Patents

Literature

32results about How to "Control settlement deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

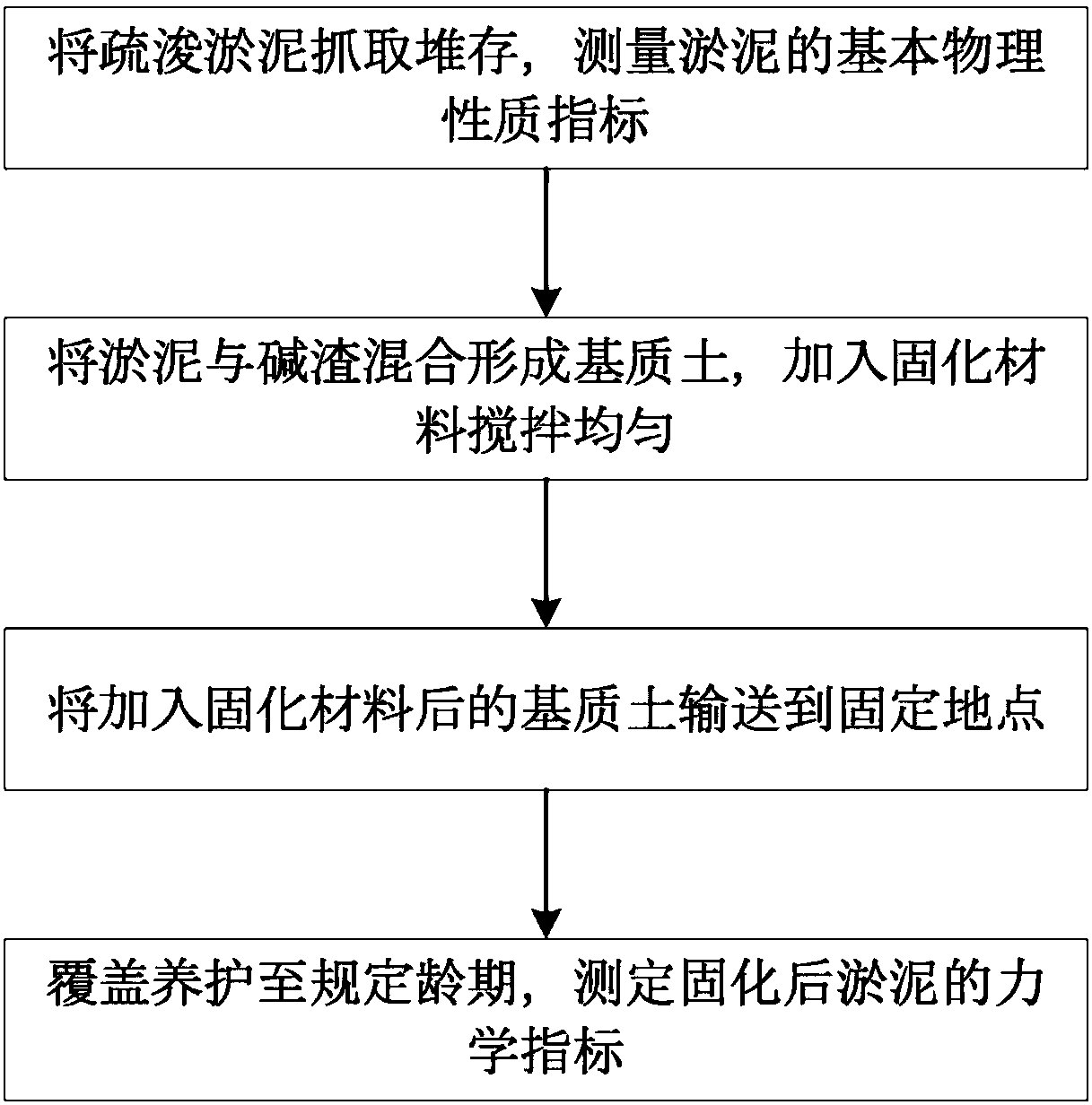

Method for solidifying sludge with high water content

InactiveCN108218317ARealize resource utilizationAchieve sustainable developmentFixation/solidifcation sludge treatmentSludgeMechanical index

The invention discloses a method for solidifying sludge with a high water content. At first, dredged sludge is collected and stored, basic physical indexes of sludge are measured, the sludge and alkali residues are mixed to form matrix soil; a curing material is added and then is evenly mixed and stirred; then the matrix soil containing the curing agent is transported to a fixed location; the matrix soil is covered and cured for a prescribed period; and finally the mechanical indexes of cured sludge are measured. The optimal ratio of alkali residues to dry sludge is 30-50:100. The curing material comprises following components in percentage by the weight of dry mixed soil: 10 to 25% of mineral powder, 0.1 to 0.5% of super absorbent resin, and 2 to 6% of sodium silicate. The cooperative effect between alkali residues and sludge with a high water content is utilized to form matrix soil; super absorbent resin is used to reduce the water content of sludge, the utilization rate of alkali residues is increased, the solidification cost is reduced, and the solidified soil has the advantages of high early strength and low compressibility and meets the engineering requirements of filling soil.

Owner:HUBEI UNIV OF TECH

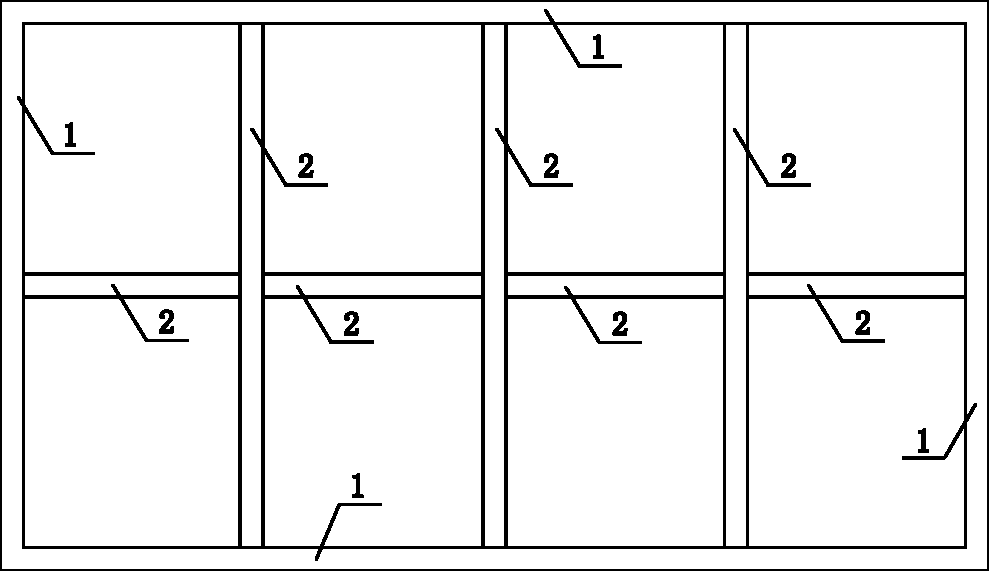

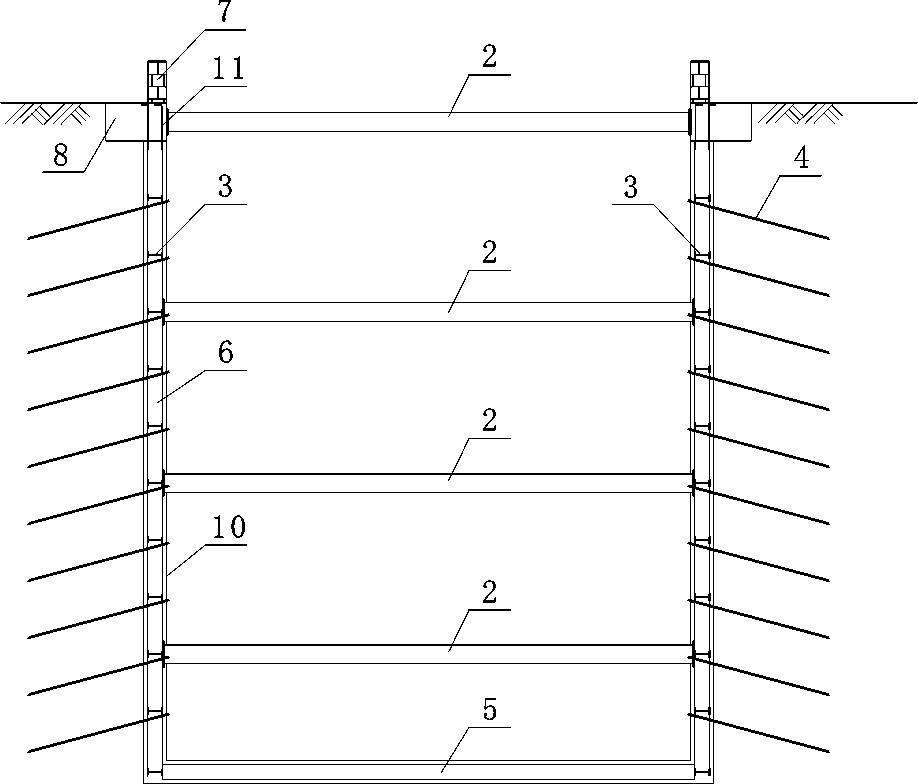

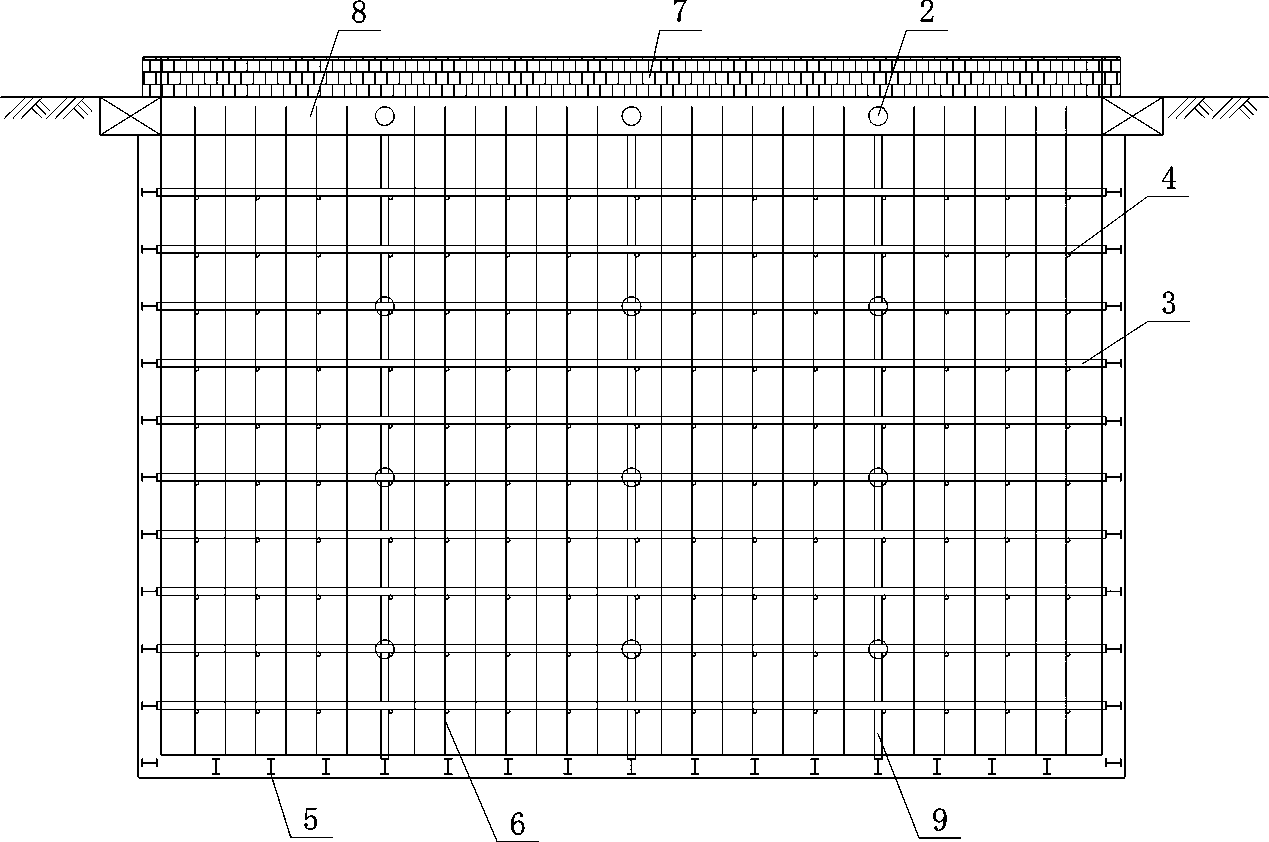

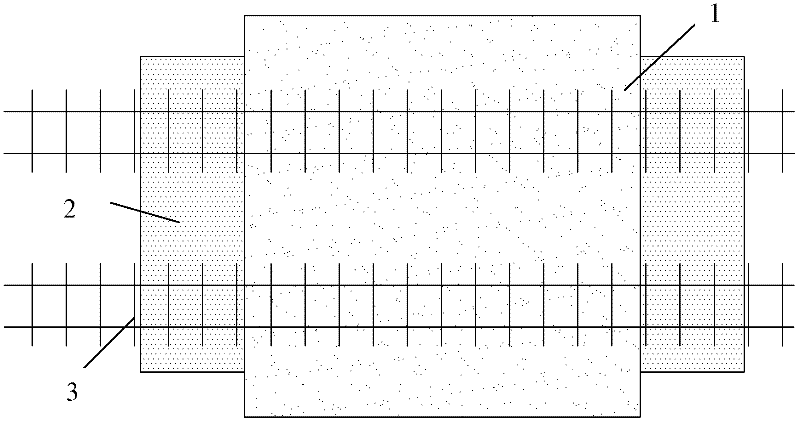

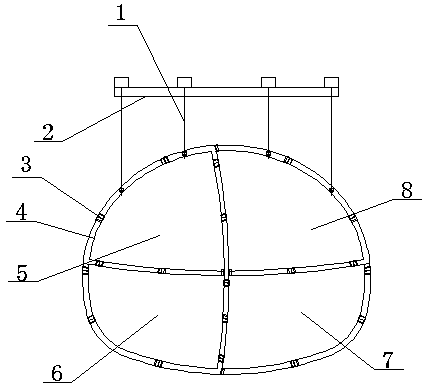

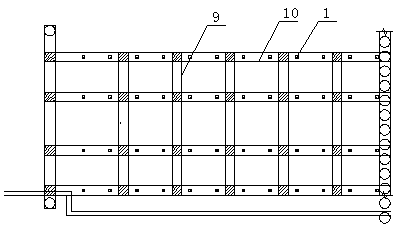

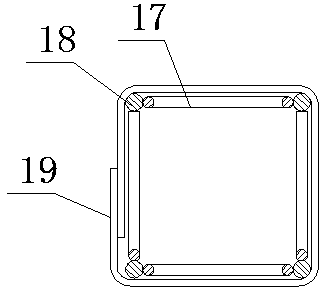

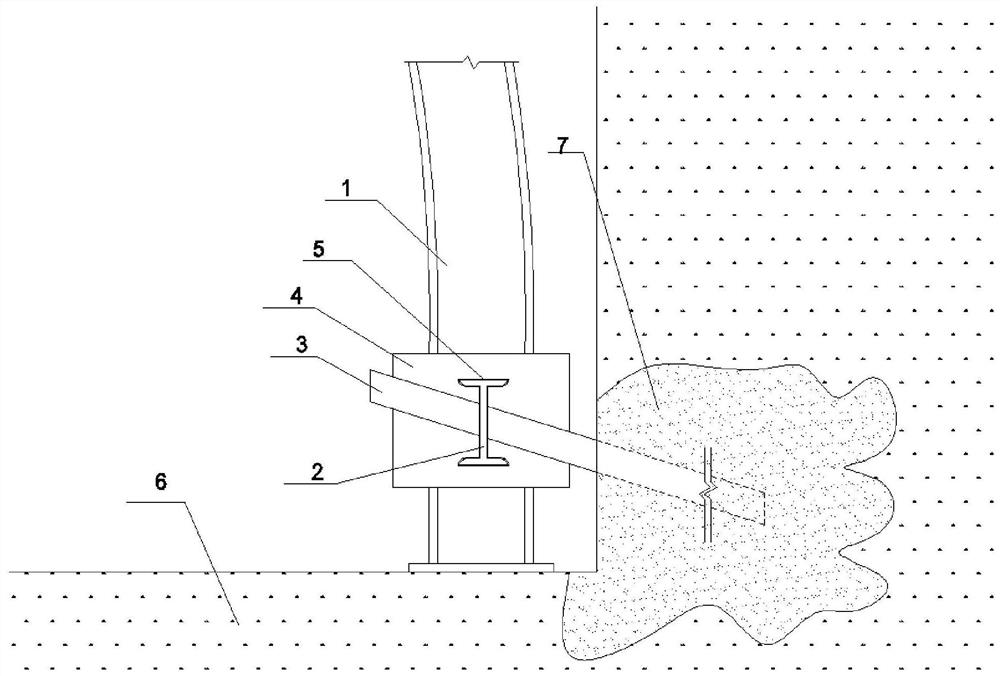

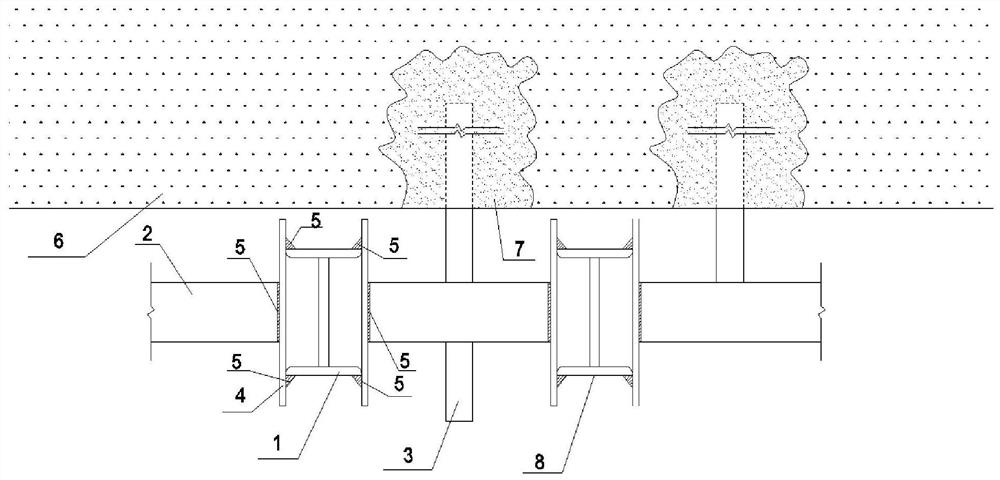

Combined lattice steel frame spray anchoring supporting method and combined lattice steel frame spray anchoring supporting structure

InactiveCN103469802AEasy to operate and constructEase of quality controlExcavationsPurlinReinforced concrete

The invention provides a combined lattice steel frame spray anchoring supporting method and a combined lattice steel frame spray anchoring supporting structure. The structure comprises a reinforced concrete top beam, an L-shaped connecting rib, lattice steel frames, a connecting rib, a horizontal inner supporter, a backing type steel hidden supporter, an advanced small conduit, a steel bar net sheet and sprayed concrete, wherein the advanced small conduit is provided with grouting holes, the lattice steel frames are formed by a plurality of sections of transverse H section steel and a plurality of sections of longitudinal section steel surrounding purlins, the horizontal inner supporter is erected between the lattice steel frames arranged at two sides of a foundation pit, and the backing type steel hidden supporter is arranged at the foundation bottom of the foundation pit. The method and the structure have the beneficial effects that the lattice steel frames are processed section by section on the ground and are combined and mounted in the pit, the operation construction is convenient, and the quality control is convenient; the support structure is excavated and supported one house rack by one house rack from top to bottom, the construction does not need large-scale mechanical equipment and can be completed through manual work, and the construction cost is low; the occupied operation are is very small, and the method and the structure are mainly suitable for the small-foundation-pit-excavation-area foundation pit support which has the square, striped and round plane shape and is convenient for inner supporter arrangement.

Owner:CHINA FIRST METALLURGICAL GROUP

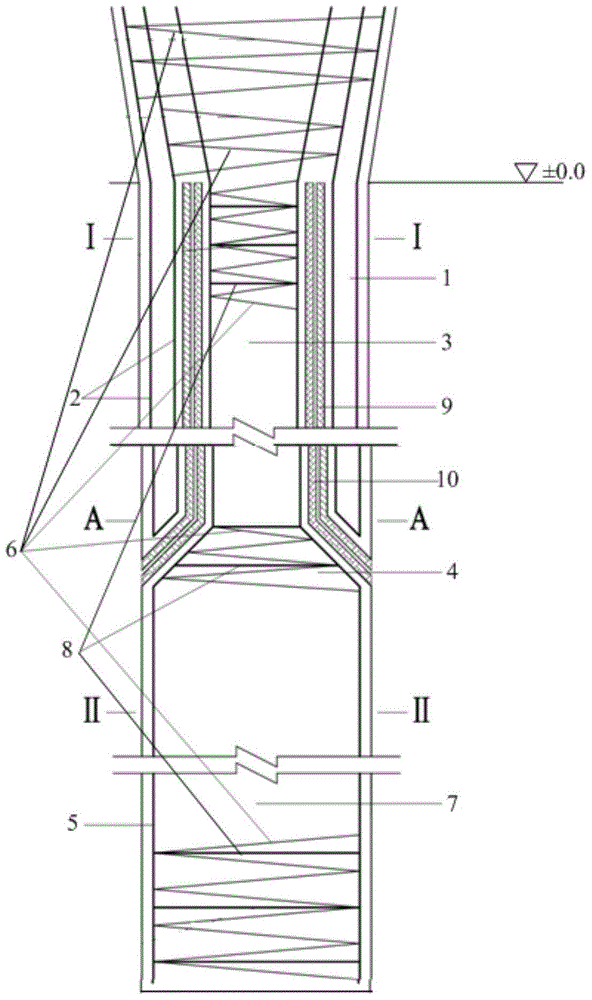

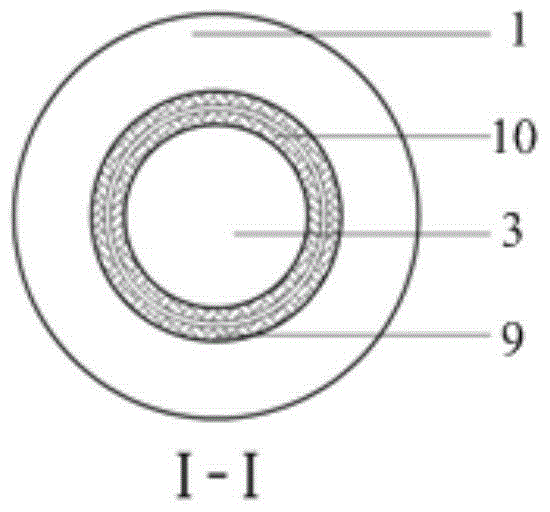

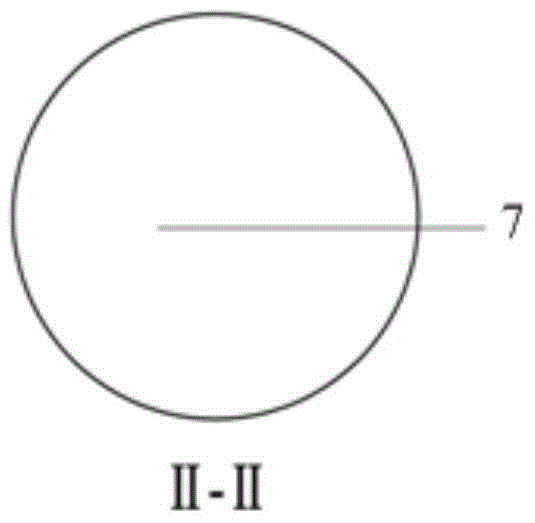

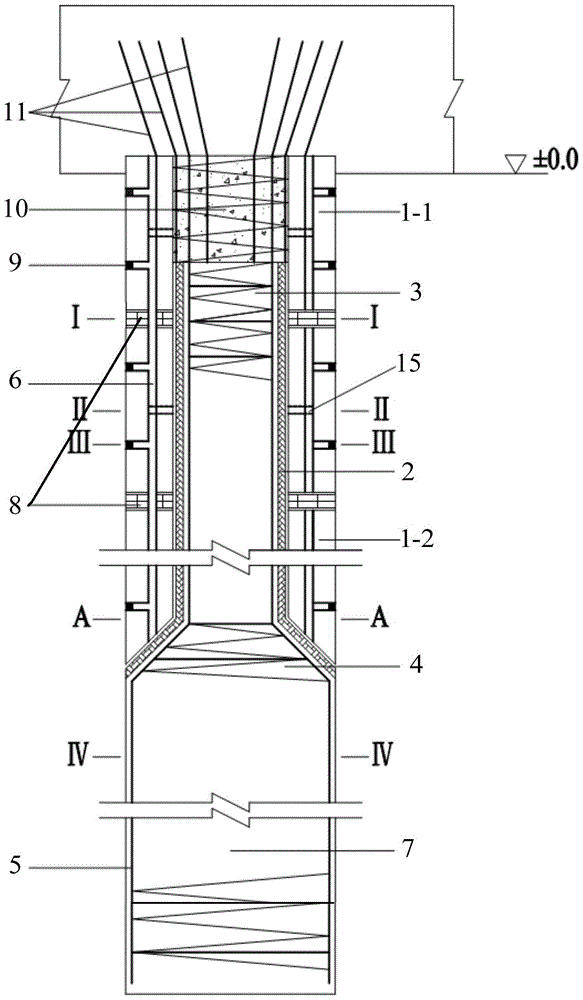

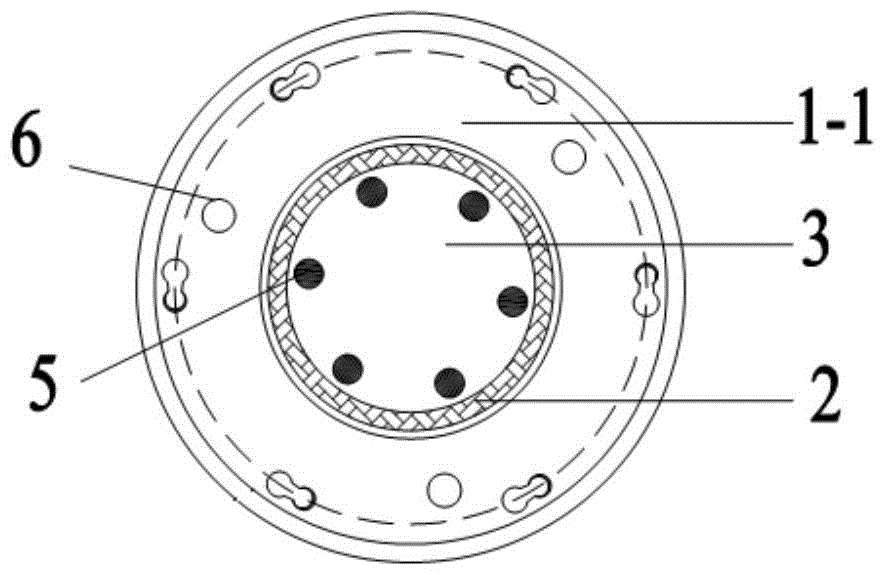

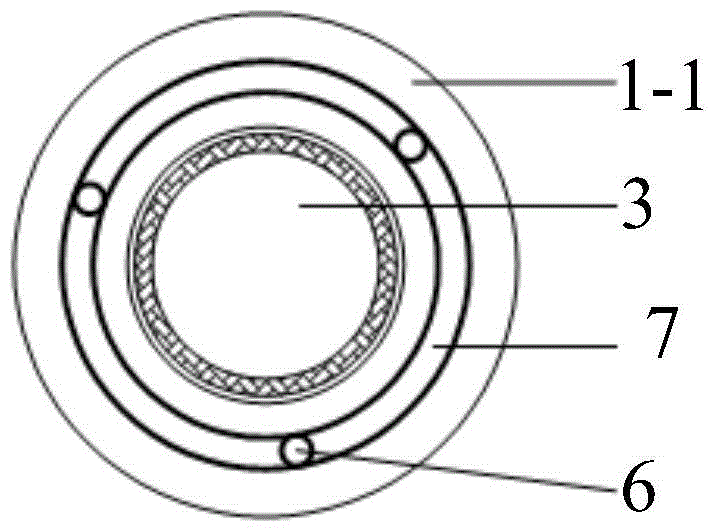

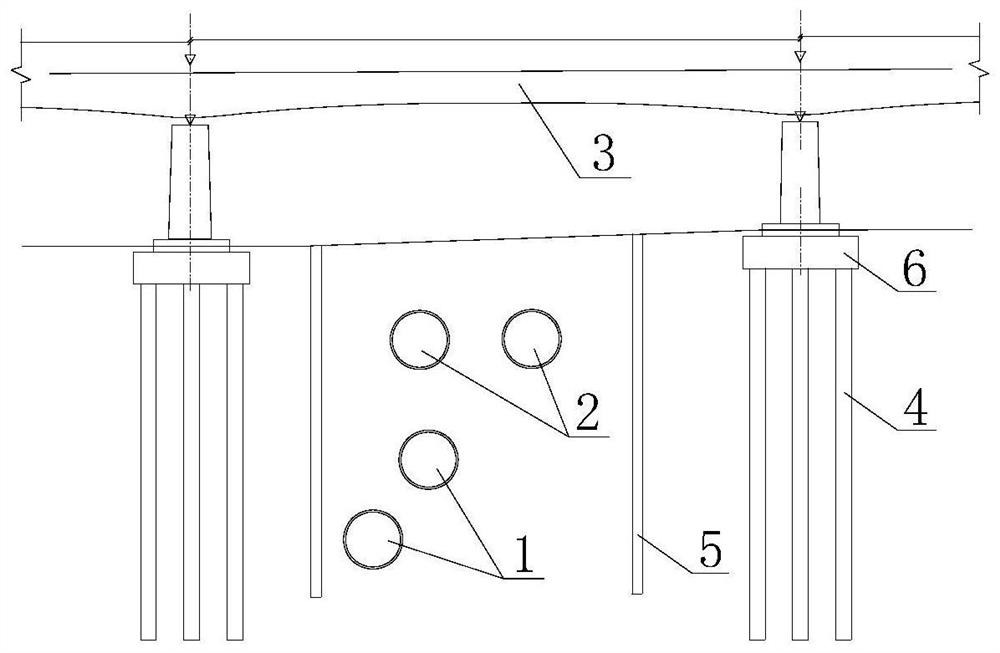

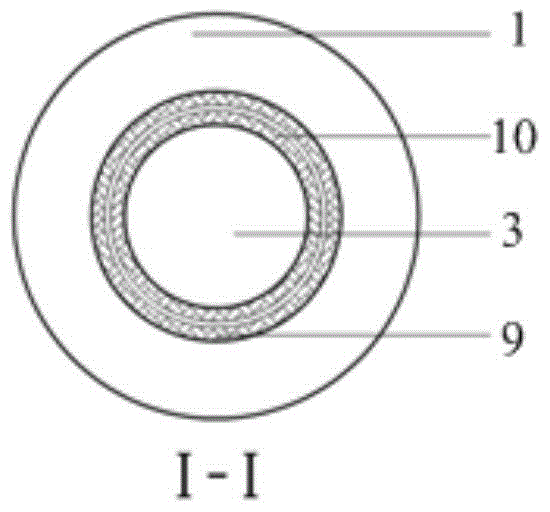

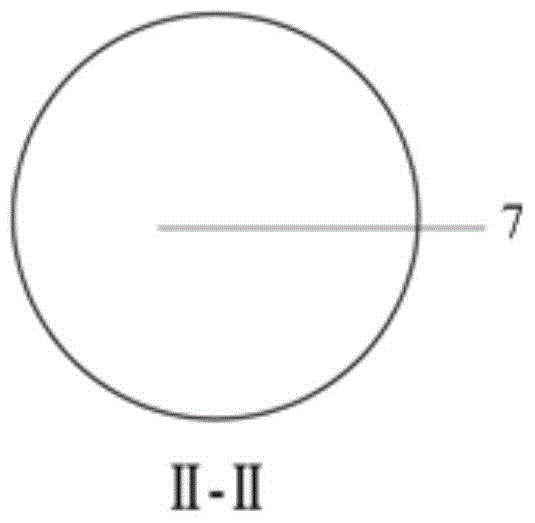

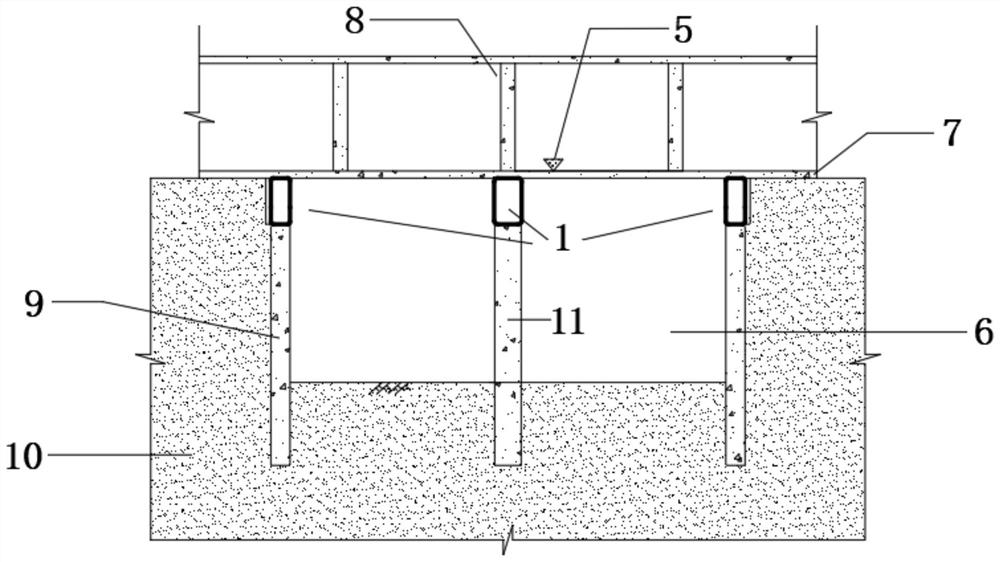

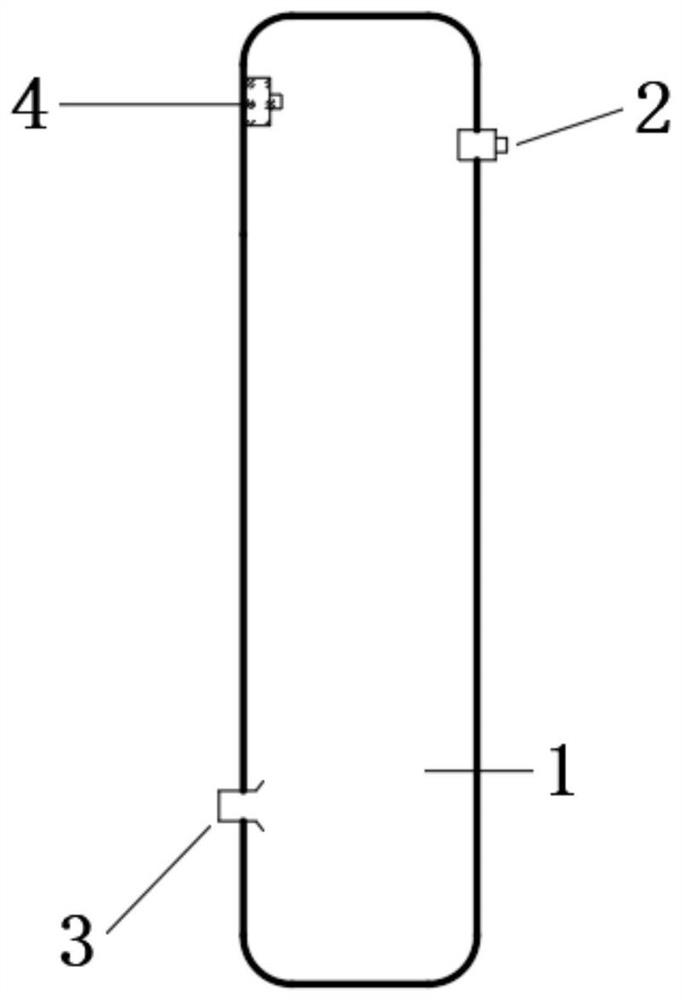

Friction pile and construction method thereof

The invention relates to the technical field of architectural engineering, and especially relates to a friction pile and a construction method thereof, in particular to a large-diameter super-long friction pile capable of fully achieving friction force of an upper side and a lower side of a foundation pile and end resistance of the foundation pile. The friction pile comprises an upper pile body, a lower pile body and a separation formwork arranged between the upper pile body and the lower pile body. An annular bevel body is arranged at the bottom of the upper pile body, and the lower pile body comprises a force transferring structural segment, a variable-section structural segment and a bearing structural segment which are sequentially connected from top to bottom. The upper pile body is arranged outside the force transferring structural segment in a sleeving mode, the bottom of a reinforcement cage of the upper pile body matches the variable-section structural segment, and the separation formwork is arranged between the upper pile body and the force transferring structural segment. On the premise that the settling volume at the top of the pile meets the deformation requirement of an upper structure, the bearing performance of whole-pile-length side friction force and pile end resistance can be fully achieved, and therefore the overall bearing capacity of the friction pile is improved; under the same upper loads, the needed pile length or pile diameter is smaller, settlement deformation of the pile top can be effectively controlled, and then engineering cost is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

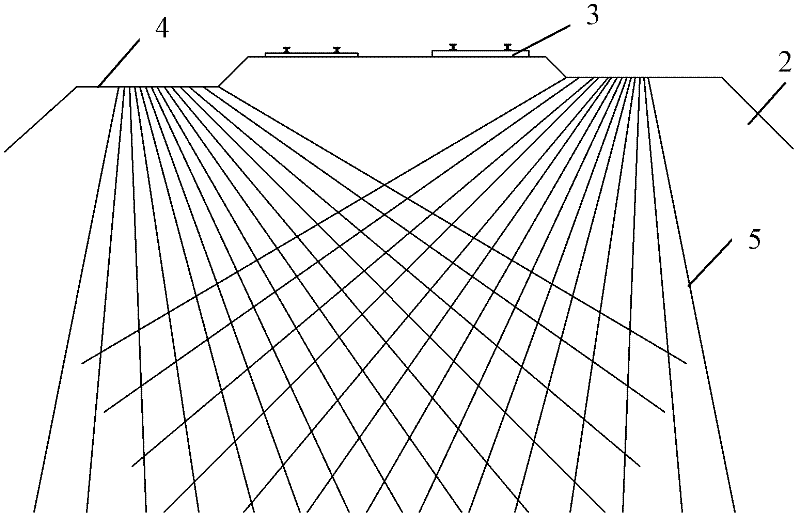

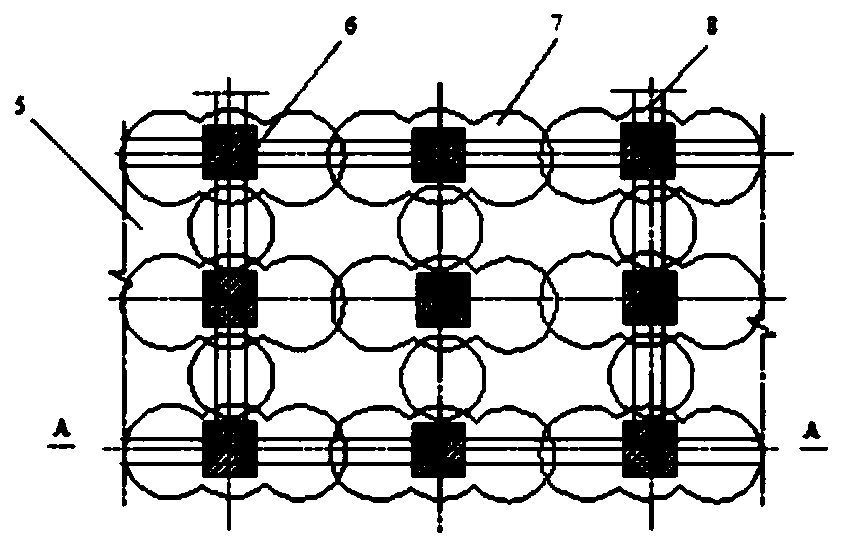

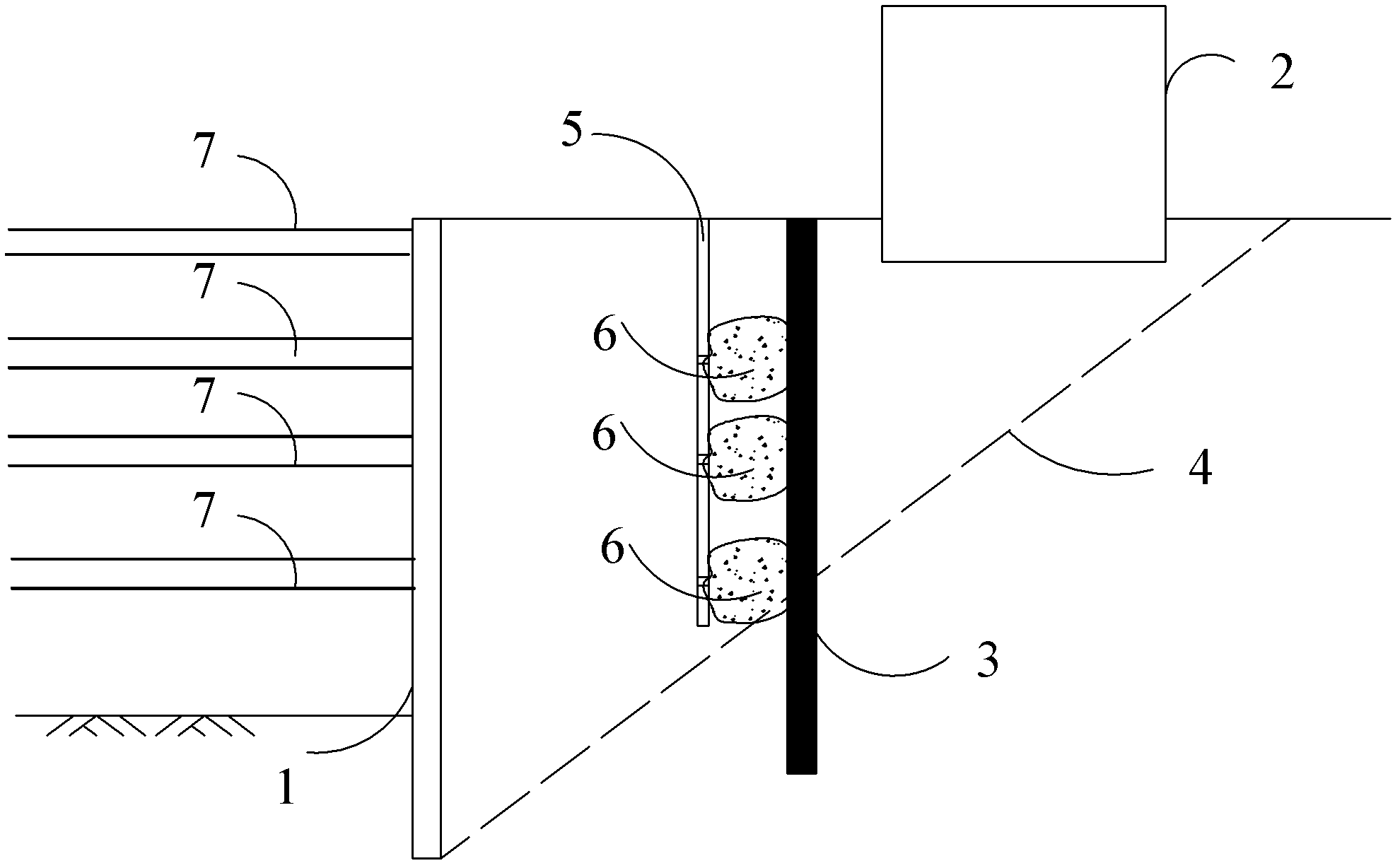

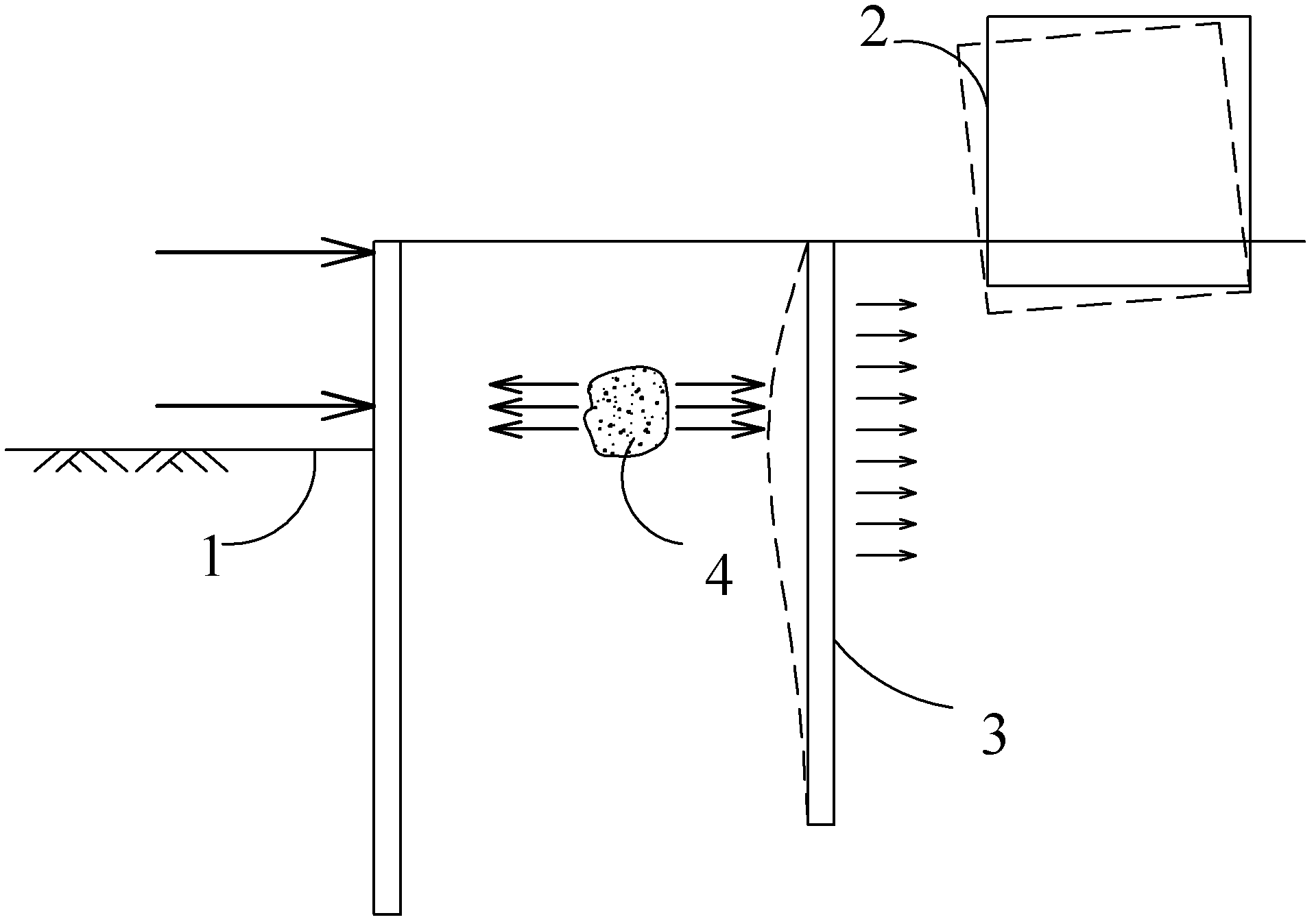

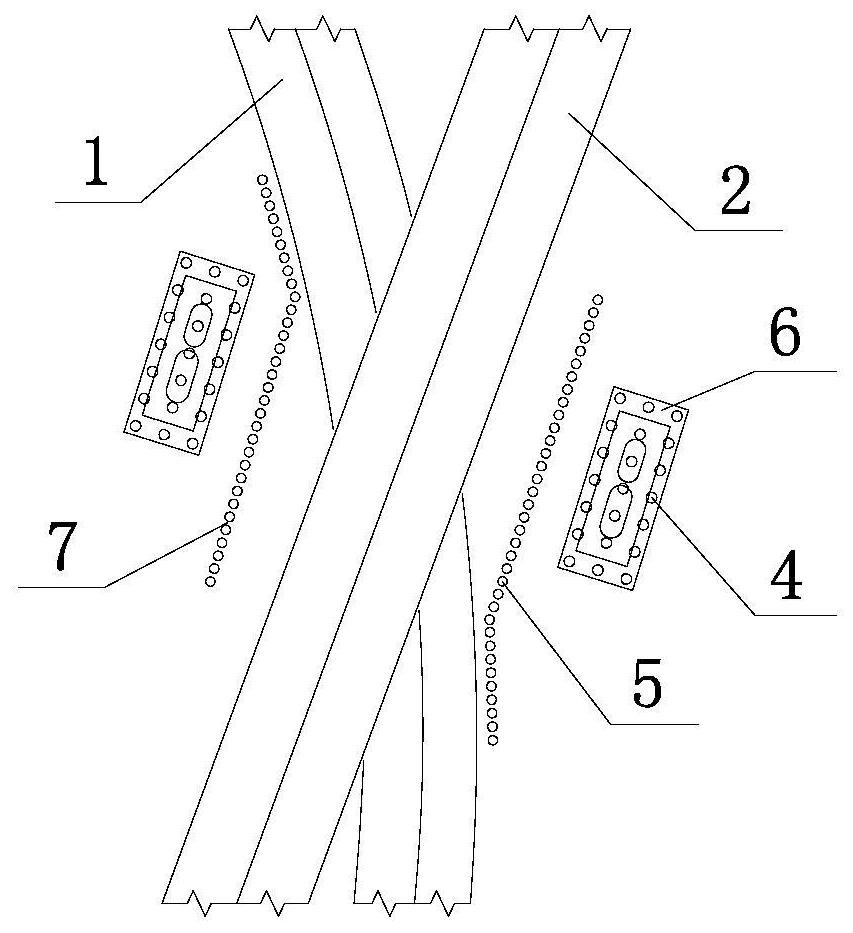

Road and bridge transition section grouting construction method used during jacking construction

InactiveCN102392402AControl settlement deformationImprove driving safetyRoadwaysFoundation engineeringEconomic benefitsFluid level

The invention relates to a road and bridge transition section grouting construction method used during jacking construction. According to the method, with a drilling pipe, a plurality rows of scallop grouting holes are drilled from railway shoulders on two sides of a road and bridge transition section towards the lower part of the railway with an inclined downward scallop manner; when one hole is produced, the drilling pipe is fetched, a shock tunnel is inserted into the hole, and grouting fluid is injected; when the grouting fluid level is 2 meters far from the ground, grouting is stopped, a grouting port is sealed, and the next hole is proceeded; an included angle range of the grouting scallop area relative to a subgrade plane is 15-75 DEG, and an adjustment range of adjacent two grouting holes 5 is 5 DEG. With the road and bridge transition section grouting construction method provided by the invention, road and bridge transition sections can be strengthened without breaking normal railway operation; the work space is small; the operation is convenient; and subsidence deformation of the road and bridge transition sections can be effectively controlled, such that uneven subsidence between the road and bridge transition sections and mass boxes can be prevented. Therefore, the method is beneficial for traffic security and personal security of a railway, and provides substantial economic benefits.

Owner:CHINA RAILWAY SIXTH GROUP +1

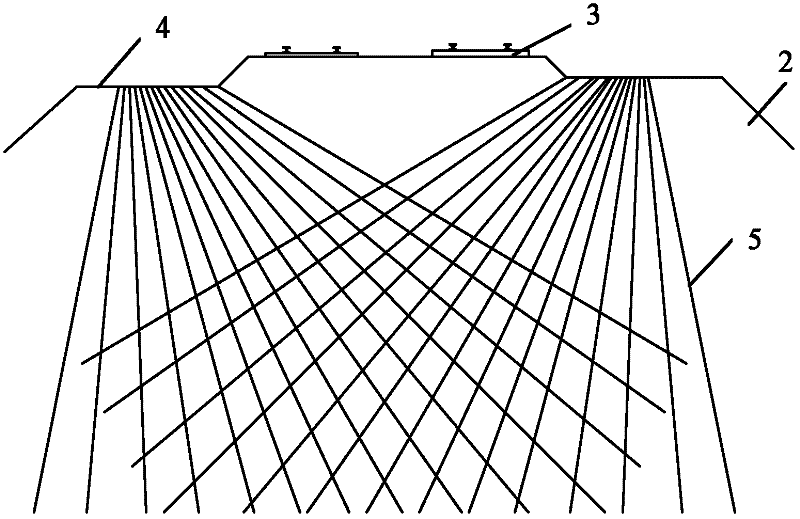

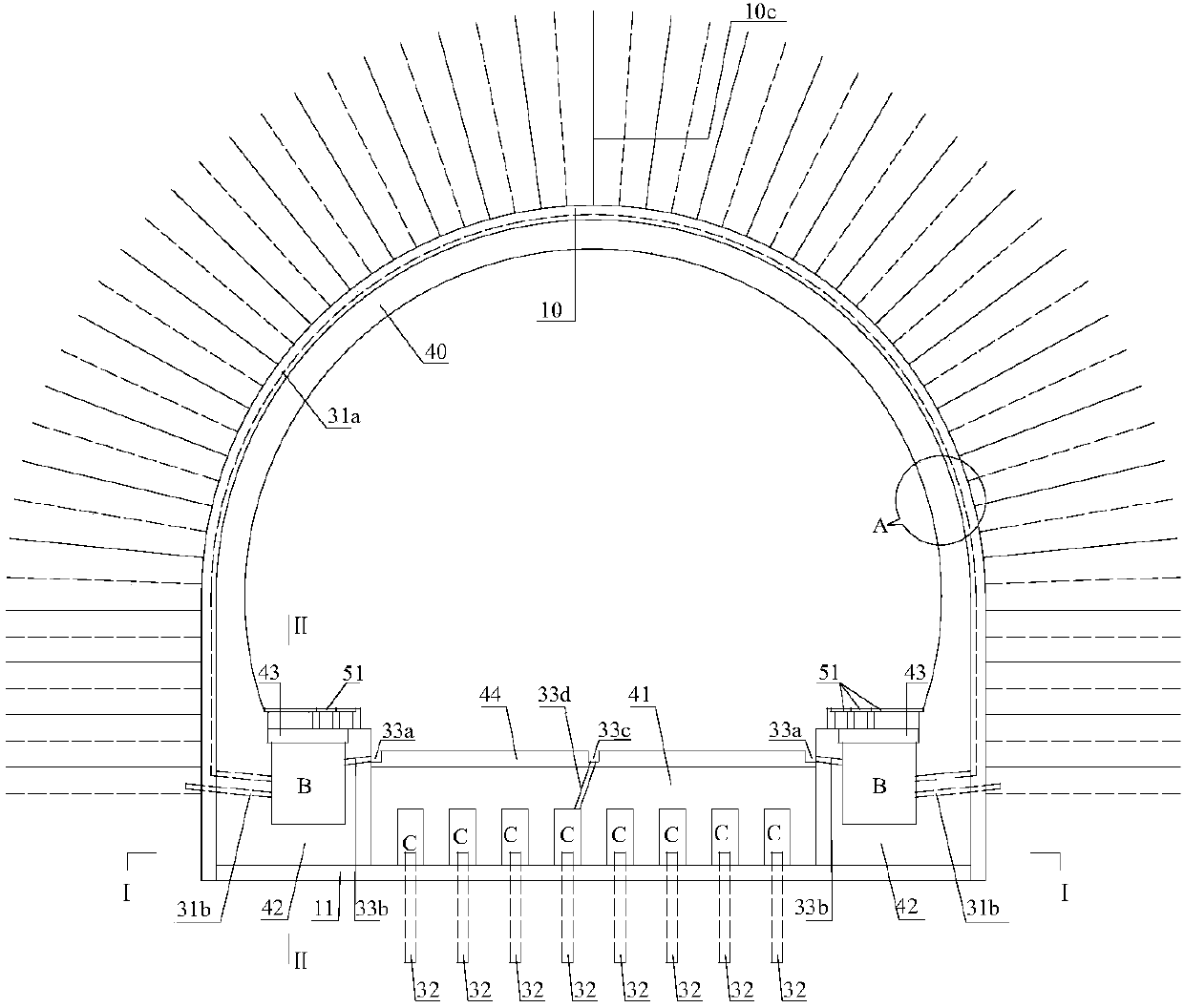

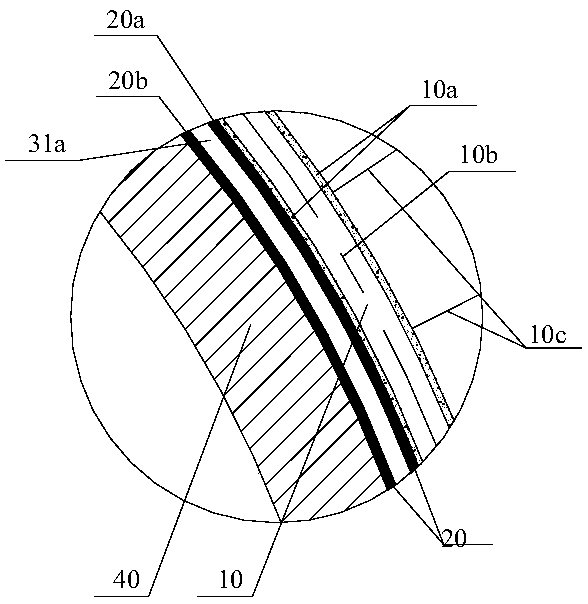

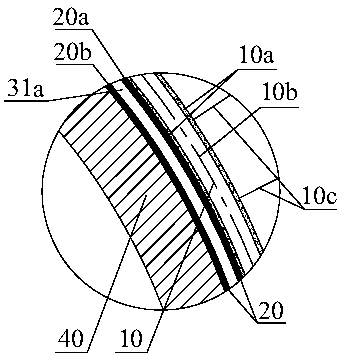

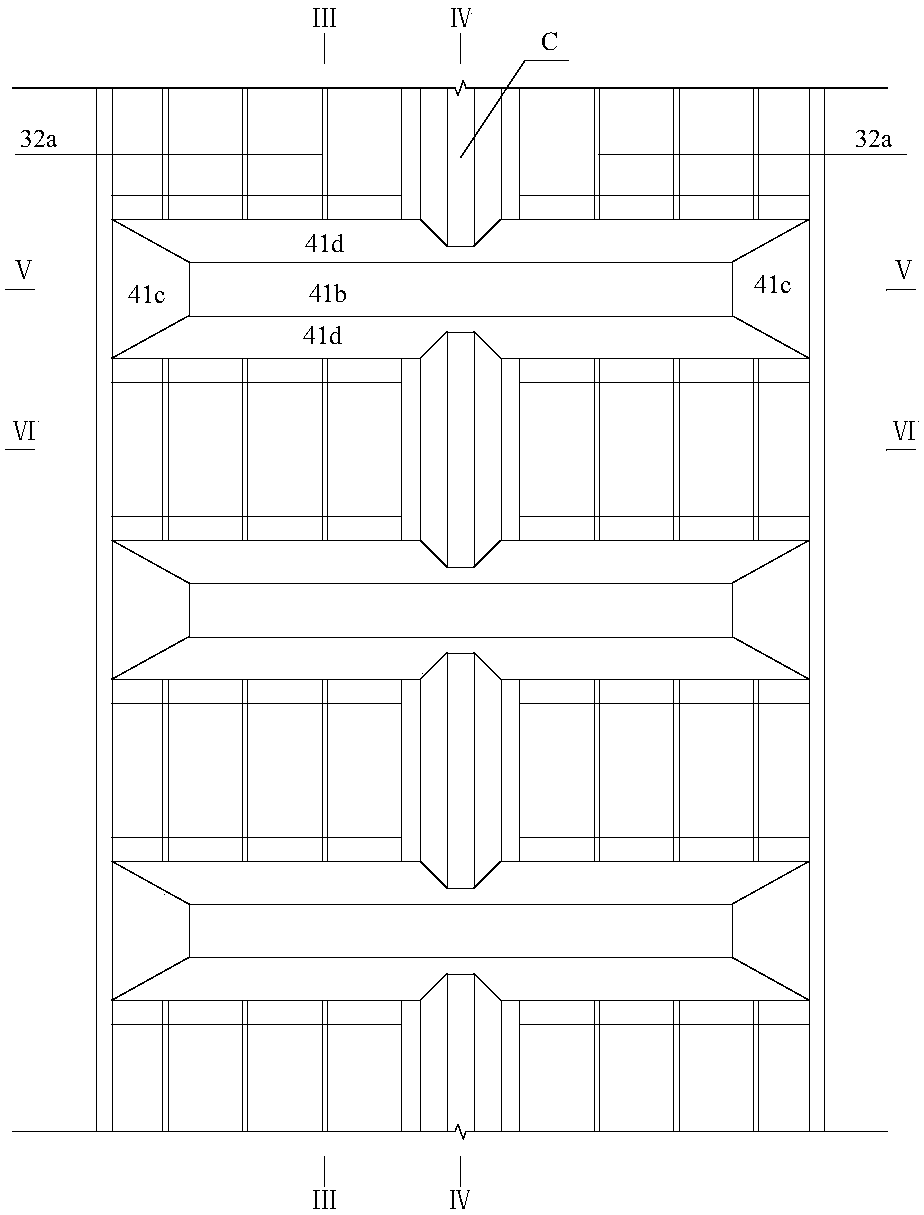

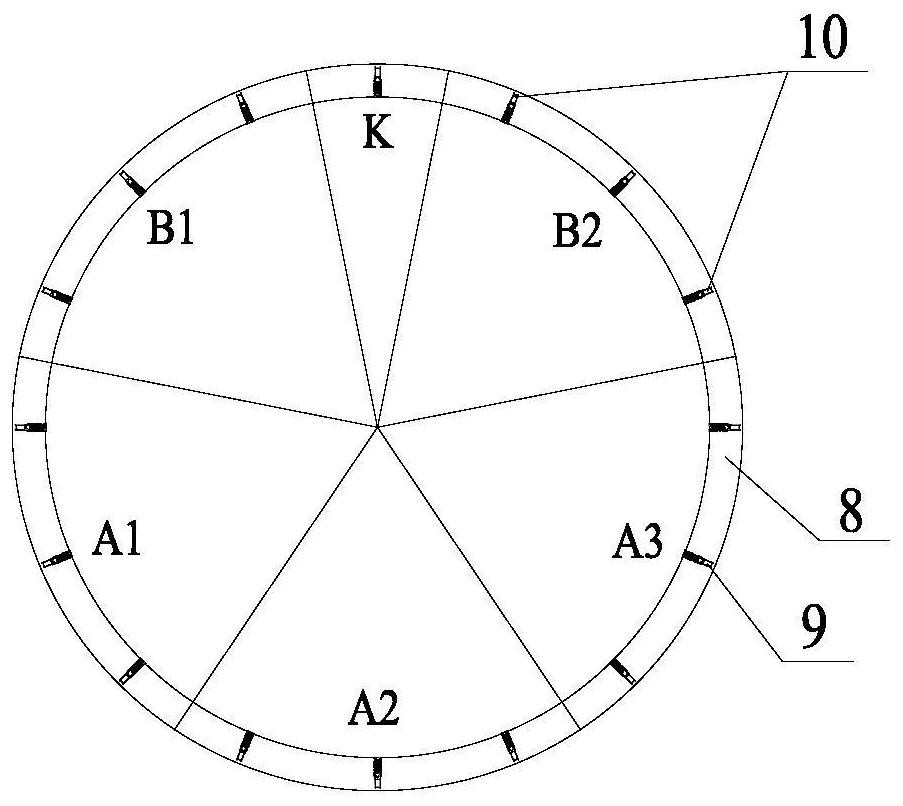

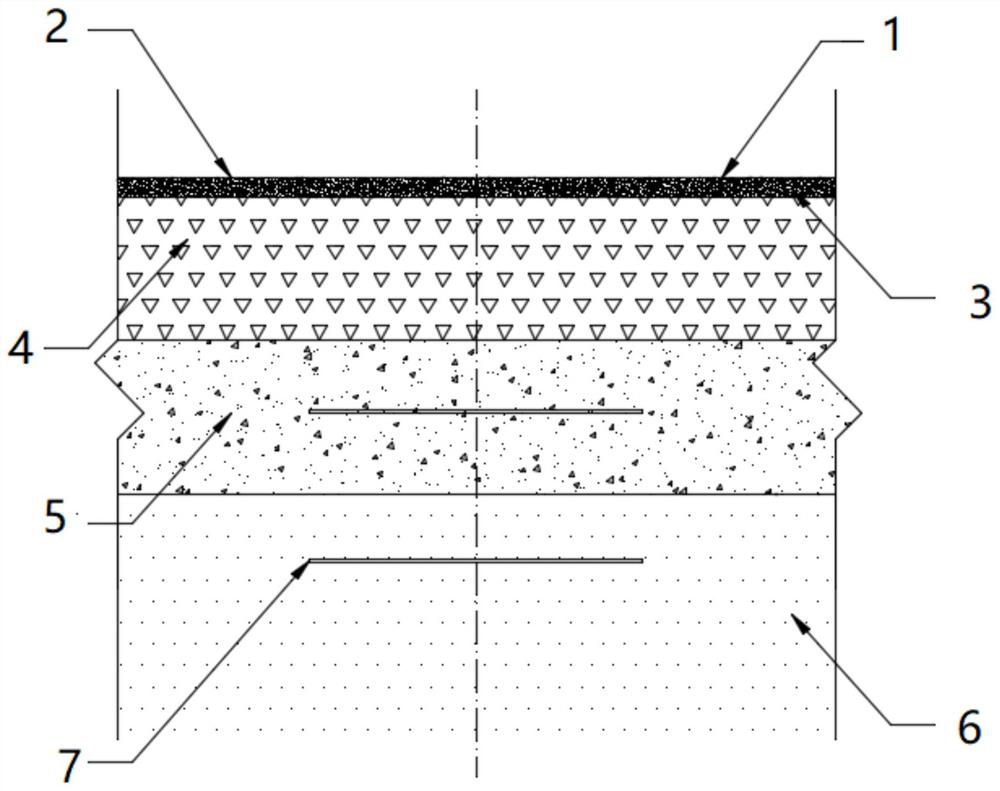

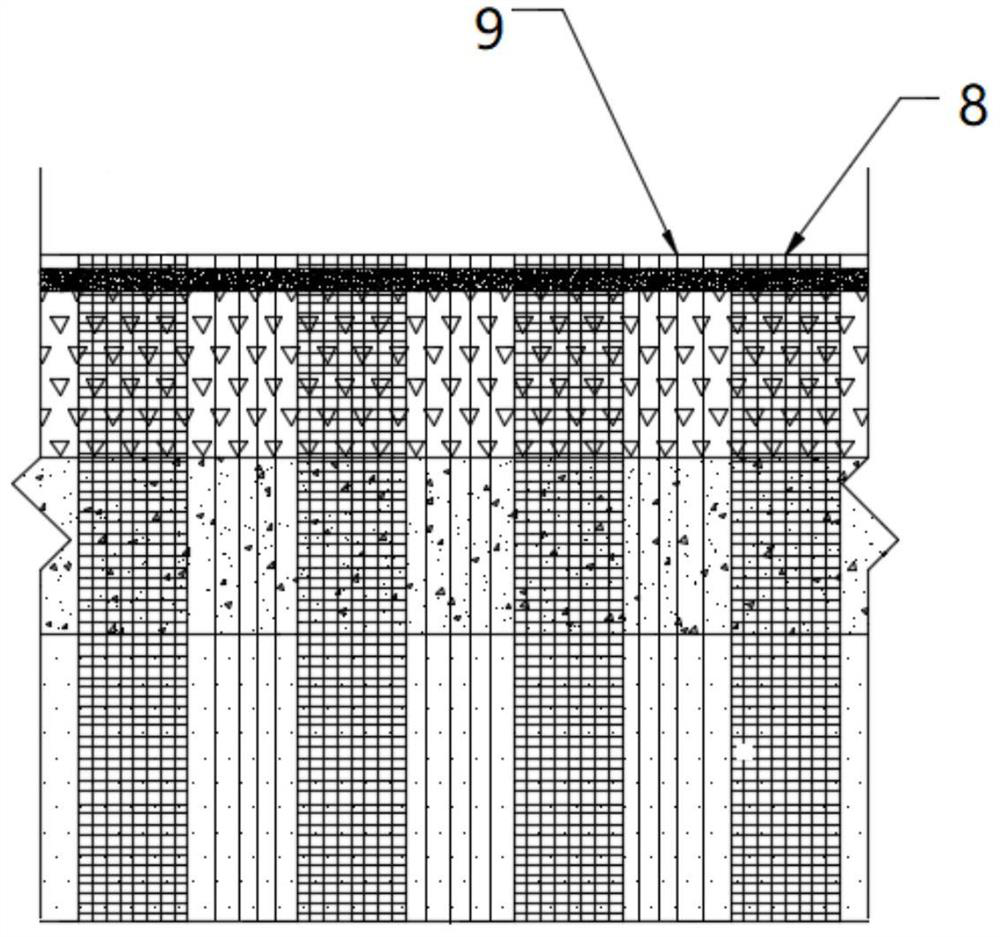

Construction structure and construction method for controlling settlement of shallow-buried and underground-excavated large-section tunnel

PendingCN111472790ASmall settlement deformationAvoid settlement deformationUnderground chambersTunnel liningArchitectural engineeringMesh reinforcement

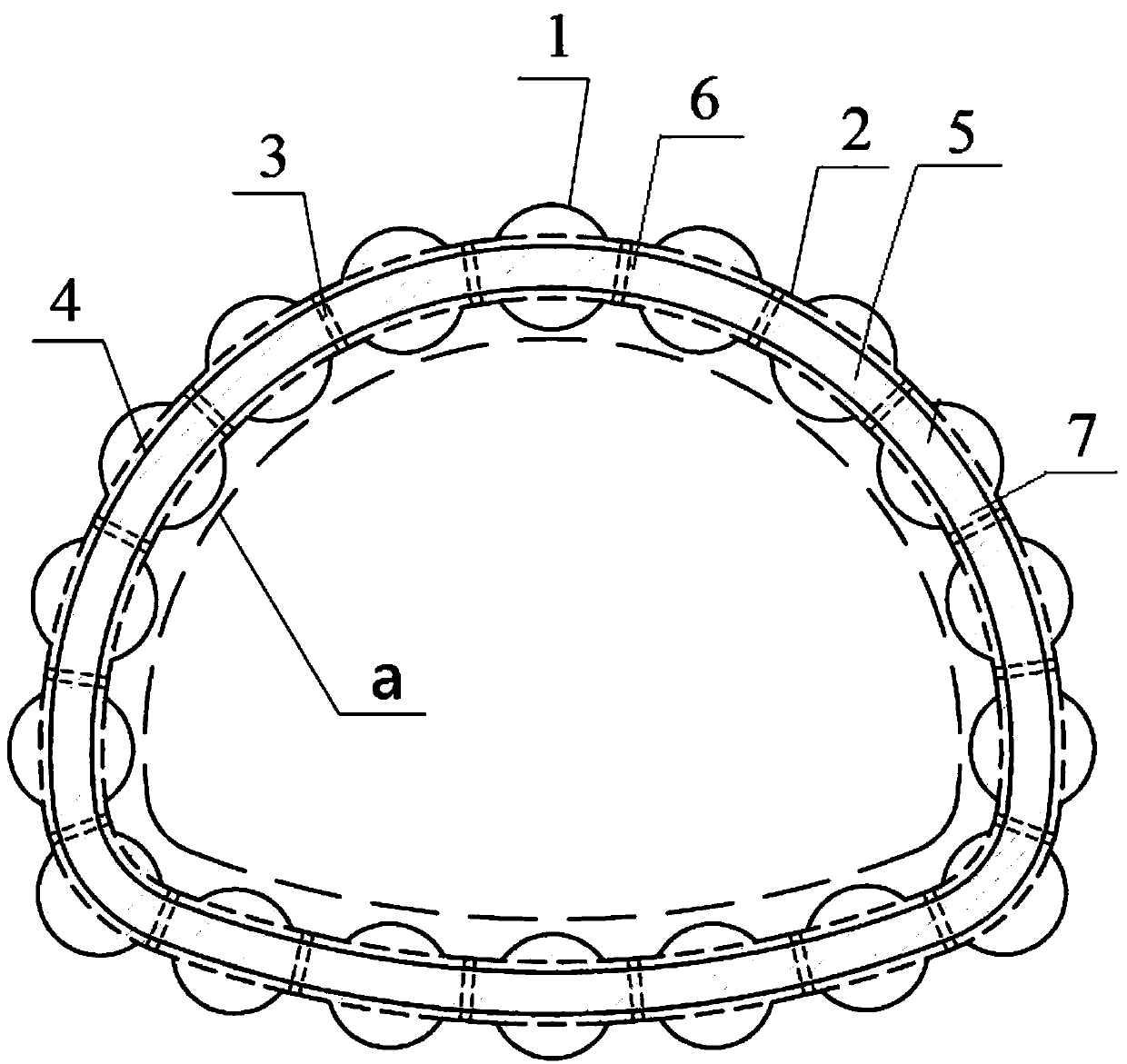

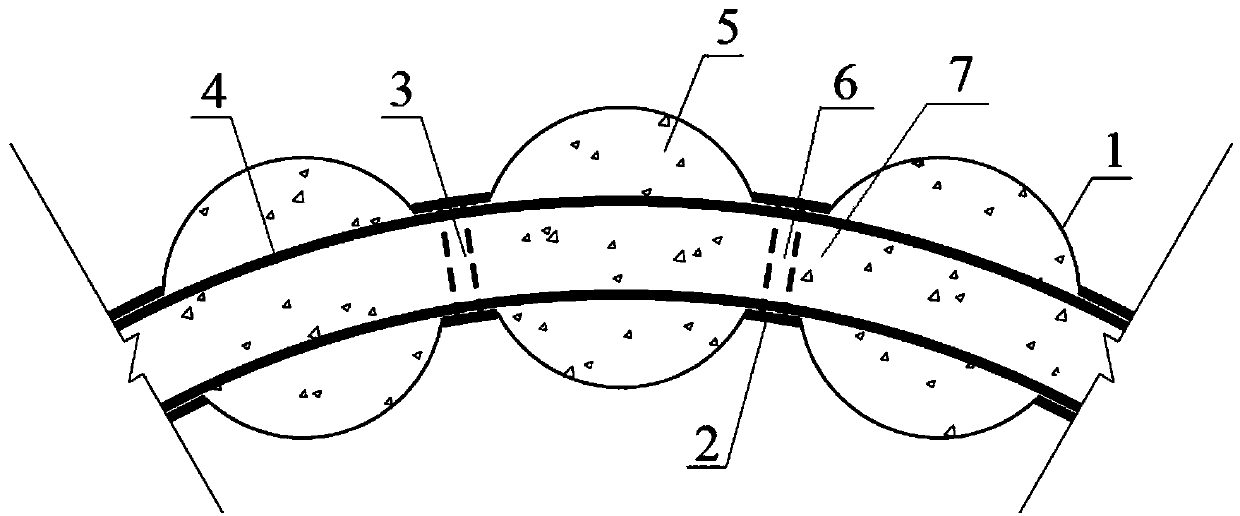

The invention discloses a construction structure and a construction method for controlling settlement of a shallow-buried and underground-excavated large-section tunnel. A full-section method has thedefects that the stability of surrounding rock is reduced due to a large excavation surface, and a double-side-wall heading method is safe in construction, but low in speed and high in cost. The construction structure comprises an oval structure defined by four fan-shaped chambers and ground steel beams (2) laid on the ground, wherein a supporting structure is arranged outside each fan-shaped chamber in a surrounding mode, each supporting structure is composed of two layers of reinforcing meshes (4) arranged outside the corresponding fan-shaped chamber and a plurality of reinforcing grids (3)laid between the two layers of reinforcing meshes, and a plurality of locking anchor rods (1) are arranged on the ground steel beams, pass through holes in the ground and then are welded in the reinforcing grids. The construction structure and the construction method are used for controlling the settlement of the shallow-buried and underground-excavated large-section tunnel.

Owner:中交哈尔滨地铁投资建设有限公司 +2

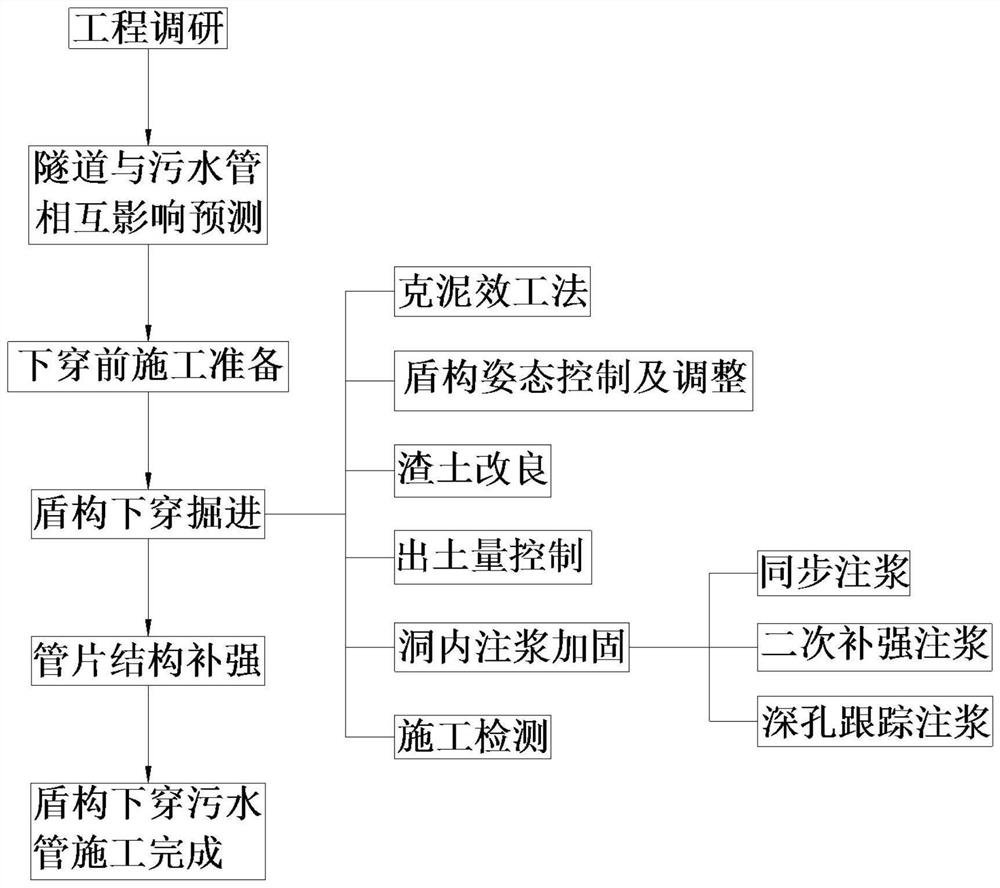

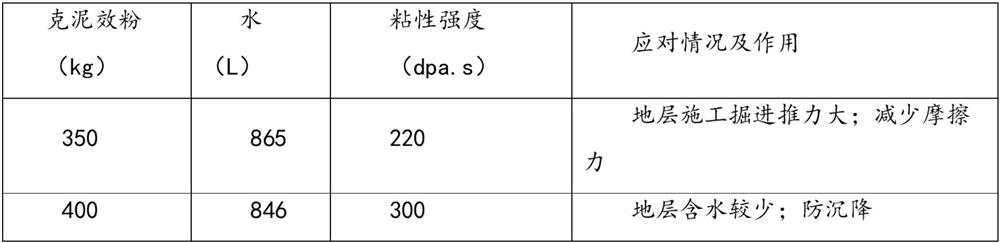

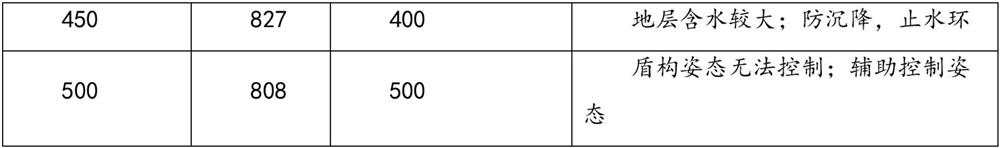

Construction method for earth pressure balance shield to pass through large-diameter sewage main pipe underground

InactiveCN111706341AReduce casualtiesReduce economic lossMining devicesUnderground chambersStatistical analysisSewage

The invention relates to the technical field of shield construction, in particular to a construction method for an earth pressure balance shield to pass through a large-diameter sewage main pipe underground, and is used for solving the problems of high construction difficulty, high risk and great casualties and economic loss easily caused by improper control when the shield passes through the large-diameter sewage main pipe underground in the prior art. The construction method comprises the following steps that 1, engineering investigation is carried out, an underwater color television and a geological radar are adopted; 2, the mutual influence of a tunnel and a sewage pipe is predicted, deformation analysis is carried out by adopting a stratum I structure model; 3, construction preparation before underneath pass is carried out, comprehensive statistical analysis is carried out by adopting a 60m experimental section; and 4, shield underneath pass tunneling is carried out, and stratum settlement is controlled through a clay shock method. According to the construction method for the earth pressure balance shield to pass through the large-diameter sewage main pipe underground, the construction difficulty and the corresponding risk can be effectively reduced through engineering investigation, prediction of the mutual influence of the tunnel and the sewage pipe, construction preparation before underneath pass and shield underneath pass tunneling, and therefore casualties and economic losses can be reduced.

Owner:郑州地铁集团有限公司

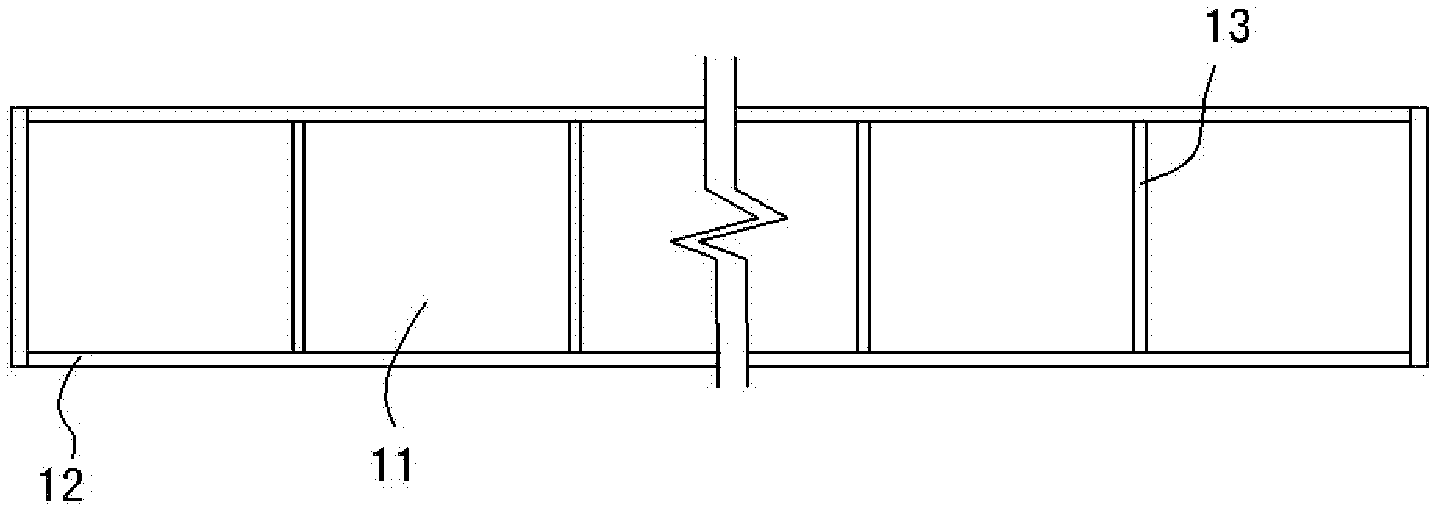

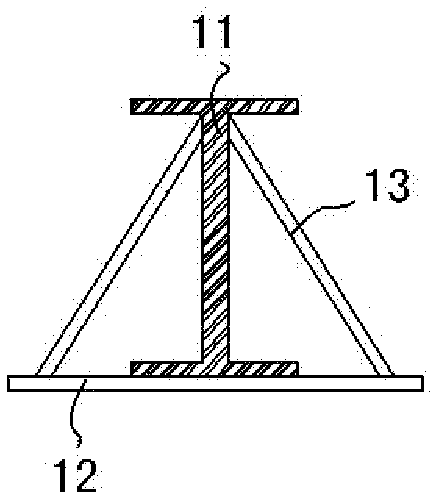

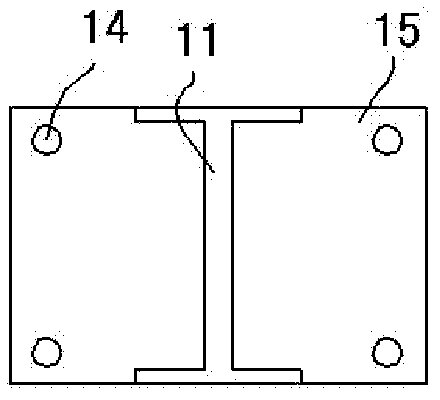

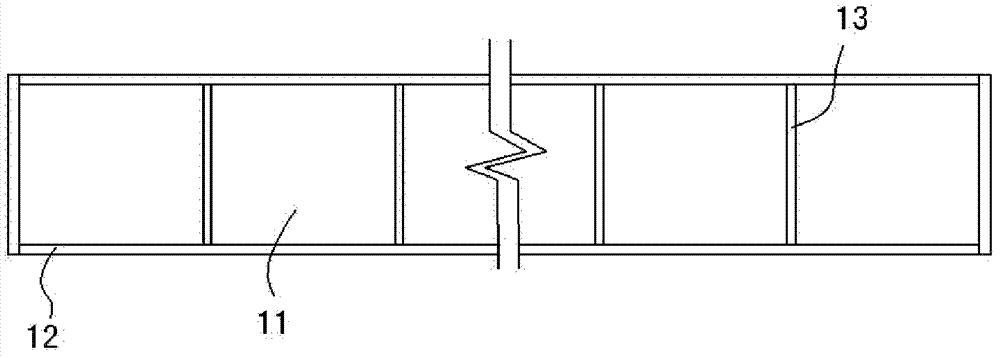

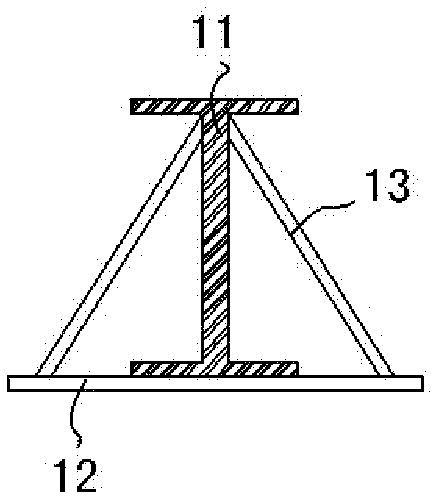

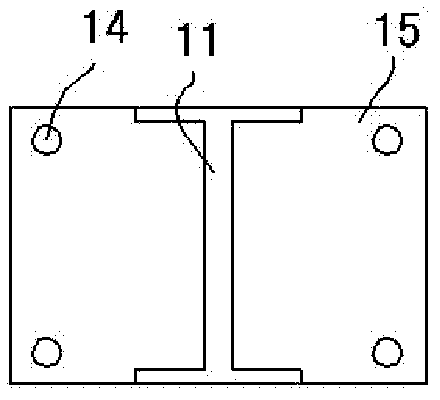

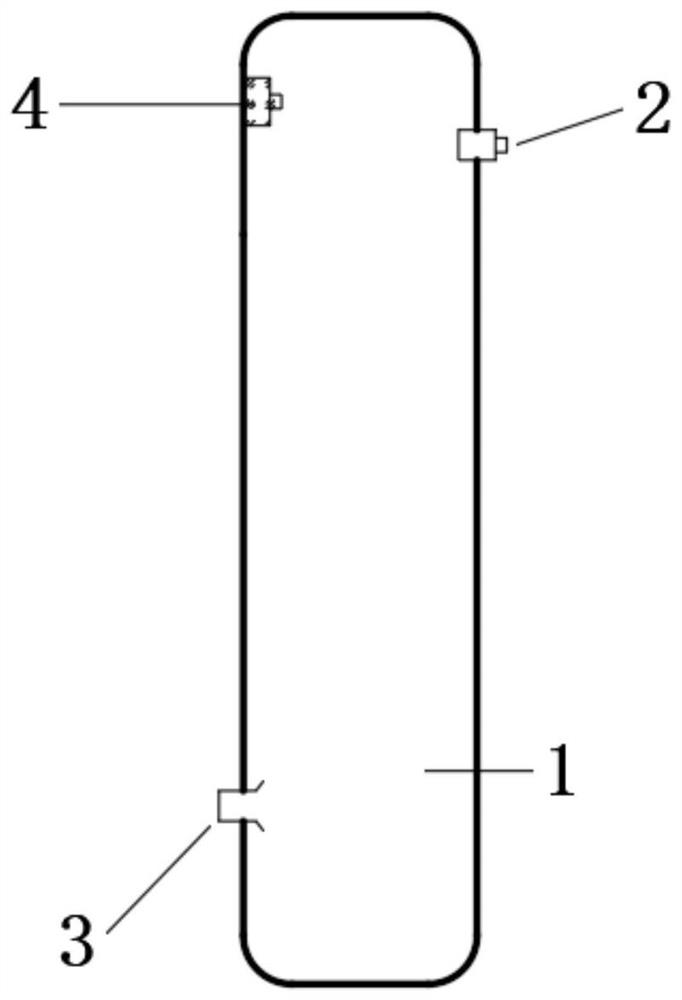

Tunnel steel temporary inverted arch with rapid assembly and disassembly

ActiveCN102562098AControl convergenceControl settlement deformationUnderground chambersTunnel liningConstruction wasteTunnel construction

The invention discloses a tunnel steel temporary inverted arch with rapid assembly and disassembly, which is characterized in that each temporary inverted arch arranged is formed by fixed joints positioned in the middle, movable joints positioned at both ends of the fixed joints and connection joints connected between the fixed joints and the movable joints; and the fixed joints, the movable joints and the connection joints are arranged in a split mode. With the tunnel steel temporary inverted arch, tunnel convergence and settlement and deformation can be effectively controlled, the tunnel steel temporary inverted arch can be conveniently and quickly dismantled after completing desired functions and can be reused, other inputs are not increased so that the tunnel construction cost is greatly reduced. Construction waste is not formed, amounts of dust and high decibel noise are not generated during installation and dismantling, excellent construction environment is supplied for the internal construction of the tunnel, and the construction security is improved.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

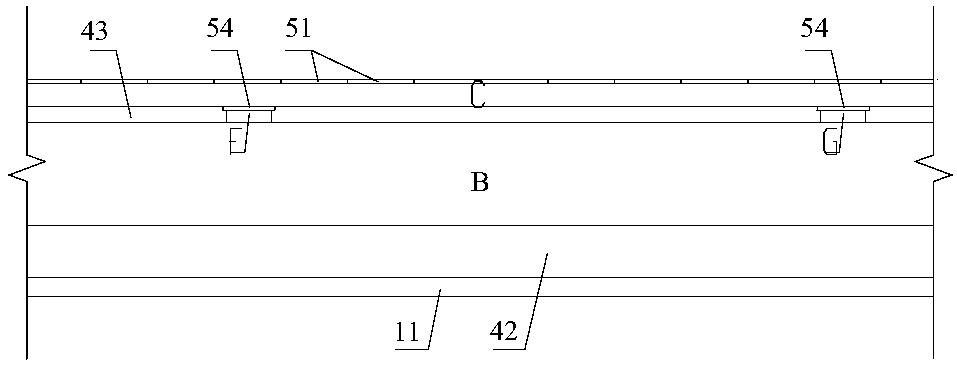

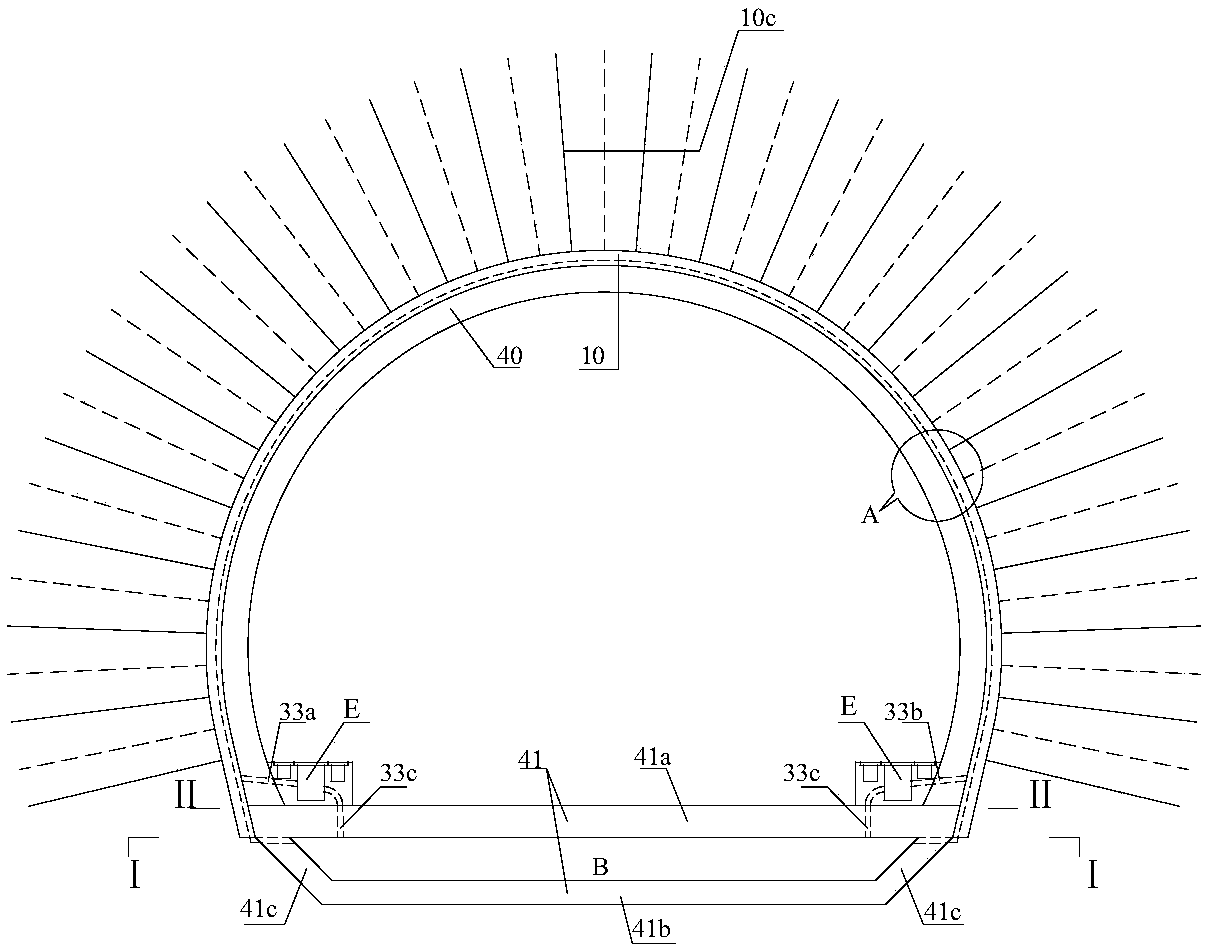

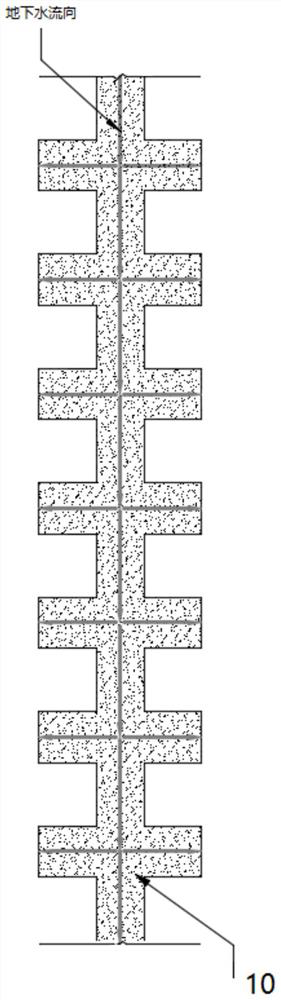

Boot last base comb-type tunnel bottom lining structure and drainage system thereof

PendingCN107905810AOvercoming the difficulty of controlling the excavation curvatureEasy to excavateUnderground chambersDrainageKarstGroundwater

The invention discloses a boot last base comb-type tunnel bottom lining structure and a drainage system thereof. The effect of underground water on a tunnel lining bottom structure is reduced or eveneliminated, the problem of karst or underground water development region tunnel inverted arch floating deformation or tunnel bottom structure cracking and damage is solved, and the tunnel constructionand operation stability and safety are ensured. The bottoms of side walls on the two sides of an arch wall secondary lining structure are provided with bases fixedly connected with the arch wall secondary lining structure, the bases are adopted as bearing structures of the arch wall secondary lining structure, and a longitudinal-through boot inner cavity inside the structure is adopted as a tunnel longitudinal drainage channel. A comb-type tunnel bottom structure with the two transverse sides in weak connection with the bases are arranged between the boot-shaped bases on the two sides, a paving bottom layer is arranged on the comb-type tunnel bottom structure, the lower portion of the comb-type tunnel bottom structure is provided with a transversely-spaced and longitudinal-through lower cavity as a tunnel bottom underground water longitudinal drainage channel. The arch wall range drainage system is communicated with the boot inner cavity, the tunnel bottom drainage system is communicated with the lower cavity, and a ballast bed accumulated water drainage system is communicated with the boot inner cavity and the lower cavity.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Combined arched tunnel lining of inversely truncated-cone-shaped hollow tunnel bottom and drainage system structure thereof

PendingCN107905812AOvercoming the difficulty of controlling the excavation curvature and other problemsEasy to excavateUnderground chambersDrainageKarstDitch

The invention discloses a combined arched tunnel lining of an inversely truncated-cone-shaped hollow tunnel bottom and a drainage system structure thereof in order to reduce and even eliminate the effect of underground water on the bottom structure of the tunnel lining, effectively solve the problems that tunnels in karst or underground water development areas inversely arch, come up and deform ortunnel bottom structures are cracked and damaged, and ensure the stability and safety of construction and operation of the tunnels. Tunnel bottom construction bodies are arranged below the bottoms oftwo side walls of an arch-wall secondary lining structure to serve as a bearing structure; each tunnel bottom construction body is of an inversely truncated-cone-shaped hollow structure and is formedby integrally pouring upper bottom plates, transverse webs at two sides, lower bottom plates and longitudinal webs, and tunnel bottom cavities are formed longitudinally at intervals in the tunnel bottom construction bodies, wherein the lower bottom plates and the longitudinal webs are arranged longitudinally at intervals. Central water ditches which are longitudinally communicated are formed along the longitudinal centers of the lower brims of the plate surfaces and communicated with all the tunnel bottom cavities. The drainage system includes a drainage system communicated with the tunnel bottom cavities within an arched-wall range, a tunnel bottom drainage system and an in-tunnel drainage system.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Red sandstone layer waterproof spraying anchor support method and waterproof device

The invention discloses a red sandstone layer waterproof spraying anchor support method. The red sandstone layer waterproof spraying anchor support method comprises the following steps: a, earthwork between piles is vertically layered and horizontally excavated in a sectioned mode; b, after vertical layering and horizontal sectioned excavation, the excavation face is excavated again in the direction perpendicular to a foundation pit support face, and thus pile bodies are exposed; c, a plastic cloth is fixedly arranged in a vertical pit excavated in the step b; and d, C20 fine stone concrete with the thickness being not smaller than 80 mm is sprayed on a steel bar mesh in the step c. The invention further discloses a waterproof device of the red sandstone layer waterproof spraying anchor support method. The device comprises the plastic cloth, the plastic cloth is vertically mounted on a stone body wall face between the support piles, a steel bar skeleton is fixedly mounted outside the plastic cloth, a grass curtain is fixedly mounted outside the steel bar skeleton, and the steel bar mesh is fixedly mounted outside the grass curtain. The problems that due to the characteristics of stone soil of a red sandstone layer, after red sandstone is supported, the support face is often difficult to support, or generates cracks and even bumps and then falls off due to water seepage of a cobble layer at the top of the red sandstone layer are solved.

Owner:甘肃建研建设工程有限公司

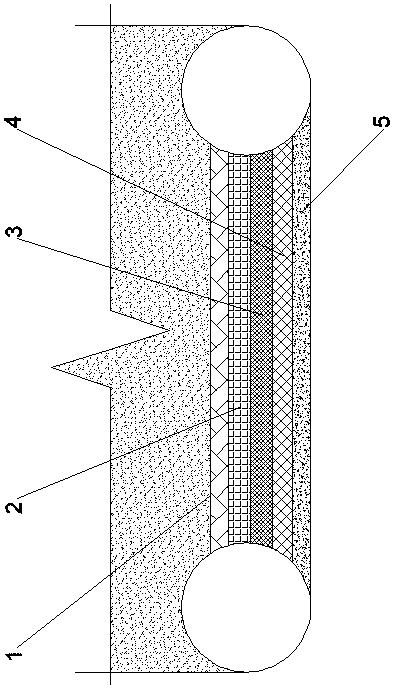

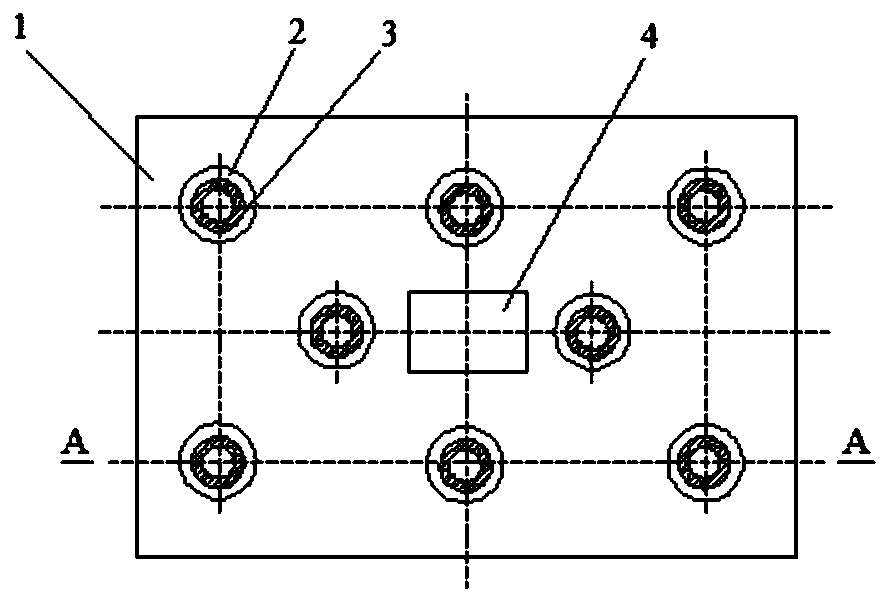

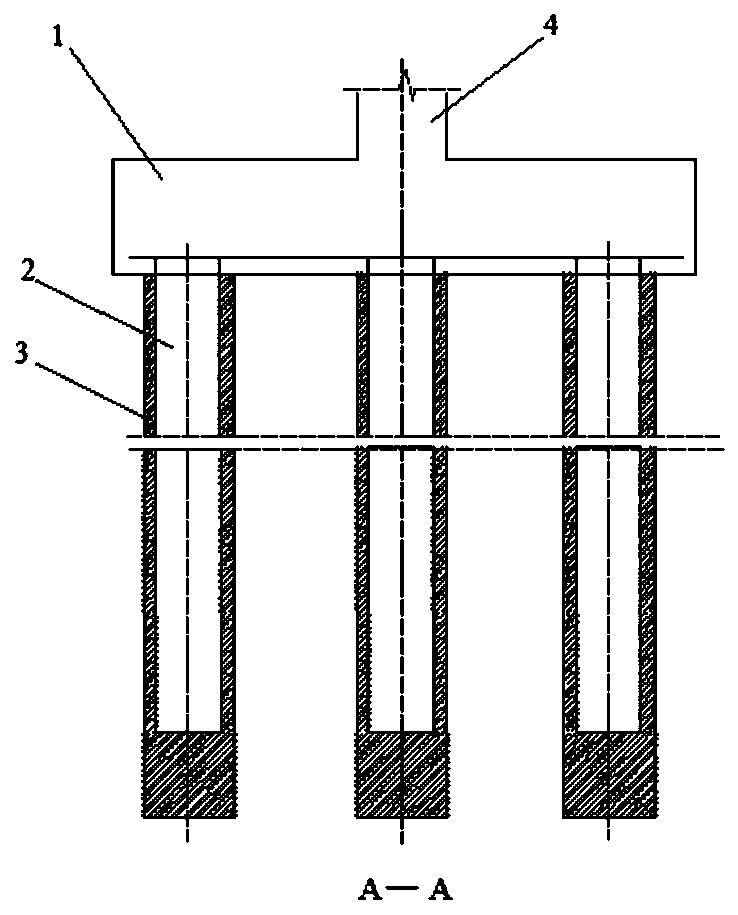

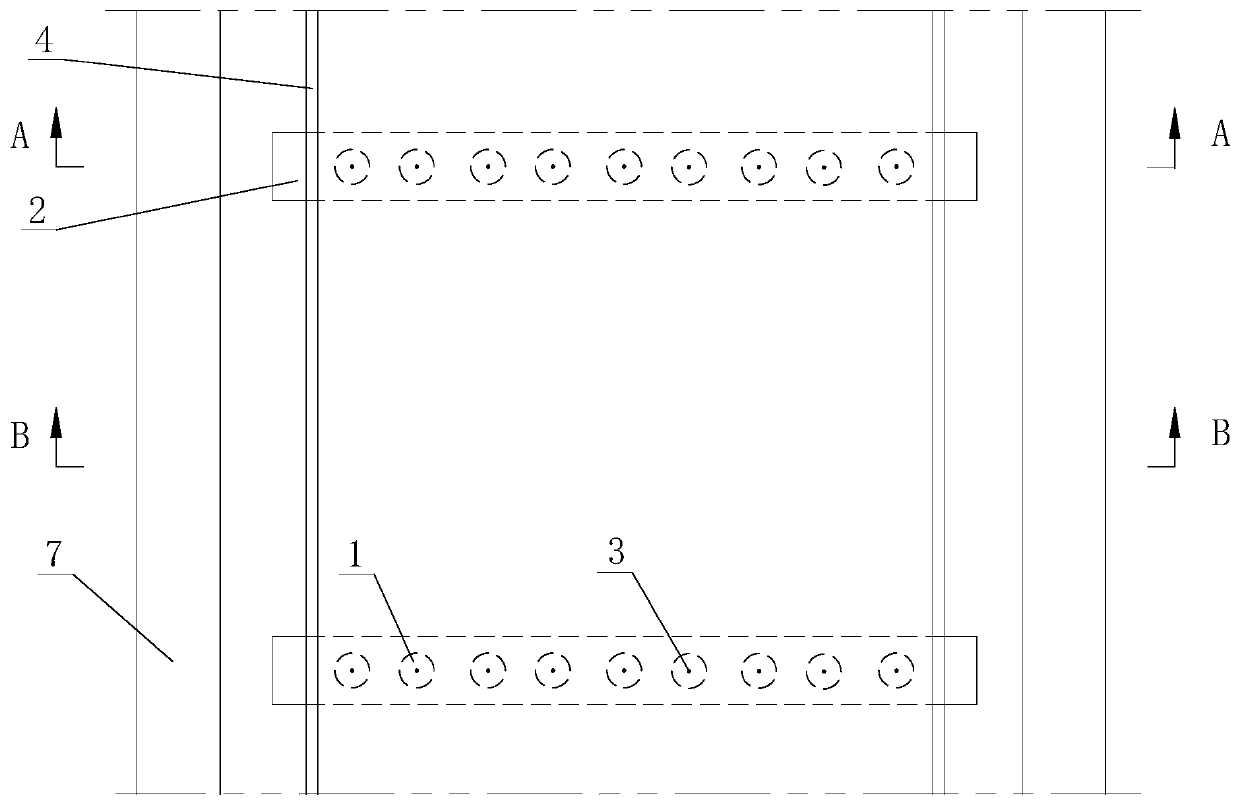

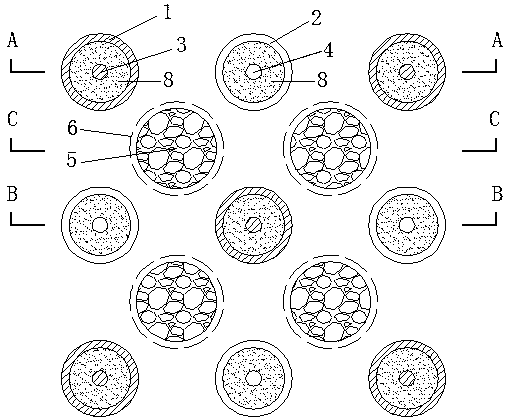

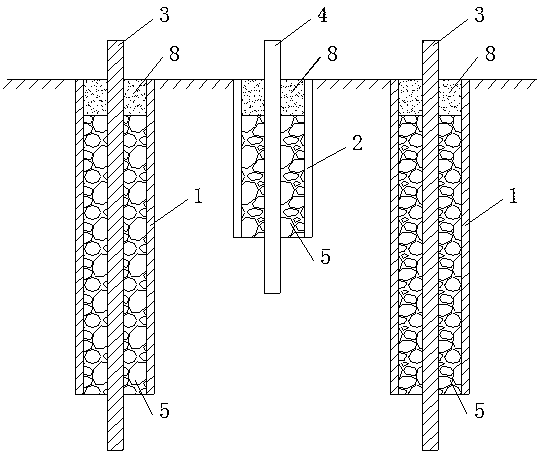

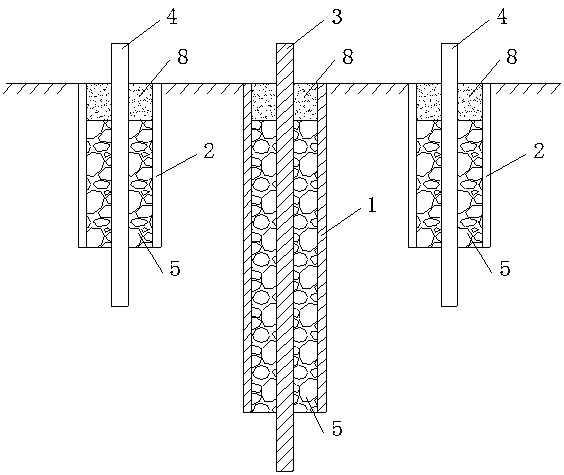

Long-short-pile composite foundation applied to deep soft soil regions

InactiveCN107829442AAvoid displacementAvoid destructionFoundation engineeringStress concentrationEngineering

The invention discloses a long-short-pile composite foundation applied to deep soft soil regions. The long-short-pile composite foundation comprises a soft soil layer, a cushion layer, a base, long piles and short piles, wherein the cushion layer is located above the soft soil layer; the base is located above the cushion layer; the long piles and the short piles are arranged in the soft soil layer; the pile tops of the long piles and the short piles are in contact with the bottom surface of the cushion layer; the pile toes of the long piles and the short piles are located in the soft soil layer; the long piles are uniformly and symmetrically located around the short piles; the short piles are uniformly and symmetrically located around the long piles. The long-short-pile composite foundation applied to deep soft soil regions is capable of uniformly sharing the upper load and preventing stress concentration, is simple and stable in structure, convenient to construct and safe and reliablein quality, and is capable of effectively controlling settlement deformation.

Owner:CHINA MCC17 GRP

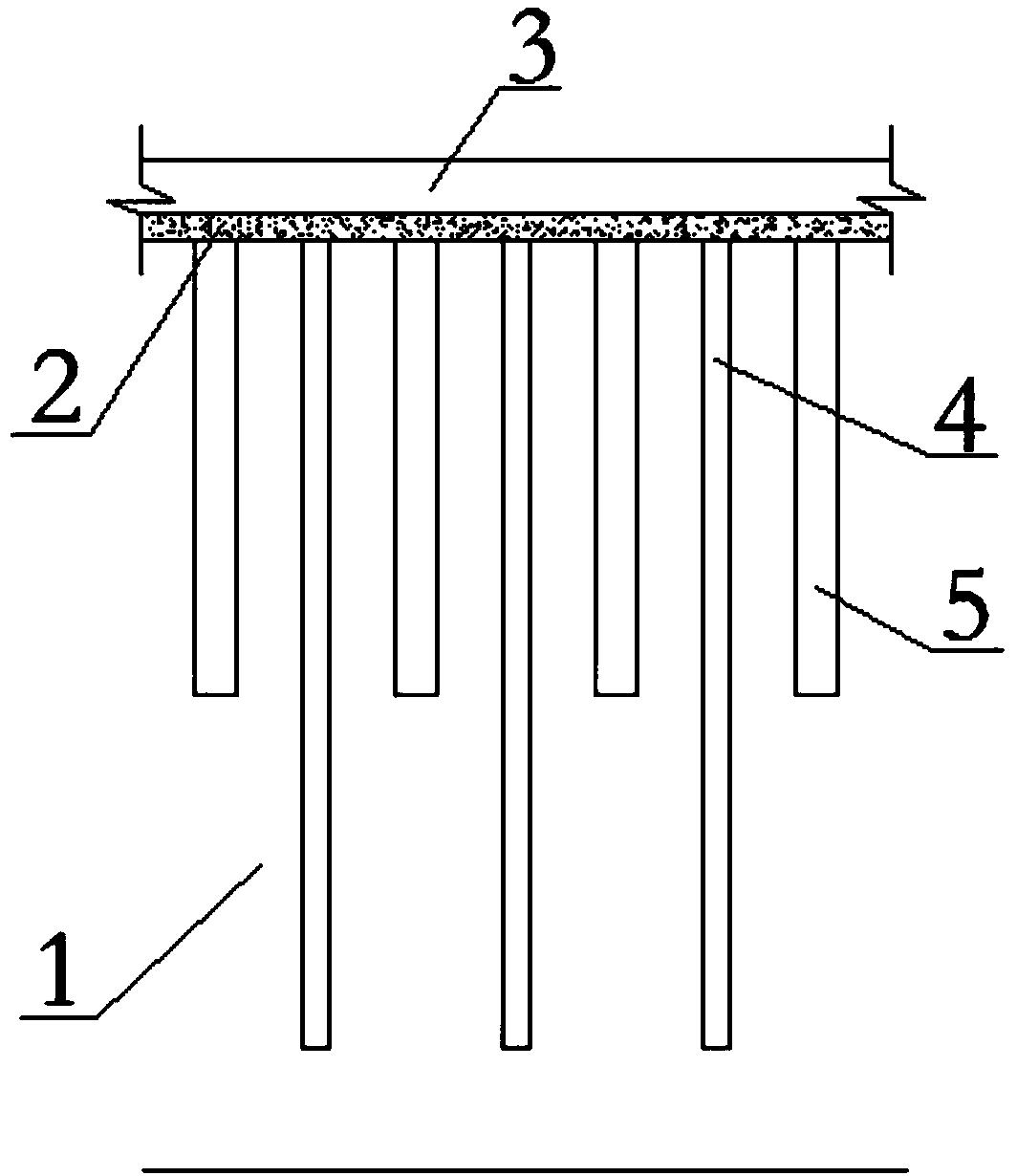

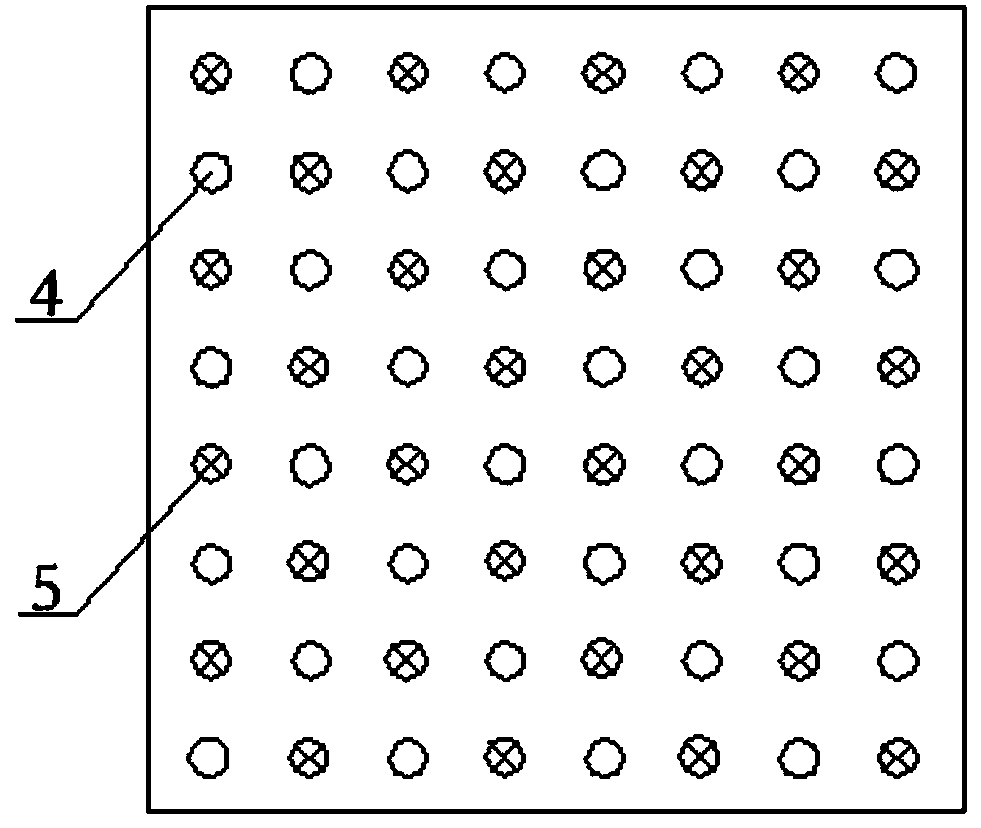

Composite foundation bearing structure imbedding precast piles in high pressure rotary jet pile

InactiveCN111321732AIncrease side resistanceIncrease end resistance standard valueFoundation testingBulkheads/pilesReinforced concreteSoil cement

The invention discloses a composite foundation bearing structure imbedding precast piles in a high pressure rotary jet pile. The composite foundation bearing structure comprises a high pressure rotaryjet pile cement soil solidifying body formed by forced mixing of cement soil curing agent slurry and foundation soil, the precast piles placed in the high pressure rotary jet pile cement soil solidifying body, and a reinforced concrete cushion cap or raft foundation, box foundation form arranged at the tops of the precast piles; and the water cement cement ratio of the cement soil solidifying agent preparation slurry is generally 0.7-1.1, and auxiliary materials and / or admixture are mixed in the slurry. The composite foundation bearing structure can significantly reduce the soil squeezing effect on the site foundation, increase the side resistance and end resistance standard value of the piles, enhance the bearing capacity characteristic value of foundation soil treated by the high pressure rotary jet pile, so that the bearing capacity of a composite foundation is improved. Through the optimization arrangement of the high pressure rotary jet pile and the reinforced concrete prefabricated piles, the settlement deformation of the foundation can be effectively controlled, and the cost of construction project can be reduced.

Owner:CHANGZHOU INST OF TECH

System and design method applying tree-root piles and pile side compacted grouting

InactiveCN102433884ALimit deformation developmentImprove shear resistanceProtective foundationExcavationsTree rootStructural engineering

The invention discloses a system and a design method applying tree-root piles and pile side compacted grouting, which can be used for effectively reducing disturbance of foundation excavation on an adjacent surrounding building and preventing the surrounding building from sinking. The tree-root piles are tightly arranged between a foundation and the surrounding building; on one hand, the tree-root piles pass through a soil body sliding area between the foundation and the surrounding building and are embedded into a soil body under the soil body sliding area, and when the soil body shifts and is deformed, the shearing resistance of a sliding face of the tree-root piles and the side resistance and rigidity provided by a pile body are improved to limit the deformation development of the soil body after pilling and reduce the sinking and deformation of the building after pilling; on the other hand, when the surrounding building near the foundation is sunk and deformed largely, the lateral deformation of the tree-root piles can be effectively controlled by the method applying pile side compacted grouting, and the deformation development rate of the surrounding building is reduced; moreover, the tree-root piles are tightly arranged, the grouting pressure can be uniformly dispersed into the foundation under protected building facilitates, and direct grouting on the foundation is avoided to make the building facilitates uniformly lifted and protruded.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

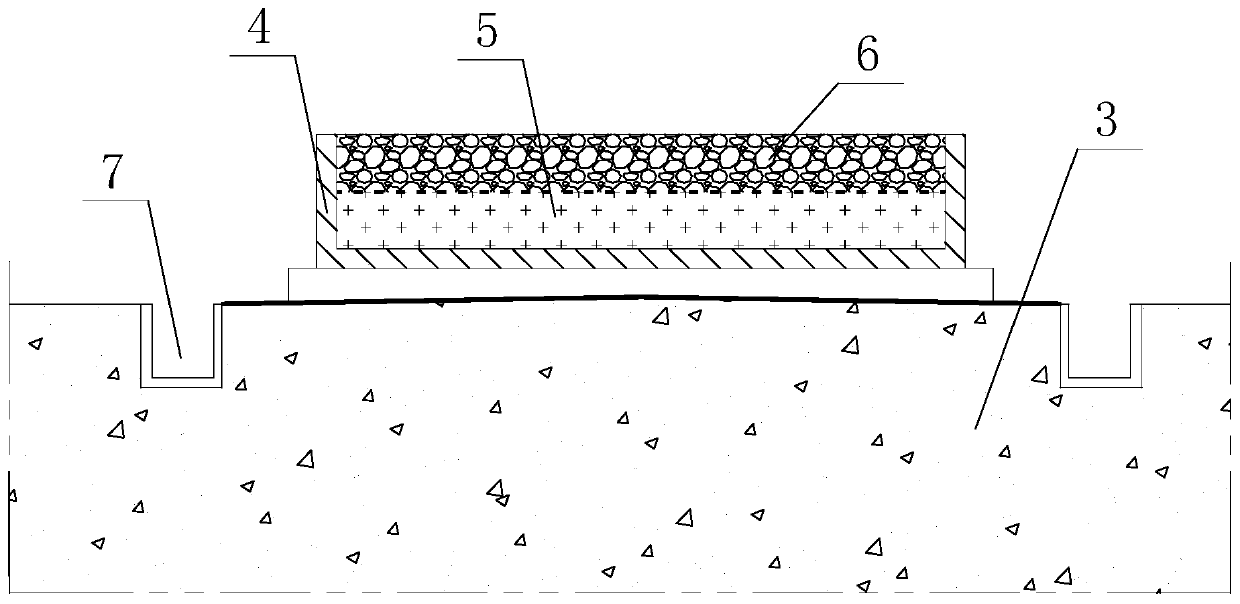

Anti-rise U-shaped roadbed structure and design method thereof

ActiveCN111395064AReduced upper loadAvoid damageGeometric CADSewerage structuresEcological environmentSoil material

The invention relates to the field of geotechnical engineering, in particular to an anti-rise U-shaped roadbed structure and a design method thereof. The anti-rise U-shaped roadbed structure comprisesa U-shaped groove body, wherein a plurality of supporting beams are arranged at the bottom of the U-shaped groove body. Reinforcing pile assemblies are connected to the bottoms of the supporting beams; each reinforcing pile assembly comprises a plurality of reinforcing piles, a first filling layer and a second filling layer are sequentially arranged in the U-shaped groove body from top to bottom,the first filling layer is formed by filling soil materials, and the second filling layer is formed by filling light soil. According to the anti-rise U-shaped roadbed structure, the upper load of thereinforcing pile assembly is reduced; most rise acting force on the side wall of the reinforcing pile can be transmitted back to a lower foundation through the anchoring effect of the pile body, so that roadbed rise deformation can be effectively controlled, the overall load of the structure can be effectively borne, and sedimentation deformation is controlled; and the construction land is greatly saved, the land is saved, and the damage to the ecological environment is reduced.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

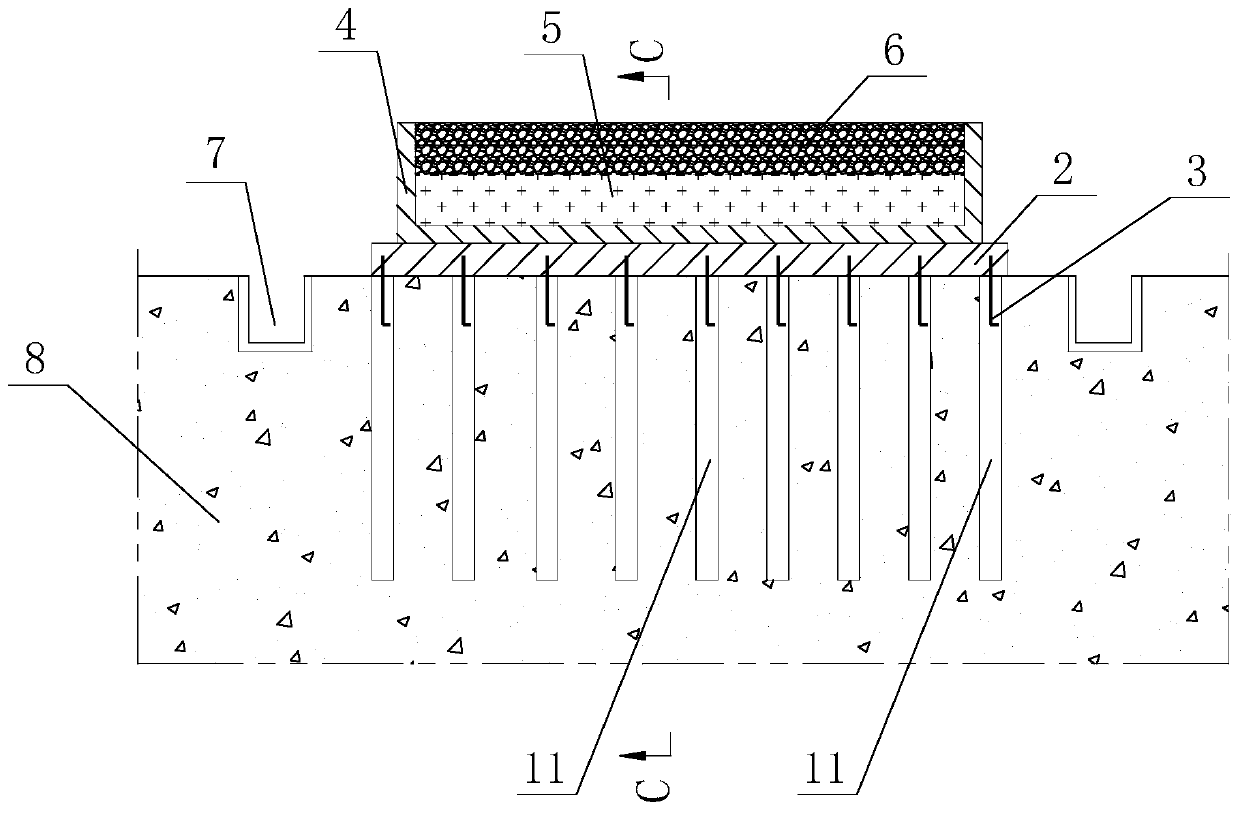

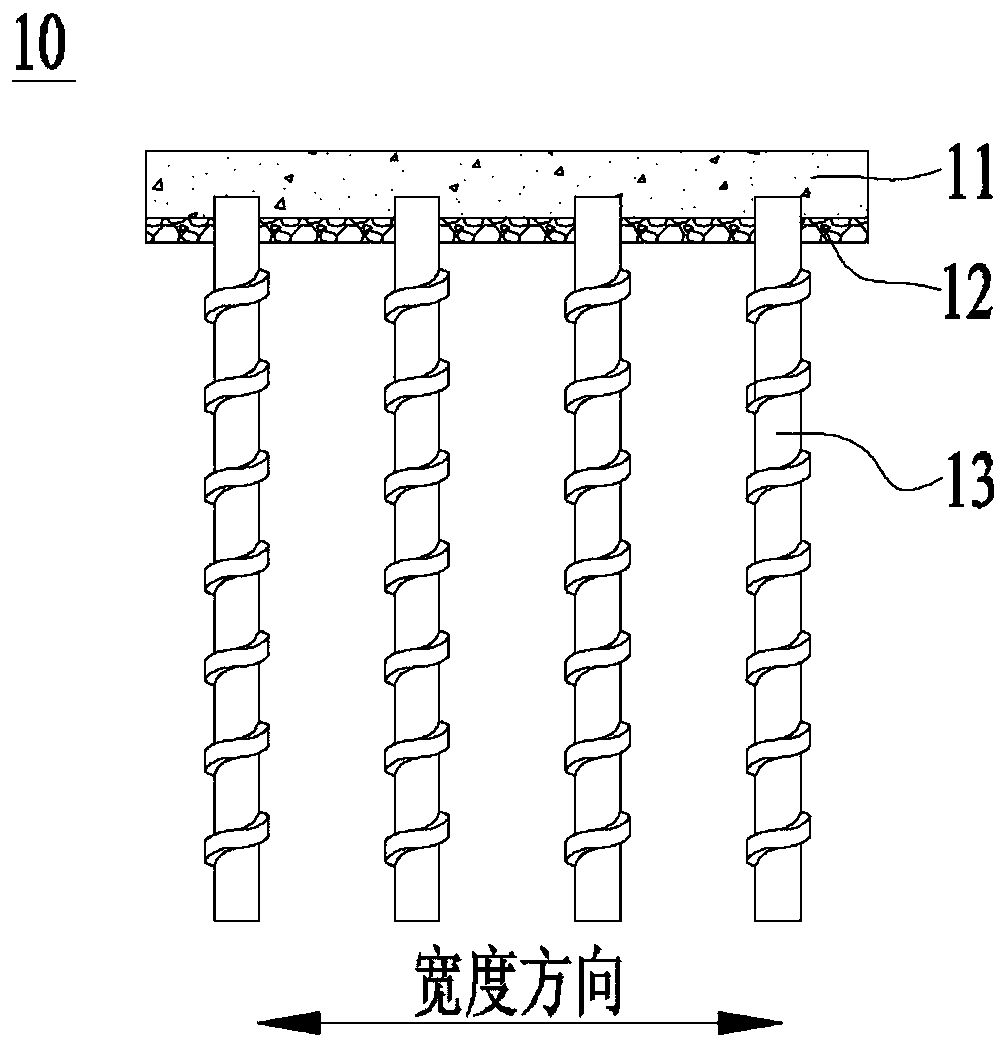

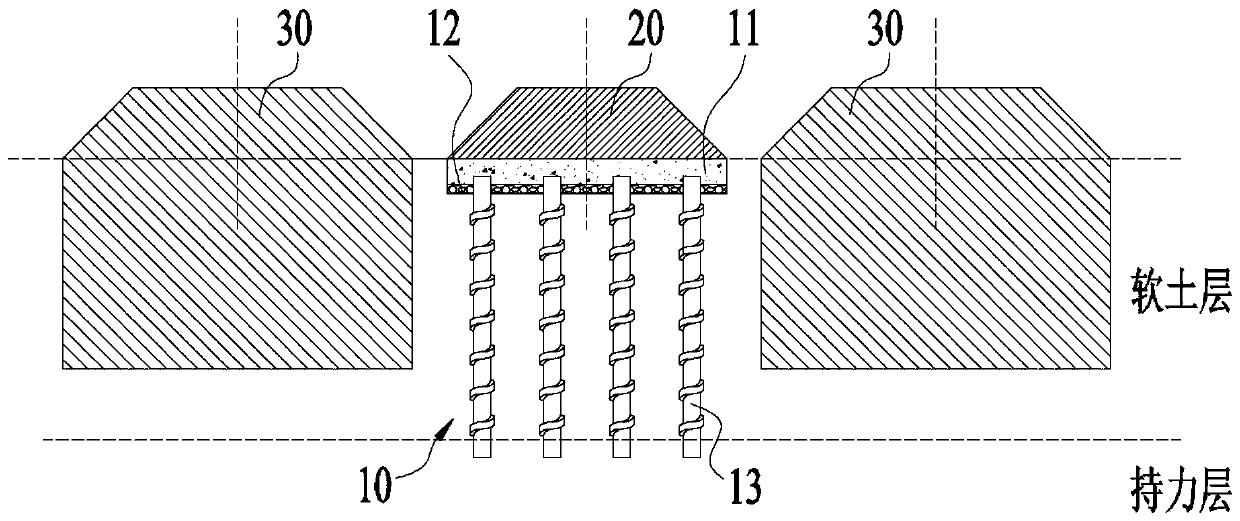

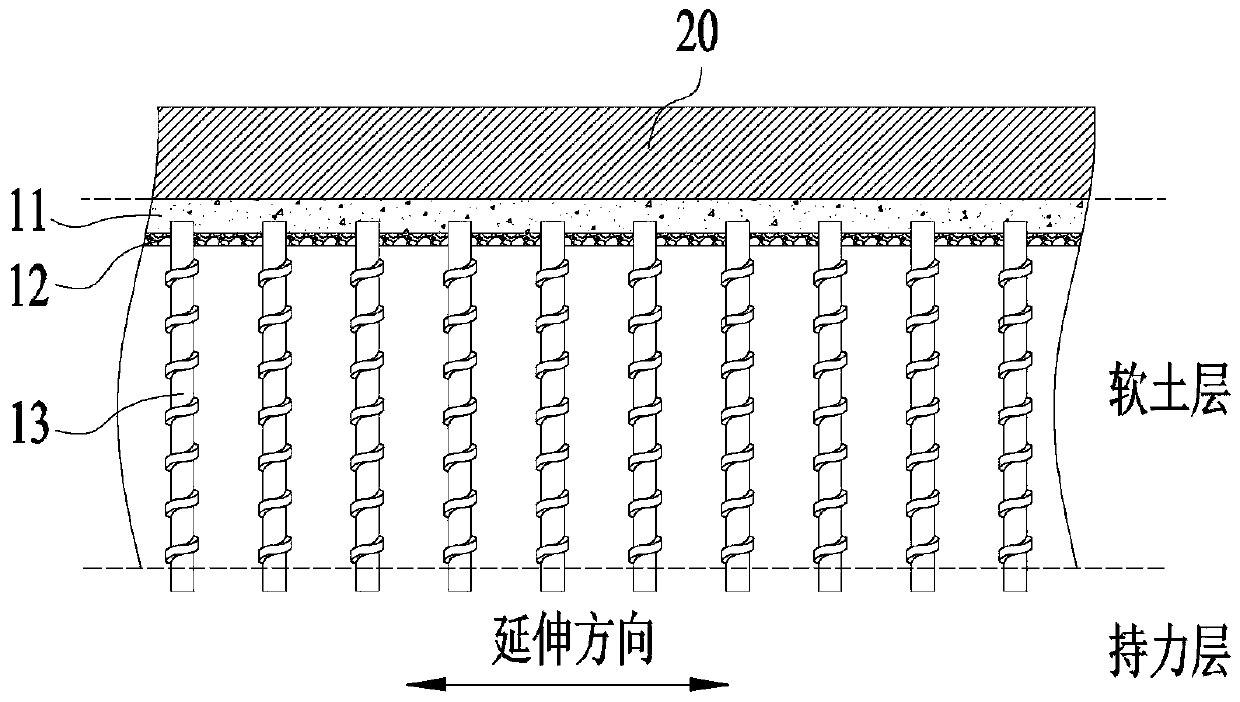

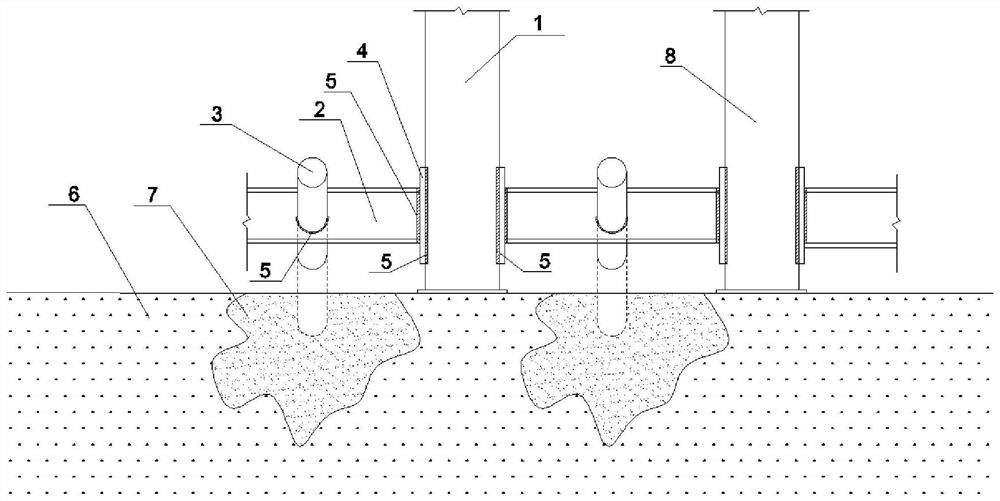

Spiral steel pile plate structure and construction method

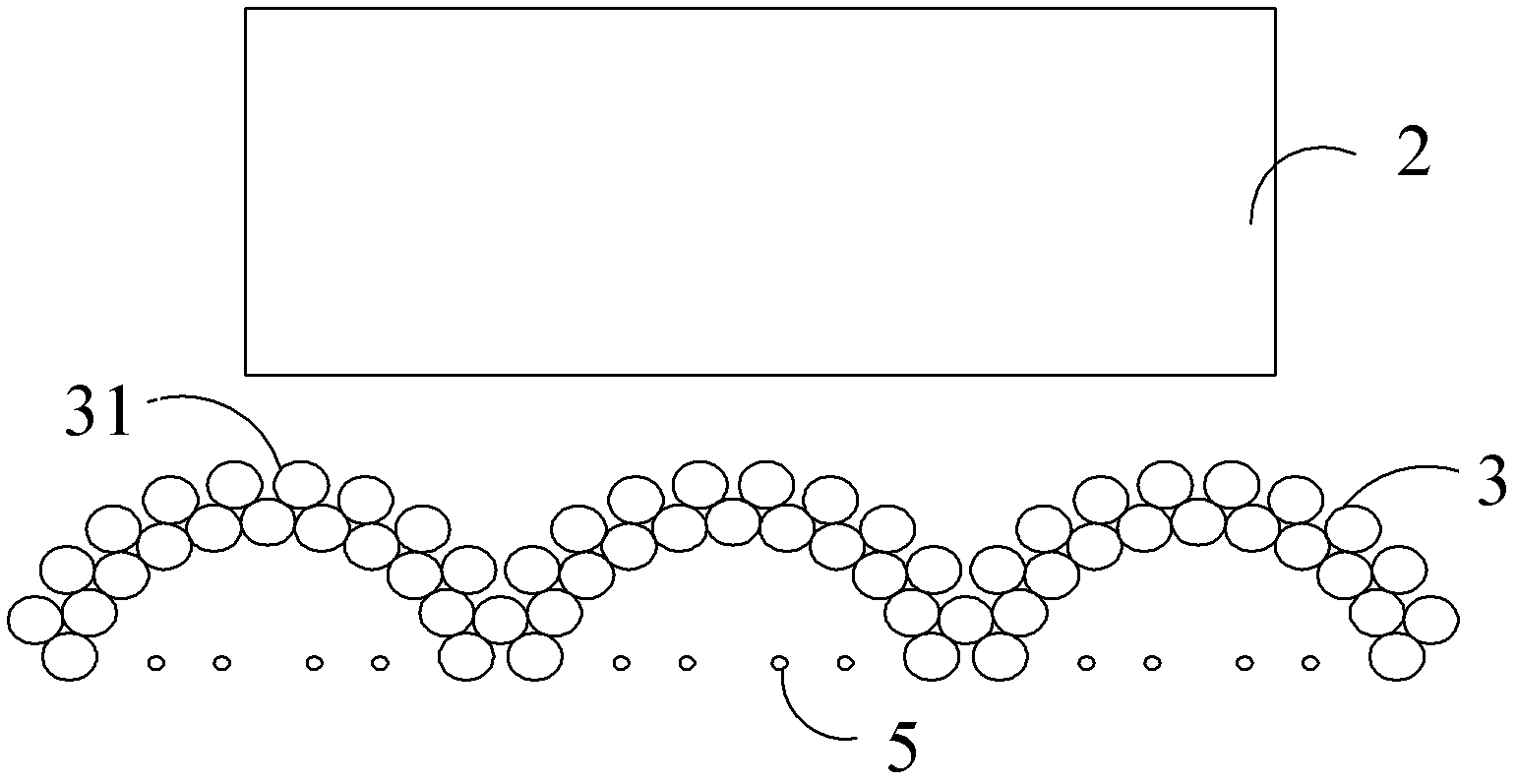

PendingCN110939018AConstruction disturbance is smallReduce the impactRailway tracksRebarReinforced concrete

The embodiment of the invention provides a spiral steel pile plate structure and a construction method. The spiral steel pile plate structure comprises a reinforced concrete bearing plate, a pluralityof spiral steel piles and a broken stone hardcore, and the multiple spiral steel piles are arranged at intervals. One ends of the multiple spiral steel piles are connected with the reinforced concrete bearing plate, and the ends, away from the reinforced concrete bearing plate, of the multiple spiral steel piles are fixed in a bearing layer; the broken stone hardcore is laid on the side, close tothe bearing layer, of the reinforced concrete bearing plate. According to the spiral steel pile plate structure and the construction method provided by the embodiment of the invention, land excavation or cement pouring is not needed; the construction disturbance is small, the influence on an existing railway can be reduced and additional settlement of the existing railway can be controlled, the spiral steel pile plate structure is small in working face, rapid in construction, high in pile forming speed, excellent in performance, good in stability and capable of well controlling settlement deformation of a newly-built railway roadbed.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A composite dynamic drainage consolidation system and construction method applied to deep saturated soft soil foundation

ActiveCN106049413BAchieve replacementAchieve drainage consolidationSoil preservationAir pollutionHigh kinetic energy

The invention provides a hybrid power drainage consolidation system composed of a vacuum shaft drainage system, a foundation hybrid consolidation system and a full compaction rolling system and a construction method. The bearing capacity of a foundation is remarkably improved, meanwhile, the effects of strong drainage, strong compaction, high kinetic energy, over pressure and the like are integrated, post-construction settlement of the saturated soft soil foundation can be effectively controlled, engineering cost can be reduced, and the construction period can be shortened; and meanwhile the treatment depth of the foundation is large, the foundation is good in reinforcement effect and remarkable in environmental protection effect, that is, vibration, noise, air pollution and the like are reduced, and the later maintenance charge is reduced.

Owner:TANGSHAN IND VOCATIONAL TECHN COLLEGE +1

A primary support foot support device and method for a large-section tunnel with weak surrounding rock

ActiveCN111058873BLarge diameterLarge grout volumeUnderground chambersTunnel liningFoot supportsPipe

The invention discloses a primary support foot support device and method for large-section tunnels with weak surrounding rocks, comprising connected connecting section steel, steel plates and grouting pipe sheds, wherein the grouting pipe sheds can be used to drive grout into the enclosure In Yanzhong; there are multiple connecting steel plates and steel plates, and the two ends of each connecting steel plate are respectively connected with steel plates to form a connecting part, and the adjacent connecting parts are used to jointly connect the same initial supporting steel; Each grouting pipe shed passes through and is connected to the corresponding connecting section steel; the grouting pipe shed is located in the middle of the adjacent primary section steel, and the adjacent grouting pipe sheds are symmetrical with respect to the initial support section steel. The invention can realize the reinforcement of the foot part of the initial support section steel through the reinforcement device, reduce the deformation and settlement of the connection section steel, and ensure the construction safety in the tunnel.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

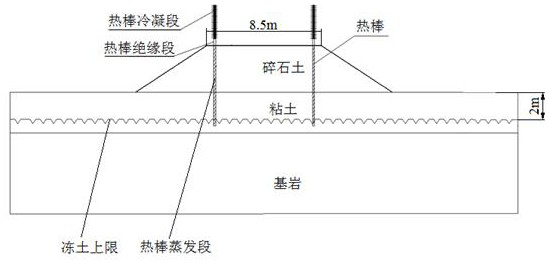

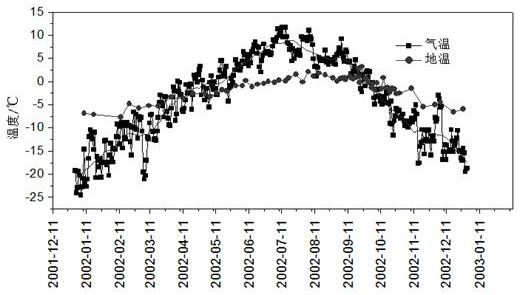

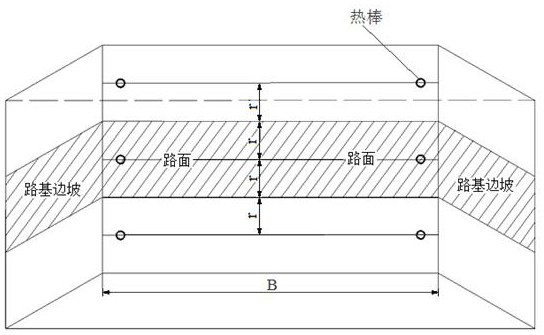

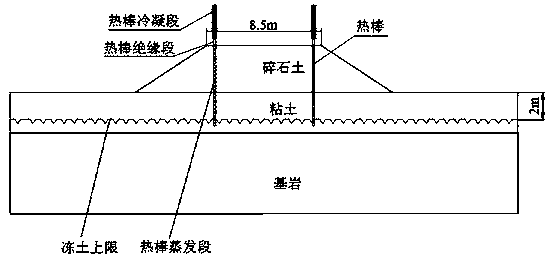

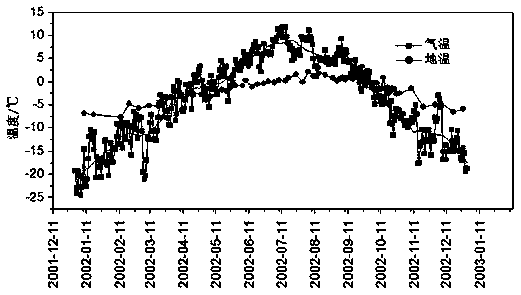

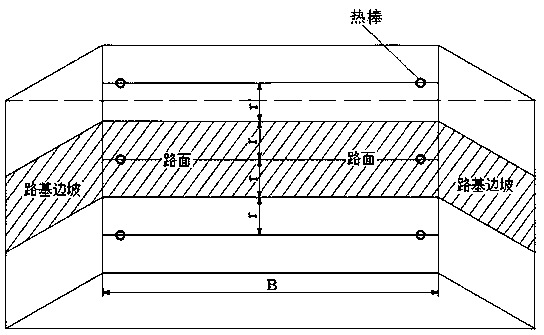

Design and calculation method of hot rod subgrade in permafrost region based on the principle of heat budget

ActiveCN110502847BScientifically and rationally design calculation methodsSimple and Feasible Design Calculation MethodGeometric CADDesign optimisation/simulationGround temperatureSoil science

The invention discloses a design and calculation method for hot rod subgrade in permafrost regions based on heat budget balance, which collects data on air temperature and wind speed in the area where the project is located, and finds out the physical parameters of subgrade filler and foundation soil and the natural characteristics of permafrost soil in the foundation. Upper limit depth and ground temperature data, measure subgrade section size; select appropriate hot rod model according to specifications and engineering needs; calculate thermal rod cooling influence radius and influence range in the roadbed; calculate annual net heat absorption of subgrade within the thermal rod cooling influence range ; Calculate the cooling capacity of a single hot rod; determine the number and arrangement of the hot rods. The basic principle of this calculation method is to ensure that the annual cooling capacity of the thermal rod is not less than the annual net heat absorption of the subgrade-foundation system, which provides a theoretical basis for the design and calculation of the thermal rod subgrade, solves the problem of thermal rod subgrade design and calculation, and has great significance Engineering application value: It is simple, feasible, scientific and reasonable, and can control the subgrade settlement and deformation caused by the degradation and thawing of permafrost.

Owner:NORTHWEST RES INST CO LTD OF C R E C +1

Permafrost region hot rod roadbed design calculation method based on heat budget balance principle

ActiveCN110502847AScientifically and rationally design calculation methodsSimple and Feasible Design Calculation MethodSpecial data processing applicationsGround temperatureAbsorption capacity

The invention discloses a permafrost region hot rod roadbed design calculation method based on heat budget balance. The method comprises the following steps: collecting air temperature and wind speeddata of a region where a project is located, finding out physical parameters of roadbed filler and foundation soil and natural upper limit depth and ground temperature data of permafrost of a foundation, and measuring the section size of a roadbed; selecting a proper hot rod model according to specifications and engineering requirements; calculating the influence radius of the hot rod refrigeration and the influence range in the roadbed; calculating the annual net heat absorption capacity of the roadbed within the hot rod refrigeration influence range; calculating the refrigerating capacity ofa single hot rod; and determining the number and arrangement mode of the hot rods. The basic principle of the calculation method is to ensure that the annual refrigerating capacity of the hot rod isnot less than the annual net heat absorption capacity of a roadbed-foundation system, a theoretical basis is provided for design and calculation of the hot rod roadbed, the problem of design and calculation of the hot rod roadbed is solved, and the calculation method has great engineering application value. The method is simple, feasible, scientific and reasonable, and roadbed settlement deformation caused by degradation and thaw collapse of permafrost of the foundation can be controlled.

Owner:NORTHWEST RES INST CO LTD OF C R E C +1

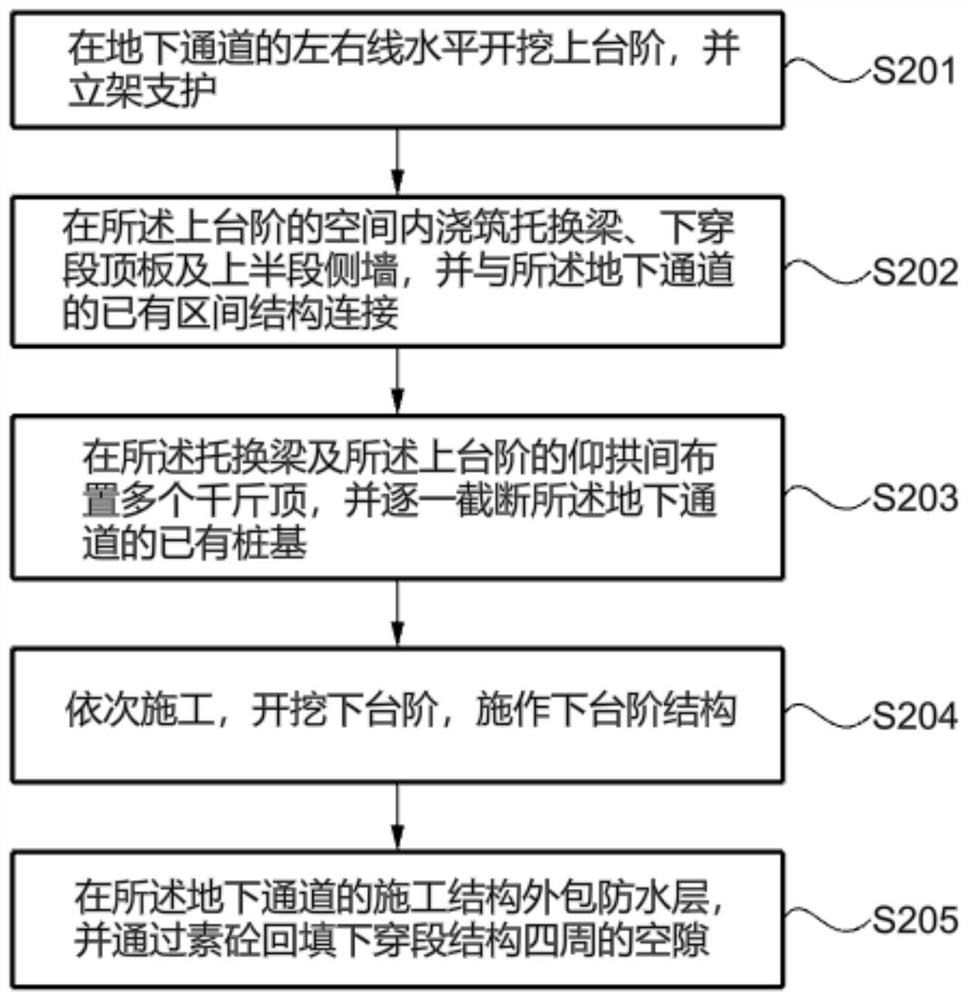

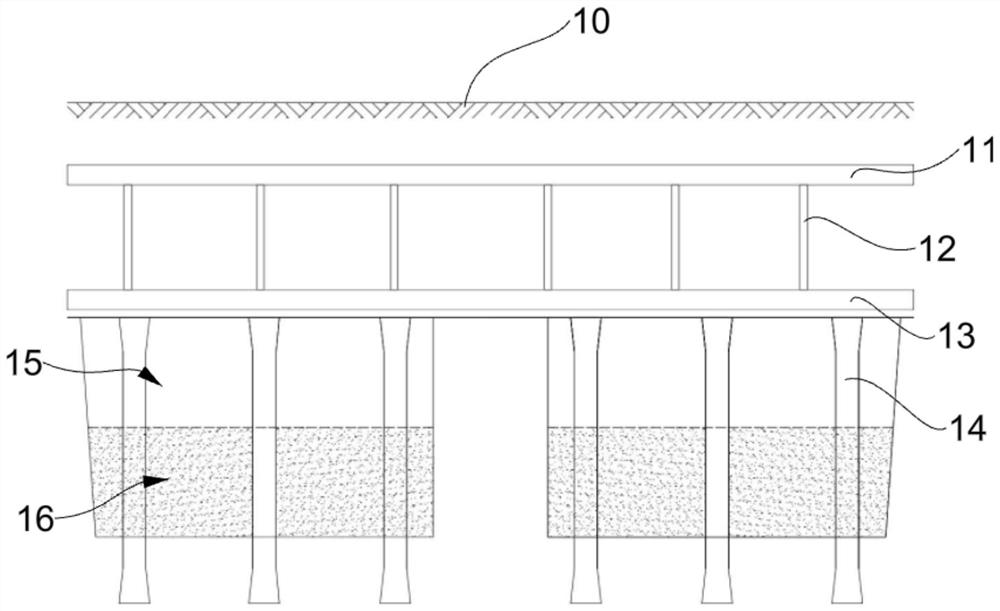

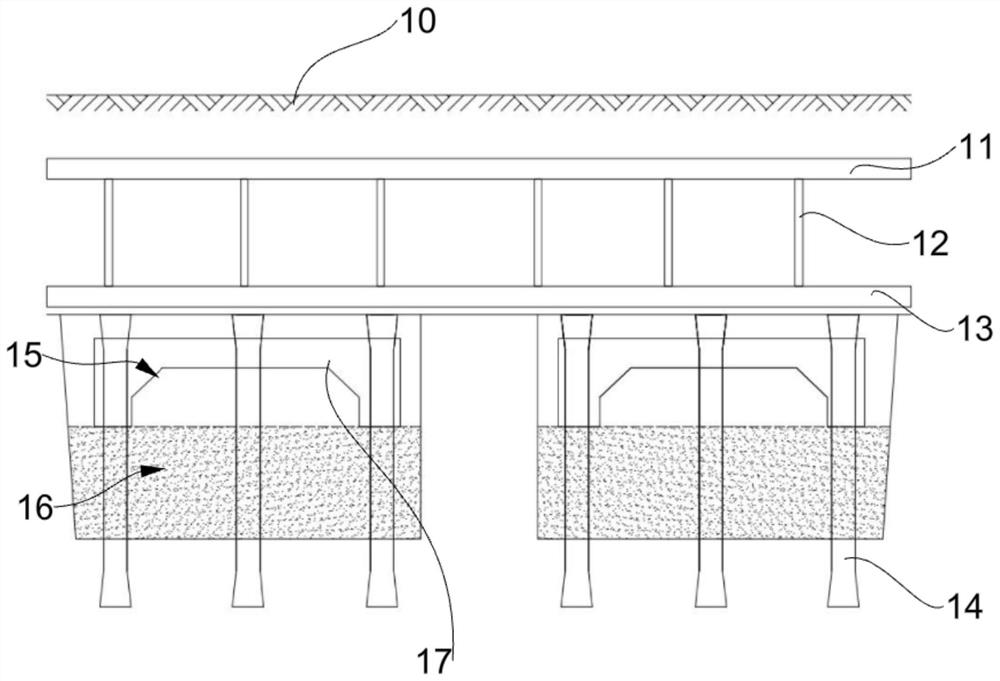

Construction method of underground passage orthogonally and closely attached to underground commercial street bottom plate

PendingCN114775684AFast constructionCost controlArtificial islandsProtective foundationArchitectural engineeringStructural engineering

The invention provides a construction method of an underground passage orthogonally and closely attached to a bottom plate of an underground commercial street, which comprises the following steps of: horizontally excavating upper steps on left and right lines of the underground passage, and supporting by a vertical frame; pouring an underpinning beam, an underpass section top plate and an upper half section side wall, and connecting with the existing interval structure of the existing underground passage; a plurality of jacks are arranged between the underpinning beam and the inverted arch of the upper step, and existing pile foundations of the underground passage are cut off one by one; sequentially constructing, excavating a lower step and constructing a lower step structure; and a waterproof layer is wrapped outside the construction structure, and gaps around the underpass section structure are backfilled through plain concrete. Pile foundation underpinning is carried out immediately after an upper step structure, namely, an underpinning beam, a bottom penetrating section top plate and an upper half section side wall, is poured. Compared with pile foundation underpinning of similar projects, due to the fact that only the upper structure is constructed, the construction period can be greatly shortened, under the protection of the existing upper structure, the construction speed of the lower step can be greatly increased, and the construction period, the manufacturing cost, the safety and the like can be well controlled.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP +2

Water-repelling shotcrete anchor support method and water-repelling device for red sandstone layer

Owner:甘肃建研建设工程有限公司

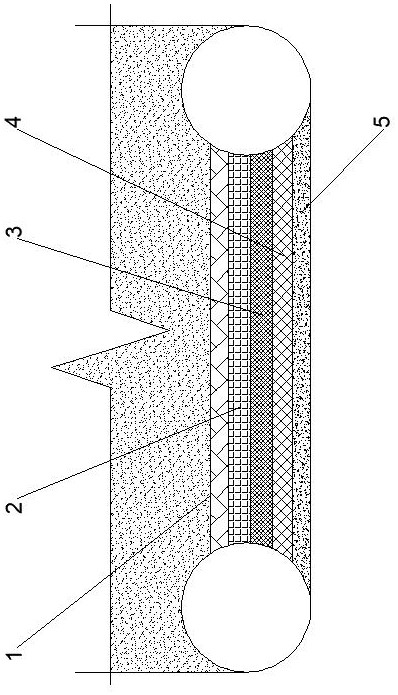

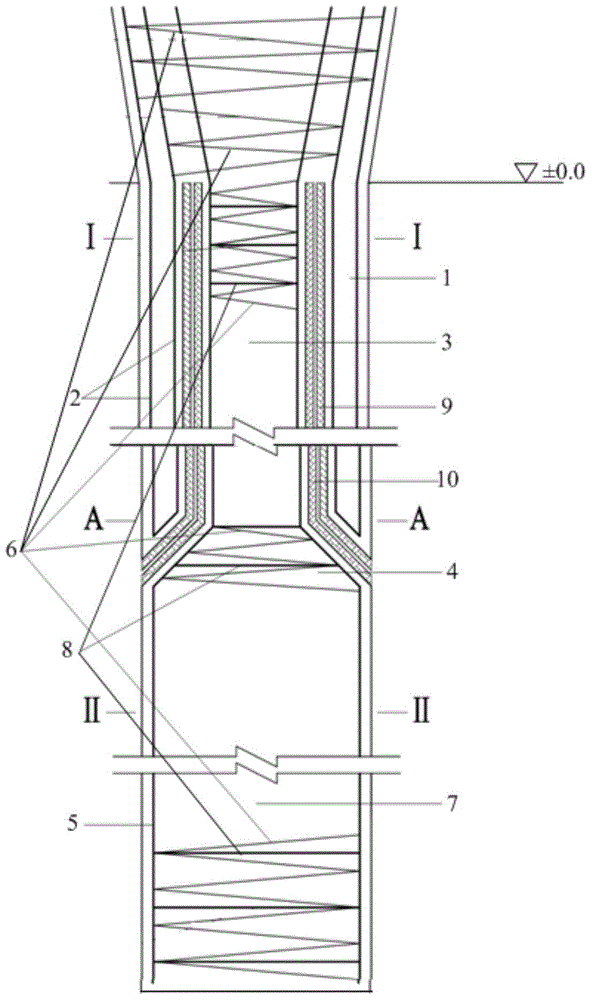

A partially prefabricated friction pile and its construction method

ActiveCN105178311BRealize standardized productionImprove bearing capacityBulkheads/pilesReinforced concreteUltimate tensile strength

The invention relates to the technical field of architectural engineering, in particular to a partially-prefabricated friction pile and a construction method thereof. The partially-prefabricated friction pile comprises an upper pile body, a lower pile body and a separation formwork arranged between the upper pile body and the lower pile body. The upper pile body comprises a standard segment and a pile bottom segment. The lower pile body comprises a force transferring structural segment, a variable-section structural segment and a bearing structural segment which are sequentially connected from top to bottom. The standard segment and the pile bottom segment are both prefabricated prestressed reinforced concrete tubular piles. Standardized production of the friction pile is achieved, the labor intensity of construction personnel is lowered, and manufacturing cost is reduced. The upper pile body is arranged outside the force transferring structural segment in a sleeving mode. Due to the split design of the upper pile body and the lower pile body, the bearing performance of whole-pile-length pile side friction resistance and pile end resistance can be fully achieved, and the overall bearing capacity of the friction pile is improved. Under the action of identical upper loads, the needed pile length or pile diameter is smaller, settlement deformation of the pile top can be effectively controlled, then the engineering cost of the friction pile is reduced, and social resources are saved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A shield tunnel multi-section, small clear distance, overlapping underpass viaduct construction method

ActiveCN110080781BSatisfy security control requirementsAvoid subjectivityUnderground chambersFoundation engineeringArchitectural engineeringStructural engineering

The invention discloses a construction method for a shield tunnel with multi-sections, small clear distances, and crossing viaducts under overlapping steps. The optimal construction sequence for the construction of the viaduct under the stacked drop; before the tunnel under the viaduct, carry out the active isolation and reinforcement of the shield tunnel under the viaduct at a short distance; carry out the construction of the shield tunnel under the viaduct; under the overlapping of multiple shield tunnels In the area passing through the viaduct, the segment structure of the shield tunnel is strengthened, and the inside of the tunnel hole is reinforced; the vibration reduction and isolation control of the track is carried out in the section passing through the viaduct under the shield tunnel.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Tunnel steel temporary inverted arch with rapid assembly and disassembly

ActiveCN102562098BControl settlement deformationReduce construction costsUnderground chambersTunnel liningEngineeringConstruction waste

The invention discloses a tunnel steel temporary inverted arch with rapid assembly and disassembly, which is characterized in that each temporary inverted arch arranged is formed by fixed joints positioned in the middle, movable joints positioned at both ends of the fixed joints and connection joints connected between the fixed joints and the movable joints; and the fixed joints, the movable joints and the connection joints are arranged in a split mode. With the tunnel steel temporary inverted arch, tunnel convergence and settlement and deformation can be effectively controlled, the tunnel steel temporary inverted arch can be conveniently and quickly dismantled after completing desired functions and can be reused, other inputs are not increased so that the tunnel construction cost is greatly reduced. Construction waste is not formed, amounts of dust and high decibel noise are not generated during installation and dismantling, excellent construction environment is supplied for the internal construction of the tunnel, and the construction security is improved.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

Road widening treatment method

InactiveCN112391892ASolve crackingImprove stabilityRoads maintainenceStructural engineeringRoad surface

The invention provides a road widening treatment method which comprises the following steps: step 1, arranging a vertical drainage system along the joint of a new roadbed and an old roadbed; step 2, selecting a filler consistent with the old roadbed filler as a new roadbed filler, filling and compacting, and firstly filling sand gravel or gravelly soil at the bottom to serve as a substrate layer;step 3, paving and roughly flattening the roadbed filling material. step 4, paving and finely leveling the roadbed filling material. and step 5, rolling the filling material. The method solves the problems of longitudinal and transverse cracks and other diseases of the pavement after the road widening and reconstruction engineering is completed, can improve the bearing capacity of the foundation,controls the settlement deformation of the newly-filled roadbed, and enhances the anti-benching capacity of the junction of the newly-filled roadbed and the old roadbed and the stability of the widened roadbed.

Owner:CHINA FIRST METALLURGICAL GROUP

A closed pre-supported tunnel structure

ActiveCN106351670BControl formation deformationIncrease stiffnessUnderground chambersTunnel liningEngineeringSteel plates

The invention relates to the technical field of tunnel building, and particularly relates to a closed pre-support tunnel structure. The closed pre-support tunnel structure comprises an annular pipe curtain structure which surrounds the outer side of a to-be-excavated tunnel limit; and the pipe curtain structure comprises a plurality of steel pipes which are distributed along the axis of a tunnel, the plurality of steel pipes are distributed along the circumferential direction of the tunnel at intervals and surround the outer side of the tunnel to form an annular structure, and the adjacent steel pipes are connected with through a steel plate to form a closed annular pre-support structure. According to the closed pre-support tunnel structure, the structure is simple, the construction is convenient, the stable tunnel excavating pre-support can be formed, the closed pre-support tunnel structure is beneficial to the rapid excavation of the tunnel, secondary lining is not needed, the construction cost is lowered, and the closed pre-support tunnel structure has great promotion values.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

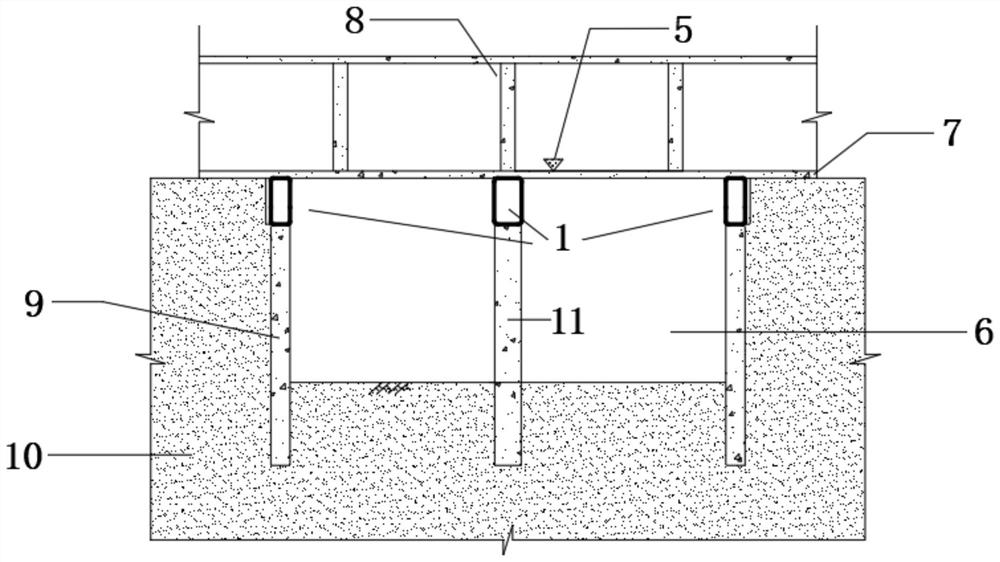

Underground engineering structure meeting double-zero condition and construction method

ActiveCN112031809AEasy to inflateSimple and fast constructionUnderground chambersFoundation testingArchitectural engineeringEngineering structures

The invention discloses an underground engineering structure meeting the double-zero condition. The underground engineering structure comprises an existing building and an underground structure, and further comprises an adjustable supporting body, an air pressure monitoring device, a deformation monitoring device and a building bottom plate; the existing building is built on the building bottom plate, the underground structure is arranged below the existing building, and the deformation monitoring device is arranged on the building bottom plate; the underground structure comprises an underground space, supporting enclosures and pile foundations, the underground space is located below the existing building, the two supporting enclosures are oppositely arranged in the underground space, thepile foundations are arranged in the underground space, and the pile foundations are located between the two supporting enclosures; and adjustable supporting bodies are correspondingly arranged at thetops of the supporting enclosures and the pile foundations, and the upper ends of the adjustable supporting bodies abut against the building bottom plate. An inflatable air bag and a one-way exhaustvalve can be prefabricated and installed in advance in a factory, the air bag body is inflated conveniently through an inflator in the construction process of a subsequent building structure, and thewhole construction process is simple, convenient and rapid.

Owner:SOUTHWEST JIAOTONG UNIV

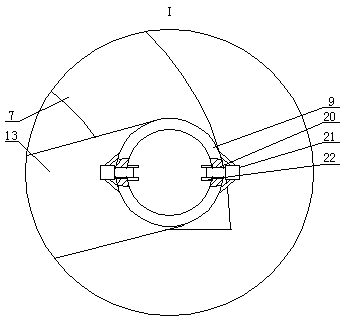

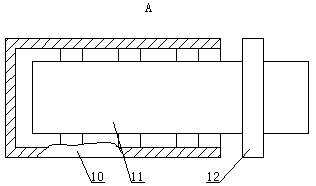

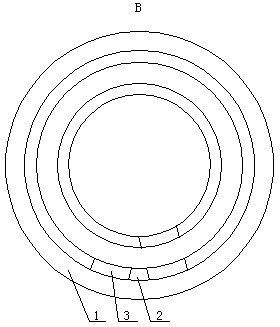

A construction device for friction piles

InactiveCN107794911BRealize the installation and fixationImprove bearing capacityBulkheads/pilesArchitectural engineeringRebar

The invention relates to a construction device of a friction pile. The construction device of the friction pile comprises a support plate, wherein an annular plate is fixedly arranged above the support plate through a fixing device; a center line of the annular plate is collinear to a center line of the support plate; two annular rails are arranged on a top surface of the support plate; a same annular rail is arranged on a bottom surface of the annular plate; the annular rail on the bottom surface of the annular plate is located right above the annular rail located on the outer side of the topsurface of the support plate; two sliding blocks are movably arranged in the annular rails on the outer side of the support plate and the bottom surface of the annular plate; a same sliding block ismovably arranged in the annular rail on the inner side of the support plate; the sliding blocks can slide along the corresponding annular rails; each sliding block is provided with a power device which is a motor; bottom surfaces of the sliding blocks located on the outer side are fixedly connected with cylinder bodies of first air cylinders; and piston rods of each two vertical first air cylinders are fixedly connected with a top surface or a bottom surface of a strip plate. A reinforcing steel bar is fixed onto a main bar of a reinforcement cage through a welding device, so that a cut-off template can be quickly installed and fixed, the labor force is saved, and the work efficiency is greatly improved.

Owner:舒伟

A friction pile and its construction method

The invention relates to the technical field of architectural engineering, and especially relates to a friction pile and a construction method thereof, in particular to a large-diameter super-long friction pile capable of fully achieving friction force of an upper side and a lower side of a foundation pile and end resistance of the foundation pile. The friction pile comprises an upper pile body, a lower pile body and a separation formwork arranged between the upper pile body and the lower pile body. An annular bevel body is arranged at the bottom of the upper pile body, and the lower pile body comprises a force transferring structural segment, a variable-section structural segment and a bearing structural segment which are sequentially connected from top to bottom. The upper pile body is arranged outside the force transferring structural segment in a sleeving mode, the bottom of a reinforcement cage of the upper pile body matches the variable-section structural segment, and the separation formwork is arranged between the upper pile body and the force transferring structural segment. On the premise that the settling volume at the top of the pile meets the deformation requirement of an upper structure, the bearing performance of whole-pile-length side friction force and pile end resistance can be fully achieved, and therefore the overall bearing capacity of the friction pile is improved; under the same upper loads, the needed pile length or pile diameter is smaller, settlement deformation of the pile top can be effectively controlled, and then engineering cost is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

An underground engineering structure and construction method satisfying the double zero condition

ActiveCN112031809BEasy to inflateSimple and fast constructionUnderground chambersFoundation testingExhaust valveArchitectural engineering

An underground engineering structure that satisfies double-zero conditions, including existing buildings and underground structures, and also includes adjustable supports, air pressure monitoring devices, deformation monitoring devices and building floors; existing buildings are built on building floors, and underground structures It is installed under the existing building, and a deformation monitoring device is installed on the building floor; the underground structure includes underground space, support enclosure and pile foundation. For protection, a pile foundation is set in the underground space, and the pile foundation is located between two supporting enclosures; an adjustable support body is arranged on the top of the support enclosure and the pile foundation, and the upper end of the adjustable support body abuts against the building floor . The inflatable airbag and the one-way exhaust valve can be prefabricated and installed in the factory in advance, and it is convenient to use the inflator to inflate the airbag body during the construction of the subsequent construction of the structure, and the whole construction process is simple and fast.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com