Processing technology of antibacterial curtain, antibacterial curtain and testing method

A technology of processing technology and testing method, which is applied in textile testing, heating/cooling fabric, spraying/jetting textile material treatment, etc., can solve the problems of low usage rate of antimicrobial agent, low utilization rate of antimicrobial agent, change of fabric style, etc., to achieve Good antibacterial durability, improved adhesion fastness, and improved fabric safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A processing method of antibacterial curtain, comprising the following steps:

[0042] 1), 100D polyester network yarn is used as raw material, and the organization is plain weave for weaving;

[0043] 2), washing, dyeing, finishing and drying the fabric in turn;

[0044] 3), carry out antibacterial finishing to polyester fabric, the treatment steps are as follows:

[0045] a. Pretreatment: the fabric to be treated is washed with deionized water;

[0046] b. Ultrasonic treatment: Dilute the nano-silver and nano-gold solutions with distilled water respectively, and add a certain amount of isopropanol solution to the nano-silver solution to obtain 6 mg / L nano-particle solutions respectively; Ultrasonic treatment is carried out with ultrasonic treatment equipment, and the ultrasonic frequency is 20-50kHz;

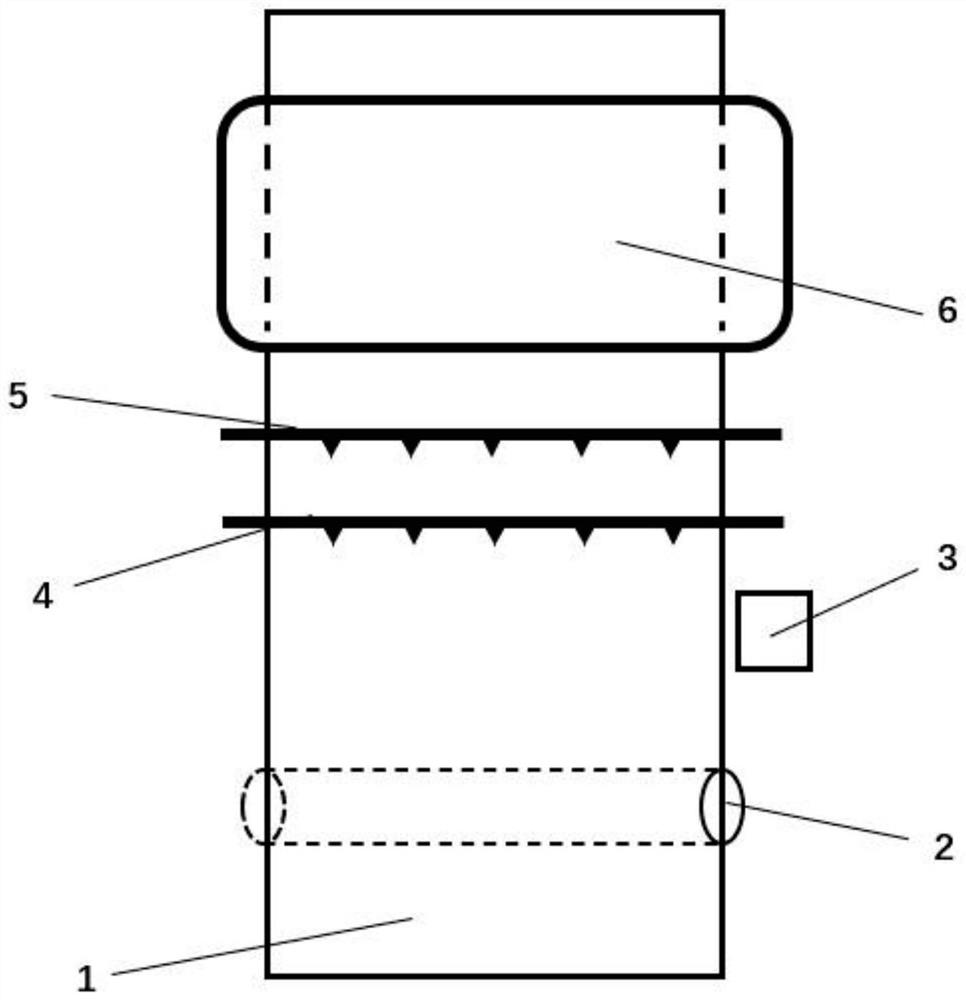

[0047] c. Spray process finishing: put the pretreated fabric into the starting position of the rolling roller of the spray equipment, start the air pump, control the...

Embodiment 2

[0053] The content of this embodiment is basically the same as that of Embodiment 1, and the same part of the content will not be repeated. The difference from Embodiment 1 is that the raw material selected for weaving is 26S cotton yarn. The setting temperature of the cotton fabric was set to 80°C for 50 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com