Grinding/polishing device for polygonal column member and grinding/polishing method

A grinding process, a grinding process technology, applied in the grinding/grinding device, grinding/grinding process field, can solve the problem of not having the known technology of the processing device disclosed, and achieve the effect of reliable grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

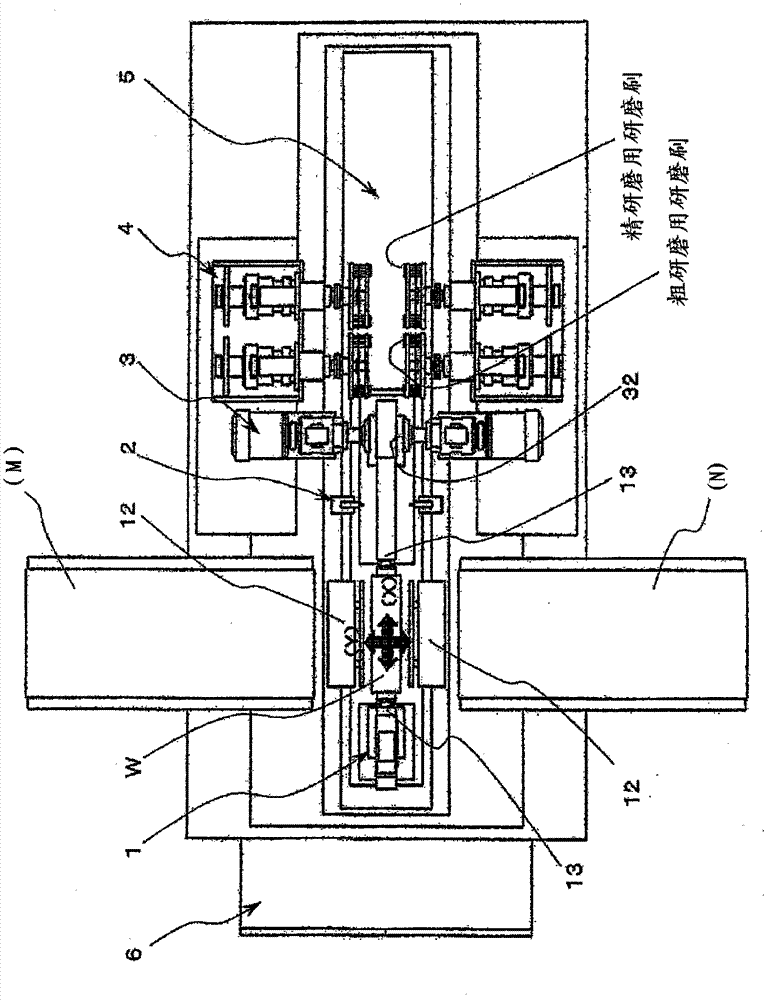

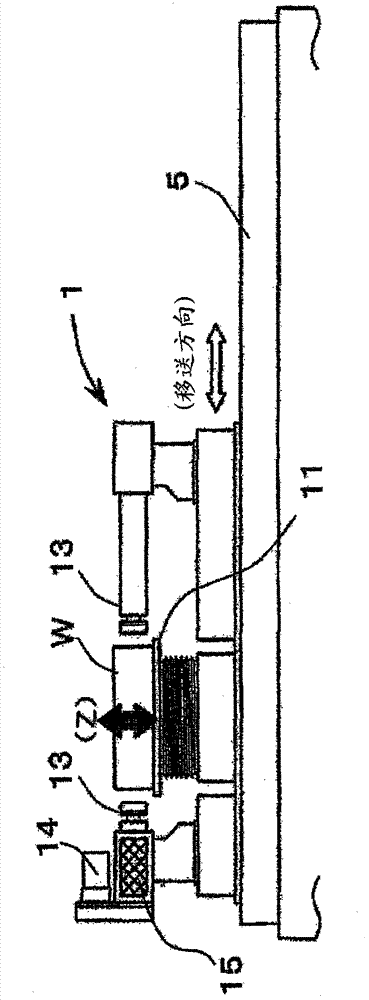

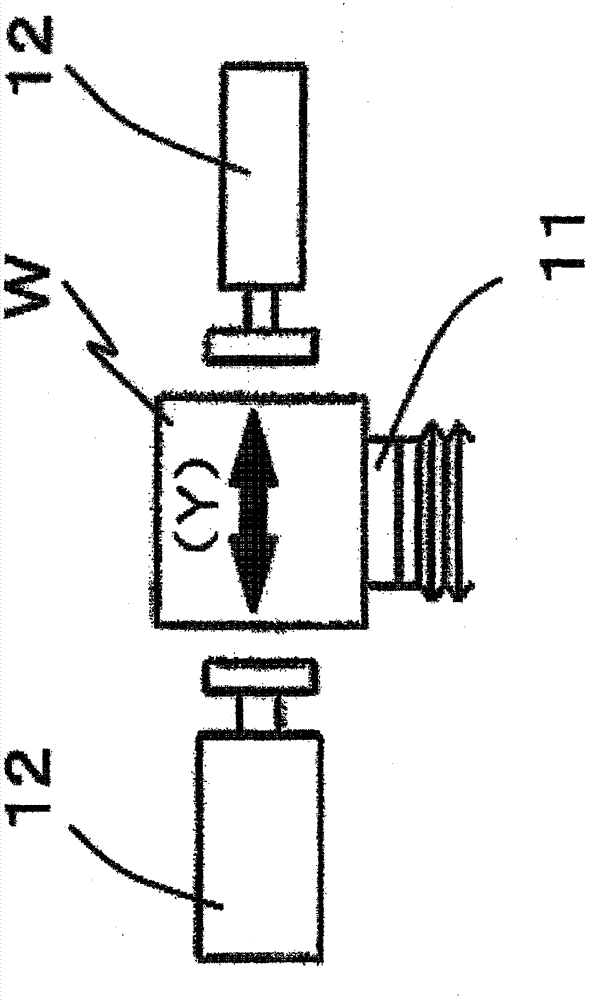

Embodiment 1

[0135] Such as Figure 9 As shown, the silicon block (W) to be processed in the present embodiment 1 is obtained by cutting out one silicon ingot. When cutting out a silicon block from a silicon ingot, use a new wire saw with a fixed abrasive method to cut a square polycrystalline silicon block (W) consisting of four flat parts (F) and four corner parts (C) in a rectangular shape. Cut into 5 columns x 5 columns = 25 pieces in total. The silicon block (W) used in Example 1 is Figure 9 and Figure 10 The silicon block A cut out from the four corners of the silicon ingot is shown. In this silicon block A, protrusions are formed on two planar parts.

[0136] Table 1 and Table 2 show the contents of the initial setting items input to the control means (6) before the start of machining.

[0137] [Table 1]

[0138]

[0139] [Table 2]

[0140]

[0141]In the initial setting items shown in the above table 1, the interval size (100mm) of the reference plane of the reference...

Embodiment 2

[0163] The silicon block (W) to be processed in Example 2 is a single crystal silicon block (W) formed by cutting a cylindrical single crystal silicon ingot produced by the crystal pulling method. The upper and lower ends of the above-mentioned monocrystalline silicon ingot are cut off and removed, and the length (in Figure 11 , the direction perpendicular to the paper surface) is cut into the range of 299.0 ~ 301.0mm (called: 300mm), such as Figure 11 As shown, vertically fix 5 rows×5 rows=25 pieces in total to the fixing jig.

[0164] With respect to the above 25 single crystal silicon ingots, the outer peripheral portion of the main body of each single crystal silicon ingot was cut and removed by using the new fixed abrasive wire saw used in the above-mentioned Example 1. At this time, processing was performed so that four arc-shaped corners (C) having a width of about 25 mm were formed in a part of the outer periphery. Simultaneously cut and form four planar parts (F) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com