Universal synchronous motor speed and position detection system based on PROFINET protocol

A technology of synchronous motor and detection system, which is applied in the direction of control system, motor control, electronic commutation motor control, etc., to achieve the effect of information sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

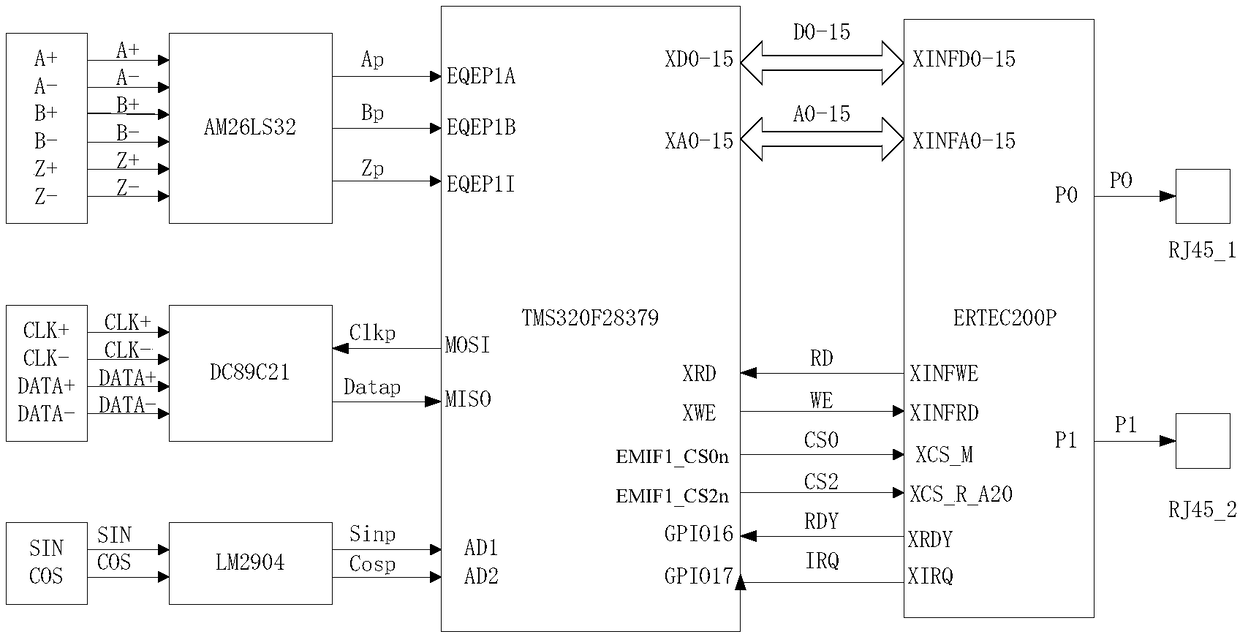

[0015] The universal synchronous motor speed and position detection system based on the PROFINET protocol of the present invention is divided into three parts, including the motor side speed and position encoder interface part, the MCU real-time control part and the PROFINET network interface part.

[0016] The interface part of the speed position encoder on the motor side is used to convert the analog or digital signal connected to the speed position encoder on the motor side into a signal form that can be accepted by the real-time control MCU part through filtering, isolation and modulation, including analog encoding Adapter circuit, incremental photoelectric encoder adaptation circuit and absolute photoelectric encoder adaptation circuit.

[0017] The input signals of the interface part of the speed position encoder on the motor side are divided into three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com