Manipulator detection device and method for residual stress of complex component

A residual stress and manipulator technology, which is applied in measuring devices, measuring forces, analyzing solids using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as the inability to meet the needs of automatic detection of complex feature specimens, and achieve a wide range of applications and limiting factors. Less, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

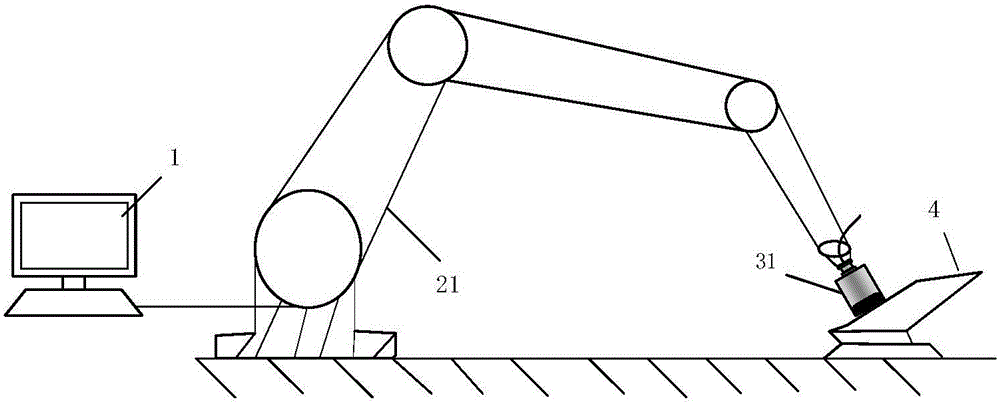

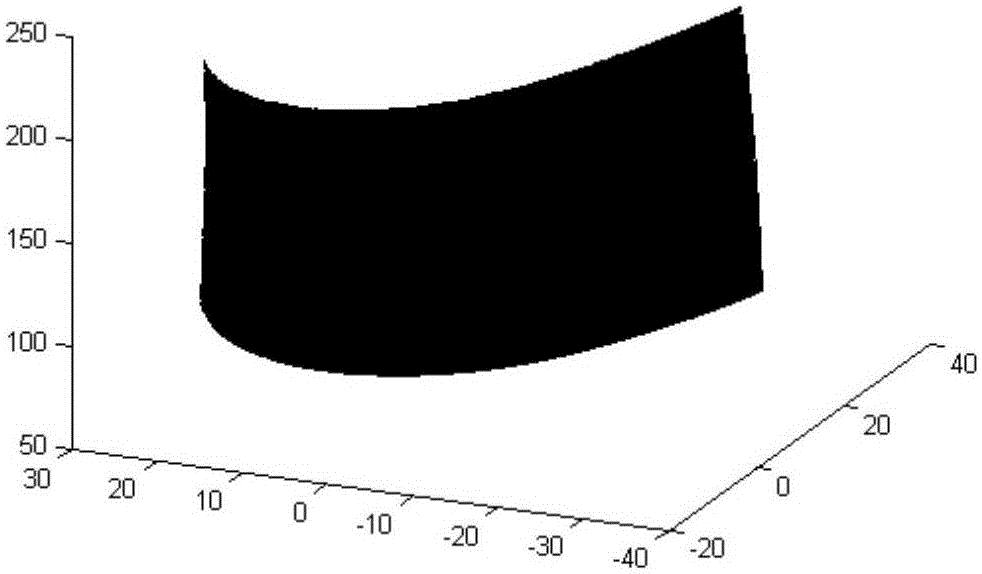

[0022] The specific embodiments of the present invention will be described below with reference to the drawings. Such as Figure 1 to Figure 6 As shown, the ultrasonic critical value longitudinal wave contact coupling refraction residual stress detection device of the complex component of the manipulator proposed by the present invention includes: an industrial computer 1, a manipulator scanning mechanism 2, an ultrasonic transceiver 3, an auxiliary mechanism, and the like. Based on the integration of structural design, motion control technology, servo drive technology and residual stress detection technology, the manipulator scanning mechanism 2 and the ultrasonic transceiver 3, and the auxiliary mechanism work together to realize the residual stress of the tested sample on the complex surface. Automatic detection. This is an automatic detection device that can be applied to complex irregular curved surfaces and has high detection efficiency. The present invention is explaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com