A Method for Quickly Pushing and Transversing the Whole Frame Bridge

A frame bridge and jacking technology, which is used in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of long bypass transition time, failure to ensure the personal safety of maintenance personnel, and the failure of common beam bridge solutions to reduce construction. The amount of engineering and construction protection, the effect of reducing the safety risks of construction operations, and reducing the workload of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0050] The frame bridge overall fast pushing lateral movement method of the present embodiment comprises the following steps:

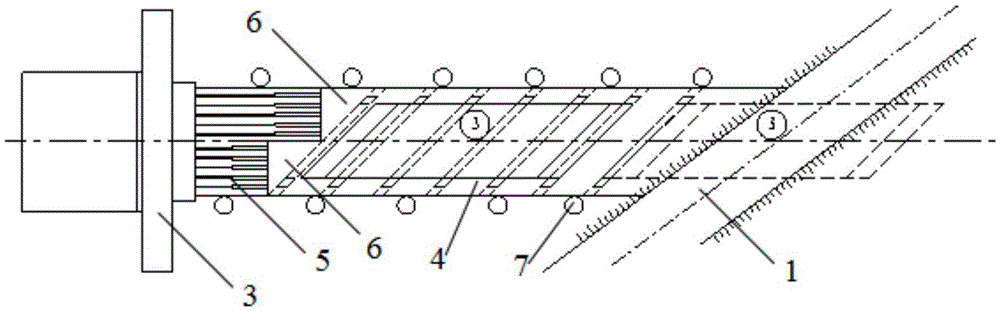

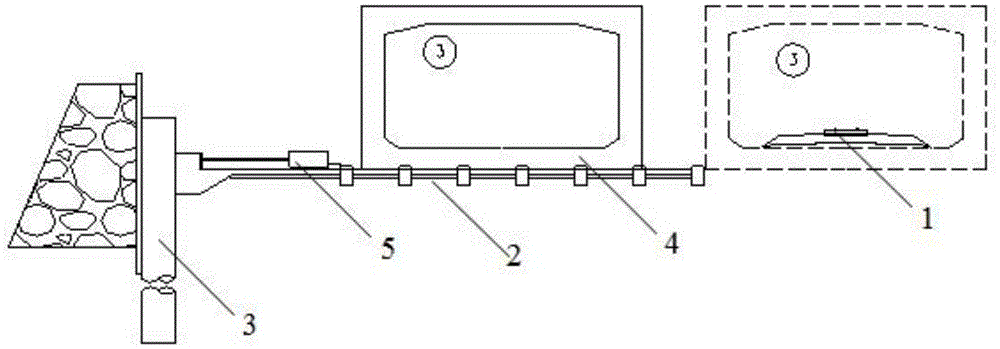

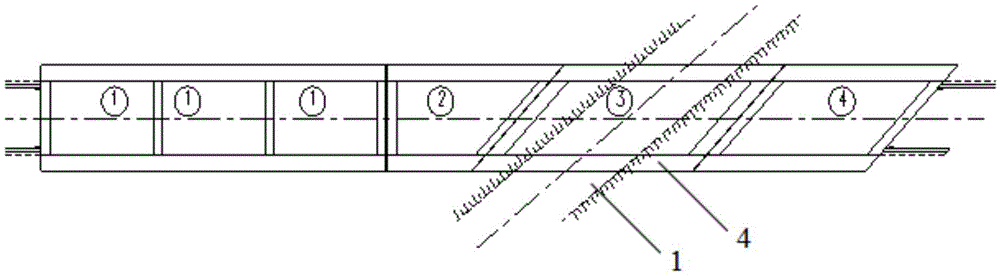

[0051] Construct the foundation pit on the side of the existing railway 1, such as Figure 1-2 As shown, the construction slide plate 2 and the hole-digging pile are constructed in the foundation pit, and the hole-digging pile is used as the pushing back 3, and the pile of digging is also provided with rubble stones behind it. After the lubricating isolation layer is set on the slide plate 2, the frame bridge 4 is prefabricated, and the top of the bottom plate of the frame bridge 4 is basically flush with the shoulder of the existing railway 1. In order to avoid "head-tying", the front end of the frame bridge is provided with a bow slope, and the slide plate 2 is provided with an upward slope along the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com