Dehydration device for wet electric precipitation outlet exhaust chimney

The technology of wet electrostatic precipitator and wet electrostatic precipitator is applied in the field of dehydration device for discharge chimney of wet electrostatic precipitator, which can solve the problems of increasing project construction investment and production and operation cost, and achieves reduction of sewage treatment volume, low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

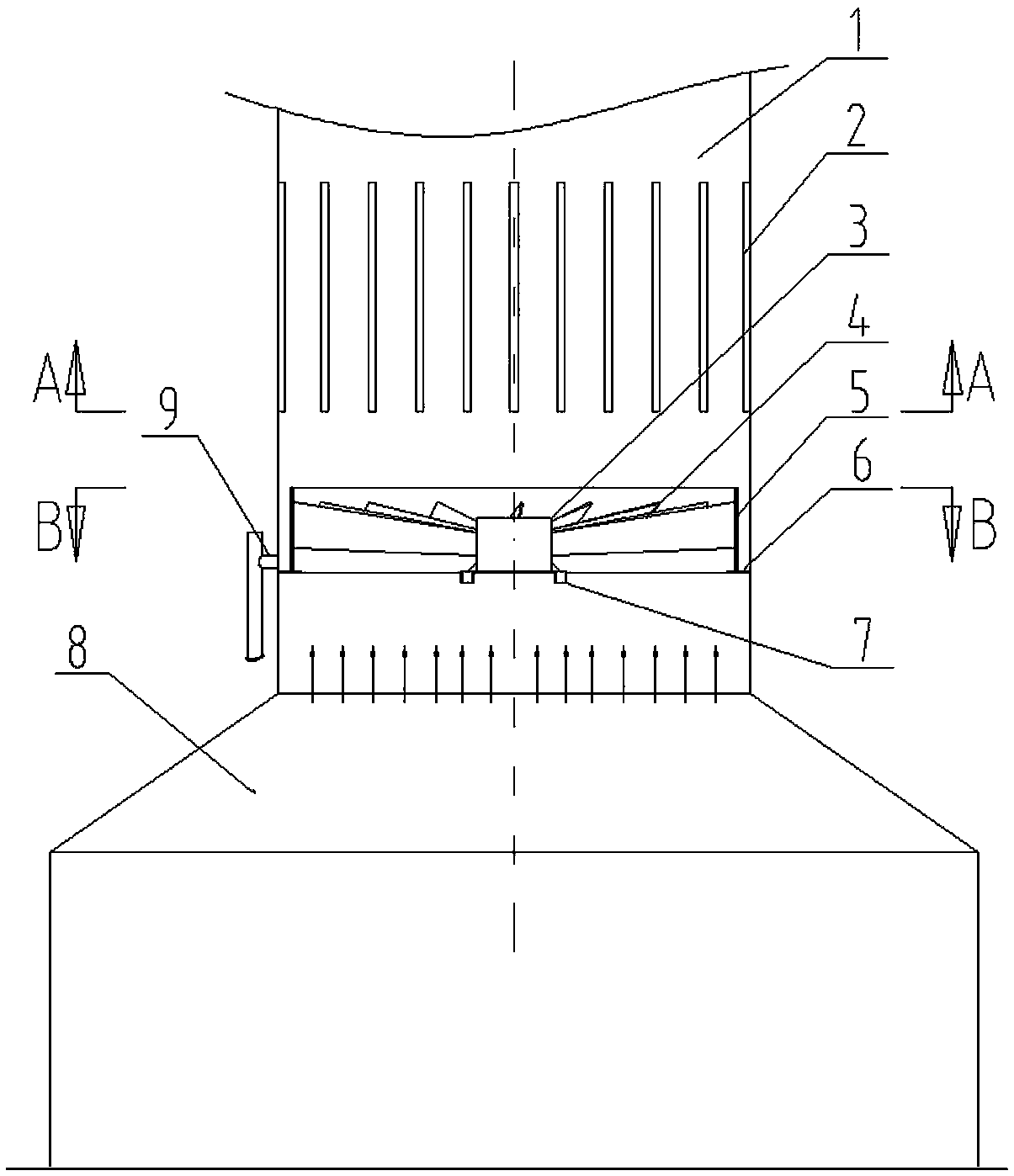

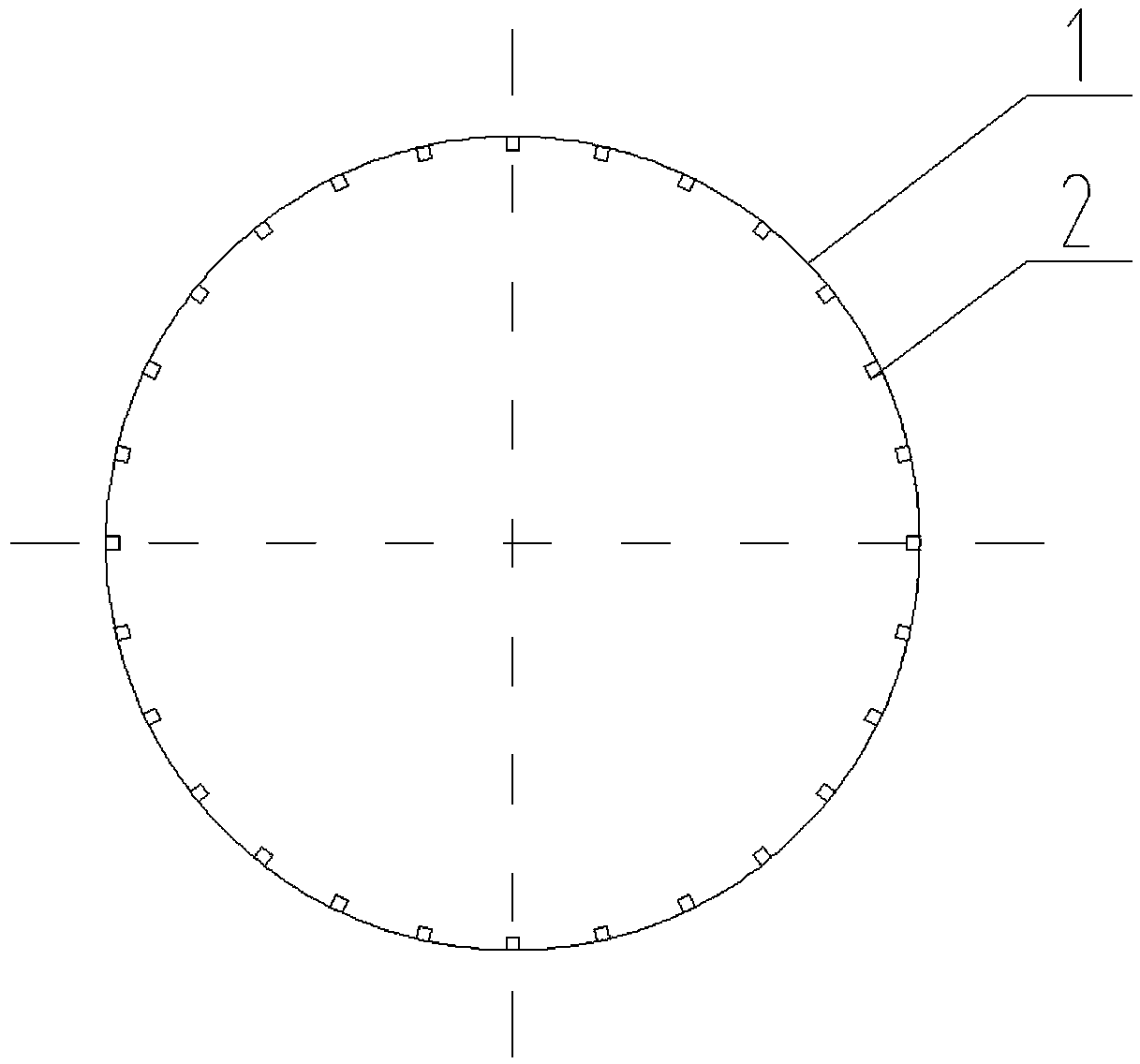

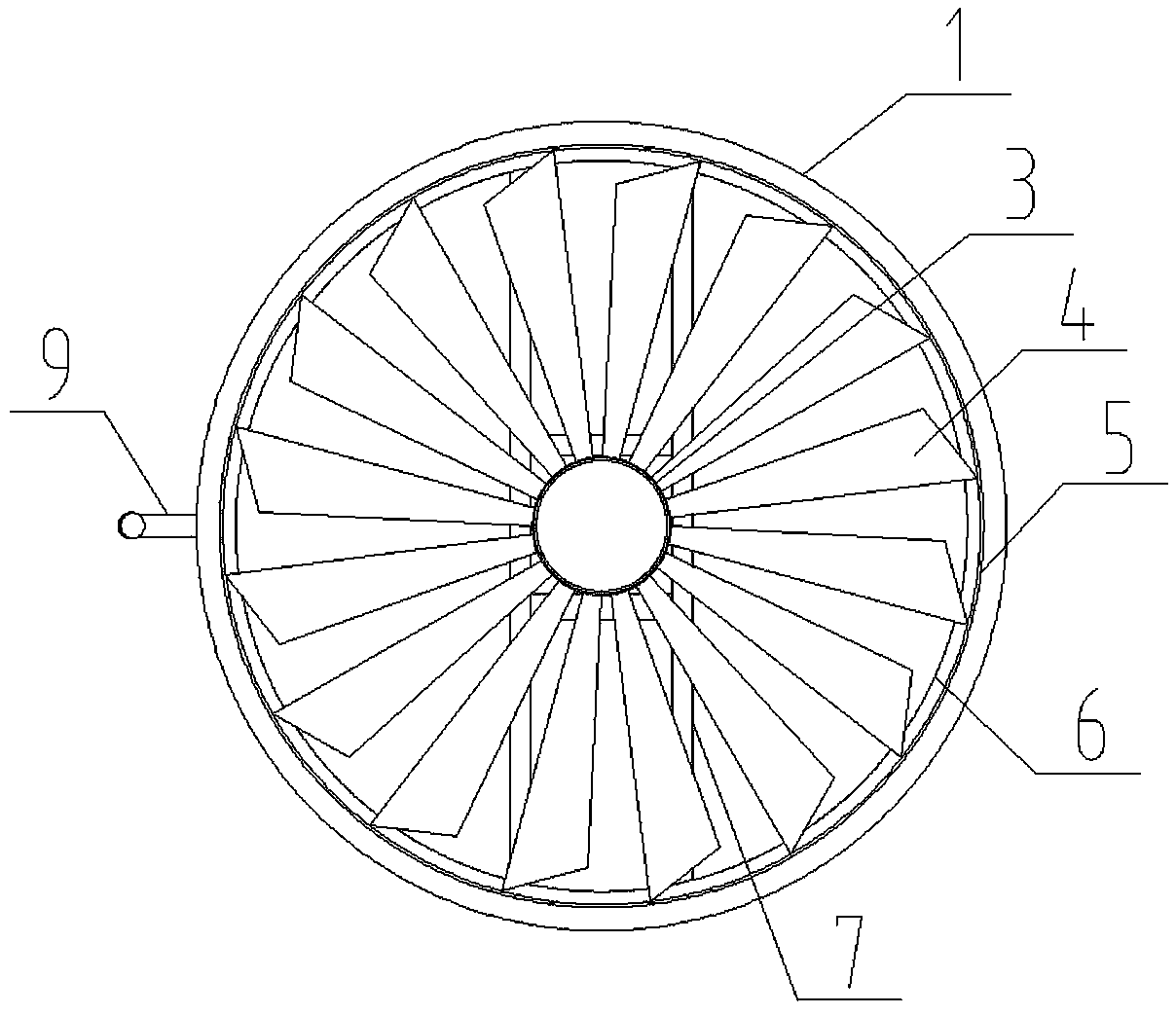

[0017] Such as figure 1 and figure 2 As shown, the dehydration device for the discharge chimney of the wet electrostatic precipitator of the present invention includes an upper casing 8 of the wet electrostatic precipitator, and a discharge chimney 1 is connected above the upper casing 8 . The exhaust chimney 1 is made of steel-lined resin flakes or fiberglass, which highly meets the requirements of the environmental assessment report. The inner wall of the discharge chimney 1 is evenly distributed with drip-catching and draining rods 2 along the circumferential direction, and the drip-catching and draining rods 2 are arranged along the longitudinal direction of the discharge chimney 1 . The drip-catching and drainage rod 2 is made of steel-lined resin scales or glass fiber reinforced plastics, and is uniformly welded on the inner wall of the discharge chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com