Remote state monitoring method and system for robots and robot production line equipment

A production line equipment and state monitoring technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as insufficient and effective use of resources, troubles in remote fault diagnosis, etc., and achieve the effect of facilitating inventory management and preventing omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

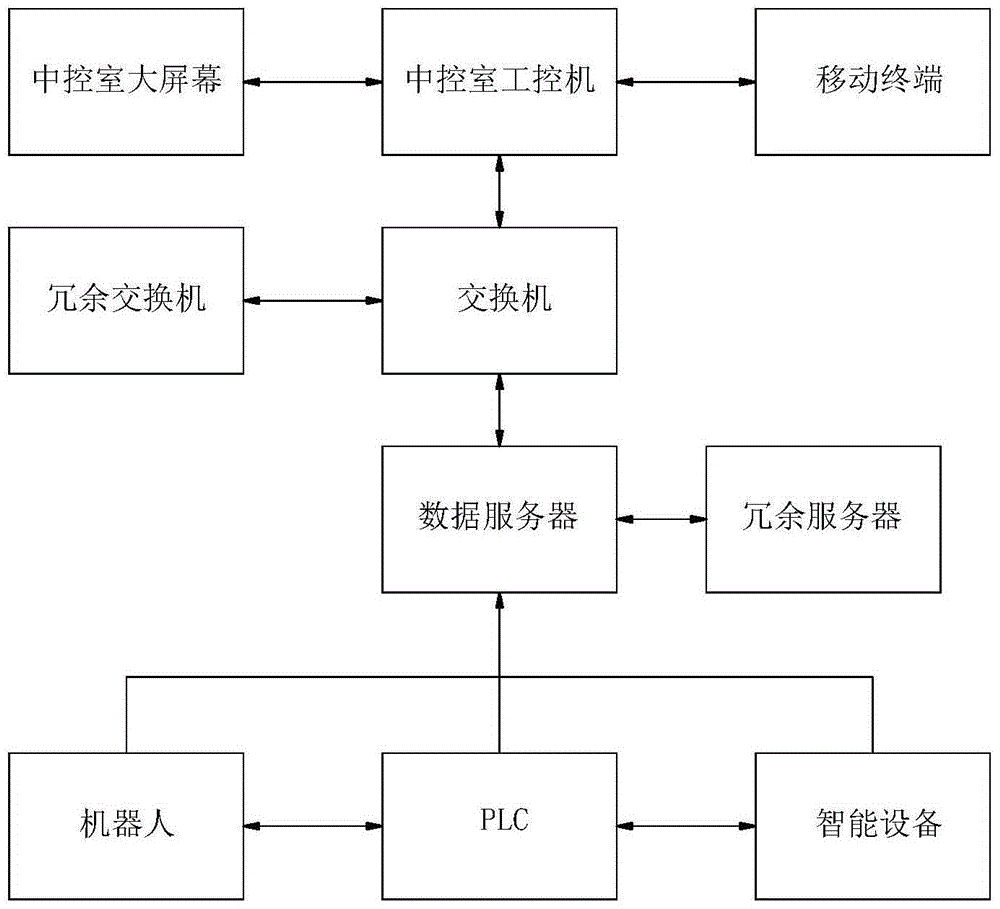

[0027] See figure 1 , is a structural schematic diagram of a remote state monitoring system for a robot and its production line equipment according to the present invention. The present invention relates to a remote state monitoring method for a robot and its production line equipment, comprising the following steps:

[0028] 1) The robot controller is equipped with an Ethernet communication interface to communicate with the data server; all intelligent devices with communication interfaces in the production line are also connected to the data server through Ethernet, and all PLCs in the production line interact with the data server through the PROFINET interface; The server is connected to the industrial computer in the central control room through the switch; the industrial computer in the central control room can display the operation interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com