Patents

Literature

66results about How to "Reduce engineering construction investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

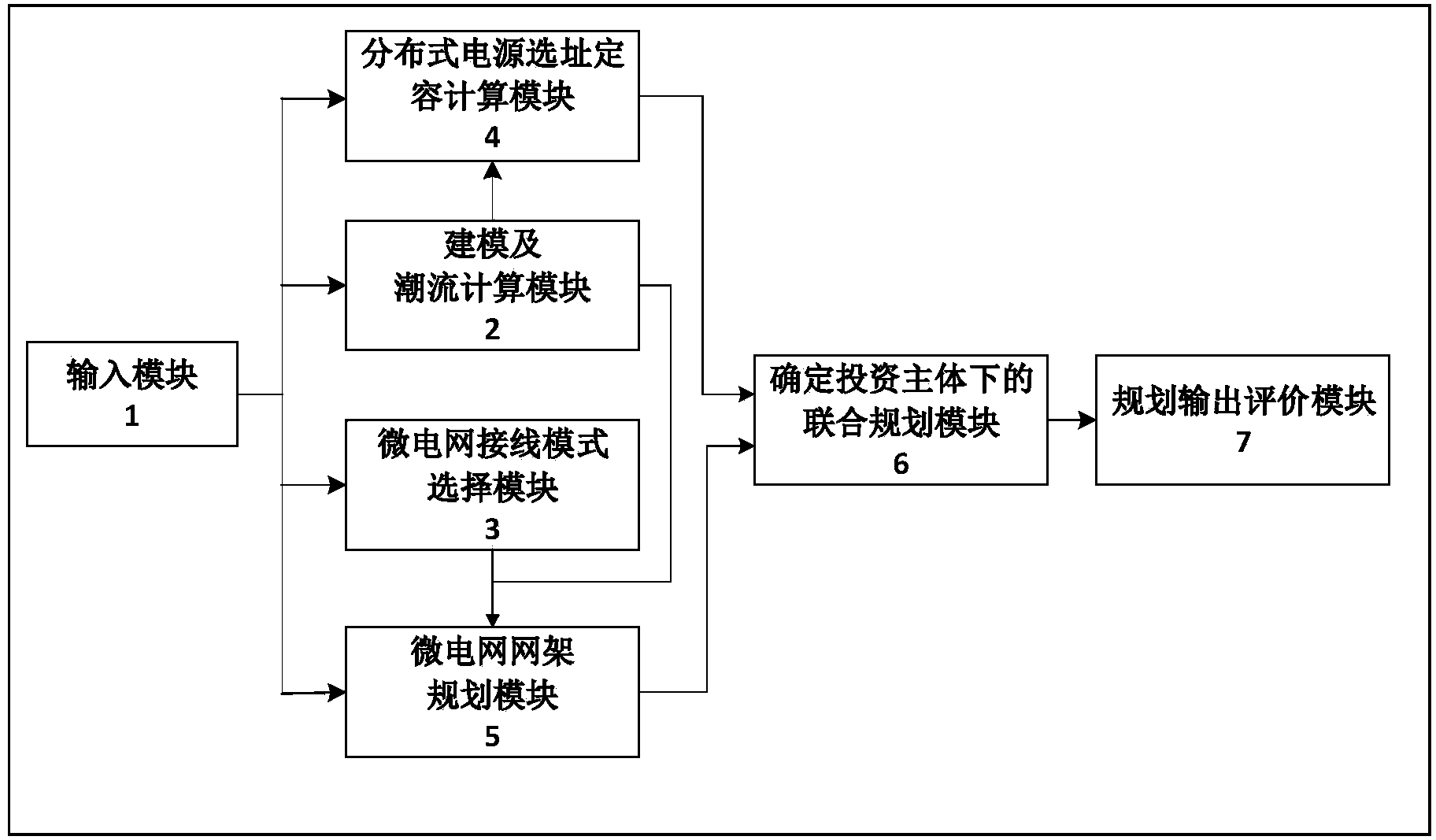

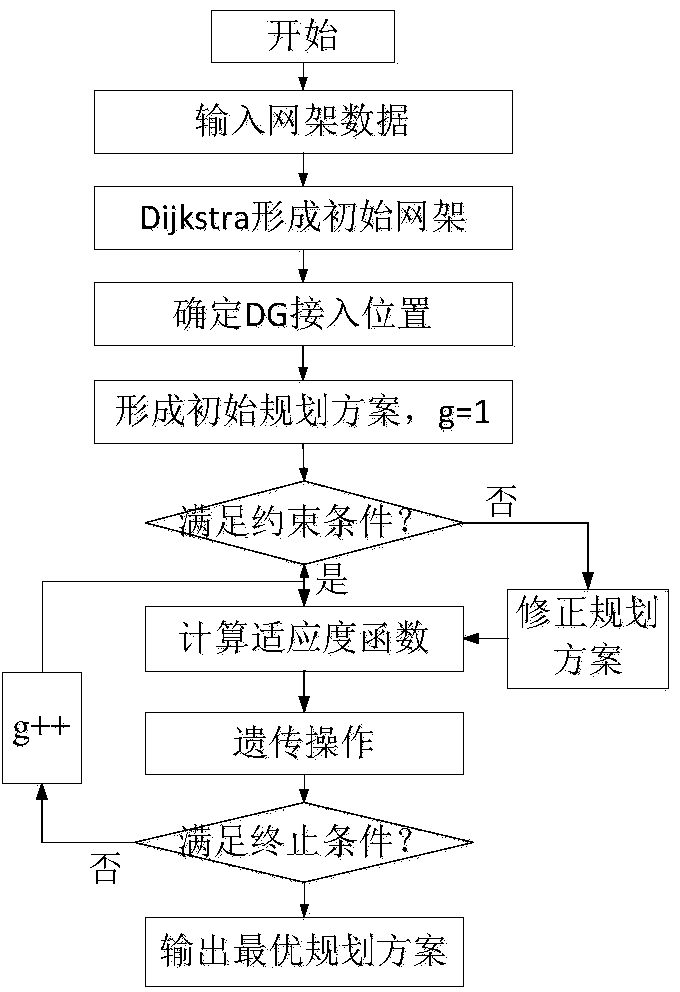

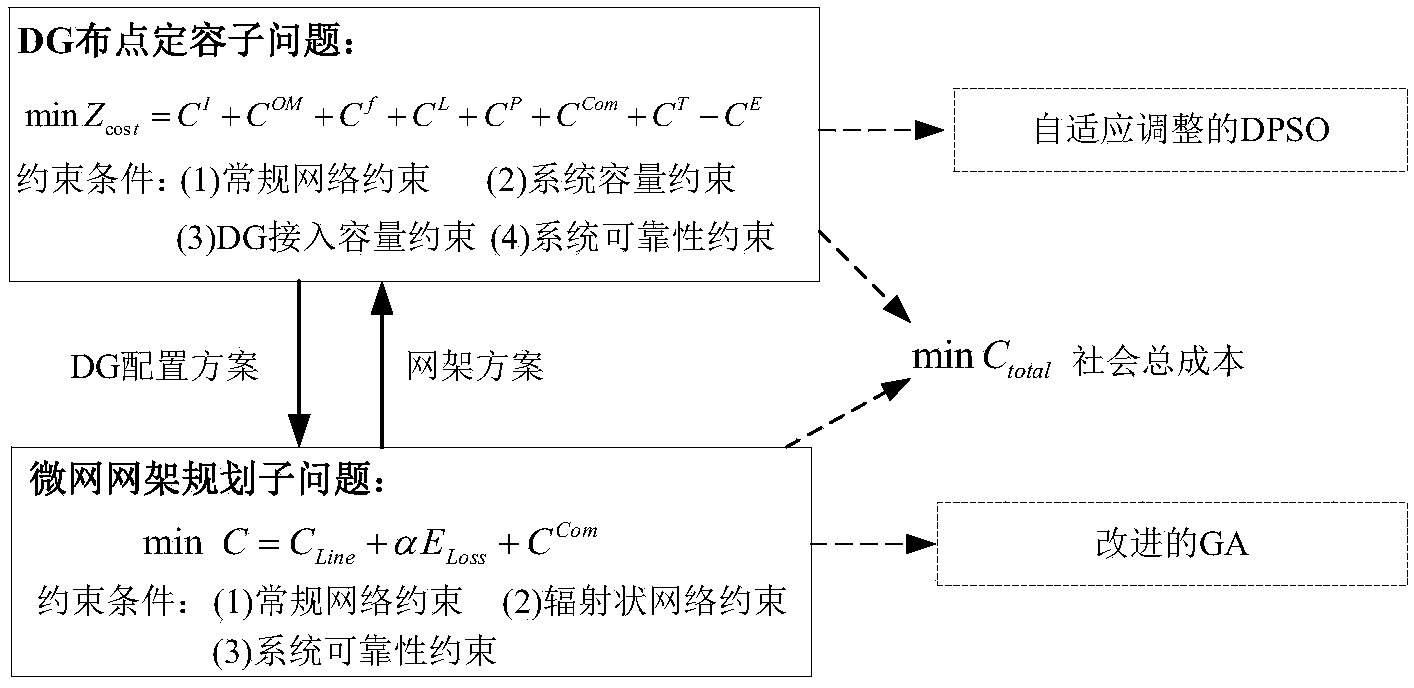

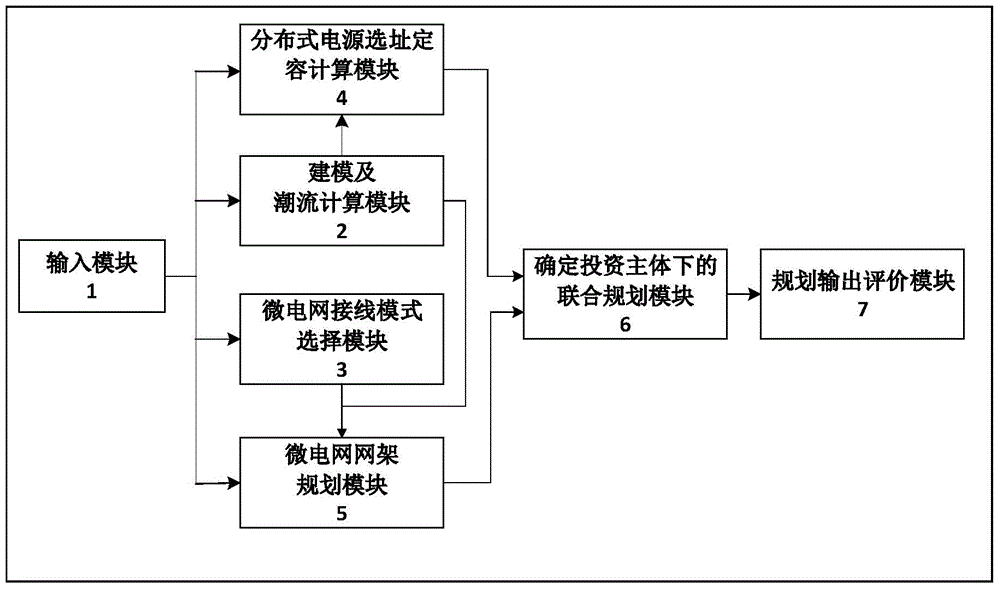

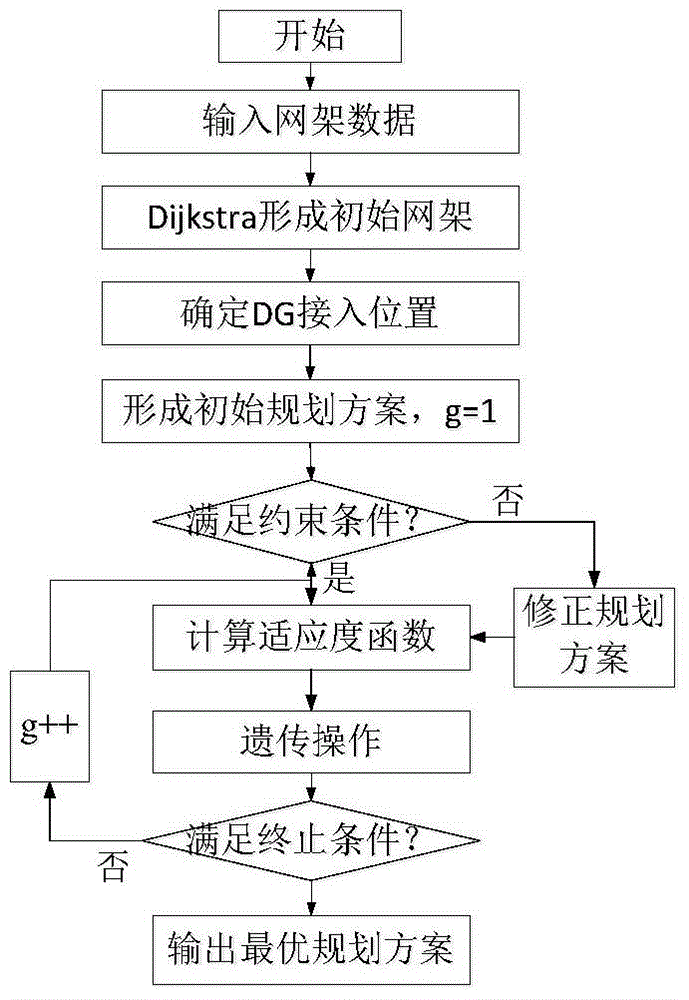

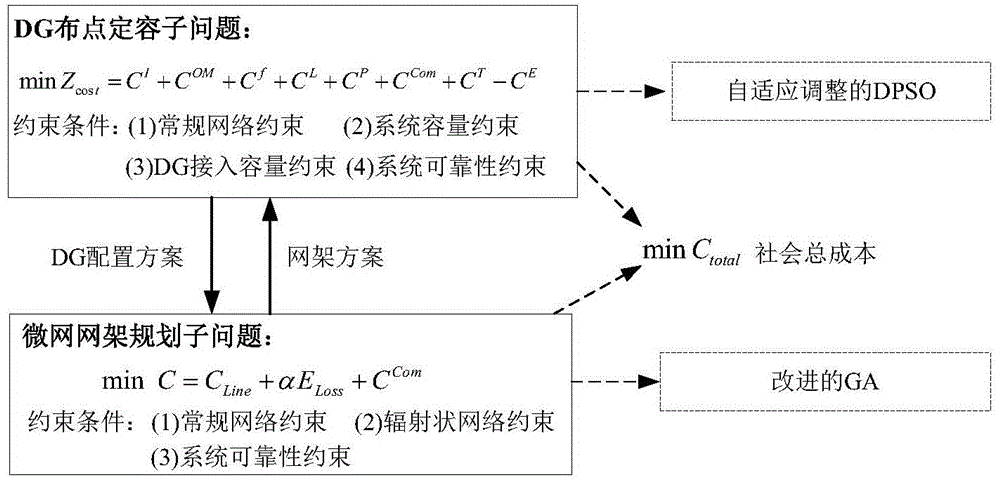

Planning method and system for optimizing micro-grid containing distributed power sources and stored energy

ActiveCN103903073AReduce engineering construction investmentForecastingSystems researchSite location

The invention discloses a planning method and system for optimizing a micro-grid containing distributed power sources and stored energy, wherein the planning method and system are based on an intelligent optimization algorithm. The planning method is used for optimizing the micro-grid containing the distributed power sources and the stored energy, and comprises the steps that basic data are provided for a planning and design scheme, and modeling and load flow calculation are performed on an area to be planned; a micro-grid wiring mode suitable for the area to be planned is determined; site locations, to be chosen, of the multi-type distributed power sources are determined; a site distribution and capacity determining model is established, and a grid frame of the micro-grid containing the distributed power sources and the stored energy is planned and designed; a joint planning scheme and a joint planning module under a decided investment subject are formed; the joint planning scheme is output and evaluated. According to the planning method and system for optimizing the micro-grid containing the distributed power sources and the stored energy, on the basis of basic characteristic study of the distributed power sources and the micro-grid, planning for optimizing the micro-grid containing the photovoltaic power sources is systematically studied, the positions, capacities and the grid frame structures of all kinds of distributed power sources in the micro-grid in the specified planning area are reasonably allocated, and the micro-grid optimization planning scheme which is complete, effective and high in integrity, and is closely integrated with engineering practice is established.

Owner:HOHAI UNIV +3

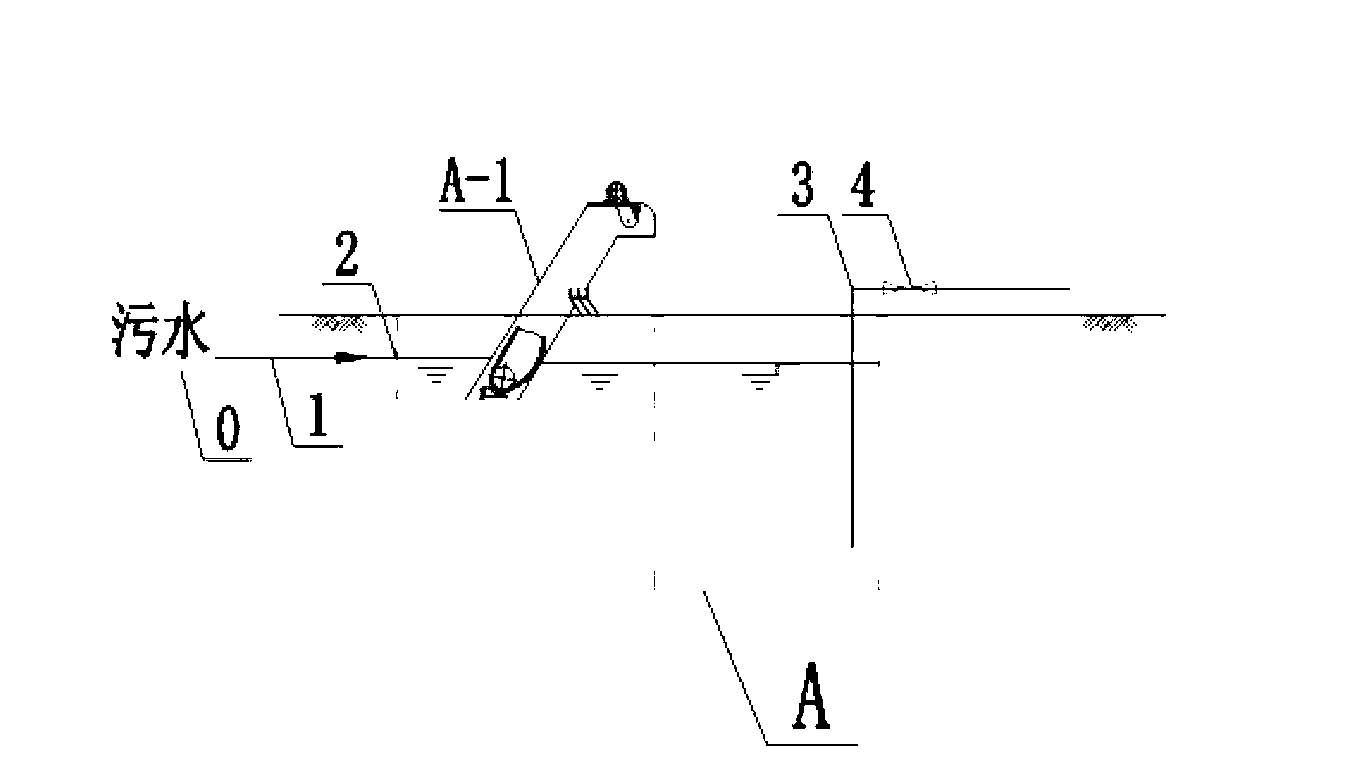

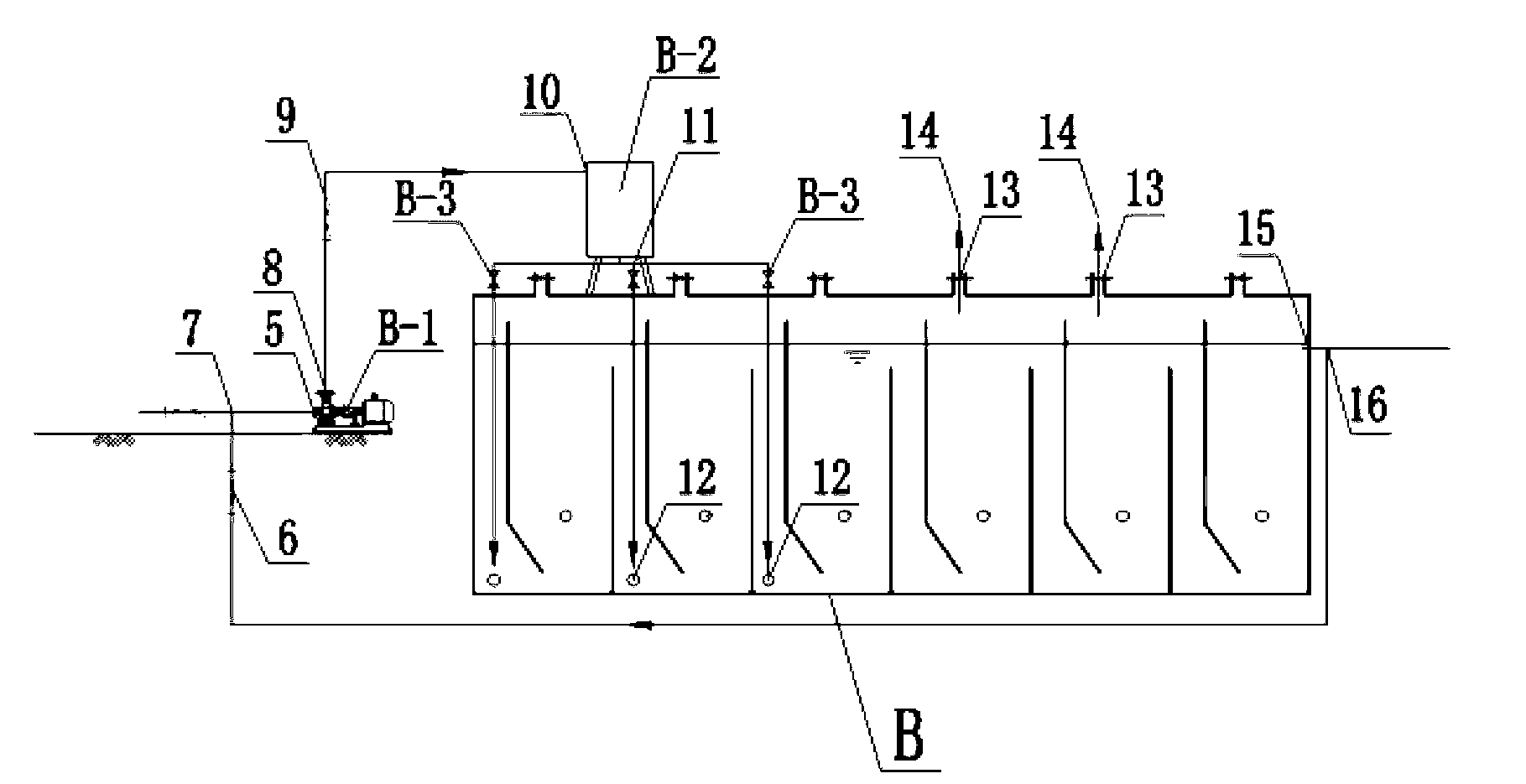

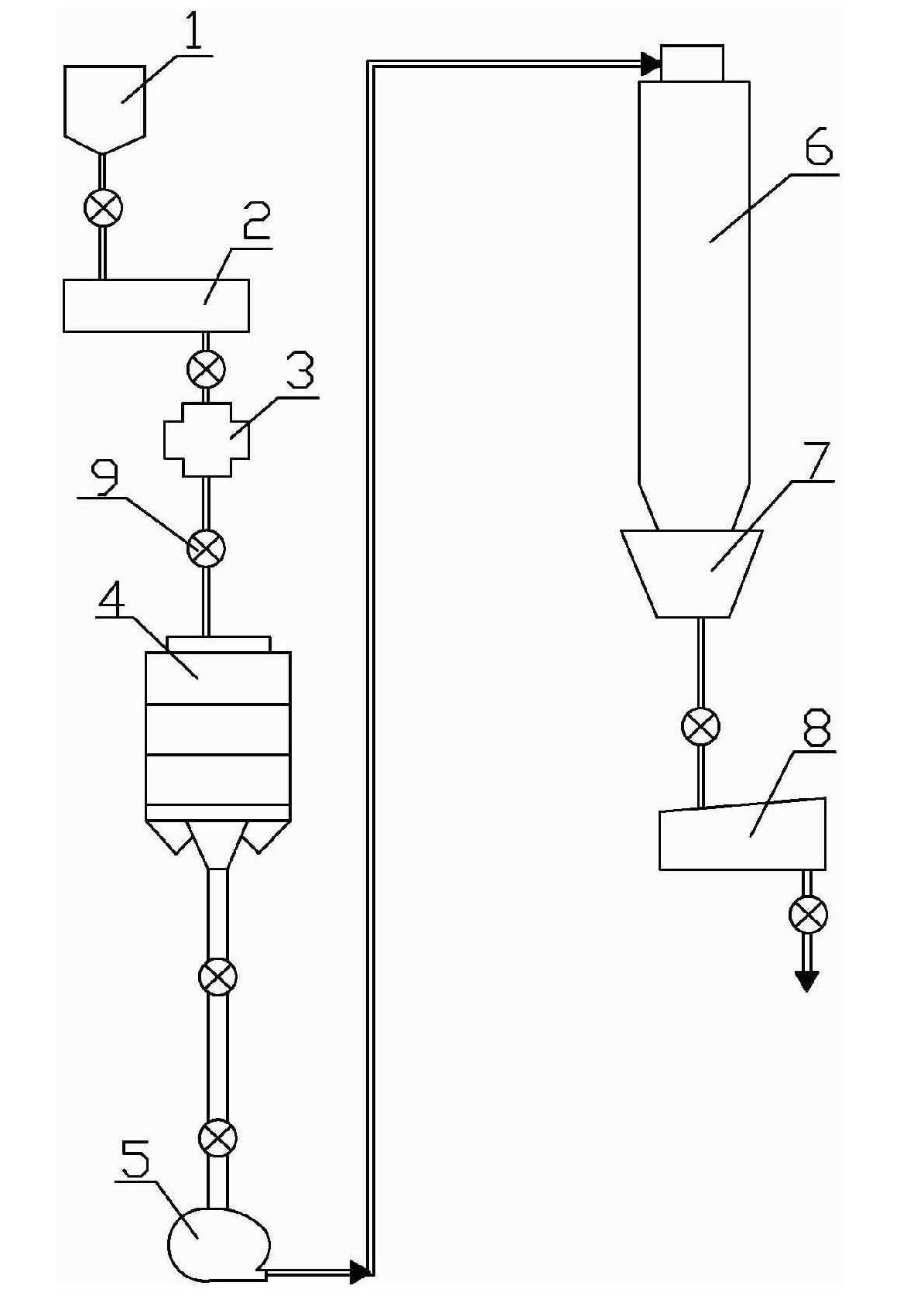

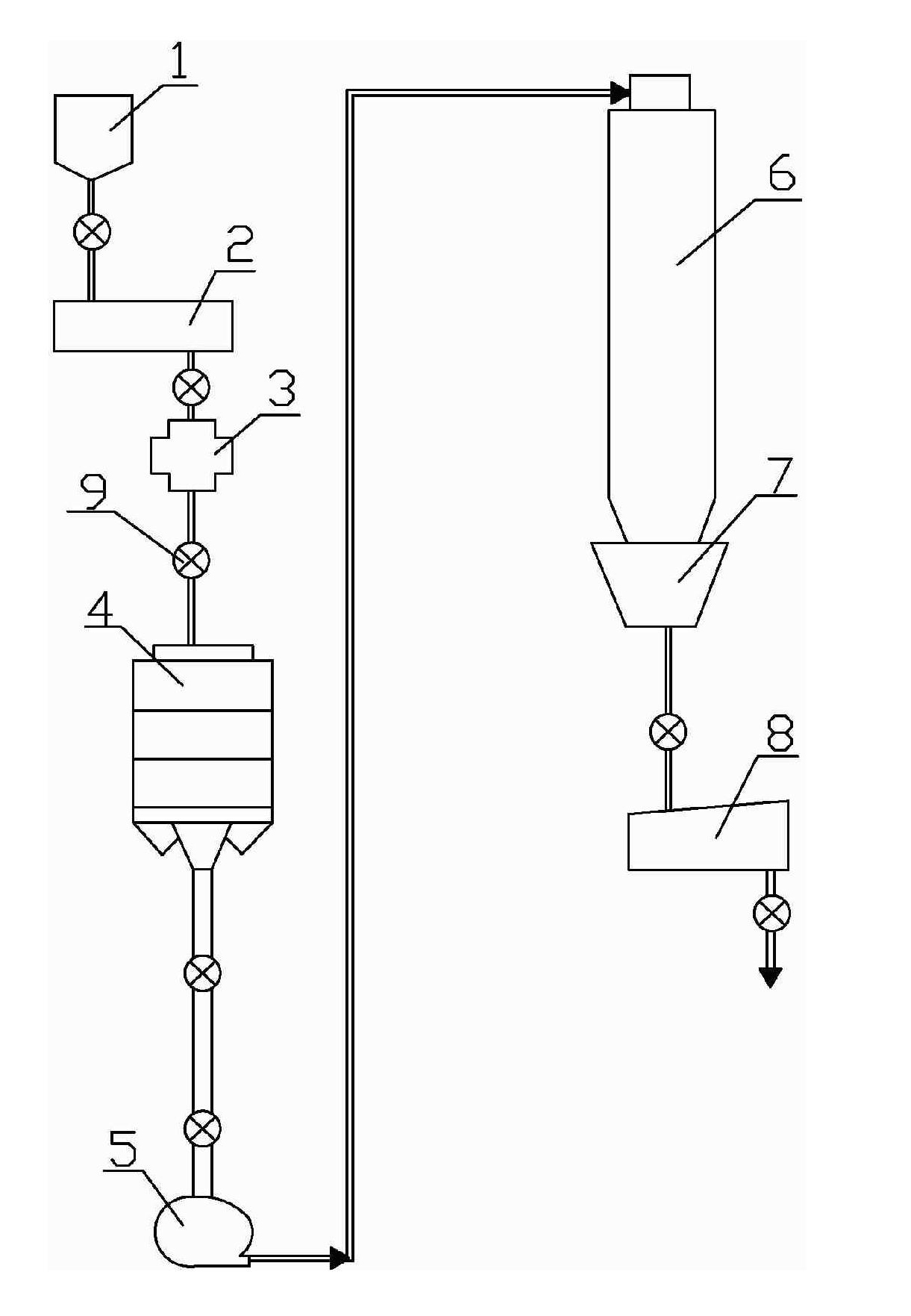

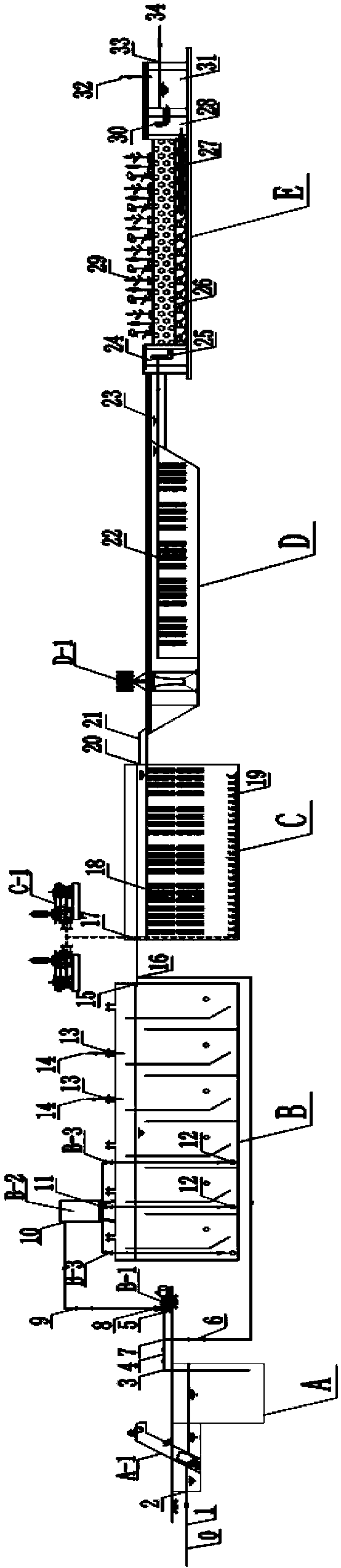

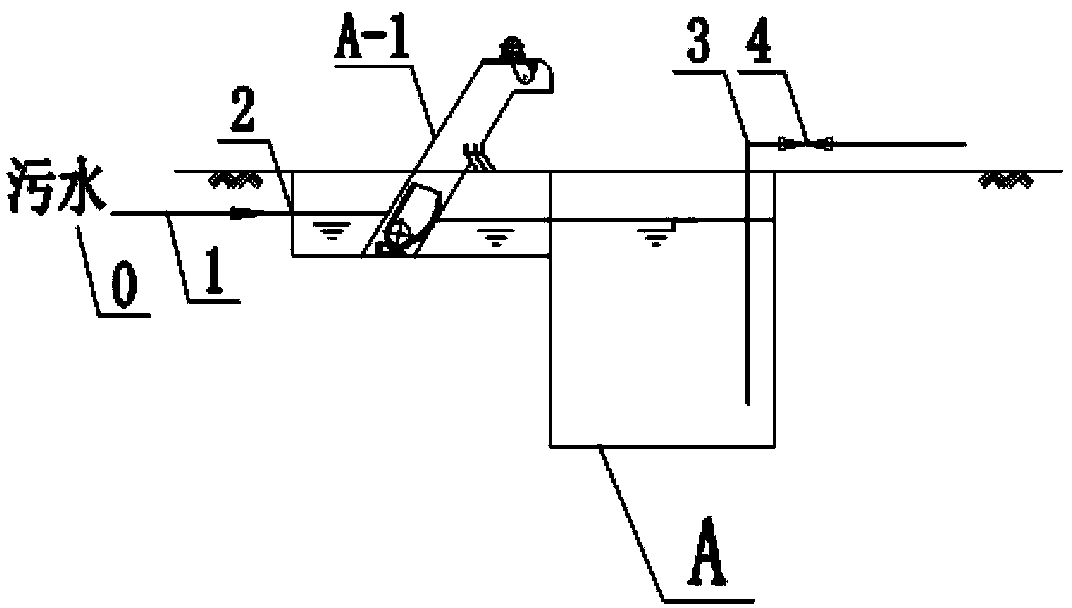

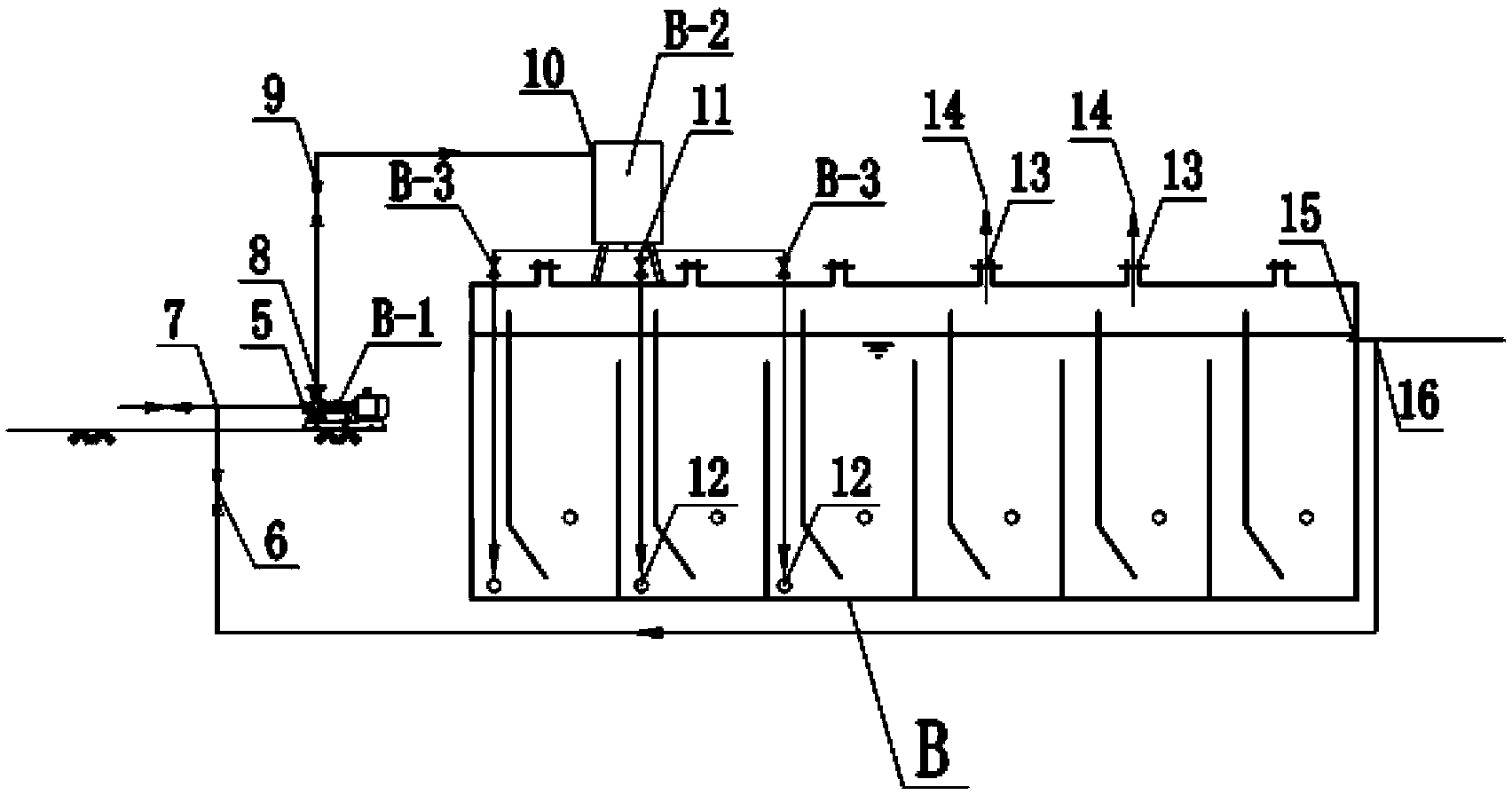

Low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method

ActiveCN102701521AEasy to handleReduce load ratioEnergy based wastewater treatmentMultistage water/sewage treatmentConstructed wetlandRural area

The invention discloses a low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method. The method comprises the steps that: 1, the to-be-treated wastewater is collected by a sewage pipe network and then is filtered by lattices, and is lifted by a pump to enter a pulse water distribution pot of a novel efficient turn-back anaerobic biochemical pool (ABR); 2, the swage subjected to the treatment in step 1 flows into a circulation-flow biological oxidization pool; 3 the effluent water from the step 2 flows into an artificial reinforced biological contact oxidization pool reconstructed by a water body from natural tunnels and reservoirs; and 4, the effluent water from the step 2 or the step 3 flows into constructed wetlands. After the sewage is treated by the above steps, the most pollutants in the water are effectively removed and the treated effluent water reaches the standard first-grade A in GB 18918-2002 ''Discharge standard of pollutants for municipal sewage treatment plant''. The energy-saving sewage treatment purification process with low cost, low energy consumption, low carbon emission and low operating cost is particularly suitable for the sewage treatment in small towns or rural areas.

Owner:武汉昌宝环保工程有限公司

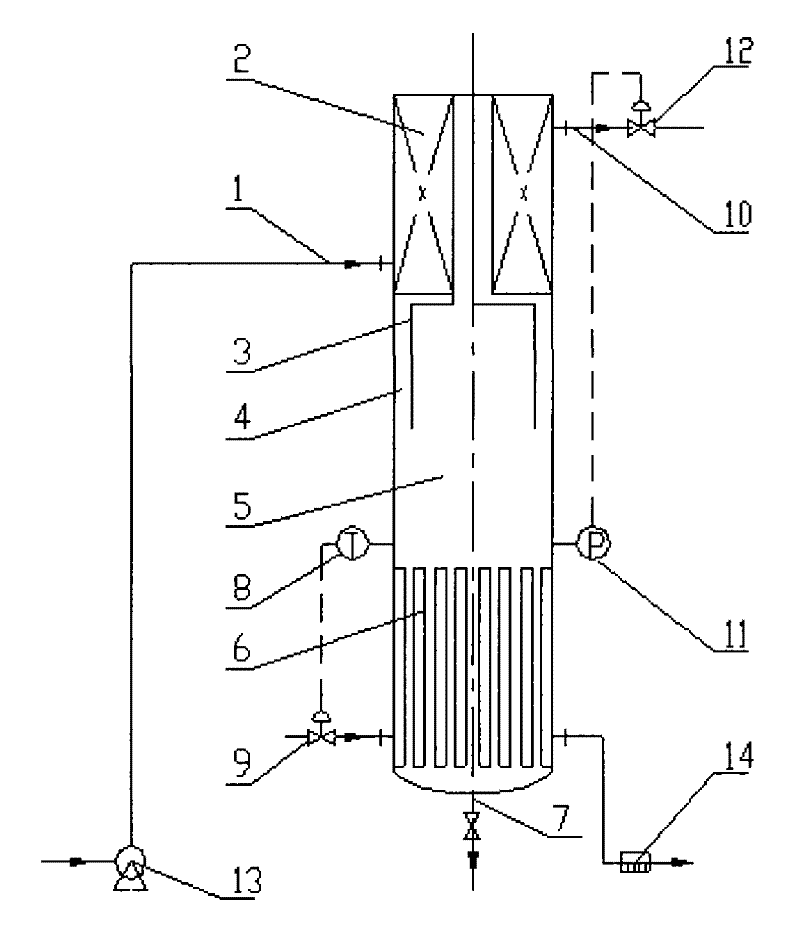

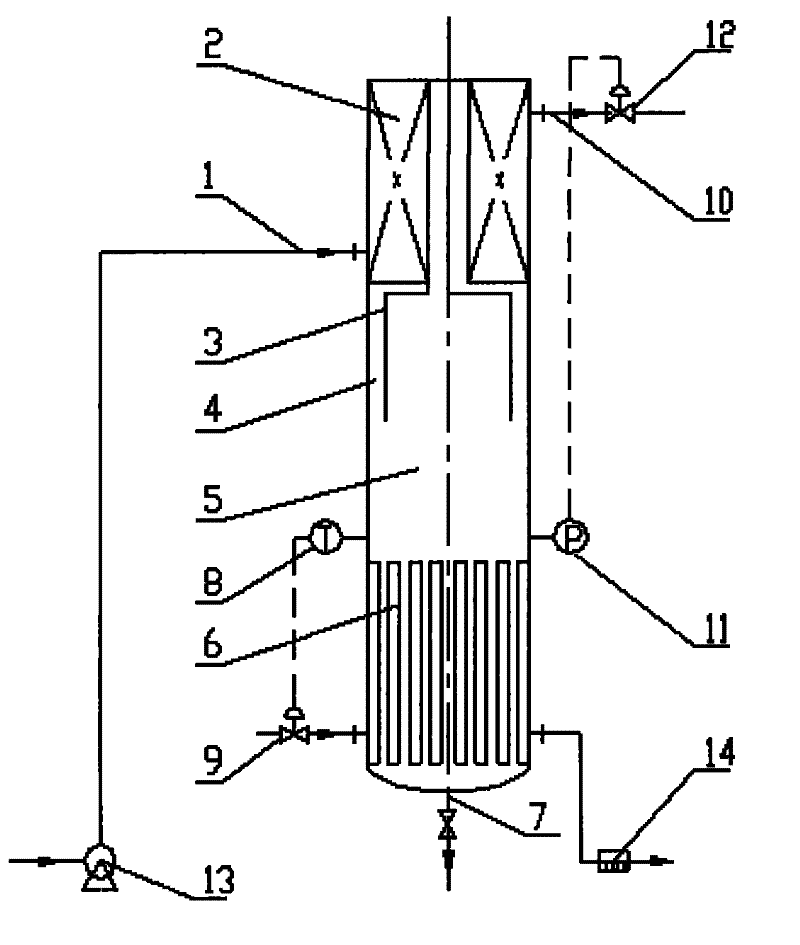

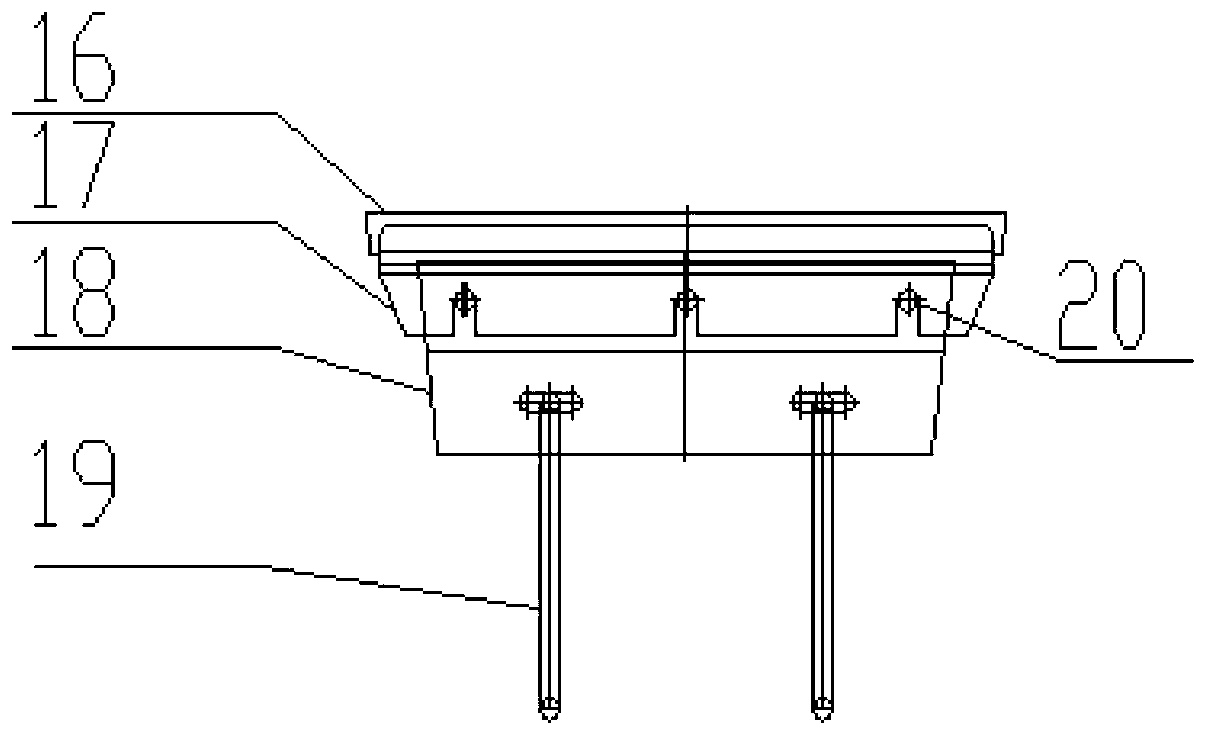

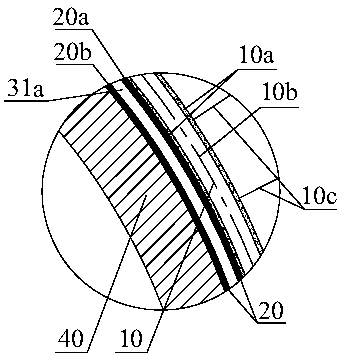

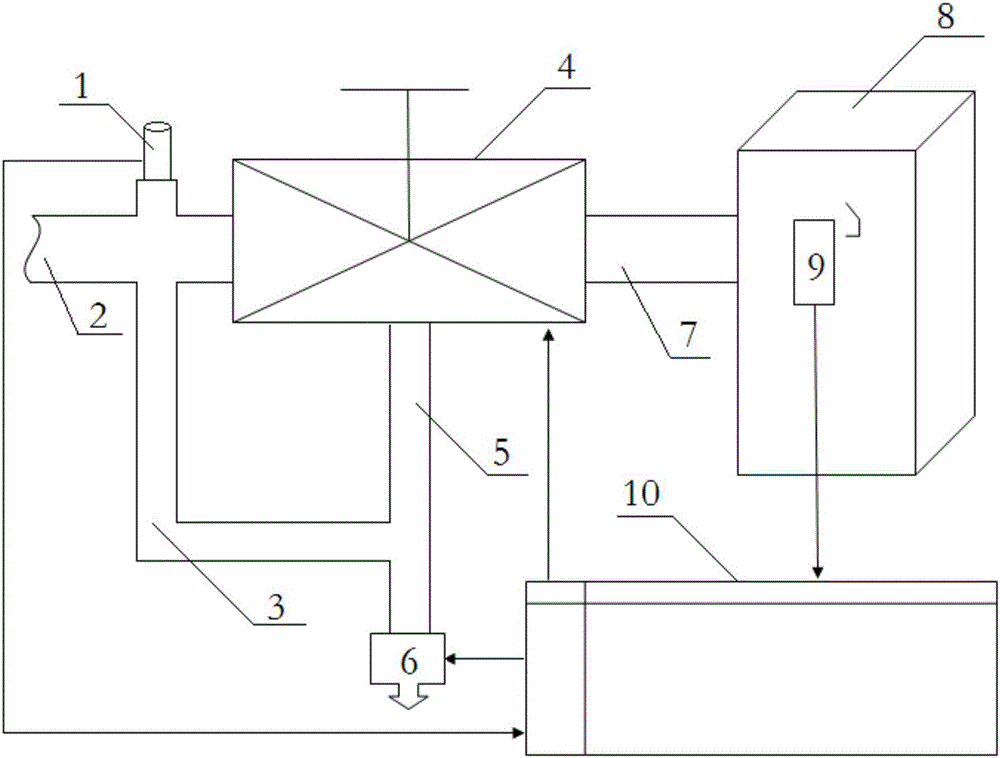

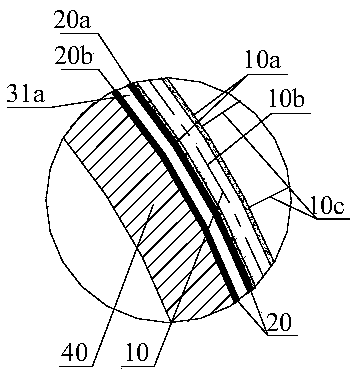

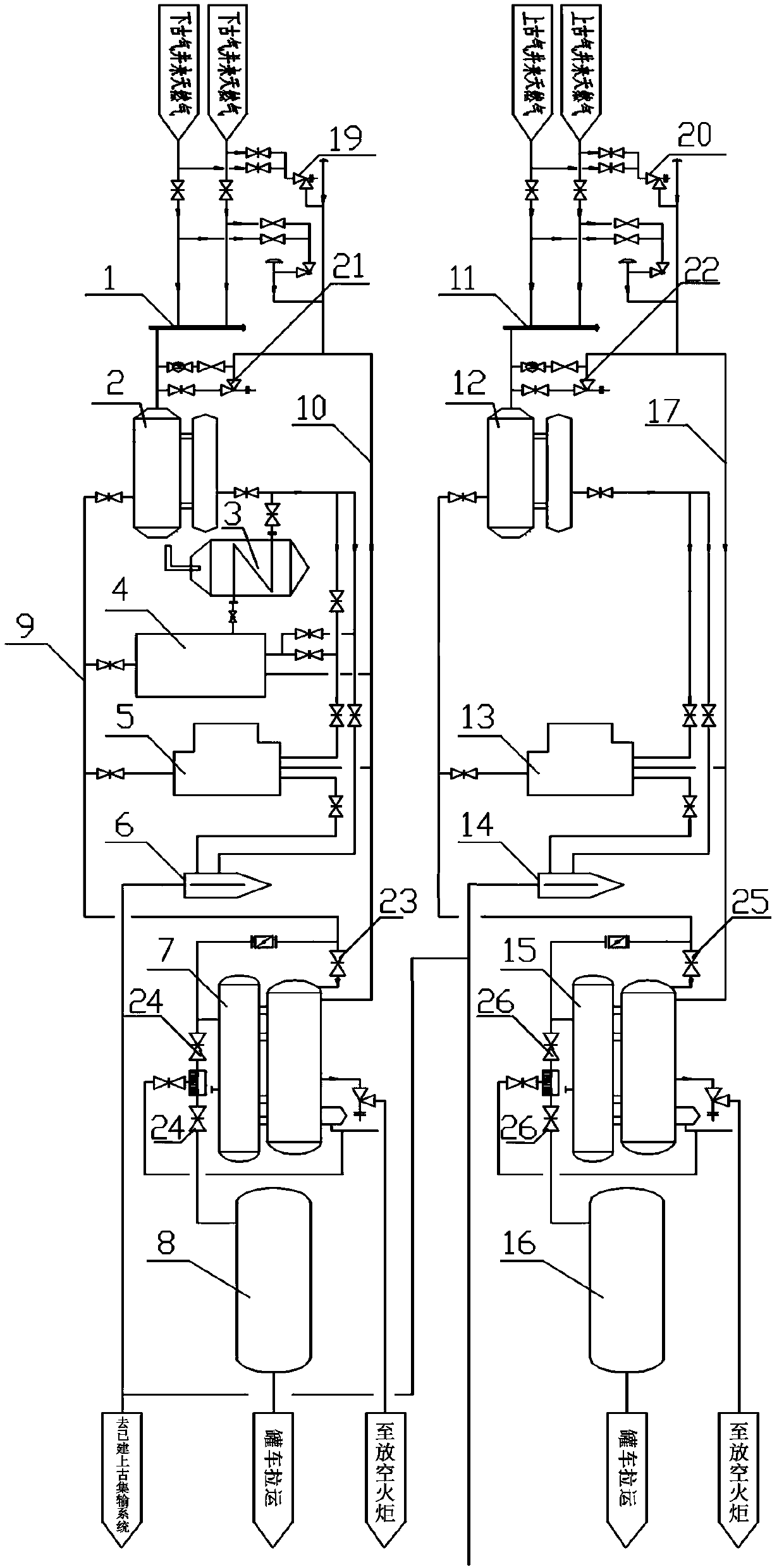

Method and apparatus for producing molten sulfur from sulfur foam

InactiveCN102267688ALower operating average temperatureReduce desulfurization costSulfur compoundsThermodynamicsProcess engineering

The present invention provides a method and apparatus for producing molten sulfur from sulfur foam. In this method, the sulfur foam is sent into the sulfur melting device through a delivery pump, and after being preheated in the heat exchange section at the upper part, it enters the settling section in the middle to settle and separate into desulfurization liquid and concentrated sulfur paste. Returning to the desulfurization system, the separated concentrated sulfur paste is heated to form molten sulfur and then discharged. The equipment consists of a delivery pump and a sulfur melting device. The sulfur melting device includes an upper heat exchange section and a lower heating section. There is also a settling separation section between the two. The desulfurization liquid output is provided on the sulfur melting device. The pipeline and the heating medium pipeline are equipped with a sulfur discharge valve at the bottom of the heating section. The sulfur melting process device of the present invention has low operating average temperature, low energy consumption and long service life of the equipment, so the cost of desulfurization can be reduced; since the heat exchange area is relatively small, the project construction investment can also be reduced.

Owner:鞍钢集团工程技术有限公司

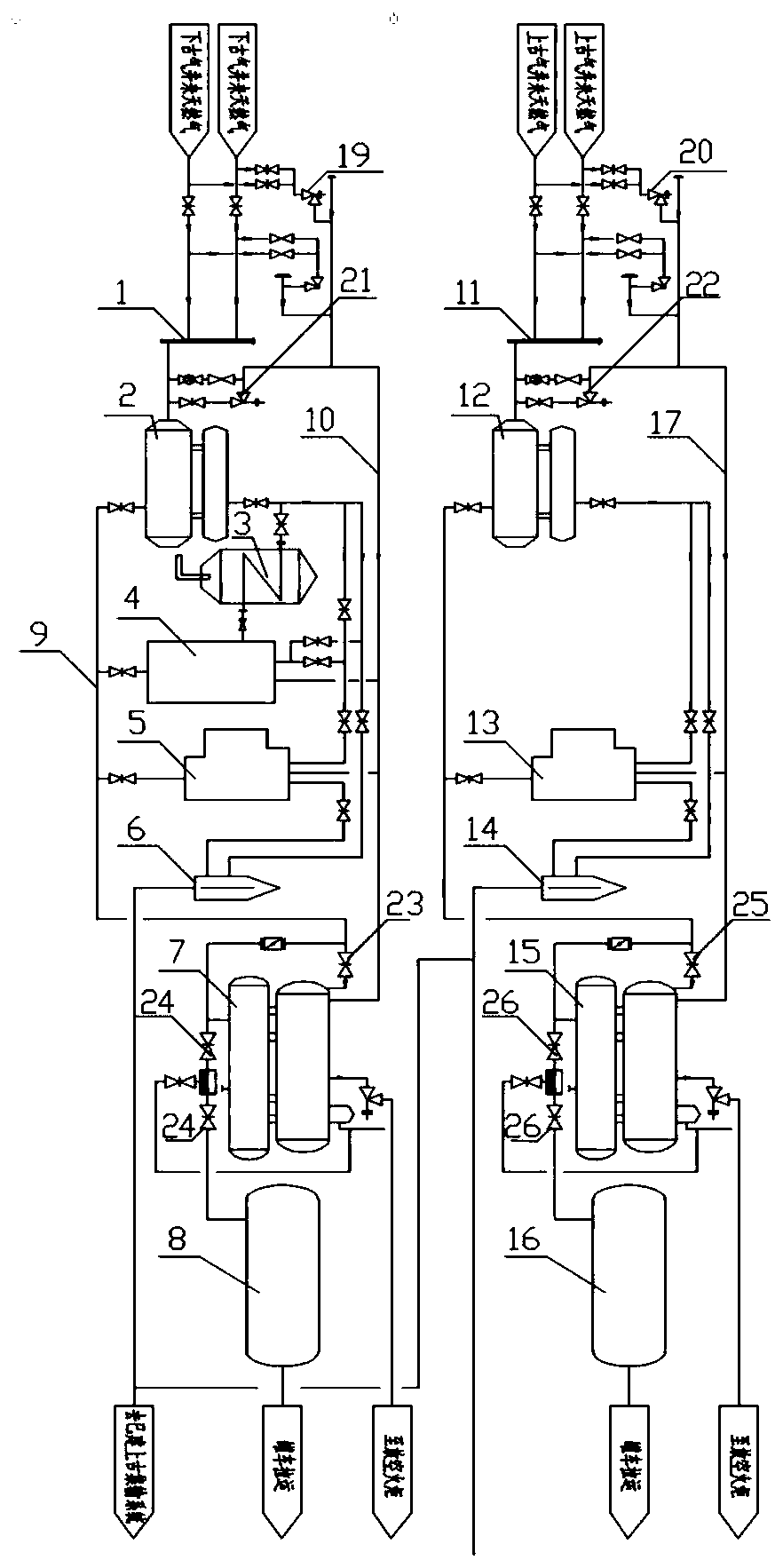

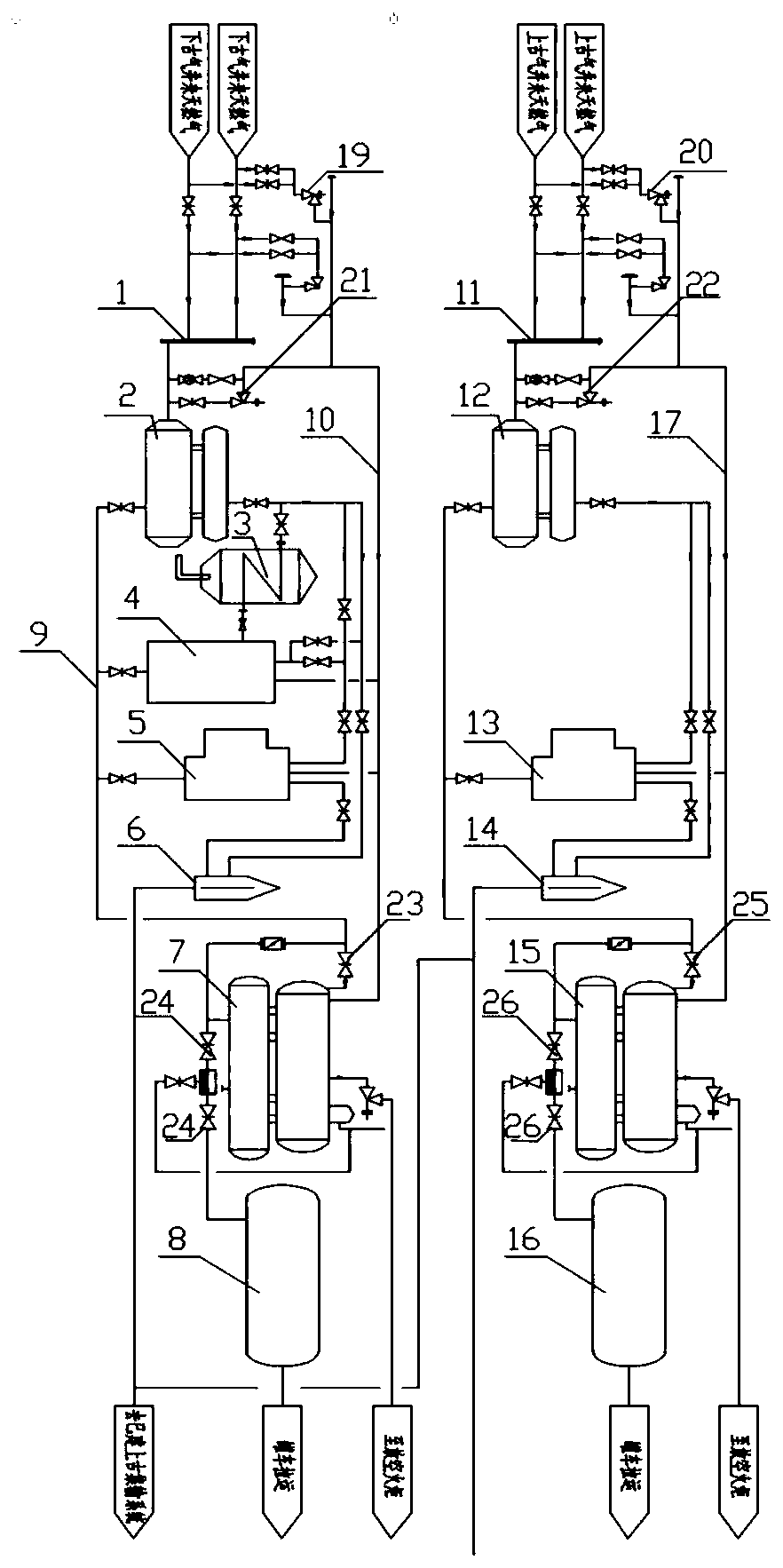

Continuous heat transfer sulfur dioxide conversion process

The invention discloses a continuous heat transfer sulfur dioxide conversion process, which is suitable for the sulfuric acid making industry. The process comprises the following steps of: allowing high-concentration SO2 smoke from a blower to pass through a primary conversion heat exchanger, heating to catalyst ignition temperature, introducing into a first-section reaction layer of a converter,controlling reaction temperature in the converter by adjusting the air quantity of a cooling fan, heating the primarily converted gas by using the primary conversion heat exchanger, and introducing the primarily converted gas into a first absorption tower; and introducing the smoke into a secondary conversion heat exchanger after SO3 is completely absorbed, heating the smoke to the catalyst ignition temperature, introducing the smoke into a second-section reaction layer of the converter, controlling reaction temperature in the converter by adjusting the air quantity of the cooling fan, heating the secondarily converted gas by using the secondary conversion heat exchanger, introducing the secondarily converted gas into a second absorption tower, and exhausting after SO3 is completely absorbed. The process overcomes a temperature control bottleneck in a high-concentration smoke conversion technology, a catalyst and steel for equipment are operated at tolerable lower temperature, and theconversion rate is over 99.85 percent.

Owner:双盾环境科技有限公司

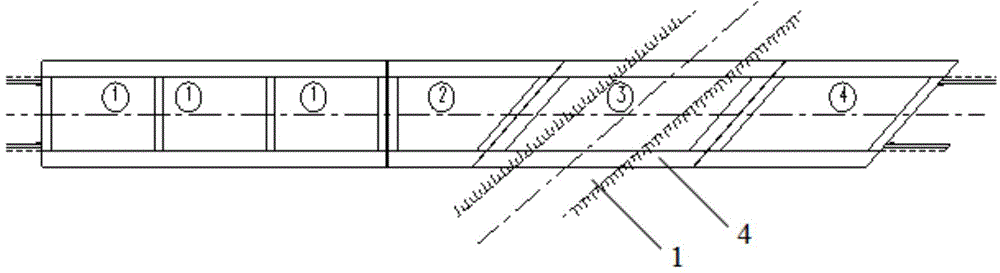

Quick pushing and transverse moving method for integral frame bridge

ActiveCN104612056AReduce post-operation and maintenance workloadReduce the height of the structureBridge erection/assemblyEngineeringNormal position

The invention discloses a quick pushing and transverse moving method for an integral frame bridge in existing rail way reconstruction, and a rail penetrates through the frame bridge. The method is characterized by comprising the steps that a sliding plate is constructed on one side of an existing rail way and a pushing back is constructed on the end of the sliding plate, the frame bridge is prefabricated on the sliding plate, and the top of a bottom plate of the frame bridge is roughly flush with the shoulder of the rail way; the pipe laying depth of pipelines on the two sides of a pushing and transverse moving area of the existing rail way is increased, and the pipe laying depth is larger than the bottom of the bottom plate of the frame bridge; a jack is installed at the back end of the frame bridge, lines and pathways of the existing rail way are dismantled, and the jack pushes and transversely moves the frame bridge; after the frame bridge is pushed and transversely moved to the position where an original rail way is removed, the lines and pathways of the existing rail way are restored in the normal position in the frame bridge. By the adoption of the form of the frame bridge, so the height of a bridge structure spanning the rail way is minimized, and a steel beam or a profiled-steel beam with the structure height in the same size is avoided; later operation and maintenance workloads of the rail way are lightened, and the requirements for safety, environment friendliness and energy conservation are satisfied.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Granular emulsion explosive and production method thereof

ActiveCN101555183ASimple processReduce engineering construction investmentExplosive working-up apparatusEmulsion explosiveOil phase

The invention provides a granular emulsion explosive and a production method thereof. The granular emulsion explosive comprises the following components by mass percent: 87 to 93 percent of oxidizer, 2 to 5 percent of water, 1.5 to 3.5 percent of emulsifier and 2.5 to 6.5 percent of fuel, wherein the oxidizer is ammonium nitrate or a mixture made by mixing ammonium nitrate with at least one of the following chemicals: sodium nitrate, aluminium nitrate, calcium nitrate and magnesium nitrate; the emulsifier is sorbitan monooleate or a mixture made by mixing sorbitan monooleate with polyisobutylene succinimide; and the fuel is at least one of the following matters: colophony, paraffin, ozokerite, asphalt and stearic acid. The method for producing the granular emulsion explosive comprises the steps of: (a) mixing the oxidizer with water under heating to form an aqueous phase material; and mixing the fuel with the emulsifier and heating the mixture for melting to form a fat phase material; (b) carrying out heating and emulsification to lead the aqueous phase material and the fat phase material to form water-in-oil type latex substance; (c) cooling and solidifying the latex substance to obtain a brittle solid; and (d) crashing the brittle solid to obtain the granular emulsion explosive.

Owner:BEIJING BGRIMM YIBO TECH +1

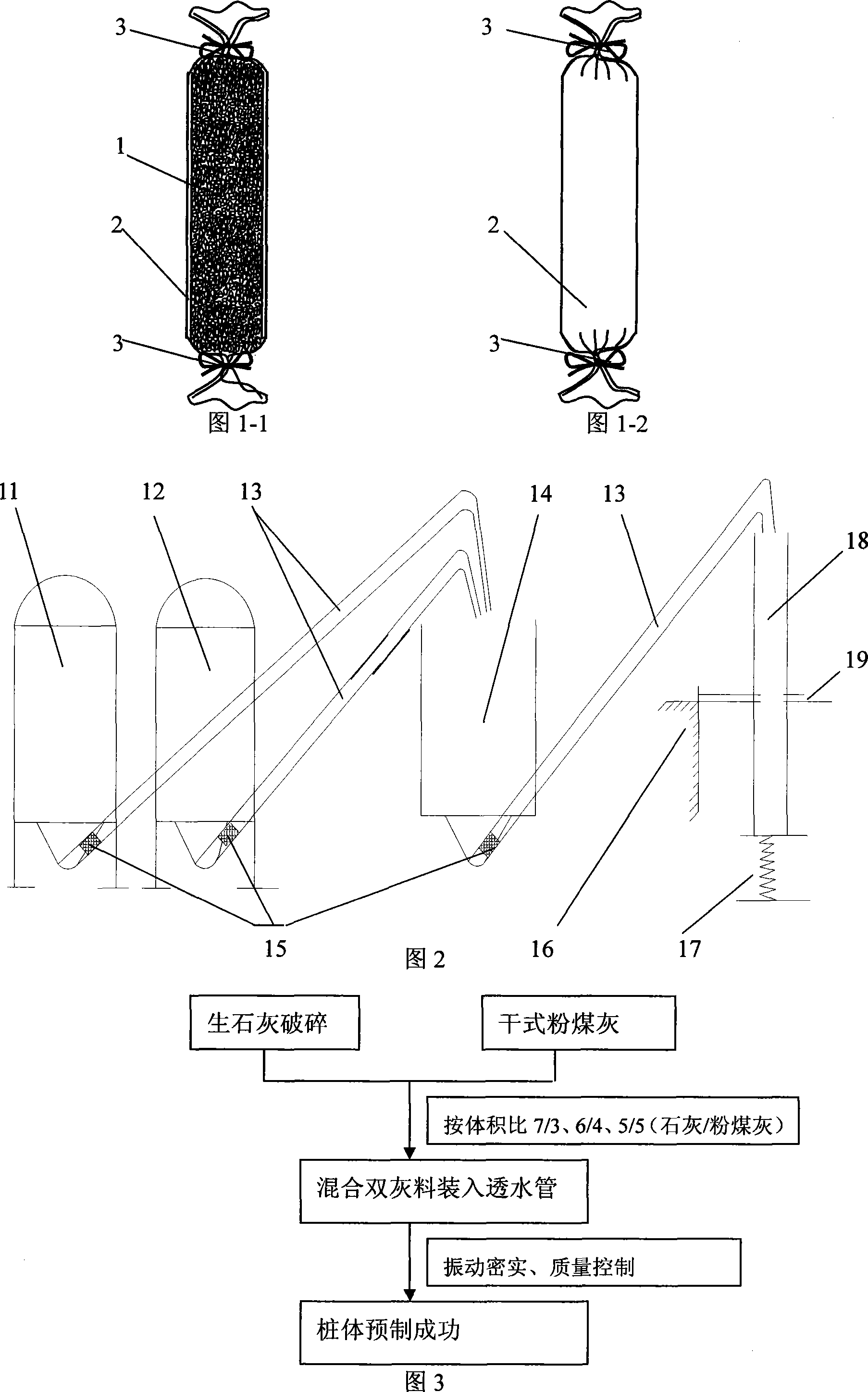

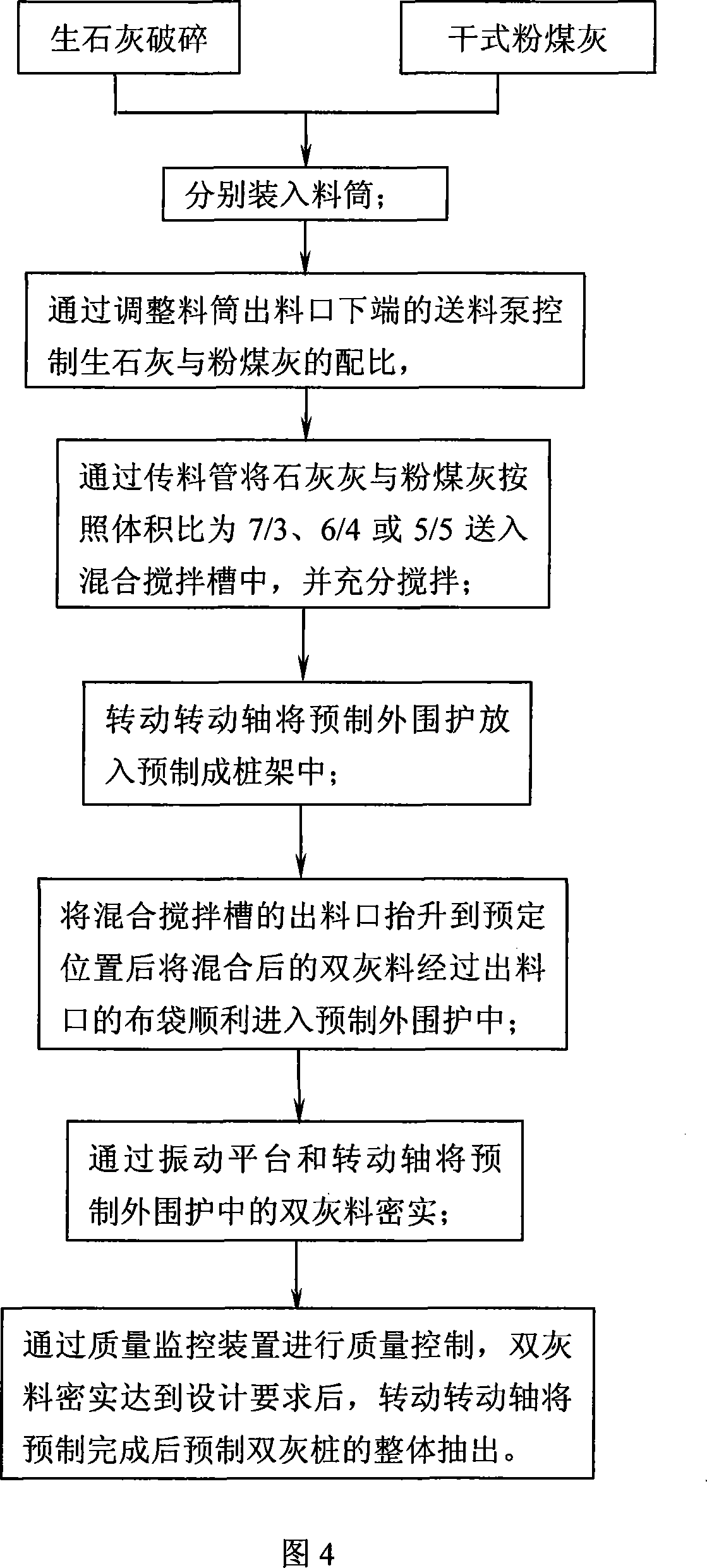

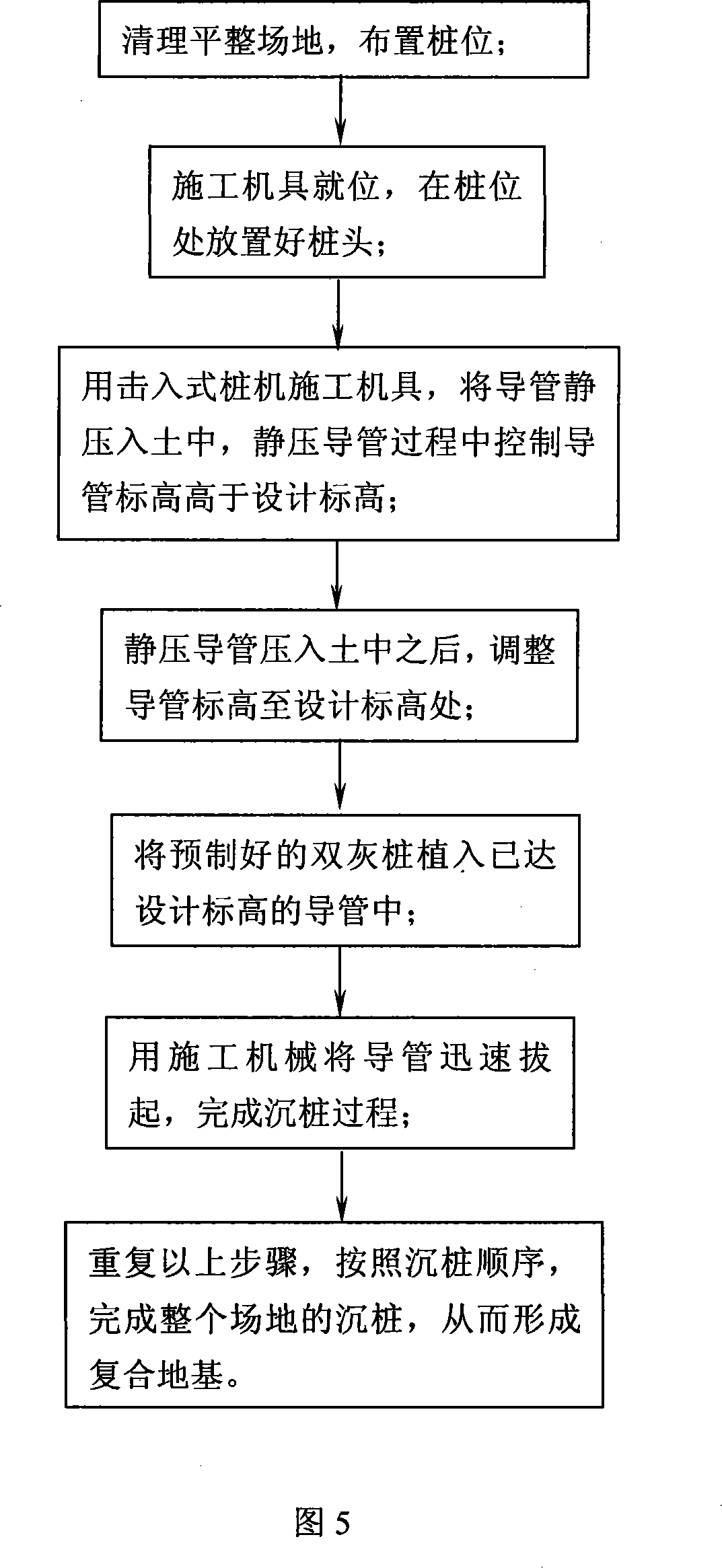

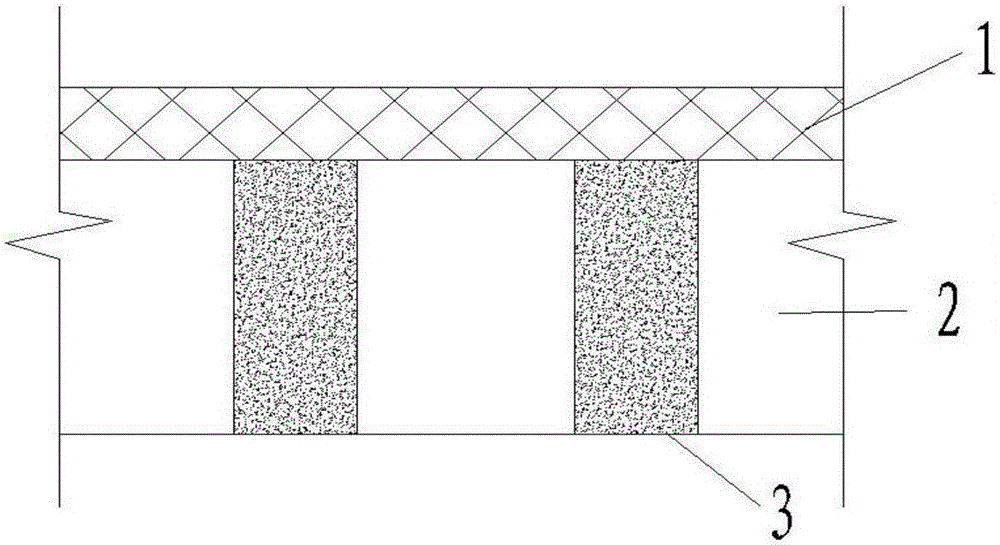

Lime coal ash precast pile and pile forming technique, and method for forming composite ground foundation

InactiveCN101239791AEasy to get materialsLow costSolid waste managementCeramic shaping apparatusStructural engineeringNonwoven fabric

The present invention discloses a lime and flyash precast pile which is used for reinforcing the soft base, the precast pile comprises a double ash material which is precast in the outer surrounding with a dense state; the double ash material is composed of lime and flyash; the bulk factor between the lime and the flyash is 7:3, 6:4 or 5:5; the lime adopts the lime with grade above III level and the water content of the flyash is 25-35%; the front and low ends of the precast outer surrounding is sealed openings; and the material of the precast outer surrounding is the nonwoven fabric with strong water permeability. The precast pile of the invention is mainly suitable for the sullage-shaped clay of the ultra-soft base, and is suitable for the ground treatment of the beach reclamation or the reinforcing of the ultra-soft ground. At the same time a pile forming technique of the precast pile and a method using the pile for forming the composite ground are disclosed in the invention.

Owner:TIANJIN RES INST OF BUILDING SCI

Solid state polymerization technique of polyester industry

The invention discloses a solid phase polymerization technique of the polyester industry. The technique comprises the following steps: the pre-crystallization processing of raw materials, then on-line dust removal, recrystallization, heat transport, main reaction, discharging of machinery, cooling and dust removal to obtain a finished product. The solid phase polymerization technique adopts a reasonable technological route and technological parameters and the whole technique is provided with reasonable production equipment for the solid phase polymerization of the polyester industry, thereby realizing high output, low energy consumption, convenient quality control and regulation and stable product quality.

Owner:ZHEJIANG UNIFULL IND FIBER

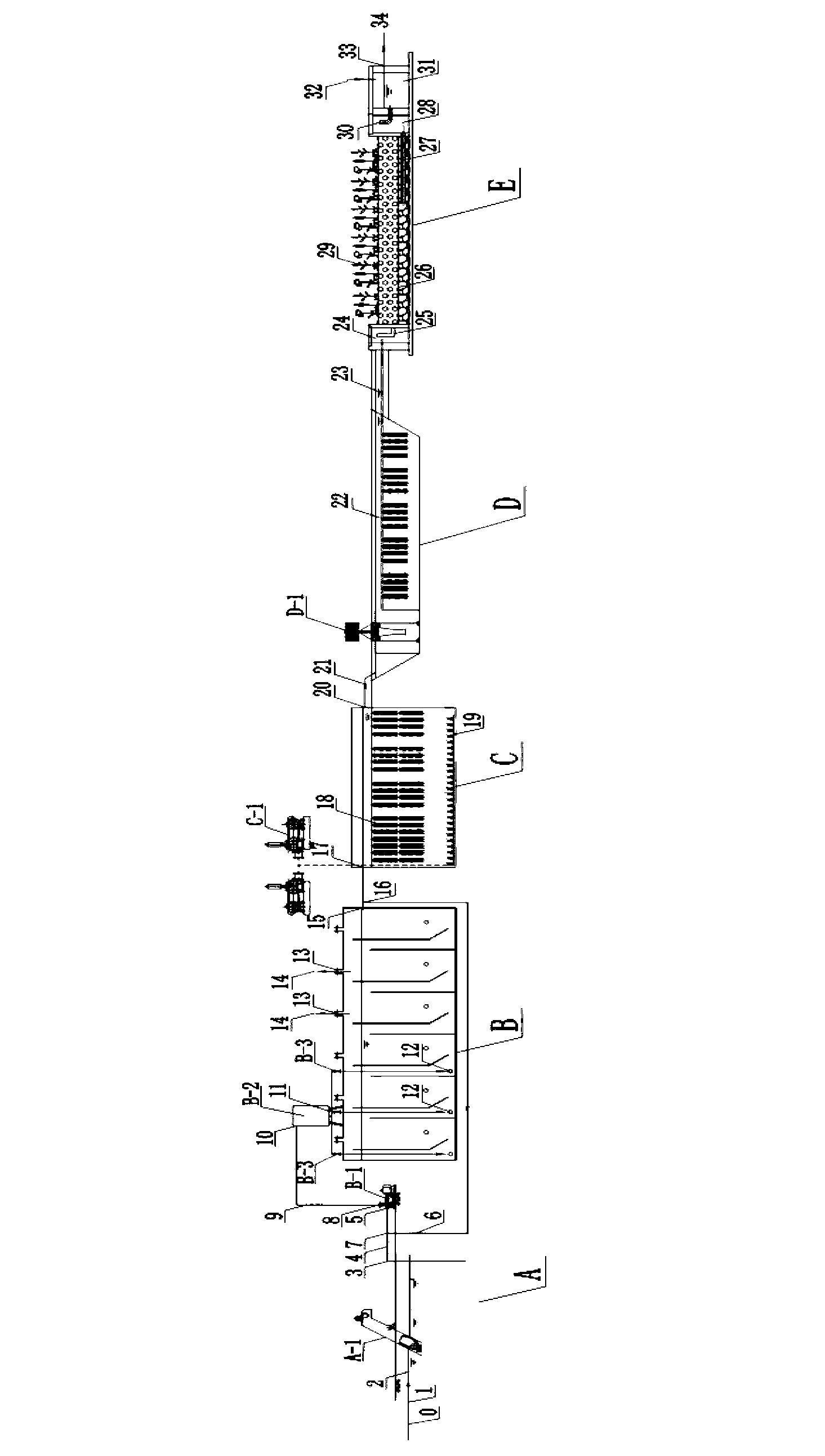

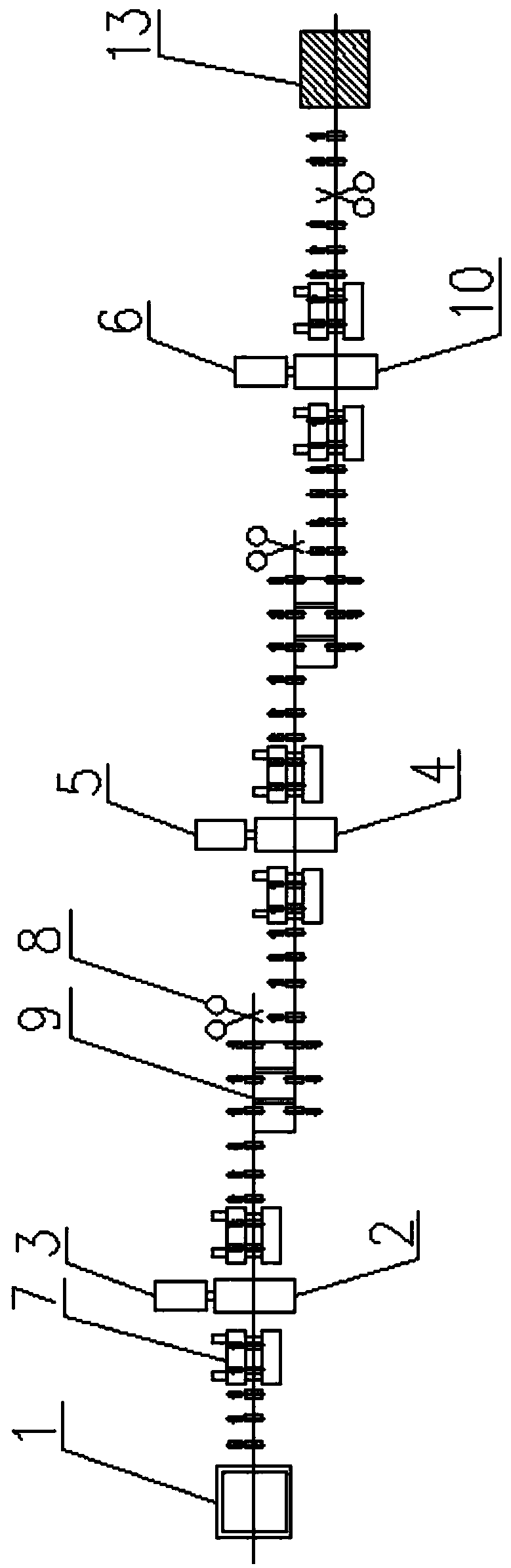

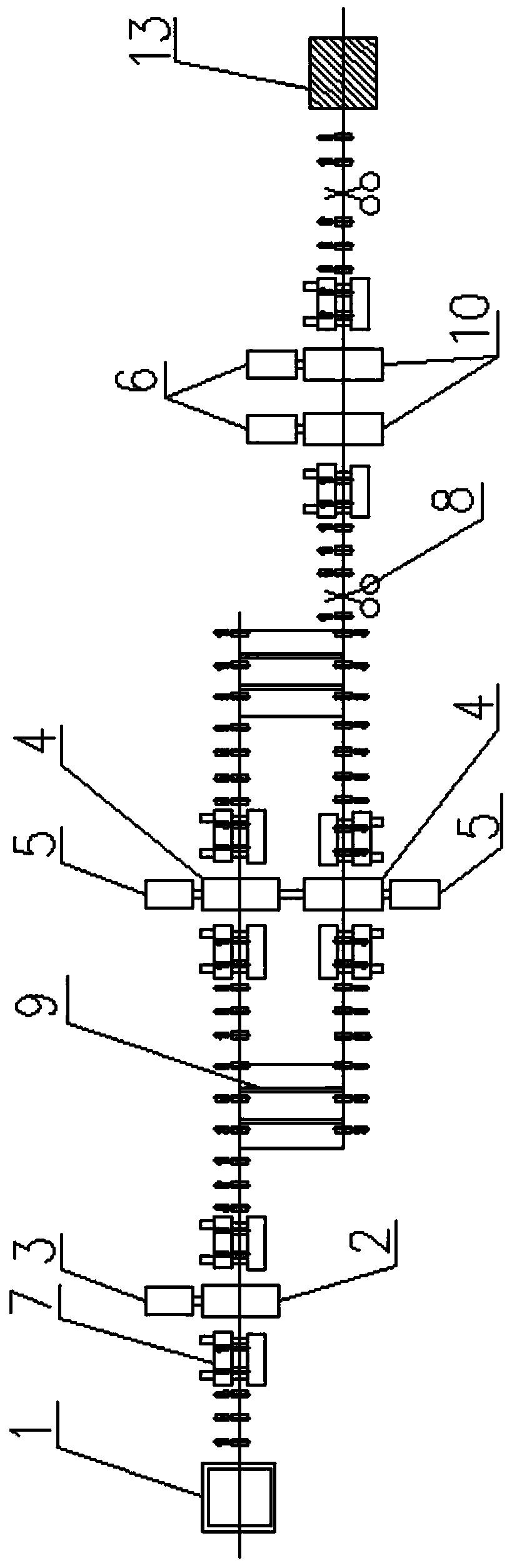

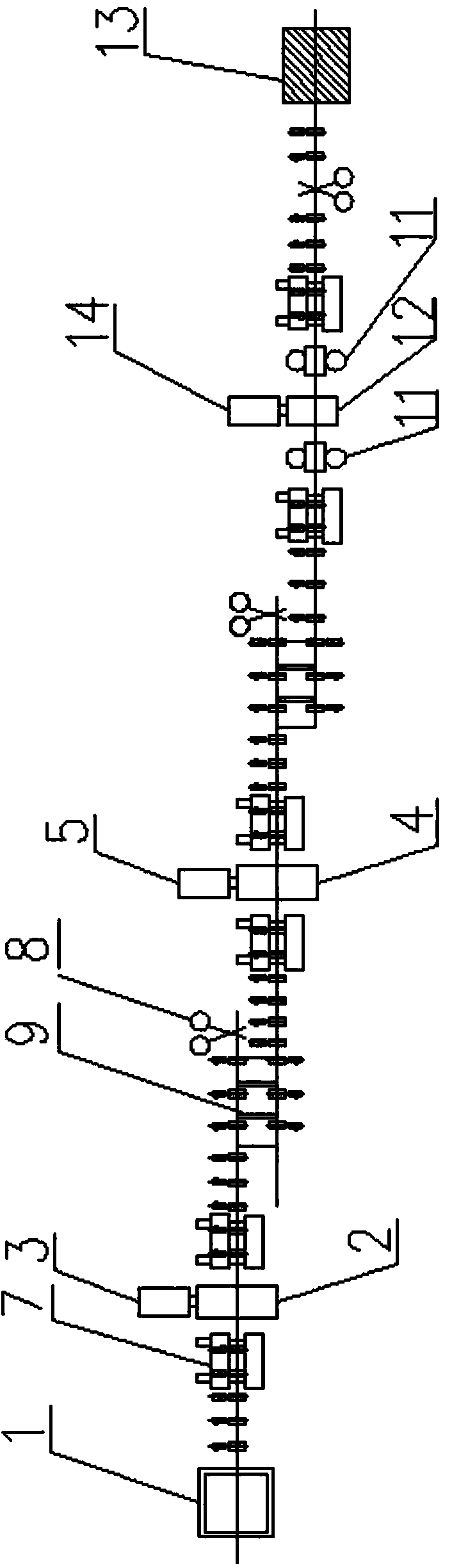

Profile steel rolling production line and production method thereof

ActiveCN103433276AReduce in quantityShorten the lengthMetal rolling arrangementsProduction lineMaterials science

The invention relates to a profile steel rolling production line and a production method thereof. The profile steel rolling production line comprises a heating unit, a rough rolling unit, a medium rolling unit, a fine rolling unit and a finishing unit, wherein each of the rough rolling unit and the medium rolling unit comprises a rolling mill and a driving device for driving the rolling mill to move along the axial direction of a rolling roller; the rolling rollers of the rolling mills are provided with rolling grooves with different groove holes; the fine rolling unit comprises a two-roller rolling mill or the fine rolling unit comprises a four-roller universal rolling mill, a two-roller edging mill and a four-roller universal rolling mill which are arranged in sequence; the two-roller rolling mill and the two-roller edging mill are provided with driving devices which move along the axial direction of rolling rollers I; the rolling rollers I are further provided with rolling grooves I with different groove holes. After a rolling piece is heated and is sequentially rolled by the upper and lower different rolling grooves through the corresponding rolling rollers on the rough rolling unit, the rolling piece enters the medium rolling unit to be sequentially rolled by the upper and lower different rolling grooves through the corresponding rolling rollers; finally, the rolling piece enters the fine rolling unit to be rolled to form a finished-product sectional material. According to the profile steel rolling production line and the production method thereof, the quantity of the rolling mills is reduced, the weight of a conveying roller bed is reduced, the production line is simplified and the production efficiency is improved.

Owner:CISDI ENG CO LTD

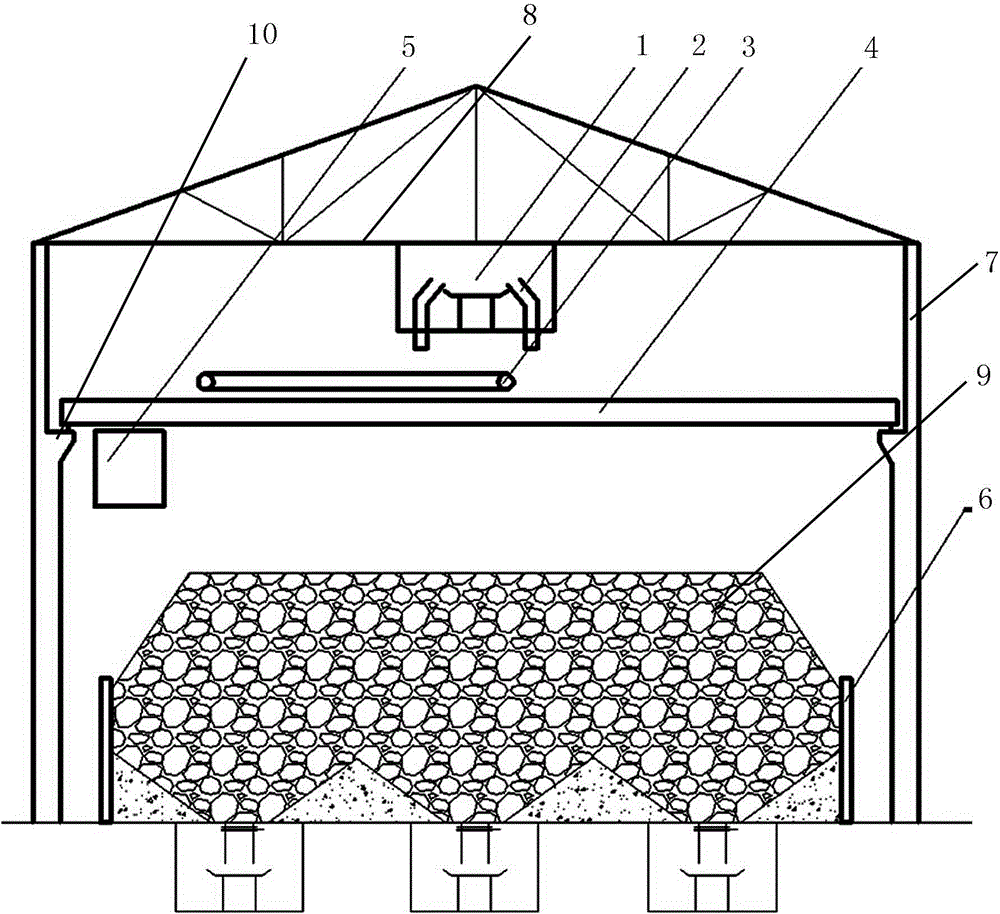

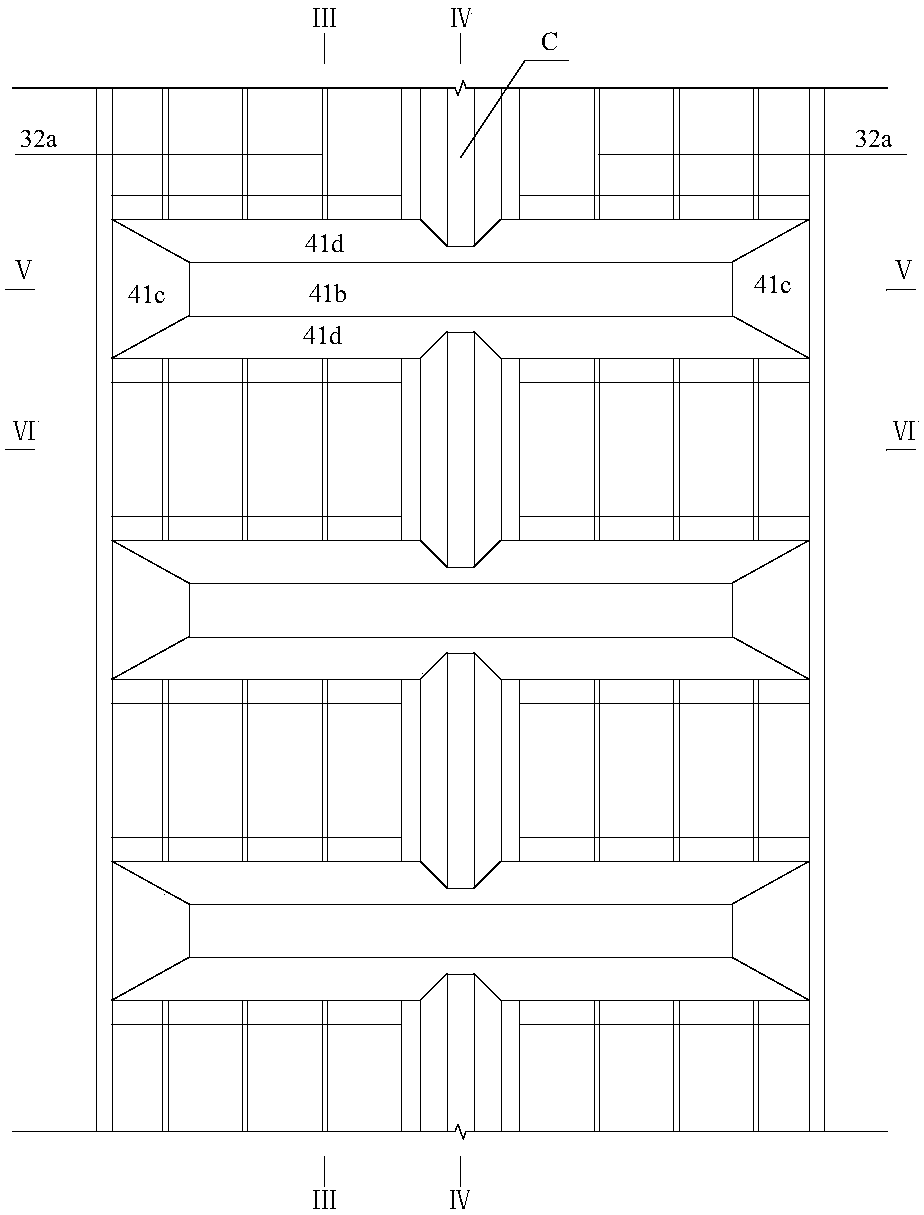

Electric dual-girder-bridge type stacking device and stacking method thereof

ActiveCN105197614ARealize unloading at any pointIncrease area stockpileLoading/unloadingConveyor partsEconomic benefitsYard

The invention relates to a stacking device and a stacking method thereof, in particular to an electric dual-girder-bridge type stacking device and a stacking method thereof, and belongs to the technical field of aluminum oxide production. The electric dual-girder-bridge type stacking device and the stacking method thereof are suitable for stacking monohydrallite. The stacking device comprise a portal frame, a feeding rubber belt conveyor and an unloading trolley are arranged below a frame beam of the portal frame, an electric dual-girder-bridge type work platform is arranged below the unloading trolley, a reversible feeding warehouse rubber belt conveyor is arranged above the electric dual-girder-bridge type work platform, and an operating chamber is arranged below the electric dual-girder-bridge type work platform. The electric dual-girder-bridge type stacking device and the stacking method thereof have the following advantages that due to the fact that the electric dual-girder-bridge type work platform is adopted for stacking, monohydrallite can be unloaded at any site, the volume of stacked monohydrallite in unit area of a monohydrallite stacking yard is effectively improved, and the occupied area is reduced. Meanwhile, the width of the stacking yard is reduced, the frame structure is adopted, project construction investment is reduced, and economic benefits are increased.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

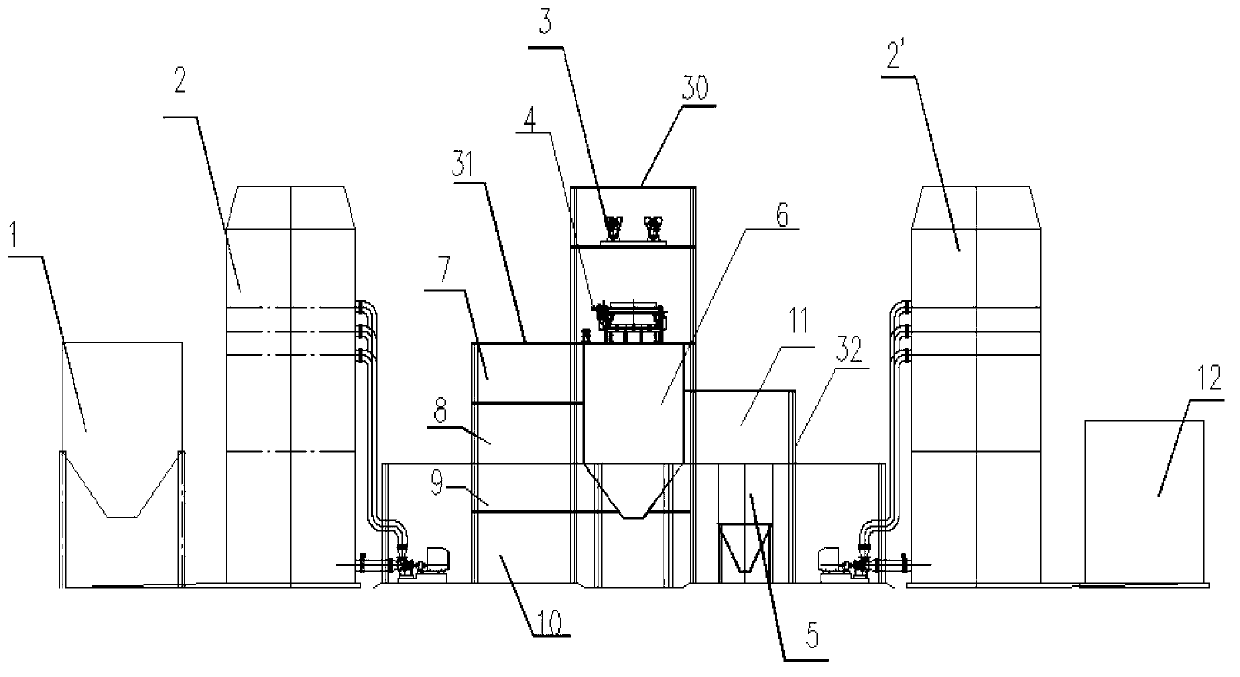

Flue gas desulphurization device and desulphurization method

InactiveCN103272466ASmall footprintReduce concentrationDispersed particle separationSlurryWaste treatment

The invention provides a flue gas desulphurization device and desulphurization method. The flue gas desulphurization device comprises a limestone slurry preparation system, a flue gas absorption system, a gypsum slurry dehydration system, a waste water treatment system and an electronic control system. According to the flue gas desulphurization device, flue gas important parts, namely a gypsum slurry dehydration system taking a disc type dehydrator as a core, the waste water treatment system and the electronic control system, are integrated and three-dimensionally arranged in one technology comprehensive building, other technological stages in flue gas desulphurization are arranged on ground at the periphery of the technology comprehensive building tightly around the technology comprehensive building, structure is compact, layout is reasonable, space resource is fully utilized, floor space is saved, labour intensity in equipment running check is reduced, engineering construction investment is saved, and energy consumption of the flue gas desulphurization device is greatly reduced.

Owner:杭州蓝轩环保科技有限公司

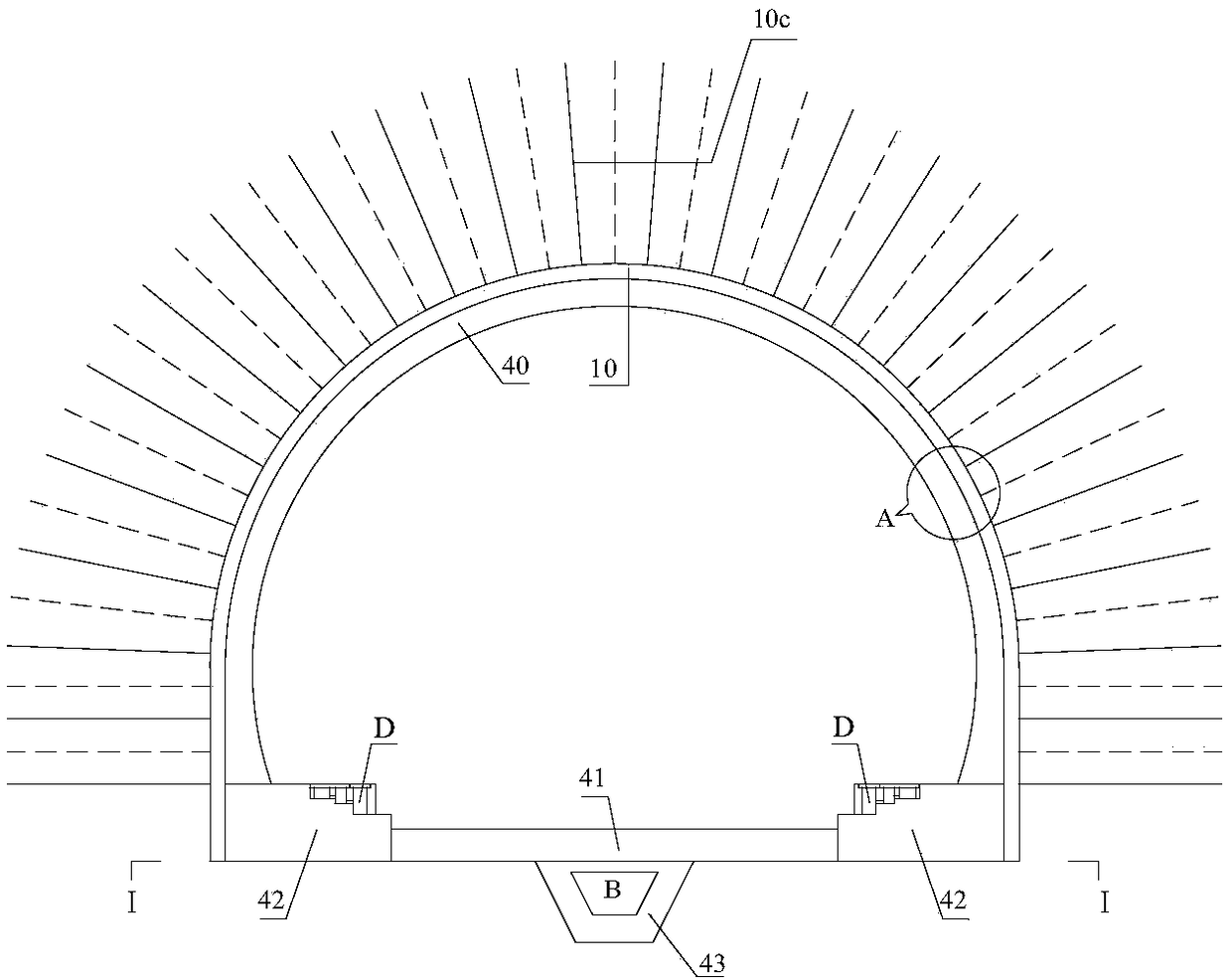

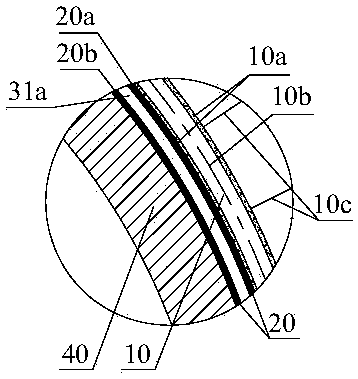

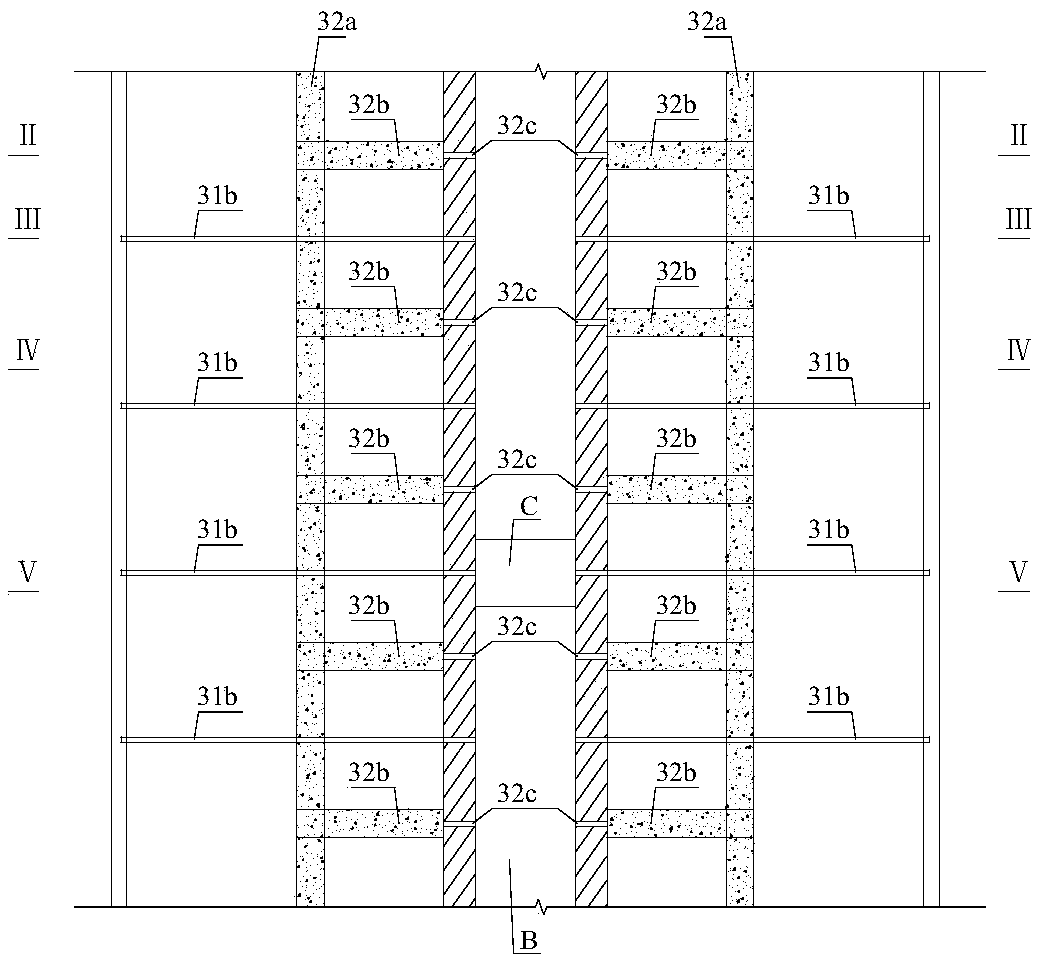

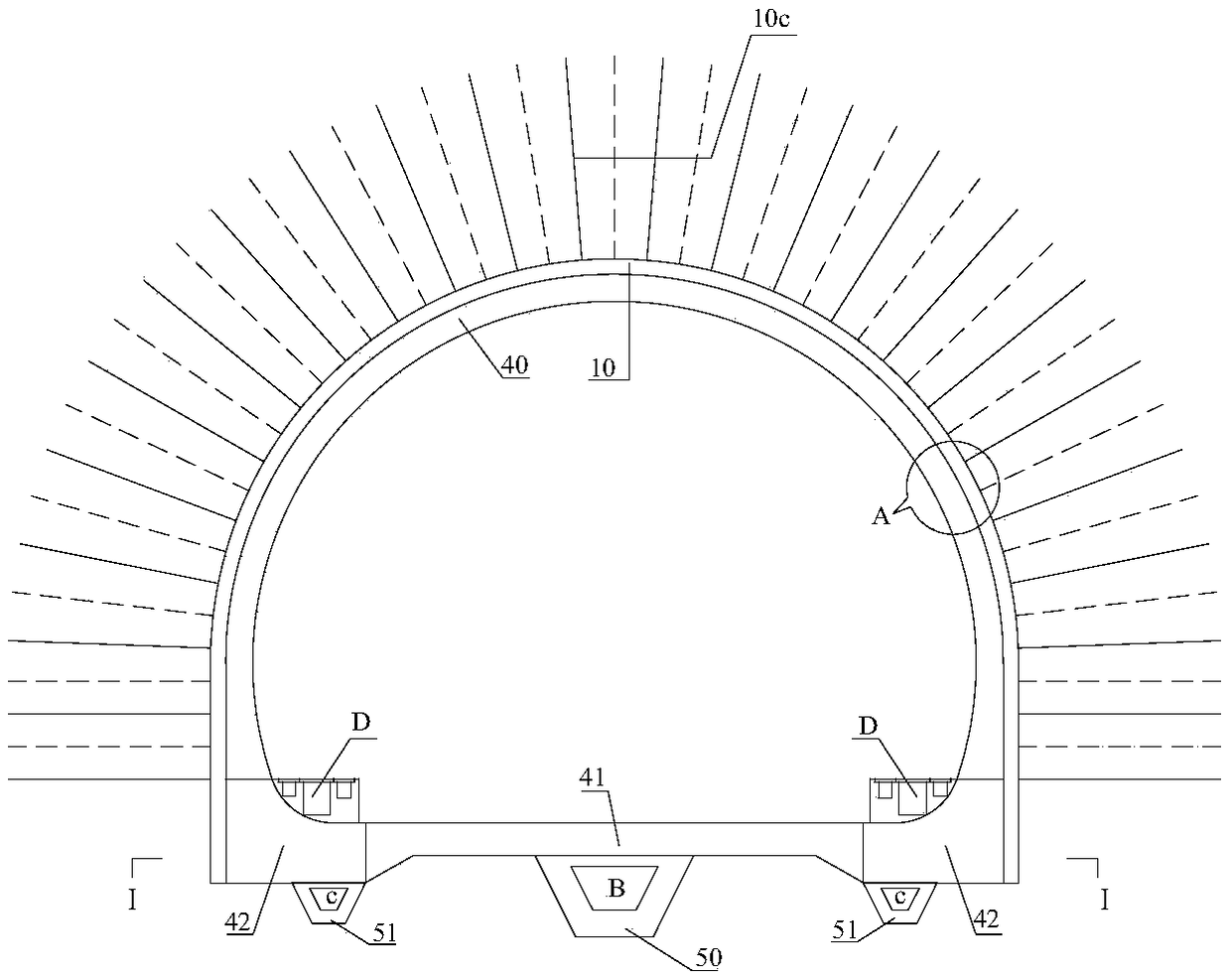

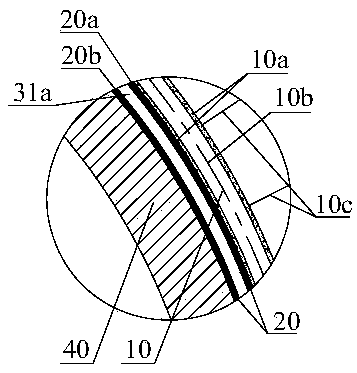

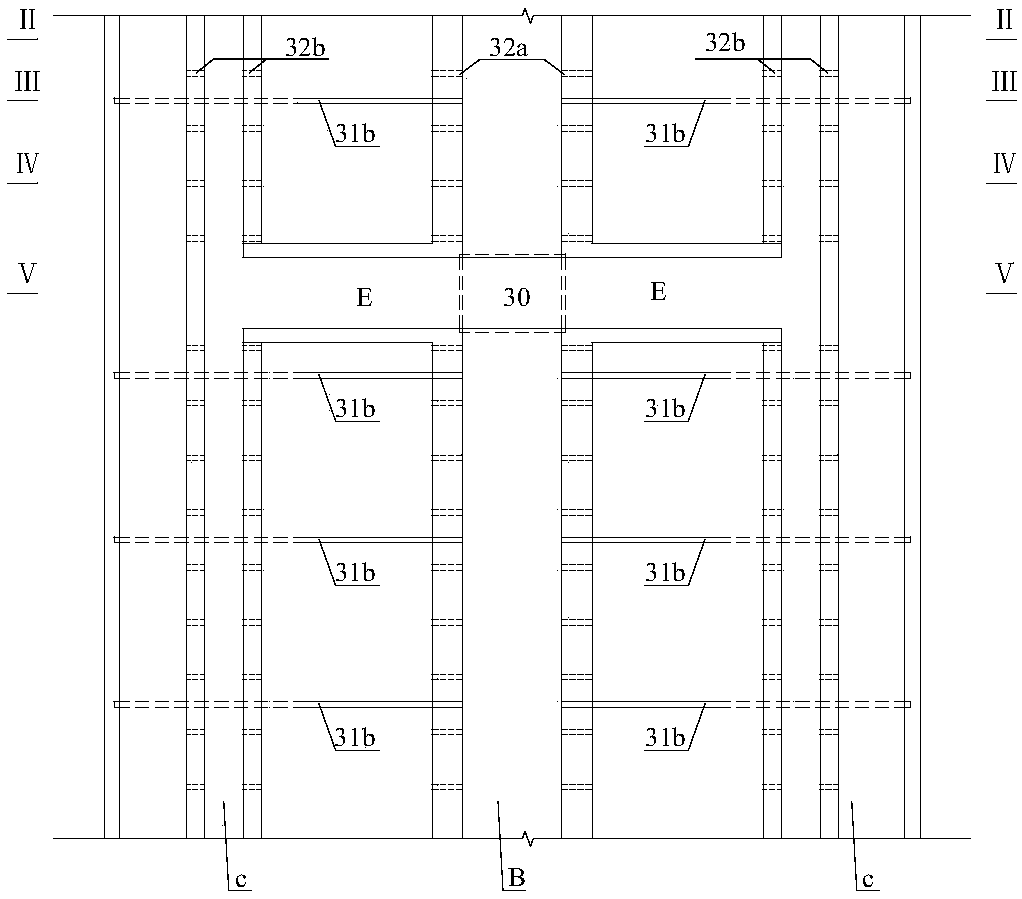

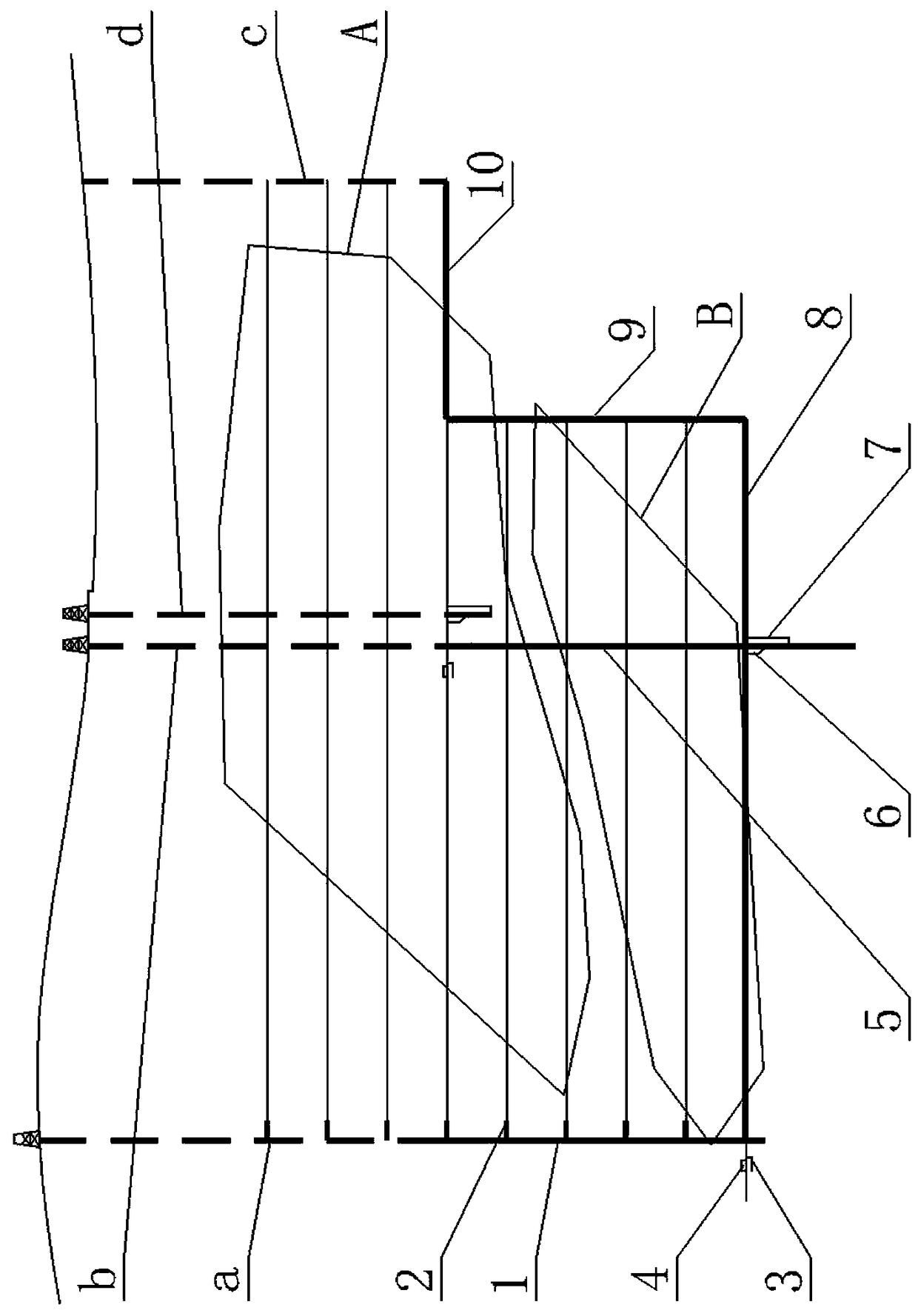

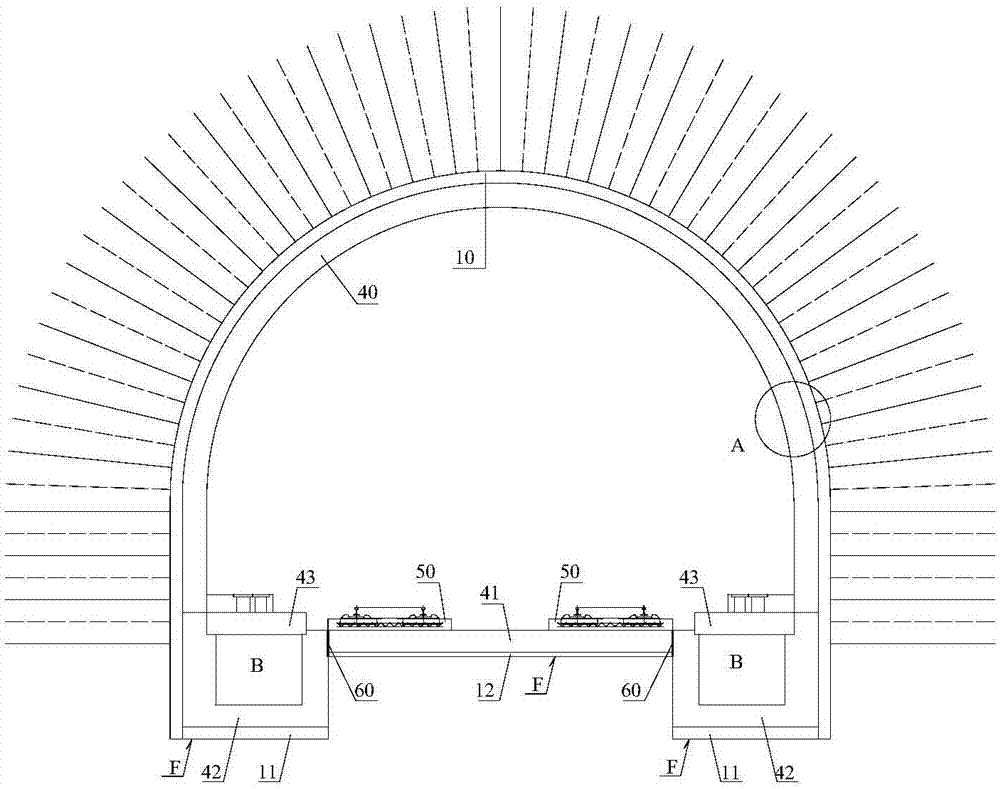

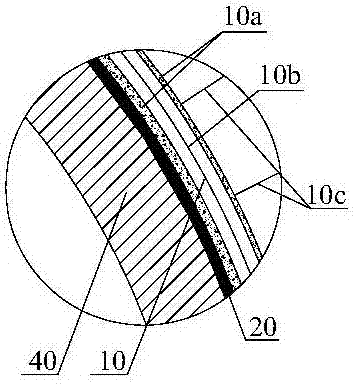

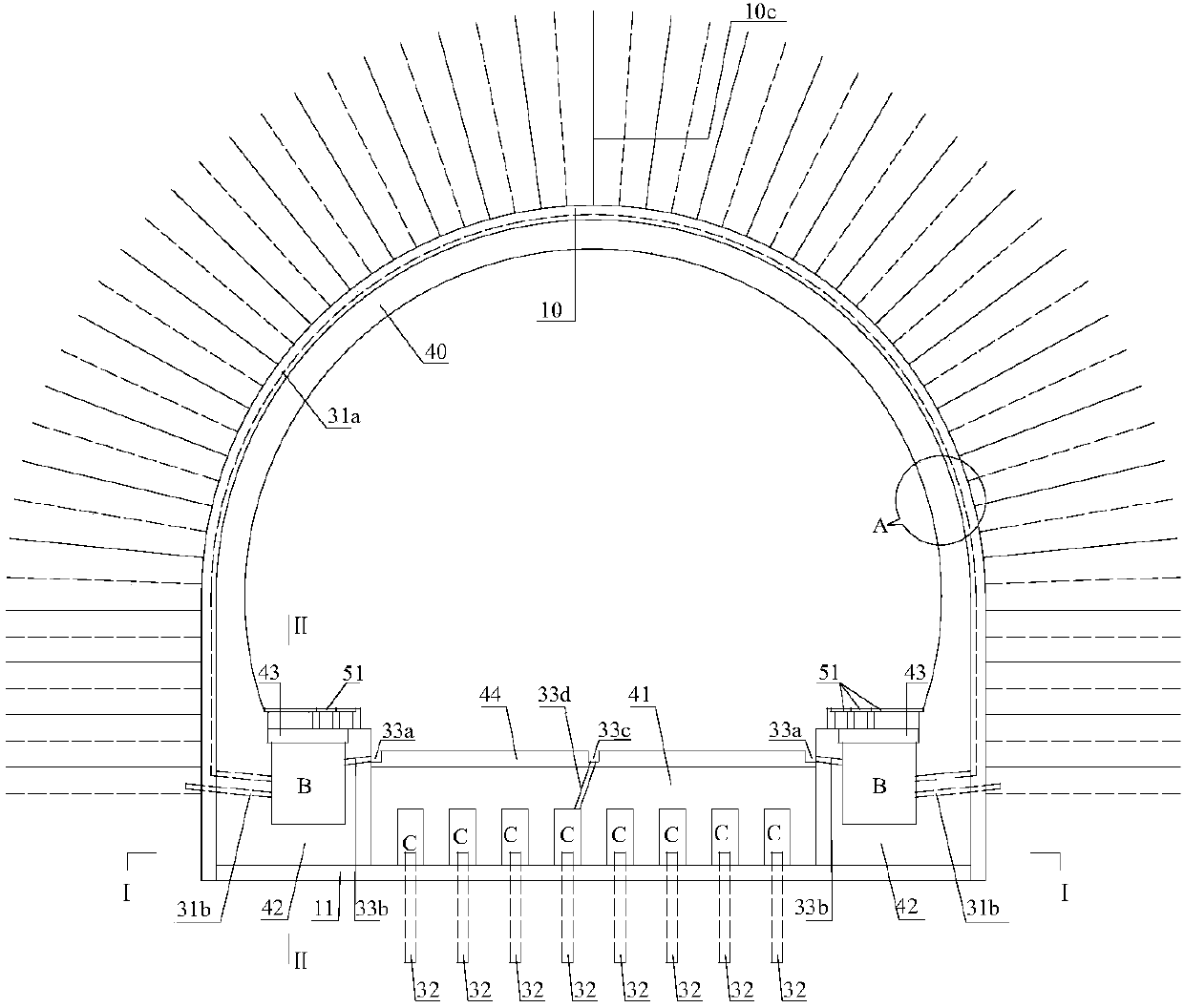

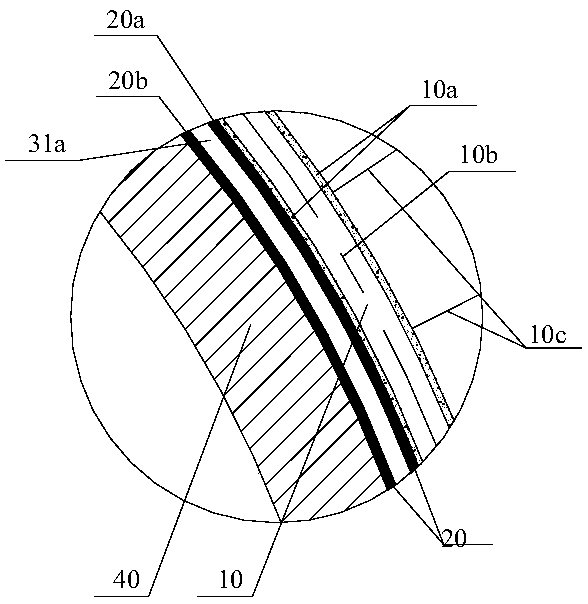

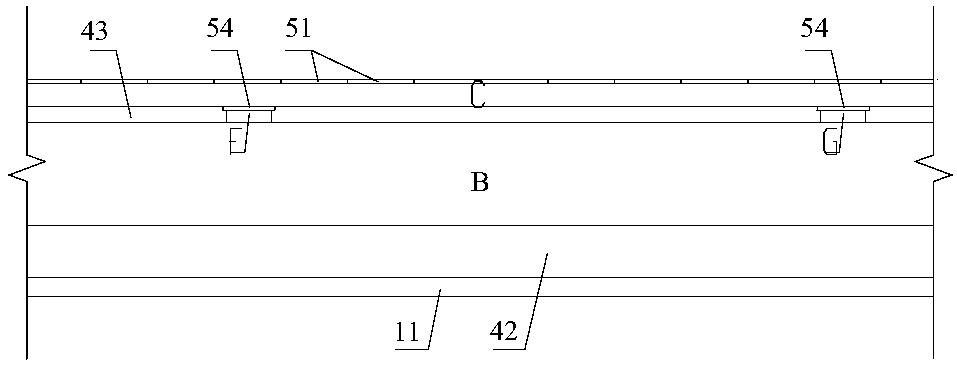

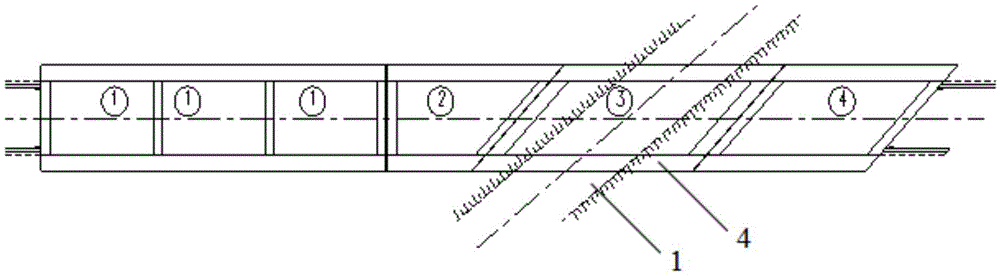

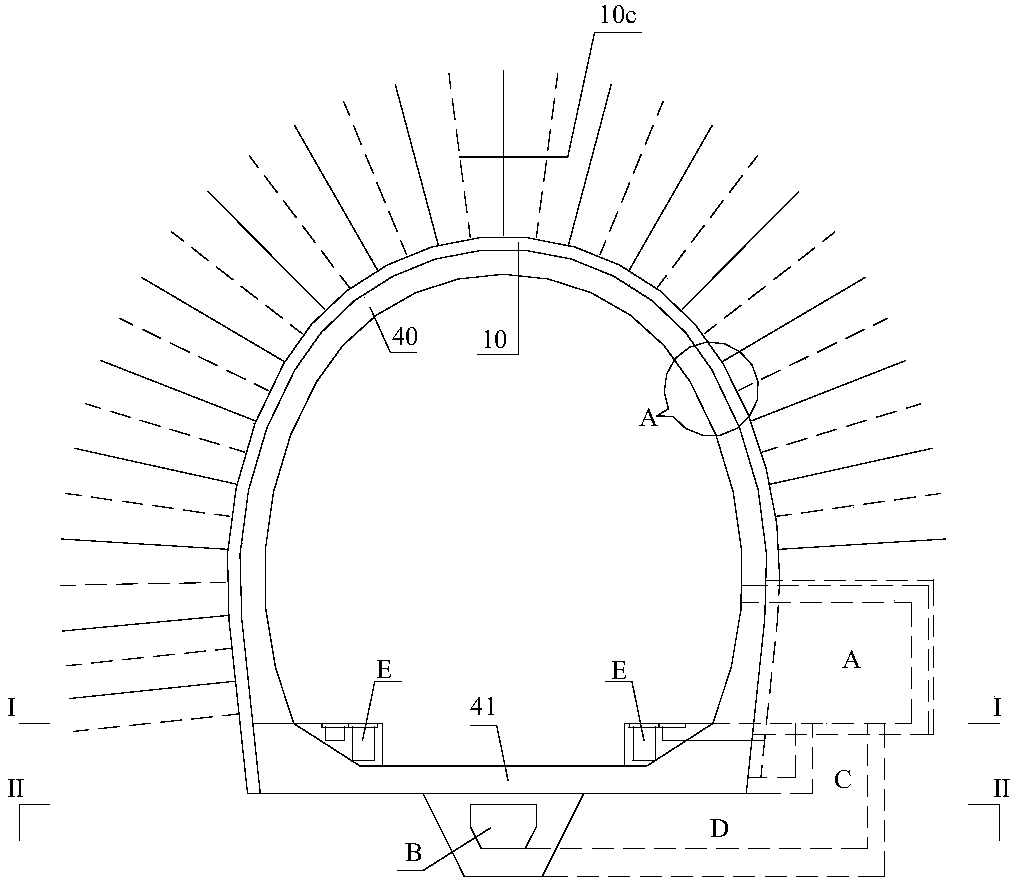

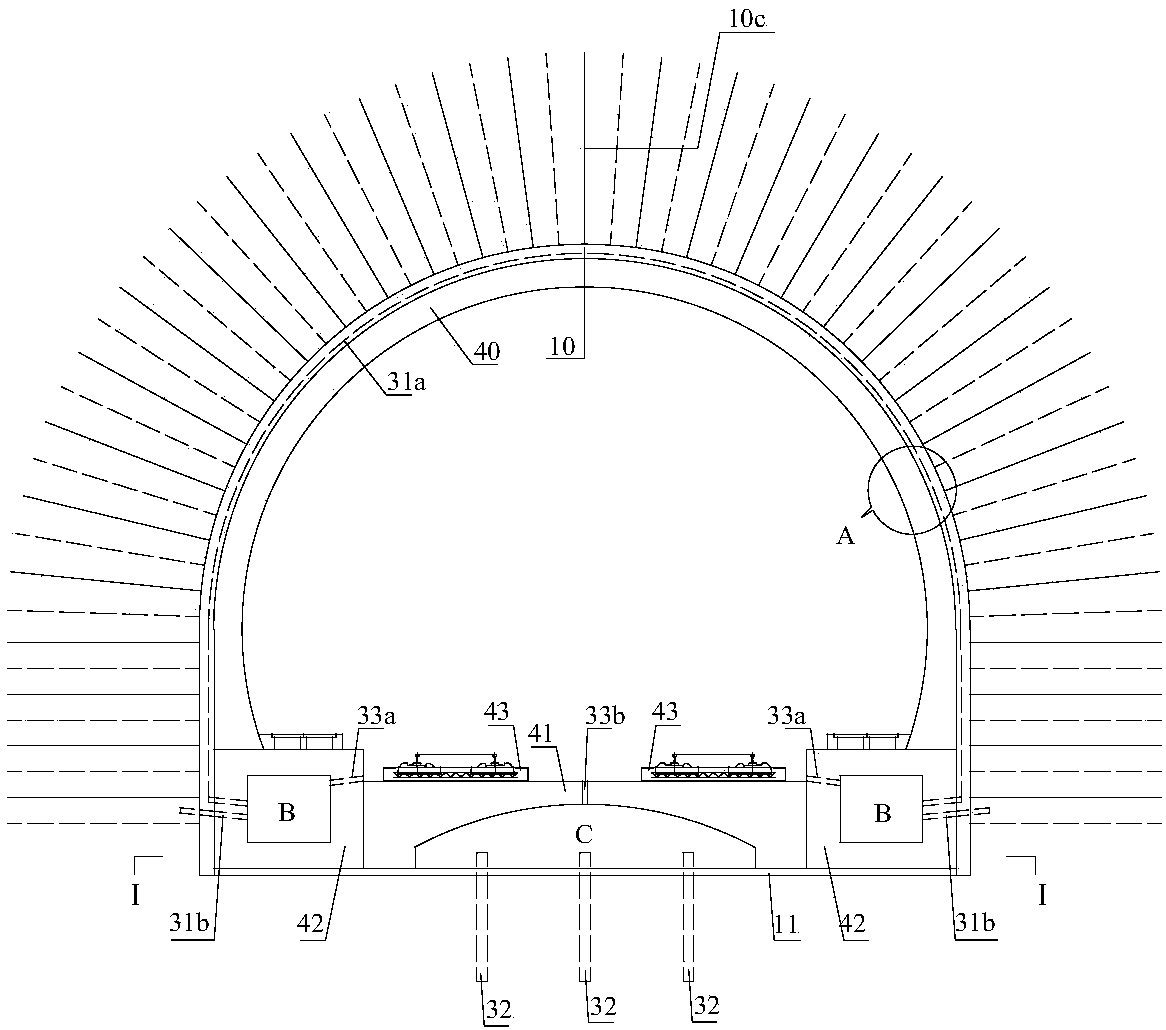

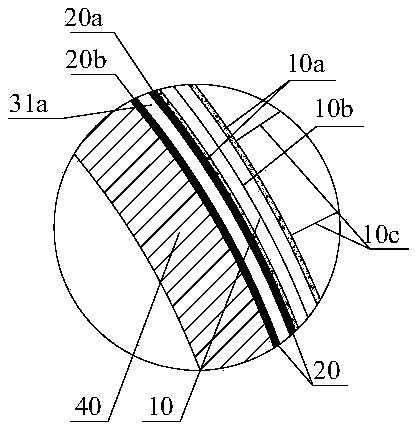

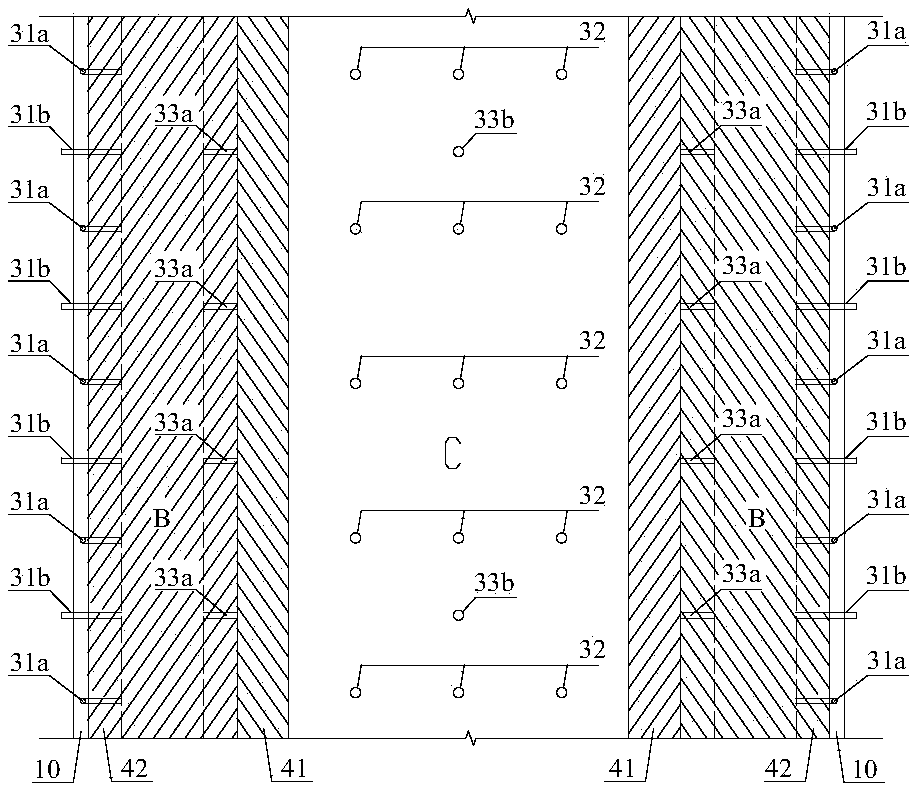

Unequal-height longitudinal beam bearing straight wall bottom plate type lining with longitudinal water collecting and releasing channel formed in tunnel bottom and drainage system structure of lining

PendingCN108222963AOvercoming the difficulty of controlling the excavation curvature and other problemsEasy to excavateUnderground chambersDrainageCommunicating cavityWater development

The invention provides an unequal-height longitudinal beam bearing straight wall bottom plate type lining with a longitudinal water collecting and releasing channel formed in the tunnel bottom and a drainage system structure of the lining. The effect of underground water on the tunnel lining bottom structure is reduced or even eliminated, and the problems that a tunnel inverted arch of a karst orunderground water development area upwards floats and deforms, or the tunnel bottom structure is cracked and damaged is effectively solved to ensure the stability and safety of tunnel construction andoperating. Longitudinal beams fixedly connected with an arch wall secondary lining structure are arranged at the bottoms of side walls on the two sides of the arch wall secondary lining structure toserve as a bearing structure of the arch wall secondary lining structure, and the sections of the longitudinal beams are unequal-height variable sections. A bottom plate is arranged between the longitudinal beams on the two sides, the two transverse ends of the bottom plate are connected with the longitudinal beams on the same side, a box-type construction body is arranged on the lower portion ofa plate body along the longitudinal center, and a longitudinal communicating cavity inside the box-type construction body serves as the water collecting and releasing channel. Drainage systems comprise the arch wall range drainage system, the tunnel bottom drainage system and the tunnel bottom interior drainage system which communicate with the water collecting and releasing channel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

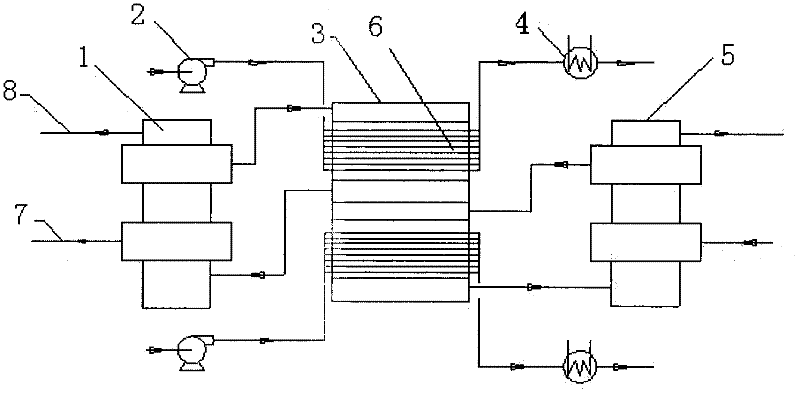

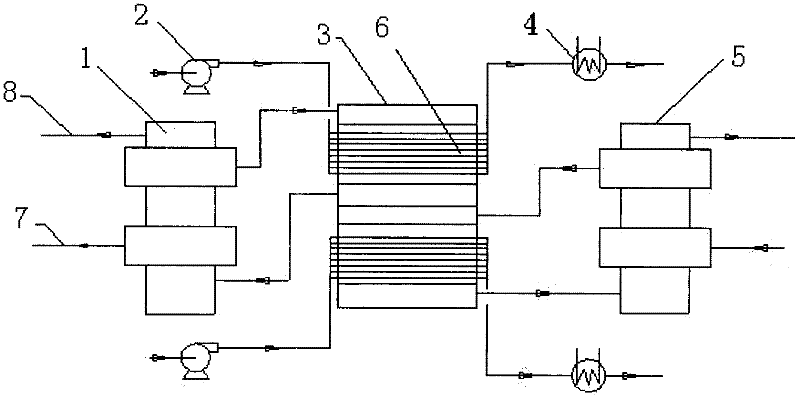

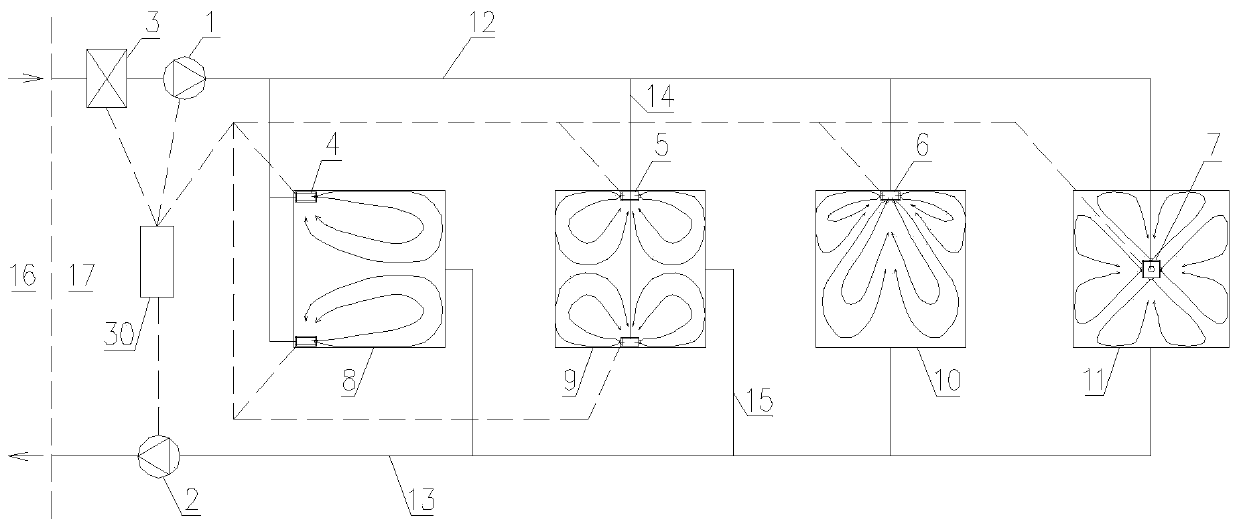

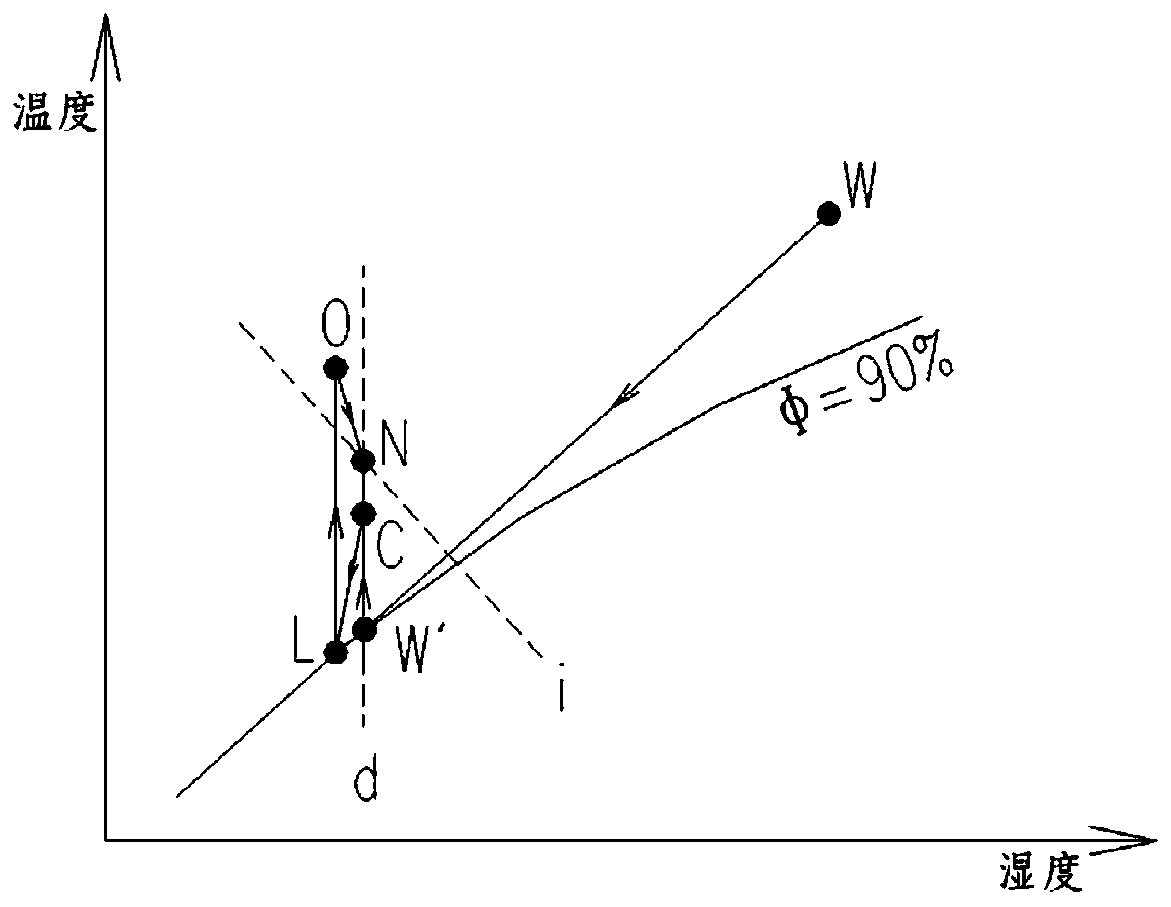

Ventilation and tail end jet flow type temperature and humidity control system and control method for underground building

ActiveCN111271782AImprove energy efficiencyThe computer room is smallDucting arrangementsMechanical apparatusThermodynamicsControl system

The invention provides a ventilation and tail end jet flow type temperature and humidity control system and control method for an underground building. The control system comprises a ventilating centralized dehumidification device, a tail end jet flow dehumidification device, an air exhaust device and a system controller, wherein the ventilating centralized dehumidification device is used for centralized processing of ventilating heat and humidity loads, and the tail end jet flow dehumidification device is used for processing of indoor heat and humidity loads; the air exhaust device is used for carrying out air exhaust tasks of underground rooms; and the system controller is connected with the ventilating centralized dehumidification device, the tail end jet flow dehumidification device and the air exhaust device, manages the united operation of all the devices in a unified mode, and effectively controls the air temperature and humidity in all the underground rooms. According to the control system, aiming at the category characteristics and dynamic rules of the heat and humidity loads in the underground building, the ventilating centralized dehumidification device and the tail endjet flow dehumidification device are used in a combined mode, two dehumidification systems with different properties are adopted to reasonably share the ventilating load and the internal load of the underground building, and the energy efficiency is higher compared with that of existing temperature and humidity control systems.

Owner:中国人民解放军火箭军工程设计研究院

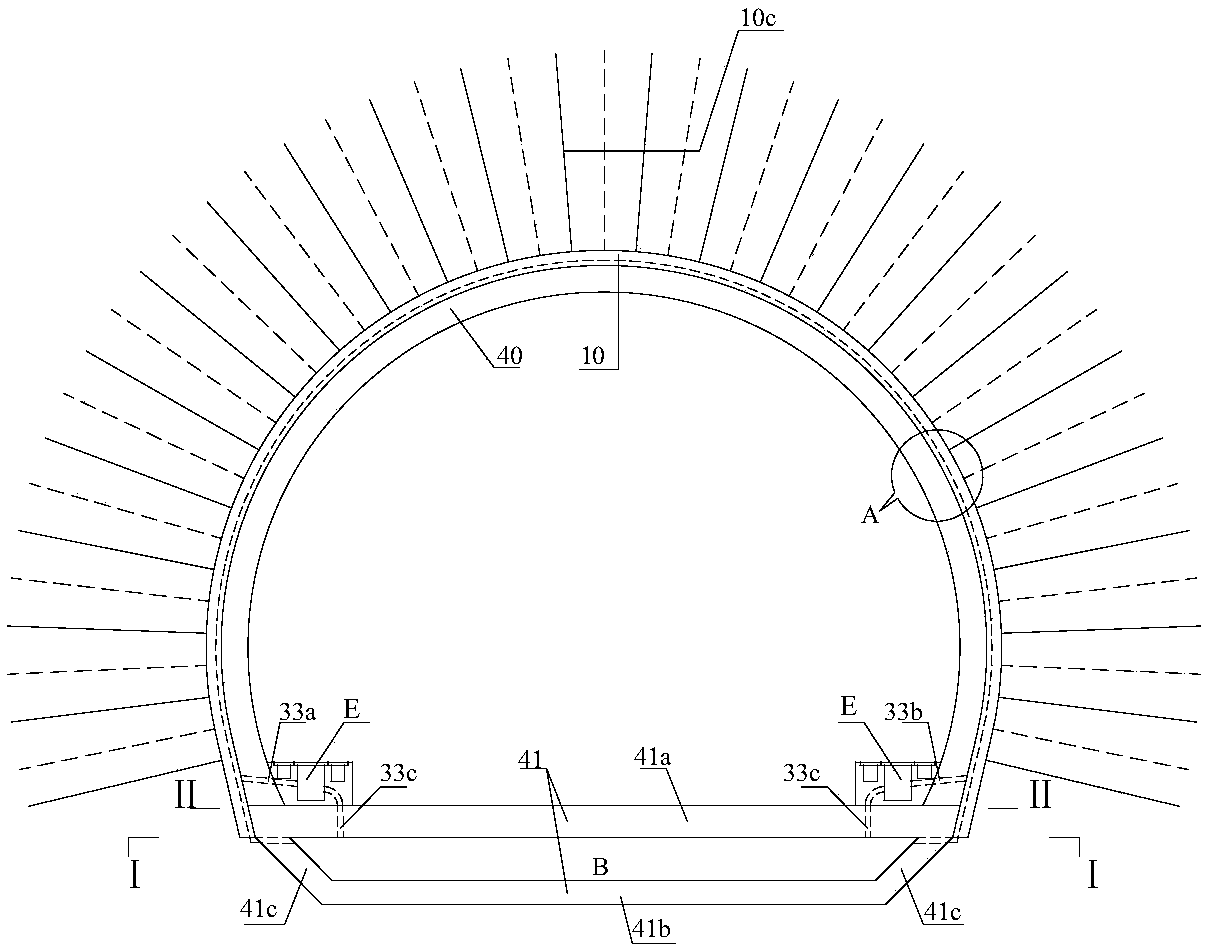

Big skewback base plate type lining and drainage system structure thereof

PendingCN108222975AOvercoming the difficulty of controlling the excavation curvature and other problemsEasy to excavateUnderground chambersDrainageWater developmentTunnel construction

A big skewback base plate type lining and a drainage system structure thereof are used for reducing and even eliminating the influence of underground water on the bottom structure of a tunnel lining,so that the problem that a tunnel inverted arch floats upwards or a tunnel bottom structure cracks and is damaged in karst or underground water development areas are effectively solved, and the stability and safety of tunnel construction and operation are ensured. Big skewbacks which are integrally solidified with an arch wall secondary lining structure are arranged at the bottoms of the two sidesof the arch wall secondary lining structure, a base plate is arranged between the big skewbacks on the two sides, and the two ends of the base plate are solidified with the skewbacks on the two endscorrespondingly. A center box-shaped construction body which extends along the longitudinal center line of a base plate body is arranged under the base plate body, and an inner cavity of the center box-shaped construction body is used as a central water collecting and drainage channel. The box-shaped construction body is arranged under the big skewbacks on the two sides, the longitudinal through inner cavity of the box-shaped construction body is used as a base water collecting channel, and in-hole side ditches are fixedly formed in the big skewbacks on the two sides. A drainage system comprises an arch wall range drainage system body, a tunnel bottom drainage system body and an in-tunnel drainage system body, wherein the arch wall range drainage system body communicates with the center water collecting and drainage channel; the tunnel bottom drainage system body and the central water collecting channel communicate with the base water collecting channel, and the in-tunnel drainage system communicates with the in-hole side ditches and the central water collecting channel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Formation method of deep development system

ActiveCN108843319ANormal benefitsNormal fluidityUnderground miningSurface miningEngineeringVentilation shaft

The invention discloses a formation method of a deep development system. The formation method comprises the following steps: (1) extending a ventilation shaft in an original development system of a mine downwards to a lowest service middle section and refitting into a new auxiliary shaft; during the ventilation shaft extending and refitting periods, continuously using an original main shaft and anoriginal auxiliary shaft in the original development system of the mine as a lifting system and maintaining the normal production of the mine; (2) opening the new auxiliary shaft, stopping the original auxiliary shaft, enabling a temporary lifting system to be composed of the new auxiliary shaft and the original main shaft and maintaining the normal production of the mine; (3) extending the original auxiliary shaft downwards to the lowest service middle section and refitting into a new main shaft; (4) enabling the new main shaft and the new auxiliary shaft to form a deep lifting system and continuously driving to form system engineering including an ore main pass so as to form the complete deep development system. The formation method disclosed in the invention has the benefits that in the deep construction process, the mine always has the complete main and auxiliary shaft lifting system, so that the normal operation can be maintained during the mine production; the construction amount and the construction investment can be reduced by making full use of the original development system of the mine.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

U-shaped wall base and bottom plate dynamic and static separation bearing type lining structure with water delivering function

PendingCN107975378AOvercoming the difficulty of controlling the excavation curvatureEasy to excavateUnderground chambersDrainageKarstEngineering

The invention discloses a U-shaped wall base and bottom plate dynamic and static separation bearing type lining structure with a water delivering function in order to eliminate the effect of groundwater on a bottom structure of a tunnel lining, the problems of floating deformation of a tunnel inverted arch and cracking damage of the tunnel bottom structure in a karst or groundwater development area are effectively solved, and the stability and safety of tunnel construction and operation are guaranteed. Deep grooves are excavated in the two transverse sides of the bottom of a tunnel to form inverted-T-shaped tunnel bottom excavation faces; U-shaped wall base construction bodies with groove-shaped cavities are arranged in the deep grooves; the U-shaped wall base construction bodies are fixedly connected with the wall bottoms of the two side edges of arch wall secondary lining structures; and the U-shaped wall base construction bodies serve as bearing structures of the arch wall secondarylining structures and longitudinal drainage channels of the tunnel. Bottom plates are arranged in the positions, above the middles of the inverted-T-shaped tunnel bottom excavation faces, between theU-shaped wall base construction bodies on the two sides, and road beds are fixedly arranged on the bottom plates; settlement seams are arranged in the connecting positions of the two transverse endsof the bottom plates and the U-shaped wall base construction bodies on the two sides, so that a surrounding rock load transmitted by the arch wall secondary lining structures is separated from a trainload transmitted by the road beds.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Boot last base comb-type tunnel bottom lining structure and drainage system thereof

PendingCN107905810AOvercoming the difficulty of controlling the excavation curvatureEasy to excavateUnderground chambersDrainageKarstGroundwater

The invention discloses a boot last base comb-type tunnel bottom lining structure and a drainage system thereof. The effect of underground water on a tunnel lining bottom structure is reduced or eveneliminated, the problem of karst or underground water development region tunnel inverted arch floating deformation or tunnel bottom structure cracking and damage is solved, and the tunnel constructionand operation stability and safety are ensured. The bottoms of side walls on the two sides of an arch wall secondary lining structure are provided with bases fixedly connected with the arch wall secondary lining structure, the bases are adopted as bearing structures of the arch wall secondary lining structure, and a longitudinal-through boot inner cavity inside the structure is adopted as a tunnel longitudinal drainage channel. A comb-type tunnel bottom structure with the two transverse sides in weak connection with the bases are arranged between the boot-shaped bases on the two sides, a paving bottom layer is arranged on the comb-type tunnel bottom structure, the lower portion of the comb-type tunnel bottom structure is provided with a transversely-spaced and longitudinal-through lower cavity as a tunnel bottom underground water longitudinal drainage channel. The arch wall range drainage system is communicated with the boot inner cavity, the tunnel bottom drainage system is communicated with the lower cavity, and a ballast bed accumulated water drainage system is communicated with the boot inner cavity and the lower cavity.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Combined arched tunnel lining of inversely truncated-cone-shaped hollow tunnel bottom and drainage system structure thereof

PendingCN107905812AOvercoming the difficulty of controlling the excavation curvature and other problemsEasy to excavateUnderground chambersDrainageKarstDitch

The invention discloses a combined arched tunnel lining of an inversely truncated-cone-shaped hollow tunnel bottom and a drainage system structure thereof in order to reduce and even eliminate the effect of underground water on the bottom structure of the tunnel lining, effectively solve the problems that tunnels in karst or underground water development areas inversely arch, come up and deform ortunnel bottom structures are cracked and damaged, and ensure the stability and safety of construction and operation of the tunnels. Tunnel bottom construction bodies are arranged below the bottoms oftwo side walls of an arch-wall secondary lining structure to serve as a bearing structure; each tunnel bottom construction body is of an inversely truncated-cone-shaped hollow structure and is formedby integrally pouring upper bottom plates, transverse webs at two sides, lower bottom plates and longitudinal webs, and tunnel bottom cavities are formed longitudinally at intervals in the tunnel bottom construction bodies, wherein the lower bottom plates and the longitudinal webs are arranged longitudinally at intervals. Central water ditches which are longitudinally communicated are formed along the longitudinal centers of the lower brims of the plate surfaces and communicated with all the tunnel bottom cavities. The drainage system includes a drainage system communicated with the tunnel bottom cavities within an arched-wall range, a tunnel bottom drainage system and an in-tunnel drainage system.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Urbsewage treatment method

ActiveCN102701521BImprove working environmentLow costMultistage water/sewage treatmentEnergy based wastewater treatmentConstructed wetlandRural area

The invention discloses a low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method. The method comprises the steps that: 1, the to-be-treated wastewater is collected by a sewage pipe network and then is filtered by lattices, and is lifted by a pump to enter a pulse water distribution pot of a novel efficient turn-back anaerobic biochemical pool (ABR); 2, the swage subjected to the treatment in step 1 flows into a circulation-flow biological oxidization pool; 3 the effluent water from the step 2 flows into an artificial reinforced biological contact oxidization pool reconstructed by a water body from natural tunnels and reservoirs; and 4, the effluent water from the step 2 or the step 3 flows into constructed wetlands. After the sewage is treated by the above steps, the most pollutants in the water are effectively removed and the treated effluent water reaches the standard first-grade A in GB 18918-2002 ''Discharge standard of pollutants for municipal sewage treatment plant''. The energy-saving sewage treatment purification process with low cost, low energy consumption, low carbon emission and low operating cost is particularly suitable for the sewage treatment in small towns or rural areas.

Owner:武汉昌宝环保工程有限公司

Rainwater flow abandoning system

InactiveCN105839761AAvoid safety hazardsSolve access to water storage equipmentSewerage structuresSewer pipelinesWater storageWater quality

The invention discloses a rainwater abandonment system, which includes a rainwater confluence pipe, a side flow sampling pipe, a sewage pipe, a rainwater abandonment device, a rainwater collection pipe, a rainwater storage tank and a waste flow control box, wherein: the side flow sampling pipe and The rainwater confluence pipe is cross-connected, and its input end is equipped with a water quality analyzer, and the output end is connected to the sewage pipe; the rainwater abandonment device is provided with a water inlet, a water outlet and a sewage outlet, and the water inlet is connected to the output end of the rainwater confluence pipe. The water outlet is connected to the input end of the rainwater collection pipe, the sewage outlet is connected to the input end of the sewage pipe, and the output end of the sewage pipe is provided with a sewage valve; the liquid level gauge is installed in the rainwater storage tank and connected to the output end of the rainwater collection pipe ; The waste flow controller controls the opening and closing of the rainwater waste flow device and the blowdown valve according to the detection results of the water quality analyzer and the liquid level gauge. The invention solves the problem that the initial runoff rainwater and excess rainwater enter water storage equipment or structures, and avoids the potential safety hazards of confluence of rain and sewage and overflow of excess rainwater.

Owner:汪传发

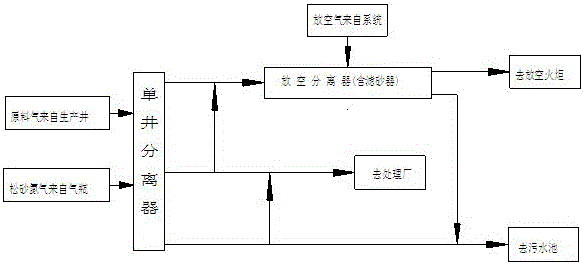

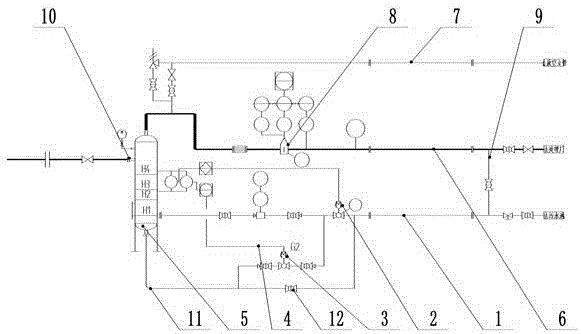

Single-well desanding device and sand discharging technology thereof

The invention discloses a single-well desanding device and a sand discharging technology thereof.Due to the fact that a novel gas-liquid-sand three-phase separation device is provided, sand in the shale gas discharging and mining process can be effectively collected, and maintenance is convenient; by means of the sand discharging technology of the device, opening and closing of different main roads and branch roads can be switched by switching valves, precise separation of gas and liquid can be achieved, and sand discharging and desanding can be conducted without shutdown.By means of the single-well desanding device and the sand discharging technology thereof, the discharging and mining efficiency of shale gas is effectively improved, energy consumed by the sand discharging process is reduced, and great economic benefit is brought.

Owner:CHUANZHONG BRANCH KEHONG GASOLINEEUM NATURAL GAS ENG SICHUAN

A Method for Quickly Pushing and Transversing the Whole Frame Bridge

ActiveCN104612056BReduce post-operation and maintenance workloadReduce the height of the structureBridge erection/assemblySlide plateEngineering

The invention discloses a quick pushing and transverse moving method for an integral frame bridge in existing rail way reconstruction, and a rail penetrates through the frame bridge. The method is characterized by comprising the steps that a sliding plate is constructed on one side of an existing rail way and a pushing back is constructed on the end of the sliding plate, the frame bridge is prefabricated on the sliding plate, and the top of a bottom plate of the frame bridge is roughly flush with the shoulder of the rail way; the pipe laying depth of pipelines on the two sides of a pushing and transverse moving area of the existing rail way is increased, and the pipe laying depth is larger than the bottom of the bottom plate of the frame bridge; a jack is installed at the back end of the frame bridge, lines and pathways of the existing rail way are dismantled, and the jack pushes and transversely moves the frame bridge; after the frame bridge is pushed and transversely moved to the position where an original rail way is removed, the lines and pathways of the existing rail way are restored in the normal position in the frame bridge. By the adoption of the form of the frame bridge, so the height of a bridge structure spanning the rail way is minimized, and a steel beam or a profiled-steel beam with the structure height in the same size is avoided; later operation and maintenance workloads of the rail way are lightened, and the requirements for safety, environment friendliness and energy conservation are satisfied.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

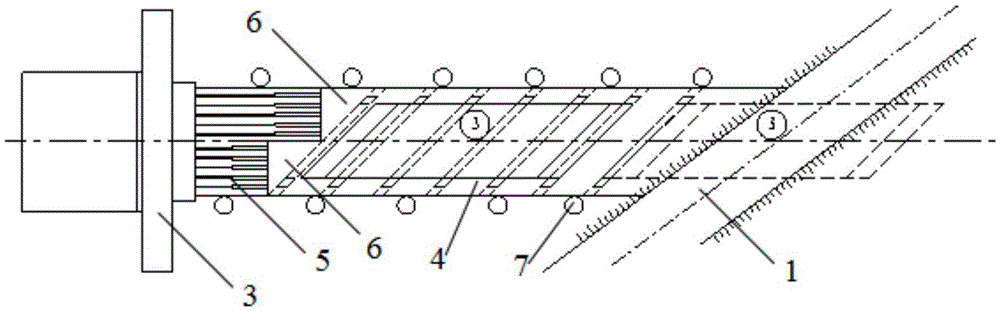

Foundation reinforcement method combining carbonatite boulder dynamic-compaction with filling and replacement

The invention discloses a foundation reinforcement method combining carbonatite boulder dynamic-compaction with filling and replacement. The foundation reinforcement method combining carbonatite boulder dynamic-compaction with filling and replacement comprises the steps that pier bodies (3) are tamped into a weak foundation (2), and a cushion course (1) is laid on the pier bodies (3) and the weak foundation (2). According to the foundation reinforcement method combining carbonatite boulder dynamic-compaction with filling and replacement, dynamic-compaction replacement is conducted on the weak foundation (2) through high-energy-level dynamic compaction, and the surface layer is reinforced through full-compaction construction. The processed filler cushion course (1) and the boulder pier bodies (3) form a composite foundation serving as a supporting layer for a building foundation on the upper portion. By the adoption of the foundation reinforcement method combining carbonatite boulder dynamic-compaction with filling and replacement, the construction cost is greatly reduced, and the bearing force meets design and standard requirements.

Owner:ZHENGYE ENG & INVESTMENT INC

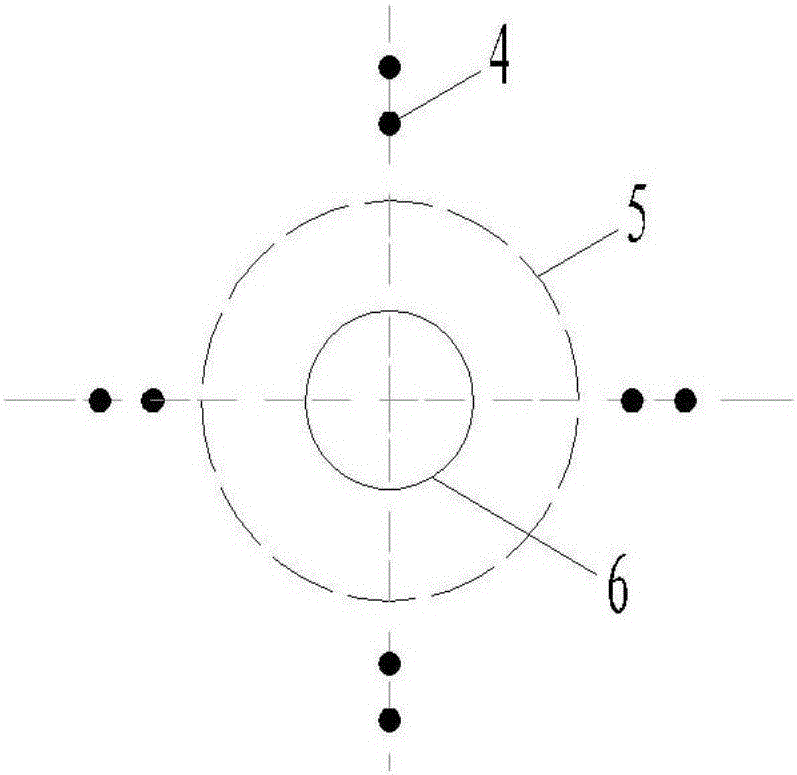

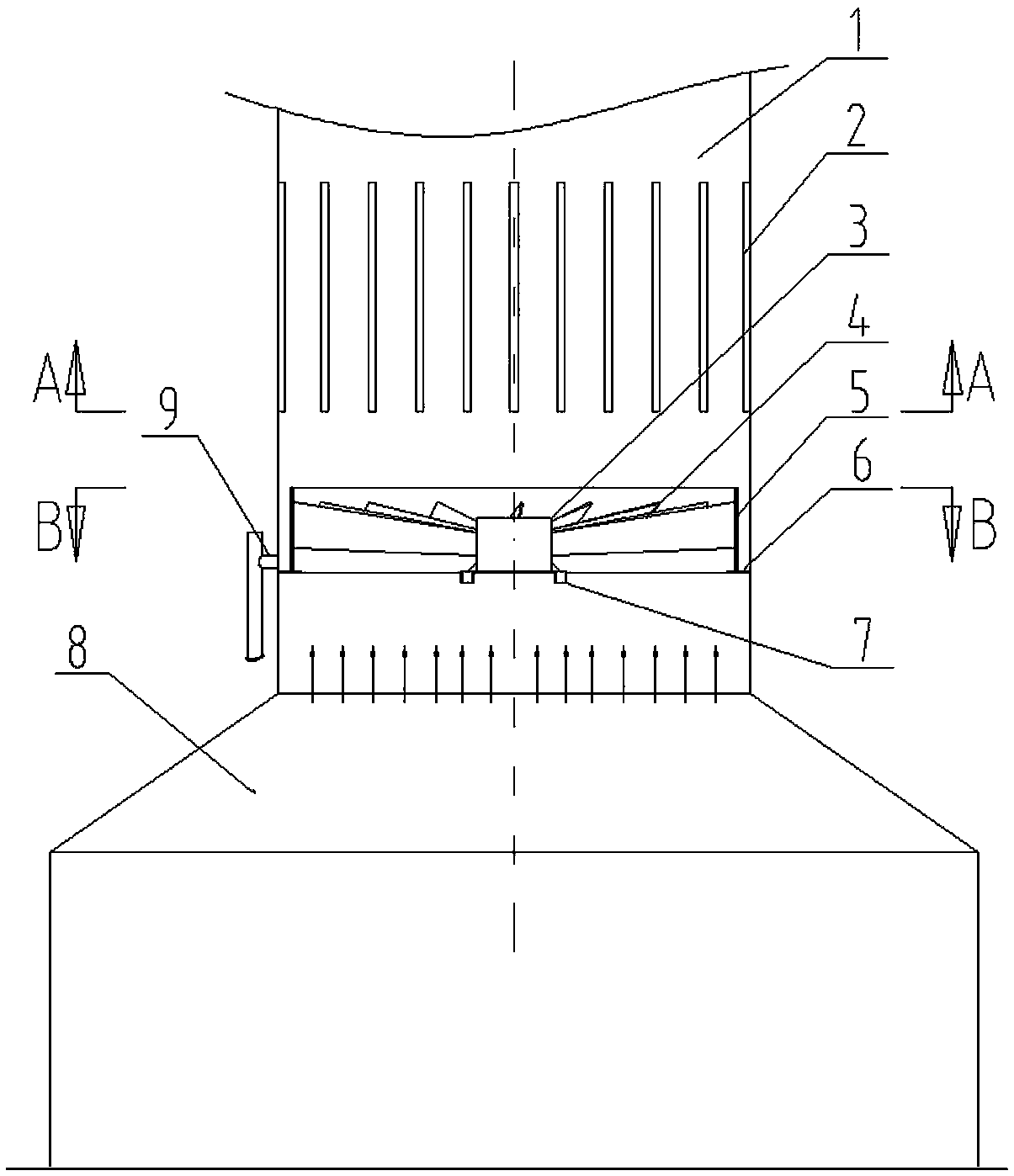

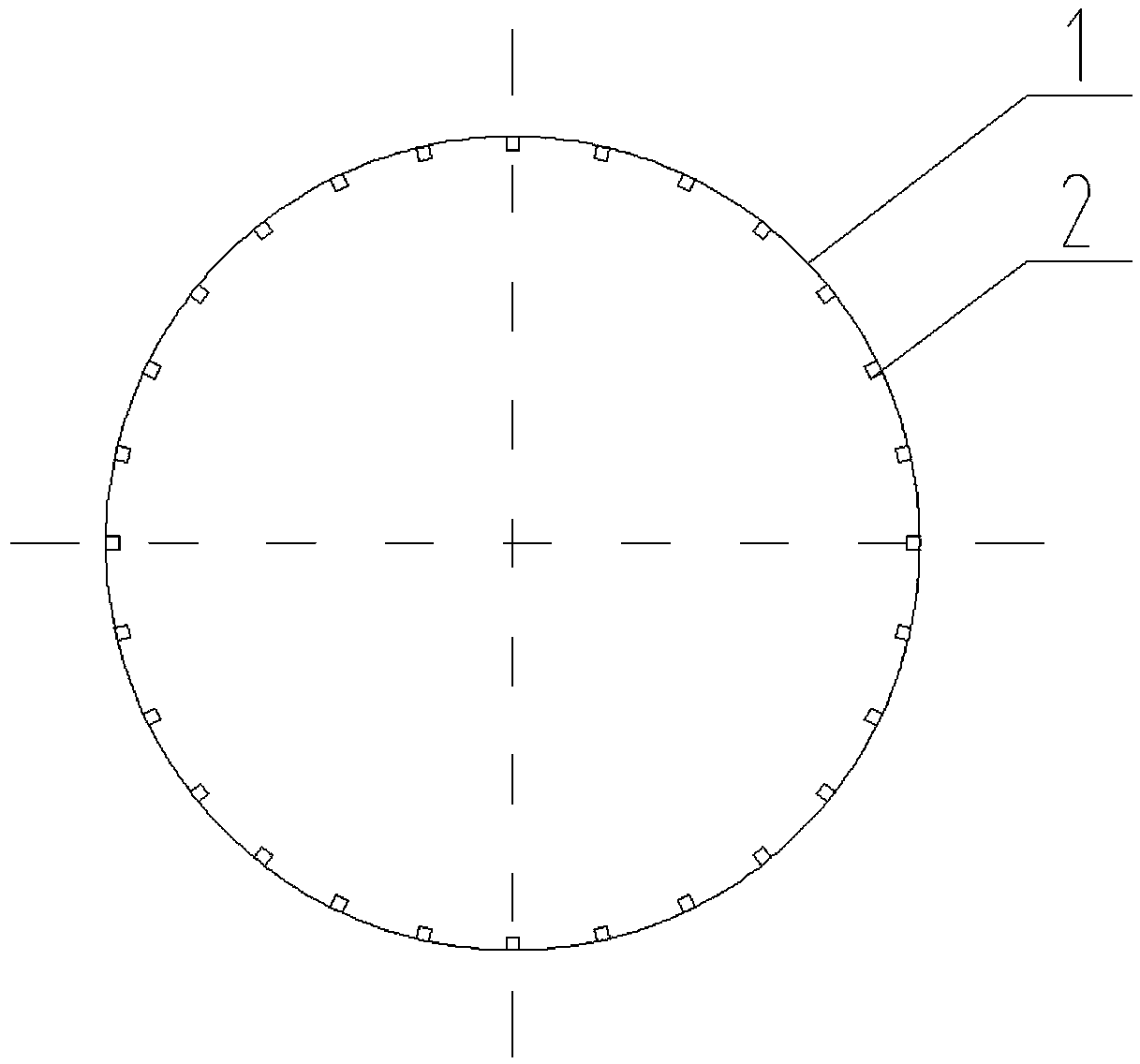

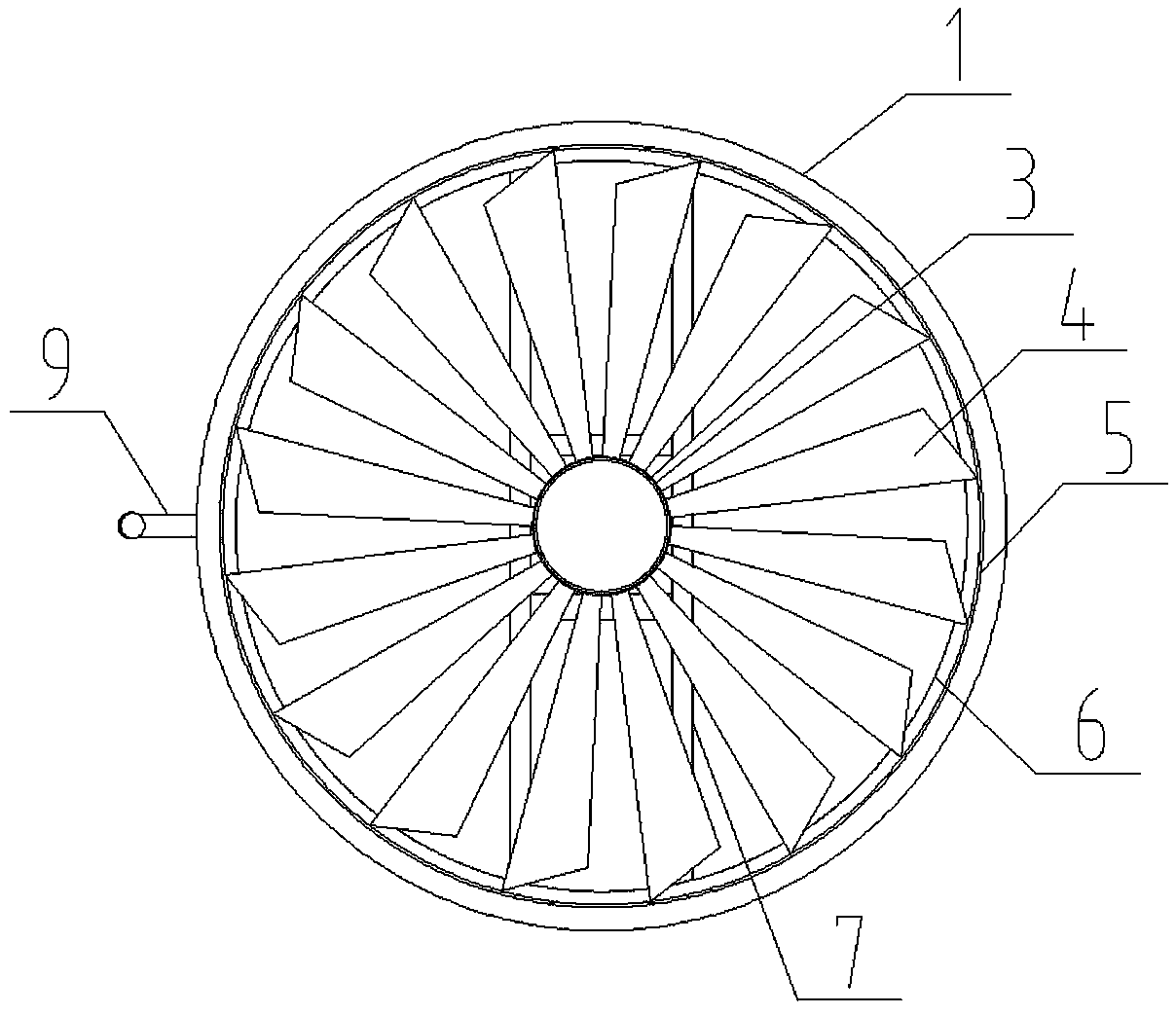

Dehydration device for wet electric precipitation outlet exhaust chimney

PendingCN108096935ASolve the rain problemObvious whiteningDispersed particle separationElectricityFlue gas

The invention relates to a wet electric precipitator, in particular to a dehydration device for a wet electric precipitation outlet exhaust chimney. The device includes an upper shell of a wet electric precipitator, and an exhaust chimney is connected on the upper shell. The dehydration device is characterized in that: liquid catching drainage rods are uniformly distributed circumferentially on the inner wall of the exhaust chimney, and are arranged along the longitudinal direction of the exhaust chimney. A cyclone apparatus is disposed below the liquid catching drainage rods in the exhaust chimney. The dehydration device can effectively remove most moisture from the flue gas in the wet electric precipitation outlet exhaust chimney, also has the characteristics of simple structure and lowcost, does not generate running cost, and also has obvious effect on elimination of exhaust fume whiteness.

Owner:朱永兵

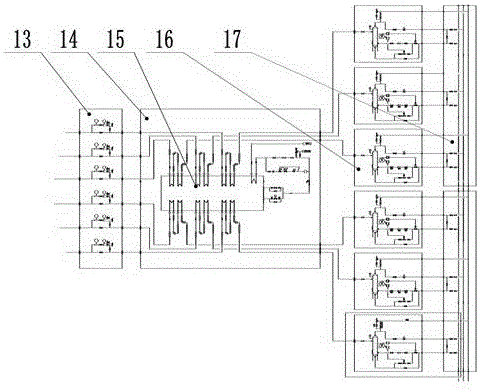

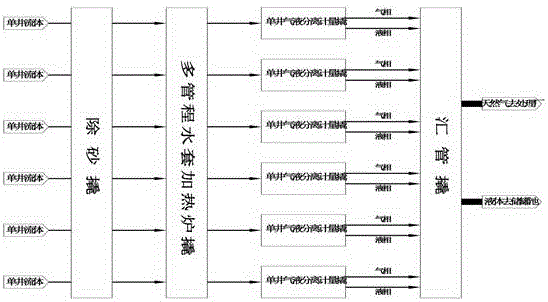

Single-well parallel gathering and transportation process

InactiveCN105863601ASimple technical processHighly integratedSurveyFluid removalThree-phaseProcess engineering

The invention discloses a single-well parallel gathering and transportation process flow. The process flow improves the shale gas process and separates and measures each single well, which not only realizes accurate measurement, but also detects three-phase gas flow through liquid level sensors. The height of the liquid level in the separator, by controlling the automatic opening and closing of the electric valve, realizes automatic gas-liquid separation and transportation, reduces labor intensity and labor costs, and is safe and reliable.

Owner:CHUANZHONG BRANCH KEHONG GASOLINEEUM NATURAL GAS ENG SICHUAN

Single-line railway bottom board type lining utilizing refuge hole for arranging inspection well and drainage system construction of said lining

PendingCN108468555AOvercoming the difficulty of controlling the excavation curvature and other problemsEasy to excavateUnderground chambersDrainageKarstEngineering

The invention provides a single-line railway bottom board type lining utilizing a refuge hole for arranging an inspection well and a drainage system construction of the said lining, aims to reduce andeven eliminate influence on a bottom structure of a tunnel lining by underground water, solves problems of floating deformation of inverted arches of tunnels or cracking damage of tunnel bottom structures in karst or underground water areas, is capable of performing checking and maintenance on a drainage system and ensuring stability and safety of tunnel construction and operation. A bottom boardstructure is arranged on the bottom part of an arch wall secondary lining structure. Two ends of the bottom board structure are fixedly connected to two ends of the arch wall secondary lining and haunching is performed on the inner sides of the connection parts. A longitudinal through central water trench is arranged along the longitudinal central axis below the bottom board structure. The inspection well is arranged in the refuge hole. Transverse connection channels connect the central water trench with the inspection well. The drainage system includes an arch wall range drainage system, a tunnel bottom drainage system and an in-tunnel drainage system communicating with the central water trench.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

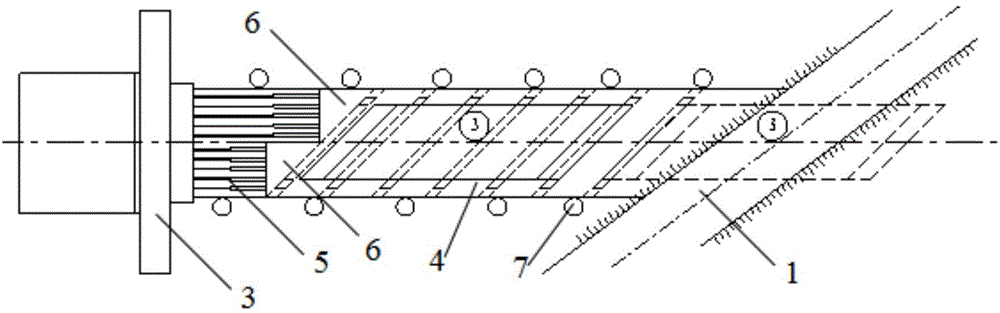

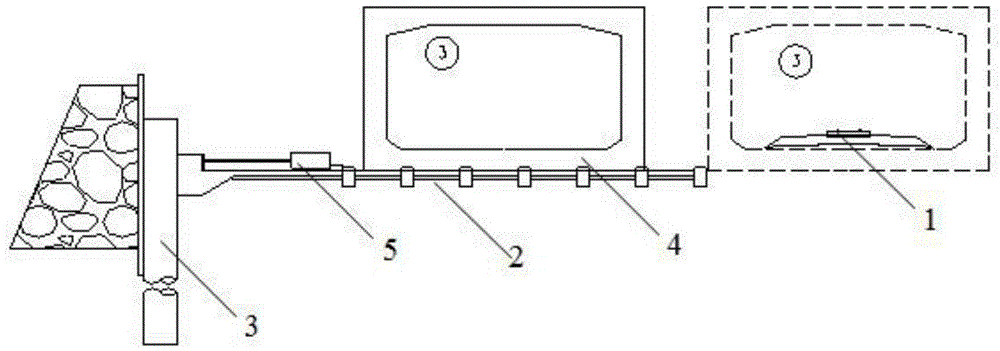

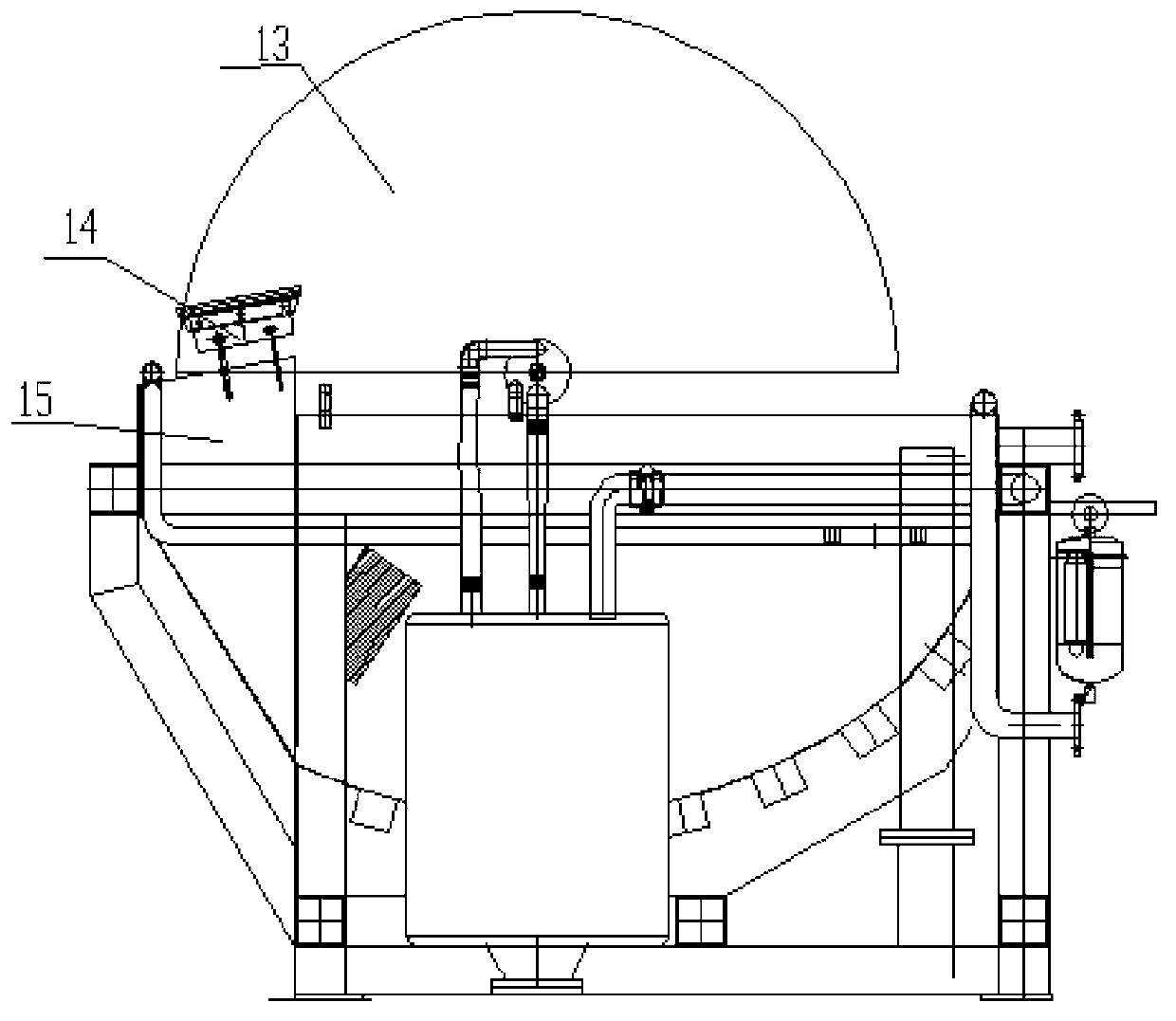

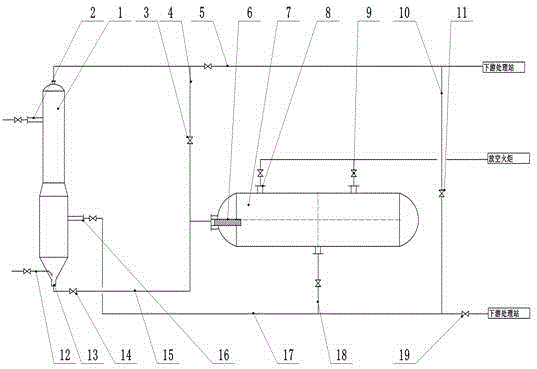

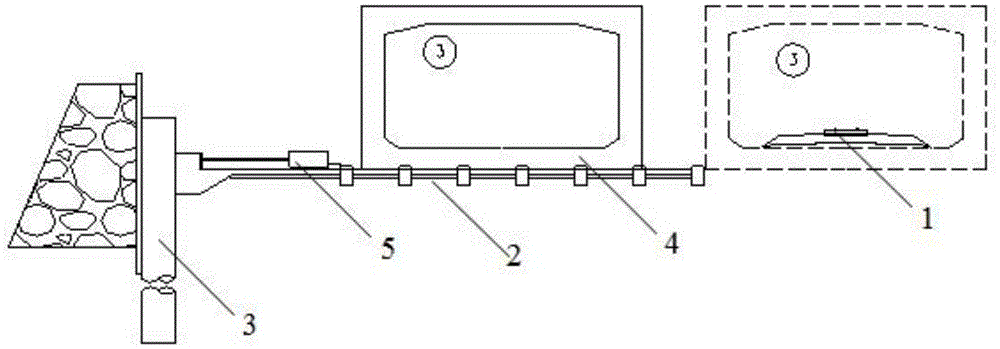

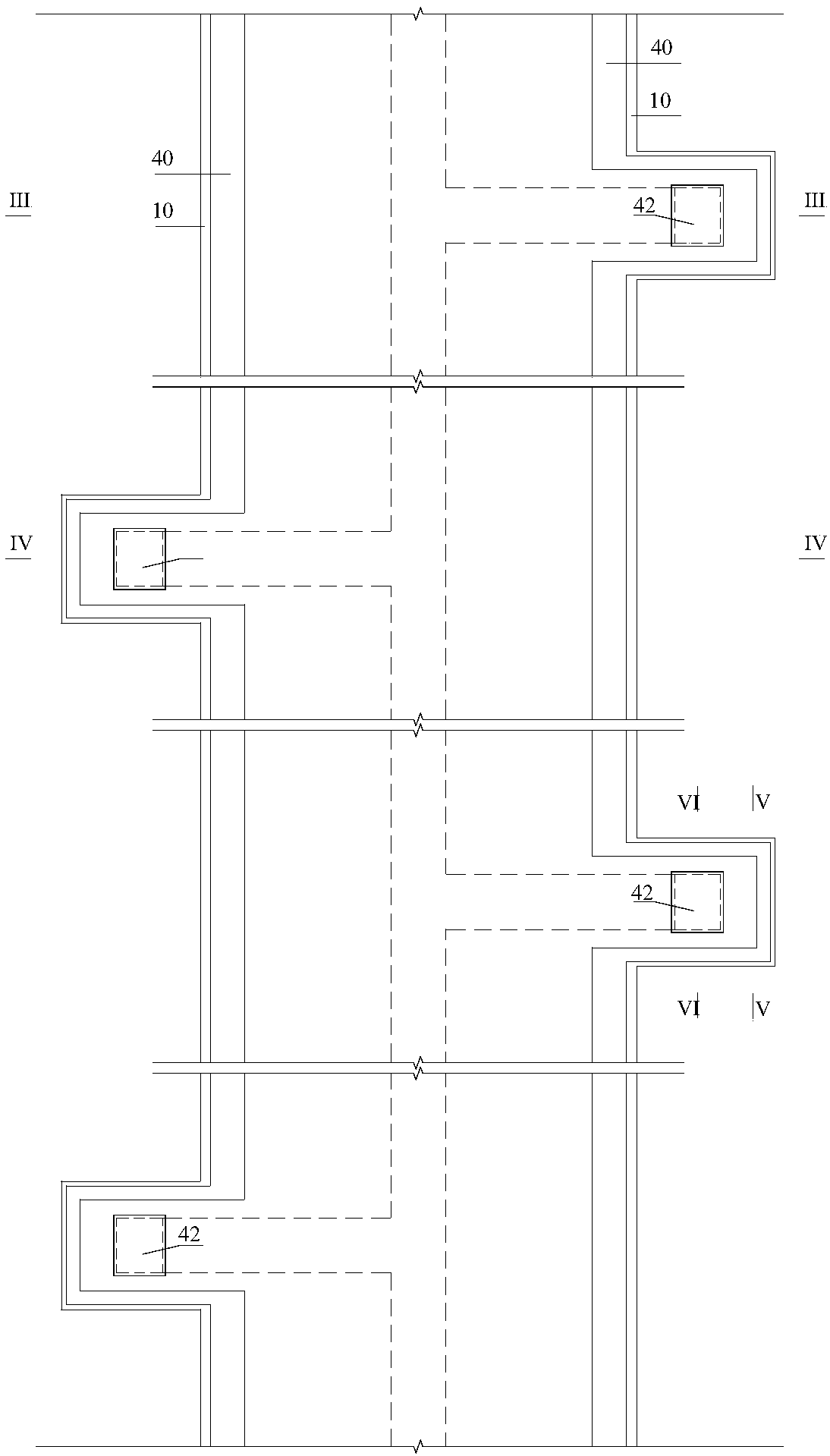

Lower paleozoic sulfur-containing natural gas and upper paleozoic sulfur-free natural gas commingled producing system

PendingCN110005376AReduce engineering construction investmentFluid removalPaleozoicSulfur containing

The invention discloses a lower paleozoic sulfur-containing natural gas and upper paleozoic sulfur-free natural gas commingled producing system, and belongs to the field of petroleum engineering. Thelower paleozoic sulfur-containing natural gas and upper paleozoic sulfur-free natural gas commingled producing system includes a lower plaeozoic outside transmission system and an upper plaeozoic outside transmission system, wherein a gas transmission pipeline of the lower paleozoic outside transmission system is connected to a gas transmission pipeline of the upper plaeozoic outside transmissionsystem; the lower plaeozoic outside transmission system includes a first gas-liquid separation device, a heating device and a liquid desulfurizer, in the area of an upper plaeozoic gas reservoir, a new lower plaeozoic outside transmission system is not needed to be established, the established upper plaeozoic outside transmission system is used, thus sulfur-containing natural gas in a lower plaeozoic well can be safely transmitted to a treatment plant, desulfuration treatment is conducted, commingled producing of an upper plaeozoic well and the lower plaeozoic well is achieved, and the purposeof lowering the investment of engineering construction is achieved.

Owner:XIAN CHANGQING TECH ENG +1

A microgrid optimization planning method and system including distributed power supply and energy storage

ActiveCN103903073BReduce engineering construction investmentForecastingControl engineeringPower grid

Owner:HOHAI UNIV +3

Joint exploitation method of upper Paleozoic sulfur-containing natural gas and lower Paleozoic sulfur-containing natural gas

The invention discloses a joint exploitation system of upper Paleozoic sulfur-containing natural gas and lower Paleozoic sulfur-containing natural gas, and belongs to the field of petroleum engineering. The joint exploitation system of the upper Paleozoic sulfur-containing natural gas and the lower Paleozoic sulfur-containing natural gas comprises a lower Paleozoic output system and an upper Paleozoic output system, and a gas conveying pipeline of the lower Paleozoic output system is connected to a gas conveying pipeline of the upper Paleozoic output system. The lower Paleozoic output system comprises a first gas-liquid separation device, a heating device and a liquid desulfurizing device. In the upper Paleozoic gas reservoir area, the lower Paleozoic output system does not need to be newly built, the built upper Paleozoic output system can be utilized for safely conveying the sulfur-containing natural gas in a lower Paleozoic well to a treatment plant to be desulfurized, an upper Paleozoic gas well and the lower Paleozoic gas well achieve joint exploitation, and the aim of reducing engineering construction investment is achieved.

Owner:XIAN CHANGQING TECH ENG +1

Box-type base and bridge-type tunnel bottom structure dynamic-static separation bearing-type lining structure and drainage system thereof

PendingCN108590697AOvercoming the difficulty of controlling the excavation curvatureEasy to excavateUnderground chambersDrainageBridge typeKarst

A box-type base and bridge-type tunnel bottom structure dynamic-static separation bearing-type lining structure and a drainage system thereof aim to eliminate the effect of underground water on a tunnel lining bottom structure, effectively solve the problem of tunnel inverted arch upwards-floating deformation or tunnel bottom structure cracking damage to an underground water development section, an underground water irregular section affected by the season and a karst area, and ensure the stability and safety of tunnel construction and operation. Box-type bases fixedly connected with an arc wall secondary lining structure into a whole are arranged at the bottoms of edge walls on the two sides of the arc wall secondary lining structure, and serving as a bearing structure of the arc wall secondary lining structure, the box-type bases are provided with through longitudinal cavities to serve as tunnel longitudinal drainage channels. A bridge-type tunnel bottom structure forming transversesupporting on the box-type bases is formed between the box-type bases on the two sides and serves as a bearing structure of a ballast bed and a train load. A through lower space is formed between thelower portion of the bridge-type tunnel bottom structure and the tunnel bottom excavation face and serves as a tunnel bottom underground water longitudinal drainage channel. An arc wall range drainagesystem communicates with the longitudinal cavities, a ballast bed accumulated-water drainage system communicates with the longitudinal cavities and the lower space, and the tunnel bottom drainage system communicates with the lower space.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com