Dual-hole hollow rectangular section bearing cutting type arched tunnel lining structure and separation drainage system

A technology of rectangular section and drainage system, applied in the direction of tunnel lining, tunnel, drainage, etc., can solve problems such as cracking and damage, and achieve the effect of controlling settlement and deformation, reducing engineering construction investment, and achieving significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

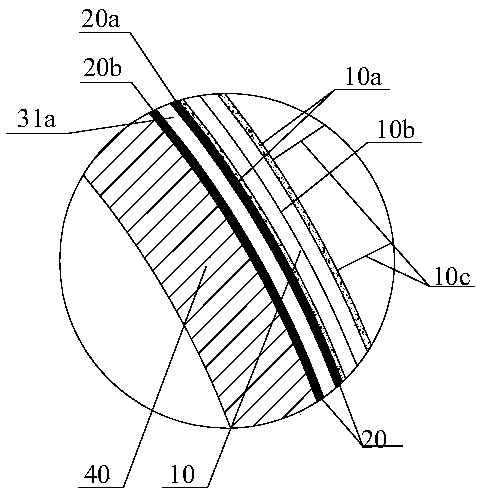

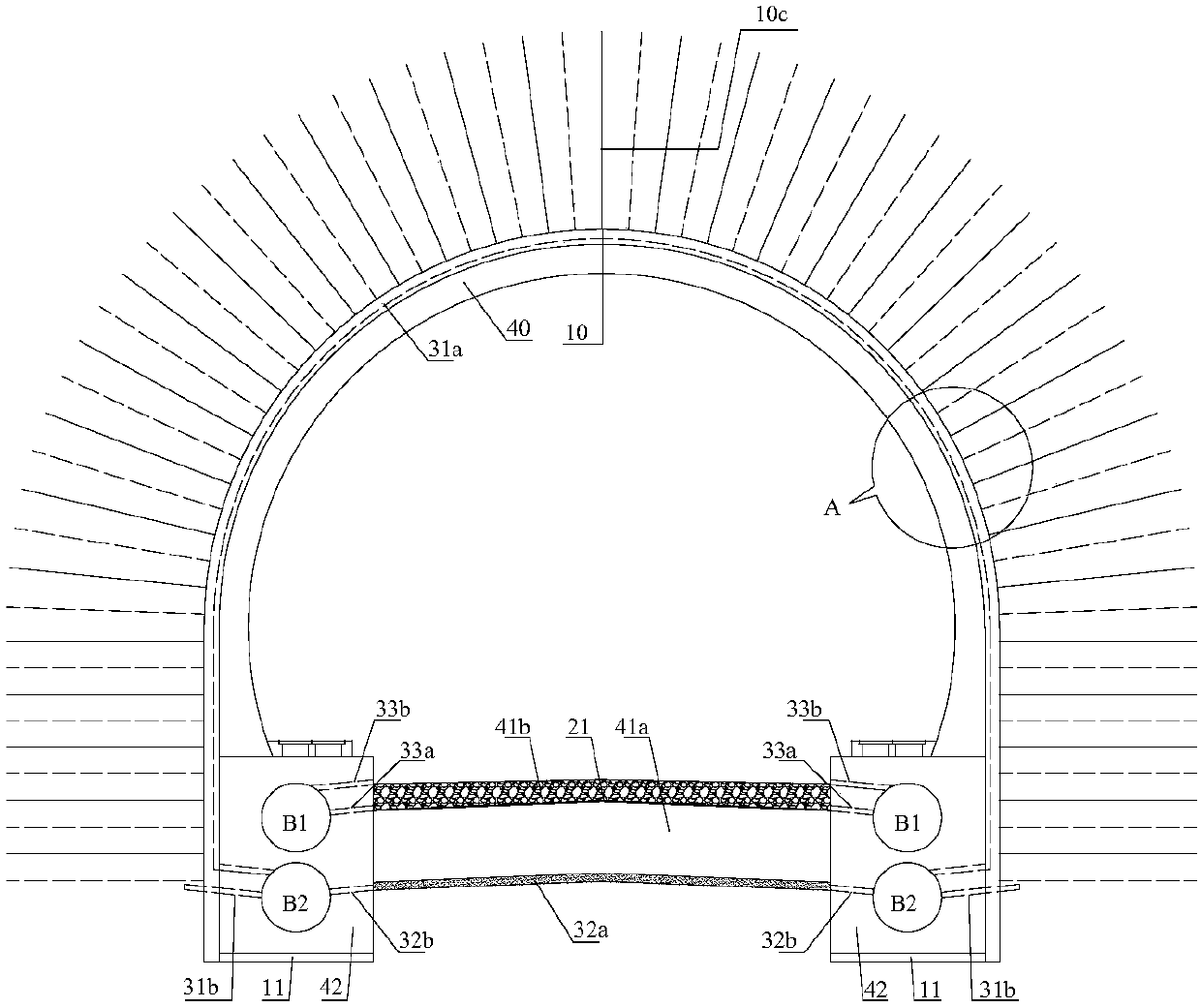

[0039] refer to figure 1 , the double-hole hollow rectangular section beam of the present invention bears the cutting-type arched tunnel lining structure and the separate drainage system, including the arch wall primary support structure 10, the arch wall secondary lining structure 40 and the arch wall range waterproof layer 20, and also includes drainage. system 30. The bottoms of the side walls on both sides of the secondary lining structure 40 of the arch wall are provided with longitudinal beams 42 that are consolidated with them, and the longitudinal beams 42 are rectangular cross-sections with an upper longitudinal cavity B1 and a lower longitudinal cavity B2. The longitudinal beams 42 not only serve as the bearing structure of the primary support structure 10 of the arch wall and the secondary lining structure 40 of the arch wall, but also serve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com