Single-well parallel gathering and transportation process

A technological process, gathering and transportation technology, applied in the direction of production fluid, wellbore/well components, measurement, etc., can solve the problems of three-phase separator medium change, waste of manpower and material resources, and rising engineering costs, so as to simplify the oil and gas technical process, The effect of high automation level and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

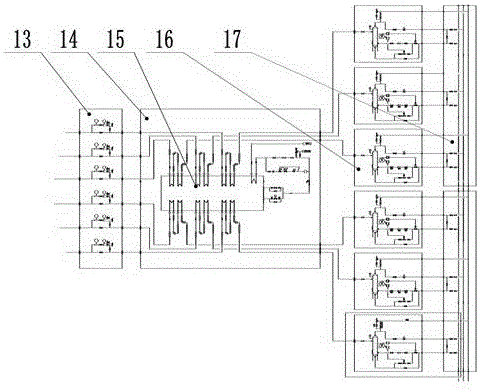

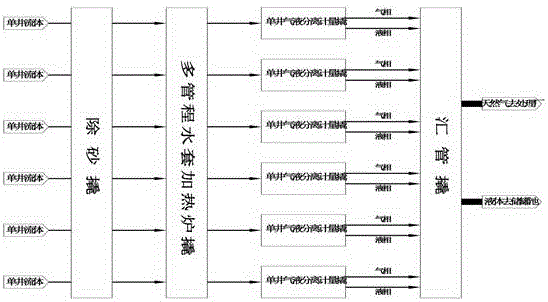

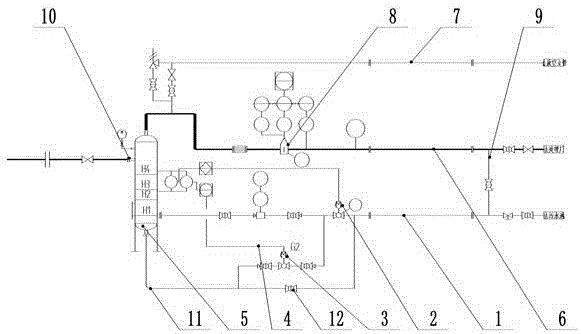

[0028] Such as Figure 1~3 As shown, a single well parallel gathering and transportation process includes the following contents:

[0029] A1. The raw material gas of each single well is respectively introduced into the sand removal skid 13 for coarse sand filtration, and the raw material gas of different single wells after the coarse sand filtration is respectively passed into different tube passes 15 of the multi-tube water jacket furnace 14 for throttling Buck. Each single well is respectively connected to the corresponding desander in the desander skid 13 for desandering respectively. The water jacket furnace 14 includes a plurality of tube passes 15, and each tube pass 15 is respectively connected to different desanders, and the raw material gas filtered by the coarse sand is passed into different tube passes 15 of the water jacket furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com