Method for green synthesis of nanoscale zero-valent iron through water hyacinth extraction liquid and application

A nano-zero-valent iron, green synthesis technology, applied in nanotechnology, chemical instruments and methods, water pollutants, etc., can solve the problems of high equipment requirements, easy to be oxidized, complicated process, etc., and achieve difficult agglomeration and good stability , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the nano-iron particle of green synthesis, comprises the steps:

[0037] 1) Weigh 60g of dried water hyacinth stem and leaf powder, place in 1L of deionized water, and extract in a water bath at 80°C;

[0038] 2) The extracted extract was vacuum filtered, centrifuged at 12000 rpm, passed through a 0.45 μm filter membrane, and the filtrate was refrigerated at 4°C in a refrigerator;

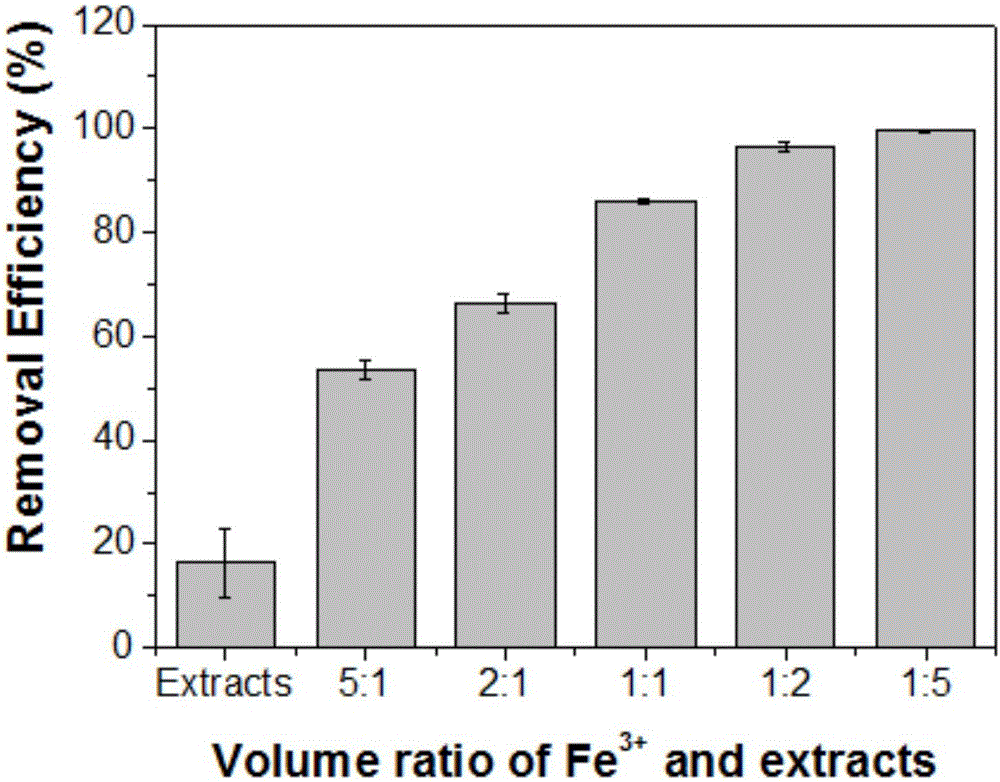

[0039] 3) Take 100ml water hyacinth stem and leaf extract and 50ml of 0.15moL / L FeCl 3 The solution is mixed and reacted under the protection of protective gas argon at a volume ratio of 2:1, and the color of the solution turns black under stirring, and a solution containing green synthesized nano-iron is obtained;

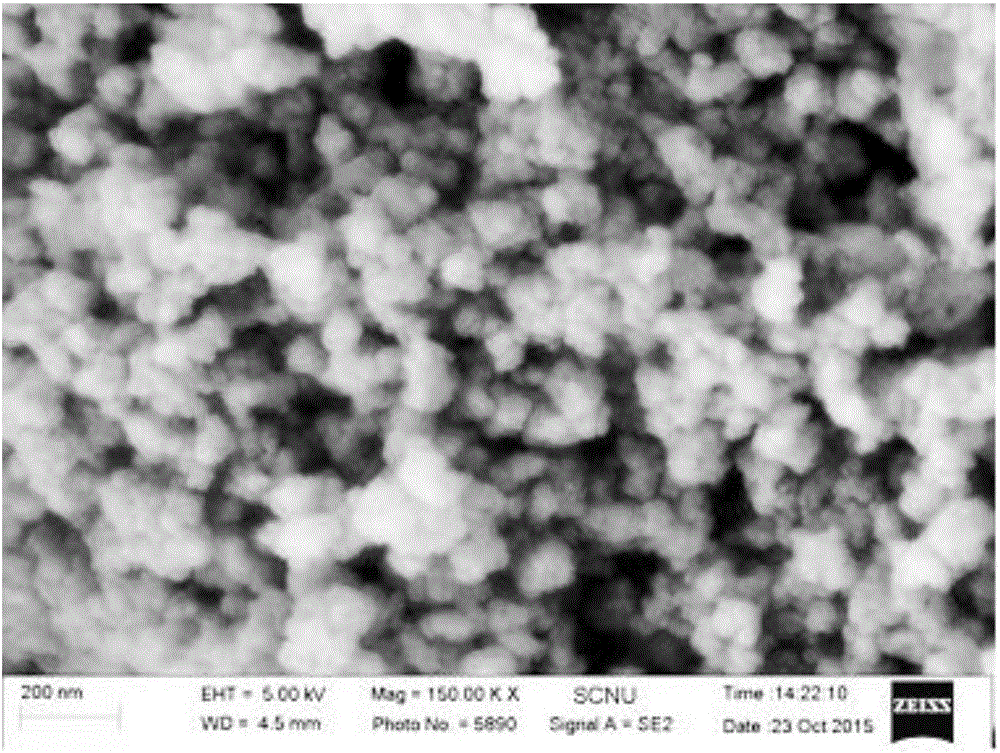

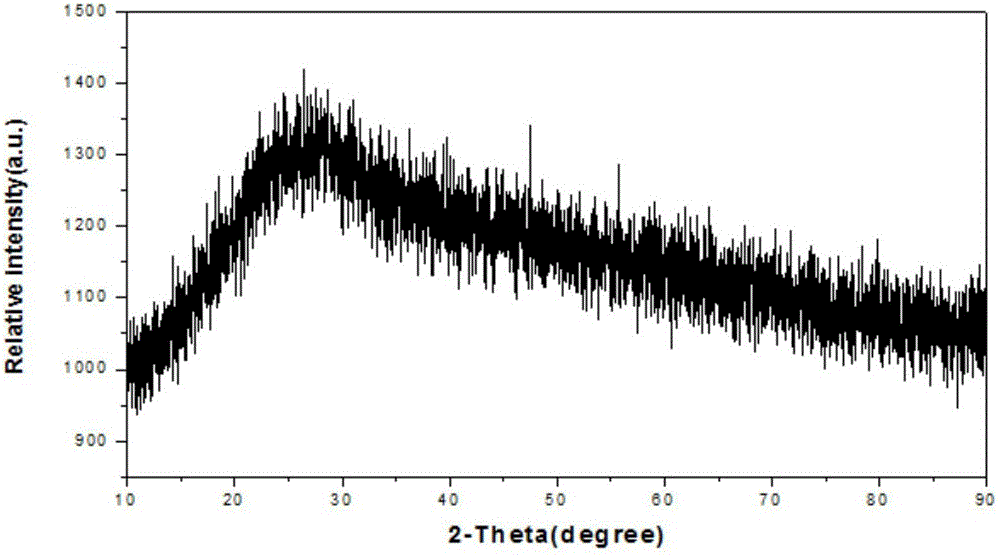

[0040] 4) Centrifuge the generated material at 12,000 rpm, wash the centrifuged material twice with acetone and ethanol, and dry at 50° C. in a vacuum oven to obtain a brown-black solid, which is green synthesized nano-zero-valent iron particles.

[0...

Embodiment 2

[0043] The preparation method of the green-synthesized nano-iron particles of green-synthesized nano-zero-valent iron comprises the following steps:

[0044] 1) Weigh 80g of dried water hyacinth stem and leaf powder, place in 1L deionized water, and extract in a water bath at 60°C;

[0045] 2) Vacuum filter the extracted extract, centrifuge at 10,000 rpm, pass through a 0.45 μm filter membrane, and store the filtrate in a refrigerator at 4°C;

[0046] 3) Take 100ml of water hyacinth stem and leaf extract and 100ml of 0.10moL / L Fe(NO 3 ) 3 The solution is mixed and reacted under the protection of protective gas neon at a volume ratio of 1:1, and the color of the solution turns yellow-green to black under stirring, and a solution containing green-synthesized nano-zero-valent iron is obtained;

[0047] 4) Centrifuge the generated material at 16000 rpm, wash the centrifuged material twice with acetone and ethanol, and dry at 60° C. in a vacuum oven to obtain a brown-black solid,...

Embodiment 3

[0050] The preparation method of the green-synthesized nano-iron particles of green-synthesized nano-zero-valent iron comprises the following steps:

[0051] 1) Weigh 70g of dried water hyacinth stem and leaf powder, place in 1L deionized water, and extract in a water bath at 70°C for 60min;

[0052] 2) vacuum filter the extracted extract, centrifuge at 11,000 rpm, pass through a 0.45 μm filter membrane, and store the filtrate in a refrigerator at 4°C;

[0053] 3) Take 150ml water hyacinth stem and leaf extract and 50ml of 0.10moL / L FeSO 4 The solution is mixed and reacted under the protection of nitrogen with a volume ratio of 3:1, and the color of the solution turns yellow-green into black under stirring, and a solution containing green-synthesized nano-zero-valent iron is obtained;

[0054] 4) Centrifuge the generated material at 16000 rpm, wash the centrifuged material twice with acetone and ethanol, and dry at 60° C. in a vacuum oven to obtain a brown-black solid, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com