Longitudinal welded pipe inner weld reinforcement grinding machine

A technology of straight seam welded pipe and grinding machine, which is applied to machine tools, grinders, grinding/polishing equipment and other directions suitable for grinding the edge of workpieces, can solve the problems of narrow space, high labor intensity, degraded use, etc., to ensure the working state , easy to operate, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following will further illustrate the inner weld reinforcement grinding machine for longitudinally welded pipes according to the present invention according to specific examples, but the specific examples and related descriptions do not constitute improper limitations to the technical solution of the present invention.

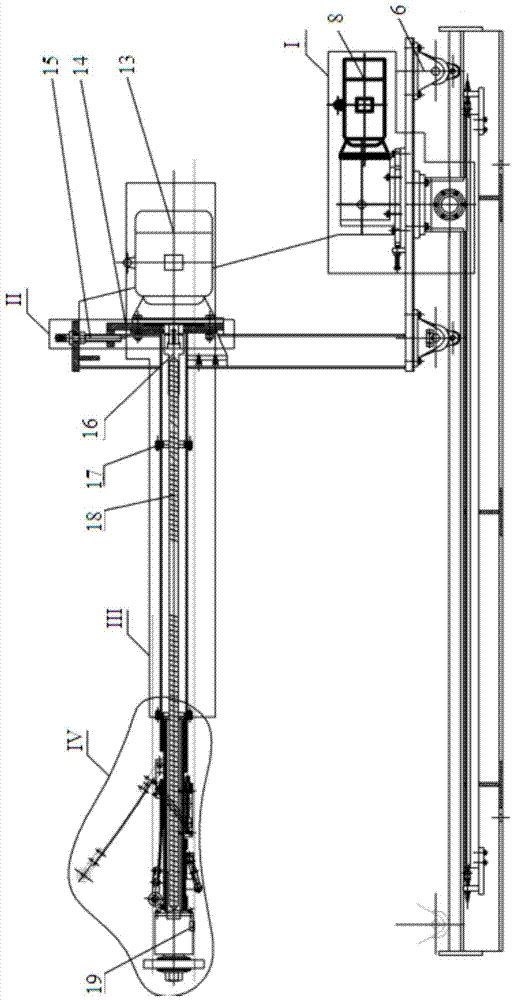

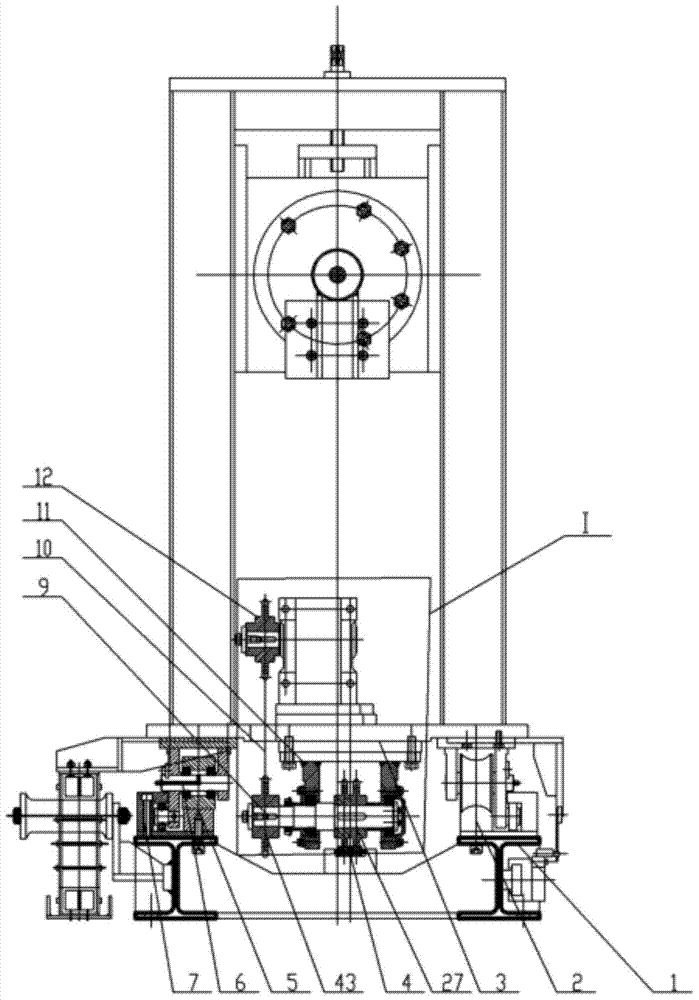

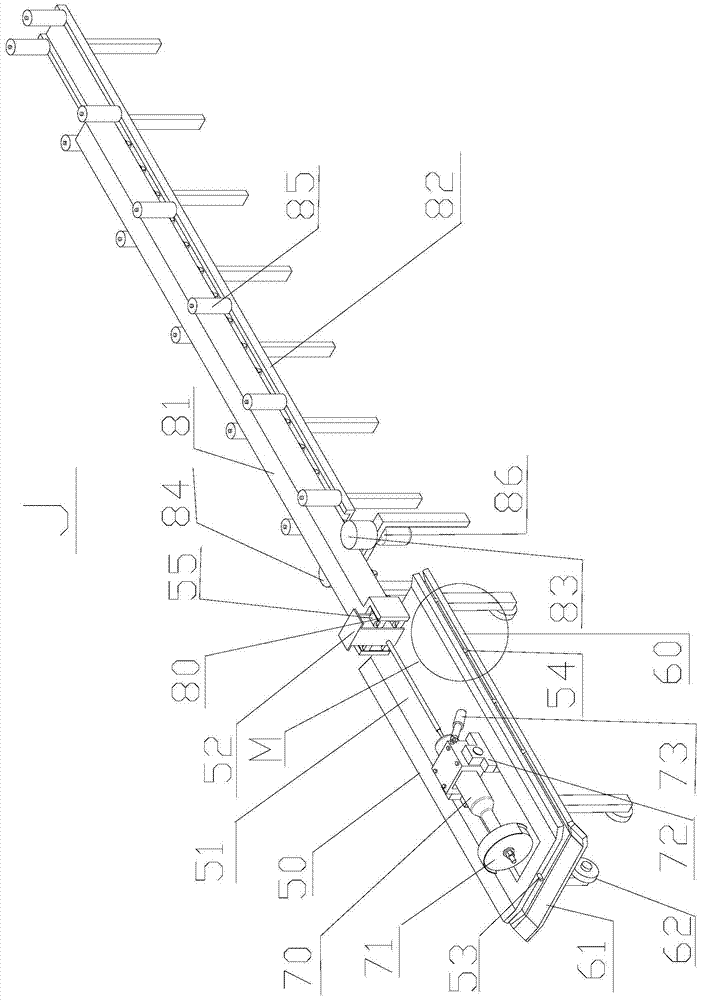

[0048] image 3 It shows the three-dimensional structure of the straight seam welded pipe inner weld reinforcement grinding machine in one embodiment of the present invention. Figure 4 Then it shows the structure of the straight seam welded pipe inner weld reinforcement grinding machine under another viewing angle.

[0049] Such as image 3 and Figure 4 As shown, the straight seam welded pipe internal weld reinforcement grinding machine J in this embodiment includes: a grinding trolley 50, a trolley platform 60, a grinding wheel machine 70 and a driving device 80; the grinding trolley 50 has a body 51, a trolley platform 60 Located below the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com