Patents

Literature

35results about How to "Huge environmental benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

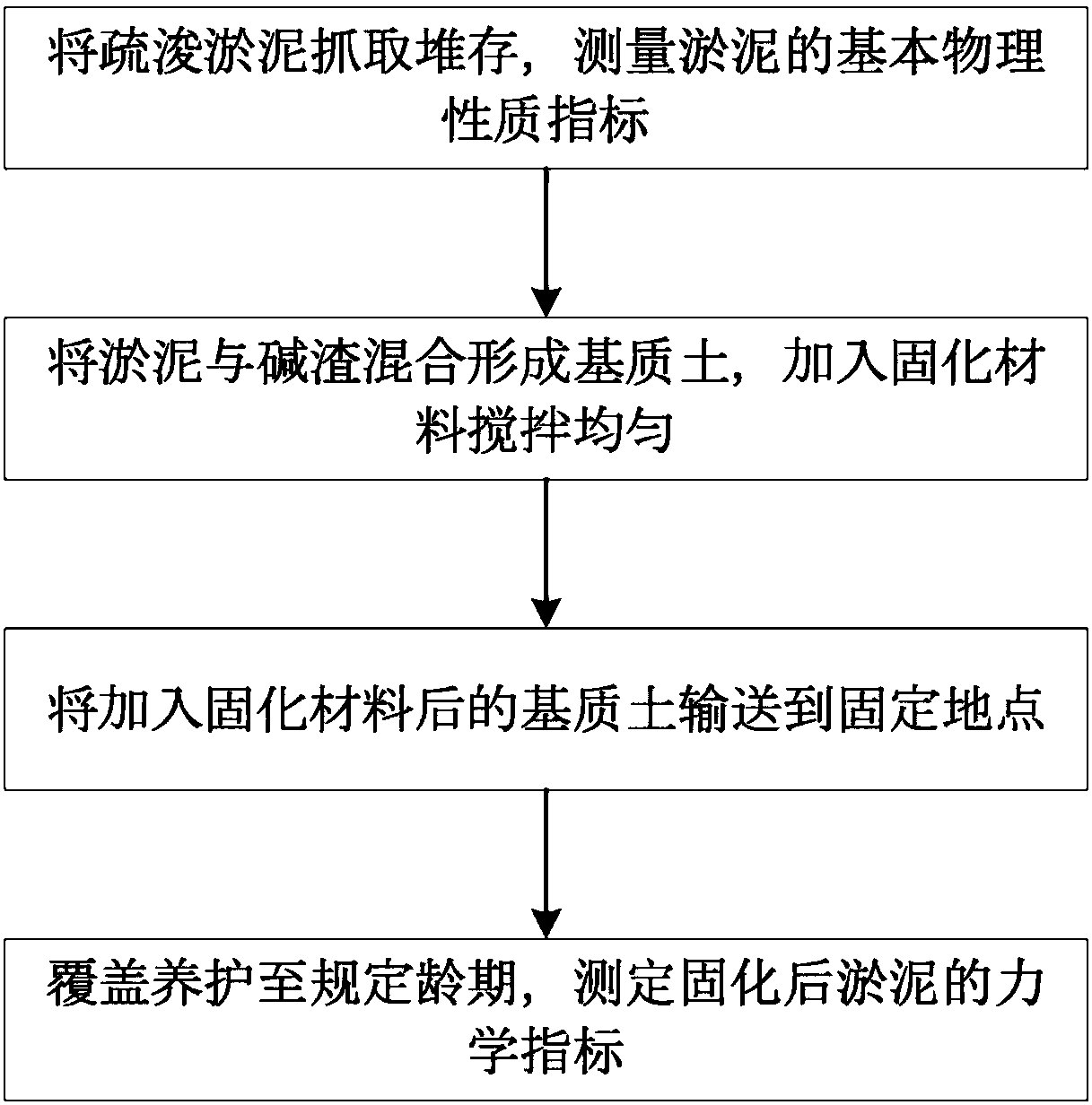

Method for solidifying sludge with high water content

InactiveCN108218317ARealize resource utilizationAchieve sustainable developmentFixation/solidifcation sludge treatmentSludgeMechanical index

The invention discloses a method for solidifying sludge with a high water content. At first, dredged sludge is collected and stored, basic physical indexes of sludge are measured, the sludge and alkali residues are mixed to form matrix soil; a curing material is added and then is evenly mixed and stirred; then the matrix soil containing the curing agent is transported to a fixed location; the matrix soil is covered and cured for a prescribed period; and finally the mechanical indexes of cured sludge are measured. The optimal ratio of alkali residues to dry sludge is 30-50:100. The curing material comprises following components in percentage by the weight of dry mixed soil: 10 to 25% of mineral powder, 0.1 to 0.5% of super absorbent resin, and 2 to 6% of sodium silicate. The cooperative effect between alkali residues and sludge with a high water content is utilized to form matrix soil; super absorbent resin is used to reduce the water content of sludge, the utilization rate of alkali residues is increased, the solidification cost is reduced, and the solidified soil has the advantages of high early strength and low compressibility and meets the engineering requirements of filling soil.

Owner:HUBEI UNIV OF TECH

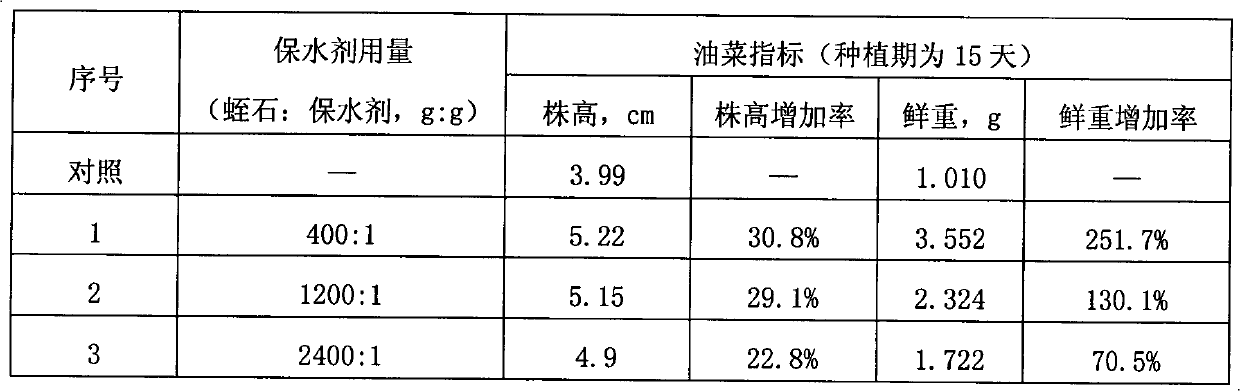

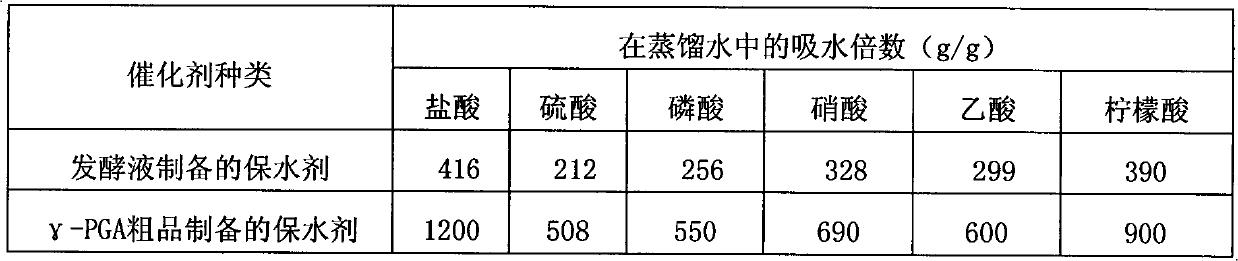

Method for preparing water-retaining agent

ActiveCN102002234AHuge environmental benefitsHuge social benefitsAgriculture tools and machinesMicroorganism based processesChemistrySaline water

The invention relates to a method for preparing a water-retaining agent, which comprises the following step of: reacting gamma-polyglutamic acid fermentation liquor prepared by fermenting through bacillus subtilis, and aqueous solution of coarse gamma-polyglutamic acid or refined gamma-polyglutamic acid prepared from the fermentation liquor with a cross-linking agent in the presence of an inorganic acid or organic acid catalyst to obtain the water-retaining agent. The water-retaining agent has the water absorption multiple of 400-1,500 in distilled water and has the water absorption multiple of 60-150 in physiological saline. The water-retaining agent prepared by the microbiological technology is environment-friendly, so the water-retaining agent has great economic, environmental and social benefits in industries such as agriculture, forestry and the like in China.

Owner:领先生物农业股份有限公司

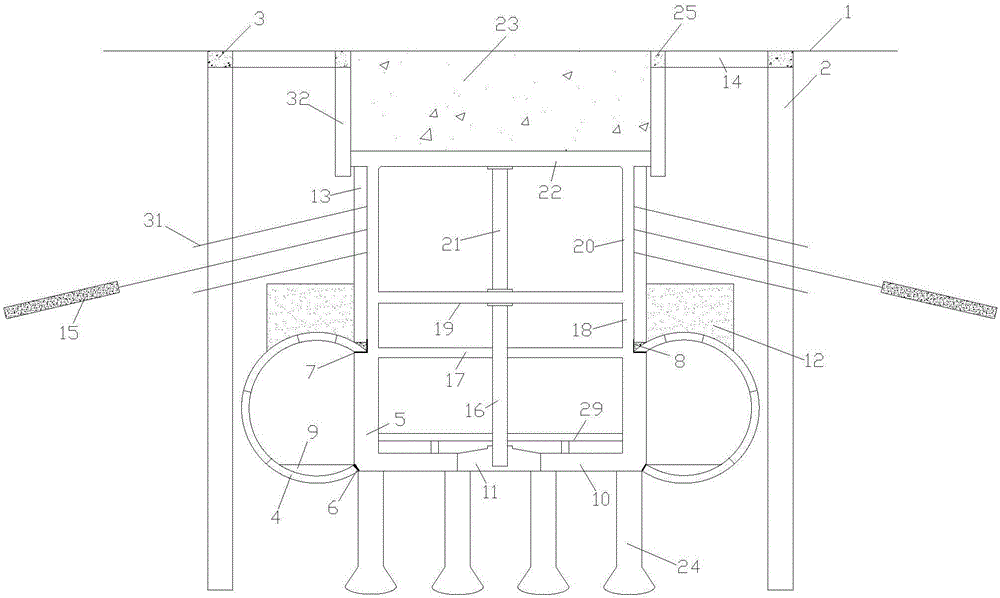

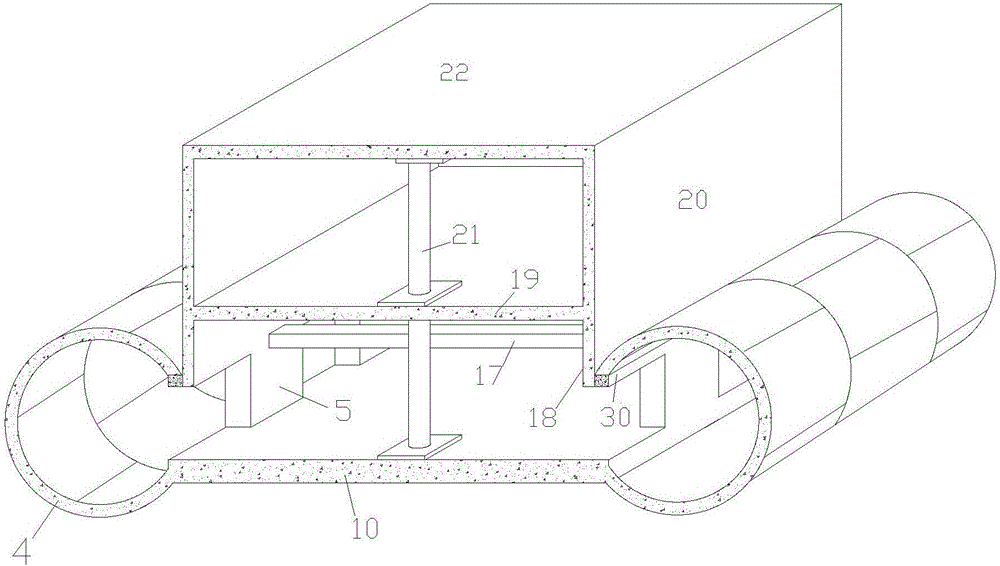

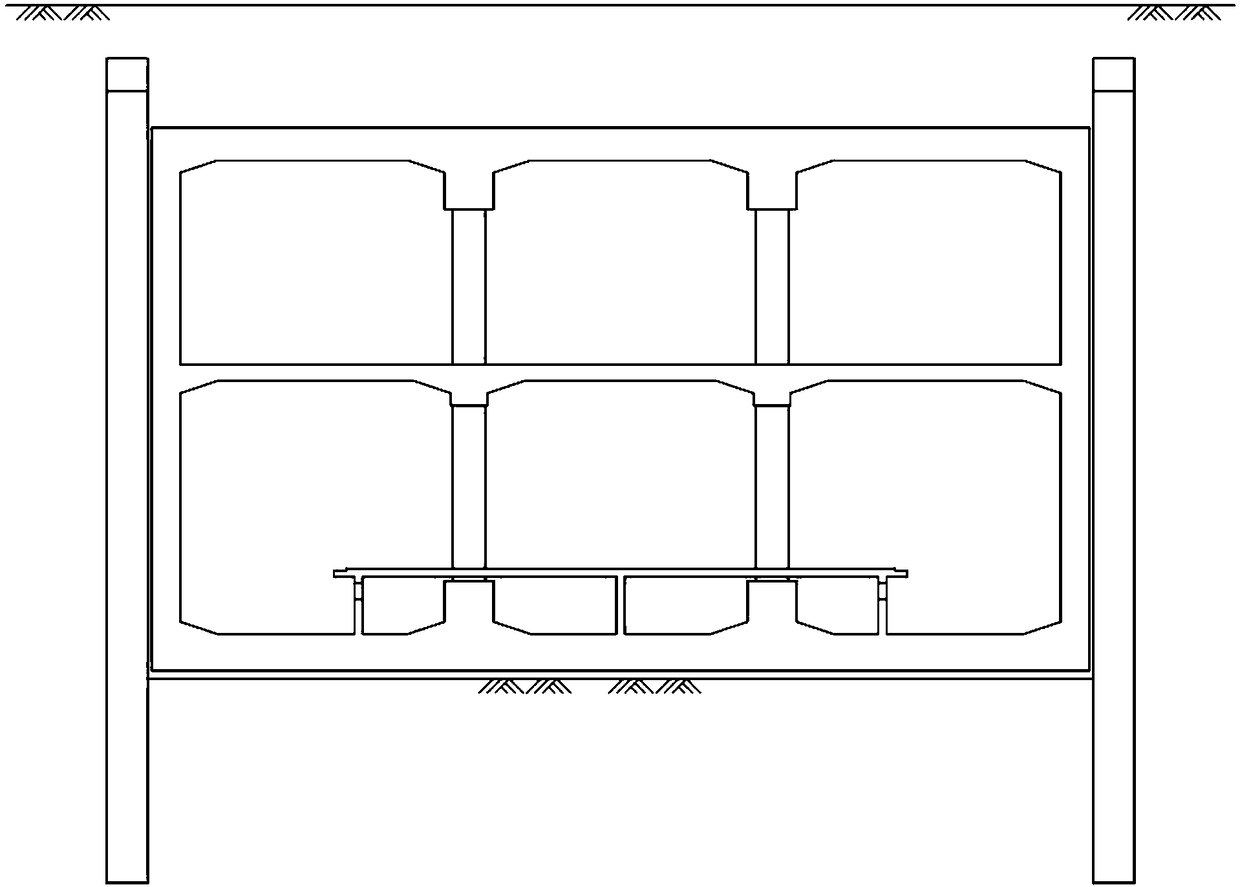

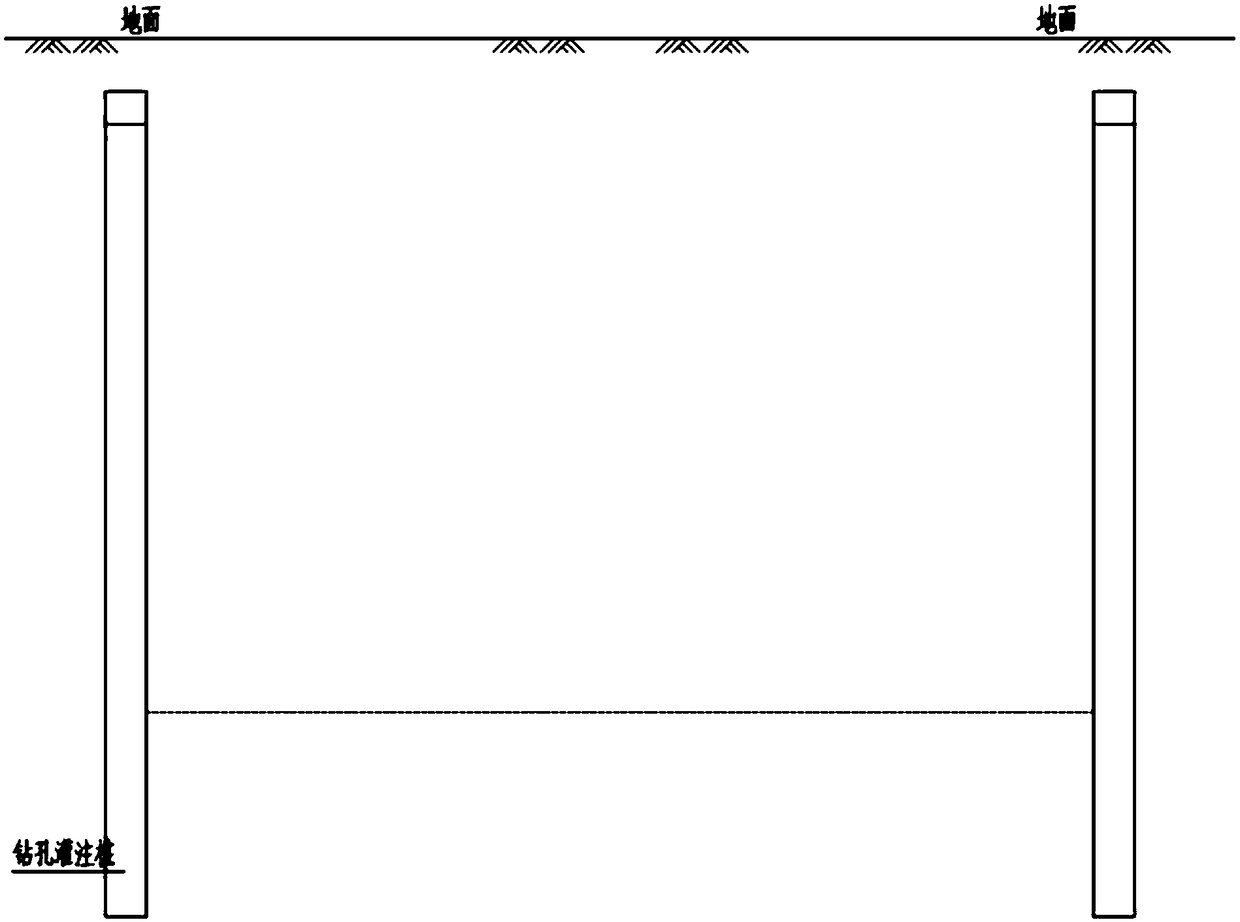

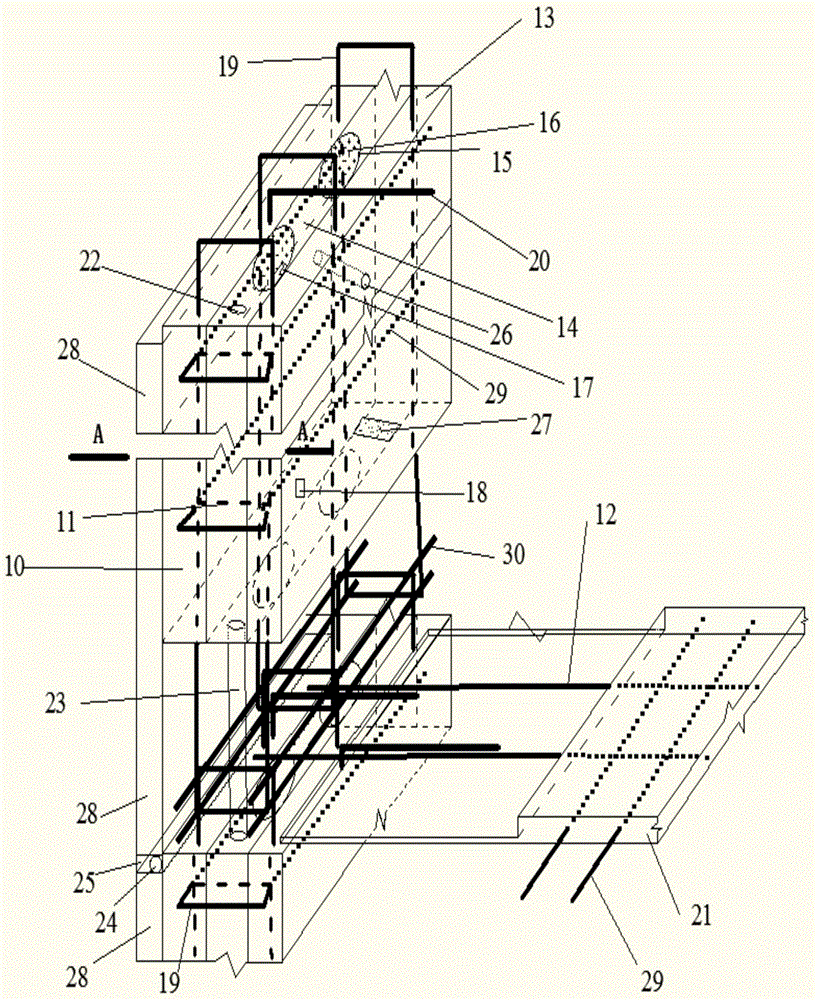

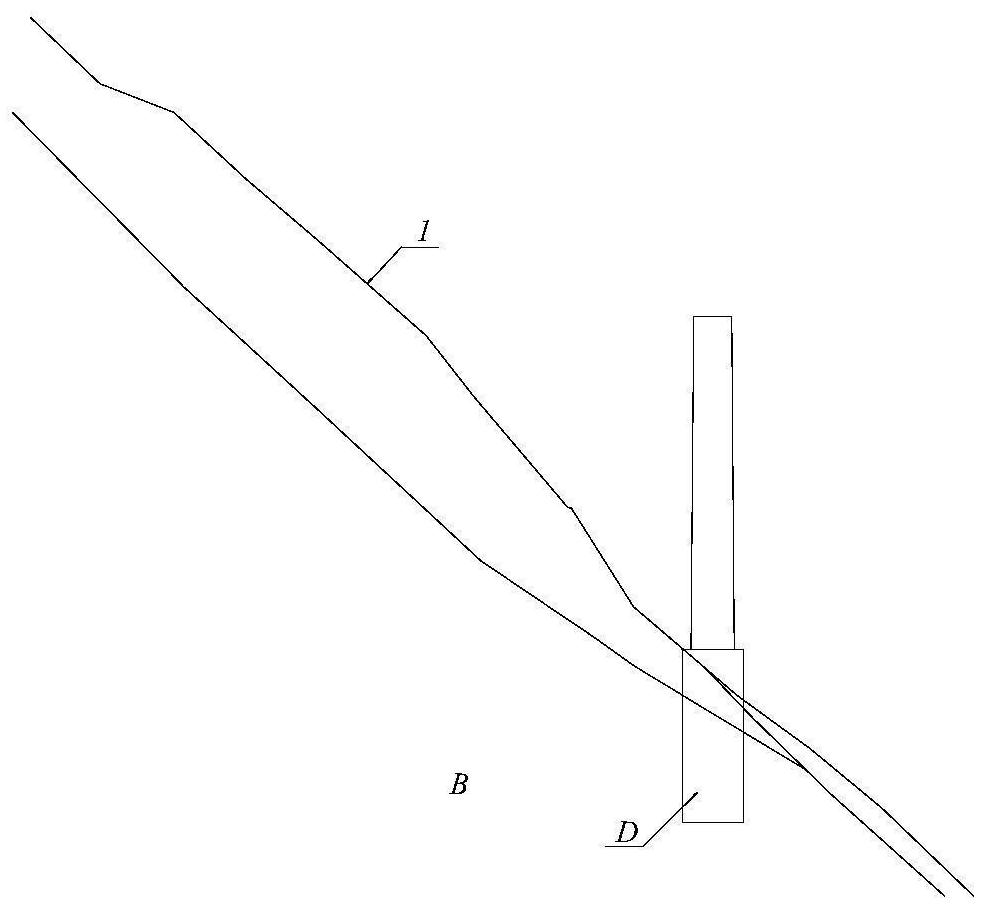

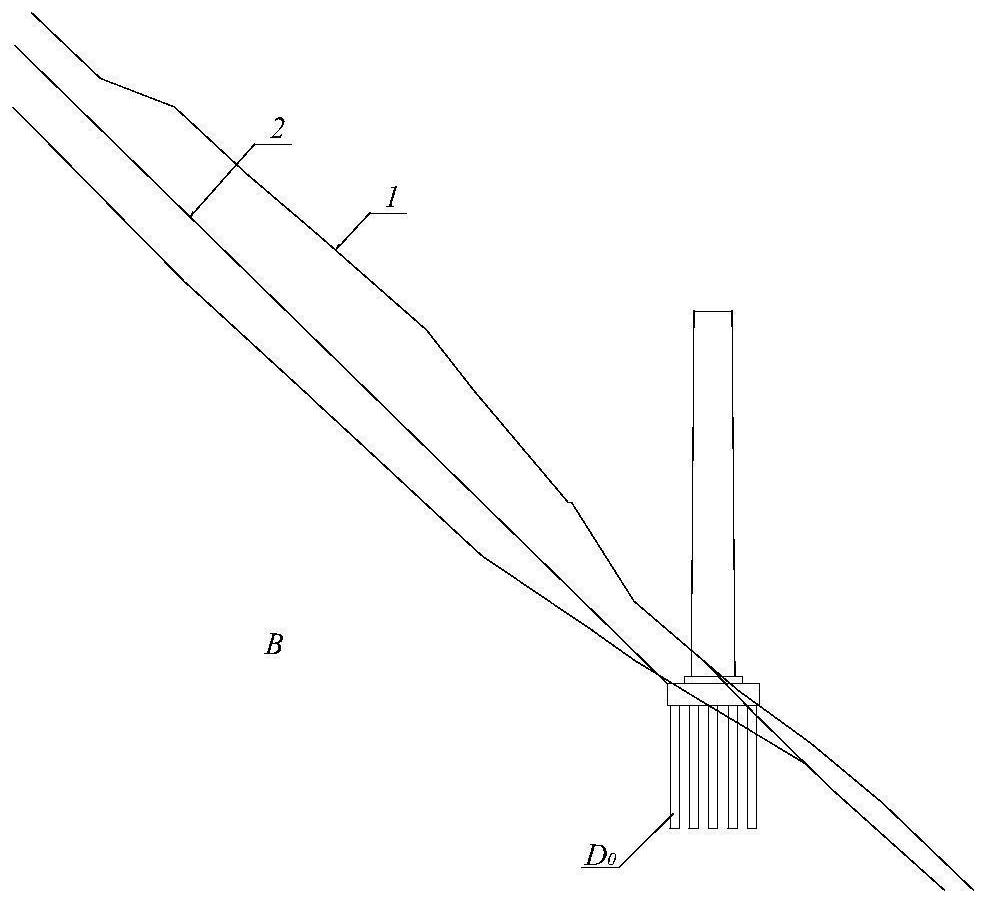

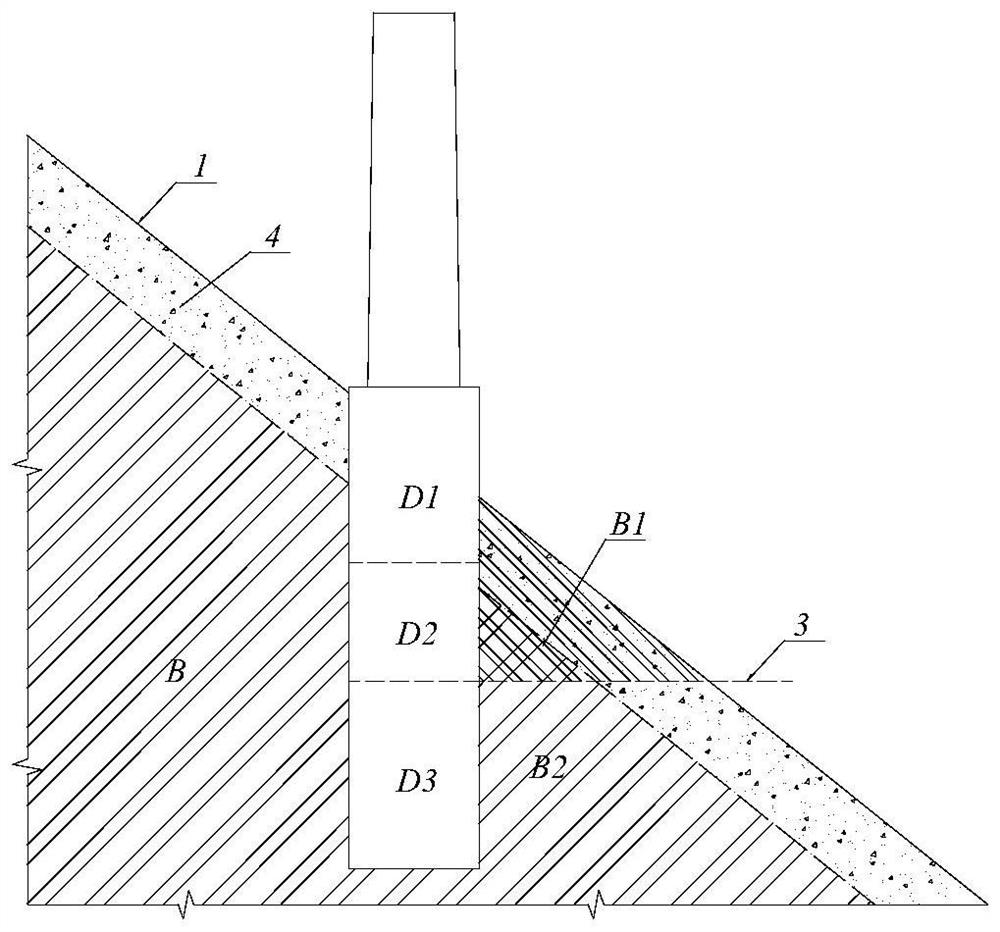

Reversed construction method for expanding and excavating stations on sectional shield tunnel foundations of subways

InactiveCN105003272AImprove construction efficiencyGuaranteed stabilityUnderground chambersTunnel liningSlurry wallSoil nailing

The invention discloses a reversed construction method for expanding and excavating stations on sectional shield tunnel foundations of subways. The expanded and excavated stations are simply supported frame wall column type double-layer subway stations in structural forms. The reversed construction method includes retaining soil and water by the aid of piles in rows and waterproof curtains or underground diaphragm walls, and resisting lateral deformation of soil mass; excavating the soil mass between openings of parallel shield tunnel segments and constructing cross passages; grouting and reinforcing the soil mass above tunnels, building foundation pit excavation supporting structures and short supporting piles of station bodies and connecting the tops of the foundation pit excavation supporting structures and the short supporting piles with the outer piles in the rows or the outer underground diaphragm walls by connecting beams; constructing the structures of the station bodies by the aid of cover and excavation top down processes, filling the station bodies with the soil mass and recovering road surfaces. Foundation pit slopes can be supported by the aid of composite soil nailing supporting technologies in excavation procedures. The reversed construction method has the advantages that the reversed construction method is reasonable and feasible, is high in operability and has important engineering application value and an important development prospect, and huge economic, social and environmental benefits can be brought by application of the reversed construction method.

Owner:BEIJING UNIV OF TECH

Titanium dioxide film adulterated with rare soil and the preparing method

InactiveCN101036879AFast preparationImprove photocatalytic activityCatalyst activation/preparationSpecial surfacesSocial benefitsOptical property

The present invention discloses a Tio2 film adulterated with rare earth, wherein the molecule percentage content of titanium and rare earth are as follows: titanium 85%-99%, rare earth 1%-15%. The preparation of the film adopts normal pressure thermal decomposition chemical vapor deposition method, wherein a propodosoma combination is deposited onto a glass substrate. The Tio2 film adulterated with rare earth of the present invention has excellent photocatalysis activity, hydrophilicity and optical property, and can be widely used for glass external wall, indoor decorating, etc,. The present invention greatly enlarges the application area of Tio2 film, and is hopeful for generating great economy, environment and social benefits.

Owner:ZHEJIANG UNIV

Method for culturing microalgae by utilizing flue gas of coal fired power plant

ActiveCN102061261AHuge societyGreat economyUnicellular algaeDispersed particle separationPtru catalystProcess engineering

The invention relates to a method for culturing microalgae by utilizing flue gas of a coal fired power plant, comprising the following steps of: firstly, introducing flue gas to a CO removing tower, and leading the trace amount of CO and NO to generate CO2 and N2 under the catalysis of active semicoke; leading the flue gas from the CO removing tower to enter a desulfurizing tower again, oxidizingSO2 in the flue gas into SO3 under the catalysis action of active semicoke by utilizing O2 contained in the flue gas, and absorbing the SO3 on a catalyst; leading the flue gas to enter a denitrifyingtower after passing through the desulfurizing tower, oxidizing the NO in the flue gas into NO2 under the catalysis of active semicoke by utilizing the O2 contained in the flue gas, and absorbing the NO2 on the catalyst; and introducing the purified flue gas to a microalgae culturing device, fixing the CO2 in the flue gas by oily microalgae and then passing through a flue gas-flue gas heat exchanger, and finally, exhausting the residual flue gas through a chimney. In the method, the flue gas of a thermal power plant is taken as one of raw materials for microalgae culture, high-quality oily microalgae is obtained as oil-producing materials, not only the environment is governed, but also fuel is produced, therefore, the method has very important social, economic and environmental benefits.

Owner:OCEAN UNIV OF CHINA

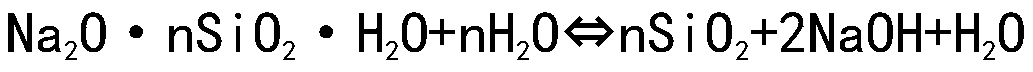

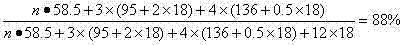

Preparation method of baking-free high-strength fly ash ceramsite

The invention discloses a preparation method of baking-free high-strength fly ash ceramsite. The preparation method comprises four stages of preparation of a mixed alkaline excitant, uniform mixing ofthe excitant and raw materials, balling by a balling disc, and maintenance and molding, wherein the mixed alkaline excitant is prepared by mixing and crushing dried desulfurized gypsum, fly ash and quick lime according to a certain ratio. The baking-free high-strength fly ash ceramsite has the advantages of low construction cost, convenience in preparation, simple process, light weight, high strength and the like, and can replace part of sandstone to prepare lightweight aggregate concrete and produce prefabricated parts; the fly ash is used as a main raw material, cement, quicklime and desulfurizing gypsum are a mixed alkaline activator and a curing agent, and sodium silicate is a binder; the comprehensive utilization approach of industrial solid waste fly ash and industrial by-product gypsum is expanded while unfired high-strength fly ash ceramsite is prepared, and the concept of the green circular economy and the sustainable development of a building material is enhanced.

Owner:ANHUI GAODI BUILDING MATERIAL CO LTD

Filling paste prepared from salt deposit exploitation tail salt and consolidated filling method thereof

ActiveCN102515683AReduce storage footprintAvoid softening damageSolid waste managementMaterial fill-upHigh concentrationEcological environment

The invention discloses filling paste prepared from salt deposit exploitation tail salt. The filling paste is characterized in that: tail salt prepared by performing ore dressing processing on sylvite or carnallite ore is taken as a filling substrate; the filling substrate mainly comprises NaCl and MgCl2, and hemihydrate gypsum CaSO4 1 / 2H2O is taken as a cementing material; NaCl serving as an aggregate for solidifying the filling substrate is added as required, and the concentration of a filling material is adjusted by controlling the adding amount of NaCl; and paste of which the mass concentration is 81-88 percent is formed by mixing and stirring the filling substrate with the cementing material. The invention further discloses a filling method for using the filling paste. High-concentration paste is prepared by using the tail salt and the cementing material, the paste filling material is solidified through a physical-chemical reaction after being pumped to an underground worked out section, and a filling body with certain strength can be formed without dehydration in a stope. Softening damage to ore columns and wall rock caused by water contained in filling slurry is avoided, and the ecological environments on the ground surface and the periphery of a mining area are protected effectively.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

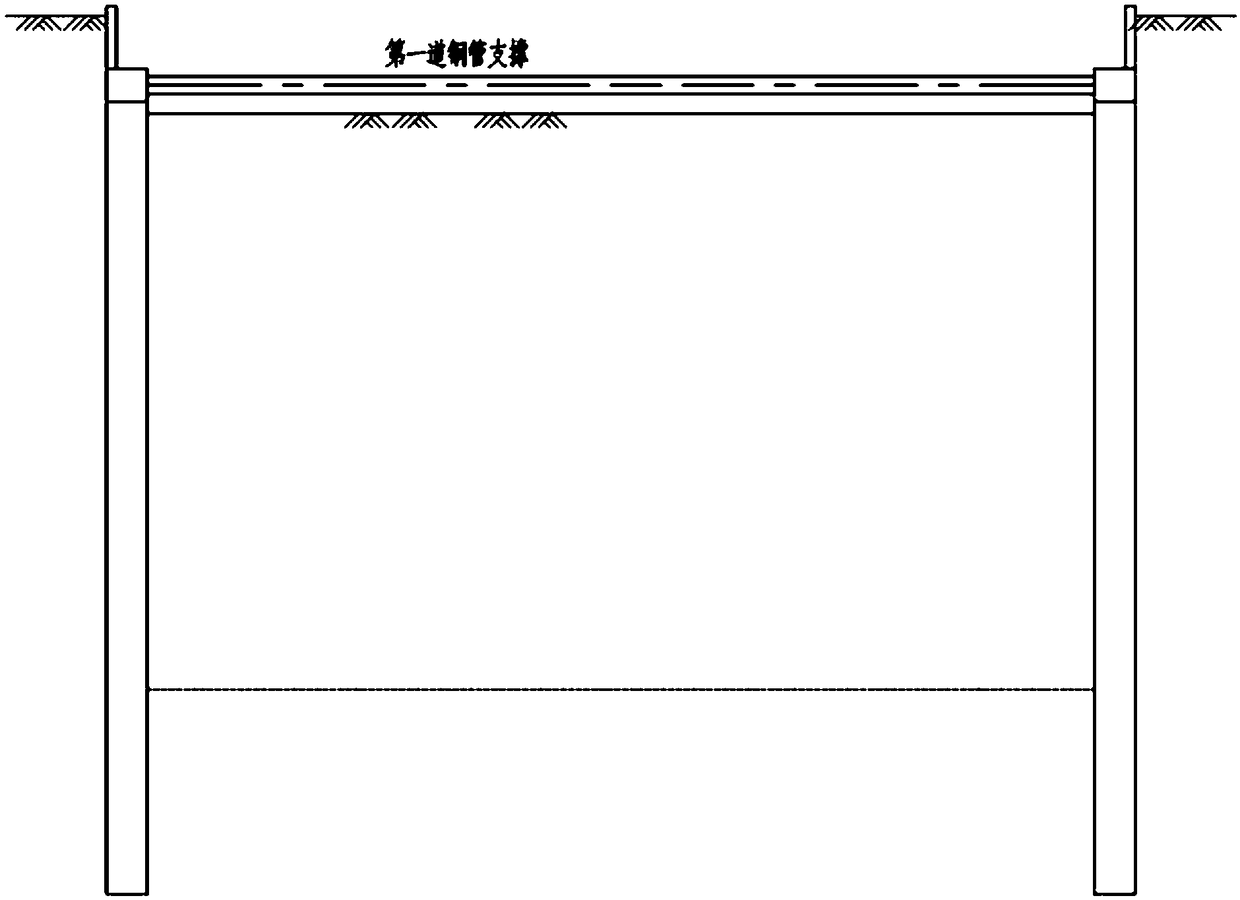

Open-cut station body structure and construction method thereof

InactiveCN108914966AGuaranteed stabilityGuaranteed lateral stabilityArtificial islandsUnderwater structuresStructural engineeringEngineering

The invention discloses an open-cut station body structure and a construction method thereof. A station body is of a two-layer double-column three-span box-shaped structure. The construction method includes the steps that a site is leveled, a precipitation well is dug, precipitation is carried out, foundation pit drainage measures are taken, and cast-in-situ bored piles are arranged; a foundationpit is dug to the depth 0.7 m below a first support, pile top crown beams are arranged, and the first steel support is erected; the foundation pit continues to be dug downwards to the bottom of the foundation pit, a second support and a third support are sequentially erected, and waist rails are put in time; a bottom plate concrete structure is poured, side wall waterproof layers are arranged, andpart of side walls are poured; inverted supports are arranged, the third steel support is detached, and a remaining side wall structure on the second floor underground and a middle plate structure onthe first floor underground are poured; and the second steel support is detached, a side wall and top plate structure on the first layer underground is poured, a top plate waterproof layer is arranged, timely backfill is carried out, backfill is carried out to the position of the first steel support, the first steel support and the inverted supports are detached after a soil layer is compacted, backfill is carried out to the ground, and a station plate structure and other internal components are arranged.

Owner:BEIJING MUNICIPAL CONSTR

Gas permeable brick for producing carbon baking furnace flame path wall by gold tailings and iron tailings

The invention relates to an air brick for carbon calcining furnace quirk wall produced by gold gangues and iron gangues, which effectively solves the problems of utilization of the gold gangues and the iron gangues and bad high temperature resistance capability of the existent air brick. The technical scheme includes using gold gangues and iron gangues as the powder raw materials, bauxite as the bone raw materials, andalusite powder as the shrinkproof agent and SiO2 fine powder as the binder, which are prepared in proportion to produce a mixture material, and then adding CA-70 calcium aluminate cement into the mixture as the delayed coagulant agent, PE fiber as the ignition substance and trimetric sodium phosphate as the plasticizing agent, which are all uniformly cast into the air bricks. The invention effectively solves the problems of utilization of the gold gangues and the iron gangues and high-temperature creep resistance performance of the air bricks, prolongs the service life and creates huge social and economic efficiencies.

Owner:郑州祥通耐火陶瓷有限公司

Clean new process for producing common and high performance isomeric viscose base carbon fiber (or film)

InactiveCN1858314AGreat economyHuge environmental benefitsFibre chemical featuresIonSurface oxidation

The new clean process of producing common and high performance viscose-base isomeric carbon fiber (or film) includes the following steps: alkali and acid washing material pulp, oxidizing or ammoniating to obtain fireproof isomeric pulp; dissolving the isomeric pulp in alkali solution to obtain spinnable isomeric viscose solution; debubbling the solution, spinning, washing with acid and deionized water and other step to obtain common isomeric viscose tow fiber or film; damp and heat drafting, drying to densify, heat shrinking to stabilize to obtain high performance fireproof isomeric viscose tow fiber or film; further soaking in ammonium salt aqua, pre-oxidizing, low temperature carbonizing, high temperature carbonizing and graphitizing of the common isomeric viscose tow fiber or film or the high performance fireproof isomeric viscose tow fiber or film to obtain common and high performance viscose-base isomeric carbon fiber or film; and final surface oxidation, sizing and drying to obtain the corresponding product.

Owner:李换位

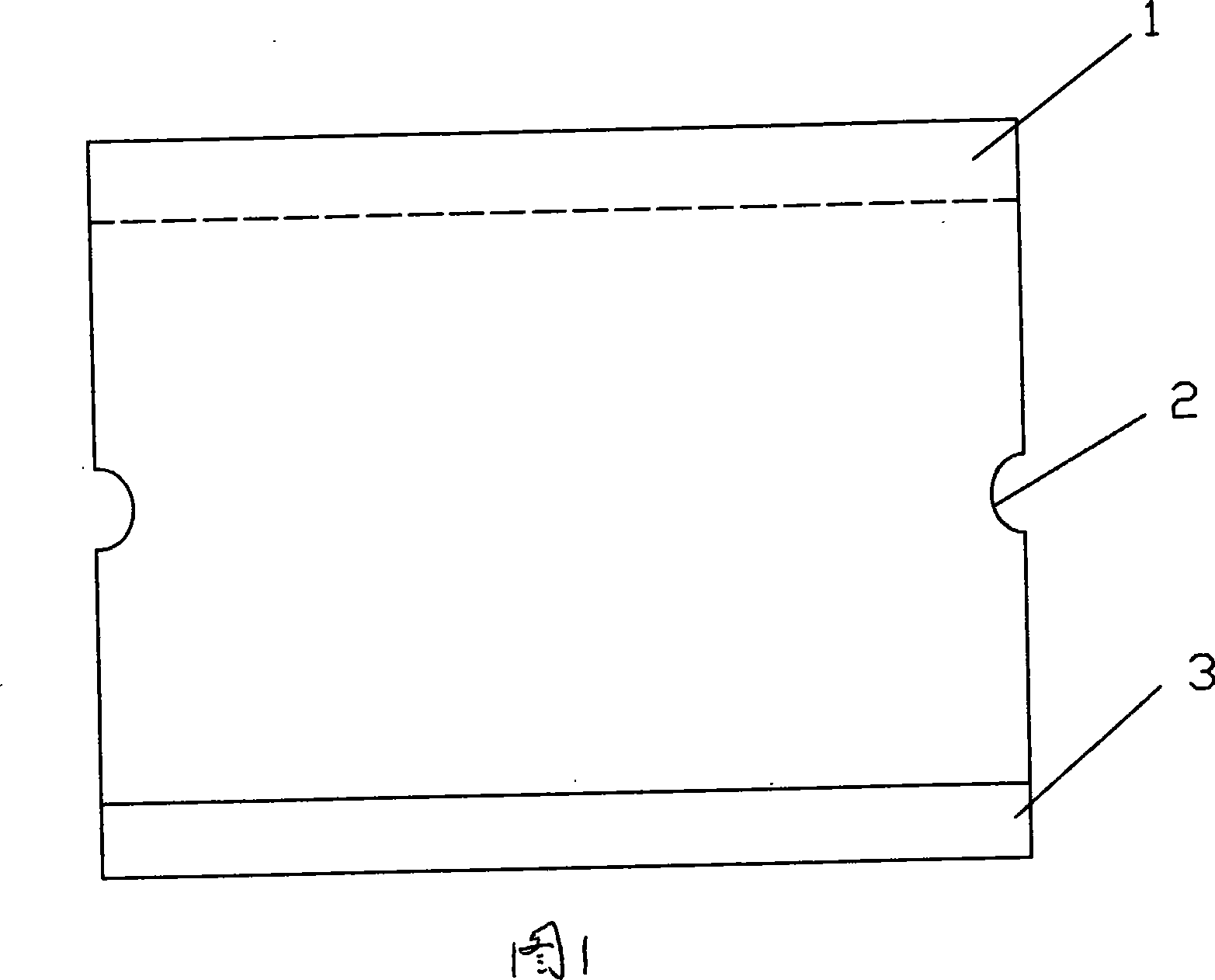

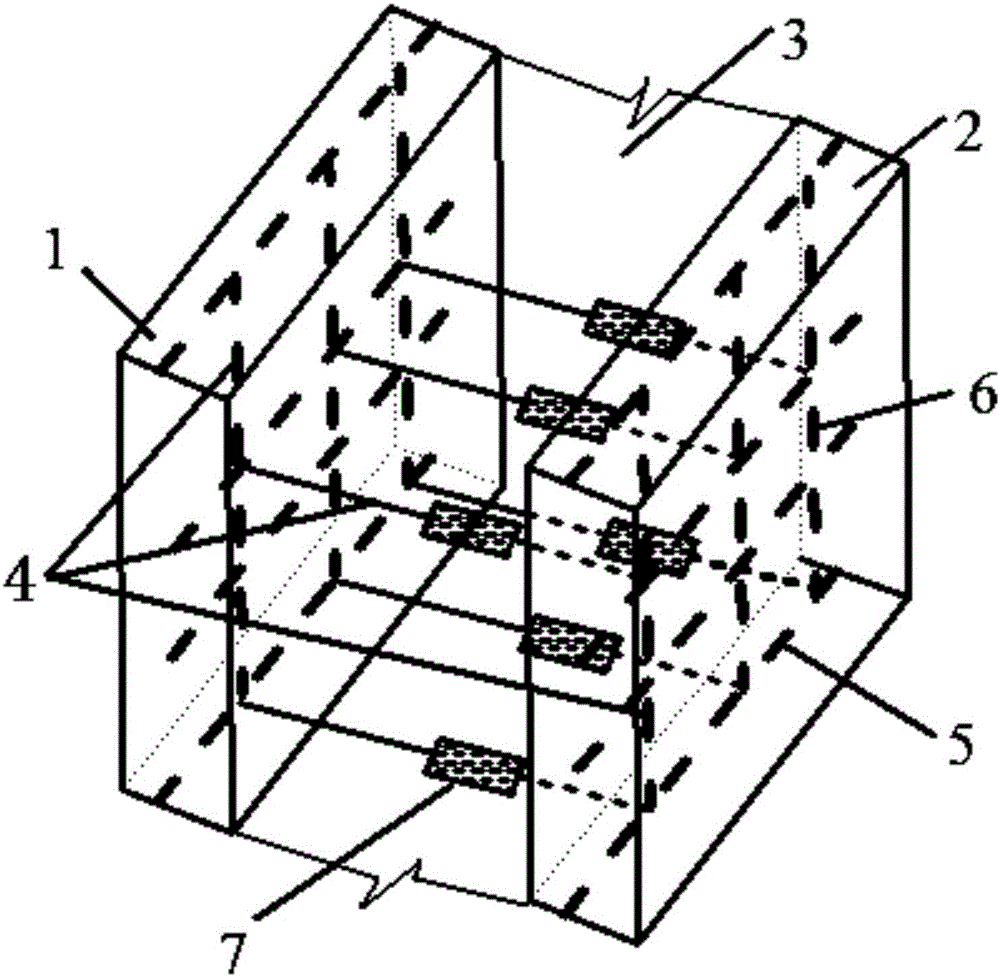

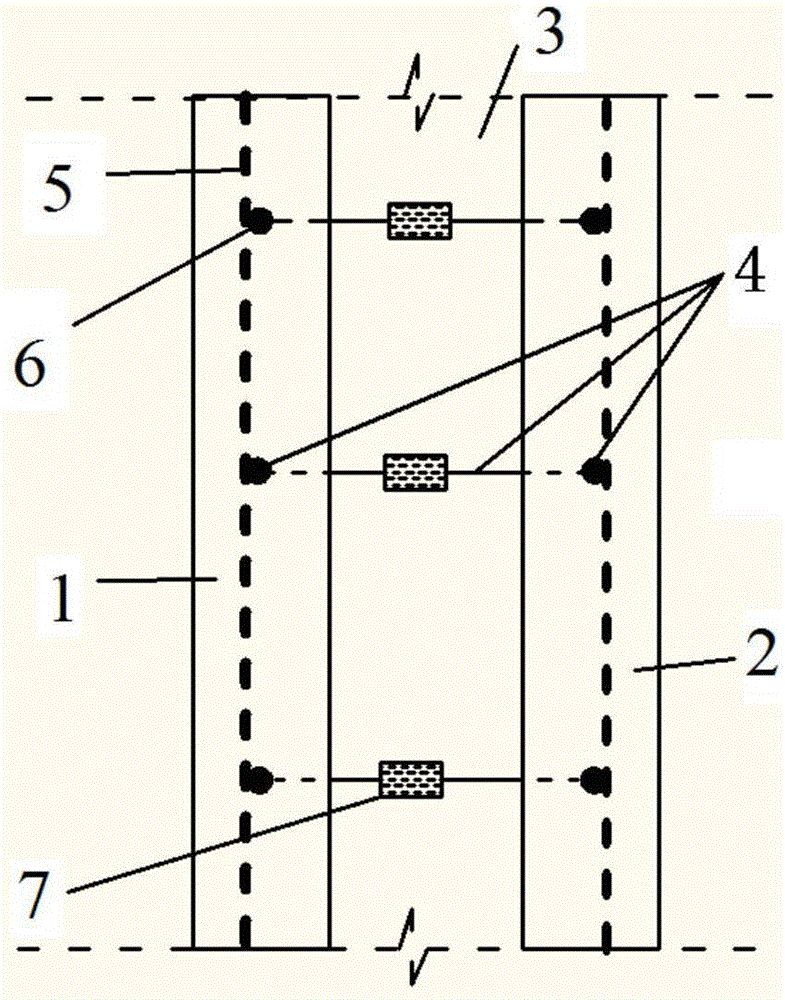

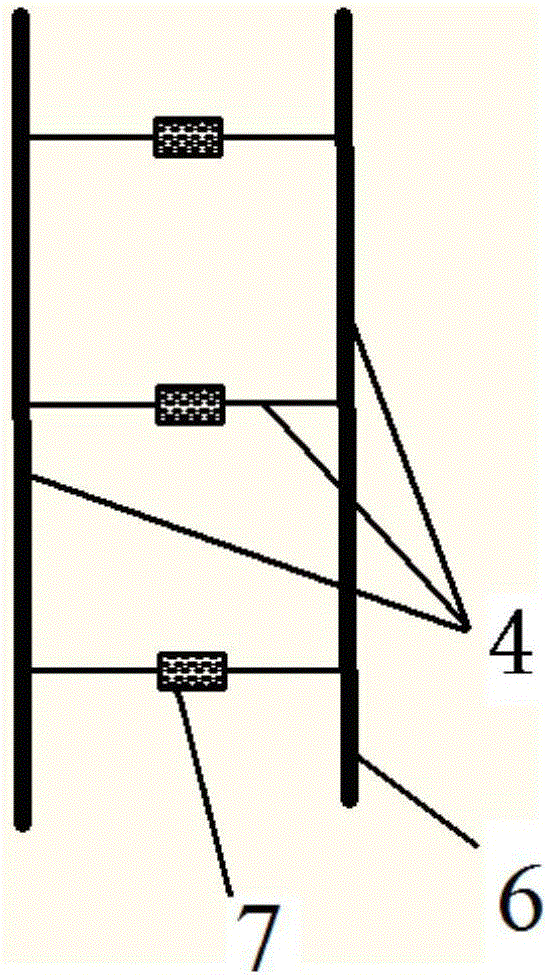

Fabricated concrete composite wallboard structure

InactiveCN105569260AImprove lateral force resistanceIncrease overturning forceBuilding componentsLine tubingWhole body

The invention provides a fabricated concrete composite wallboard structure. The fabricated concrete composite wallboard structure comprises an outer wallboard arranged towards the outside of a building, an inner wallboard arranged towards the inside of the building, and a reinforcing rib located between the outer wallboard and the inner wallboard, wherein the outer wallboard, the reinforcing rib and the inner wallboard are tied to form a whole body via a net rack; a functional compound layer is adhered to the outer surface of the outer wallboard; a part extending out of the outer wallboard, the reinforcing rib and the inner wallboard of the net rack is combined with cast-in-place concrete to form a hidden beam; a core hole used for reducing self weight of the structure is formed in the reinforcing rib along a vertical direction; a pipeline channel arranged along an axial direction of the core hole and used for laying pipelines is arranged in the core hole; and / or the core hole is also filled with core hole filling materials used for preserving heat and insulating heat; a pipeline box corresponding to the pipeline channel is pre-buried in the inner wallboard. Through type and quantity of the core hole filling materials, different heat preservation requirements in southern and northern regions are met; type and thickness of sound absorbing layers can be adjusted to meet the sound insulation requirement of the building, so that the application range of the multifunctional fabricated concrete composite wallboard is extended.

Owner:CENT SOUTH UNIV +1

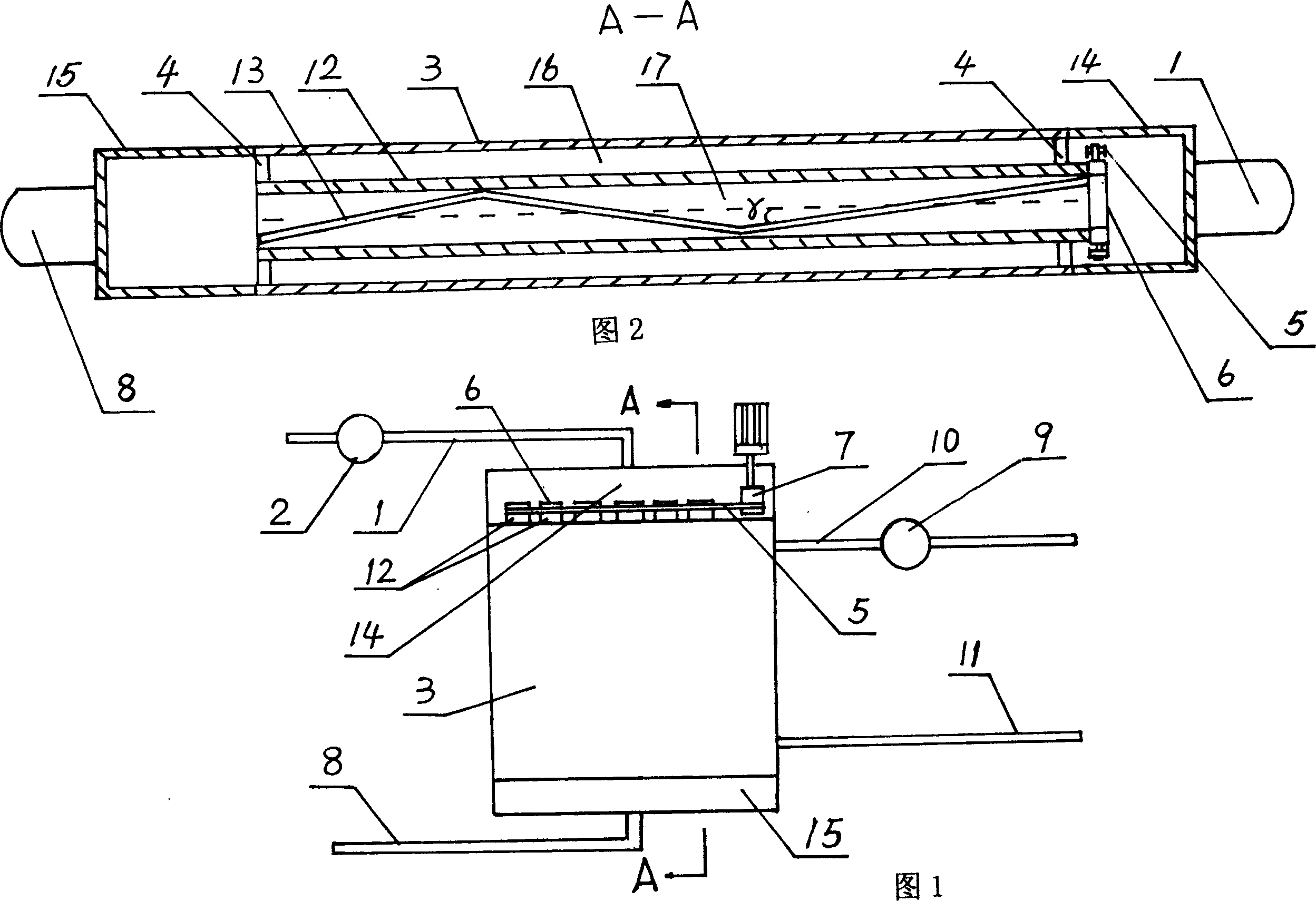

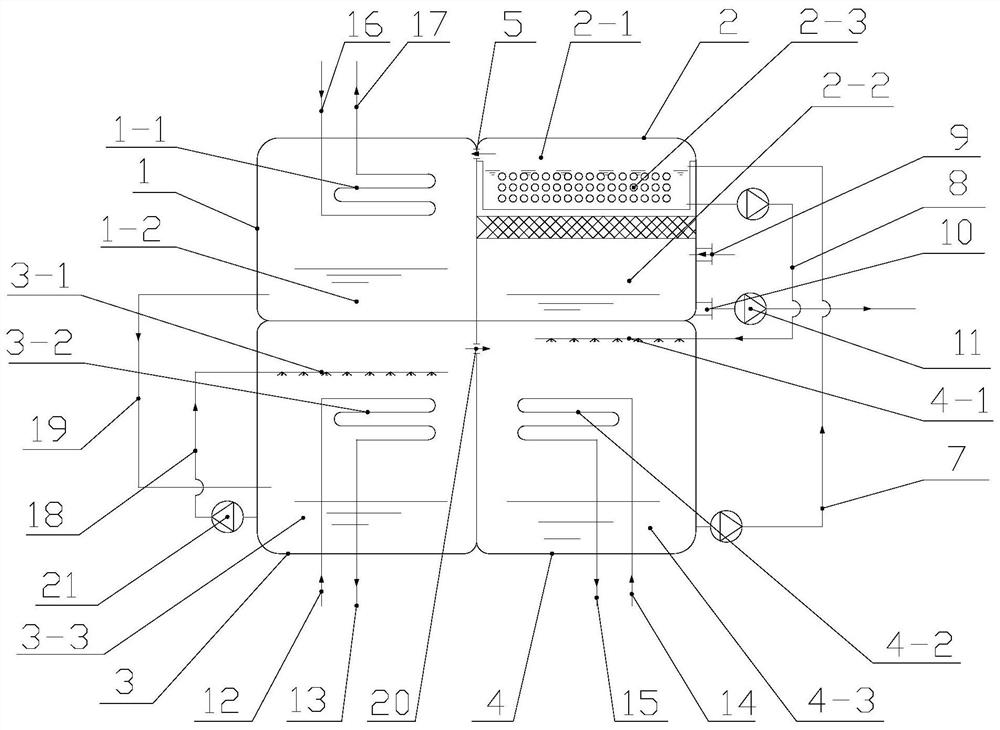

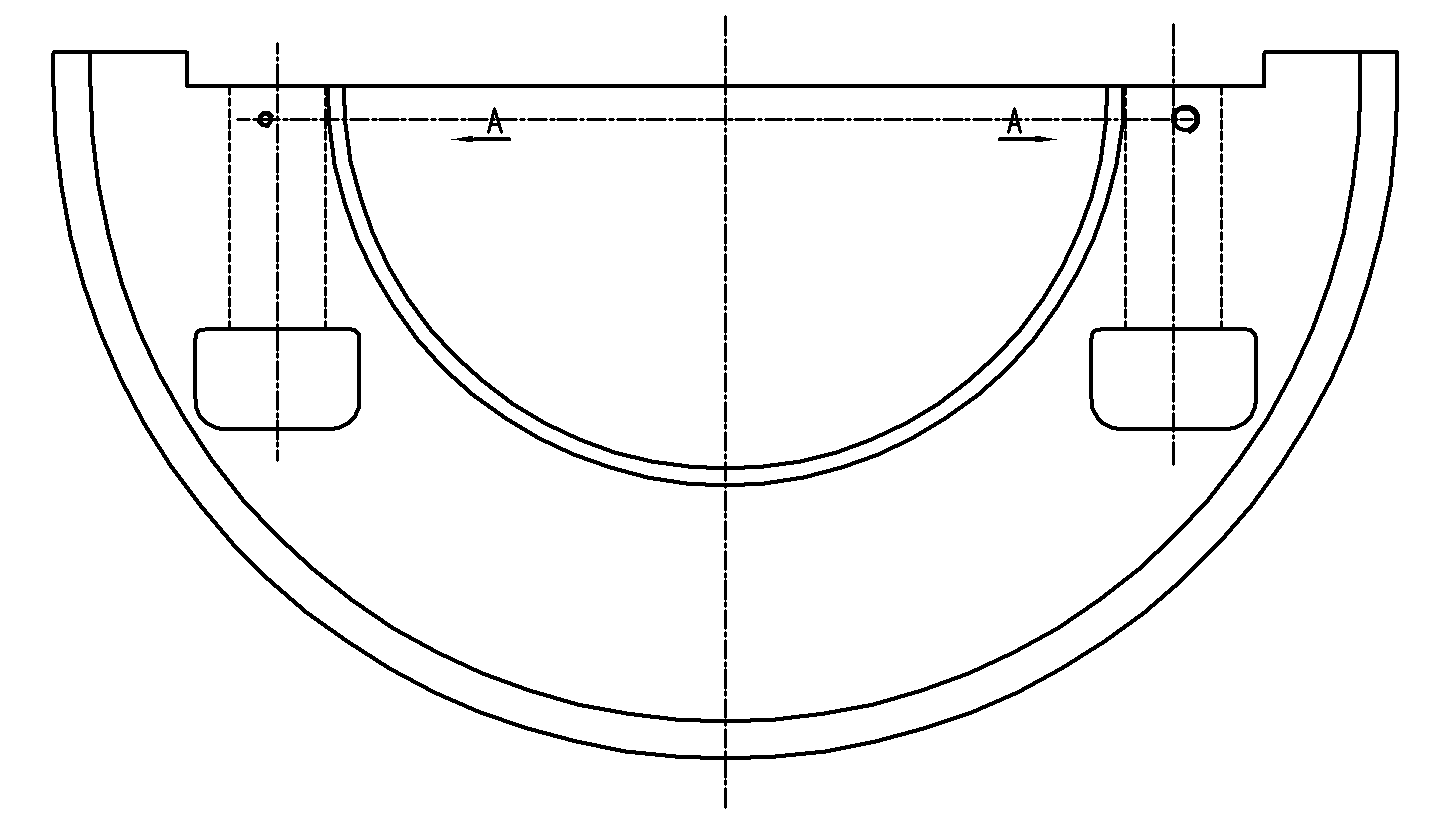

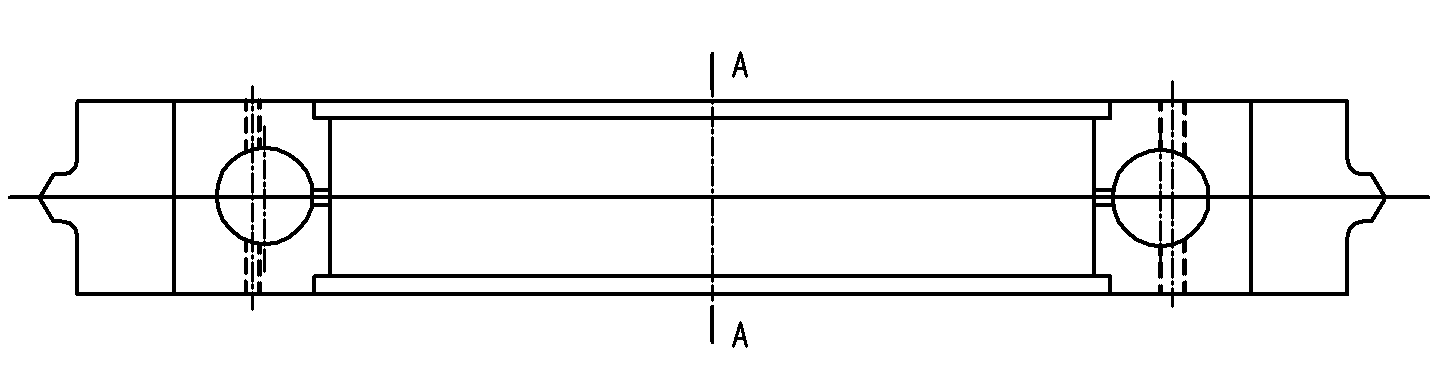

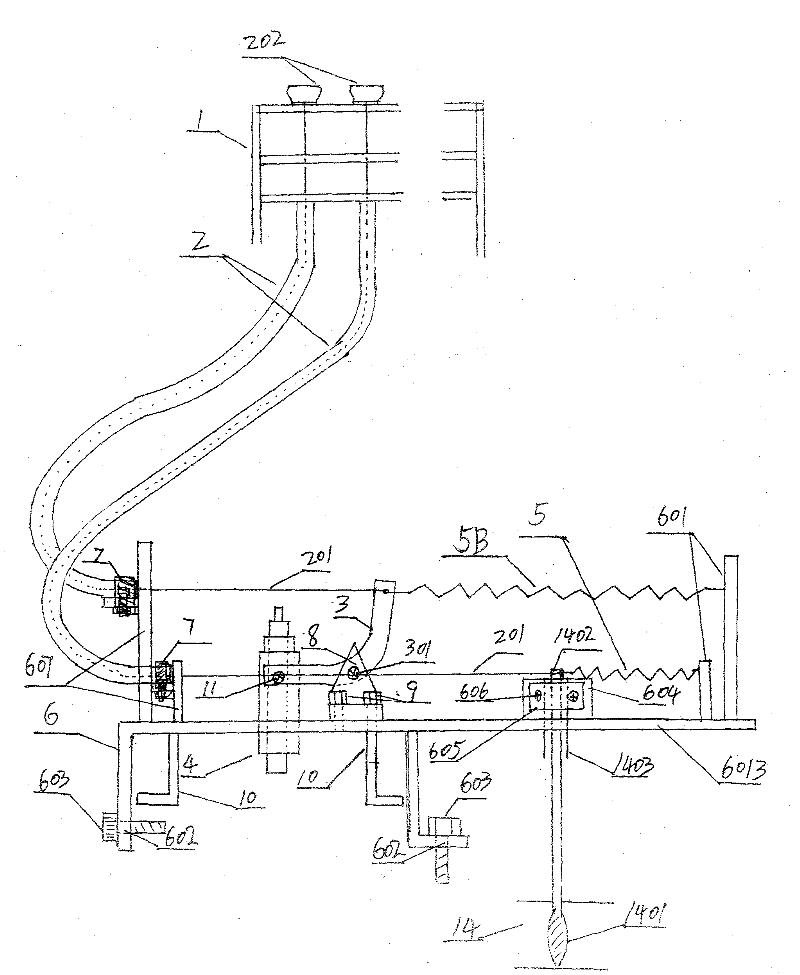

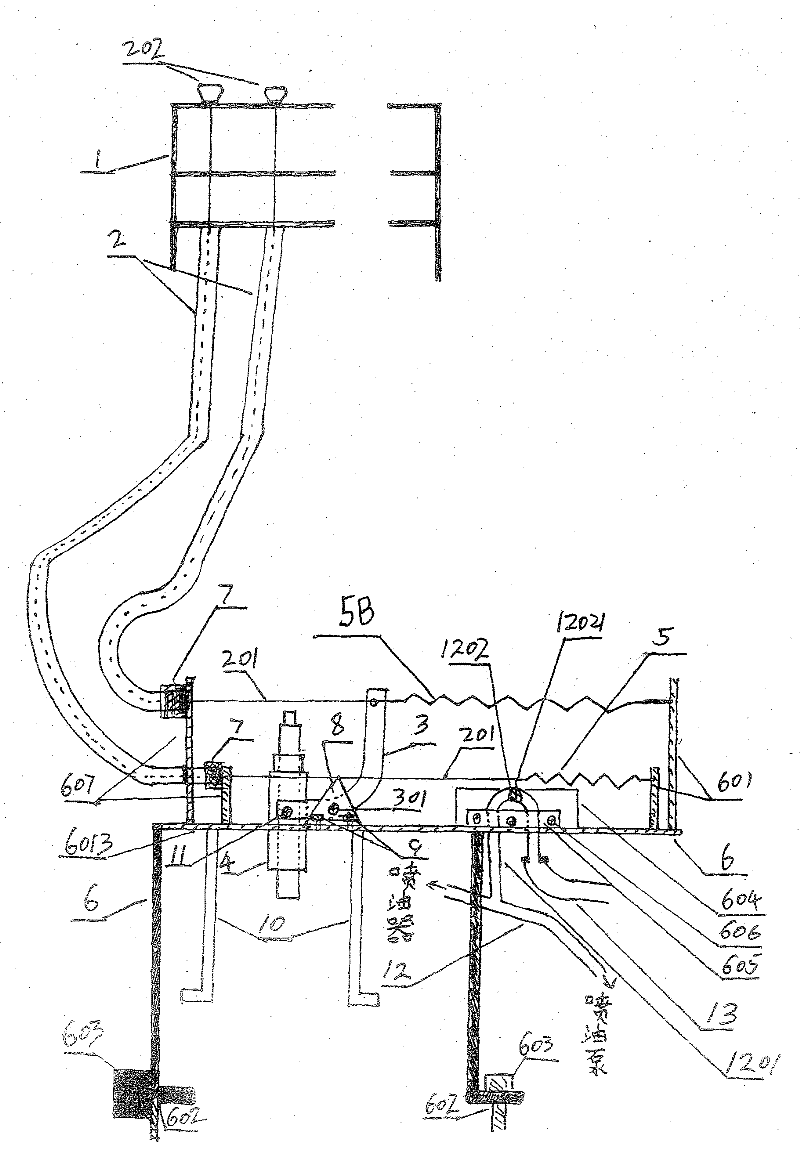

Collection device for cold water solidification heat

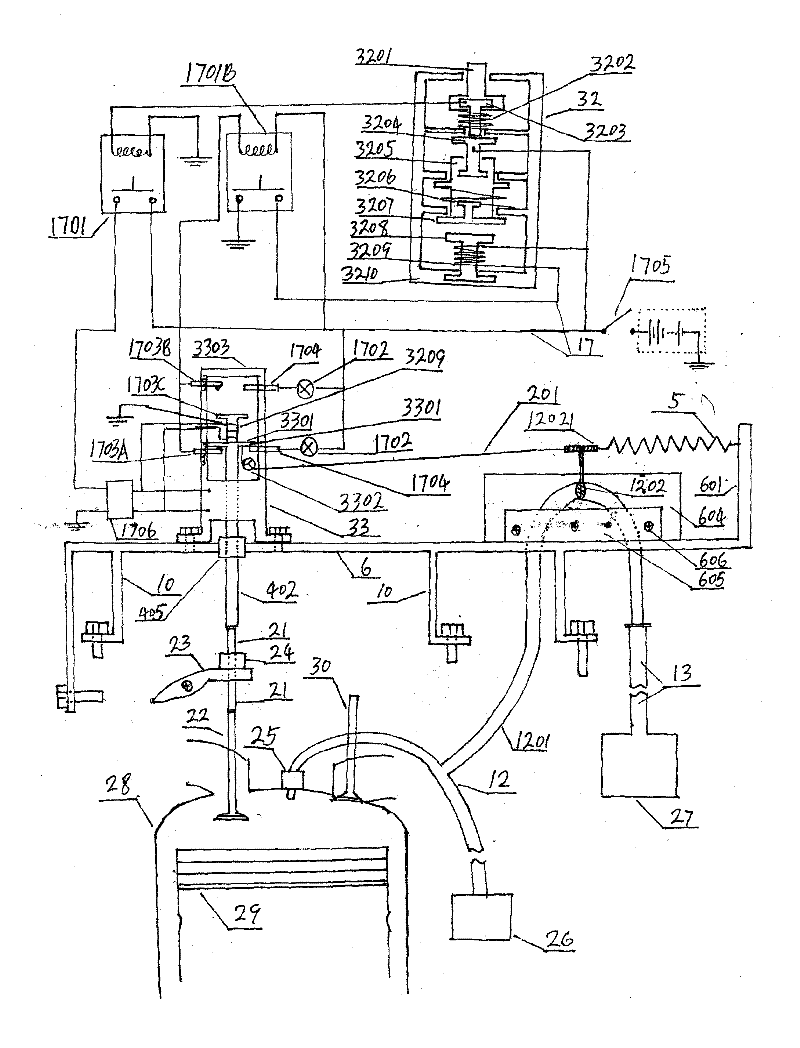

InactiveCN1800746AAddress situations where requirements cannot be metHigh heat extraction efficiencyOther heat production devicesFood processingMotor speedReducer

The invention relates to a collector of cold water solidification heat. The heat exchange icing pipe (12) is fixed inside the heat exchange icing device (3) while they are sealing connected by the sealing ring (4) to form a water-glycol space (16); the heat exchange icing pipe (12) has a water-ice space (17); the continuous scrapping plate (13) is arranged inside the heat exchange icing pipe (12) while its one end is connected to the main axle (6) on the end of heat exchange icing pipe (12); and the main axle (6) is connection to the motor speed reducer (7) inside the cold water inlet cover (14) via the chain transmission. The invention has simple structure and high heat-collection efficiency, while it can break the point of 0Deg. C to ice the water and attain the solidification heat.

Owner:HARBIN INST OF TECH

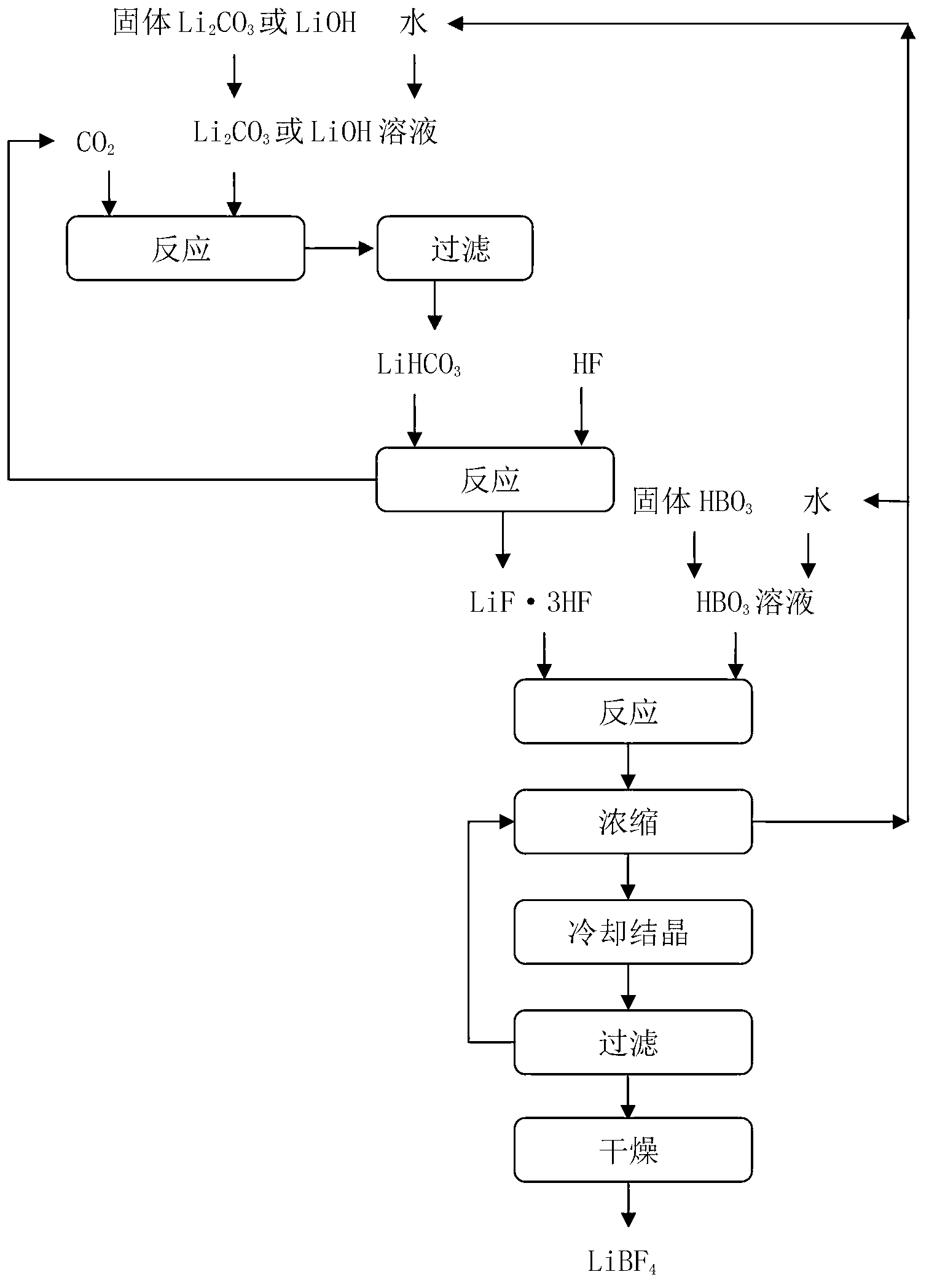

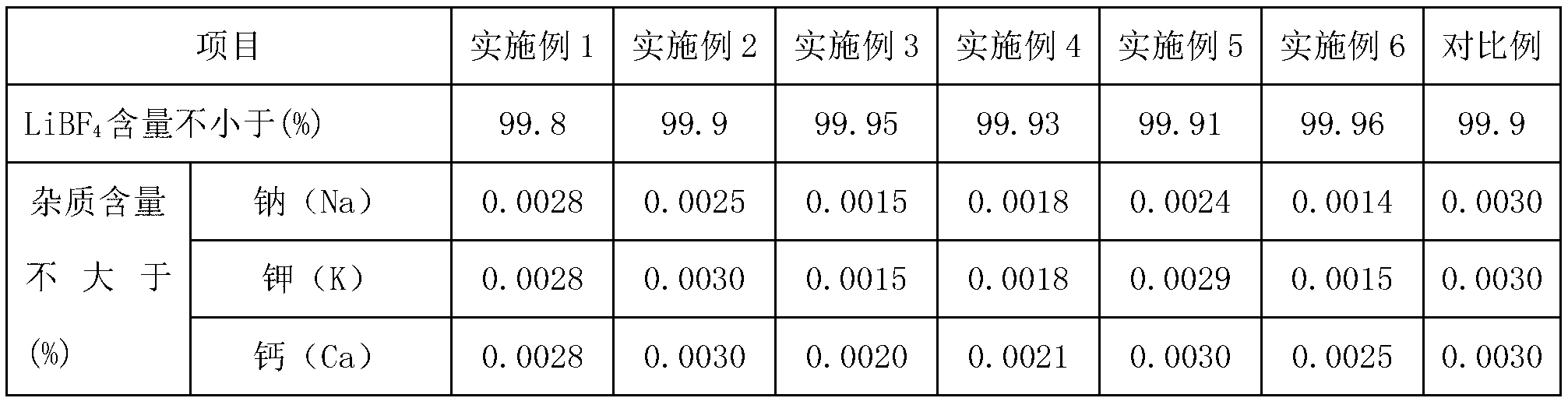

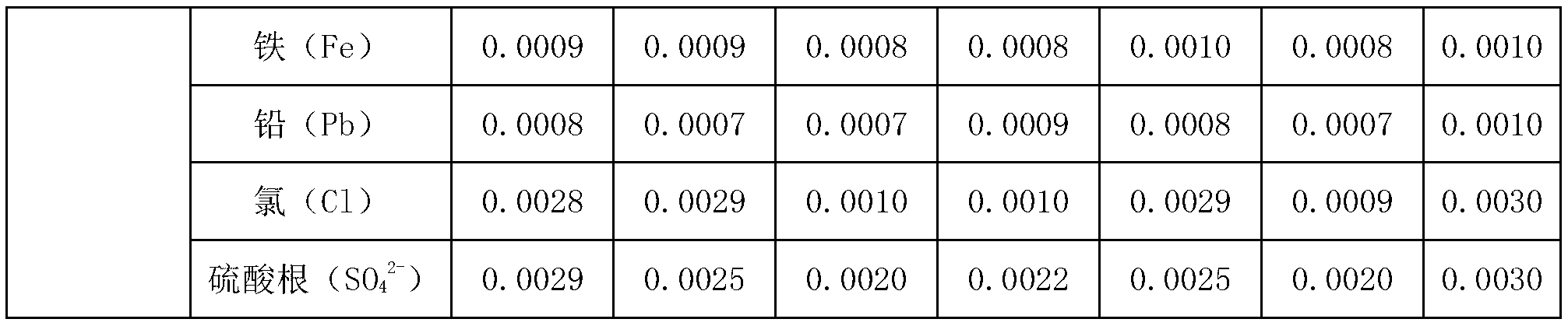

Preparation method for lithium tetrafluoroborate

The invention discloses a preparation method for lithium tetrafluoroborate, and the method comprises the following steps: 1) preparing lithium carbonate or lithium hydroxide into slurry, continuously feeding into CO2 for reaction to generate LiHCO3, and filtering a reaction solution to obtain a LiHCO3 solution; 2) mixing the LiHCO3 solution obtained in step 1) with anhydrous hydrofluoric acid for reaction at a room temperature to obtain a LiF.3HF solution; 3) reacting the LiF.3HF solution obtained in step 2) with a boric acid solution to obtain a lithium tetrafluoroborate solution; and 4 ) concentrating the lithium tetrafluoroborate solution obtained in step 3), cooling the concentrated solution to give crystals, filtering and drying the crystals to obtain the lithium tetrafluoroborate. According to the preparation method of the present invention, the product quality is improved, the obtained product meets requirements of lithium-ion batteries either as a novel lithium salt or as a film-forming additive for lithium ion battery electrolyte; the raw materials adopted are readily available and inexpensive, the raw material utilization is high, thus improving productivity, reducing production costs, and being suitable for industrial mass production.

Owner:DO FLUORIDE CHEM CO LTD

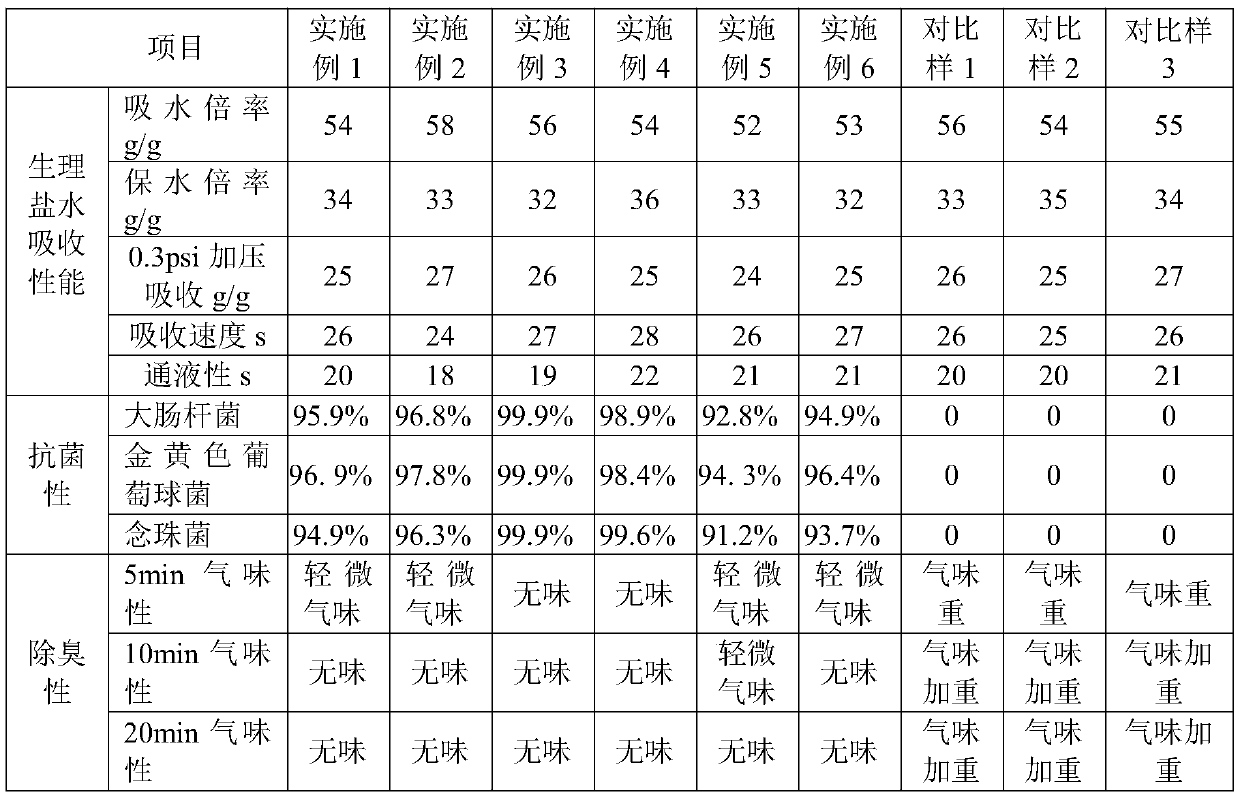

Anti-microbial deodorizing super absorbent resin compound

InactiveCN110075342AImprove washdown resistanceStrong antibacterial and deodorizing effectAbsorbent padsBandagesCross-linkPolymer science

The invention provides an anti-microbial deodorizing super absorbent resin compound which comprises a pre-crosslinked acrylic polymer. In parts by weight, 0.5-20 parts of plant antibacterial agent isjointed in 100 parts of pre-crosslinked acrylic polymer; a cross-linking agent is used for treating the surface of the pre-crosslinked acrylic polymer; the plant antibacterial agent is prepared from the following materials by weight percent: 20%-35% of tea leaves, 30%-45% of folium artemisiae argyi and 25%-45% of leonurus. A method of combining the pre-crosslinked acrylic polymer with the plant antibacterial agent includes the following steps: jointing the plant antibacterial agent in the pre-crosslinked acrylic polymer; or bonding the plant antibacterial agent on the surface of the pre-crosslinked acrylic polymer by adopting a cross-linking solution for performing surface thermo-crosslinking treatment; adopting the cross-linking solution for performing surface thermo-crosslinking treatment on the pre-crosslinked acrylic polymer at 70-180 DEG C, thereby acquiring the super absorbent resin compound.

Owner:邦丽达(福建)新材料股份有限公司

Method for preparing biodiesel from oil with high acid value

ActiveCN102533455AIncrease contact areaExtension of timeFatty acid esterificationBiofuelsBiodieselReaction rate

The invention discloses a method for preparing biodiesel from oil with a high acid value. The method comprises the steps as follows: mixing oil with a high acid value with methanol, adding compound acid catalyst, carrying out esterification reaction, removing crude methanol through flash vaporization, adding potassium hydroxide methanol solution, performing transesterification reaction, removing crude methanol through flash vaporization again, standing liquid from which crude methanol is removed and settling for 4 to 5 hours, and removing glycerol through separation to obtain crude biodiesel.The method has the characteristics of low device investment, simple process, low manufacturing cost, high reaction rate and high conversion rate of products.

Owner:山东锦江生物能源科技有限公司

Dry-type cement filling method realized by aid of extracted tail salt of salt deposit

ActiveCN102562145AEffective protectionAvoid destructionUnderground miningSurface miningEcological environmentSalt deposit

The invention relates to a dry-type cement filling method realized by the aid of extracted tail salt of a salt deposit. The dry-type cement filling method is characterized in that a filling material in the method is tail salt remained after beneficiation processing of sylvine or carnallite ores; the main ingredients of the tail salt are NaCl or NaCl and MgCl2; the filling material is solid, and is conveyed in a well by modes of drop shaft sliding, underground automobile conveying, belt conveying and the like; the filling method is used for cement filling; and when the main ingredients of the tail salt are NaCl and MgCl2, cementing agent is added in the filling material, and is clay or saturated NaCl brine. By the aid of tail salt dry-type cement filling, a filling body with the certain strength can be formed in a hollow area, damage of ore pillars and surrounding rocks can be prevented effectively, surface collapse and subsidence are prevented, and recovery safety is maintained. A large quantity of tail salt is utilized, occupied area of stacked tail salt is greatly reduced, and the ground surface of a mining area and surrounding ecological environments are protected effectively.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

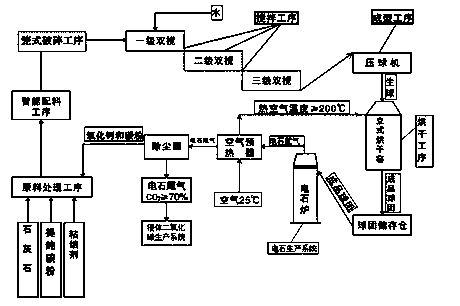

Method for producing calcium carbide by virtue of waste gas

ActiveCN104355312AGreat economyHuge environmental benefitsEnergy inputCalcium carbideThermal energySeparation technology

The invention relates to a process technology for producing calcium carbide by virtue of waste gas, dust and waste heat, and belongs to the technical field of industrial production of calcium carbide. Dust in the waste gas produced in calcium carbide production is recovered as a part of raw materials for calcium carbide production according to a chemical principle of calcium carbide production, a new powdery raw material is supplemented, a high-performance Xuguang calcium carbide binder is added to prepare pellets, a great amount of heat produced by combusting carbon monoxide in the calcium carbide waste gas and the sensible heat of furnace gas are taken as heat sources for drying the calcium carbide pellets, tail gas containing more than or equal to 70 percent of carbon dioxide is produced by the combustion of carbon monoxide, carbon dioxide is separated by a pressure swing absorption gas separation technology or a membrane separation technology, and according to market demands, liquid carbon dioxide with high added value is prepared by a cryogenic technology, or dry ice is further prepared. According to the process technology, the calcium carbide waste gas, dust and waste heat are effectively utilized, energy is saved, consumption is reduced, and the economic benefits of a calcium carbide enterprise are comprehensively improved.

Owner:云南云博天环境科技有限公司

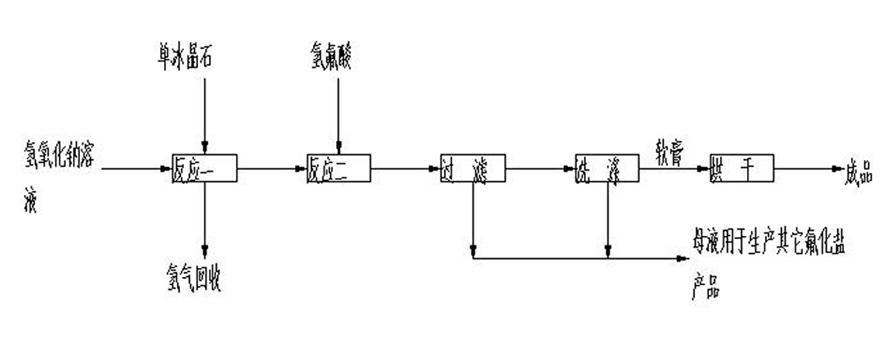

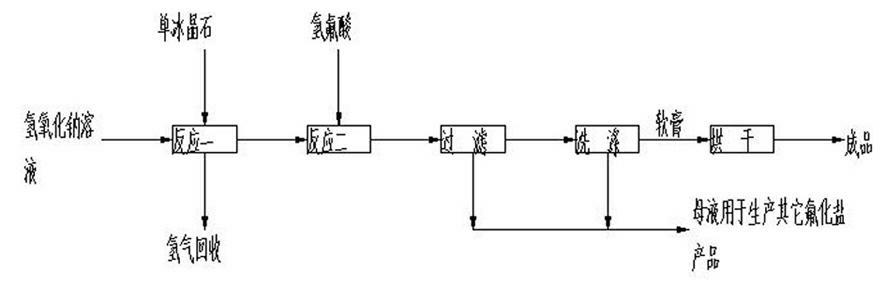

Method for comprehensively utilizing chemical byproduct single cryolite

ActiveCN102107900ALow impurity contentIncrease profitHydrogen productionAluminium fluoridesHydrofluoric acidFluoride products

The invention belongs to the technical field of polysilicon production, in particular to a method for comprehensively utilizing a chemical byproduct single cryolite during production of polysilicon. The method comprises the following steps of: reacting the single cryolite with sodium hydroxide solution to generate hydrogen and sodium aluminate slurry; and reacting the sodium aluminate slurry withhydrofluoric acid to prepare cryolite for aluminum, wherein the byproduct, namely hydrogen in the reaction process is purified and recovered to serve as a byproduct; and mother liquid is used for producing other fluoride products, or being neutralized by adding lime and then being discharged. The byproduct, namely single cryolite, of polysilicon is used for producing cryolite for aluminum, so rawmaterials are readily available, cost is low and the utilization ratio of the raw materials is high; the produced cryolite for aluminum has low impurity content and meets national standard; and wasteis changed into treasure, which accords with production ideas of comprehensive utilization of resources, energy conservation and environmental protection.

Owner:BAIYIN ZHONGTIAN CHEM

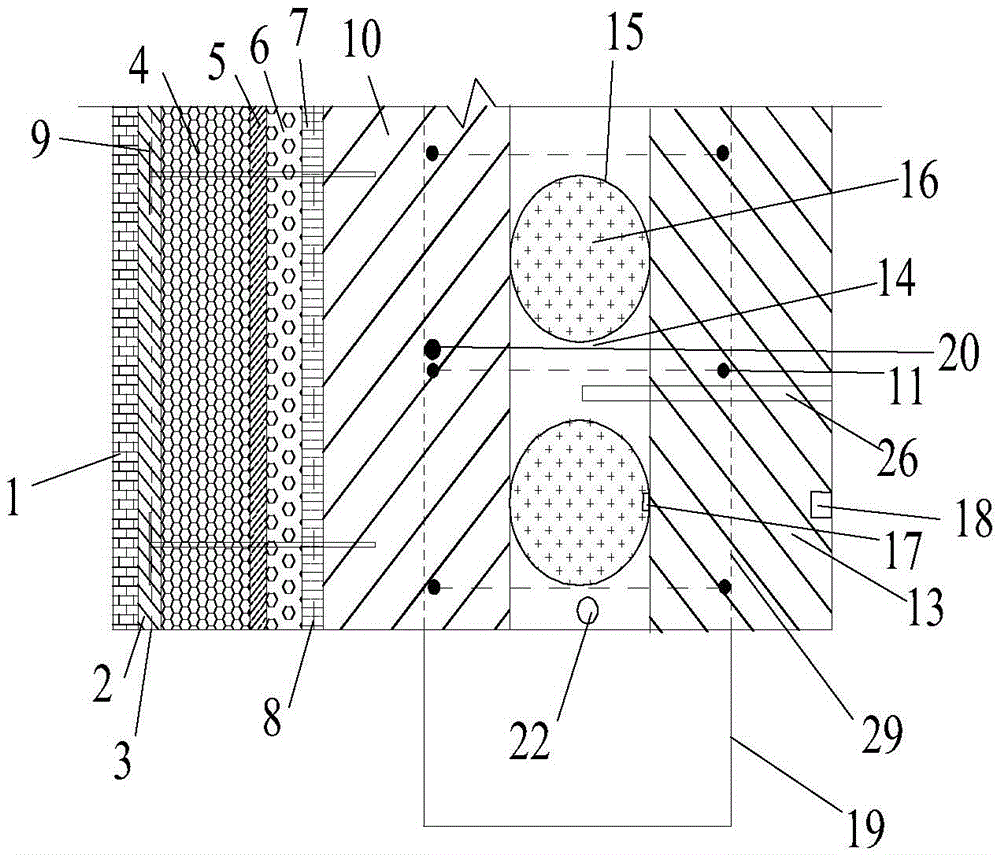

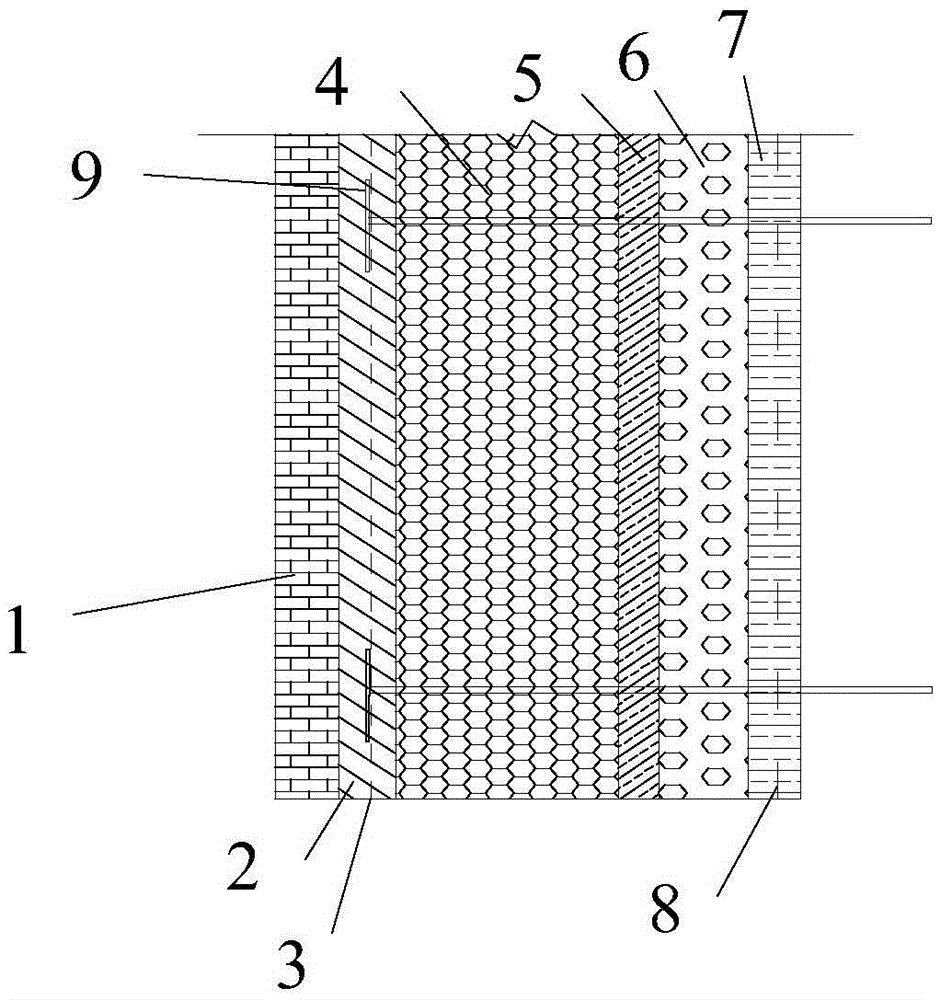

Assembly type reinforced concrete wall structure based on thermal bridge partition technology

ActiveCN105735517AEnvironmentally friendlyHigh degree of mechanizationWallsHeat proofingSocial benefitsReinforced concrete

The invention provides an assembly type reinforced concrete wall structure based on the thermal bridge partition technology. The assembly type reinforced concrete wall structure comprises an exterior wall panel, a wall panel intermediate layer, an interior wall panel and trusses. A wall is of a sandwich structure formed by the exterior wall panel, the wall panel intermediate layer and the interior wall panel from outside to inside. Chord members of the trusses are embedded in the exterior wall panel and the interior wall panel correspondingly. Web members of the trusses penetrate through the wall panel intermediate layer, and the two ends of the web members are connected with chord members of the exterior wall panel and chord members of the interior wall panel correspondingly. The web member of each truss is provided with a web member connecting part used for cutting off a thermal bridge between the exterior wall panel and the interior wall panel. The assembly type reinforced concrete wall structure based on the thermal bridge partition technology has the advantages of being capable of cutting off the thermal bridge, integral in structure and function, good in integrity and the like, overcomes the defects of an existing assembly type concrete wall panel system and has good economic and social benefits.

Owner:CENT SOUTH UNIV +1

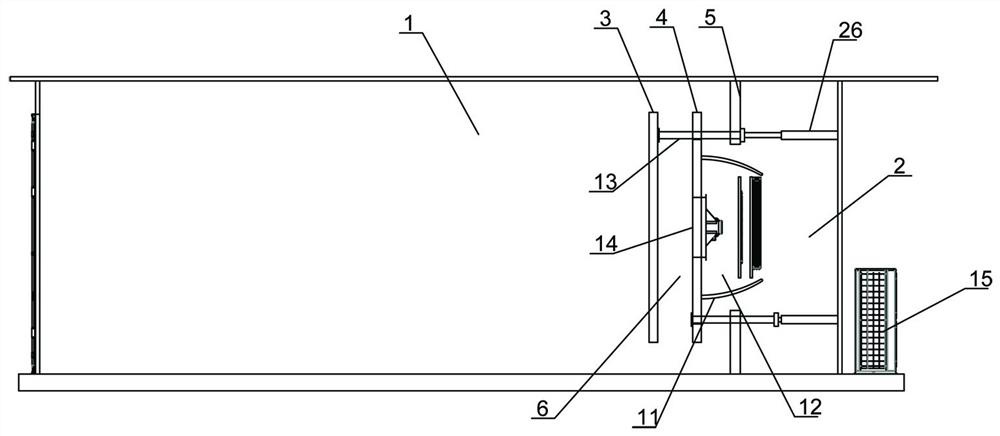

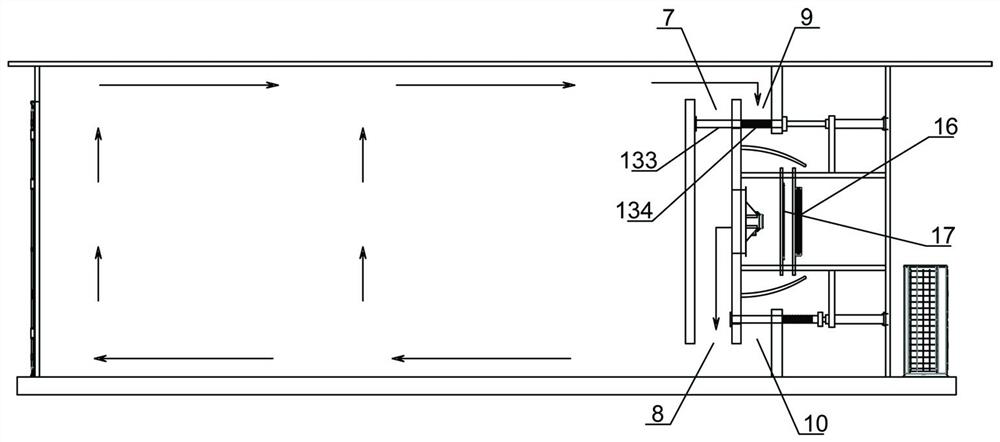

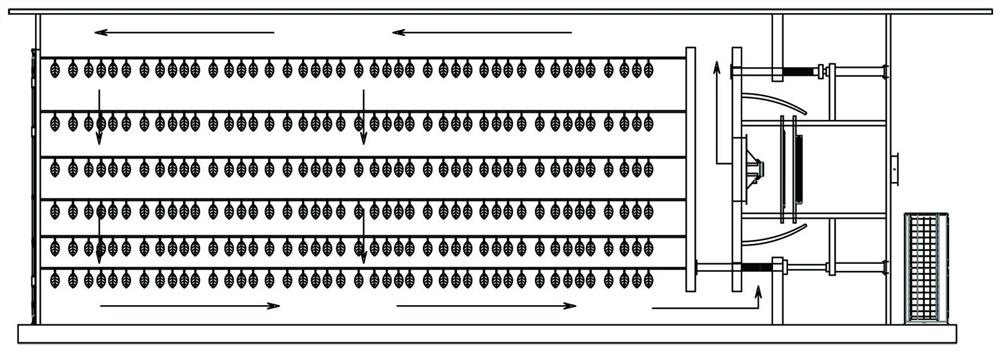

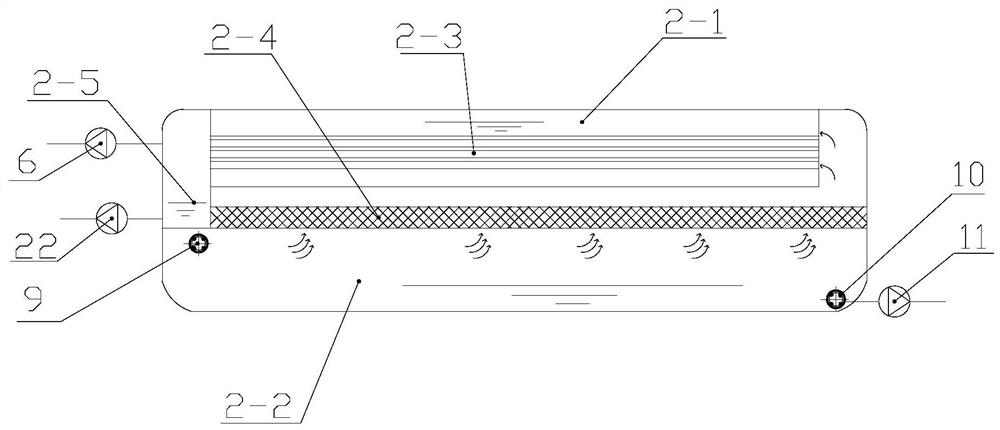

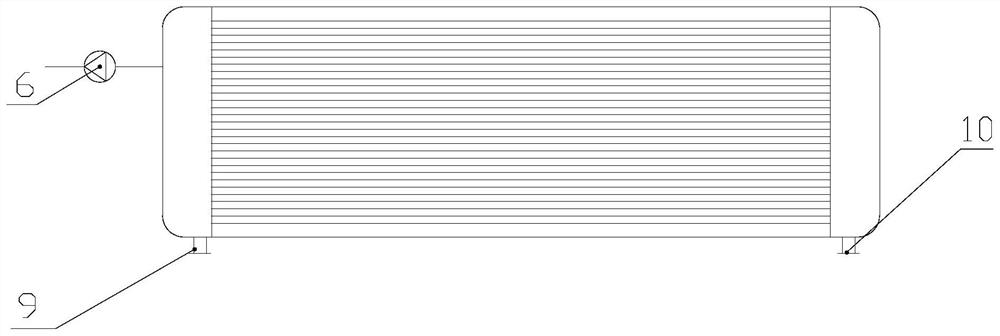

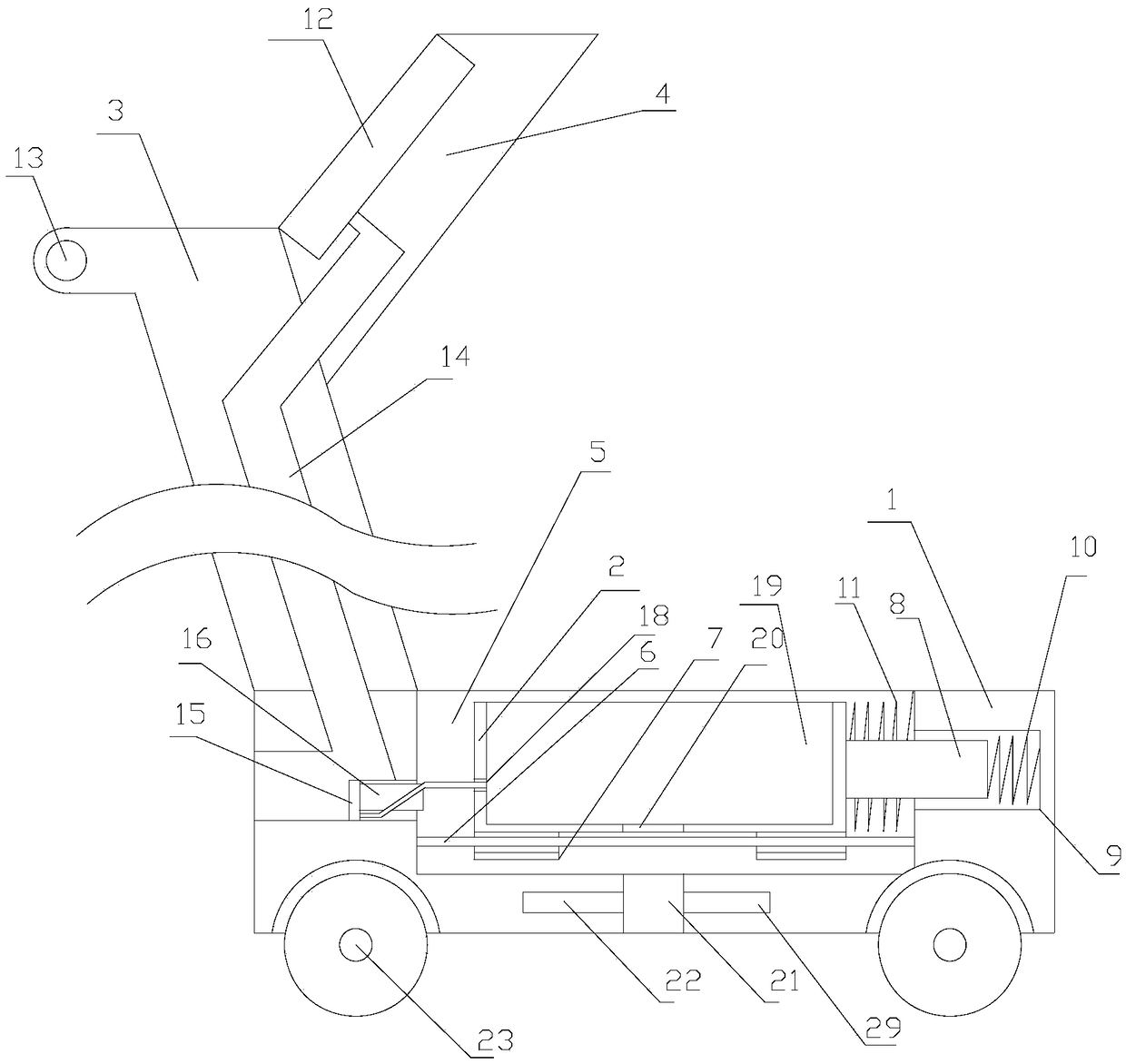

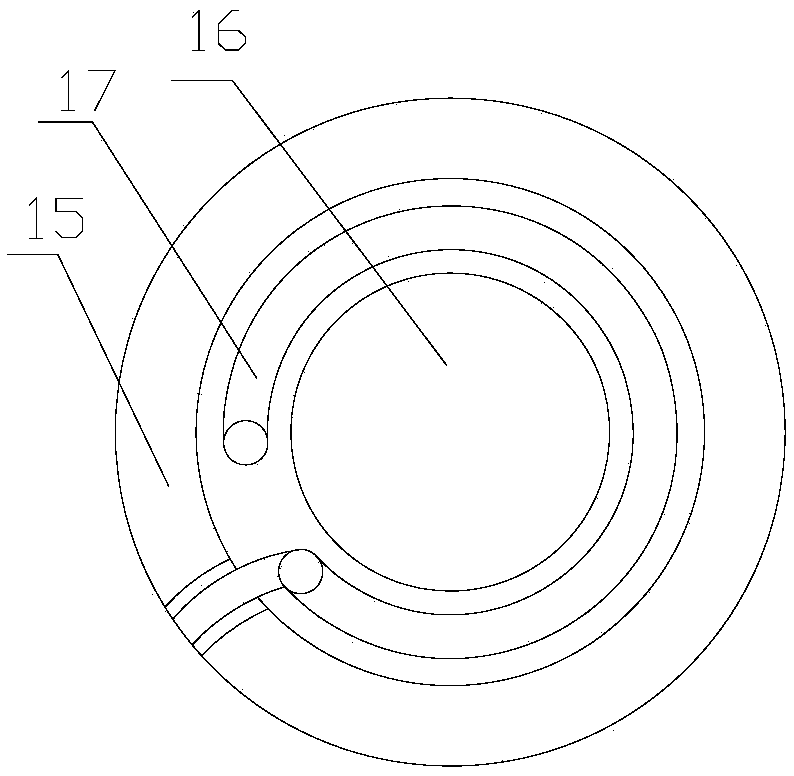

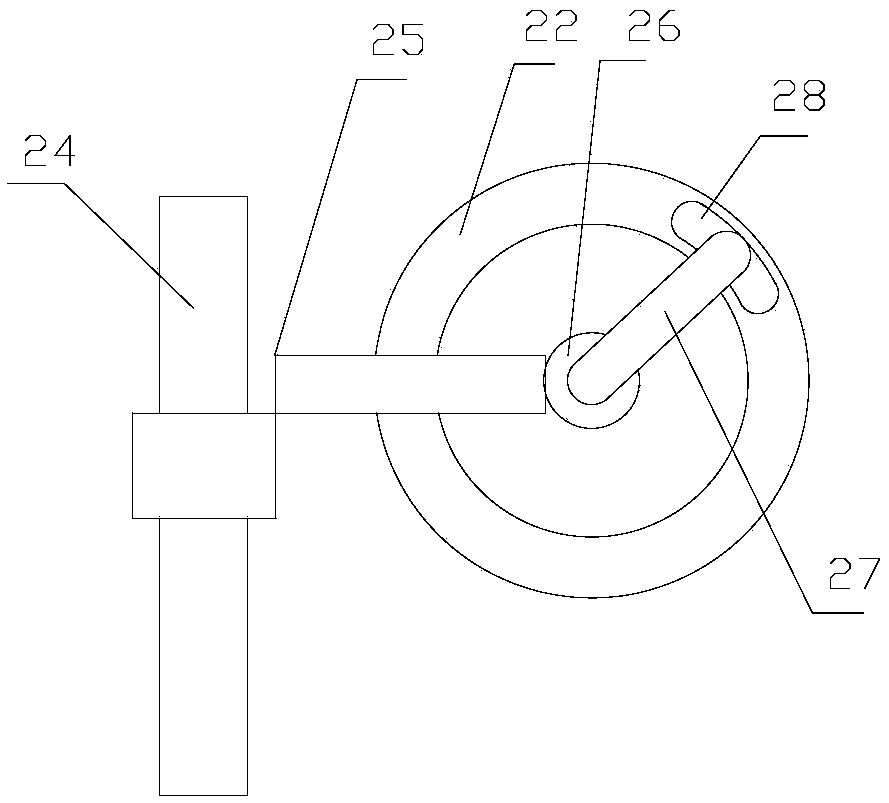

Heat pump tobacco leaf bulk curing barn capable of alternately operating airflow

PendingCN113261692ARealize automatic switchingConsistent spin speedTobacco preparationGreenhouseProcess engineering

The invention belongs to the technical field of tobacco leaf curing, and particularly relates to a heat pump tobacco leaf bulk curing barn capable of alternately operating airflow, an air source heat pump is used as a main heat source, an auxiliary heating wire is used for auxiliary heating, a heat source is generated in a heating chamber, the heat source is blown into an air inlet duct by a fan, and under the switching of an alternate switching device, automatic switching of upward air circulation and downward air circulation is achieved, different switching durations can be set according to different periods of tobacco leaf curing by taking the temperature difference between the upper portion and the lower portion in the tobacco containing chamber and the delayer as starting signals during switching, and the situation that tobacco leaves at the same position are located at the upstream or the downstream of airflow in the whole curing period is avoided; the dehydration speed and the yellowing degree of the tobacco leaves in upper and lower greenhouses are kept relatively consistent, the problems that the tobacco leaf yellowing dehydration speed is different and the baking quality of the tobacco leaves in upper and lower greenhouses is difficult to consider in the existing equipment and process are effectively solved, and the curing barn is low in cost and high in energy utilization rate and has huge economic, environmental and social benefits.

Owner:HENAN AGRICULTURAL UNIVERSITY

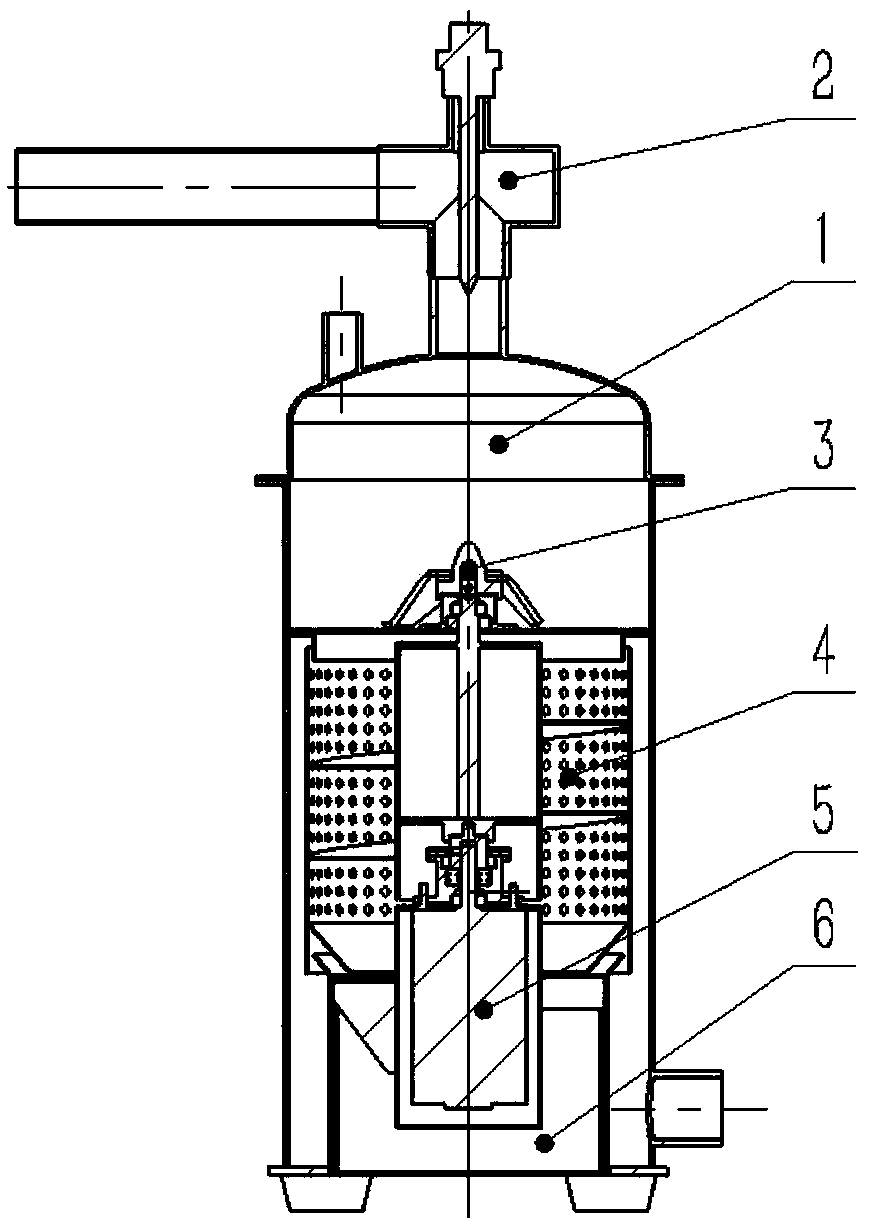

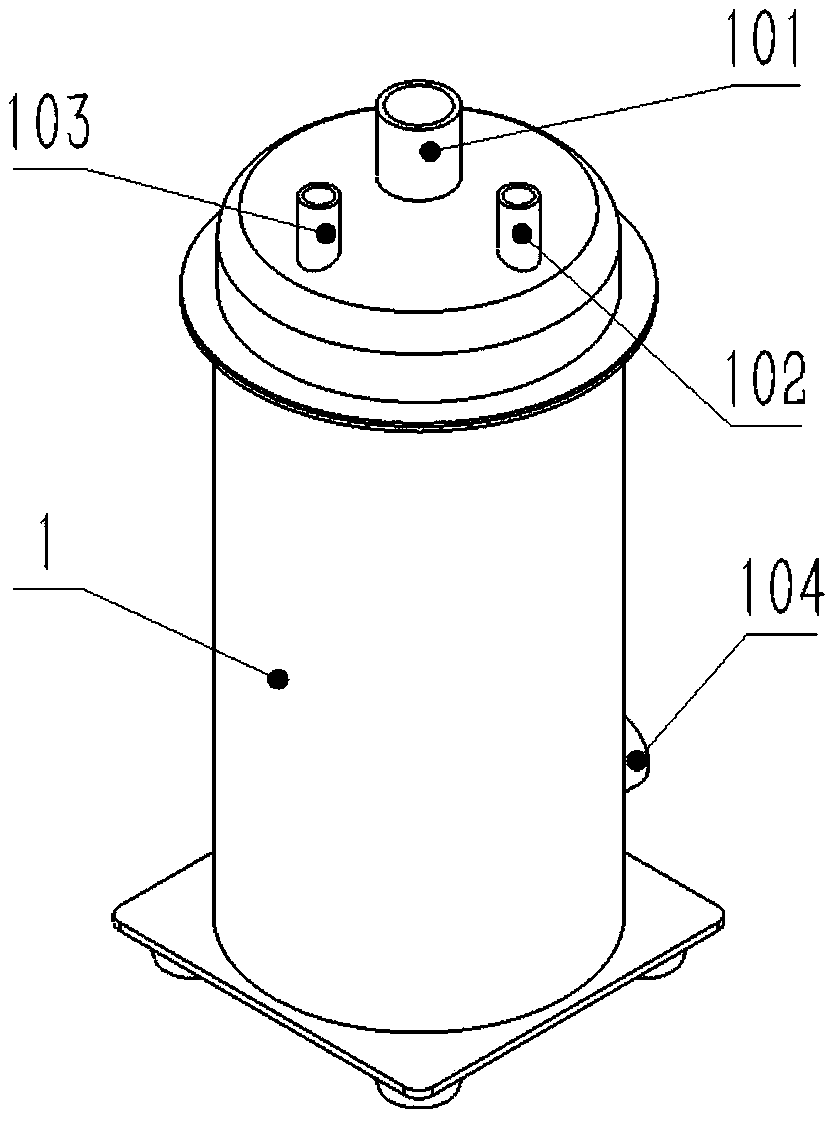

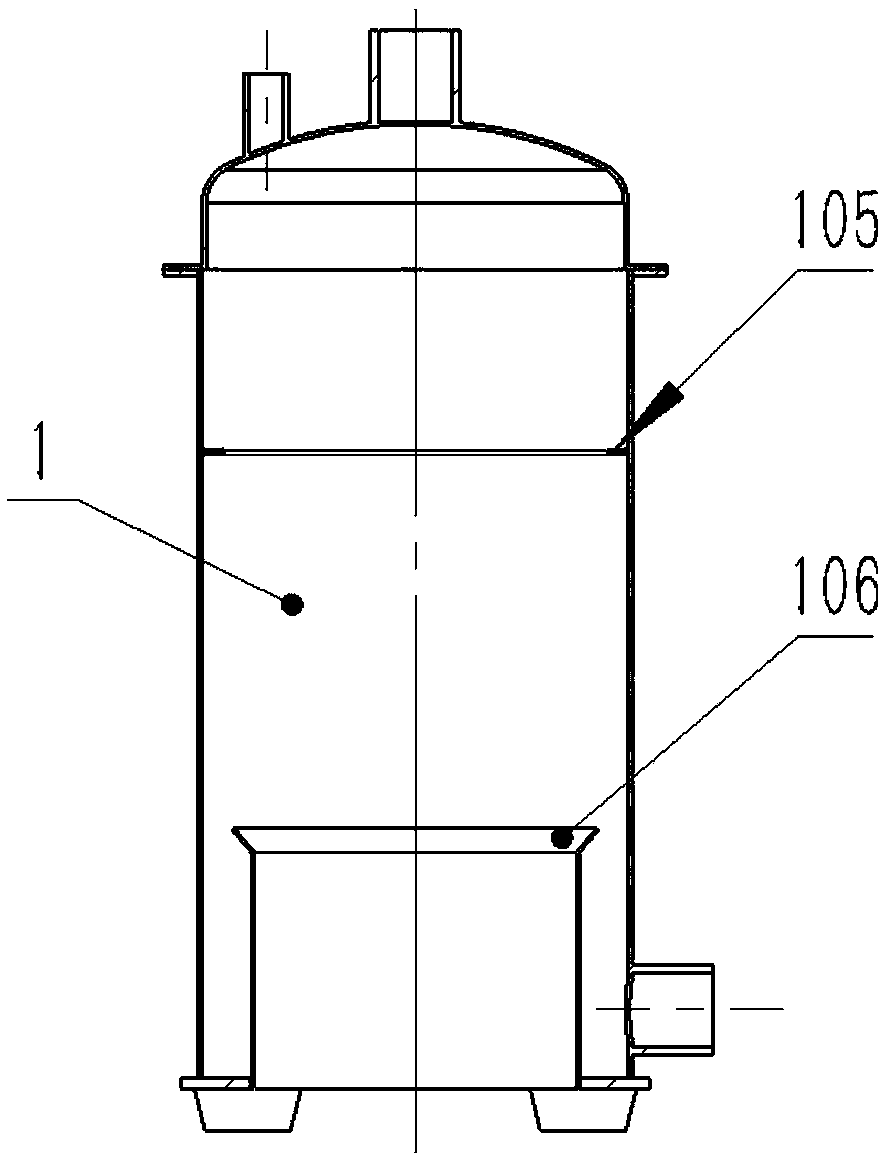

Direct cooling machine

PendingCN111623550ACorrosiveEasy to depositEnergy efficient heating/coolingClimate change adaptationLithium bromideWastewater

The invention discloses a direct cooling machine and belongs to the technical field of waste heat utilization. Through the direct cooling machine, the problems that high-temperature industrial wastewater cannot be utilized as a driving heat source of an existing absorption type refrigeration unit, and consequently heat in the wastewater cannot be effectively utilized are solved. A dilute lithium bromide solution in an absorber is conveyed into a lithium bromide solution cavity through a dilute lithium bromide solution pipe, the lower portion of the lithium bromide solution cavity communicateswith the upper portion of the absorber through a strong lithium bromide solution pipe, a strong lithium bromide solution formed in the lithium bromide solution cavity is conveyed into the absorber through the strong lithium bromide solution pipe, wastewater enters a flash evaporation chamber through communication of a wastewater inlet pipe, flash evaporation is conducted, steam obtained after flash evaporation moves upwards, heat exchange is conducted between the steam and the dilute lithium bromide solution in the lithium bromide solution cavity, a refrigerant water falling film of the dilutelithium bromide solution evaporates, evaporated steam enters the condenser through a first steam channel, and the wastewater obtained after flash evaporation is discharged from an evaporator througha wastewater withdrawing pipe.

Owner:HIT HARBIN INST OF TECH KINT TECH

Method and device for non-destructive testing of pavement quality by radar

ActiveCN109212523ARealize non-destructive testingAids in personal safetyDesign optimisation/simulationSpecial data processing applicationsNon destructiveVoid ratio

The invention provides a method and a device for non-destructive testing of pavement quality by a radar. The method comprises the following steps of (1) determining a dielectric coefficient of a pavement through a full reflection method; (2) determining a number of the factor in a corresponding void ratio range; (3) creating an FDTD model of a steel bridge pavement, and performing comparative analysis on the FDTD model and a waveform chart of actual pavement radar reflection wave; (4) detecting a slide and emptying part of the steel bridge pavement; and (5) making control measures for qualityproblems such as pavement thickness, compactness, bottom slip and emptying. The method measures thickness of the steel bridge pavement scientifically according to pavement radar, determines an impactfactor mu of a corresponding shape according to different void ratio ranges, so as to improve measurement accuracy of compactness, and realizes non-destructive test of cracks of the steel bridge pavement and bottom slip and emptying disease. The device for non-destructive testing of pavement quality by a radar is convenient to install a bottom inspection radar and an operation table, and facilitates data detection.

Owner:CHONGQING CONSTR RESIDENTIAL ENG +2

Treatment device for kitchen waste water and discharged waste

The invention belongs to the field of kitchen equipment and discloses kitchen waste water pump drainage and kitchen waste treatment equipment, which comprises an outer shell component, a pumping device, a smashing device, a separating device, a motor component and a residue barrel. The invention provides the kitchen equipment which can pump waste water in cookers and smash and separate residues. The equipment can clean water accumulated in a pot through a pumping function, send waste water containing solid wastes including vegetable leaves, broken bones and the like to the equipment, and smashthe solid wastes, the smashed residues enter the separating device together with the waste water, water is thrown out and discharged out of the equipment under the action of a centrifugal force generated through high speed rotation, residues enter the residue barrel to be collected and treated, further, the equipment allows running water to enter to clean automatically, and after being introducedinto the equipment, high temperature steam can sterilize the equipment at a high temperature, so as to keep the equipment clean and sanitary all the time.

Owner:南京博思闻科技有限公司

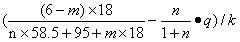

Design method for built-in foundation of high and steep slope bridge

ActiveCN113158285AImprove economyIn line with the actual forceGeometric CADClimate change adaptationArchitectural engineeringSteep slope

The invention discloses a design method for a built-in foundation of a high and steep slope bridge, which provides a more scientific design basis for the design of the built-in foundation and greatly improves the engineering economy of the built-in foundation. Comprising the following steps: (1) initially simulating building-in foundation design parameters; (2) calculating the lateral pressure P1 of the most unfavorable shear-resistant height below the anchoring surface according to the stress of the anchoring point; (3) calculating the shear capacity T of the rock mass in the most unfavorable height range below the anchoring surface; (4) judging whether the shear capacity T of the rock mass at the worst height below the anchoring surface is greater than the lateral pressure P1 at the worst height below the anchoring surface; (5) calculating the vertical allowable bearing capacity [P] of the built-in foundation according to the built-in foundation degree H determined in the step (4); (6) checking whether the vertical allowable bearing capacity [P] of the foundation meets the design requirement according to the following formula: [P] is greater than or equal to P + W; and if the requirement of the formula is not met, deepening the length H of the built-in foundation further, and repeating the step 4 and the step 5 until the design requirement is met.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

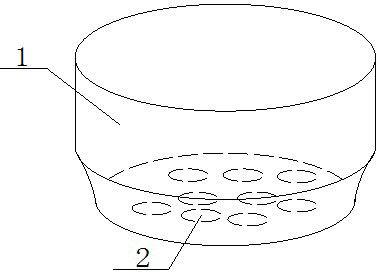

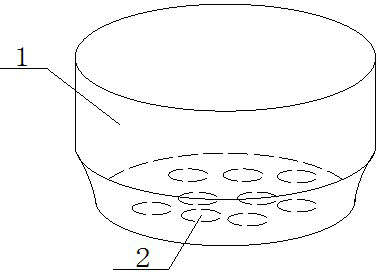

Ventilating plastic flowerpot and preparation method thereof

InactiveCN102422790ASolve the breathability problemReach the effect of recyclingReceptacle cultivationPlastic materialsEngineering

The invention relates to a ventilating plastic flowerpot and a preparation method thereof. The ventilating plastic flowerpot is characterized by comprising a flowerpot main body made of plastic materials; air holes are formed on the bottom of the flowerpot main body; the air holes are not close to the bottom side edge of the flowerpot main body. The preparation method of the flowerpot comprises the following steps of collecting waste and old plastics as raw materials; mixing and crushing the raw materials with a mixer; pouring the crushed materials into a mould pressing sintering furnace to shape through sintering; rushing out the air holes with a stamping mould, and then cooling the mould and finally forming into the ventilating plastic flowerpot. The flowerpot and the preparation method provided by the invention are low in price and high in quality, solve the ventilation property problem of the flowerpot, reach the effect of recycling wastes, are less in investment and large in environment-friendly benefit, and have certain market prospect.

Owner:WUJIANG CITY LI DA LUSTRE FINISHED PROD

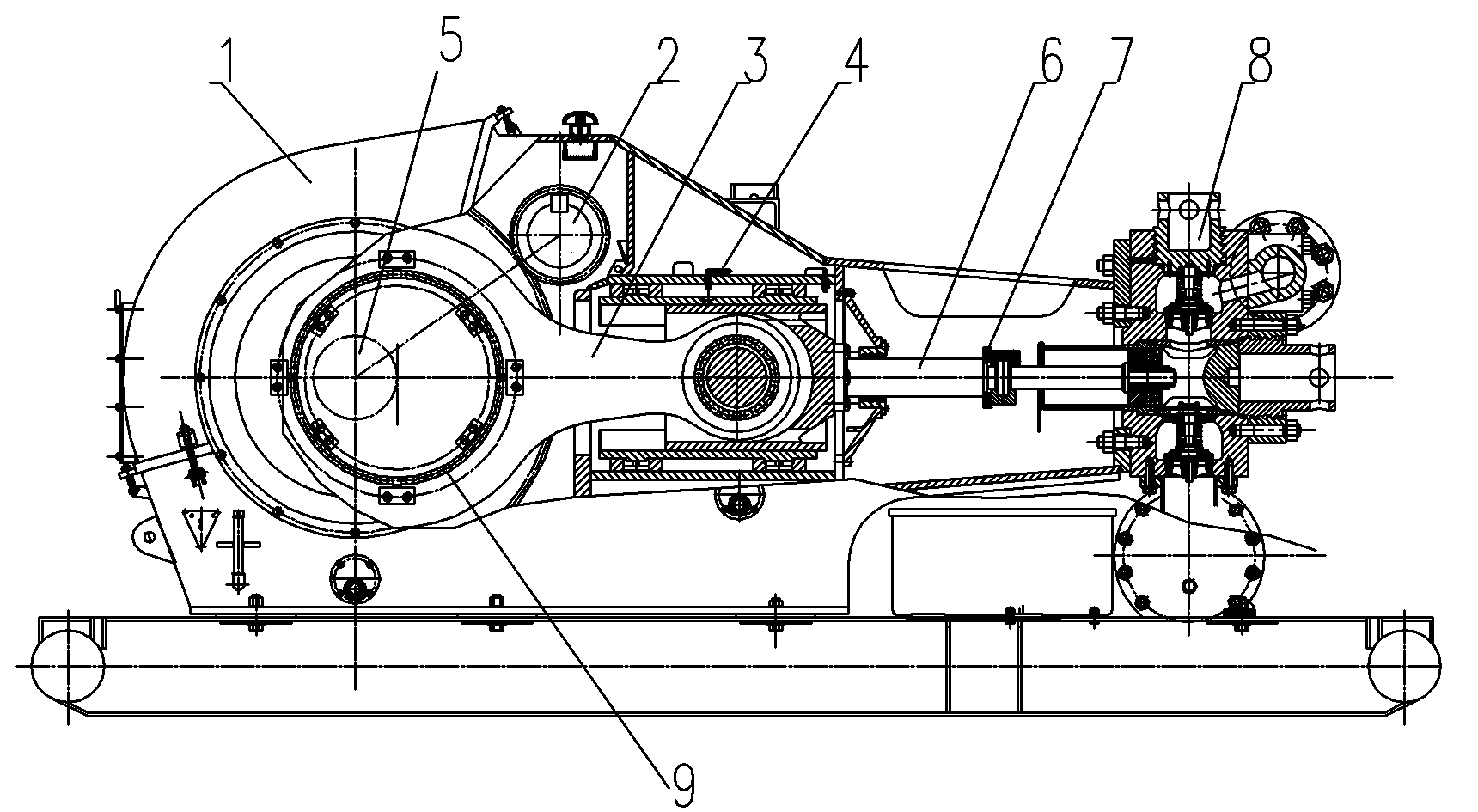

Light large-power drilling mud pump

ActiveCN103321867AImprove bearing capacityIncrease output powerPumpsPositive-displacement liquid enginesMetallic materialsHardness

The invention discloses a light large-power drilling mud pump. The light large-power drilling mud pump comprises a pump shell, a small gear shaft, a crank shaft, a large gear shaft, a gear ring, a connecting rod, a mud blocking plate and a fluid end, wherein the structure sizes of the pump shell, the small gear shaft, the crank shaft, the large gear shaft, the gear ring, the connecting rod, the mud blocking plate and the fluid end equal those of a pump shell, a small gear shaft, a crank shaft, a large gear shaft, a gear ring, a connecting rod, a mud blocking plate and a fluid end of a low-power-grade drilling mud pump, the overall Brinell hardness of the large gear shaft is HB235-265, and the Rockwell hardness of the tooth surface of the large gear shaft is HRC50-55. According to the technical scheme, on the premise that the weight of the whole set of equipment is not increased, operation reliability of the equipment is improved, product quality is guaranteed, purchasing cost of metal materials is reduced, and profits are practically improved. The population and the application of the light large-power drilling mud pump have huge economic and environmental benefits.

Owner:JIAOZUO JINBIAO MACHINERY MFG

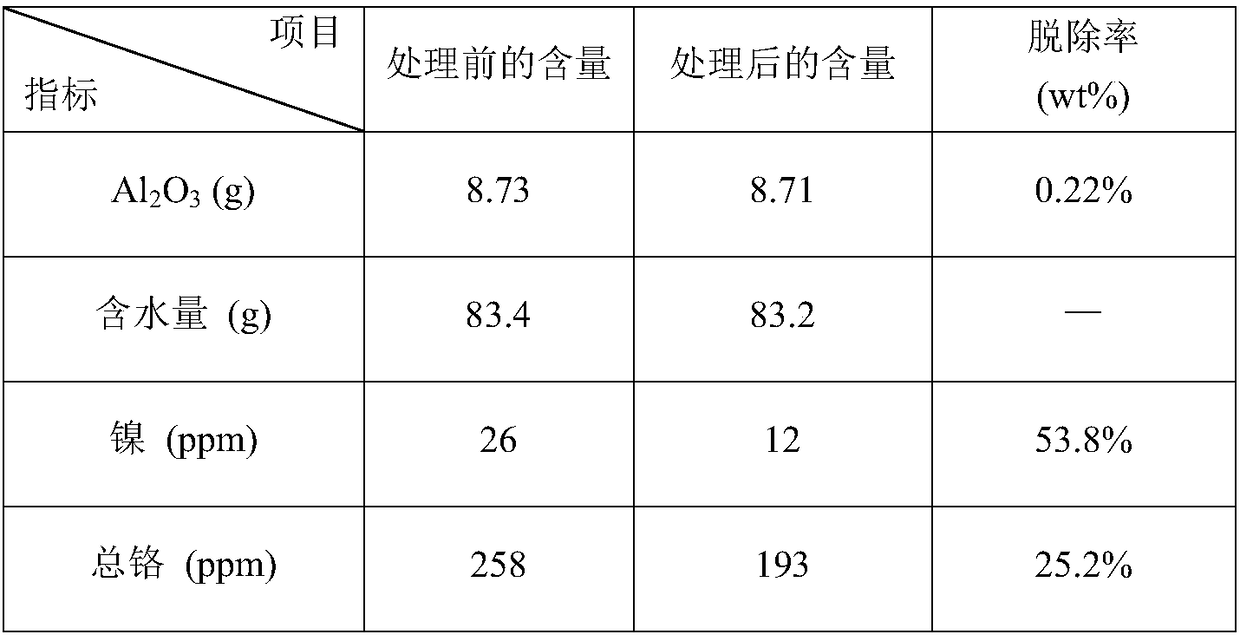

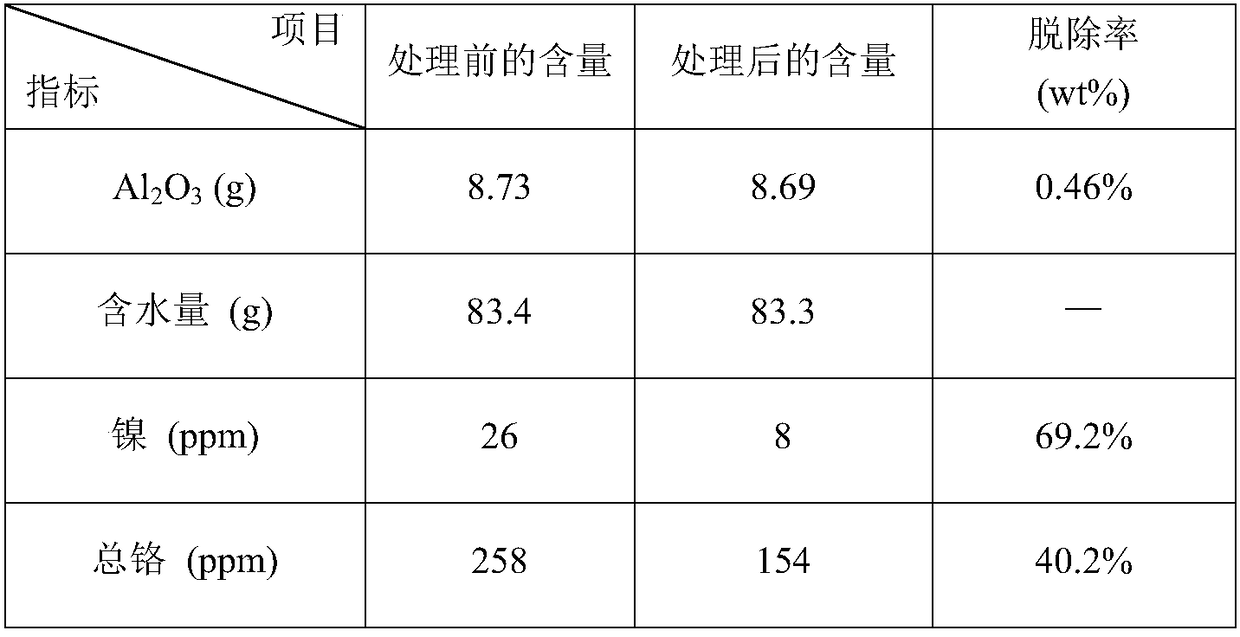

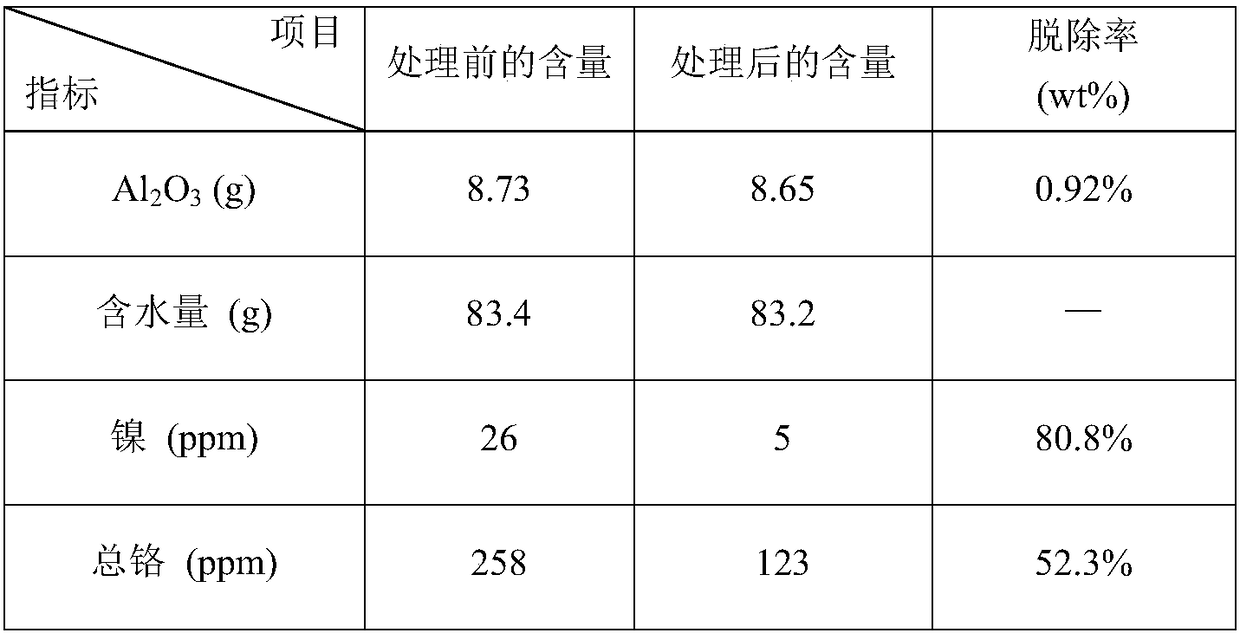

Method for removing heavy metals chromium and nickel in aluminum slag

The invention discloses a method for removing heavy metals chromium and nickel in aluminum slag. The method comprises the following steps: (1) adding filter residue and water into a three-necked flask, and then adding ammonia water and a strong oxidant in sequence to obtain a mixed liquid through reaction; (2) filtering the mixed liquid. According to the method provided by invention, a low-cost reagent raw material is utilized to simultaneously effectively remove the heavy metals chromium and nickel in the aluminum slag with an one-step method, and the aluminum loss during the treatment process is very small, so that the aluminum slag after removal of the heavy metals can be directly prepared into a water purifier product with standard heavy metals, the occupation utilization of the aluminum slag is greatly improved, the resource utilization of the aluminum slag is realized, huge economic and environmental benefits are brought, and the environmental pollution is reduced.

Owner:SHENZHEN CHANGLONG TECH CO LTD

Heat treatment technology for heavy drill rod with diameter being larger than or equal to phi 175 mm

ActiveCN111394563AReduce use costReduce the number of replacementsFurnace typesProcess efficiency improvementTemperingThermodynamics

The invention discloses a heat treatment technology for a heavy drill rod with the diameter being larger than or equal to phi 175 mm. The heat treatment technology comprises the following steps that (1) the drill rod is heated and austenitized; (2) the drill rod processed through the step (1) is immersed into hot water at the temperature of 75-100 DEG C for quenching, and the drill rod is taken out after being integrally and directly quenched to form a quenched sorbite structure; and (3) the drill rod obtained in the step (2) is cooled to obtain a final finished product. The heat treatment technology is ingenious, the heavy drill rod is quenched into the quenched finished product through a hot water quenching mode, the production efficiency is very high, the cost is only 50% of that of common quenching and tempering heat treatment, and the whole technology is more environmentally friendly; the service life of the obtained heavy drill rod is prolonged by 75% or above compared with thatof an existing heavy drill rod subjected to quenching and tempering heat treatment, the use cost of the drill rod is reduced, in addition, steel resources are saved, and especially, under the condition that heavy drill rods are nearly increased exponentially every year, economic benefits and environmental benefits are great.

Owner:江阴吉中特殊钢带有限公司

Machine external apparatus for maintaining multi-cylinder engine high-efficiency operation

InactiveCN101349201BExtended maintenance cycleIncrease or decrease quantityOutput powerMachines/enginesSocial benefitsFixed frame

The invention provides an off-machine device for maintaining efficient operation of multi-cylinder engines, which belongs to the engine field and is used for overcoming the defect that the multi-cylinder engines are low in working mechanical efficiency in low power state. The off-machine device consists of a fuel or gas control mechanism, an air pressure control mechanism, as well as a fixing frame which carries the fuel or gas control mechanism and the air pressure control mechanism. After the off-machine device is arranged on a corresponding multi-cylinder engine, the operation of increasing or decreasing the number of working cylinders can be accomplished during the operation of the engine, so as to allow the engine to operate with high mechanical efficiency, thereby achieving the aimsof saving energy and reducing emission. Moreover, as the off-machine device does not need to change an internal structure and parameters of the corresponding engine, the off-machine device not only can be applied to produce new engines, but also is suitable for reforming old engines of users in active service on a large scale, thereby having great economic benefit, social benefit and environmental benefit.

Owner:颜丙仁

Method of reinforcing quality of regenerated coarse aggregate by three stages with strong acid

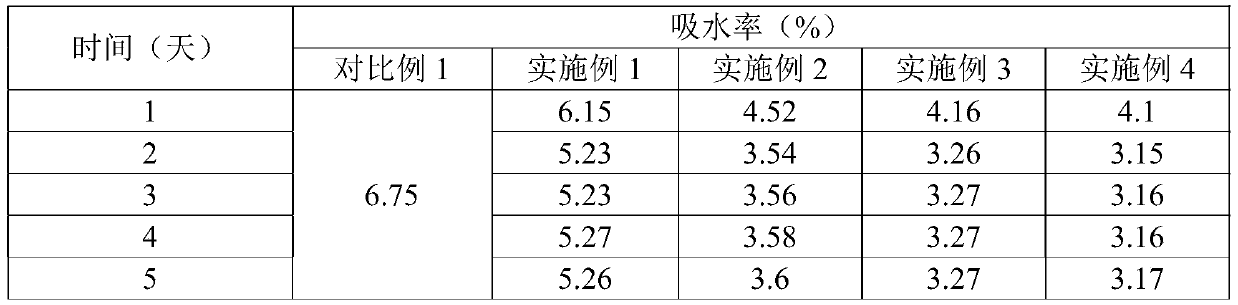

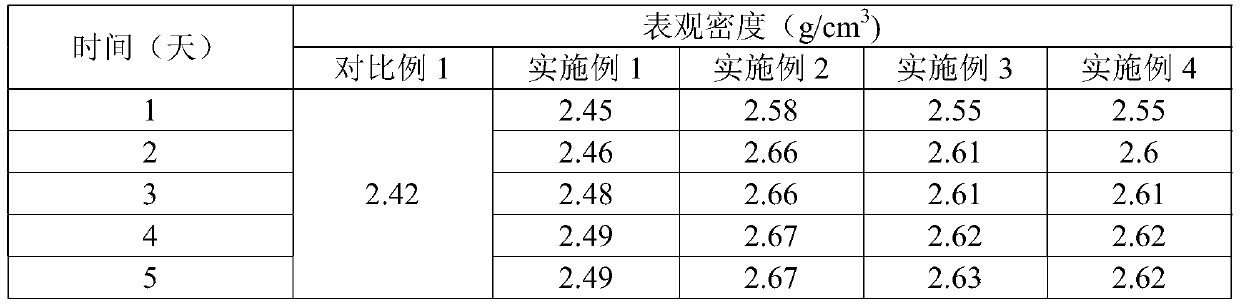

ActiveCN110937836AQuality improvementResolve disposal issuesSolid waste managementPhysical chemistryStrong acids

The invention discloses a method of reinforcing quality of regenerated coarse aggregate by three stages with strong acid, particularly including: 1) soaking the regenerated coarse aggregate in a hydrochloric acid solution for a certain time; 2) adding a nitric acid solution to the hydrochloric acid solution after the soaking for a certain time to soak the coarse aggregate for a certain time, and moving out the coarse aggregate; 3) repeatedly washing the coarse aggregate in clear water until the water is neutral, and moving out the coarse aggregate; 4) placing the coarse aggregate in a sulfuricacid solution to soak the coarse aggregate for a certain time, and moving out the coarse aggregate; 5) repeatedly washing the coarse aggregate in clear water until the water is neutral, and moving out the reinforced coarse aggregate. In the method, the regenerated coarse aggregate is soaked in the strong acids, so that firstly, the mortar attached to the surface and in interior is corroded, and then sulfuric acid and residual Ca<2+> are reacted to form a compact layer, thus improving the apparent density and water absorption rate. The method reinforces the regenerated coarse aggregate in useperformance and reaches engineering application specification standard.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com