Patents

Literature

58results about How to "Good antibacterial durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

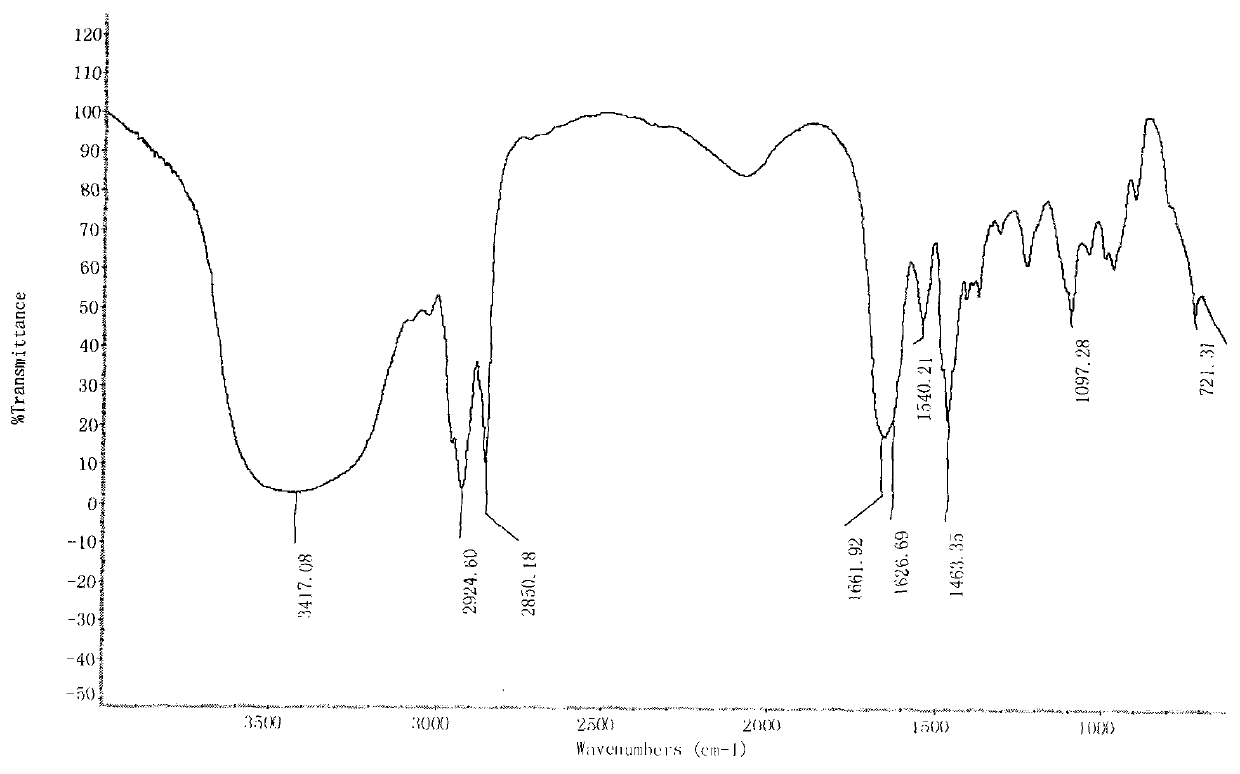

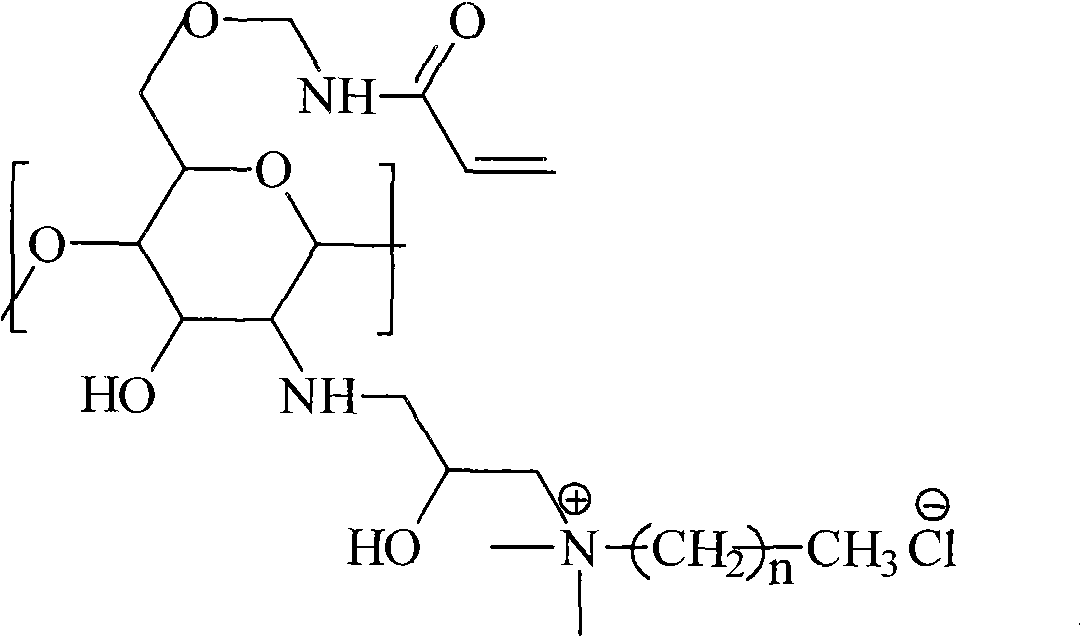

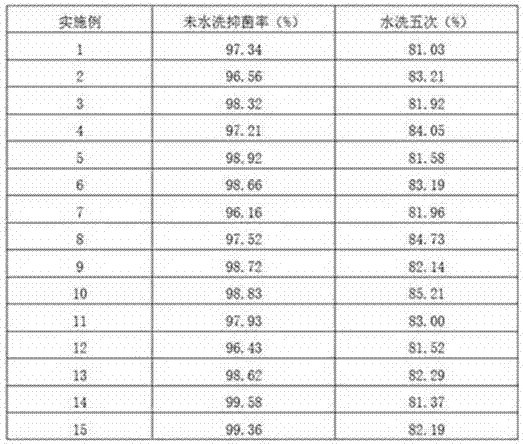

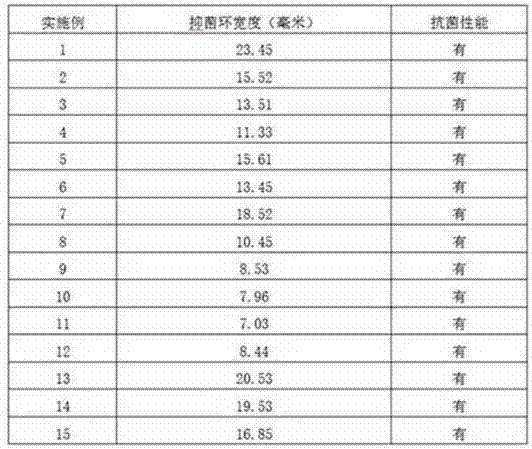

Water-soluble chitosan quaternary ammonium salt antibiotic finishing agent and preparation and application thereof

The invention relates to a water-soluble chitosan quaternary ammonium salt antibiotic finishing agent. The invention is characterized in that the antibiotic finishing agent is names as O-methacrylamide-N-hydroxypropyl alkyl dimethyl ammonium chloride chitosan and the concrete structural formula is as follows. The preparation thereof includes that: alkyl dimethyl tertiary amide and epichlorohydrin are taken as raw materials to synthesize 2, 3-epoxy alkyl dimethyl ammonium chloride, then the 2, 3-epoxy alkyl dimethyl ammonium chloride is introduce onto the ammonium group of chitosan, so as to obtain N-hydroxypropyl alkyl dimethyl ammonium chloride chitosan HDCC, and then crosslinking is carried out on the HDCC and hydroxymethyl acrylamide is carried out, thus obtaining NMA-HDCC. The quaternary ammonium salt antibiotic finishing agent contains water-soluble group and fibrous reactivity group and has good water solubility, the bacterial inhibition rate of finished cotton fabrics is close to 100%, and the finishing agent can be combined with cellulose fiber by covalent bond and is wash-resistant; and cost is low, raw material is environmental friendly, environmental pollution is less, thus having industrialization application prospect.

Owner:DONGHUA UNIV

Clothing degerming liquid and preparation method thereof

ActiveCN102499259AImprove the safety of useImprove stabilityBiocideFungicidesMicroemulsionMesoporous silicate

The invention relates to clothing degerming liquid and a preparation method thereof. The method comprises the following steps of: preparing mesoporous silicate nano-silver-loaded antibacterial agent suspension; preparing microemulsion containing an organic antibacterial agent; and adding and mixing an emulsifier, a chelating and anchoring stabilizer, a softener and a thickener. The clothing degerming liquid disclosed by the invention has high using safety, clothing degerming rate of over 99 percent and high stability. Due to the adoption of the clothing degerming liquid, after clothes are washed by water for 20 times, the antibacterial ratio of the clothes is still over 90 percent. The clothing degerming liquid has excellent antibacterial and durable performances, is non-toxic, has no irritation on the skin and has a deodorization effect on fabrics. The clothing degerming liquid disclosed by the invention has simple production process and low equipment investment, is easy for industrial production, is environmental-friendly and has strong market competitiveness.

Owner:BEIJING CHAMGO NANO TECH

Polyquaternium polymer emulsion antibacterial agent, preparation method thereof and application thereof

ActiveCN106565912ALarge-scale industrial productionReduce the effects of oxygen-enriched pollutionAntifouling/underwater paintsBiochemical fibre treatmentFunctional monomerPolymer science

The invention discloses a polyquaternium polymer emulsion antibacterial agent, a preparation method thereof and an application thereof. The polyquaternium polymer emulsion antibacterial agent comprises the following raw material components in parts by weight: 0.3-3 parts of cationic antibacterial monomer, 0.3-0.7 part of initiator, 60-80 parts of water, 1-14 parts of hard monomer, 1-17 parts of soft monomer, 0.1-1 part of waterproof functional monomer, 0.1-0.3 part of crosslinking functional monomer and 0.1-0.7 part of adhesion functional monomer. According to the technical scheme of the invention, the soap-free emulsion synthesis technique is adopted, so that no emulsifier is adopted. The water oxygen-rich pollution can be reduced. The obtained polyquaternium polymer emulsion antibacterial agent is strong in antibacterial performance, free of dissolution, and good in durability. The polyquaternium polymer emulsion antibacterial agent can make up the blank in the market and can be widely applied to the antibacterial treatment of fabric antibacterial finishing, automotive metal and plastic decorative materials, floors, ceramic products and home appliances. Meanwhile, the polyquaternium polymer emulsion antibacterial agent can be applied to the antibacterial and preservative treatment of aqueous coatings, inks, adhesives and the like.

Owner:GUANGZHOU UNIVERSITY

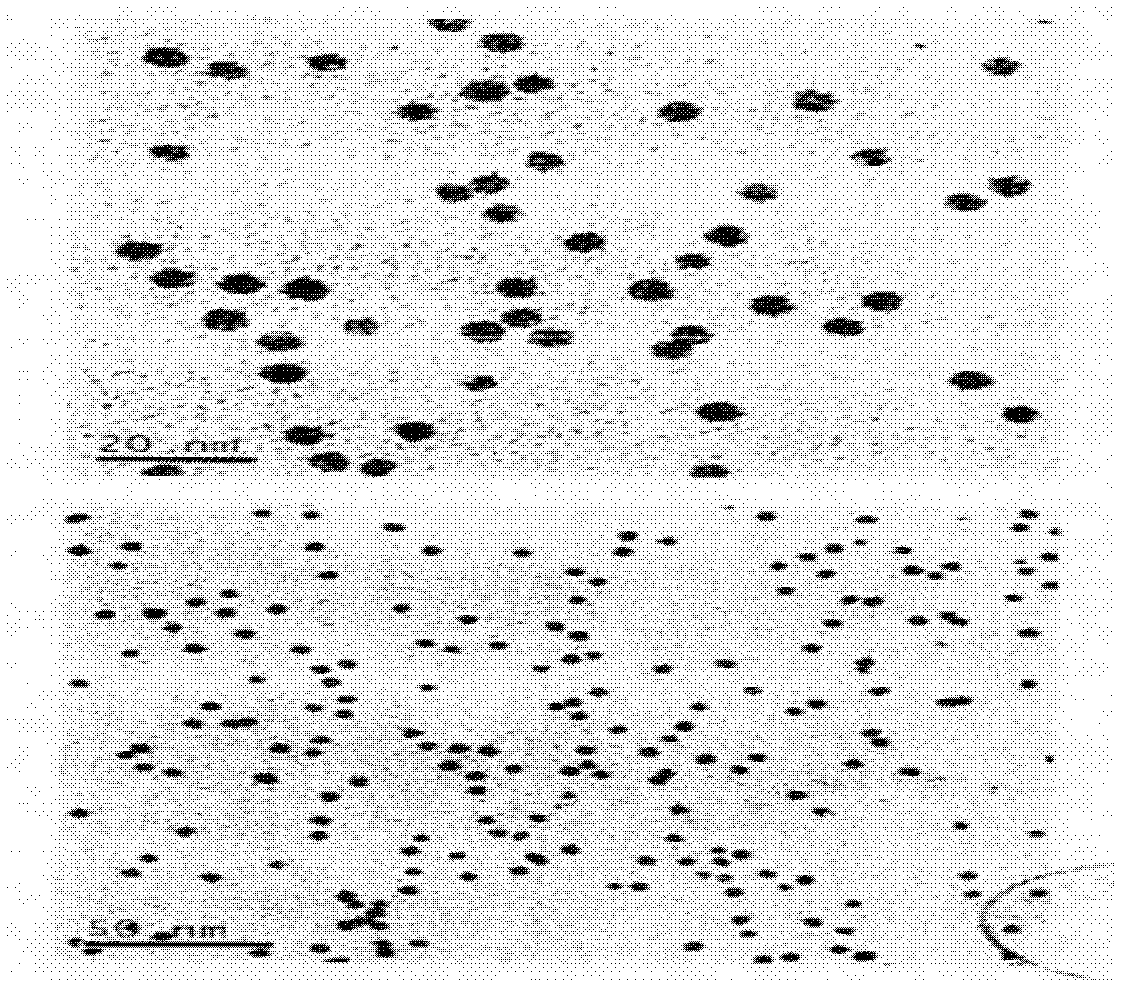

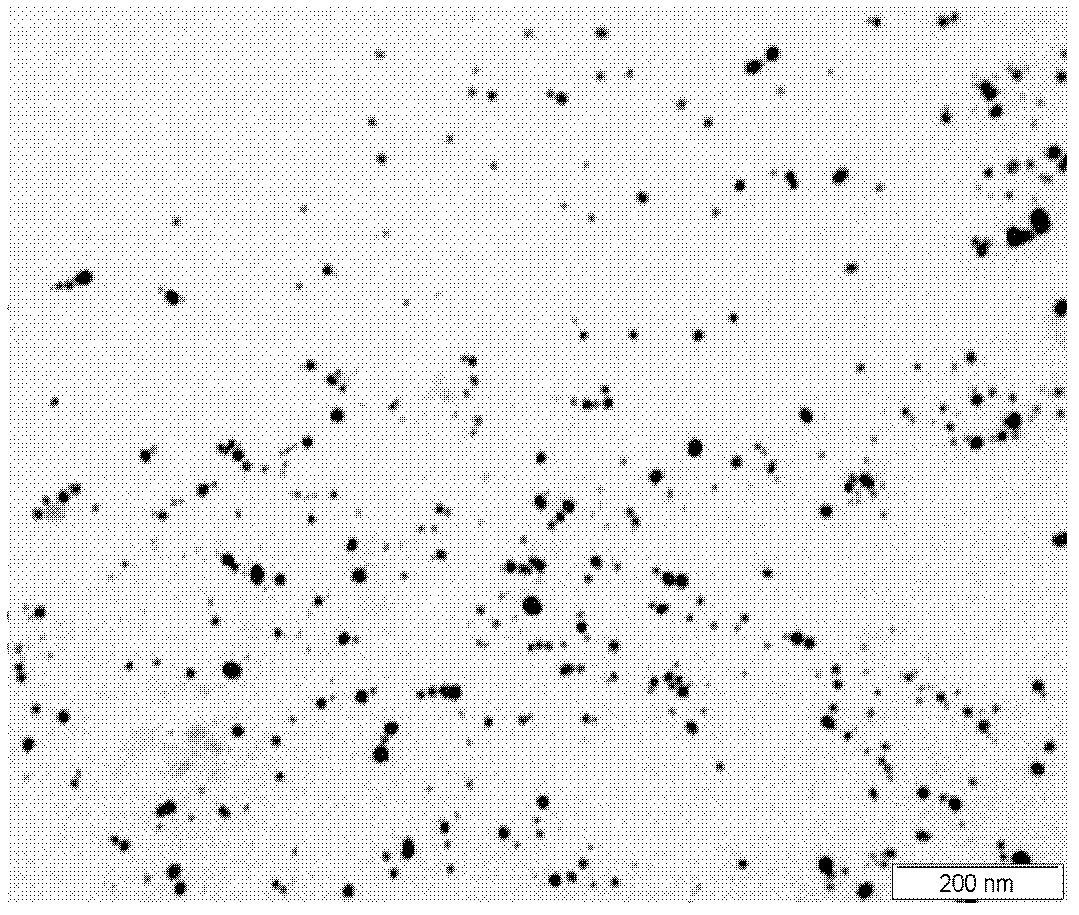

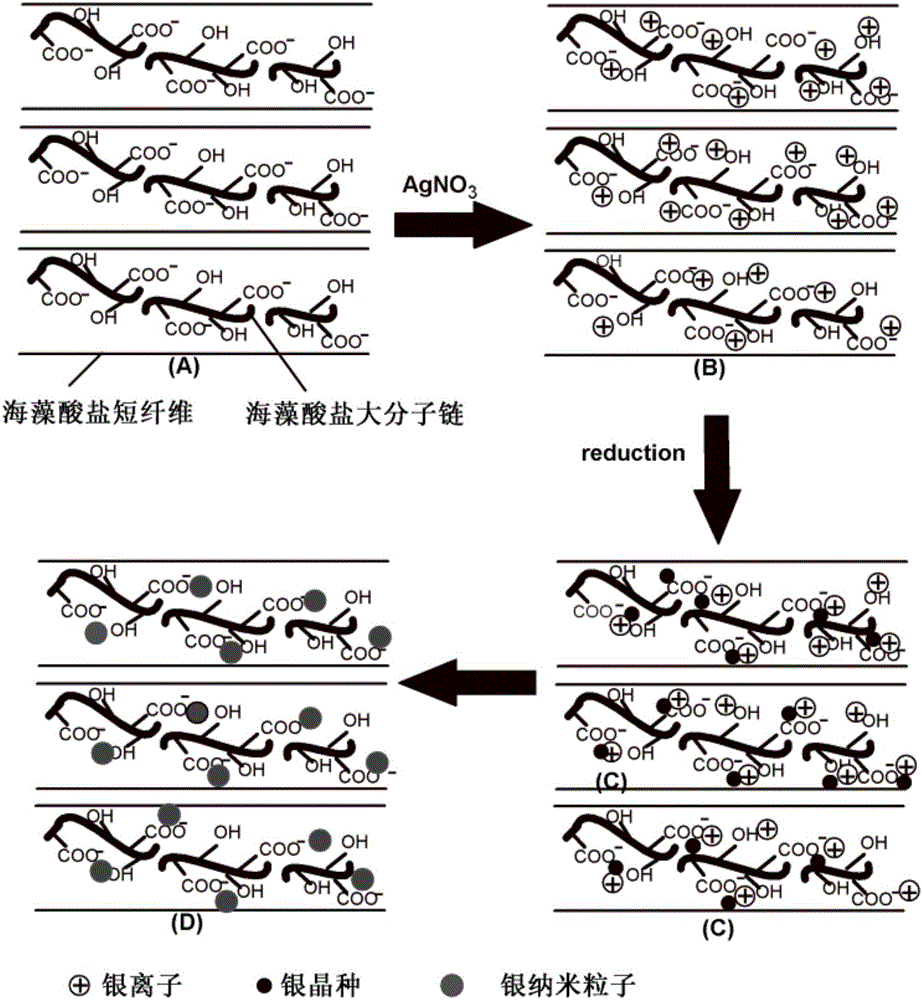

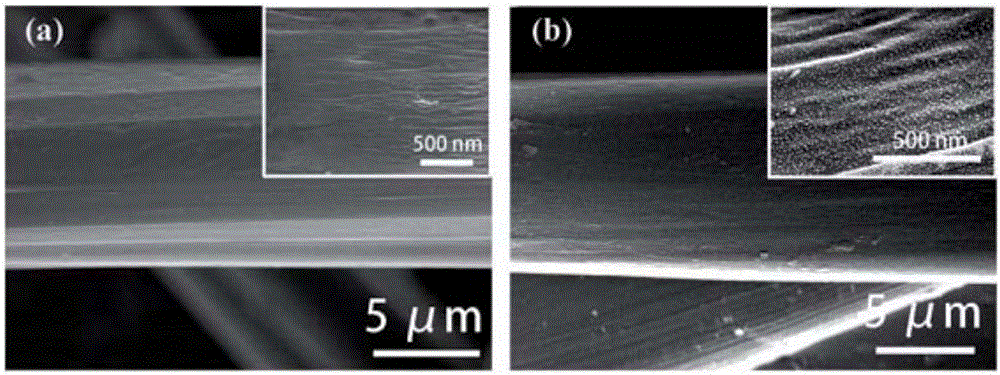

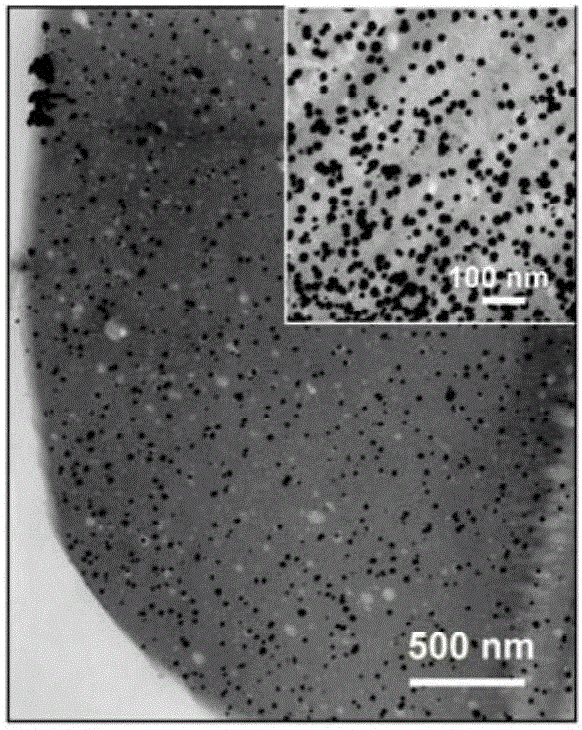

Preparation method of nano-silver alginate fiber

ActiveCN103147167ASmall particle sizeUniform particle size distributionAlginate artificial filamentsWet spinning methodsFiberBiocompatibility Testing

The invention discloses a preparation method of a nano-silver alginate fiber. The preparation method comprises the following steps of: preparing an alginic acid silver complex which is a precursor of nano-silver by using algal polysaccharides and soluble silver salts, and then preparing a sodium alginate based nano-silver colloid system through a chemical reduction method; then adding fiber-grade sodium alginate into the sodium alginate based nano-silver colloid system to obtain a nano-silver algae spinning solution; and finally, obtaining a nano-silver algae primary fiber through wet spinning, and carrying out stretching, sizing, drying and oiling treatments to obtain the nano-silver alginate fiber. The prepared nano-silver alginate fiber integrates the excellent performances of the nano-silver and the alginate fiber, so that the novel fiber has excellent flame retardance, biocompatibility, moisture absorption permeability and the like, also has excellent antimicrobial performance, antistatic performance and irradiation resistance and can be widely used in medical treatment, the fire-fighting field, the military field, the aerospace field, the health textile field and the like.

Owner:QINGDAO UNIV

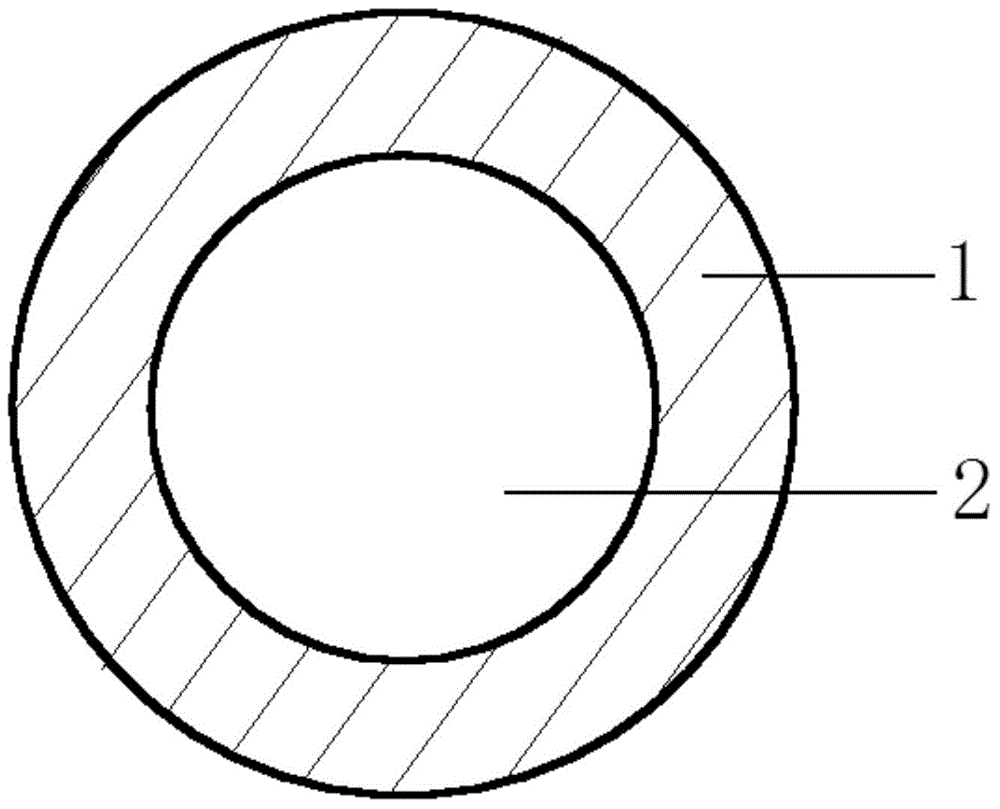

Copper-based antimicrobial fiber and preparation method thereof

ActiveCN105671682AImprove spinnabilityGood antibacterial durabilityMelt spinning methodsConjugated synthetic polymer artificial filamentsMasterbatchCopper

The present invention provides copper-based antimicrobial fiber and a preparation method thereof, a cross-section of the copper-based antimicrobial fiber has a skin-core structure, a skin layer comprises an antimicrobial agent and carrier resin, a core layer comprises a fiber-forming polymer, and the preparation method of the copper-based antimicrobial fiber comprises the following steps: mixing evenly carrier resin powder and antimicrobial masterbatch ingredients of copper-based antimicrobial agent powder to obtain mixed powder; adding the mixed powder into a twin-screw extruder for extruding to obtain antimicrobial masterbatch; compounding and spinning the antimicrobial masterbatch as the skin layer and the fiber-forming polymer as the core layer to obtain the copper-based antimicrobial fiber. The beneficial effects are as follows: the copper-based antimicrobial fiber produced by the method has good spinnability, cross-sectional shape uniformity, long spinning pack replacement cycle, good antimicrobial effect and good durability, and has good antimicrobial effect especially on fungi.

Owner:CTA HIGH TECH FIBER

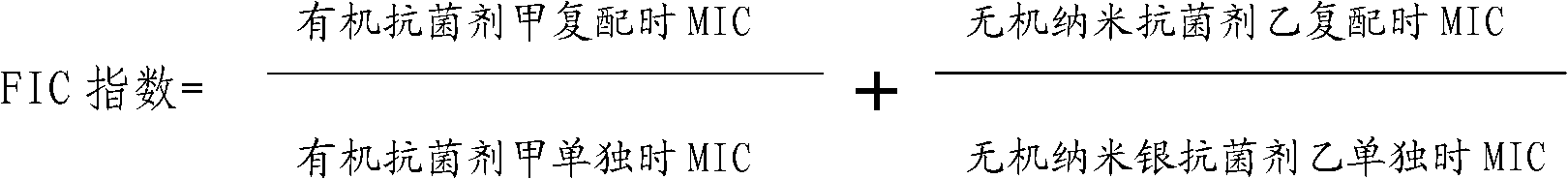

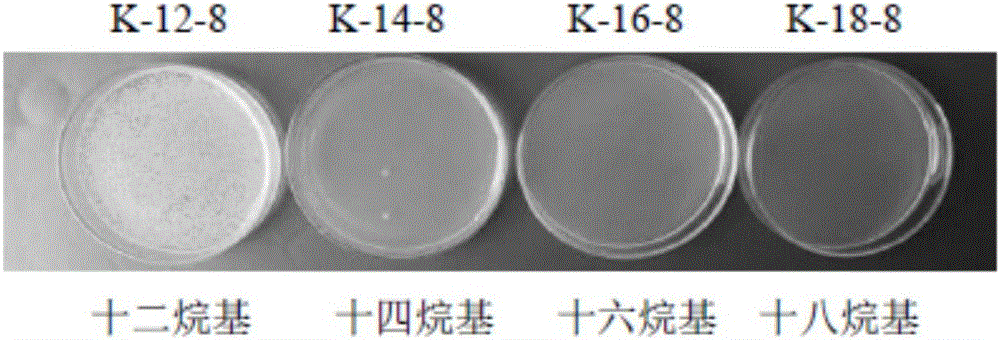

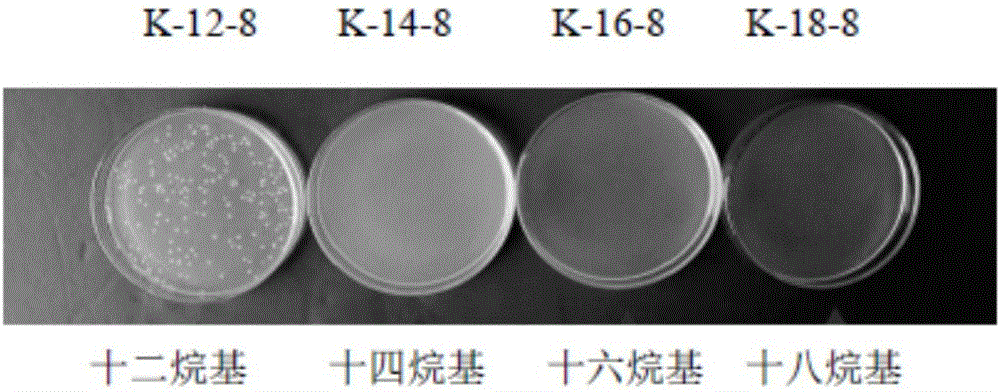

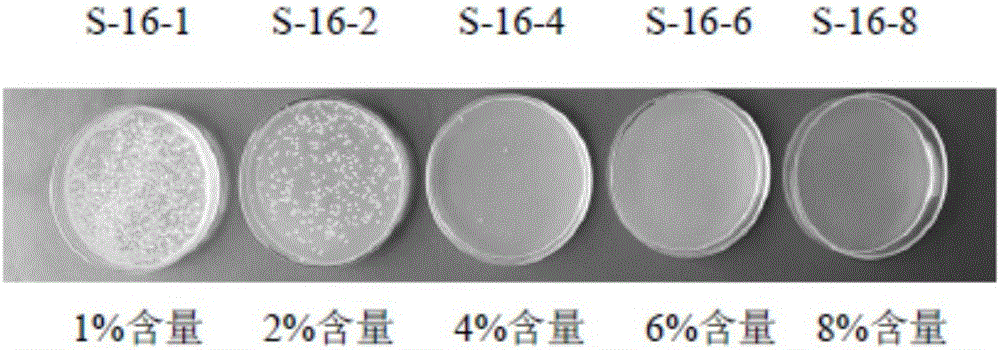

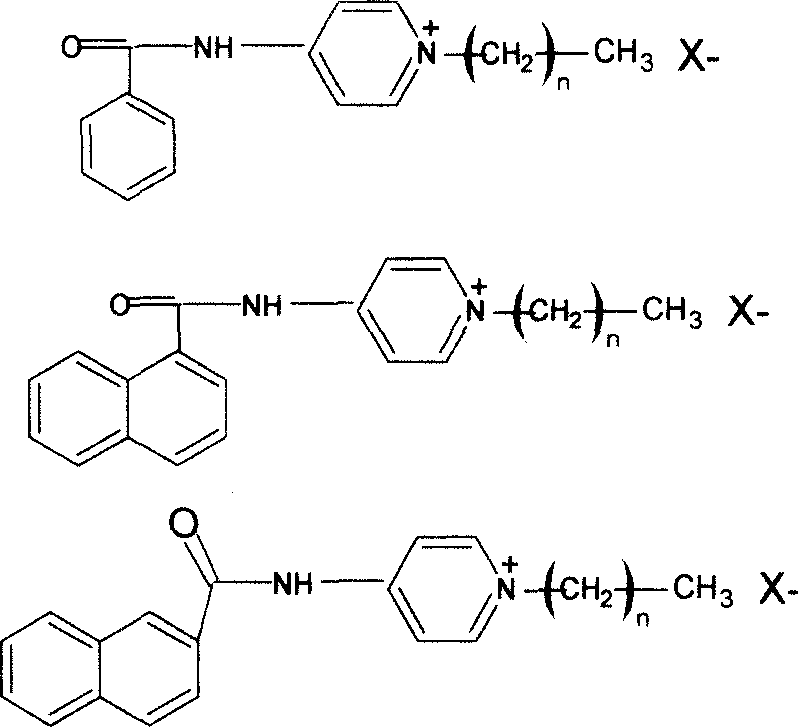

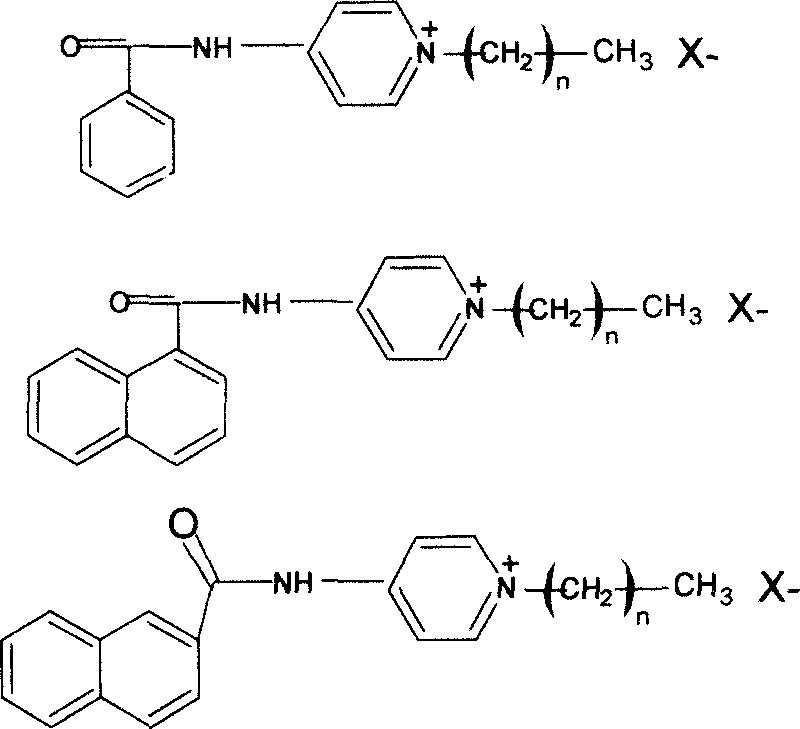

Pyridyl quaternary ammonium salt antiseptic and its prepn process

InactiveCN1973625AImprove the bactericidal effectGood antibacterial durabilityBiocideFungicidesSolventAntimicrobial

The present invention is pyridyl quaternary ammonium salt antiseptic and its preparation process. The pyridyl quaternary ammonium salt antiseptic is 4-phenylamido-1-polyalkyl pyridyl ammonium halide or 4-(1 or 2-naphthyl amido)-1-polyalkyl pyridyl ammonium halide. It is used in antiseptic finishing of protein fiber, acrylon and other fiber. The preparation process includes the following steps: 1. setting benzoyl chloride or naphtholyl chloride inside acetone as organic solvent, cooling to 1-5 deg.c, adding 4-aminopyridine to react for 2 hr to obtain benzoyl aminopyridine or naphtholyl aminopyridine, filtering and stoving; and 2. dissolving the product of the last step in N, N-dimethyl sulphoxide solvent, adding alkyl halide, heating to 100-120 deg.c to react for 4-5 hr to obtain 4-phenylamido-1-polyalkyl pyridyl ammonium halide or 4-(1 or 2-naphthyl amido)-1-polyalkyl pyridyl ammonium halide, and vacuum drying.

Owner:DONGHUA UNIV

Self-cleaning antibacterial fluorocarbon coating

InactiveCN104403476AStrong self-cleaning abilityImprove conversion rateAntifouling/underwater paintsPaints with biocidesSolventKetone

The invention discloses a self-cleaning antibacterial fluorocarbon coating which comprises the following components in parts by weight: 40-60 parts of fluorine-containing polyacrylate resin, 5-13 parts of a silane coupling agent, 1-6 parts of amino resin, 3-15 parts of titanium dioxide, 2-6 parts of calcium carbonate, 10-28 parts of modified nano titanium dioxide, 2-6 parts of silicon nitride, 2-8 parts of zinc molybdate, 5-10 parts of 2,2,4-trimethyl-1,3-pentanediol isobutyrate, 0.3-1.2 parts of 5-chloro-2-methl-4-isothiazolin-3-ketone, 0.2-1.2 parts of defoaming agent, 0.5-1.8 parts of wetting agent, 0.3-0.8 parts of flatting agent, 0.6-1.5 parts of a curing agent and 30-60 parts of a solvent. The self-cleaning antibacterial fluorocarbon coating disclosed by the invention is high in self-cleaning ability and good in antibacterial property and can be applied in building outer walls.

Owner:ANHUI JINDUN PAINT

In-situ synthesis method of nano-silver alginate short fibers

InactiveCN106049036AImprove antibacterial propertiesGood antibacterial durabilityBiochemical fibre treatmentHeat resistant fibresFiberSodium ascorbate

The invention discloses an in-situ synthesis method of nano-silver alginate short fibers. The method comprises the following steps of performing complexation on soluble silver salt and alginate short fibers by means of performing double-dip-double-nip treatment according to a padding method under a dark condition at a room temperature; then immersing into a reducing agent bath solution, reacting for 15 to 60 min at a temperature of 30 to 80 DEG C, and reducing Ag<+> complexed on the alginate short fibers into silver nanoparticles in an in-situ manner; later, washing by utilization of distilled water, and naturally airing to obtain the nano-silver alginate short fibers, wherein a reducing agent is one or more of glucose, sodium ascorbate or citric acid, and the soluble silver salt is a silver nitrate or silver-ammonia solution. The method disclosed by the invention has the advantages that the effects of simple technology, and easiness in control and industrialized production are achieved; for the prepared nano-silver alginate short fibers, the silver nanoparticles are distributed on the surface of the fibers and inside the fibers, the particle diameter is 5 to 30 nm, the antibacterial property is excellent, the durability is good, and the fibers can be applied to the fields of medical health, fire protection, military, spaceflight, healthcare textile and the like.

Owner:QINGDAO UNIV

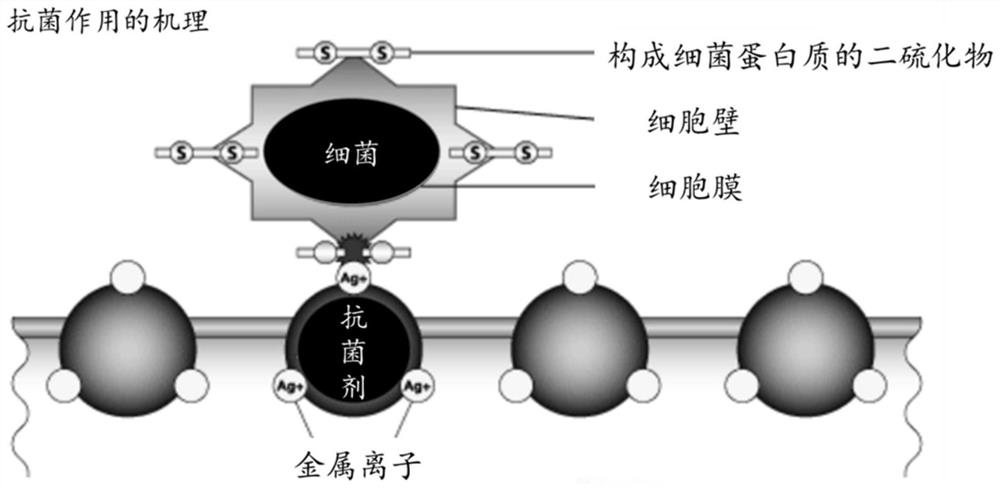

Antibacterial polycarbonate composite and preparation method and application thereof

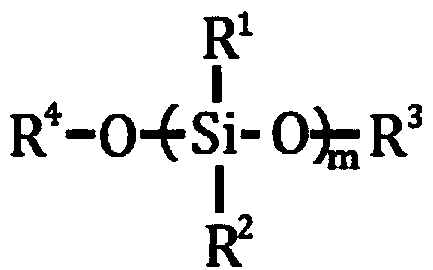

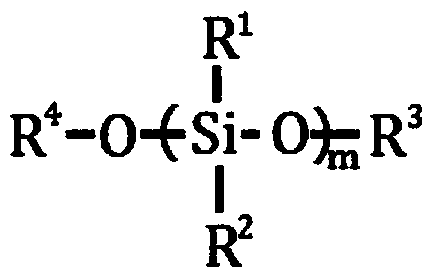

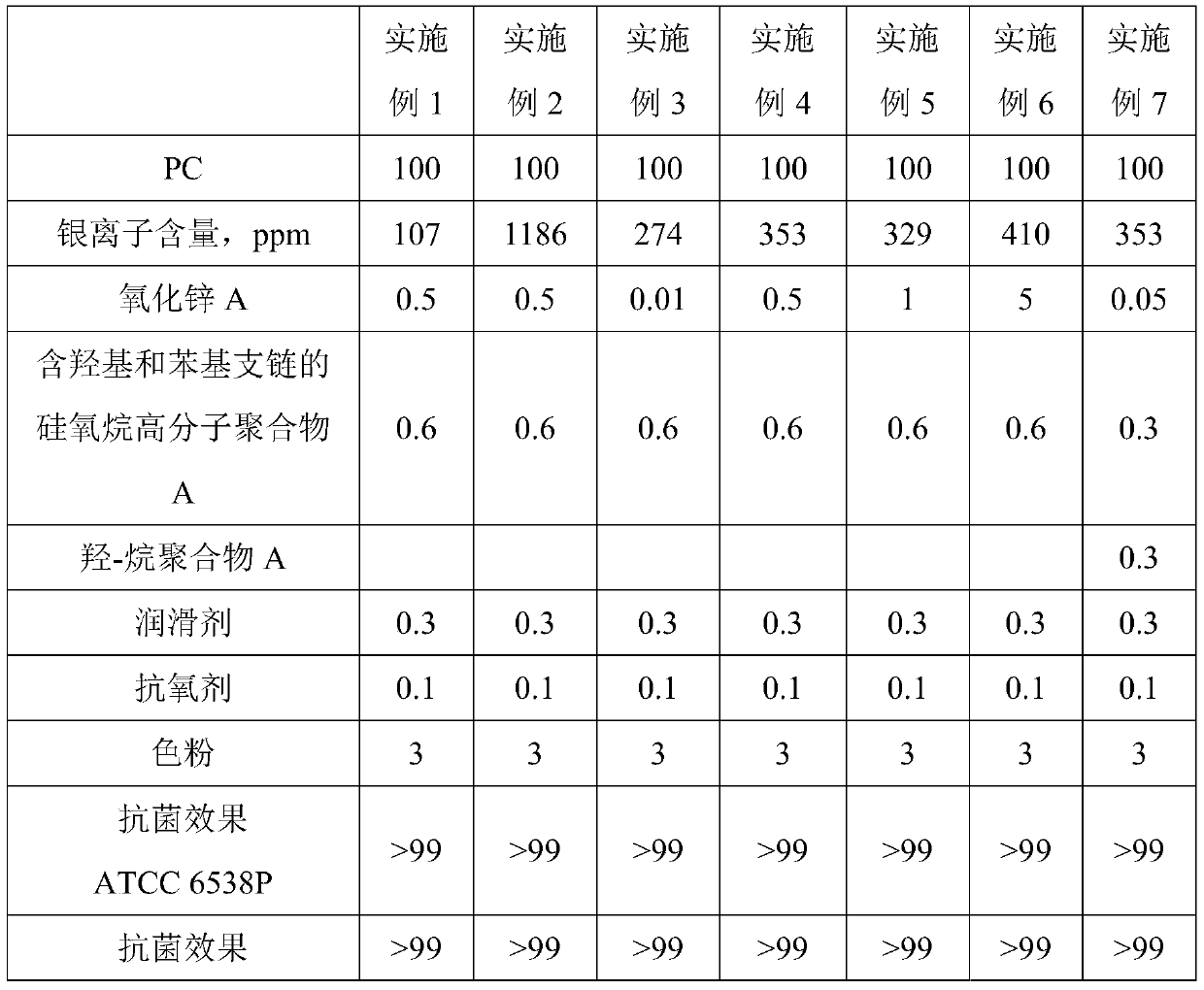

The invention discloses an antibacterial polycarbonate composite. The antibacterial polycarbonate composite includes, by weight, the following components of 100 parts of polycarbonate, 0.01 to 5 partsof nano metal oxides, 0.01 to 5 parts of siloxane type polymer containing hydroxyl and alkyl branched chains and / or siloxane polymer containing hydroxyl and phenyl branched chains; based on the total weight of the antibacterial polycarbonate composite, the silver ion content is 100-1200 parts per million. With nano-oxides added to increase the dispersion of silver ions and with the siloxane typepolymer containing the hydroxyl and alkyl branched chains and / or the siloxane polymer containing the hydroxyl and phenyl branched chains added as color stabilizers, the antibacterial polycarbonate composite has the advantages of good color stability and antibacterial properties.

Owner:KINGFA SCI & TECH CO LTD

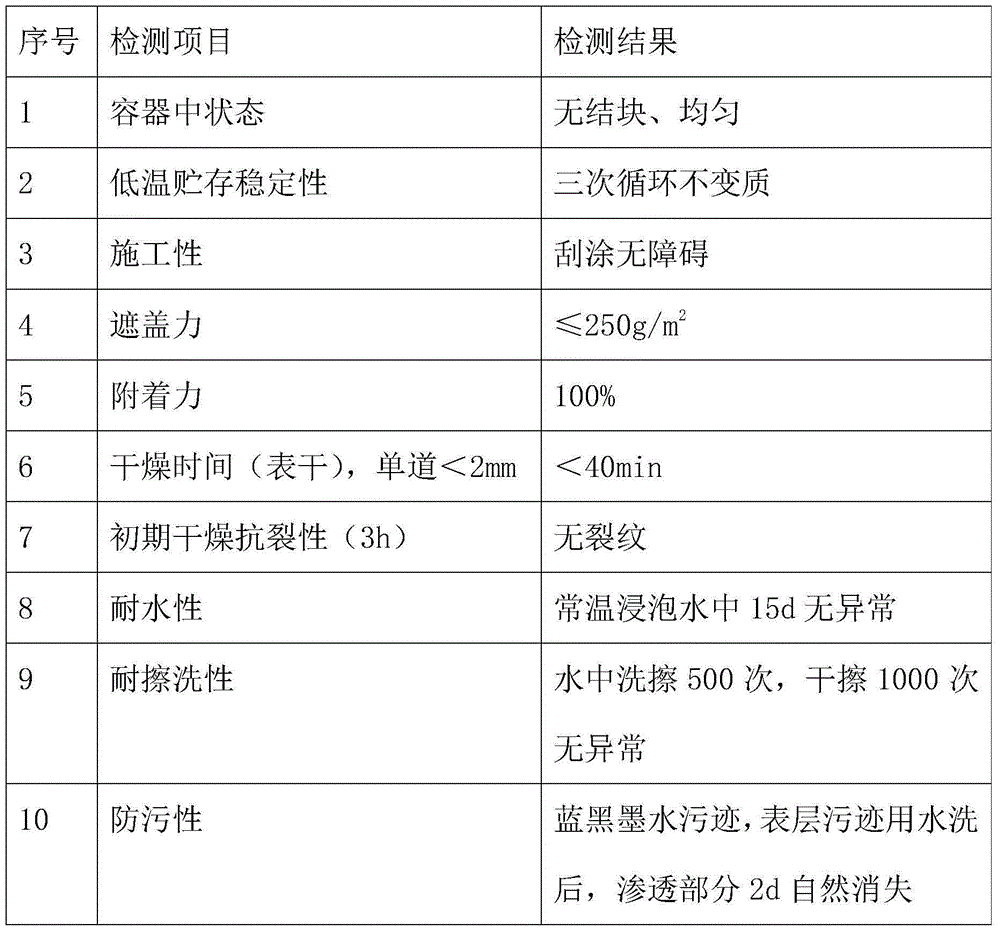

Scrubbing-resistant anti-microbial inner wall emulsion paint

InactiveCN105131672AHigh strengthImprove wear resistanceAntifouling/underwater paintsPaints with biocidesEmulsionPolyphosphate

The invention discloses a scrubbing-resistant anti-microbial inner wall emulsion paint. The emulsion paint comprises raw materials: modified PVA, methyl methacrylate, polymethyl methacrylate, light calcium carbonate, talcum powder, lithopone, calcined kaolin, hydroxyethyl cellulose, a dispersant SN-5040, a dispersant SN-5027, a multifunctional auxiliary agent AMP-95, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, an antifoaming agent NXZ, negative ion-anti-microbial additives, sodium polyphosphate, a flatting agent, a nano stain-resistant agent NZM-1, propylene glycol, 5-chloro-2-methyl-4- isothiazolin-3-ketone and deionized water. The inner wall emulsion paint is not easy to generate powder, has good scrubbing resistance and stain resistance, is safe and environmentally friendly, and has a long anti-microbial validity period.

Owner:TIANCHANG YINHU PAINT

Preparation method for Beta-cyclodextrin nano-silver antibacterial fabric

The invention relates to a preparation method for a Beta-cyclodextrin nano-silver antibacterial fabric. The specific steps are as follows: a Beta-cyclodextrin solution, a silver nitrate solution and asodium borohydride solution are prepared in the same volume; the silver nitrate solution is added into the Beta-cyclodextrin solution and stirred, so that a colorless, uniform and transparent solution is obtained; the sodium borohydride solution is dripped into the colorless, uniform and transparent solution to react, so that a Beta-cyclodextrin nano-silver solution is prepared; the obtained Beta-cyclodextrin nano-silver solution is added with water to prepare a Beta-cyclodextrin nano-silver aqueous solution, and cross-linking agent is added into the Beta-cyclodextrin nano-silver aqueous solution and stirred, so that a uniformly mixed antibacterial finishing solution is obtained; and a fabric is dipped and rolled in the antibacterial finishing solution twice, baked, washed and dried, so that the Beta-cyclodextrin nano-silver antibacterial fabric is obtained. The preparation method adopts Beta-cyclodextrin as a protective agent, adopts the chemical reduction method to prepare nano-silver, and carries out antibacterial finishing on the fabric with polycarboxylic acid serving as the cross-linking agent, and after antibacterial finishing, the fabric has good antibacterial durability.

Owner:TIANJIN BAOXINGWEI TECH

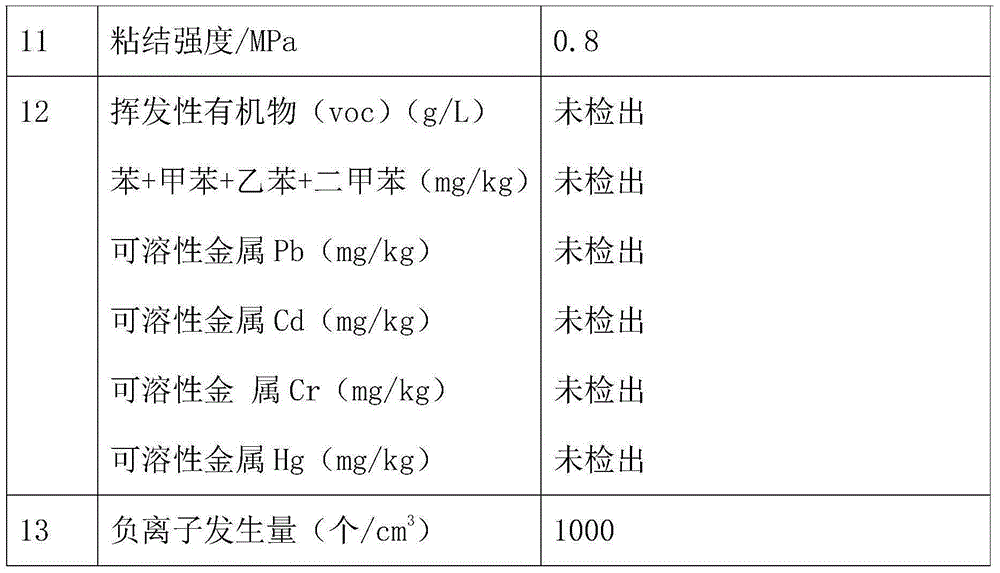

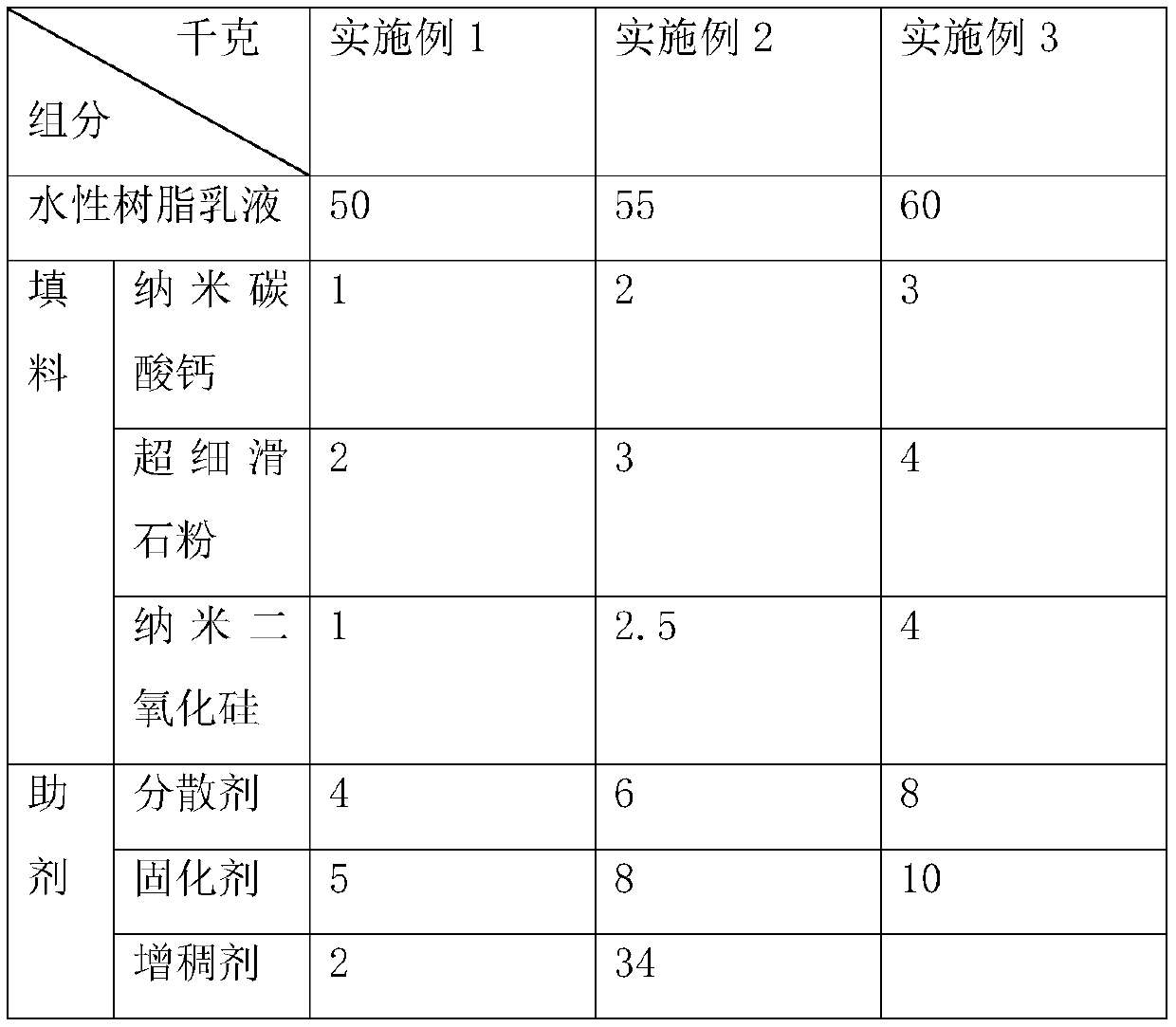

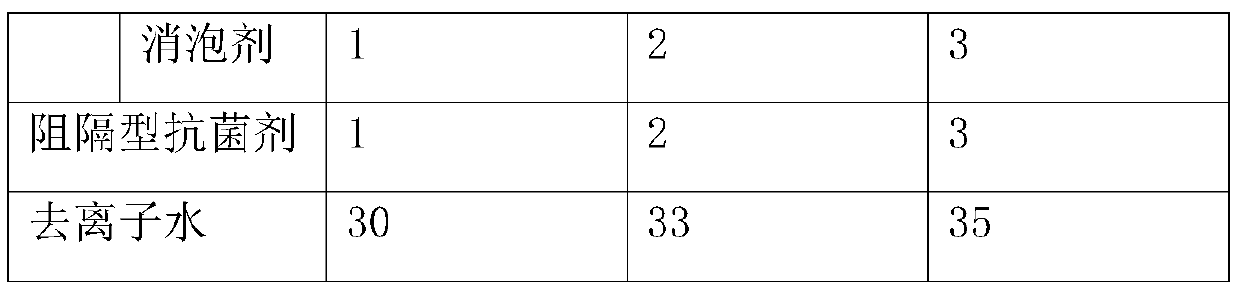

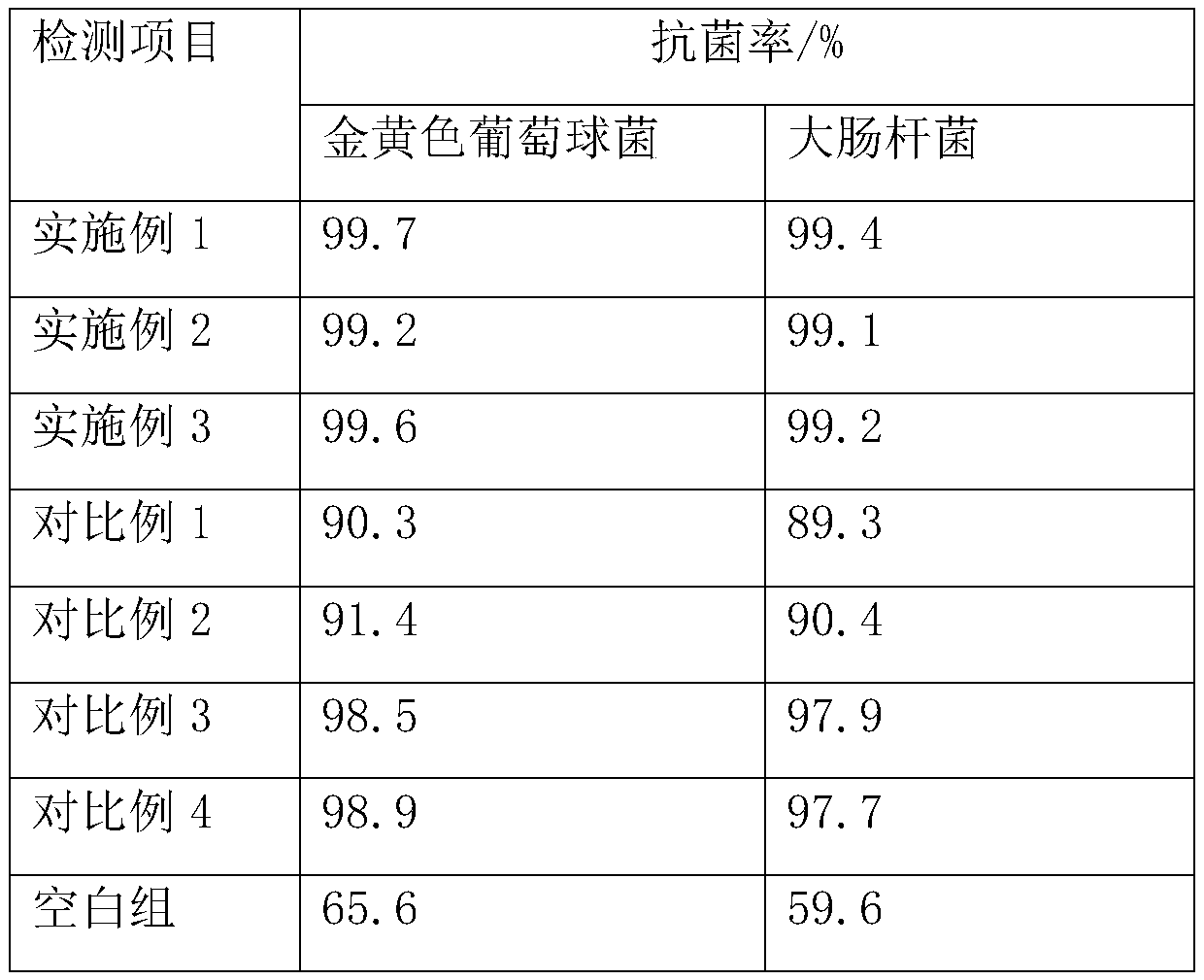

Paint used for cosmetic packaging bottles, and preparation method and coating technology thereof

ActiveCN110093101AImprove water resistanceImprove mechanical propertiesAntifouling/underwater paintsPretreated surfacesEpoxyAcrylic resin

The invention discloses paint used for cosmetic packaging bottles, and a preparation method and coating technology thereof. The paint includes waterborne resin emulsion, a filling material, an auxiliary agent, a barrier-type antibacterial agent and deionized water; the waterborne resin emulsion is formed by amino silicone oil modified acrylic resin emulsion and montmorillonite modified waterbornepolyurethane emulsion according to a mass ratio being 1 : 1-1.2 through mixing; the barrier-type antibacterial agent includes epoxy resin emulsion, a film-forming auxiliary agent, chitosan, a lotus leaf hydrophobic agent and antibacterial liquid; and the antibacterial liquid is prepared by mixing silver-loaded zeolite, eucalyptus oil and lemon oil according to a mass ratio being 1 : (0.5-0.9) : (0.6-1) to grind into particle sizes that are less than or equal to 1 [mu]m. The coating technology of the paint includes three steps which successively are surface pretreatment, primary spraying and secondary spraying. The paint has advantages of being good in barrier property and high in antibacterial property.

Owner:广州澳盈日化包装用品有限公司

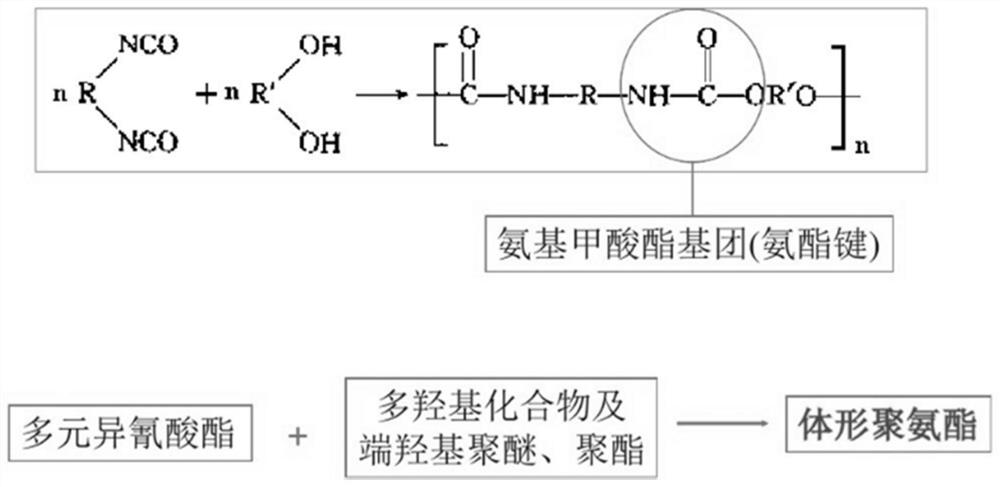

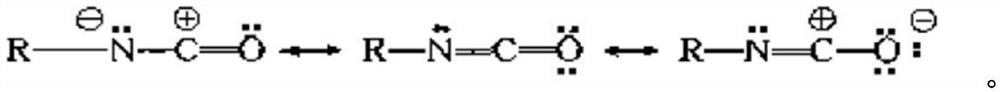

Method for preparing polyurethane adhesive used for building

InactiveCN105368368AGood antibacterial effectImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesiveFiltration

The invention provides a method for preparing a polyurethane adhesive used for building. The method comprises the following steps: 1) adding radix astragali powder in water, boiling the material, insulating the material, adding absolute ethyl alcohol, stirring the materials, cooling the materials, performing ultrasonic extraction to obtain a primary filtrate, adding filter residue in an ethanol solution, performing ultrasonic extraction to obtain a secondary filtrate, merging the filtrates, performing rotary evaporation concentration to obtain a radix astragali extract product; 2) performing ultrasonic dispersion on porous zinc phosphate and the radix astragali extract product, drying the material to obtain an antibacterial filling material; 3) preparing an antibacterial solution, adding a stearic acid solution, stirring the materials, performing pumping filtration, washing and drying the product to obtain the modified antibacterial filling material; 4) blending polyol, a chain extender, a stabilizing agent, an antifoaming agent and the modified antibacterial filling material under vacuum, adding a catalyst and stirring a mixture under vacuum to obtain a component A; 5) stirring diisocyanate and an activator under vacuum to obtain a component B; and 6) uniformly mixing the component A and the component B to obtain the polyurethane adhesive used for building. The prepared adhesive has good antibacterial property.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

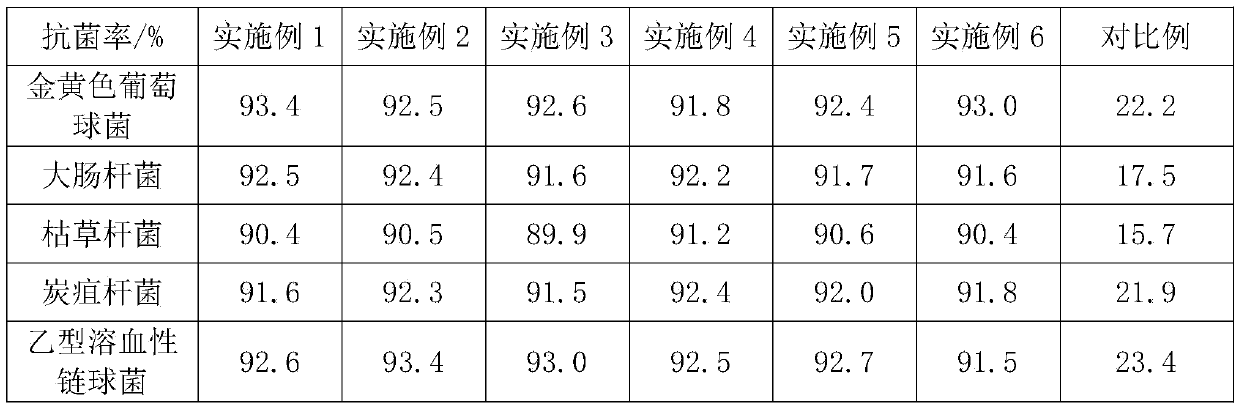

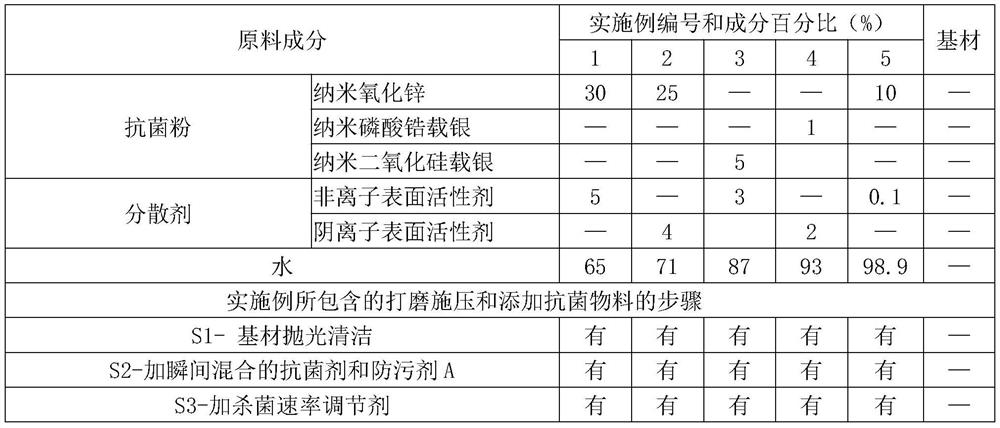

Production process of antibacterial polished tile, preparation method of antibacterial agent and antibacterial polished tile

The invention discloses a production process of an antibacterial polished tile. The production process comprises the following specific steps: S1) cleaning and polishing a glaze surface of a common polished tile to obtain a to-be-treated polished tile; S2) dropwise adding an antibacterial agent and an antifouling agent A, which are instantly mixed, on the surface of a glaze layer of the to-be-treated polished tile, and then pressing and polishing the to-be-treated polished tile by using millstone until the glossiness of the to-be-treated polished tile meets set requirements; S3) dropwise adding a sterilization rate regulator on the surface of the glaze layer of the to-be-treated polished tile, and pressing and polishing the to-be-treated polished tile by using the millstone until the glossiness meets the set requirements; and S4) dropwise adding an antifouling agent B containing an antibacterial solution to the surface of the glaze layer of the to-be-treated polished tile, and pressingand polishing the to-be-treated polished tile by the millstone until the glossiness meets the set requirement, thereby obtaining the antibacterial polished tile. The invention further provides a preparation method of the antibacterial agent for the production process of the antibacterial polished tile and the antibacterial polished tile prepared according to the production process of the antibacterial polished tile, and the prepared antibacterial polished tile has a good antibacterial effect and stable and lasting antibacterial performance.

Owner:佛山市三水普朗克新型材料有限公司

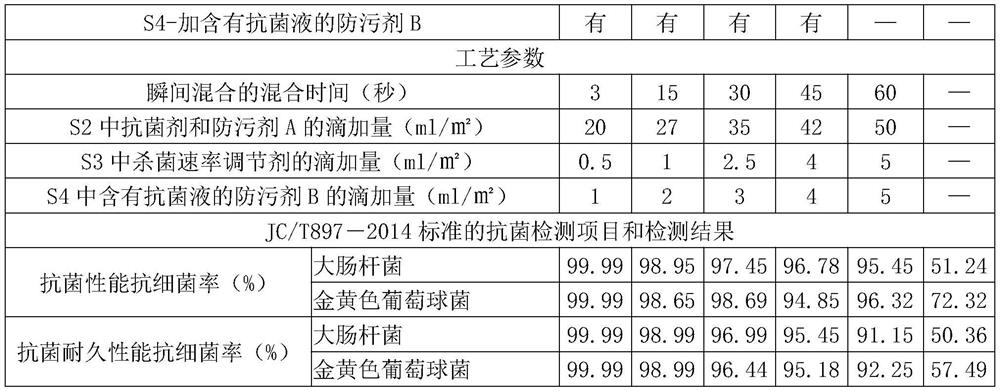

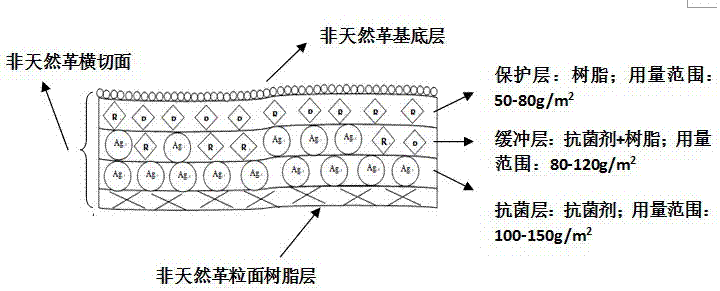

Sandwich treatment method of antibacterial non-natural leather

The invention discloses a sandwich treatment method of antibacterial non-natural leather. The sandwich treatment method comprises the following steps of (1) using a certain amount of an antibacterial agent as a first layer, spraying to the substrate surface of the non-natural leather, and drying the treated non-natural leather at the temperature of 50 to 60 DEG C; (2) mixing the antibacterial agent and resin according to a certain ratio, using a certain amount of a mixed solution as a second layer, spraying to the substrate surface of the non-natural leather obtained in step (1), and drying at the temperature of 50 to 60 DEG C; (3) using a certain amount of resin as a third layer, spraying to the substrate surface of the non-natural leather obtained in step (2), and drying at the temperature of 50 to 60 DEG C; then, ironing at the temperature of 100 DEG C and pressure of 70Kg, so as to obtain the antibacterial non-natural leather. The sandwich treatment method has the advantages that the finished product of non-natural leather can be treated, the suitability is wide, the practicality is strong, the operation is simple and convenient, and the prepared antibacterial non-natural leather has a good antibacterial property and an antibacterial lasting property.

Owner:SICHUAN UNIV

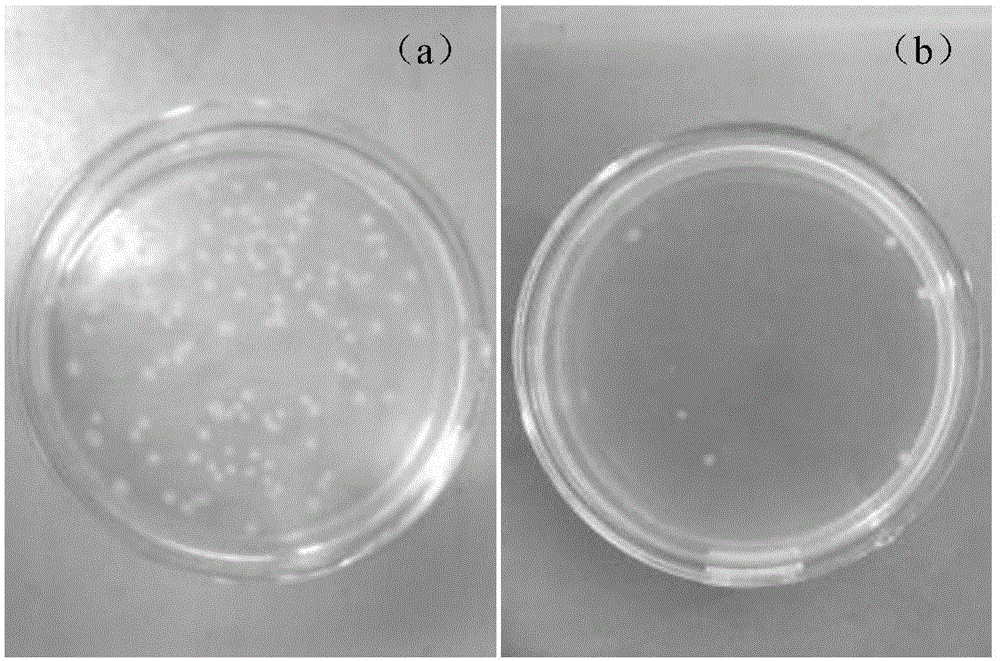

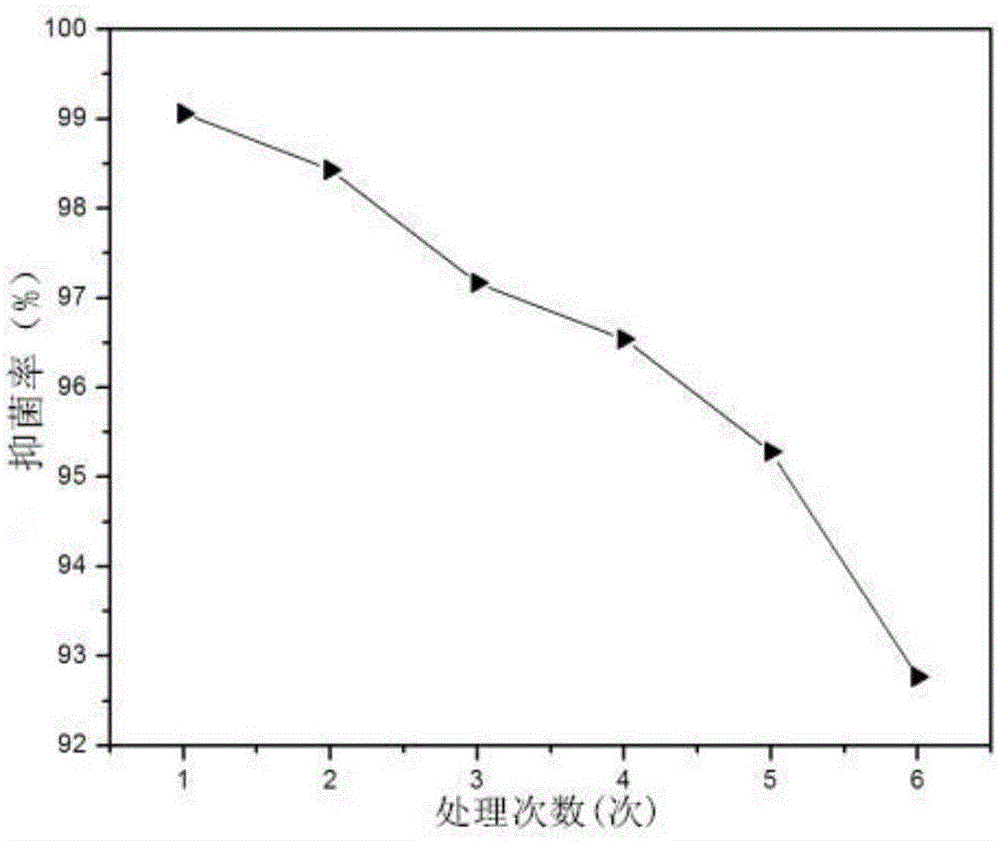

Rare earth cerium doped copper-zinc composite oxide as well as preparation method and application of rare earth cerium doped copper-zinc composite oxide

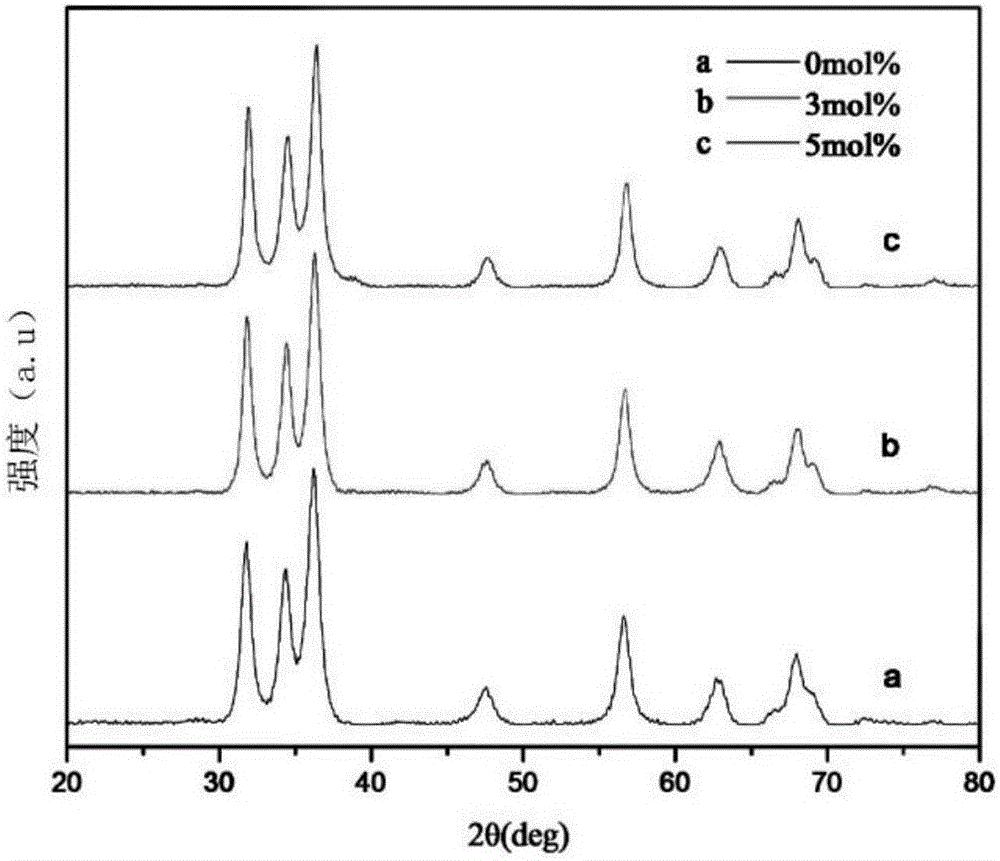

InactiveCN106417375AAvoid reunionLarge specific surface areaBiocideDisinfectantsHeat resistanceCrystal structure

The invention discloses a rare earth cerium doped copper-zinc composite oxide as well as a preparation method and application of the rare earth cerium doped copper-zinc composite oxide. The composite oxide is spherical Ce-CuO-ZnO particles, the particle size is 30-50nm, the crystal structure is wurtzite crystal form, and the energy gap is 2.68-3.05eV. The composite oxide comprises the following components according to mole percentage: 1.00-9.00% of CuO, 0.05-0.20% of Ce, and 90.80-98.95% of ZnO. According to the invention, the energy gap of ZnO is reduced, and the required excitation energy is lowered; and moreover, the copper-zinc composite oxide also has perfect heat resistance, the preparation technology is simple, the preparation cost is low, and the antibacterial rate still can exceed 92% after six times of repeated use while the antibacterial durability is good.

Owner:HEBEI UNIV OF TECH

Waterproof finishing agent and preparation method and application method thereof

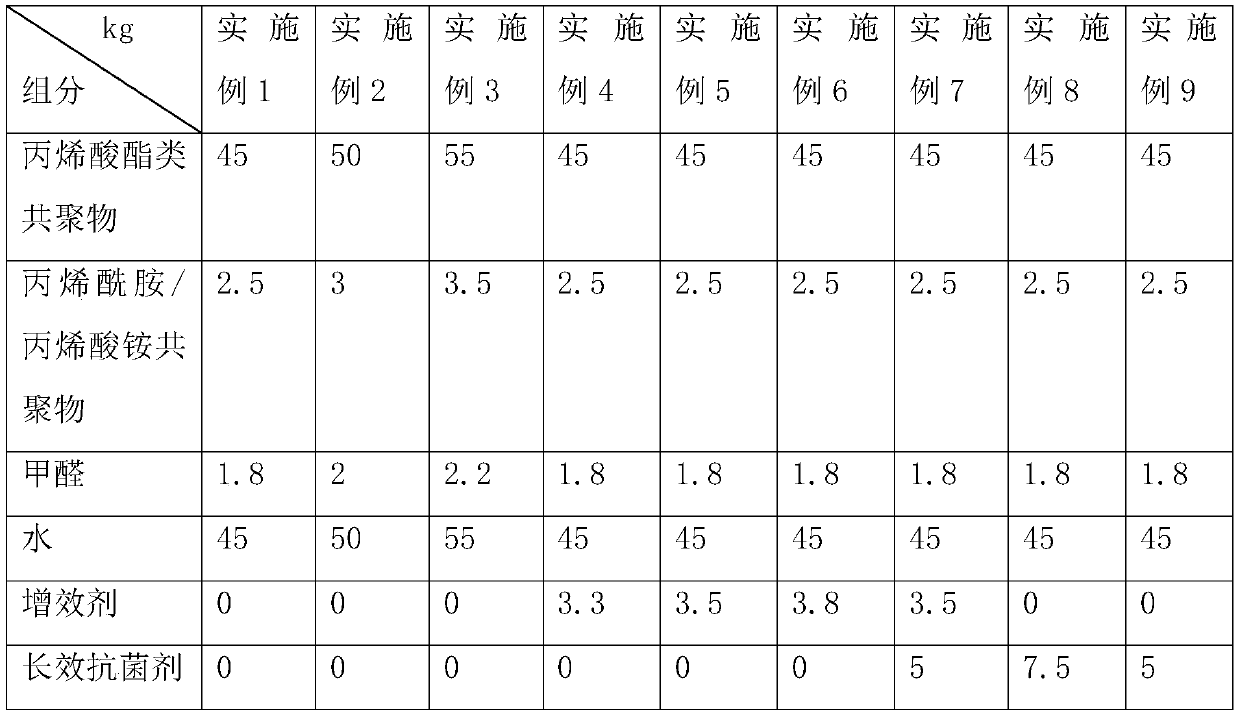

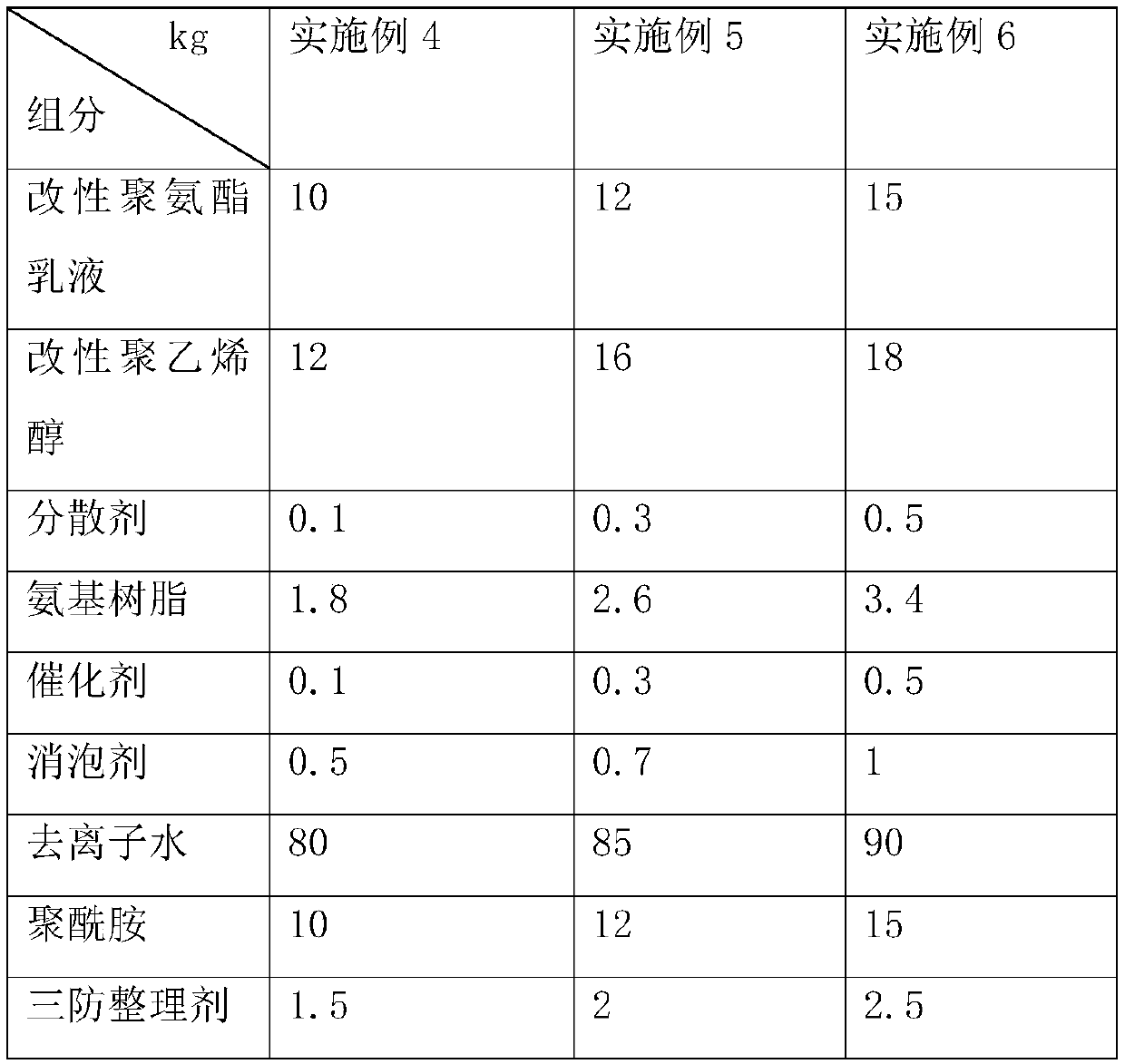

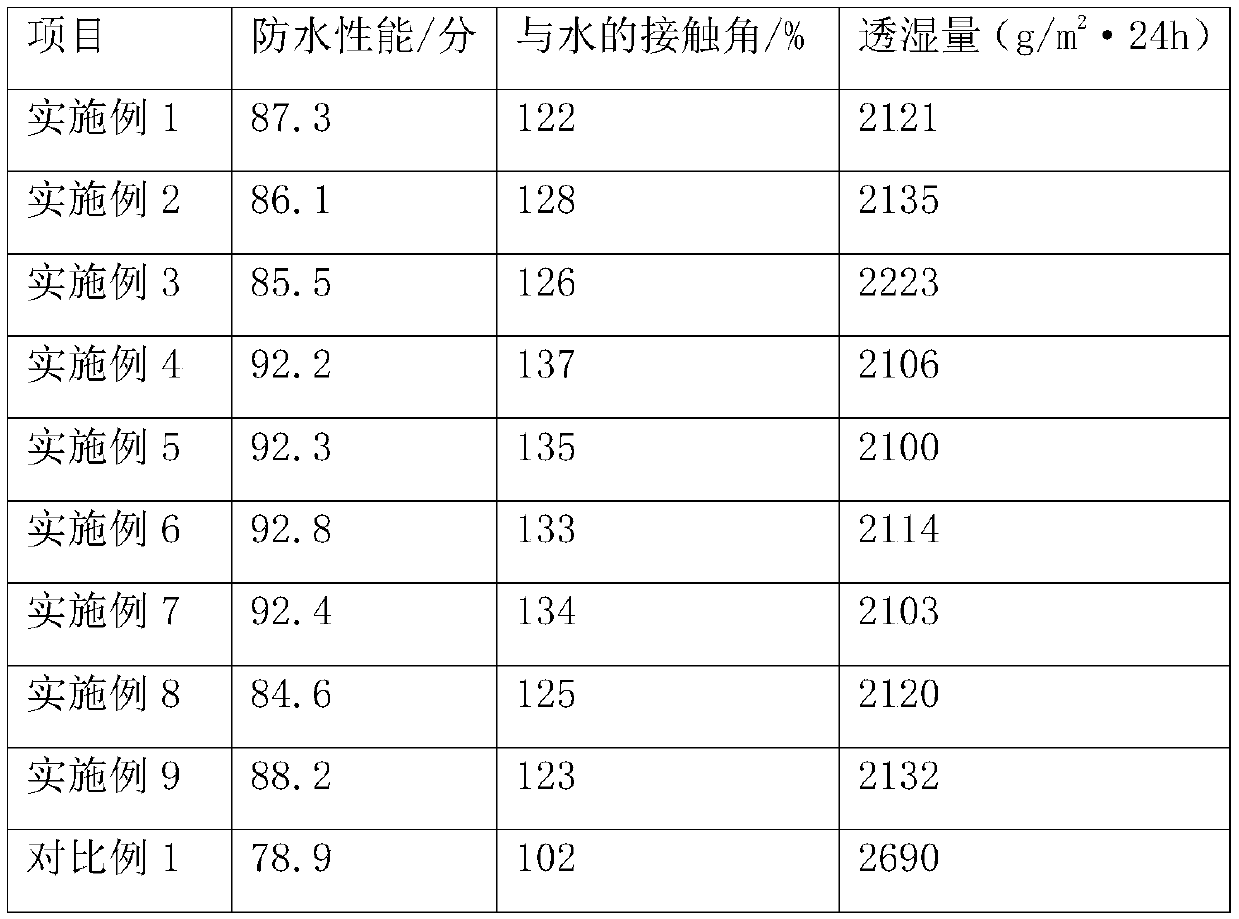

InactiveCN110409181AGood film formingImprove waterproof performanceBiochemical fibre treatmentLiquid repellent fibresMoisture permeabilityMaterials science

The invention discloses a waterproof finishing agent and a preparation method and application method thereof. the waterproof finishing agent is prepared from, by weight, 45-55 parts of an acrylate copolymer, 2.5-3.5 parts of an acrylamide / ammonium acrylate copolymer, 1.8-2.2 parts of formaldehyde and 45-55 parts of water. The waterproof finishing agent can make the surface elasticity of a waterproof curtain for a bathroom good and soft, and has the advantages of being good in waterproof performance, low in breathability and moisture permeability, and excellent in antibacterial performance.

Owner:三赢家居用品(河源)有限公司

Guanidine salt antibacterial paint

InactiveCN106009856AImprove the bactericidal effectGood antibacterial durabilityAntifouling/underwater paintsPaints with biocidesEmulsionFoaming agent

The invention discloses guanidine salt antibacterial paint. The guanidine salt antibacterial paint is characterized by being prepared from the following components in parts by weight: 45 to 65 parts of acrylic emulsion, 1 to 5 parts of maleic anhydride, 1 to 10 parts of ethylene glycol, 10 to 30 parts of filling material, 1 to 10 parts of dispersant, 1 to 5 parts of de-foaming agent, 1 to 5 parts of pigment and 1 to 8 parts of guanidine salt type polymer. A coating of the antibacterial paint has good sterilization property and lasting antibacterial property and has relatively good safety.

Owner:上海巨峰化工有限公司 +1

PU antibacterial coating as well as preparation method and application thereof

InactiveCN113372801AHigh solid contentImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesPolymer scienceMeth-

The invention discloses a PU antibacterial coating as well as a preparation method and application thereof. The PU antibacterial coating comprises a component A and a component B, the component A is prepared from the following raw materials: hydroxy acrylic resin, thermoplastic acrylic resin, saturated polyester resin, aluminum paste, an antibacterial agent, a diluent, a drier and a flatting agent; and the component B is prepared from the following raw materials: a hexamethylene diisocyanate tripolymer and a solvent I. According to the PU antibacterial coating, the solid content is 35% or above during construction, and VOC emission is reduced (the VOC emission value is smaller than or equal to 700 g / L); the metal texture of the aluminum-silver powder paint is improved; and meanwhile, the PU coating disclosed by the invention is good in antibacterial effect, good in antibacterial coating dispersity, high in antibacterial efficiency and good in antibacterial durability.

Owner:HUNAN SOKAN NEW MATERIAL

Method for prolonging antibacterial persistence of polyolefin microfiltration membrane

InactiveCN108031305AImprove antibacterial propertiesHigh strengthMembranesSemi-permeable membranesPolymer sciencePolyolefin

The invention belongs to the technical field of antibacterial polyolefin microfiltration membranes and in particular relates to a method for prolonging the antibacterial persistence of a polyolefin microfiltration membrane. A cast membrane solution comprises the following raw materials in parts by weight: 36-42 parts of polyolefin material, 6-10 parts of 4,4'-biphenol p-phthalonitrile resin, 16-20parts of bisphenol A type phthalonitrile resin containing ether nitrile chain segments, 4-8 parts of silicon carbide powder, 1-2 parts of tribasic lead sulfate and 4-6 parts of nitrated chitosan antibacterial agent. Due to the preparation of the nitrated chitosan antibacterial agent, composite particles with stronger antibacterial property are obtained, the composite particles are uniformly dispersed in a membrane layer so as to have better antibacterial permanence, the permeability is kept not to be reduced on the basis that the strength is improved and the thickness of a film is reduced, the composite particles still have better hydrophility after being sufficiently dried for 96 h in a 50-DEG C drying oven, and meanwhile, the antibacterial effect can reach 90-100% of that before dryingtreatment, and therefore, the antibacterial property is persistent.

Owner:刘顶康

Method for ventilation and antibiotic finishing of viscose non-woven cloth for medical treatment and public health

InactiveCN108951129ALarge liquid absorptionImprove breaking strengthBiochemical fibre treatmentVegetal fibresCarboxylic acidChloroacetic acids

The invention discloses a method for ventilation and antibiotic finishing of viscose non-woven cloth for medical treatment and public health. The method comprises the following steps: dipping a clothsample into a sodium hydroxide solution, adding chloroacetic acid for generating etherification reaction, neutralizing by virtue of an ethanol solution of acetic acid, washing with an ethanol-water mixed solution, and drying; adding a silver nitrate into a protecting agent, namely a beta-cyclodextrin solution in the same volume, dropwise adding a reducing agent, namely a sodium borohydride solution, and magnetically stirring for reaction, so as to obtain a beta-cyclodextrin-nano-silver water solution; adding a cross-linking agent, namely butane tetracarboxylic acid into the obtained beta-cyclodextrin-nano-silver water solution, and uniformly stirring and mixing, so as to obtain antibiotic finishing liquid; and carrying out carboxymethylation on viscose non-woven cloth, dipping the viscosenon-woven cloth into the antibiotic finishing liquid, carrying out pre-baking and baking, washing with hot water, washing with cold water, and finally, drying.

Owner:安徽利通达纤维新材料有限公司

Antibacterial medical hemostatic sponge and preparation method thereof

InactiveCN111617308AGood antibacterial durabilityAvoid infectionSurgical adhesivesPharmaceutical delivery mechanismLiver hemorrhageBiochemistry

The invention provides an antibacterial medical hemostatic sponge. The antibacterial medical hemostatic sponge is prepared from a biological macromolecule, halloysite and an antibacterial agent, wherein the biological macromolecule is used as a porous sponge skeleton, and the halloysite is loaded with the antibacterial agent. The application also provides a preparation method of the antibacterialmedical hemostatic sponge. The long-acting antibacterial hemostatic material provided by the invention can realize efficient hemostasis, and has effective hemostasis effects for a liver hemorrhage model. The antibacterial hemostatic sponge provided by the invention has good long-term antibacterial properties. In addition, the preparation method is simple and easy to implement, has no pollution tothe environment, and easily realizes mass production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of simple long-acting antibacterial fabric coating

ActiveCN110670353AGood antibacterial durabilityHigh bactericidal activityBiochemical fibre treatmentBiotechnologyBacterial virus

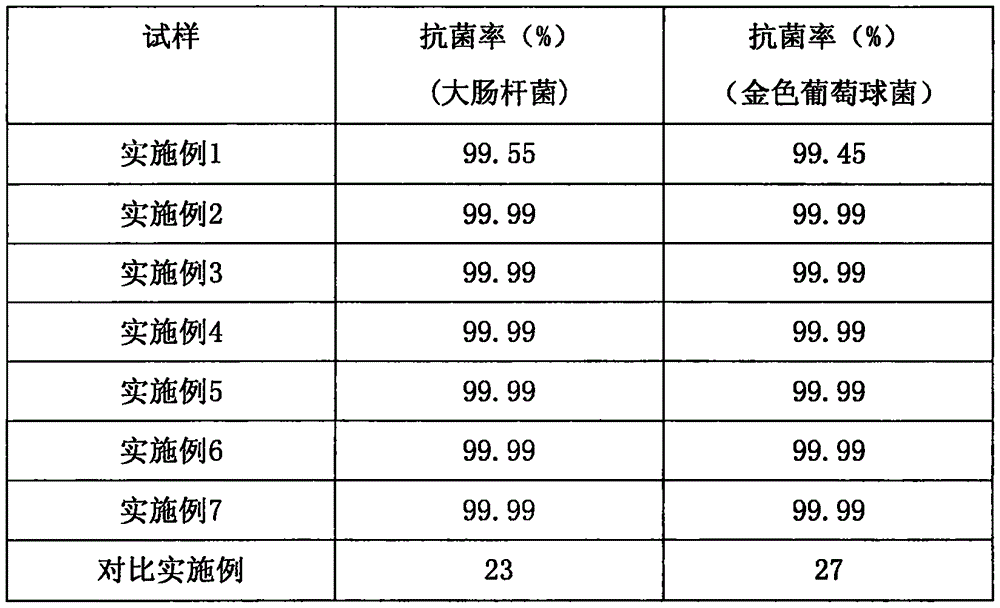

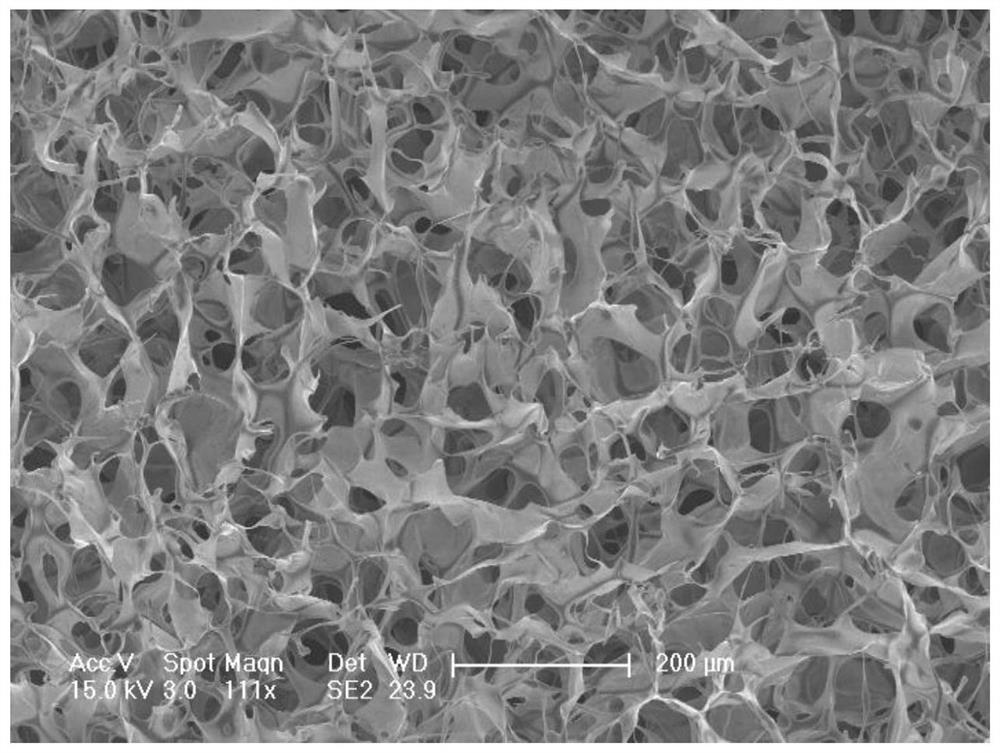

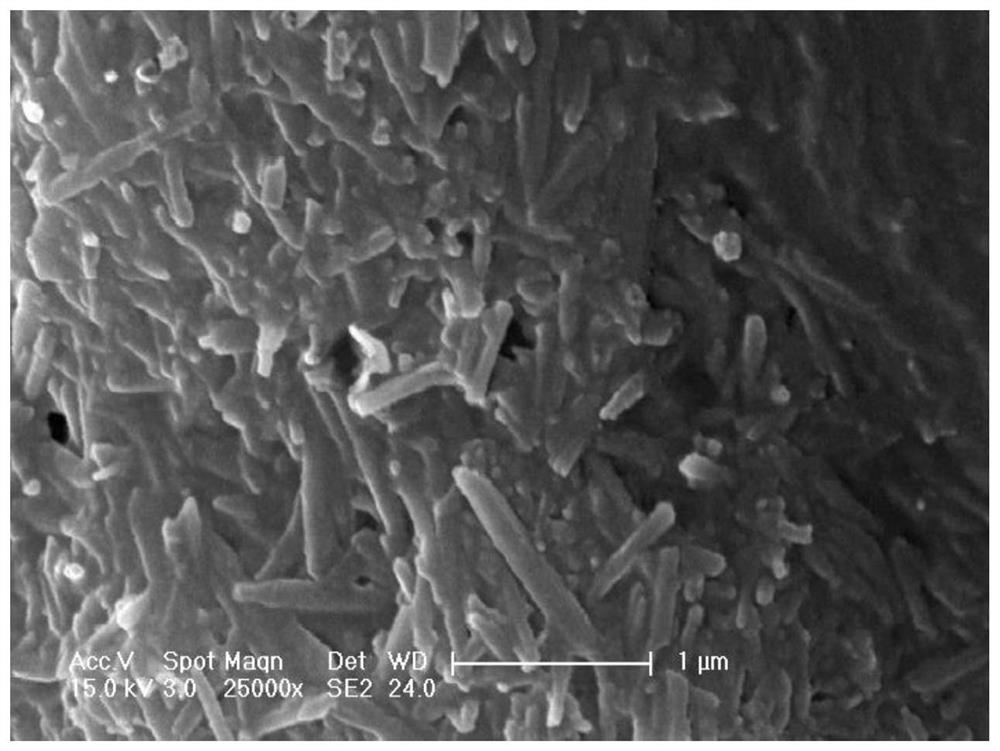

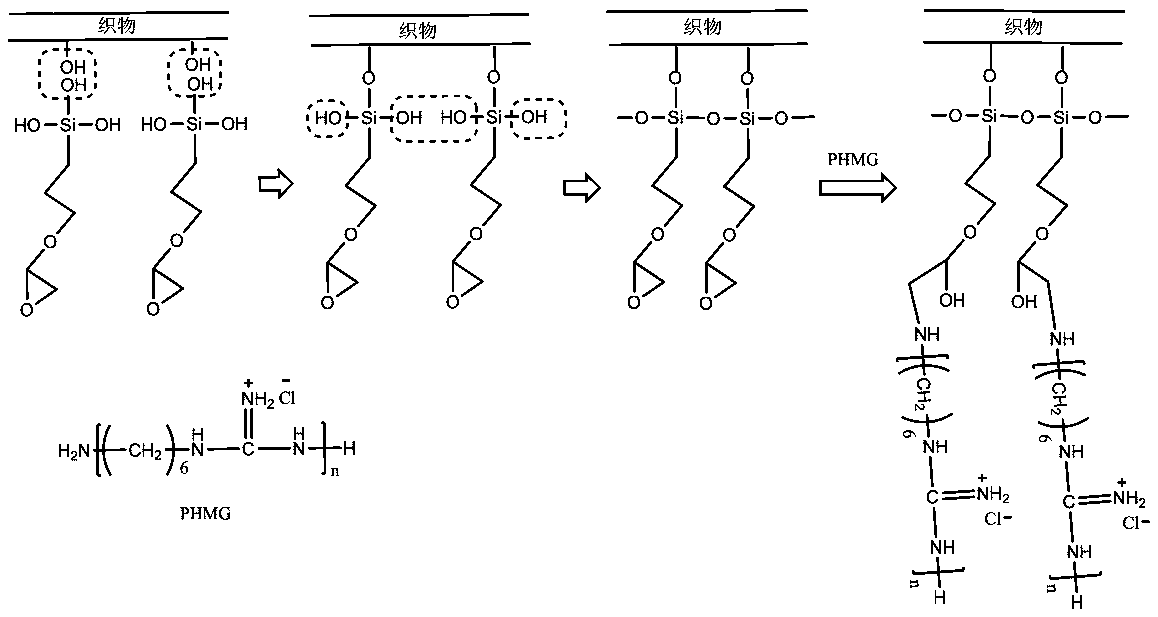

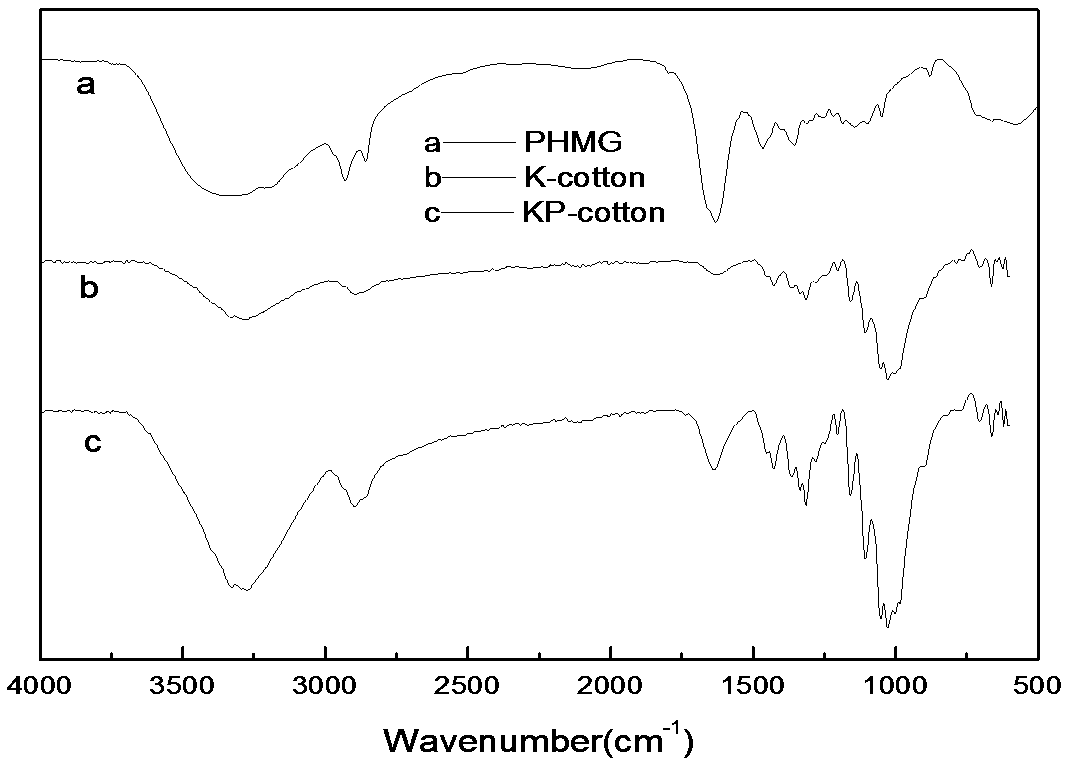

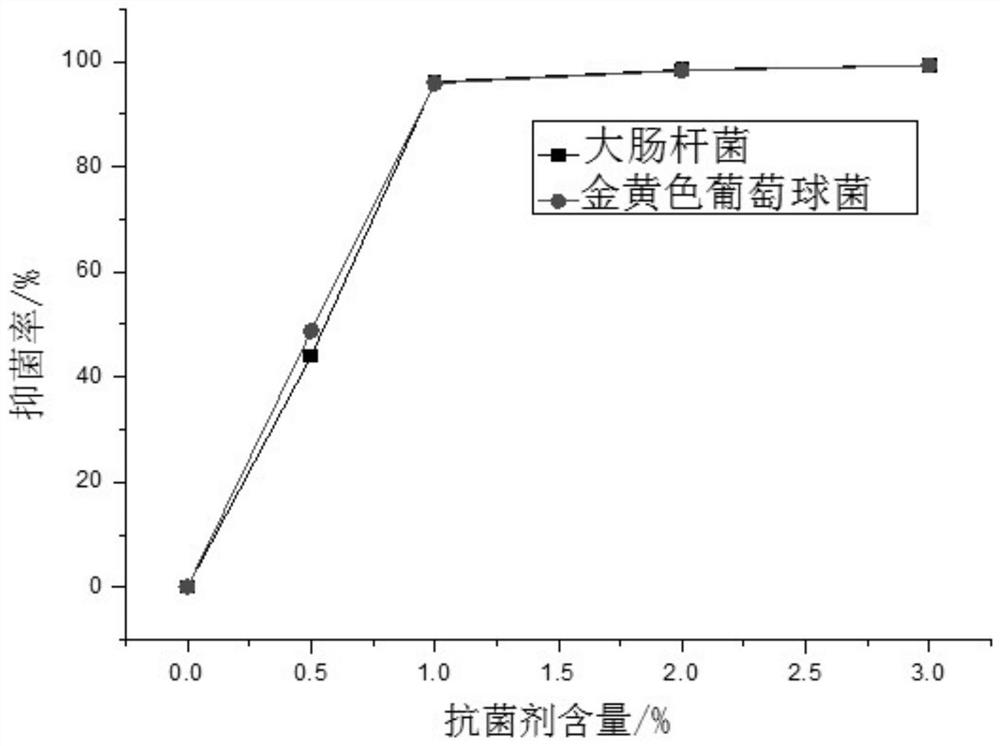

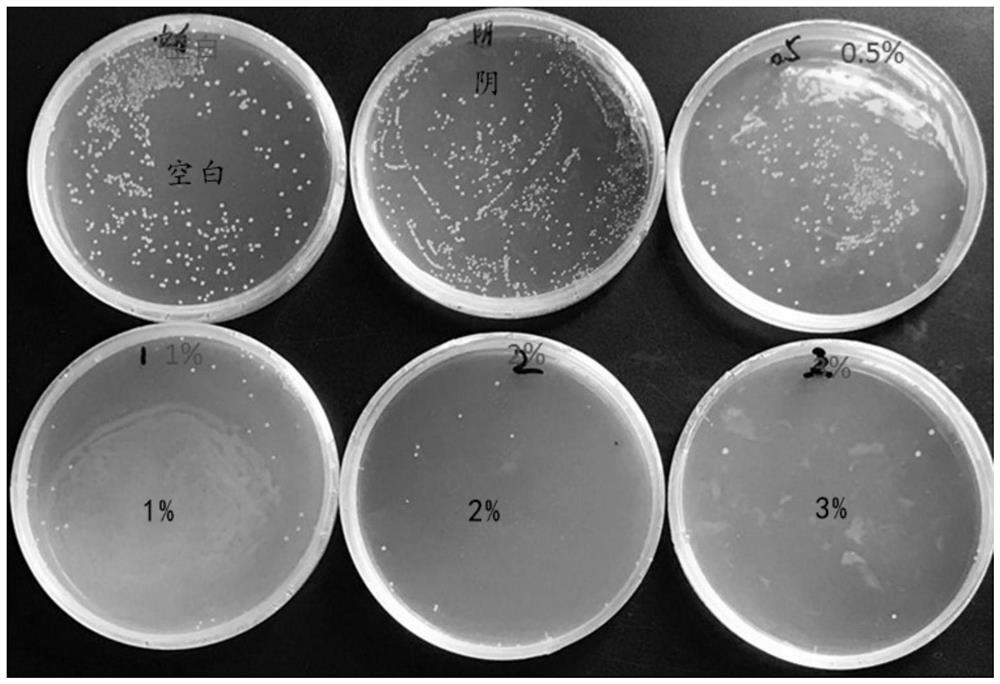

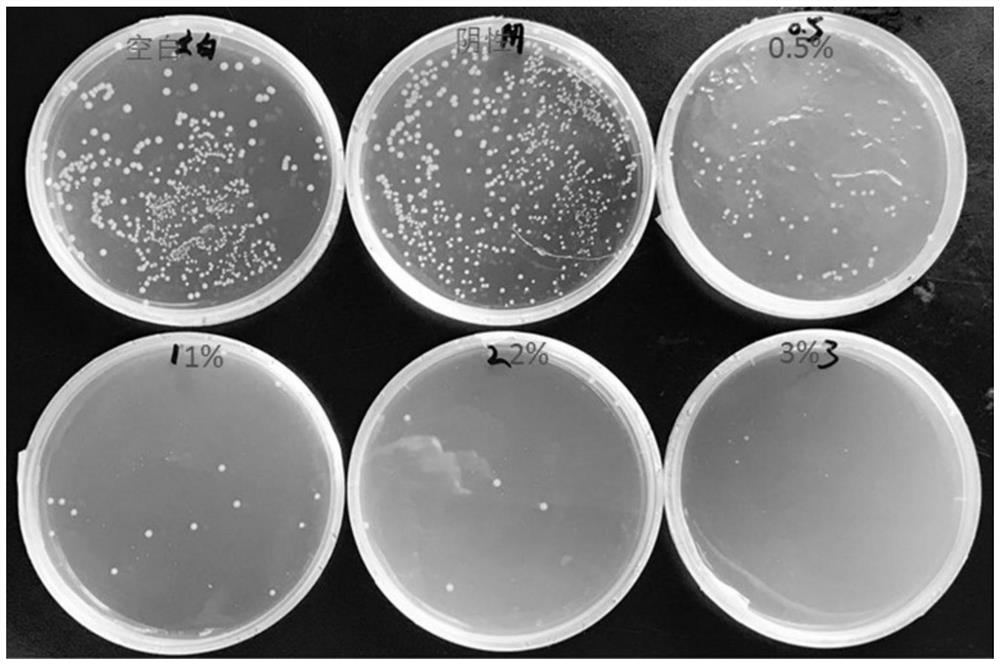

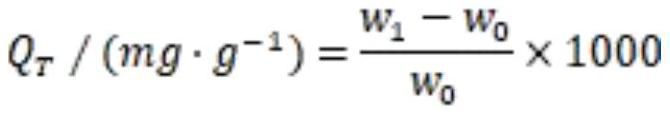

The invention discloses a long-acting antibacterial fabric coating and a preparation method thereof, and belongs to the field of green functional polymer materials. The preparation method comprises the following main operation steps: (1) preparing a gamma-glycidoxypropyltrimethoxysilane (KH560) solution, namely a treatment solution A; (2) preparing a polyhexamethylene guanidine hydrochloride (PHMG) solution, namely a treatment solution B; (3) soaking a treated fabric in the treatment solution A and the treatment solution B respectively to form an antibacterial coating on the surface of the treated fabric. KH560 is used as a bridge to fix PHMG on the surface of the fabric, and the reaction mechanism is as shown in figure 1; the treated fabric has excellent antibacterial performance, the antibacterial rate of gram-negative bacteria representing escherichia coli and gram-positive bacteria representing staphylococcus aureus reaches 99.0% or above, the antibacterial effect of the fabric isbasically unchanged after being eluted by 100%, the whole treatment process is simple to operate, the cost is low, and the method has important significance for improving the production and living environment of people and preventing spread of bacterial viruses.

Owner:ANHUI UNIVERSITY

Preparation method of bacteriostat stainless steel cup

InactiveCN105559480AImprove performanceGood antibacterial durabilityBiocideDisinfectantsMetallurgySS - Stainless steel

The invention relates to a preparation method of a bacteriostat stainless steel cup, and belongs to the technical field of preparation of stainless steel products. The preparation method comprises the following steps: making 1Cr18Ni9 stainless steel into the shape of a cup, and immersing the cup in a FeCl3.6H2O solution of which the percentage by mass is 18-22% for performing 1500-1800W ultrasonic treatment for 30-35 minutes; after ultrasonic treatment, soaking the treated cup in a NaOH solution of 10-12mol / L for 1-2 hours at 60-65 DEG C, and repeatedly and thoroughly cleaning the soaked cup with ionized water till the pH value of cleaning liquid is neutral; finally, soaking the cleaned cup in antibacterial liquid for 20-24 hours, and then drying the soaked cup so as to obtain a product. The preparation method is simple in technology, industrialized production is easy to realize, and the prepared cup is good in comprehensive performance, and is good in bacteriostat effect.

Owner:王显祺

A kind of grafted antibacterial polypropylene and its preparation process

The invention relates to a novel grafted antibacterial polypropylene, which is mainly obtained by grafting polypropylene and maleic anhydride to obtain an intermediate, which is then prepared by nucleophilic reaction with a brominated organic antibacterial agent; wherein the organic antibacterial agent molecule contains a or multiple -N-S bonds, one or more C=C bonds, one or more ring structures. The novel grafted antibacterial polypropylene of the present invention can be used alone as an antibacterial PP material, or can be blended with polypropylene as an antibacterial additive masterbatch, or multi-layer co-extruded with PP to greatly improve the antibacterial performance of the PP surface. The new grafted antibacterial polypropylene of the present invention has good adhesion to substrate PP, good antibacterial performance durability, excellent mechanical properties, and good high temperature stability. Due to the small amount of addition, it does not affect the mechanical properties of the base material, which solves the problem of the existing production process. There are problems such as poor antibacterial performance of PP products, easy precipitation and loss of antibacterial agents, and short antibacterial cycle. Moreover, the preparation process is simple, the cost is low, and the method has huge market application prospects and market value.

Owner:汕头市远生实业有限公司

Antibacterial lining aluminum plate applied to household appliances and preparation method of antibacterial lining aluminum plate

InactiveCN114133821AImprove antibacterial propertiesGood antibacterial durabilityAntifouling/underwater paintsPaints with biocidesPolymer scienceMeth-

The invention provides an antibacterial lining aluminum plate applied to household appliances. The antibacterial lining aluminum plate comprises an aluminum plate body and an antibacterial coating covering the surface of the aluminum plate body. The antibacterial coating is prepared from the following components in parts by weight: 45-65 parts of N-[4-(sulfonamide) phenyl] acrylamide / brominated 3-allyl benzothiazole / N-trihydroxymethyl methacrylamide / glycidyl methacrylate copolymer, 5-10 parts of 2, 2-bis [4-(4-aminophenoxy) phenyl]-1, 1, 1, 3, 3, 4-tetramethyl-1, 3-pentanediol monoisobutyrate, 5-10 parts of a silane coupling agent, 1-5 parts of a coupling agent, 1-5 parts of a coupling agent, 1-5 parts of a coupling agent, 1-5 parts of a coupling agent and 1-5 parts of a coupling agent. The coating is prepared from the following components in parts by weight: 4 to 6 parts of 1, 1, 1, 3, 3-hexafluoropropane, 0.8 to 1.2 parts of aluminum dihydroxyamino acetate, 10 to 15 parts of filler, 1 to 2 parts of dispersing agent, 0.5 to 1.5 parts of defoaming agent, 0.3 to 0.8 part of flatting agent and 40 to 50 parts of solvent. The invention further discloses a manufacturing method of the antibacterial lining aluminum plate applied to the household appliances. The antibacterial lining aluminum plate applied to the household appliances is remarkable in antibacterial effect, good in antibacterial durability and long in service life.

Owner:江苏中来能源科技开发集团有限公司

Preparation method of polylactic acid material with anti-adhesion and sterilization functions

ActiveCN113461995AGood antibacterial durabilityBroad-spectrum and long-lasting antifouling and antibacterial functionAntifouling/underwater paintsPaints with biocidesSolventChemistry

The invention discloses a polylactic acid material with anti-adhesion and sterilization functions, which is prepared by the following steps: 1) stirring and dissolving a biodegradable material polylactic acid in a good solvent, adding a poor solvent to realize phase separation, and fully stirring to obtain a coating solution; 2) uniformly coating a polylactic acid sheet with the solution obtained in the step 1), and drying; 3) stripping the top layer polylactic acid by using an adhesive tape to obtain a super-hydrophobic surface; and 4) dispersing chlorophyll in absolute ethyl alcohol, coating on the super-hydrophobic surface of polylactic acid, and drying. The surface of the material has the super-hydrophobic performance of resisting initial adhesion of bacteria, and the adhered bacteria can be killed through photodynamic force. A super-hydrophobic and photodynamic synergistic antibacterial mode is adopted, the dosage of a bactericide is small, the sterilization efficiency is high, the antibacterial long-term effect is good, the controllability is high, and bacteria cannot be induced to generate drug resistance. The polylactic acid material with anti-adhesion and sterilization functions prepared by the invention is non-toxic and harmless, has good biological and environmental compatibility, and can be used in the aspect of bacterial infection resistance of medical or packaging materials.

Owner:ZHENGZHOU UNIV

A kind of preparation method of antibacterial stainless steel cup

InactiveCN105559480BImprove performanceGood antibacterial durabilityBiocideDisinfectantsMaterials science

The invention relates to a preparation method of a bacteriostat stainless steel cup, and belongs to the technical field of preparation of stainless steel products. The preparation method comprises the following steps: making 1Cr18Ni9 stainless steel into the shape of a cup, and immersing the cup in a FeCl3.6H2O solution of which the percentage by mass is 18-22% for performing 1500-1800W ultrasonic treatment for 30-35 minutes; after ultrasonic treatment, soaking the treated cup in a NaOH solution of 10-12mol / L for 1-2 hours at 60-65 DEG C, and repeatedly and thoroughly cleaning the soaked cup with ionized water till the pH value of cleaning liquid is neutral; finally, soaking the cleaned cup in antibacterial liquid for 20-24 hours, and then drying the soaked cup so as to obtain a product. The preparation method is simple in technology, industrialized production is easy to realize, and the prepared cup is good in comprehensive performance, and is good in bacteriostat effect.

Owner:王显祺

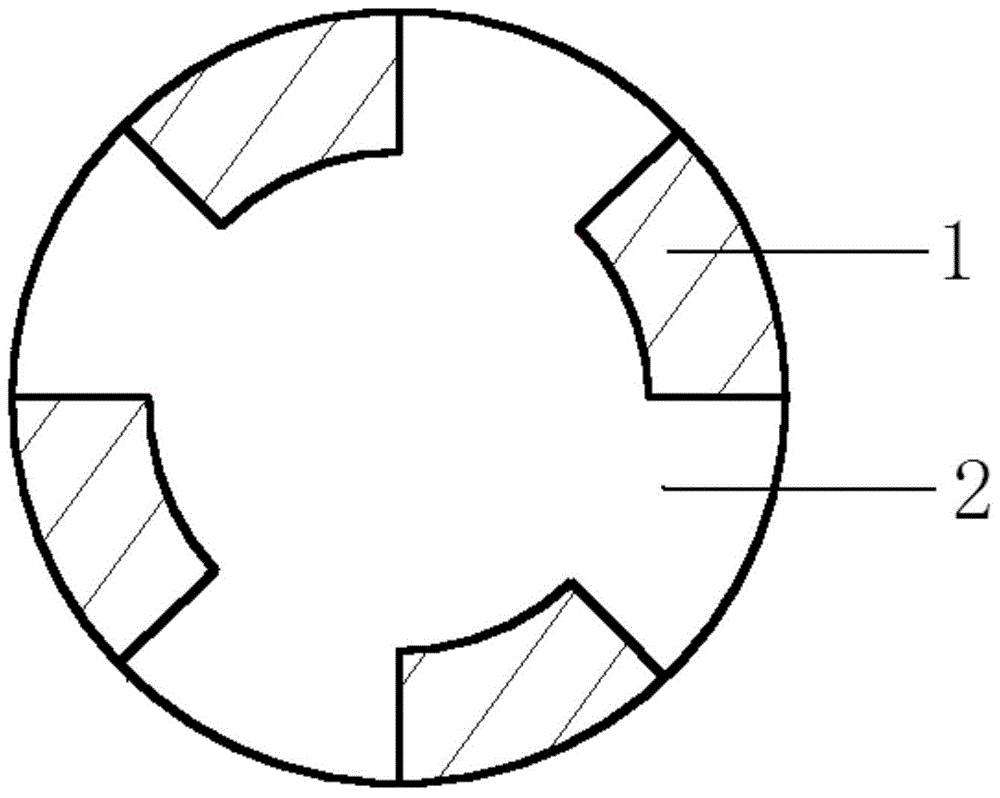

Antibacterial medical suture line and preparation method

InactiveCN112358458AImprove antibacterial propertiesGood antibacterial durabilitySuture equipmentsBiocideCelluloseFiber

The invention discloses an antibacterial medical suture line and a preparation method thereof, belongs to the field of medical materials, and particularly relates to an antibacterial medical suture line and a preparation method thereof. The antibacterial medical suture line is obtained by conducting antibacterial finishing on composite fibers of a skin-core structure, wherein the composite fiber comprises hydroxypropyl cellulose, L-ascorbyl ester, a glutaraldehyde skin layer and a PPDO or PLA core layer, and the skin layer also contains PPDO or PLA. The prepared antibacterial medical suture line is good in antibacterial effect; the antibacterial durability is good, and the antibacterial durability effect reaches 5 d or above; the water immersion resistance is good, the reduction amplitudeof the antibacterial effect is small after water immersion is conducted for 24 h, and the antibacterial effect is at least improved by 25% or above.

Owner:嘉兴市轩禾园艺技术有限公司

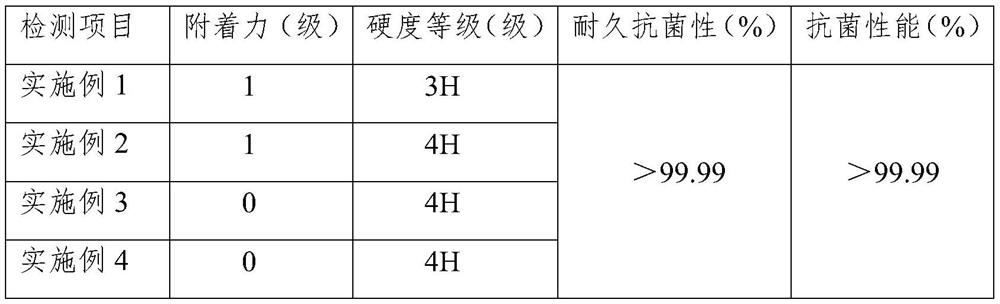

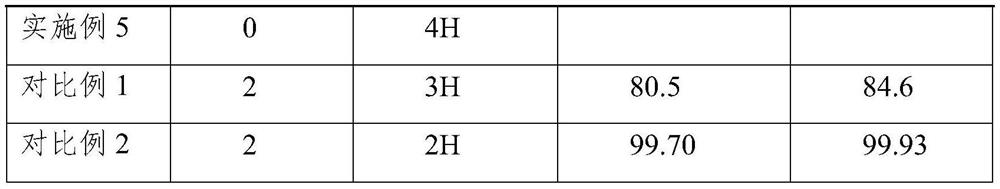

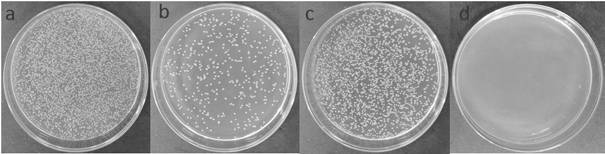

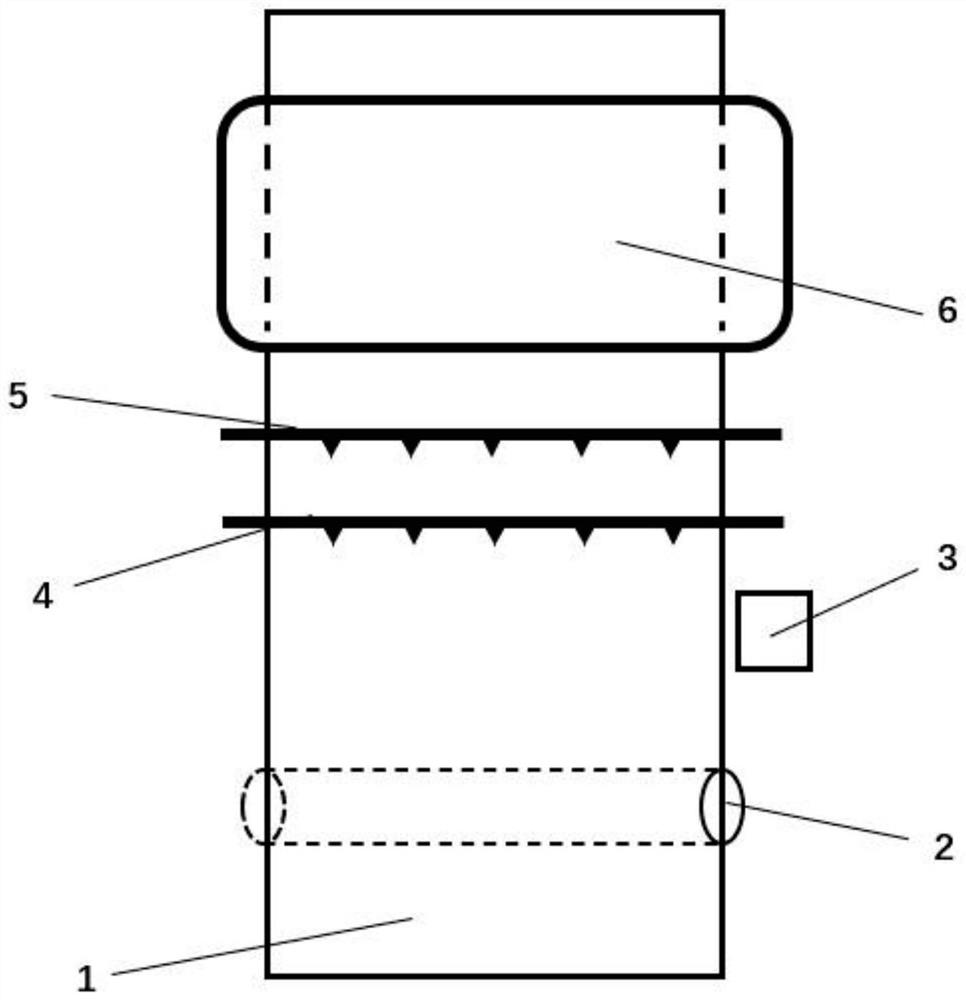

Processing technology of antibacterial curtain, antibacterial curtain and testing method

PendingCN114836976AImprove adhesion fastnessImprove antibacterial durabilityBiochemical fibre treatmentHeating/cooling textile fabricsProcess engineeringAnti bacterial

The invention provides a processing technology of an antibacterial curtain, the antibacterial curtain and a testing method. The processing technology comprises the following steps: 1) pretreatment: carrying out deionized water washing treatment on a curtain fabric to be treated; 2) ultrasonic treatment: carrying out ultrasonic treatment on the antibacterial finishing agent by adopting ultrasonic treatment equipment, wherein the ultrasonic frequency is 20-50kHz; 3) spraying process finishing: putting the pretreated curtain fabric into spraying equipment, and spraying an antibacterial finishing agent on the surface of the fabric; and 4) setting: directly feeding the curtain fabric sprayed with the antibacterial finishing agent into setting equipment through a rolling roller. According to the curtain produced through the pretreatment-ultrasonic treatment-spraying process finishing-shaping process, compared with a curtain without the pretreatment-ultrasonic treatment-spraying process finishing-shaping process, the adsorption fastness of nano particles on the surface of the fabric is greatly improved, and the antibacterial rate can still reach 90% or above after 50 times of water washing; and after antibacterial treatment, the curtain fabric can still maintain the original fabric style.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com