Foundation reinforcement method combining carbonatite boulder dynamic-compaction with filling and replacement

A technology for replacing foundations with carbonate rocks, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as lack of application, meet design and specification requirements, reduce engineering construction investment, and improve strength and uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

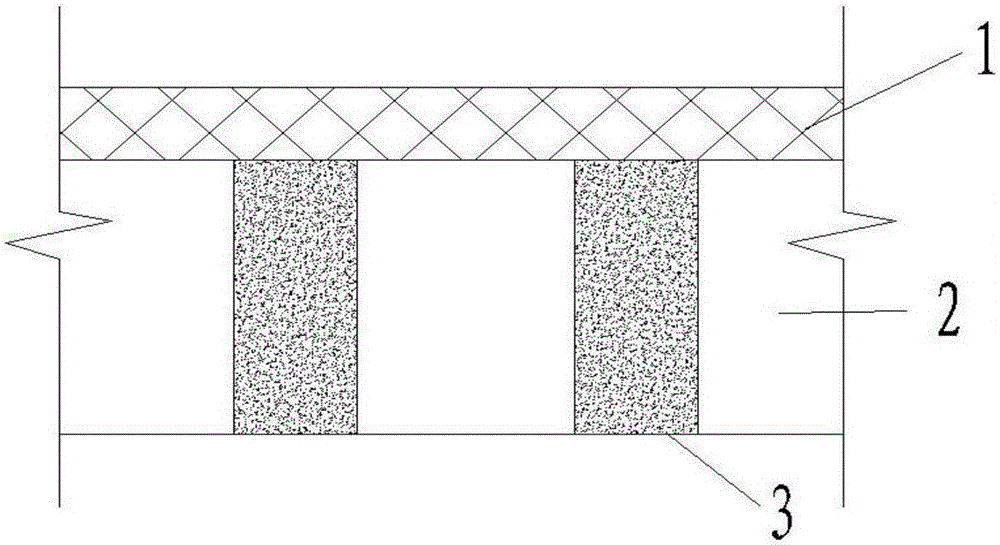

[0017] A method for reinforcing the ground with dynamic tamping and replacement of large carbonate rocks (see figure 1 ), the specific implementation steps are as follows:

[0018] Step 1: Clean up and level the construction site, pre-lay a layer of compacted cushion layer 1 with a thickness of 500mm and a particle size of no more than 100mm, and use natural graded carbonate rock blocks with a clay content of no more than 5% for the cushion layer 1 filler.

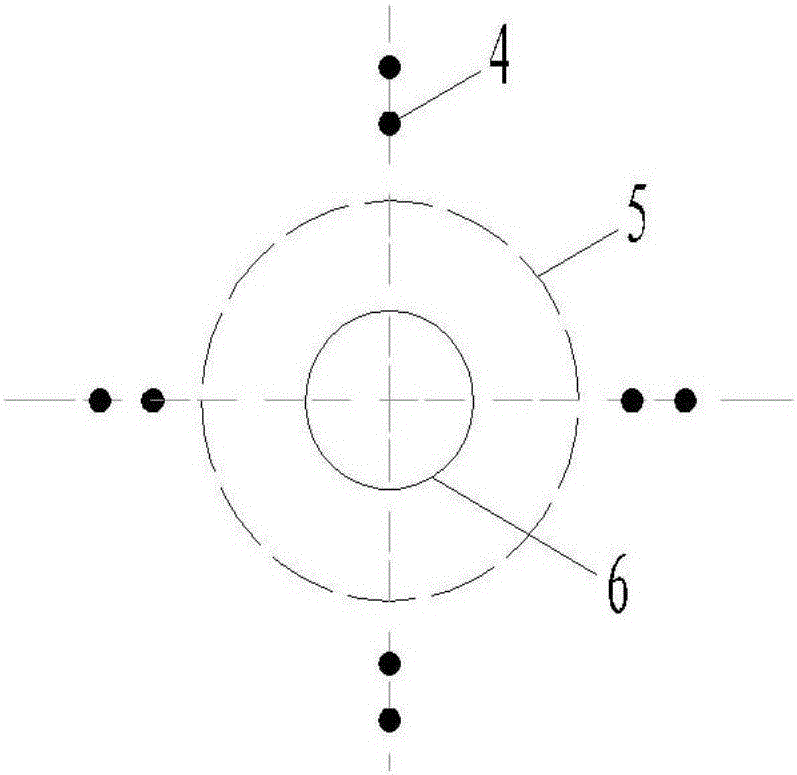

[0019] Step 2: Mark the position of the ramming point 6, and measure the site and the elevation around the ramming point.

[0020] Step 3: Use 8000kN·m tamping energy to carry out dynamic tamping replacement. A circular rammer with a diameter of 2.5m and a weight of 45t is selected for use. Lift the rammer to a height of 18m first, then turn on the uncoupling device, ram and record the depth of the ramming pit one by one, and arrange 8 observation points 4 at selected positions around the edge line 5 of the ramming pit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com