Lime coal ash precast pile and pile forming technique, and method for forming composite ground foundation

A technology of fly ash and prefabricated piles, which is applied in the direction of manufacturing tools, sheet pile walls, ceramic molding machines, etc., can solve the problems that the construction quality is not easy to control the environmental conditions and construction noise, flying dust and noise effects, etc., to achieve the foundation treatment method Simple, solve the effect of flying dust and noise, and easy to control the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

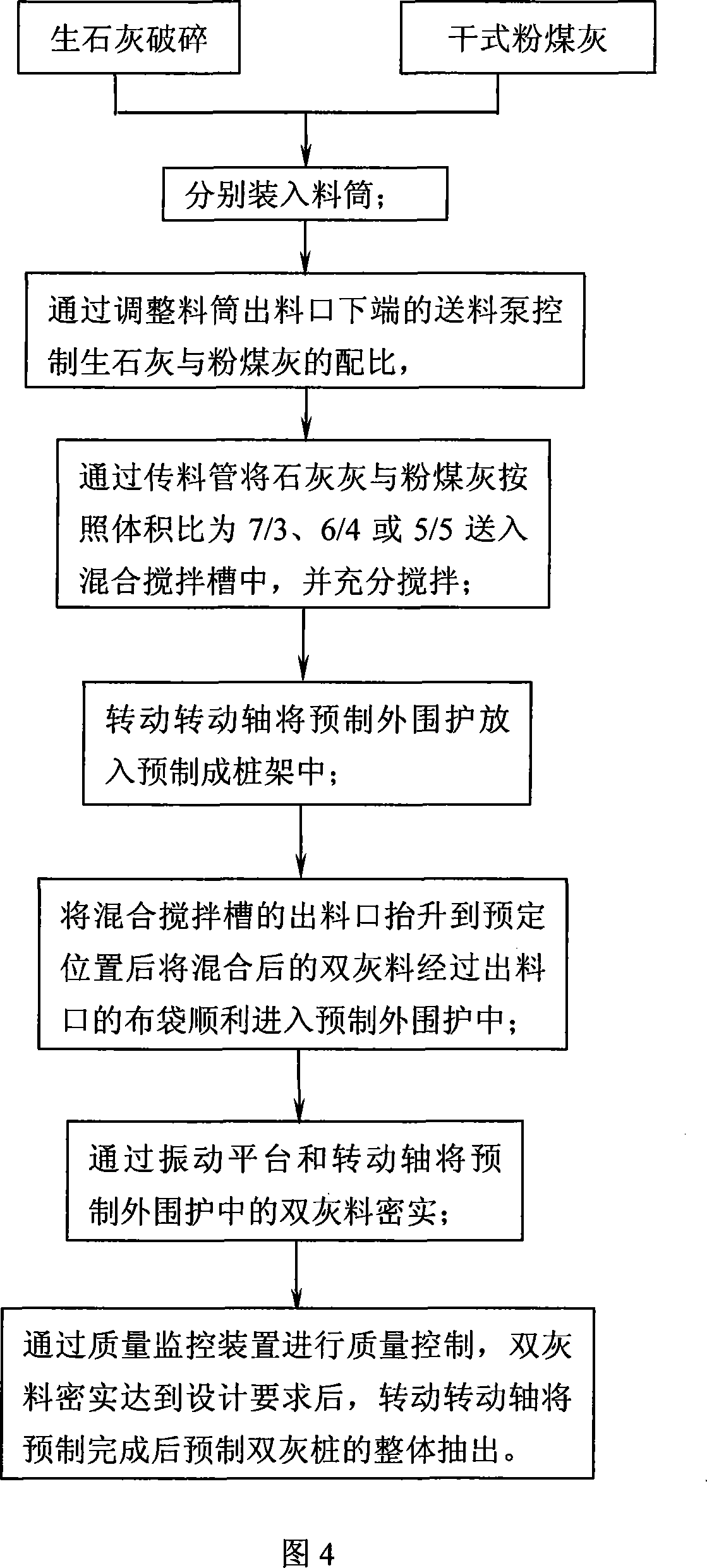

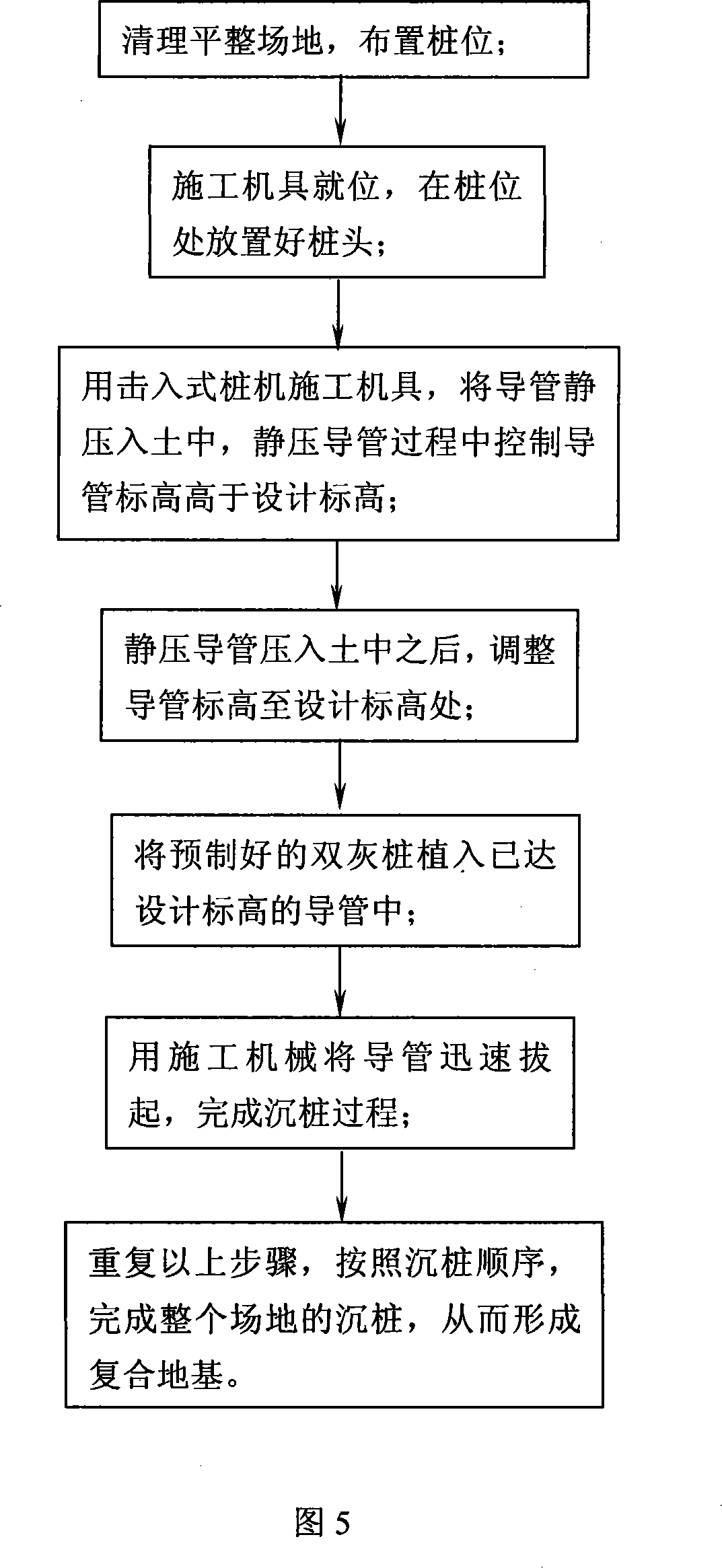

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

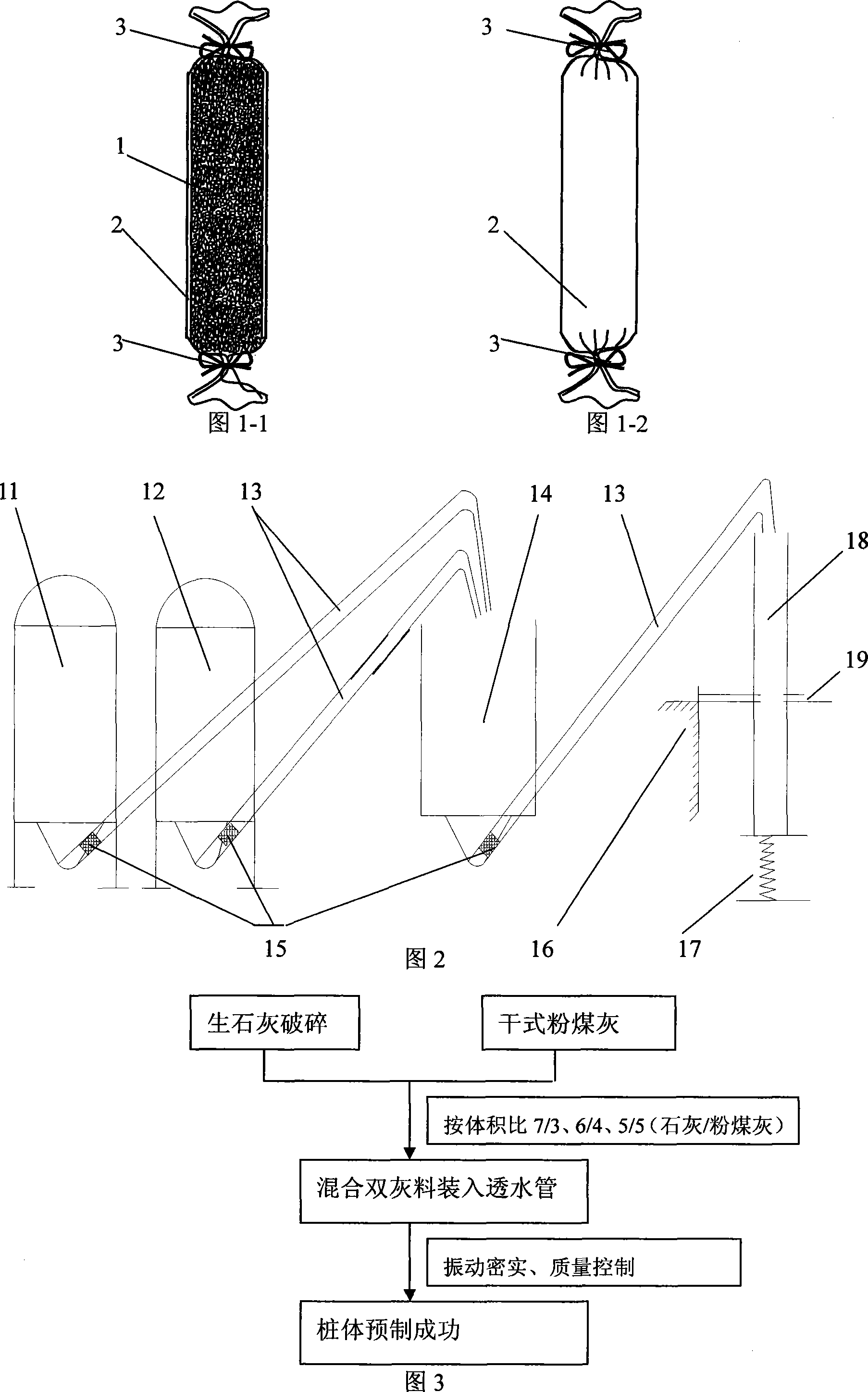

[0024] Description of relevant components and details in the accompanying drawings. In Fig. 1-1 and Fig. 1-2: 1 pair of ash materials, 2 prefabricated pile shells, 3 package binding; in Fig. 2: 21 first material barrel, 22 second material barrel, 23, feeding pipe, 24 mixing and stirring Groove, 25 feeding pumps, 26 fixed vibrating platforms, 27 vibrating tables, 28 prefabricated pile frames, 29 rotating shafts.

[0025] As shown in Fig. 1-1 and Fig. 1-2, the structure of the lime and fly ash prefabricated pile of the present invention comprises the double ash material 1 that is arranged in the prefabricated outer enclosure, that is, the compact state in the prefabricated pile shell 2; The material 1 is composed of lime and fly ash; the volume percentage between the lime and fly ash is 7:3, 6:4 or 5:5; the package is formed at the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com