Workshop production monitoring system and method

A monitoring system and workshop technology, applied in the general control system, control/regulation system, program control, etc., can solve problems such as low level of informatization, unstable communication network, and unstable realization of functions, so as to achieve automation and coherence Sexuality, the effect of reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

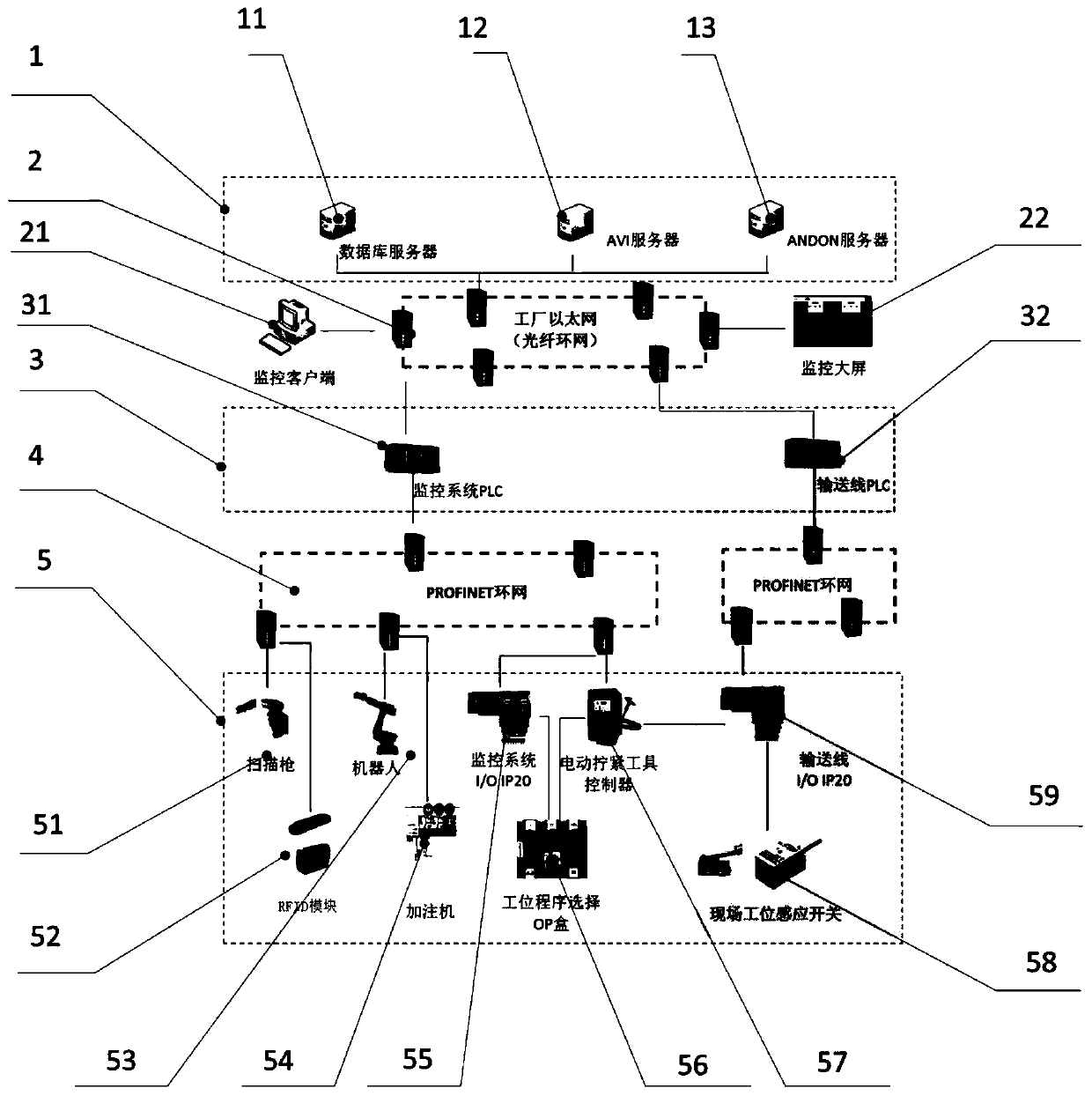

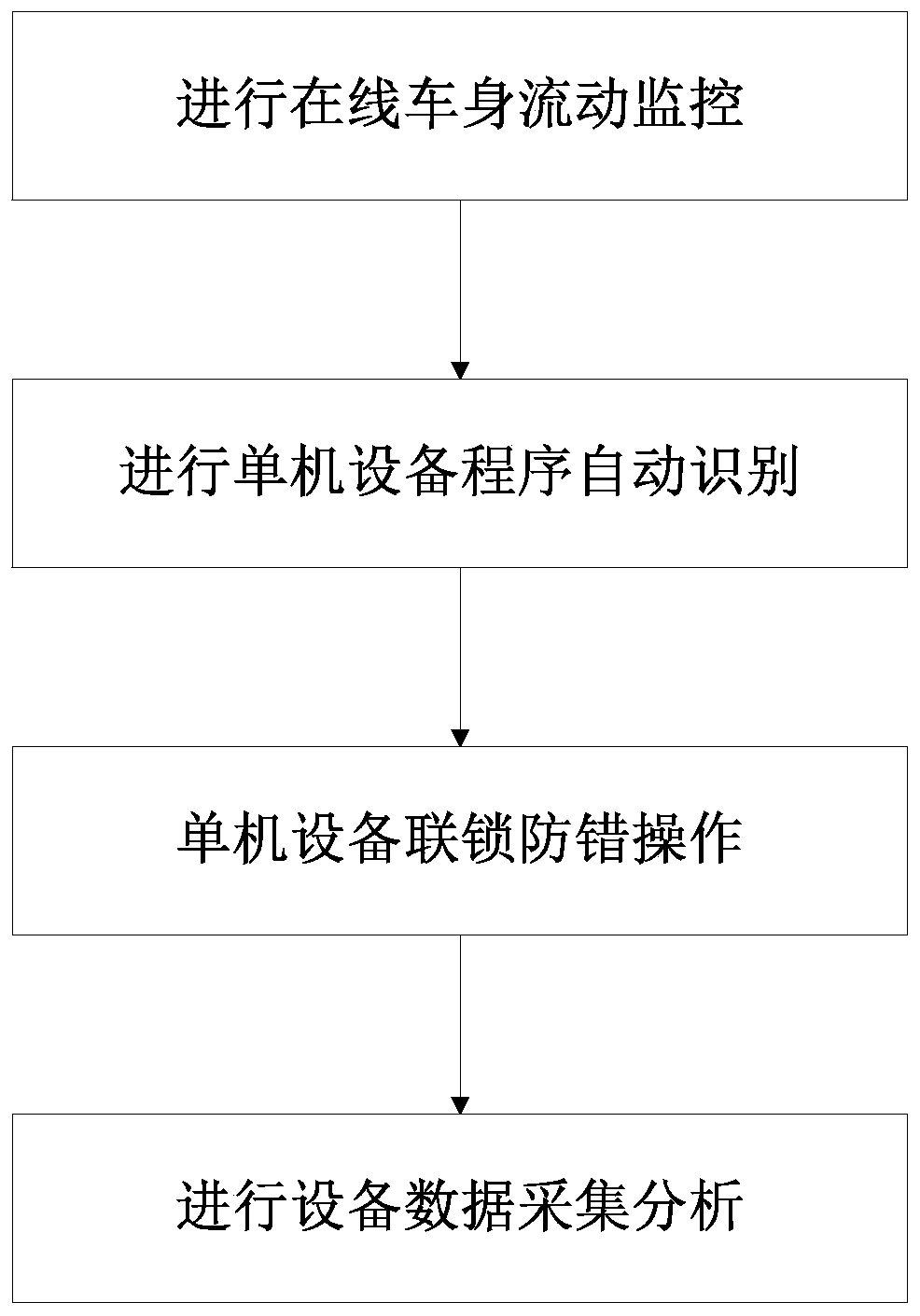

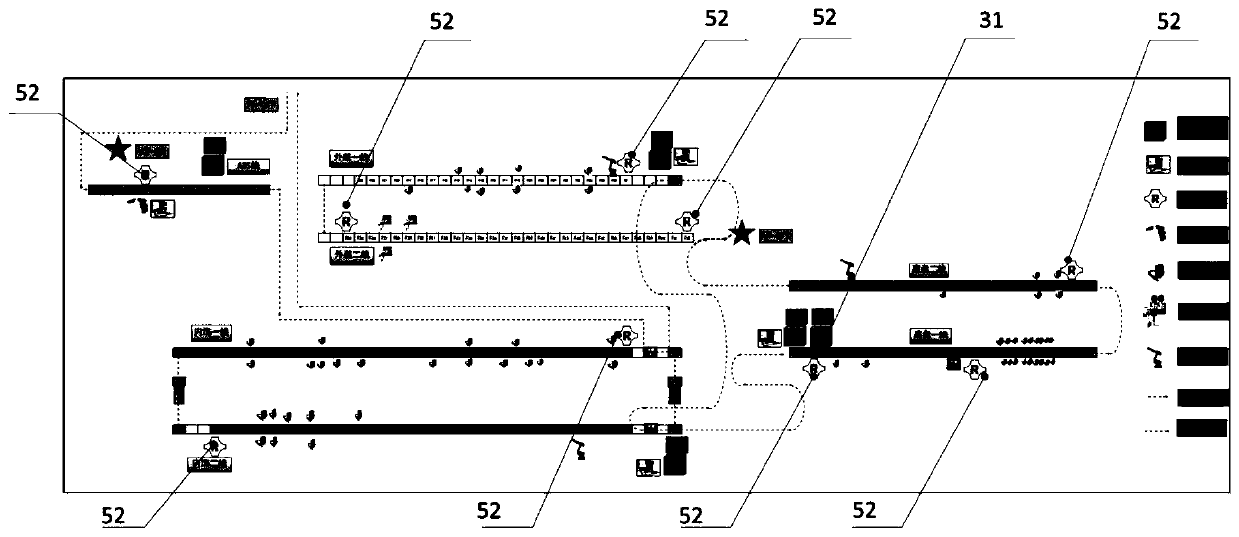

[0046] The invention provides a workshop production monitoring system, such as Figure 1-3 As shown, the present invention provides a kind of workshop production monitoring system, comprises monitoring layer 1, control layer 3, equipment layer 5; Described monitoring layer 1 comprises database server 11, AVI server, ANDON server 13, monitoring client 21 and The monitoring layer network 2, the database server 11, the AVI server and the ANDON server 13 are responsible for the collection of all data in the workshop and the operation management of the monitoring software, and monitor through the monitoring client 21; the control layer 3 includes the monitoring system PLC31 and the transmission line PLC32, the monitoring system PLC31 is responsible for controlling the production monitoring system and its underlying equipment. The assembly line of the workshop includes painting lines, interior decoration lines, chassis lines and exterior decoration lines, and its electronic control s...

Embodiment 2

[0077] This embodiment is consistent with the content of embodiment 1, and only the specific application implementation of steps S2 and S3 will be described.

[0078] Steps S2 and S3 take the electric tightening equipment in the assembly workshop as an example, such as Figure 4 , Figure 5 as shown,

[0079] S21. Establishment of stand-alone equipment program: the electric tightening equipment controller establishes a corresponding program CH for each fastening point, different torques correspond to different CHs, and sets different torque parameters, including torque information and tightening program parameters; and establishes a tightening program according to the process flow Number JOB, JOB contains the CH of each fastening point, the number of fastening points, and the order of fastening points;

[0080] S22. Establishment of program configuration table: establish the corresponding table of body configuration information MTOC and electric tightening equipment program ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com