Flue gas desulphurization device and desulphurization method

A technology of a dosing device and a dehydrator, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of high labor intensity in operation and inspection, low space utilization rate, and reduced energy consumption of flue gas desulfurization devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

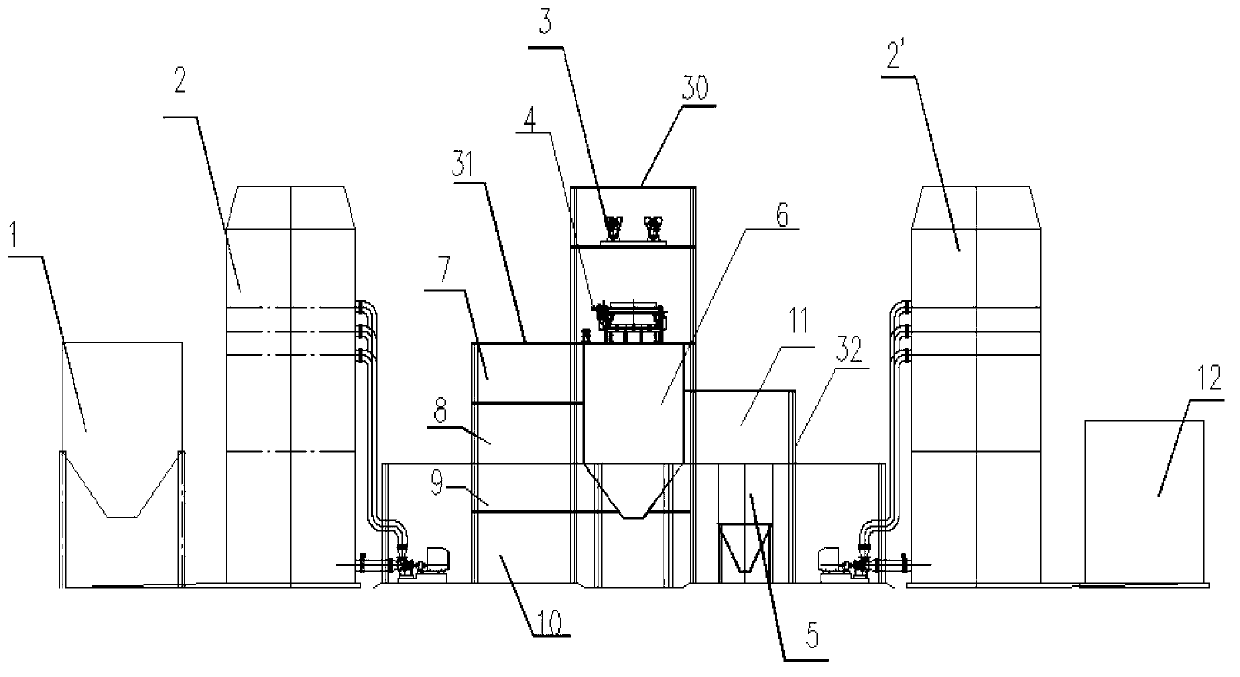

[0024] Such as figure 1 The flue gas desulfurization device of the present invention includes a limestone slurry preparation system, a flue gas absorption system, a gypsum slurry dehydration system, a waste water treatment system and an electric control system; it is three-dimensionally arranged in the process complex building and on the ground around it.

[0025] The limestone slurry preparation system includes a limestone powder bin 1, a limestone slurry preparation tank and a limestone slurry transfer pump.

[0026] The flue gas absorption system includes an absorption tower circulating pump, an oxidation fan, No. 1 absorption tower 2, No. 2 absorption 2', a gypsum slurry discharge pump, and an accident slurry tank 12.

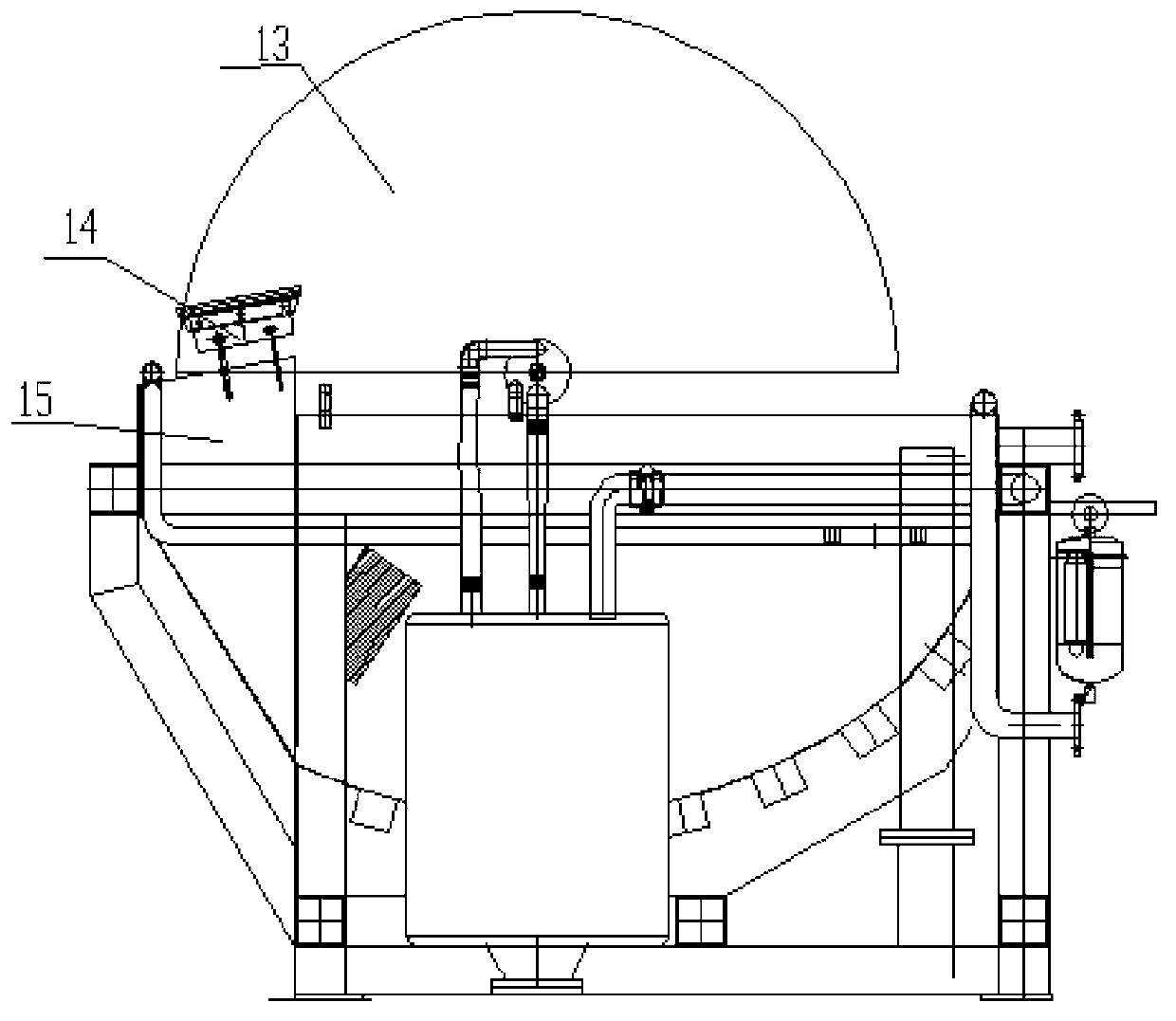

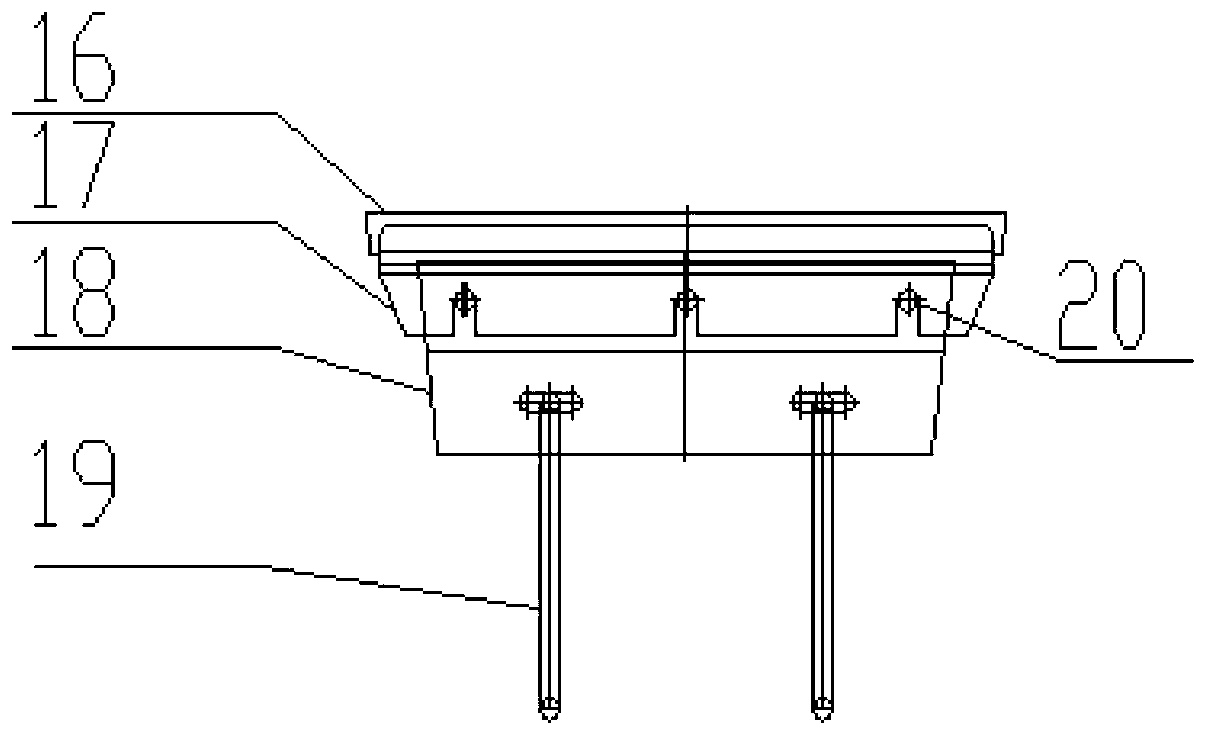

[0027] The gypsum slurry dewatering system includes a gypsum cyclone 3, a disc dehydrator 4, and a gypsum storage bin 6; the gypsum cyclone 3, a disc dehydrator 4, and a gypsum storage bin 6 are free from space. The gypsum cyclone 3 is located at the top end, the ...

Embodiment 2

[0037] Such as figure 1 As shown, the absorbent used in the flue gas desulfurization device of the present invention—limestone powder is transported to the power plant by a transport vehicle. The limestone powder silo 1 is unloaded by the transport vehicle. The limestone powder stored in the limestone powder silo 1 is prepared by adding water to form a limestone slurry , Use the limestone slurry transfer pump to send the limestone slurry into the No. 1 absorption tower 2 and the No. 2 absorption tower 2'. The limestone slurry is sprayed by the absorption tower circulation pump to realize the sulfur-containing boiler flue gas in the No. 1 absorption tower 2, 2 The reaction absorption in No. 2 absorption tower, the limestone slurry after the reaction is completed to form a gypsum slurry, and the oxidation fan is used to blow air into the absorption tower, so that the desulfurization reaction can be fully carried out. The accident slurry tank 12 is used for the storage of gypsum sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com