Low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method

A technology of urban sewage and treatment methods, applied in urban sewage treatment, system integration of new high-efficiency anaerobic biochemical and aerobic biochemical treatment devices, economical and energy-saving sewage treatment technology, can solve problems that are difficult to adapt to urban sewage treatment, and achieve sewage Good treatment effect, reduced engineering construction investment, and reduced carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

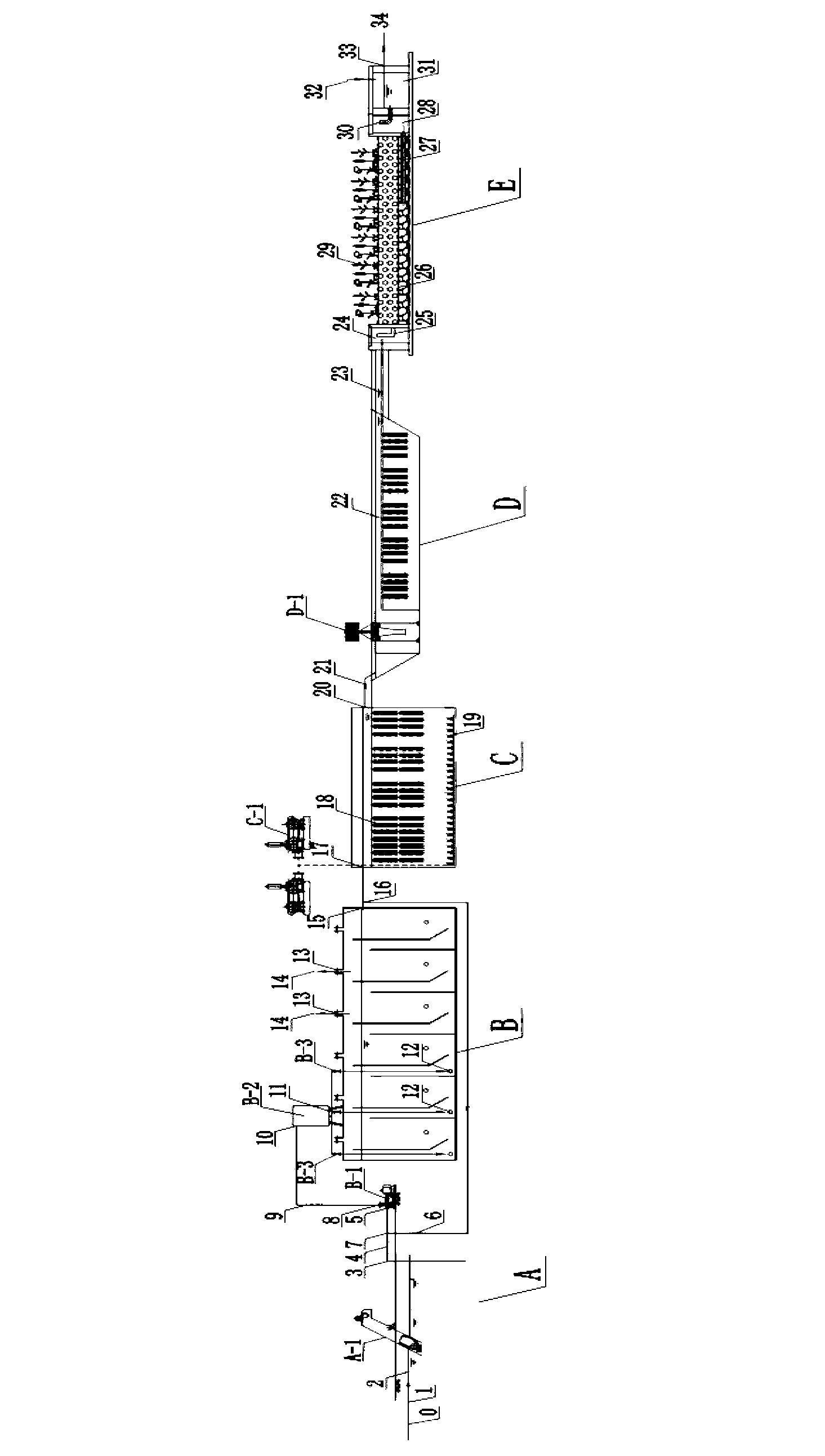

[0062] Embodiment 1: a kind of low energy consumption, low carbon emission, economical and energy-saving urban sewage treatment method, its steps are:

[0063] Sewage treatment process: grille / collection tank + baffled anaerobic biochemical (or hydrolytic acidification) tank + circulating flow biological oxidation tank + aerobic biological contact oxidation pond + constructed wetland (see attached for flow chart Figure 7 ).

[0064] Using this method to treat sewage, the steps are:

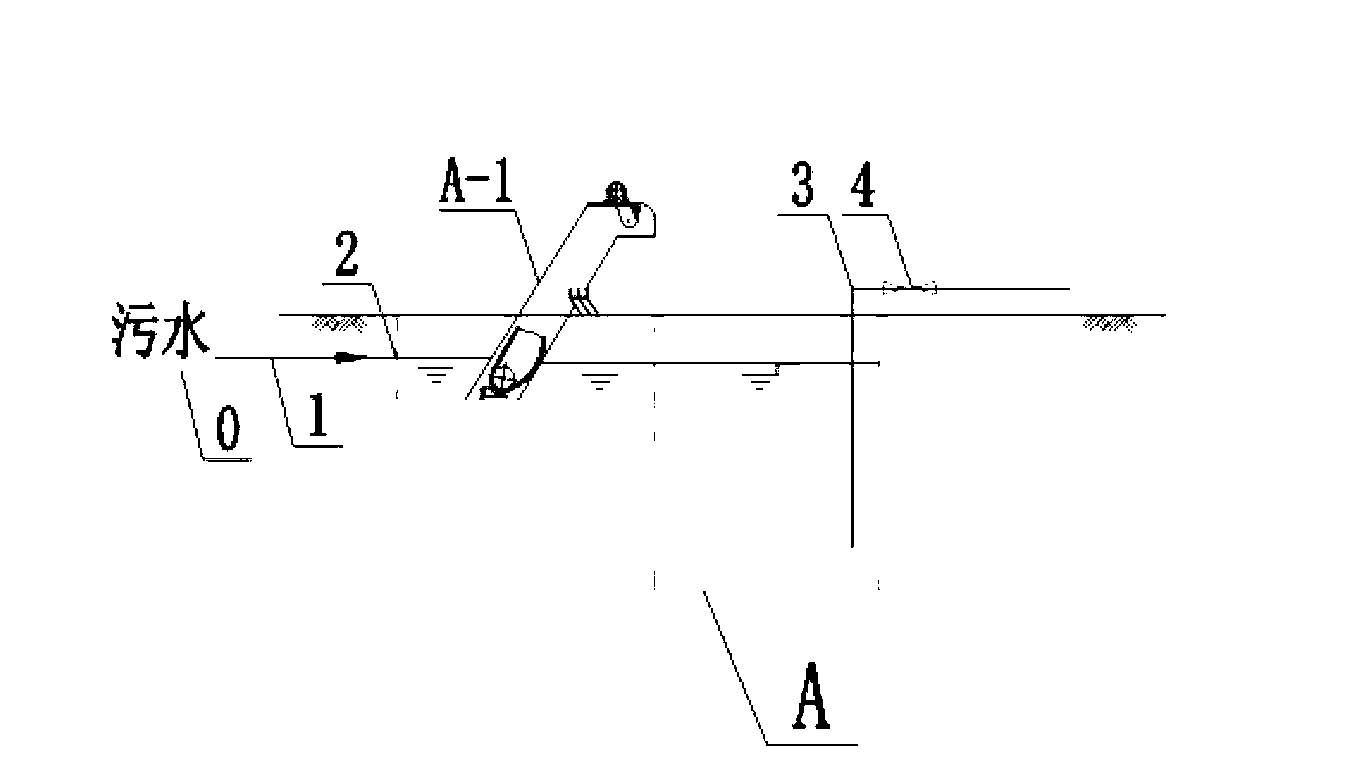

[0065] (1) Sewage 0 to be treated flows through the sewage inlet pipe 1 through the mechanical grille A-1 to remove large particles of suspended solids and garbage, and then enters the grille / sump A.

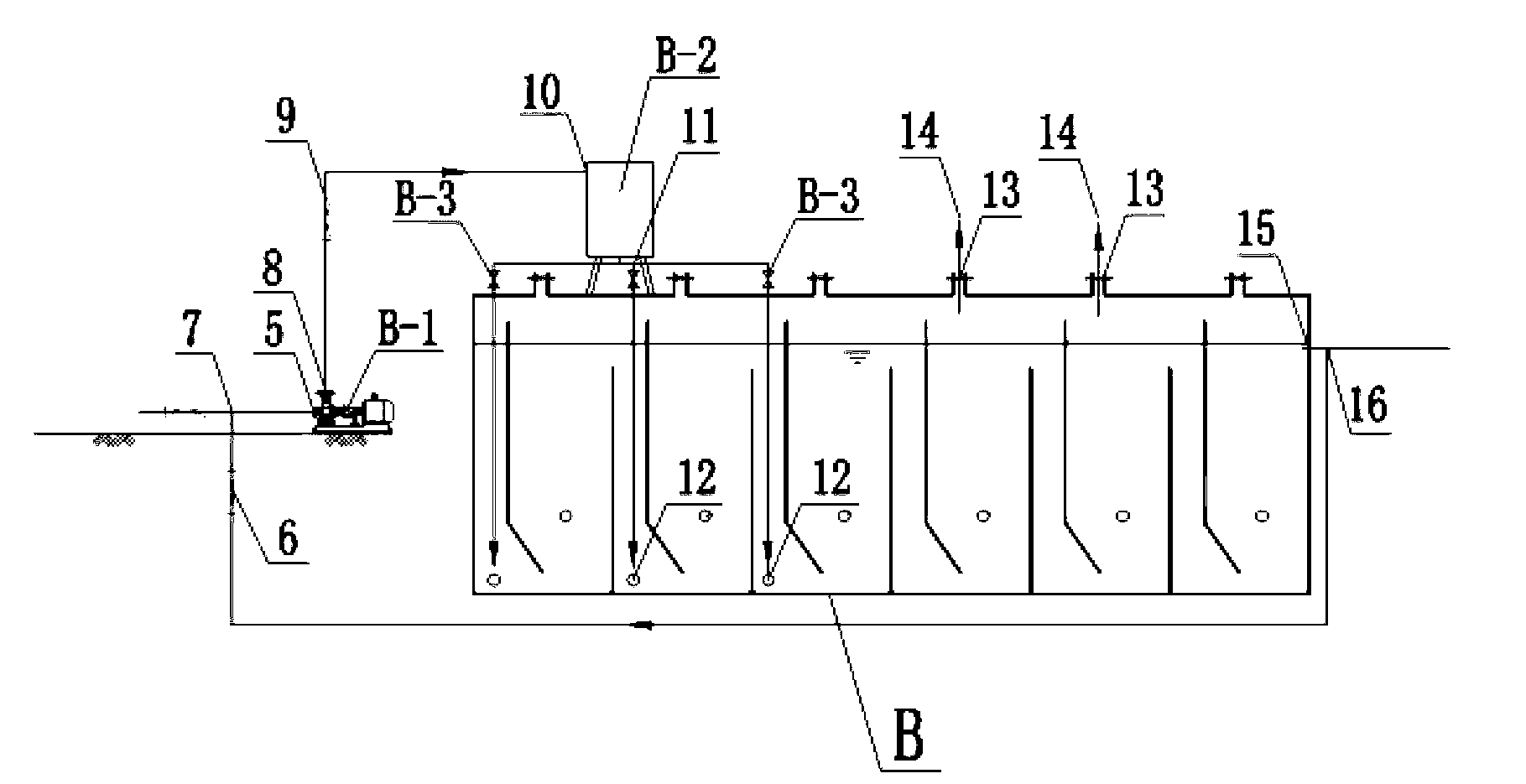

[0066] (2) The sewage in the grid / collection tank A is lifted by the self-priming pump B-1 and enters the pulse tank B-2 through the self-priming pump outlet pipe 8. After the sewage enters the pulse tank B-2, the water outlet is controlled by the solenoid valve B-3, and enters the baffle type an...

Embodiment 2

[0079] Embodiment 2: a low-energy, low-carbon emission, economical and energy-saving urban sewage treatment method, the steps are:

[0080] Sewage treatment process: grille / collection tank + baffled anaerobic biochemical (or hydrolytic acidification) tank + circulating flow biological oxidation tank + aerobic biological contact oxidation pond (see attached for flow chart Figure 8 ).

[0081] Using this method to treat sewage, the steps are:

[0082] (1) Sewage 0 to be treated flows through the sewage inlet pipe 1 through the mechanical grille A-1 to remove large particles of suspended solids and garbage, and then enters the grille / sump A.

[0083] (2) The sewage in the grid / collection tank A is lifted by the self-priming pump B-1 and enters the pulse tank B-2 through the self-priming pump outlet pipe 8. After the sewage enters the pulse tank B-2, the water outlet is controlled by the solenoid valve B-3, and enters the baffle type anaerobic biochemical (or hydrolytic acidifica...

Embodiment 3

[0094] Embodiment 3: a low-energy, low-carbon emission, economical and energy-saving urban sewage treatment method, the steps of which are:

[0095] Sewage treatment process: grille / collection tank + baffled anaerobic biochemical (or hydrolytic acidification) tank + circulating flow biological oxidation tank + constructed wetland (see attached for flow chart Figure 9 ).

[0096] (1) The sewage 0 to be treated flows through the sewage inlet pipe 1 through the mechanical grille A-1 to remove large particles of suspended solids and garbage, and then enters the grille / sump A.

[0097] (2) The sewage in the grid / collection tank A is lifted by the self-priming pump B-1 and enters the pulse tank B-2 through the self-priming pump outlet pipe 8. After the sewage enters the pulse tank B-2, the water outlet is controlled by the solenoid valve B-3, and enters the baffle type anaerobic biochemical (or hydrolytic acidification) device B from the water inlet 12 in the way of partition wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com