Production process of antibacterial polished tile, preparation method of antibacterial agent and antibacterial polished tile

A production process and technology of polished tiles, applied in the field of ceramics, can solve problems such as unstable antibacterial effect of antibacterial polished tiles, increased production costs, and substandard testing, and achieve good applicability and flexibility, low cost, and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Further, the present invention also proposes a method for preparing an antibacterial agent for the production process of the above-mentioned antibacterial polished tiles, comprising the steps of:

[0059] P1) Weighing the raw materials for preparing the antibacterial agent, including: antibacterial powder, dispersant, defoamer and water;

[0060] P2) Mix the prepared raw materials evenly, use an ultrasonic disperser to disperse the aggregates in the mixture, or put them into a sand mill for grinding to obtain the antibacterial powder suspension;

[0061] P3) The antibacterial powder suspension is stable and uniform, without stratification, precipitation or gel phenomenon, that is, the antibacterial agent is obtained.

[0062] The preparation method of the above-mentioned antibacterial agent is simple in process, easy to implement, and low in cost.

[0063] The antibacterial powder suspension needs to be tested for compatibility to ensure that after mixing evenly, a uni...

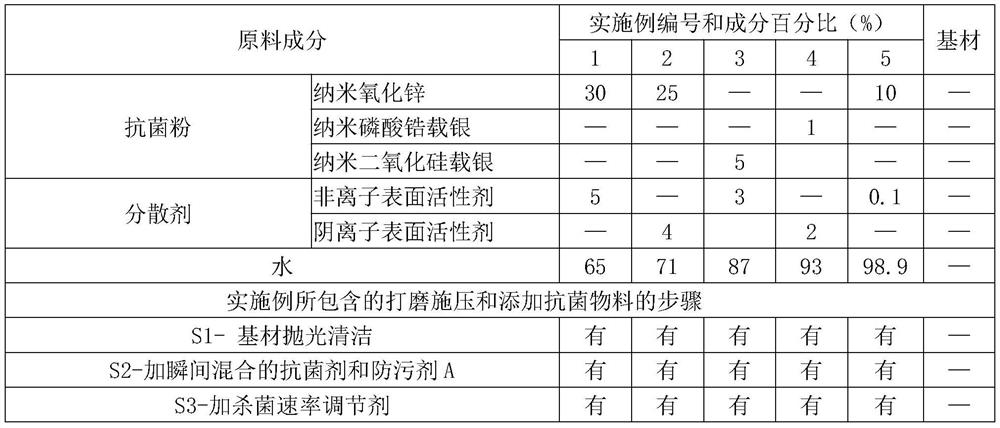

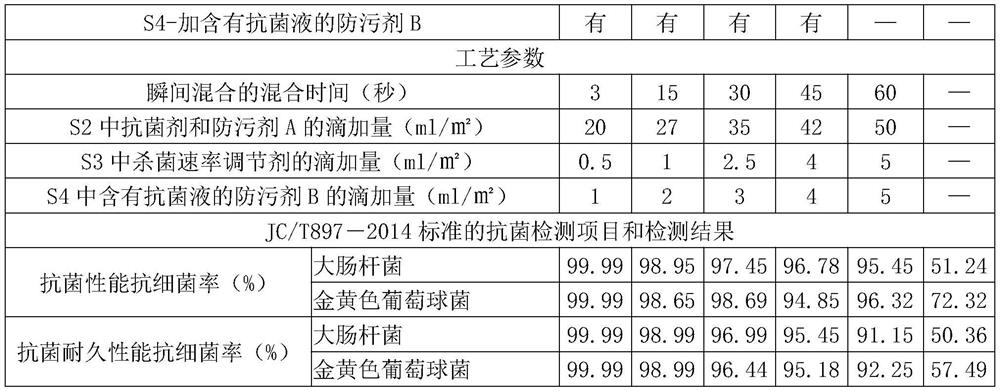

Embodiment 1-5

[0076] The antibacterial polished tile of each embodiment is made according to the following description:

[0077] 1. The production process of the antibacterial polished tiles comprises the following steps:

[0078] A production process of antibacterial polished tiles, comprising the following specific steps:

[0079] S1) Clean and polish the glazed surface of the ordinary polished tile according to the conventional polished tile process to obtain the polished tile to be treated;

[0080] S2) On the surface of the glaze layer of the polished tile to be treated, drop the antibacterial agent and antifouling agent A which are separately packaged and mixed instantly before dripping on the surface of the glaze layer, and then the grinding disc is pressed and polished until the glossiness reaches the set value. Require;

[0081] S3) Adding a sterilizing rate regulator dropwise on the surface of the glaze layer of the polished tile to be treated, and grinding with pressure from a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com