In-situ synthesis method of nano-silver alginate short fibers

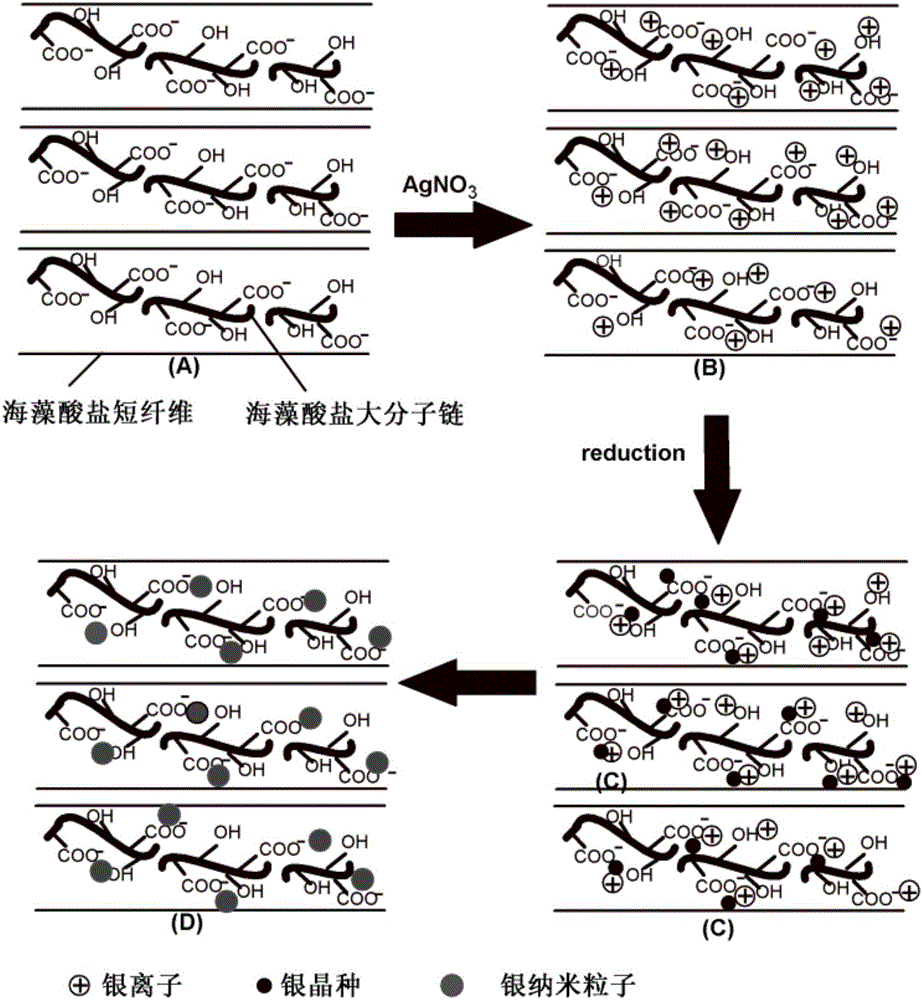

An alginate, in-situ synthesis technology, applied in fiber processing, plant fibers, flame-retardant fibers, etc., can solve the problem of unsatisfactory distribution uniformity of nano-silver particles, difficulty in controlling the spinnability index of spinning solution, and nano-particles. Silver particles are prone to agglomeration and other problems, achieving the effects of easy control and industrial production, excellent antibacterial properties, and easy control to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method comprises the following steps:

[0041] The first step, preparation molar concentration is respectively the soluble silver salt bath liquid of 10mmol / l, the reducing agent bath liquid that molar concentration is 10mmol / l, for subsequent use;

[0042] Under the condition of avoiding light and room temperature, the alginate short fiber is immersed in the soluble silver salt bath solution by padding method, so that the soluble silver salt and the alginate short fiber are complexed. After two dipping and two rolling, the obtained Fiber A;

[0043] Wherein, the bath ratio of the alginate short fiber and the soluble silver salt bath liquid is 1:25, the time of each dipping is 15min, and the excess rate of each squeeze is 100%;

[0044] In the second step, the fiber A is immersed in the reducing agent bath and reacted at 80°C for 30 minutes to make the Ag complexed on the short alginate fiber + In situ reduction to nano silver particles, fiber B is obt...

Embodiment 2

[0051] The preparation method comprises the following steps:

[0052] The first step, preparation molar concentration is respectively the soluble silver salt bath liquid of 20mmol / l, the reducing agent bath liquid that molar concentration is 20mmol / l, for subsequent use;

[0053] Under the condition of avoiding light and room temperature, the alginate short fiber is immersed in the soluble silver salt bath solution by padding method, so that the soluble silver salt and the alginate short fiber are complexed. After two dipping and two rolling, the obtained Fiber A;

[0054]Wherein, the bath ratio of alginate short fiber and soluble silver salt bath liquid is 1:50, the time of each dipping is 20min, and the scraping ratio of each squeeze water is 100%;

[0055] In the second step, the fiber A is immersed in the reducing agent bath and reacted at 60°C for 60 minutes to make the Ag complexed on the short alginate fiber + In situ reduction to nano silver particles, fiber B is obt...

Embodiment 3

[0062] The preparation method comprises the following steps:

[0063] The first step, preparation molar concentration is respectively the soluble silver salt bath liquid of 30mmol / l, the reducing agent bath liquid that molar concentration is 30mmol / l, for subsequent use;

[0064] Under the condition of avoiding light and room temperature, the alginate short fiber is immersed in the soluble silver salt bath solution by padding method, so that the soluble silver salt and the alginate short fiber are complexed. After two dipping and two rolling, the obtained Fiber A;

[0065] Wherein, the bath ratio of alginate short fiber and soluble silver salt bath liquid is 1:50, and the time of each dipping is 20min, and the excess rate of water squeezing every time is 100%;

[0066] In the second step, the fiber A is immersed in the reducing agent bath and reacted at 60°C for 60 minutes to make the Ag complexed on the short alginate fiber + In situ reduction to nano silver particles, fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com