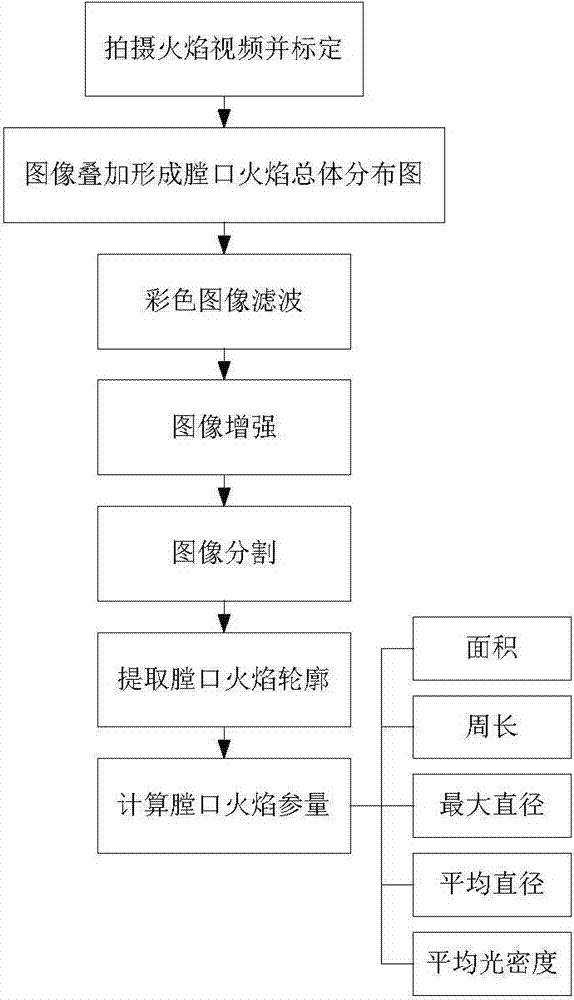

Transient flame detection method based on image processing

A flame detection and image processing technology, applied in the field of flame detection, can solve the problems of poor measurement accuracy, poor measurement repeatability, joint analysis of the overall distribution law of no flame, etc., and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following takes a certain transient flame video shooting and analysis process as an example to illustrate the specific implementation method, wherein the transient flame generating device is a cannon.

[0034] Step 1: Take a video of the transient flame. The high-speed camera is placed at an appropriate distance from the muzzle, and the entire transient flame area is required to cover 2 / 3 or more of the field of view of the high-speed camera. The camera is perpendicular to the firing direction of the muzzle, and a calibration rod is set up in the opposite direction of the muzzle firing direction. It is used to calibrate the image pixel and the actual size. The high-speed camera is used to shoot the transient flame video. When the shell is fired, the high-speed camera is triggered to shoot. Because the high-speed camera has a high frame rate, the first frame or even several frames in the video are not included. Background image of transient flame I B , the video con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com