Method and apparatus for producing molten sulfur from sulfur foam

A technology of sulfur foam and equipment, applied in the field of desulfurization, can solve the problems of short corrosion resistance period of heat exchange section, high temperature of effluent clear liquid, heavy equipment weight, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

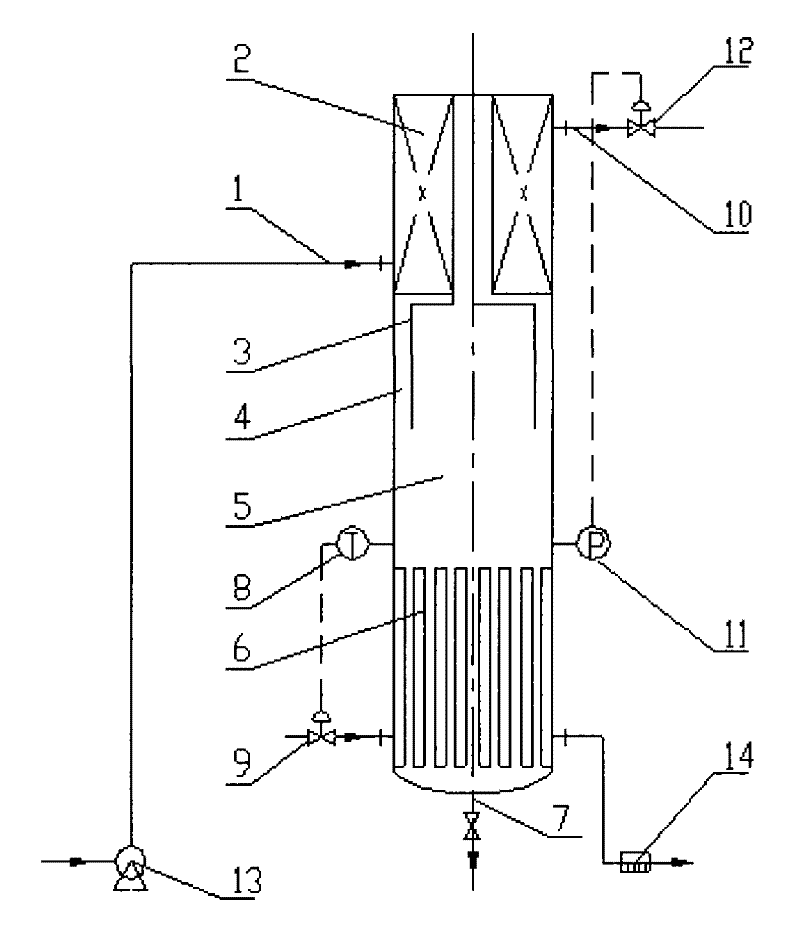

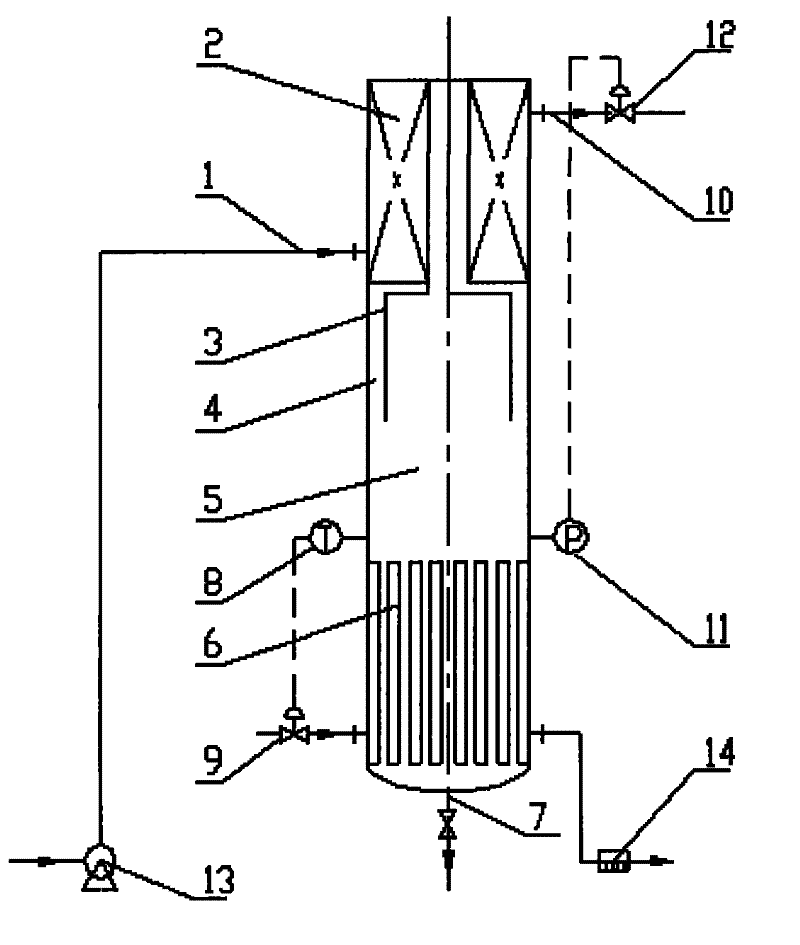

[0012] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0013] As shown in the figure, the sulfur foam from the desulfurization system enters the sulfur melting device through the delivery pump 13 from the sulfur foam inlet 1 of the heat exchange section 2 of the sulfur melting device. The device is the main component. In the embodiment of the present invention, that is, the heat exchange section 2 in the drawings adopts a spiral plate heat exchanger. The sulfur foam entering the heat exchange section 2 passes through the cold fluid channel of its heat exchanger in the form of forced convection, and then passes through the annular gap 4 between the outer circumference of the draft tube 3 arranged below the heat exchange section 2 and the outer casing of the sulfur melting device , into the settling separation section 5. After the preheating and agitation of the heat exchange section 2 and through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com