Boot last base comb-type tunnel bottom lining structure and drainage system thereof

A drainage system and tunnel bottom technology, applied in tunnel lining, drainage, wellbore lining, etc., can solve problems such as cracking and damage of tunnel bottom structure, floating deformation of tunnel invert, etc., to control settlement deformation, improve section bending stiffness, overcome The effect that the excavation curvature is not easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

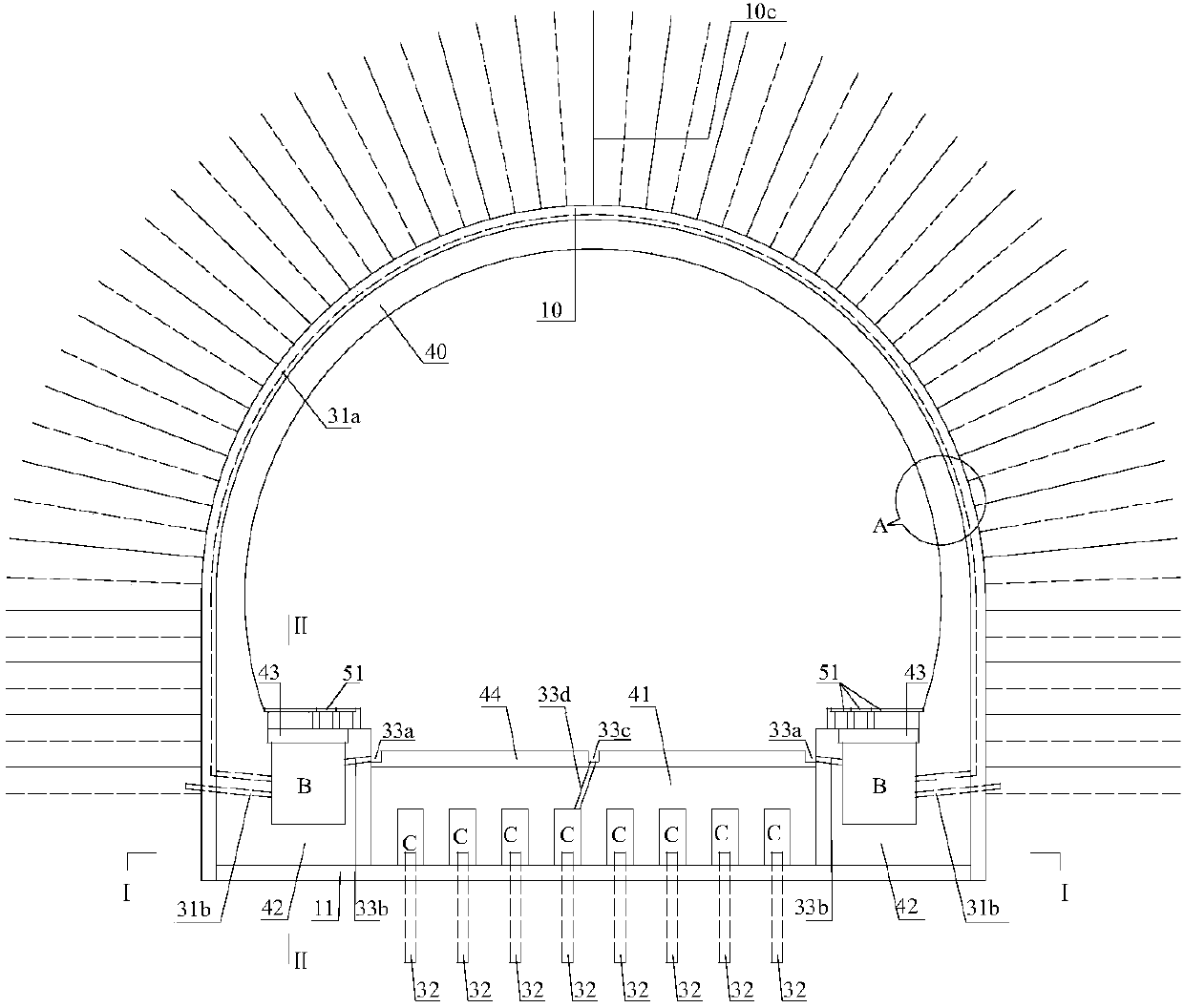

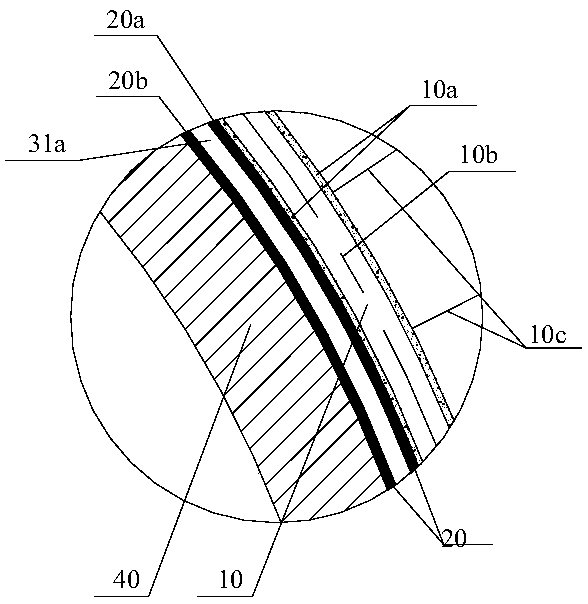

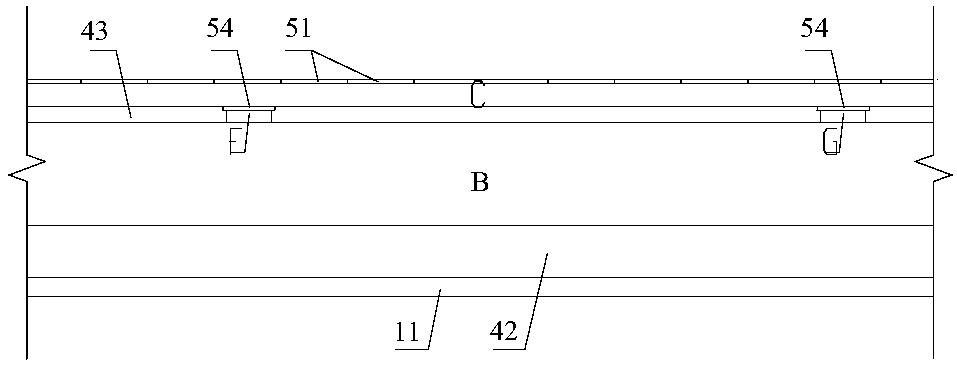

[0041] refer to figure 1 and Figure 5 , the present invention's boot-type foundation comb-type tunnel bottom lining structure and its drainage system, including arch wall primary support structure 10, arch wall secondary lining structure 40 and arch wall range waterproof layer 20, and drainage system. The bottom of the two side walls of the arch wall secondary lining structure 40 is provided with a pedestal 42 consolidated with it as a load-bearing structure of the arch wall secondary lining structure, and the cavity B in the shoe longitudinally penetrates inside it as a longitudinal drainage channel of the tunnel. Utilizing the bases 42 on both sides as the load-bearing structure of the secondary lining 40 of the arch wall not only improves the section bending stiffness, but also greatly increases the stress-bearing area of the base, and can effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com