Dual surface grinding machine

A double-face grinding machine and grinding technology, which is applied in the direction of grinding machines, machine tools suitable for grinding workpiece planes, grinding workpiece supports, etc., can solve problems such as lack of reliable benchmarks, failure to meet grinding requirements, and improper placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

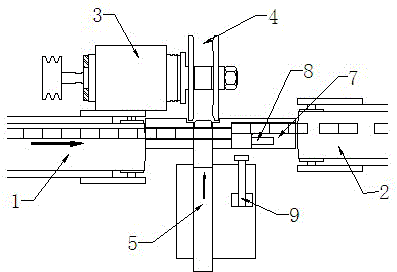

[0013] Such as figure 1 As shown, the double-end grinding machine of the present invention includes a feed conveyor belt 1 and a discharge conveyor belt 2, and the magnetic tiles are placed longitudinally on the feed conveyor belt 1, so that the end faces of the magnetic tiles are located in the front-rear direction, The magnetic tiles can run forward with the feed conveyor belt 1 driven by the motor; one side of the feed conveyor belt 1 is provided with a grinding head 3, and the front end of the grinding head 3 is provided with a grinding machine for grinding the front and rear ends of the magnetic tiles. Grinding wheel set 4, the opposite side of the grinding wheel set 4 is provided with a clamping tool 5 that can clamp the magnetic tile to be ground and send it to the grinding position for grinding. The width between the two grinding discs of the grinding wheel set Compatible with the width of the magnetic tile, so that the two end faces of the magnetic tile can be ground ...

Embodiment 2

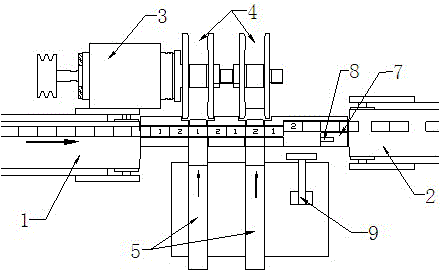

[0015] On the basis of Embodiment 1, the grinding wheel group can further be set to more than two groups, and the distance between more than two groups of grinding wheel groups is set to more than two magnetic tiles, so that the grinding wheel groups facing each group of grinding wheel groups are facing The magnetic tiles are located at the position to be ground at the same time. In the present invention, the grinding wheel sets 4 are preferably arranged in two groups, and the distance between the two sets of grinding wheel sets is set as the distance between two magnetic tiles, so that the front and rear two sets of grinding wheel sets are facing each other. The magnetic tile to be ground is located at the position to be ground at the same time, and the working process is described in detail in combination with specific embodiments.

[0016] Depend on figure 2 It can be seen that the double-end surface grinder of this embodiment includes a feed conveyor belt 1 and a discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com