Anti-microbial deodorizing super absorbent resin compound

A technology of superabsorbent resin and composition, which can be used in absorbent pads, medical science, bandages, etc. It can solve the problems of less research on the antibacterial and deodorizing properties of polyacrylate superabsorbent resins, and achieve excellent antibacterial and deodorant Performance, excellent water absorption performance, effect of improving washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

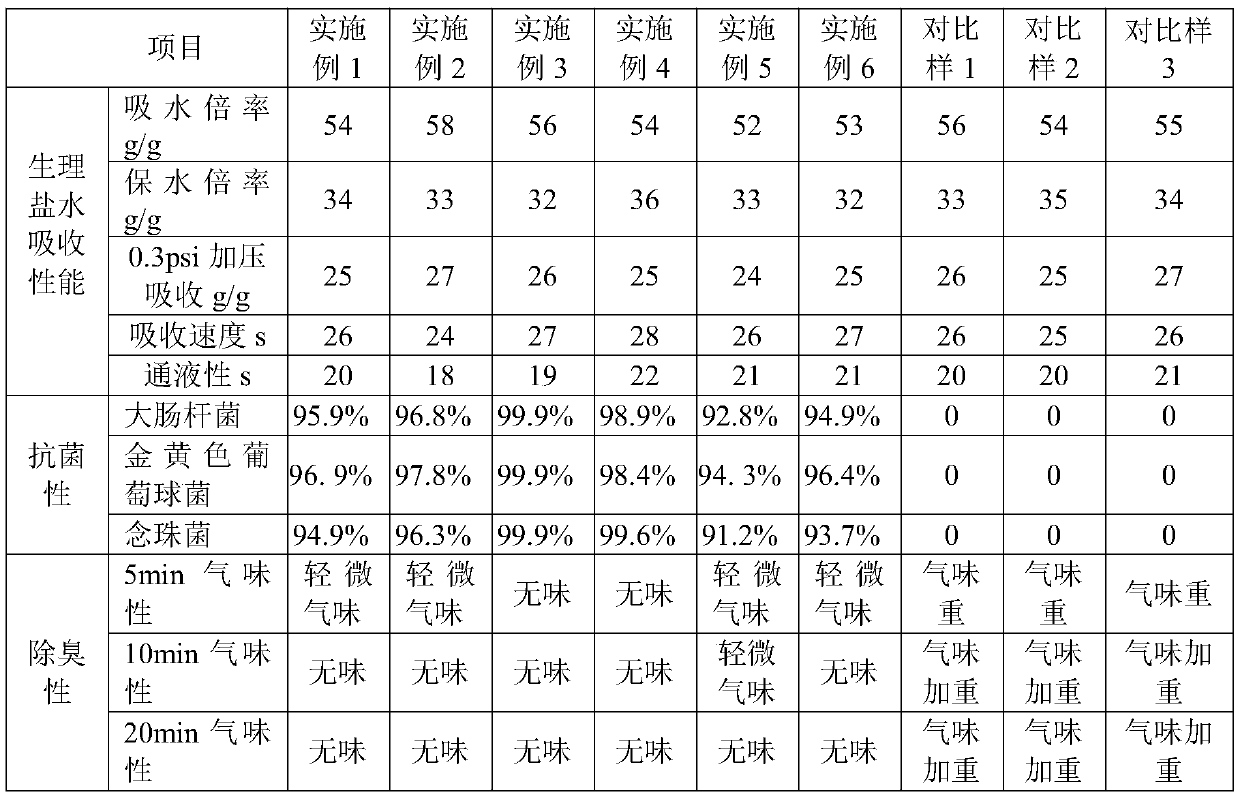

Examples

Embodiment approach

[0061] The plant antibacterial agent of the present invention is composed of at least one of tea leaves, wormwood, motherwort, such as single-component tea, wormwood or motherwort, or a combination of two components, such as tea / wormwood, tea leaves / Motherwort or Motherwort / Motherwort can also be a composition of tea leaves, Artemisia wormwood, and Motherwort. As a specific implementation method, it includes:

[0062] The plant antibacterial agent is a plant composition configured from wormwood and motherwort according to the following mass percentages:

[0063] Artemisia 5%-95%;

[0064] Motherwort 5%-95%.

[0065] As another specific embodiment, the plant antibacterial agent is a plant composition configured from tea leaves and Motherwort according to the following mass percentages:

[0066] Tea 5%-95%;

[0067] Motherwort 5%-95%.

[0068] In a specific embodiment, the plant antibacterial agent can also be a plant composition configured from tea leaves and wormwood i...

Embodiment 1

[0098] The pre-crosslinked acrylic acid polymer of the present embodiment is prepared according to the following steps:

[0099] 1) Accurately weigh 200g of acrylic acid, neutralize it with sodium hydroxide to a neutralization degree of 80%, then add deionized water for mixing, and then the total mass concentration of acrylic acid and sodium acrylate is 40%.

[0100] 2) Add 0.1g of N,N'-methylenebisacrylamide to the reaction system, continue to stir for 5min, then gradually raise the temperature to 60°C, then add 0.1g of sodium sulfite and 0.1g of sodium persulfate to initiate the polymerization reaction for 90s , to obtain a pre-crosslinked acrylic gel-like polymer.

[0101] 3) The pre-crosslinked acrylic acid gel polymer obtained in step (2) was granulated, and dried at a temperature of 160° C. for 30 minutes to obtain a granular pre-crosslinked acrylic acid polymer.

[0102] The superabsorbent resin composition of the present embodiment consists of the following components...

Embodiment 2

[0107] The pre-crosslinked acrylic acid polymer of the present embodiment is prepared according to the following steps:

[0108] 1) Accurately weigh 200g of acrylic acid, neutralize it with sodium hydroxide to a degree of 60%, then add deionized water to mix, and then the total mass concentration of acrylic acid and sodium acrylate is 60%.

[0109] 2) Add 0.1g of N,N'-methylenebisacrylamide to the reaction system, continue to stir for 5min, then gradually raise the temperature to 60°C, then add 0.1g of sodium sulfite and 0.1g of sodium persulfate to initiate the polymerization reaction for 90s , to obtain a pre-crosslinked acrylic gel-like polymer.

[0110] 3) The pre-crosslinked acrylic acid gel polymer obtained in step (2) was granulated, and dried at a temperature of 160° C. for 30 minutes to obtain a granular pre-crosslinked acrylic acid polymer.

[0111] The superabsorbent resin composition of the present embodiment consists of the following components:

[0112] Accurat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com