Patents

Literature

67results about How to "Strong self-cleaning ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly diatom ooze wall material powder and wall material and preparation method thereof

InactiveCN101700965AImprove adsorption capacityAdequate adsorptionMoisture absorptionAir purification

The invention discloses environment-friendly diatom ooze wall material powder and a wall material as well as a preparation method and application thereof. The diatom ooze wall material with macromolecule sieve structure is prepared by taking a plurality of natural environment-friendly non-metal material having strong adsorbability and good plasticity as main materials through a simple process. The environment-friendly diatom ooze wall material powder has the advantages of low cost, air purification, moisture absorption, deodorization, inflaming retarding, heat insulation, easy popularization,and the like.

Owner:QINGDAO CHUANSHAN NEW MATERIALS

Self-cleaning antibacterial fluorocarbon coating

InactiveCN104403476AStrong self-cleaning abilityImprove conversion rateAntifouling/underwater paintsPaints with biocidesSolventKetone

The invention discloses a self-cleaning antibacterial fluorocarbon coating which comprises the following components in parts by weight: 40-60 parts of fluorine-containing polyacrylate resin, 5-13 parts of a silane coupling agent, 1-6 parts of amino resin, 3-15 parts of titanium dioxide, 2-6 parts of calcium carbonate, 10-28 parts of modified nano titanium dioxide, 2-6 parts of silicon nitride, 2-8 parts of zinc molybdate, 5-10 parts of 2,2,4-trimethyl-1,3-pentanediol isobutyrate, 0.3-1.2 parts of 5-chloro-2-methl-4-isothiazolin-3-ketone, 0.2-1.2 parts of defoaming agent, 0.5-1.8 parts of wetting agent, 0.3-0.8 parts of flatting agent, 0.6-1.5 parts of a curing agent and 30-60 parts of a solvent. The self-cleaning antibacterial fluorocarbon coating disclosed by the invention is high in self-cleaning ability and good in antibacterial property and can be applied in building outer walls.

Owner:ANHUI JINDUN PAINT

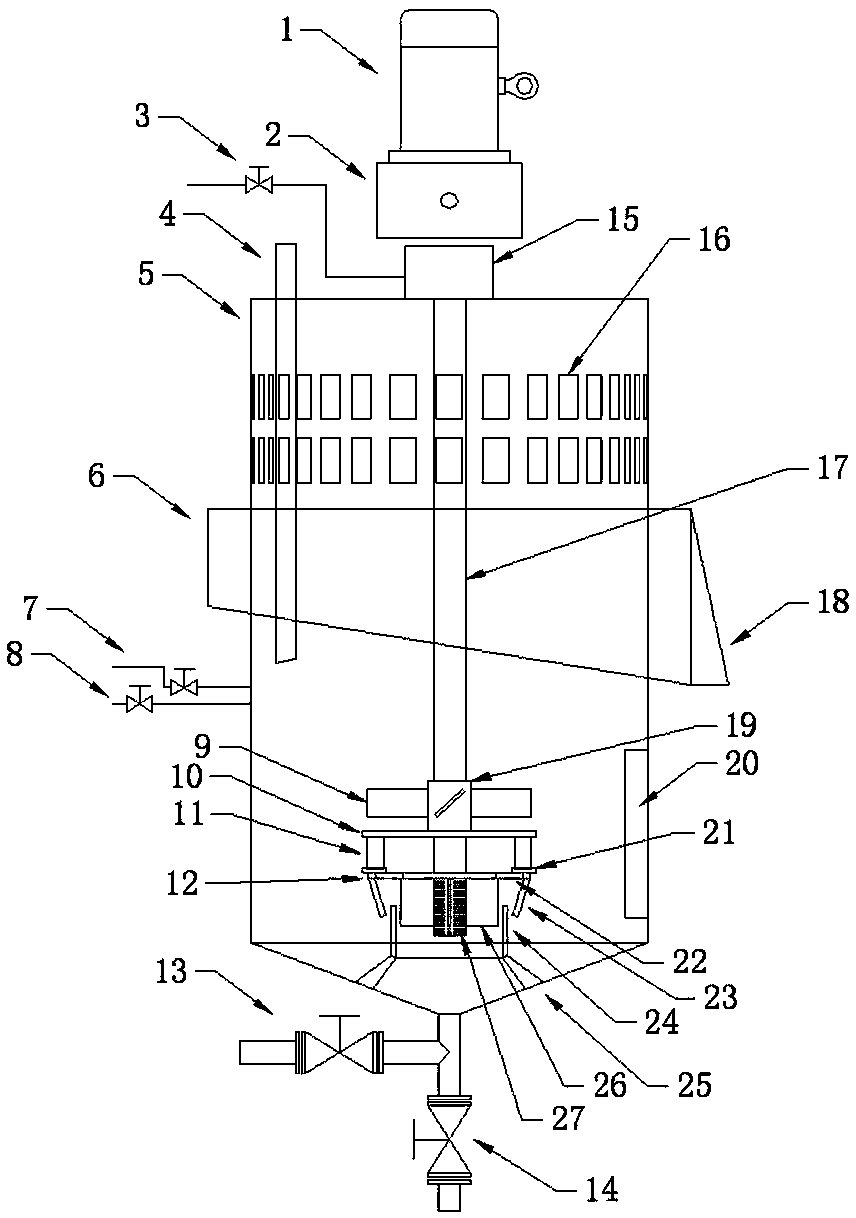

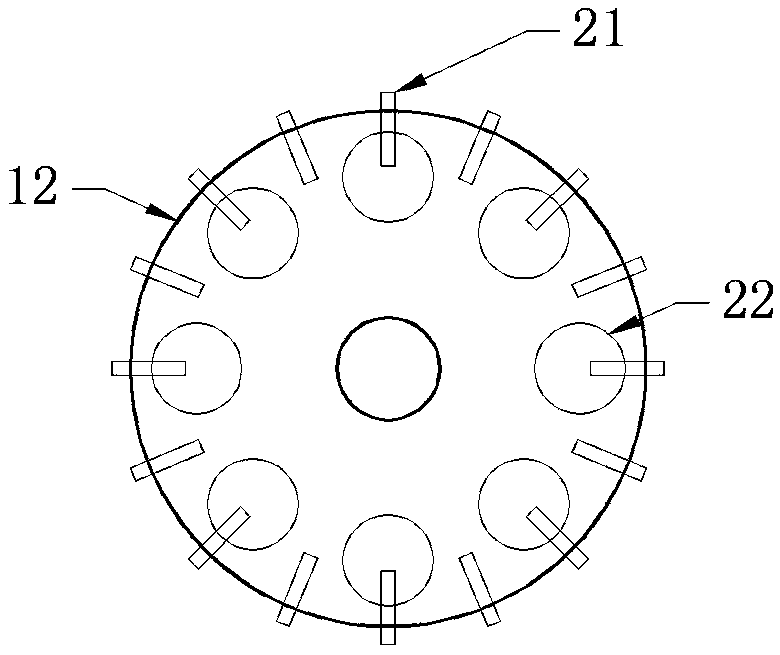

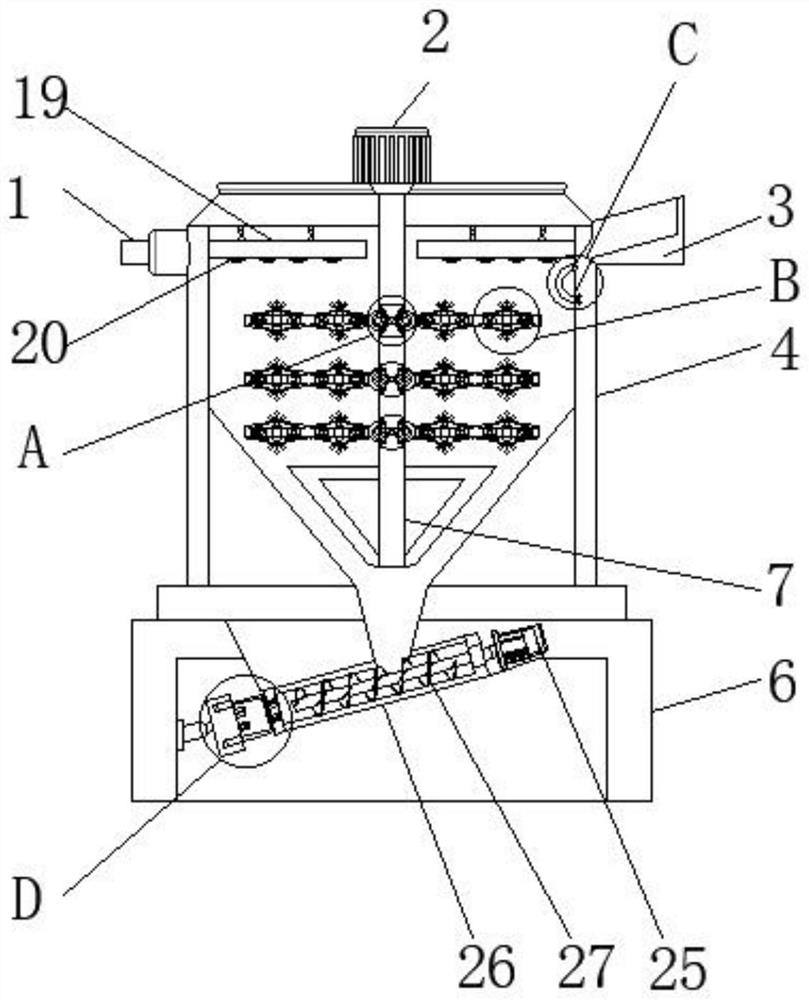

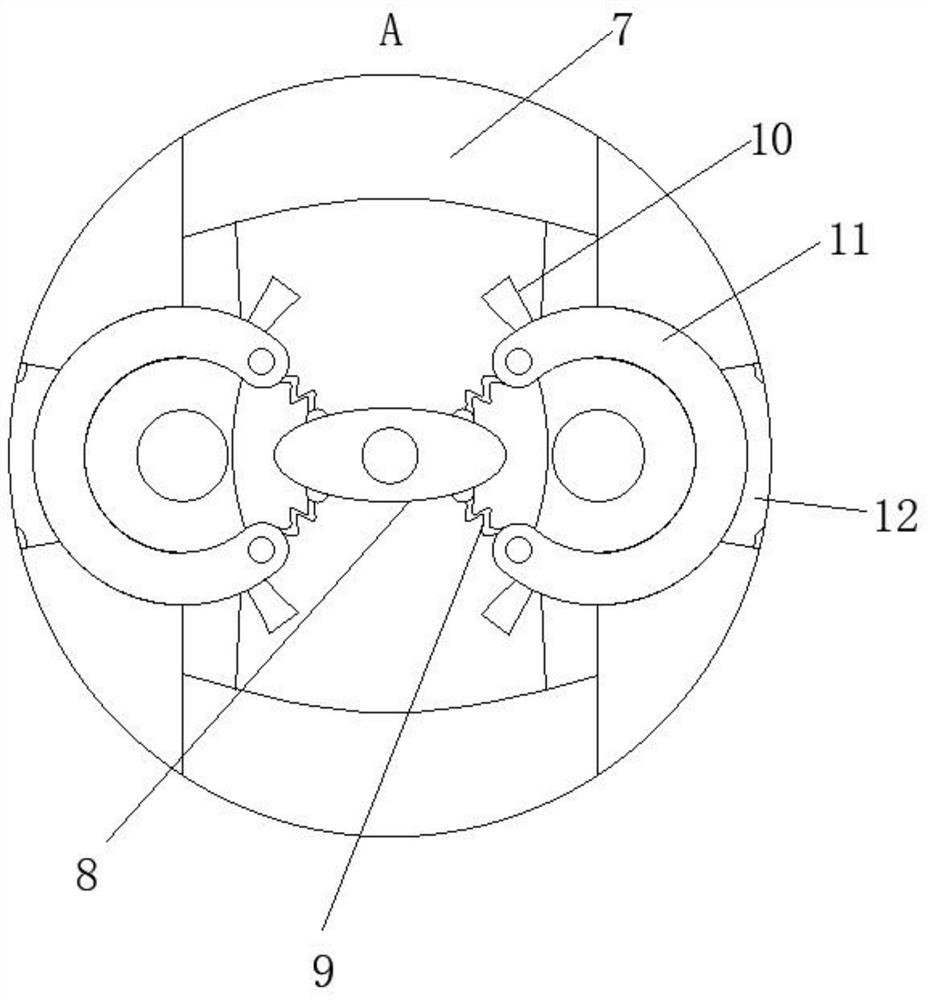

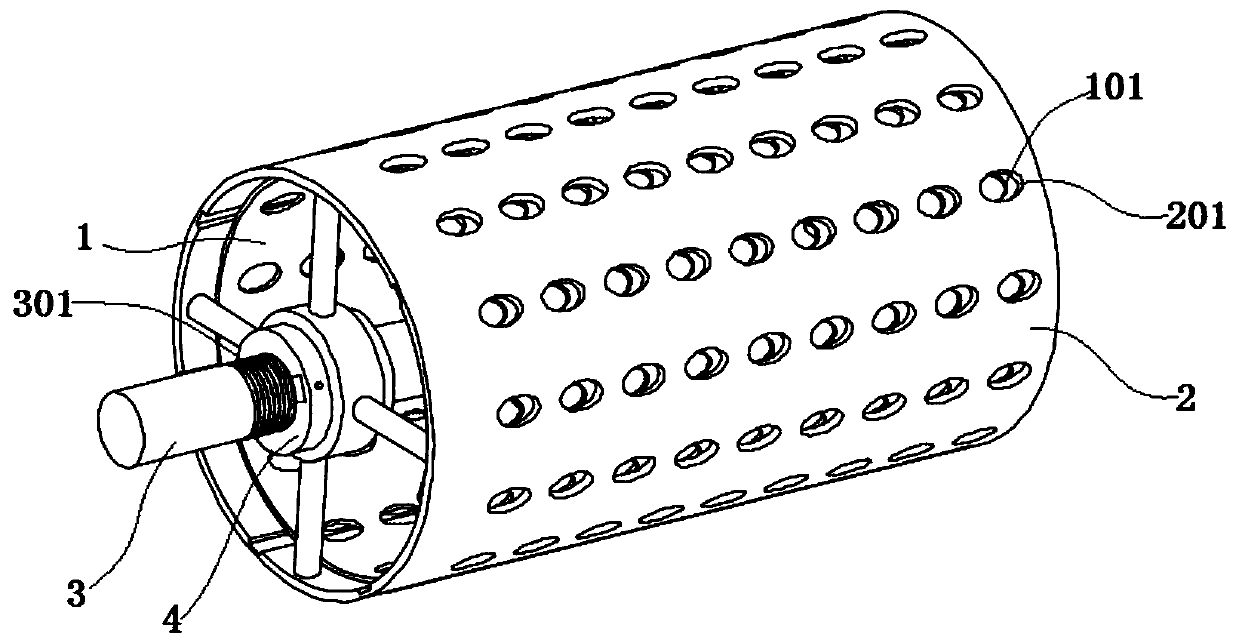

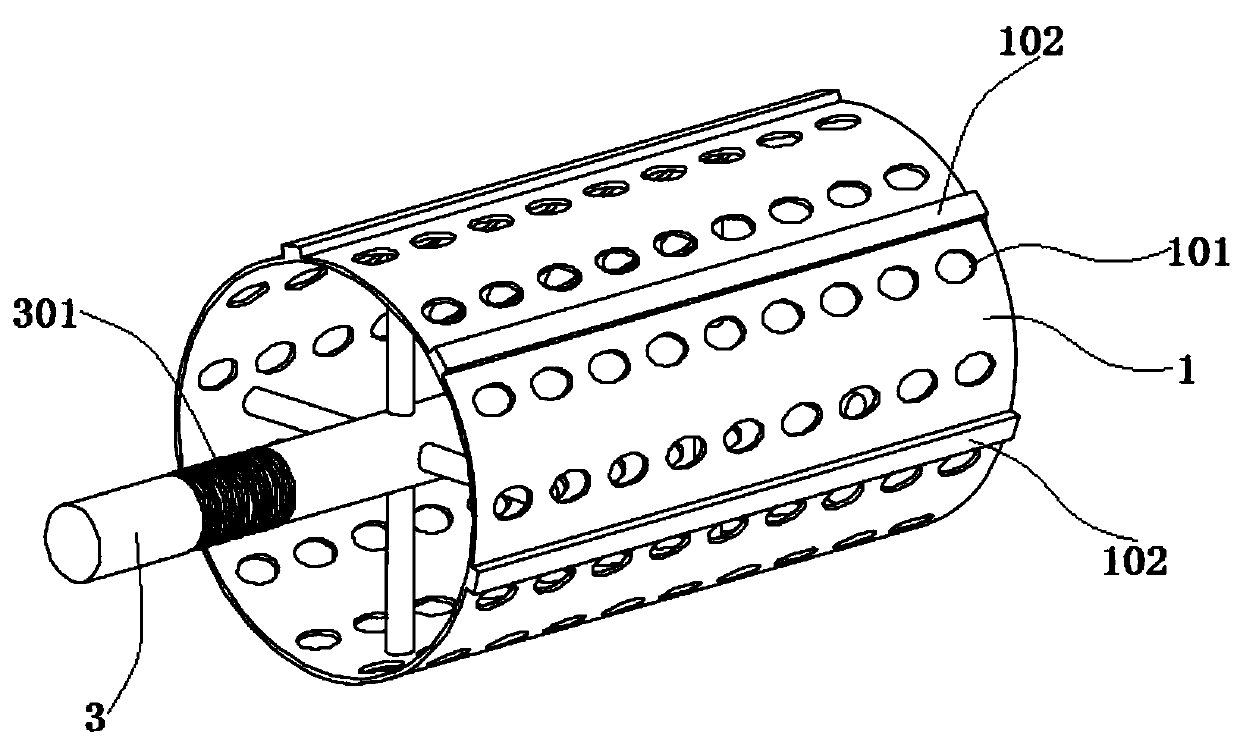

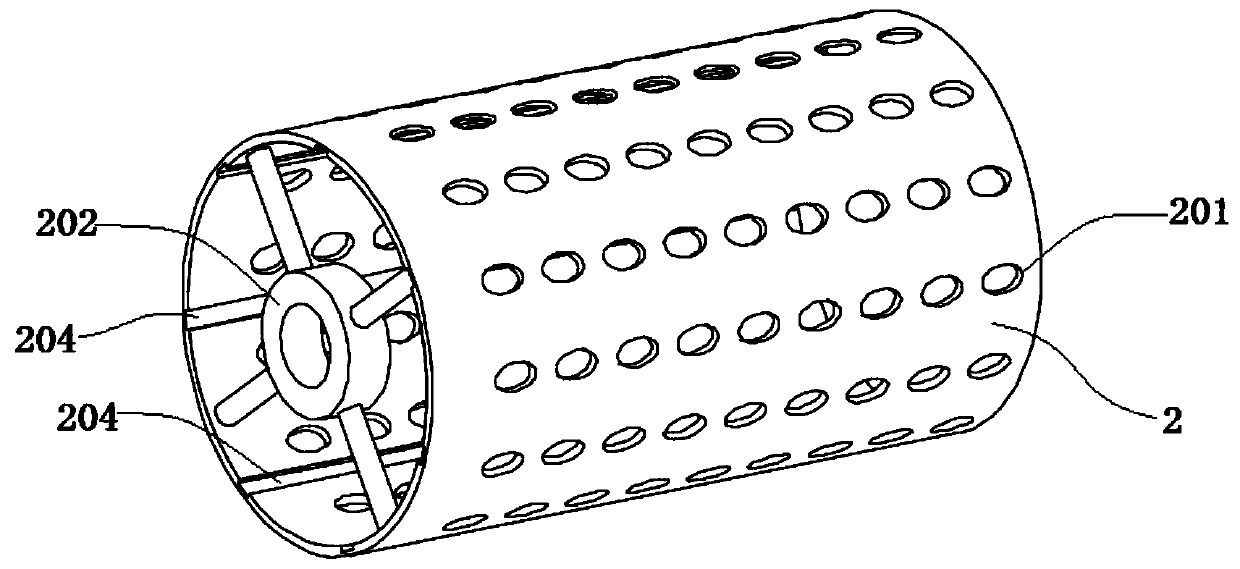

Rotor-wing floating brush mineral flotation machine

ActiveCN104174506ASimple and reliable system structureLow costFlotationMineral flotationCircular disc

The invention discloses a rotor-wing floating brush mineral flotation machine. A lower air inlet valve is arranged at the cone bottom of a barrel body. A hollow spindle is provided with an air through hole and can rotate and have the effect of an air guide pipe, a multi-hole turntable, a cone cover and blades are welded with the hollow spindle to form a whole, and holes and convex bars are formed and arranged in / on the turntable. An annular brush part formed by integrally welding a moving shaft sleeve, a rotor swing and a disc is arranged above the multi-hole turntable, and the moving shaft sleeve of the annular brush part is in clearance fit with the spindle and can flexibly rotate and move vertically. Annularly-arranged elastic nylon brushes are arranged on the disc. A cylinder fixed by a bar plate is arranged under the disc. A flow blocking plate is arranged on the inner wall of the barrel body. The rotor-wing floating brush mineral flotation machine is simple and reliable in structure and efficient and quick in floatation. The floatation is strengthened, the self-cleaning effect is very good and blockage is never found by means of floating elastic brushes. The primary effect is used for the blades, the secondary effect is used for hole penetrating and turning of liquid, the tertiary effect is used for the rotor-wing floating brushes and is played with liquid series connection, mixing and foaming are promoted, and efficient floatation is achieved.

Owner:巴彦淖尔市金昊煤炭有限责任公司

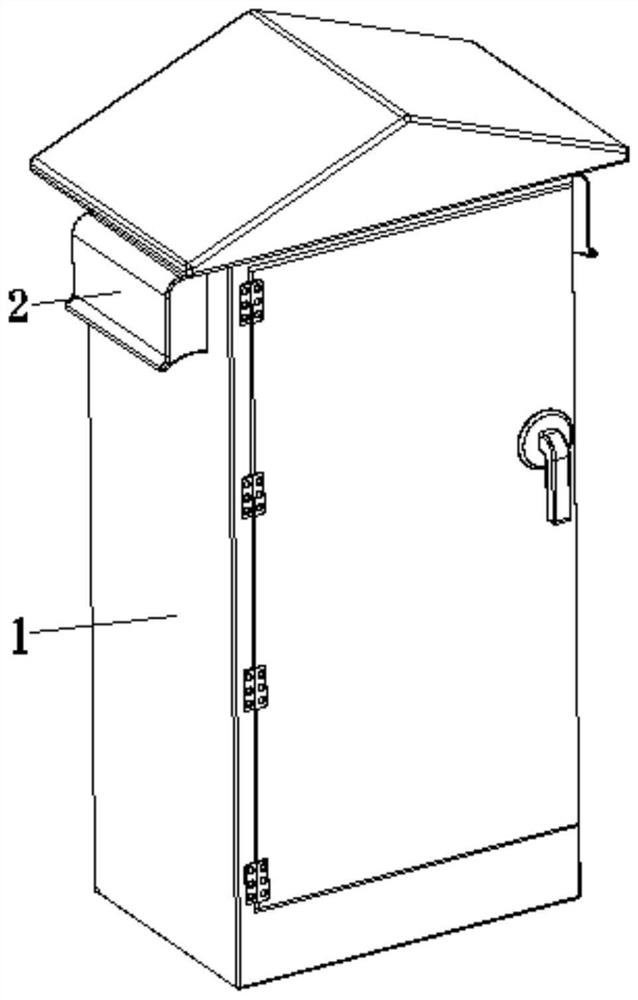

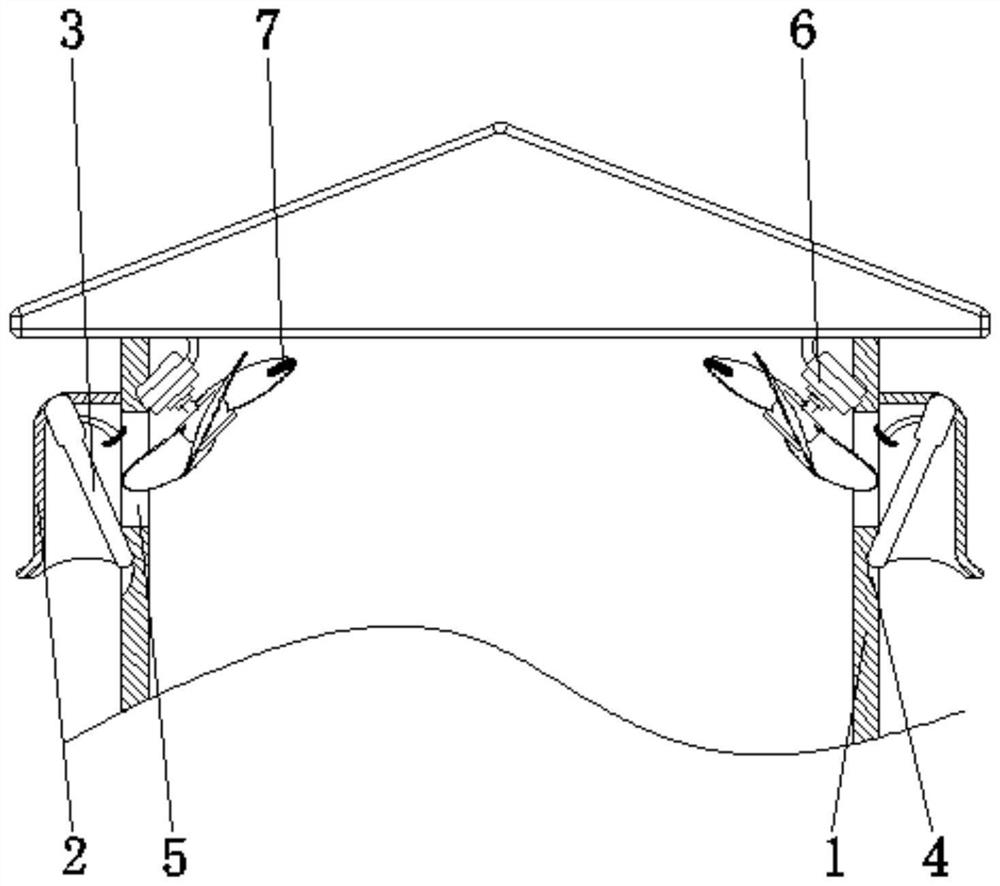

Outdoor electric power cabinet

ActiveCN112821261AReduce adhesionReduce tanglingDispersed particle filtrationTransportation and packagingElectric power equipmentFan blade

An outdoor electric power cabinet disclosed by the present invention comprises a cabinet body, a rainproof cover, a filtering device and a slag discharging groove, the rainproof cover is fixed at two corresponding sides of the top of the surface of the cabinet body, and the filtering device is fixed between the top of the surface of the cabinet body and the two corresponding sides of the inner wall of the rainproof cover. The slag discharging groove is formed in the surface of the cabinet body and is located at the bottom of the filtering device, an air inlet is formed in the surface of the cabinet body and is located at the position of the filtering device, a heat dissipation mechanism is fixed to the top of the inner wall of the cabinet body and is located at the position of the air inlet, and a magnetic block is fixed to the back face of a fan blade of the heat dissipation mechanism. The invention relates to the technical field of power devices. According to the outdoor electric power cabinet, the purposes of filtering and self-cleaning are achieved, dust and sundries can be timely filtered and self-cleaned, adhesion to the surface of a filter screen is reduced, blockage can be effectively prevented, the filtering effect is good, meanwhile, heat dissipation is facilitated, the service life of components is prolonged, and the use performance is improved.

Owner:安徽奥德斯电气有限公司

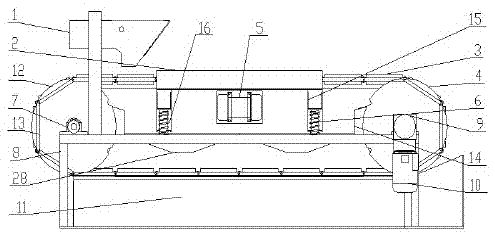

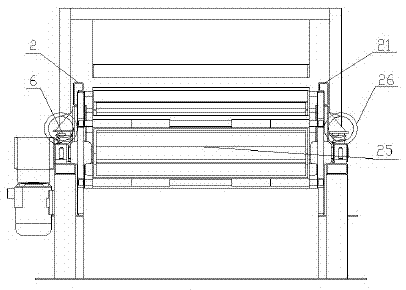

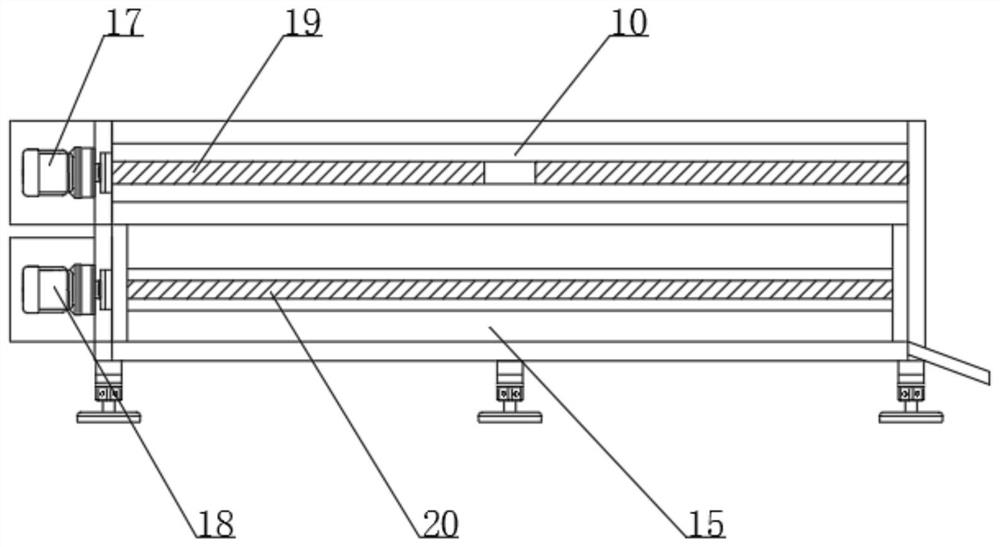

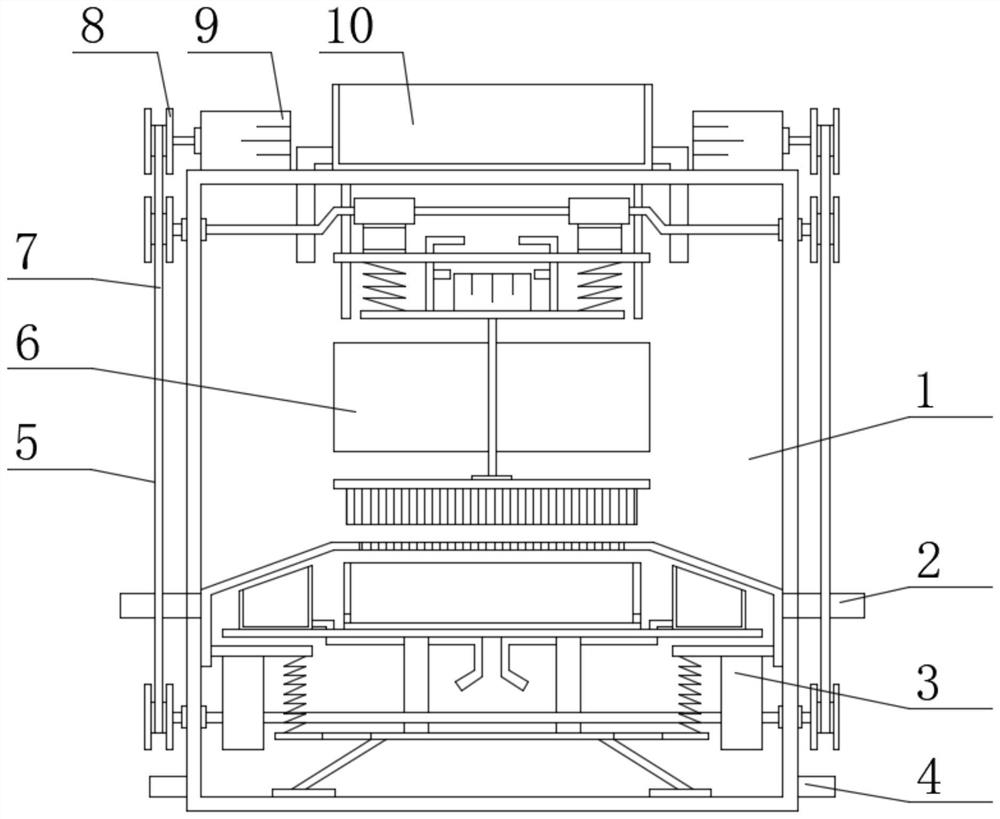

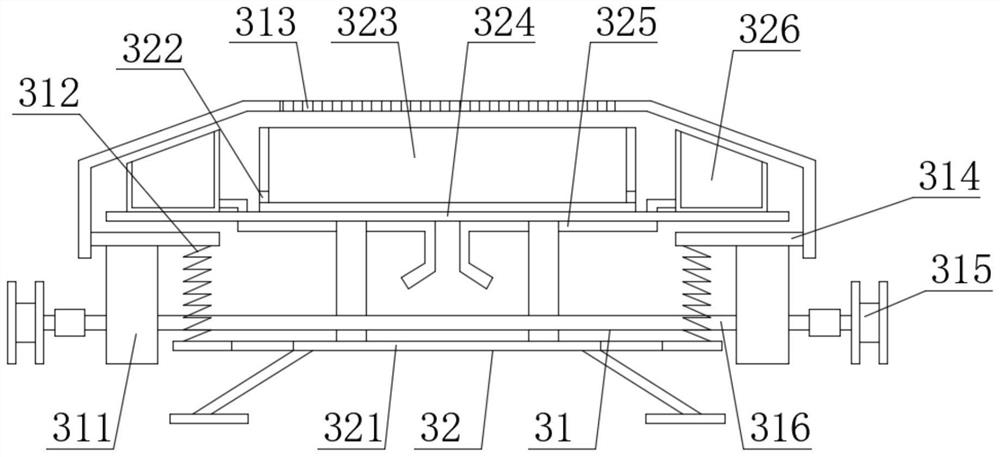

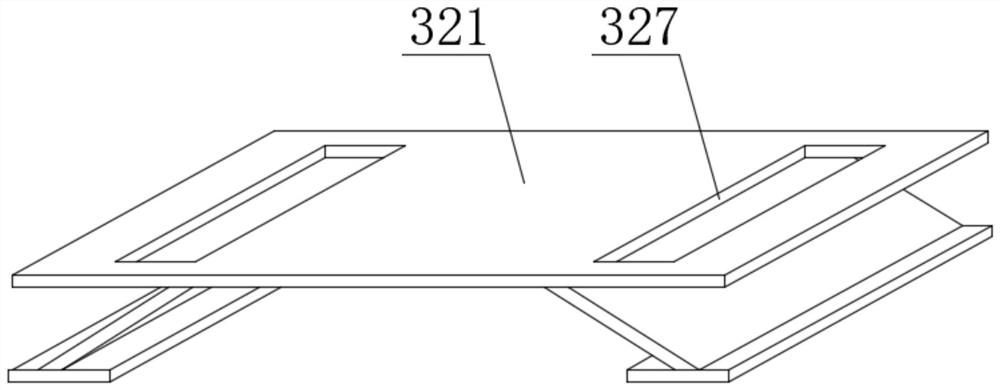

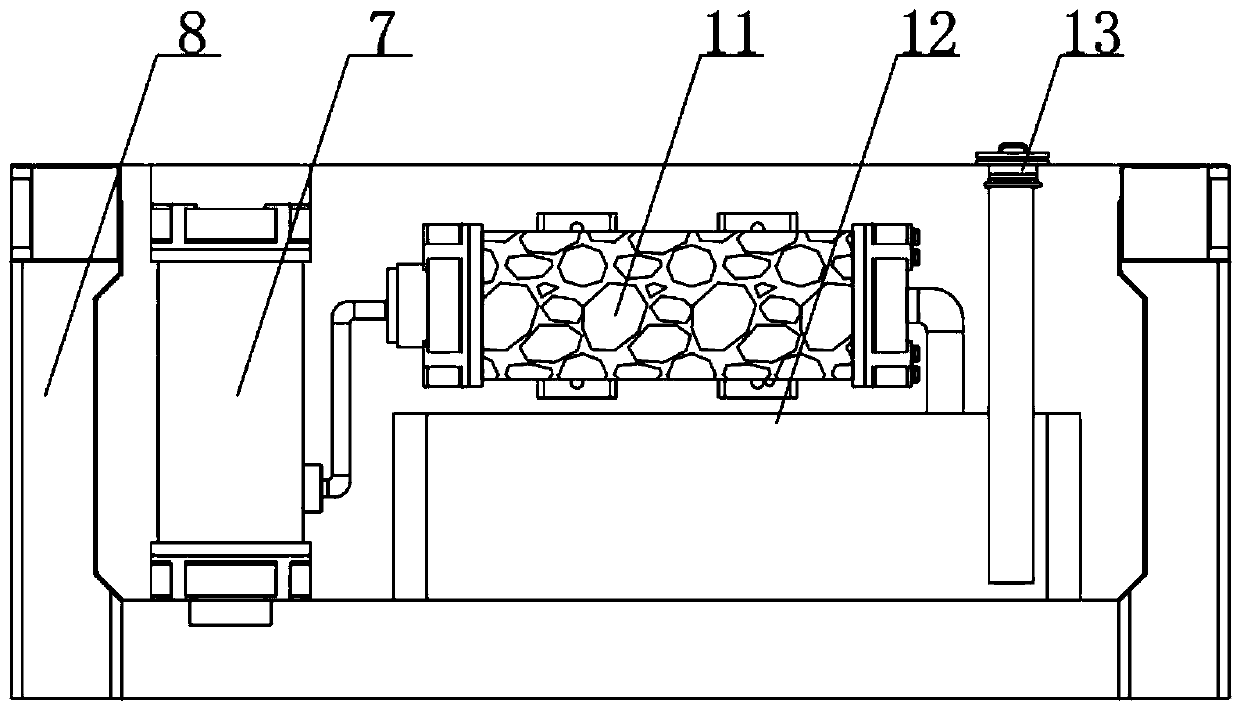

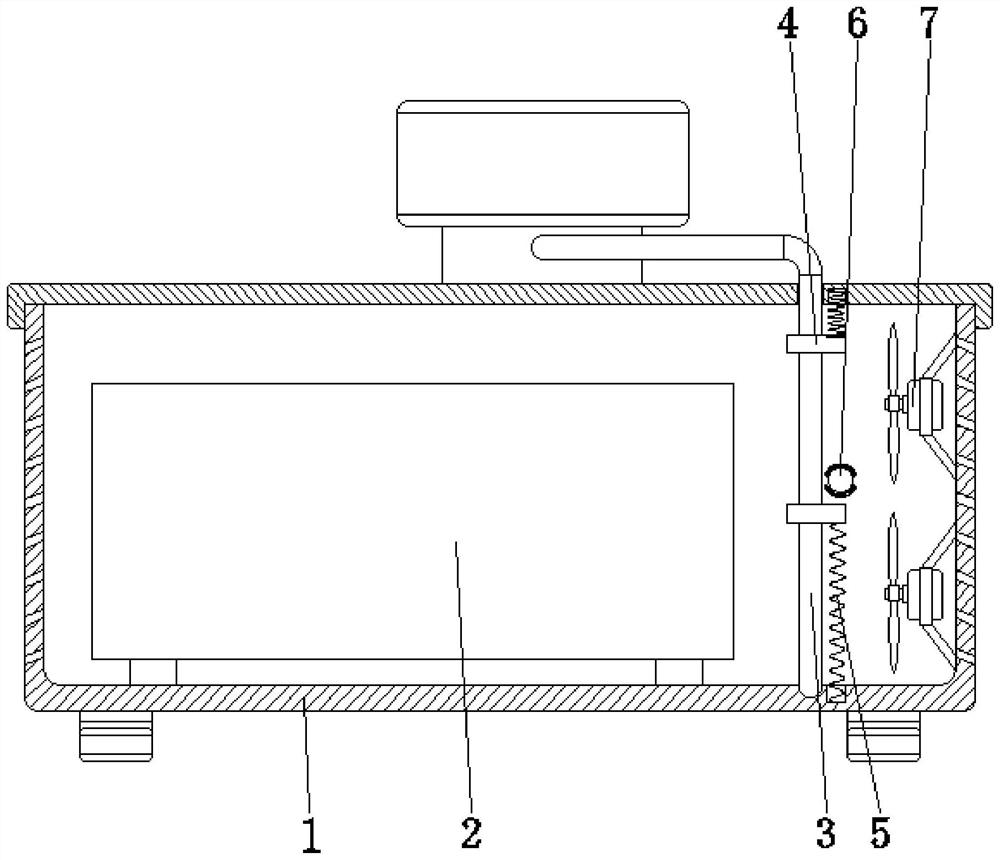

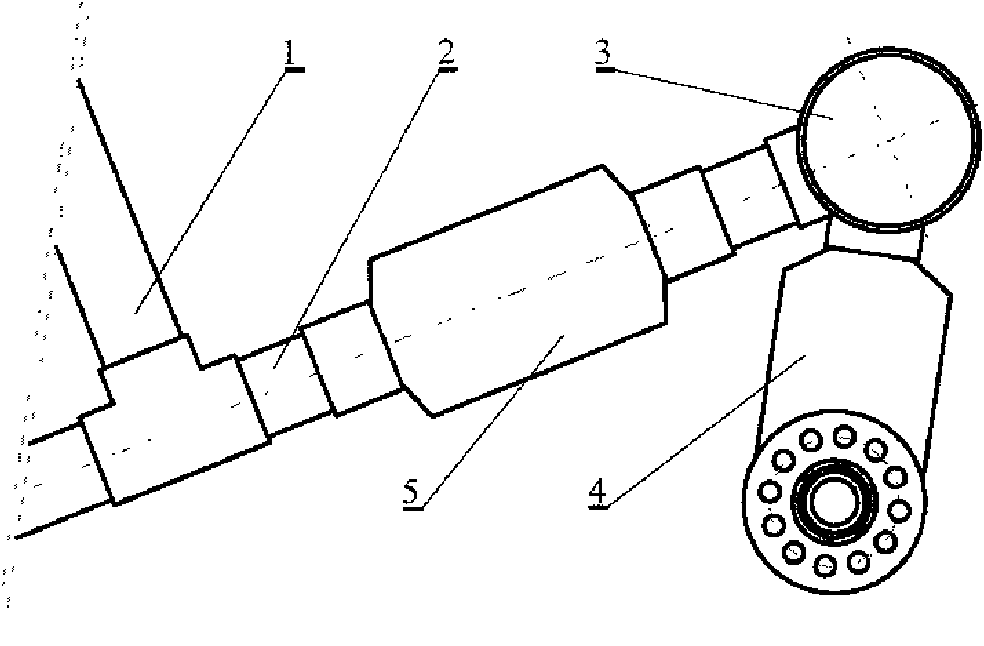

Continuously-circulating screen vibrating sieve

ActiveCN105436067AStrong self-cleaning abilityExtended service lifeSievingScreeningTransmitted powerReduction drive

The invention discloses a continuously-circulating screen vibrating sieve. The continuously-circulating screen vibrating sieve is mainly composed of a screen circulation system, a screen excitation system and a screen circulation driving system. The screen circulation system is formed by assembling screen trays, a chain and chain wheels. The screen trays are hinged together through connecting shafts. The screen excitation system is composed of funnels, excitation motors and supporting springs, wherein the funnels are provided with groove-shaped tracks. The funnels are arranged below the circulating screen trays on the screen circulation system. Rollers supporting the circulating screen trays roll in the groove-shaped tracks. The screen circulation driving system is composed of a chain transmission motor and a speed reducer. The chain transmission motor transmits power to the driving chain wheel through the speed reducer, and the driving chain wheel drives the whole screen circulation system to move. The continuously-circulating screen vibrating sieve is simple in structure and convenient to manufacture; the screen can circulate continuously, the self-cleaning capacity is high, and the defects that the self-cleaning capacity of an existing drilling fluid vibrating screen is poor, screen blocking and screen burning are likely to occur, and the solid-phase liquid content after separation is high can be effectively overcome.

Owner:SOUTHWEST PETROLEUM UNIV

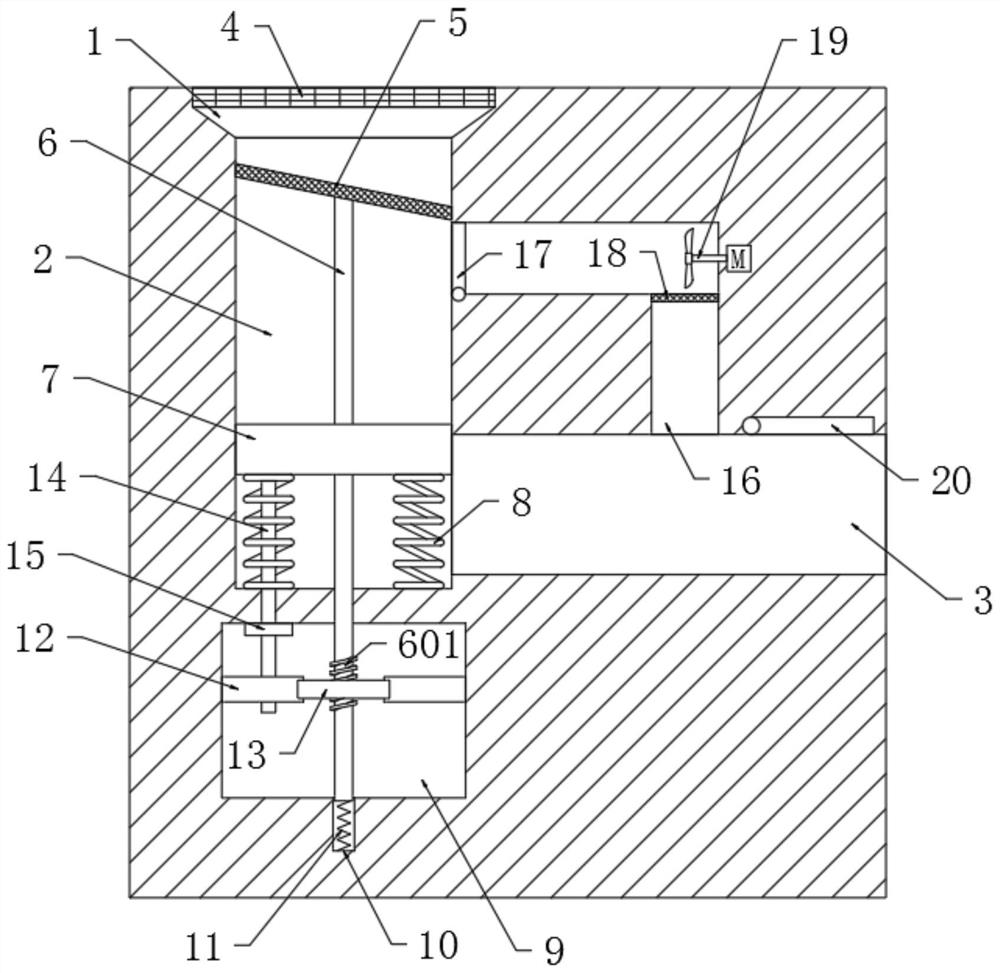

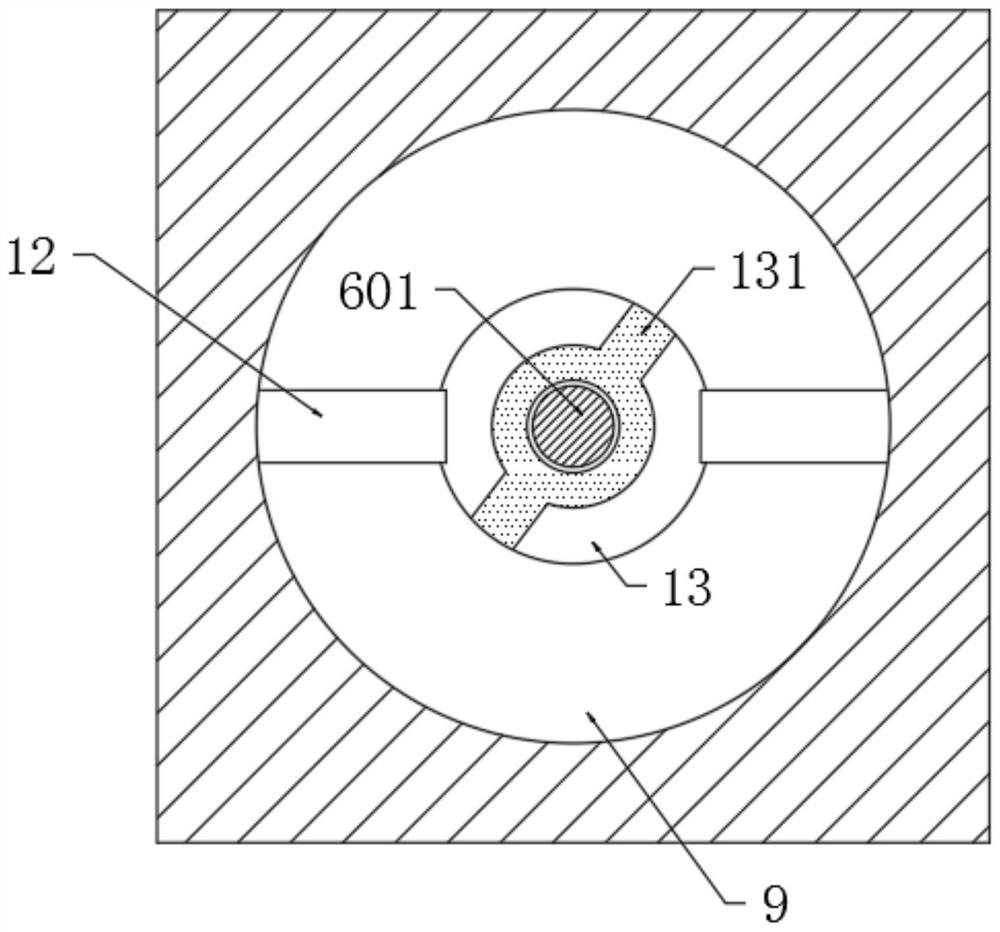

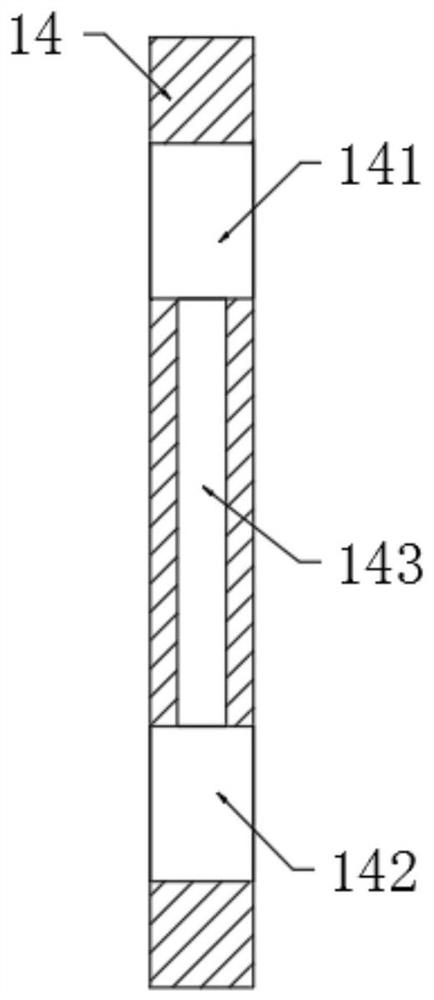

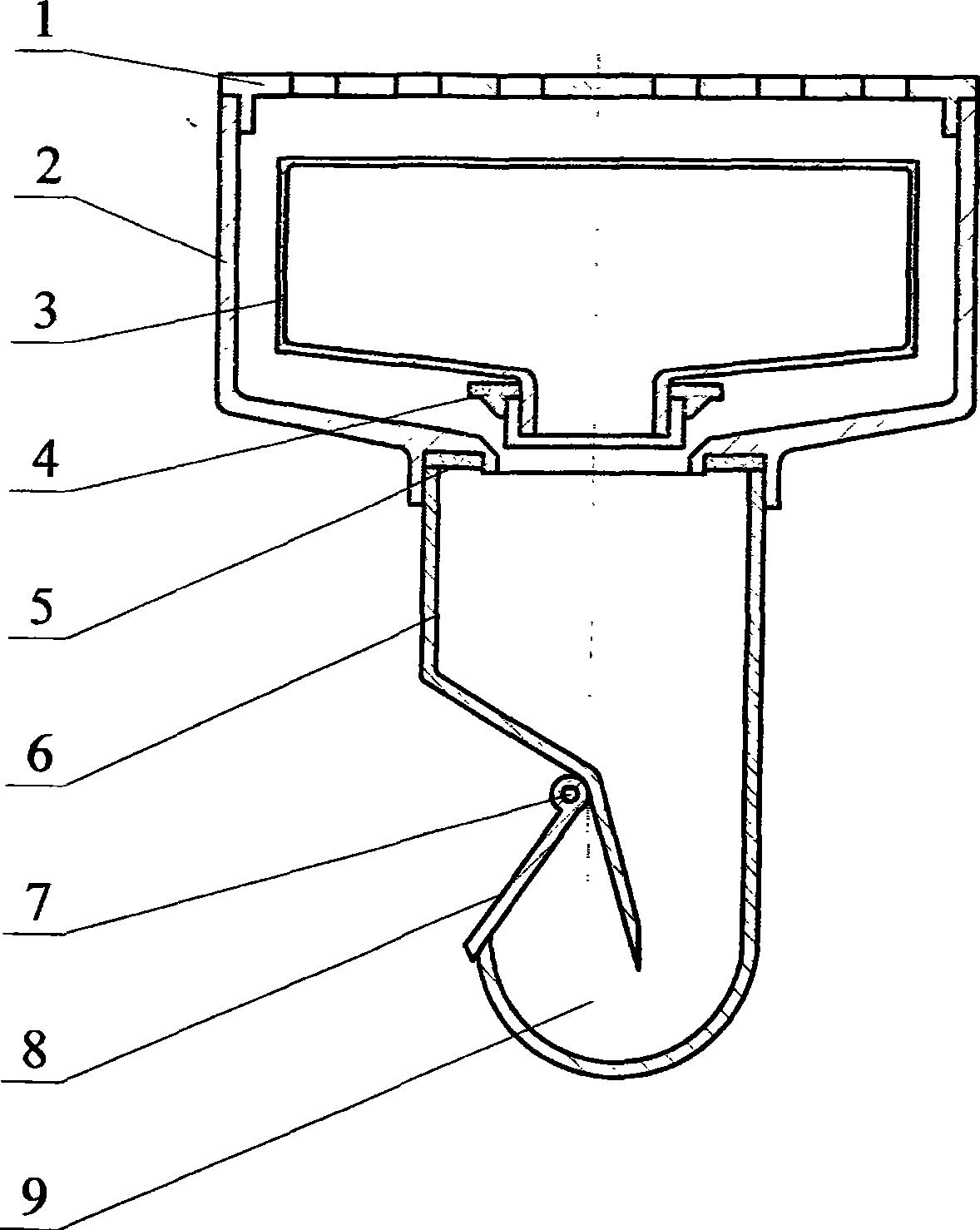

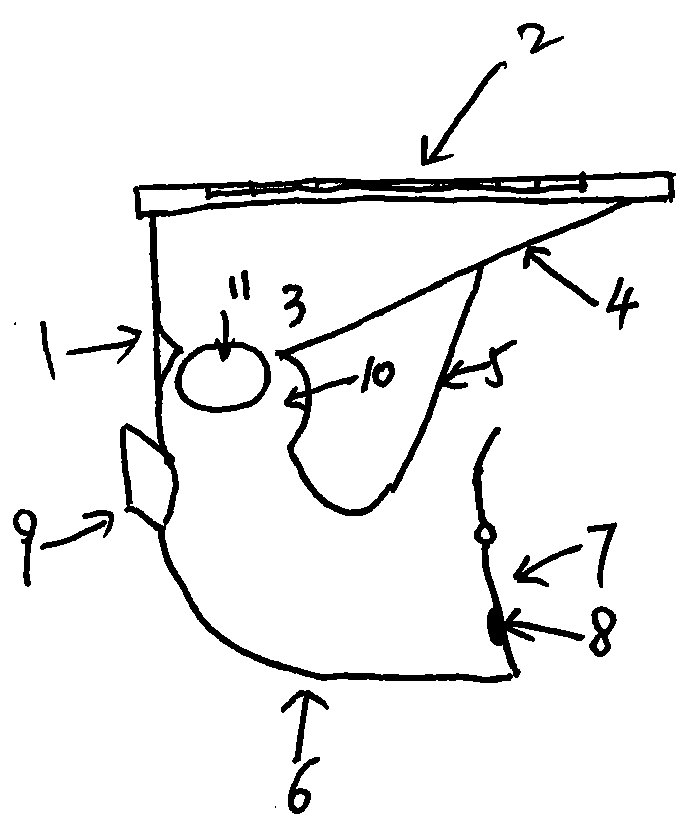

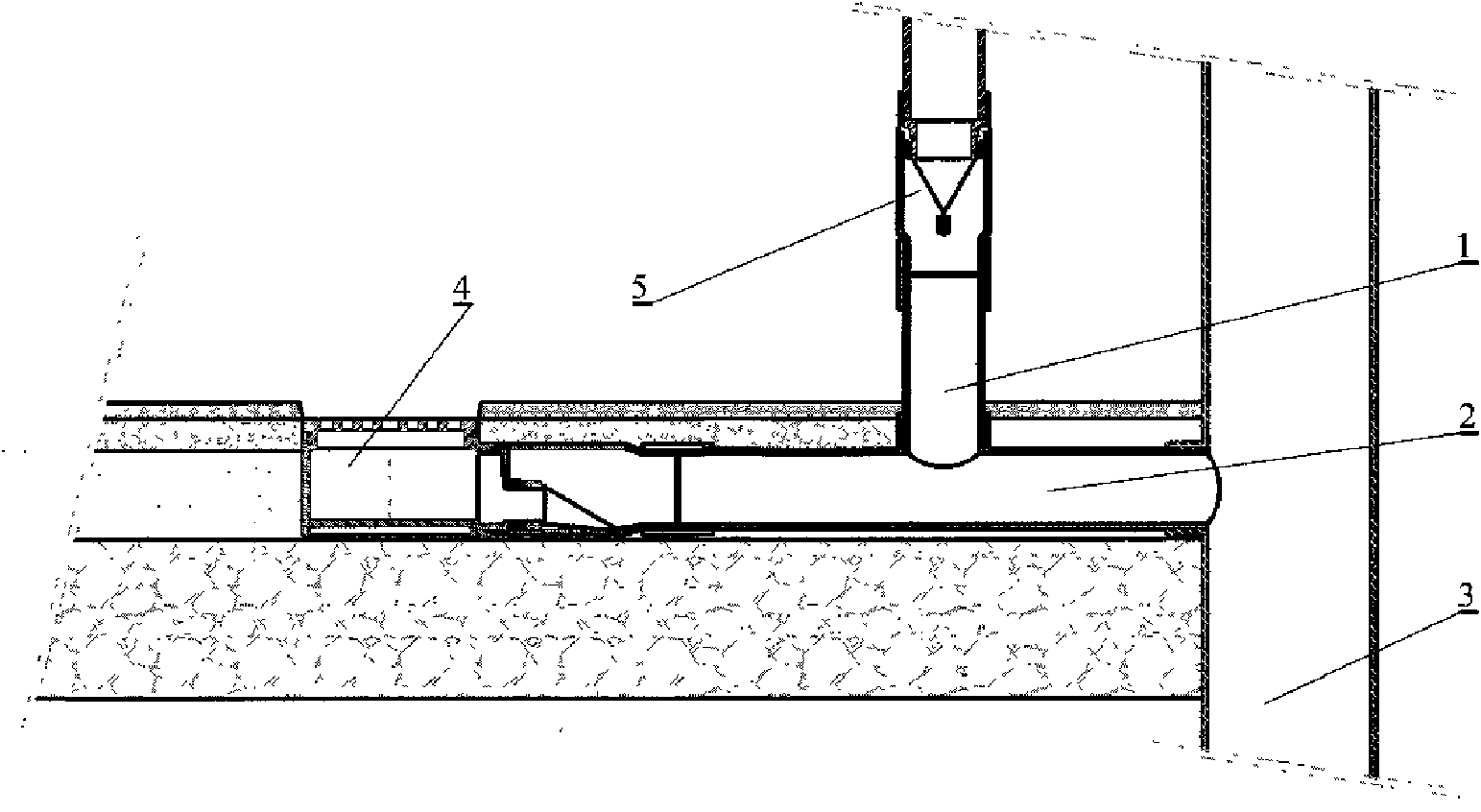

Anti-blocking self-cleaning floor drain drainage device

ActiveCN111894108ASpeed up drainageStrong self-cleaning abilitySewerage structuresClimate change adaptationSewageMechanical engineering

The invention discloses an anti-blocking self-cleaning floor drain drainage device. The device comprises a floor drain opening and a drainage groove which are formed in the ground, the upper end of the drainage groove communicates with the floor drain opening, a floor drain cover is arranged at the floor drain opening, a sewer pipe is laid in the groove wall of the bottom of the drainage groove, the sewer pipe communicates with the drainage groove, the upper end of the drainage groove is slidably connected with an inclined first filter screen, the first filter screen inclines towards one sideof the sewer pipe, and the lower end of the drainage groove is slidably connected with a piston plate. The device has the advantages that when the sewage amount is large, the first filter screen bearslarge water pressure, the first filter screen and a sliding rod obviously slide downwards, so that a rotating plate rotates to make an electrifying layer in contact with two conductive plates, a circuit where a first electric valve plate is located is electrified, the drainage groove communicates with an auxiliary pipe, part of sewage is discharged from the sewer pipe through the auxiliary pipe,flow dividing and drainage are achieved, and therefore the drainage speed of a floor drain is increased.

Owner:上海乾郁安装工程有限公司

Graphene coating and preparation method thereof

InactiveCN107629663AImprove insulation performanceImprove scratch resistancePolyurea/polyurethane coatingsEpoxy resin coatingsAdhesiveElectrical impedance

The invention discloses a graphene coating. The graphene coating is prepared from components in parts by weight in a formula as follows: 20-50 parts of an adhesive, 2-15 parts of a graphene dispersionliquid with the solid content being 0.3%-8%, 0.01-0.5 parts of a surfactant and 5-20 parts of deionized water. According to the preparation method, the components are stirred and mixed together in proportion according to the formula; the mixed components are stirred until an emulsion is completely and uniformly mixed, and the emulsion is filtered by screen cloth once and left to stand for 4 h orlonger; after foam is completely defoamed, the coating can be subjected to uniform application on a machine. A film formed after application of the graphene coating has the characteristics of very high hardness, very low resistance, high heat insulation property and scratch resistance, good self-cleaning capability and higher heat insulation effect.

Owner:上海谷奇核孔膜科技股份有限公司

High-resilience anti-blocking polyurethane bar screen and preparation method thereof

InactiveCN111014028AWear-resistantStrong toughnessSievingScreeningPolymer scienceHigh wear resistance

A high-resilience anti-blocking polyurethane bar screen is composed of tensioning hooks, a fixing plate, bolts, round steel and a polyurethane bar screen surface. The polyurethane bar screen surface is characterized in that a steel wire rope core polyurethane coated rubber bar is used as a reinforcing area, aramid fiber rope core polyurethane coated rubber bars are used as warps, frameless polyurethane coated rubber bars are used as wefts, and joint points are subjected to hot melting welding to form screening areas; and all screen pores of the screen surface are inverted-cone-shaped. The production process comprises the following steps: firstly, trapezoidal-section coated rods are produced on an extruder by taking a steel wire rope, an aramid rope or frameless different materials as corewires; secondly, hot melting welding is conducted on screen mesh joint points according to hole pattern requirements, the steel wire rope core polyurethane coated bar is arranged at the installation position of a tensioning hook, the aramid fiber rope core polyurethane coated rubber bars are set as the warps, the frameless polyurethane coated rubber bars are set as the wefts; and thirdly, the tensioning hook, the round steel and a fixing plate are tightened through bolts at the edge of the screen. The high-resilience anti-blocking polyurethane bar screen has the characteristics of high wear resistance, good elasticity, strong toughness, strong screen pore deformability and excellent self-cleaning effect.

Owner:ANHUI FANGYUAN PLASTIC & RUBBER

Industrial method for preparing PPTA spinning slurry with solid sulphuric acid

ActiveCN101555631AIncrease contact areaFast dissolutionSpinning solutions preparationMonocomponent polyamides artificial filamentLiquid crystallineSlurry

The invention discloses an industrial method for preparing PPTA spinning slurry with solid sulphuric acid, comprising the following steps: (1) granular solid sulphuric acid and dried PPTA resin with logarithmic viscosity number of 4.0-8.0dl / g are fully mixed, and are prepared into a liquid crystalline solution containing 16-23 percent of PPTA by weight percent via heating dissolving and pre-deaeration; (2) the obtained liquid crystalline solution is mixed, kneaded and sheared to form uniform liquid crystalline slurry under the temperature of 60-100 DEG C; and (3) the formed liquid crystalline slurry is further mixed and deaearted under the conditions of the temperature of 60-100 DEG C and the pressure of 0.09MPa to obtain stable and uniform PPTA / H2SO4 liquid crystalline solution, i.e. spinning solution. The method has good mixing effect, can rapid extrude under high shearing rate without the degradation of the liquid crystalline solution caused by high shearing rate and high temperature.

Owner:中国平煤神马控股集团有限公司

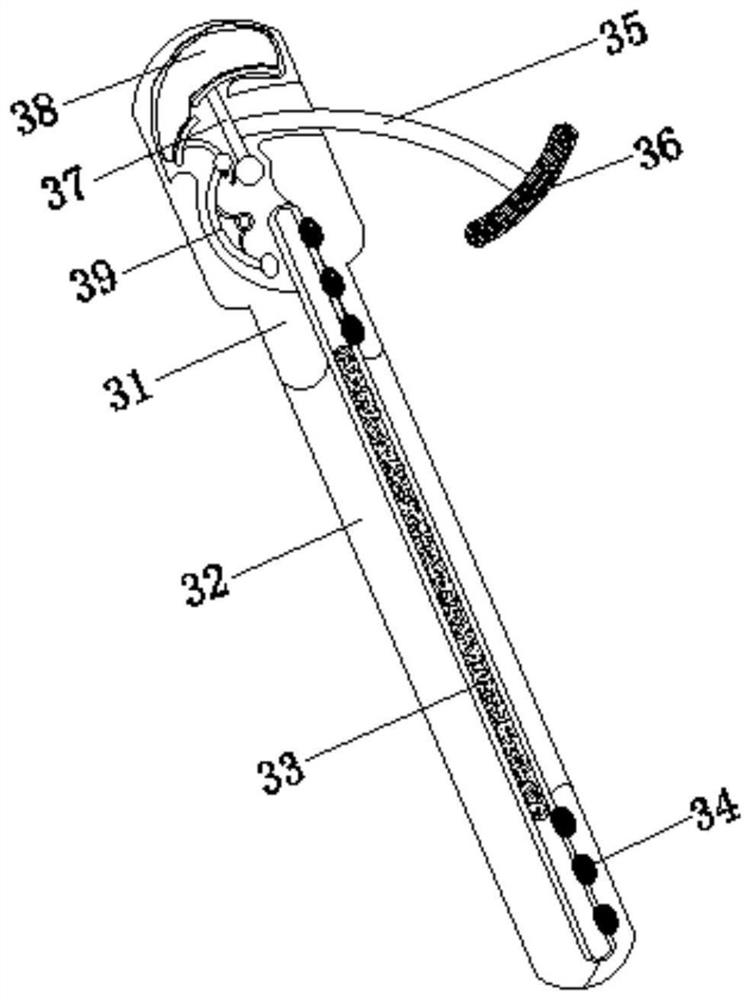

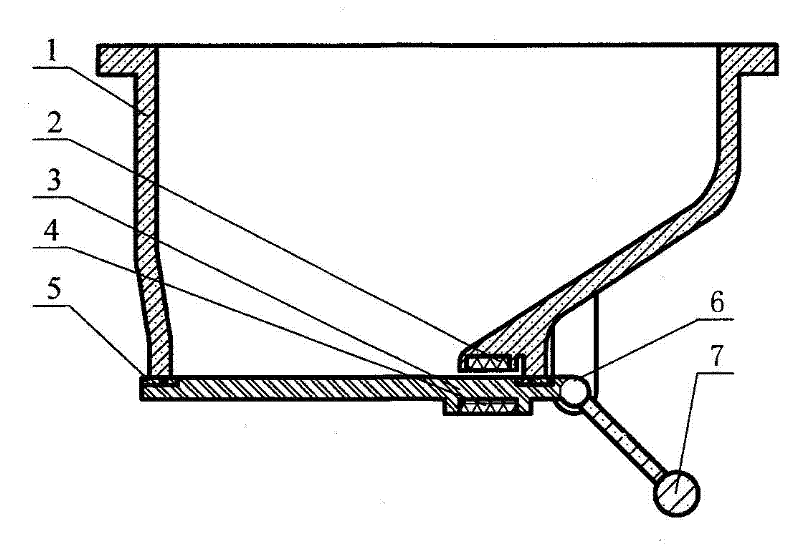

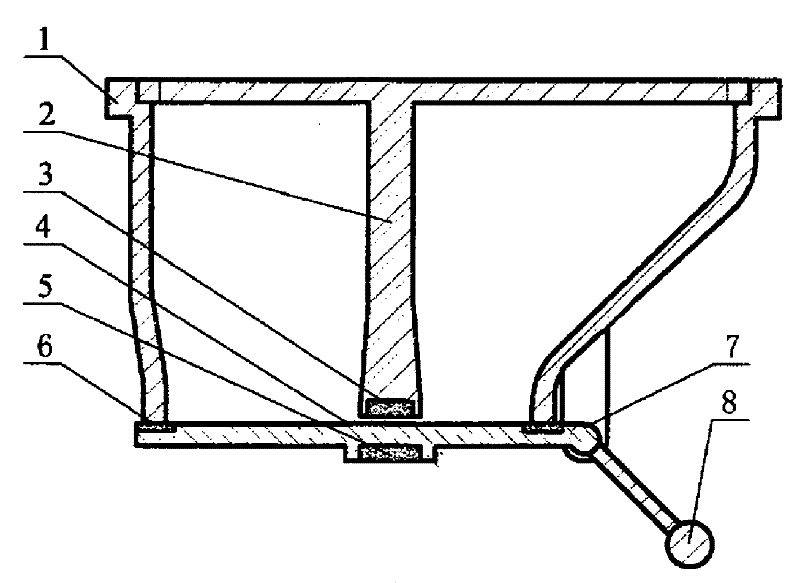

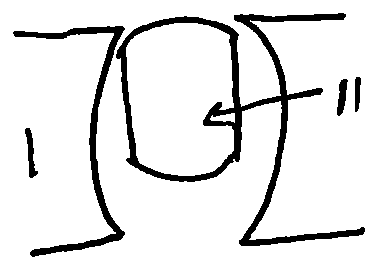

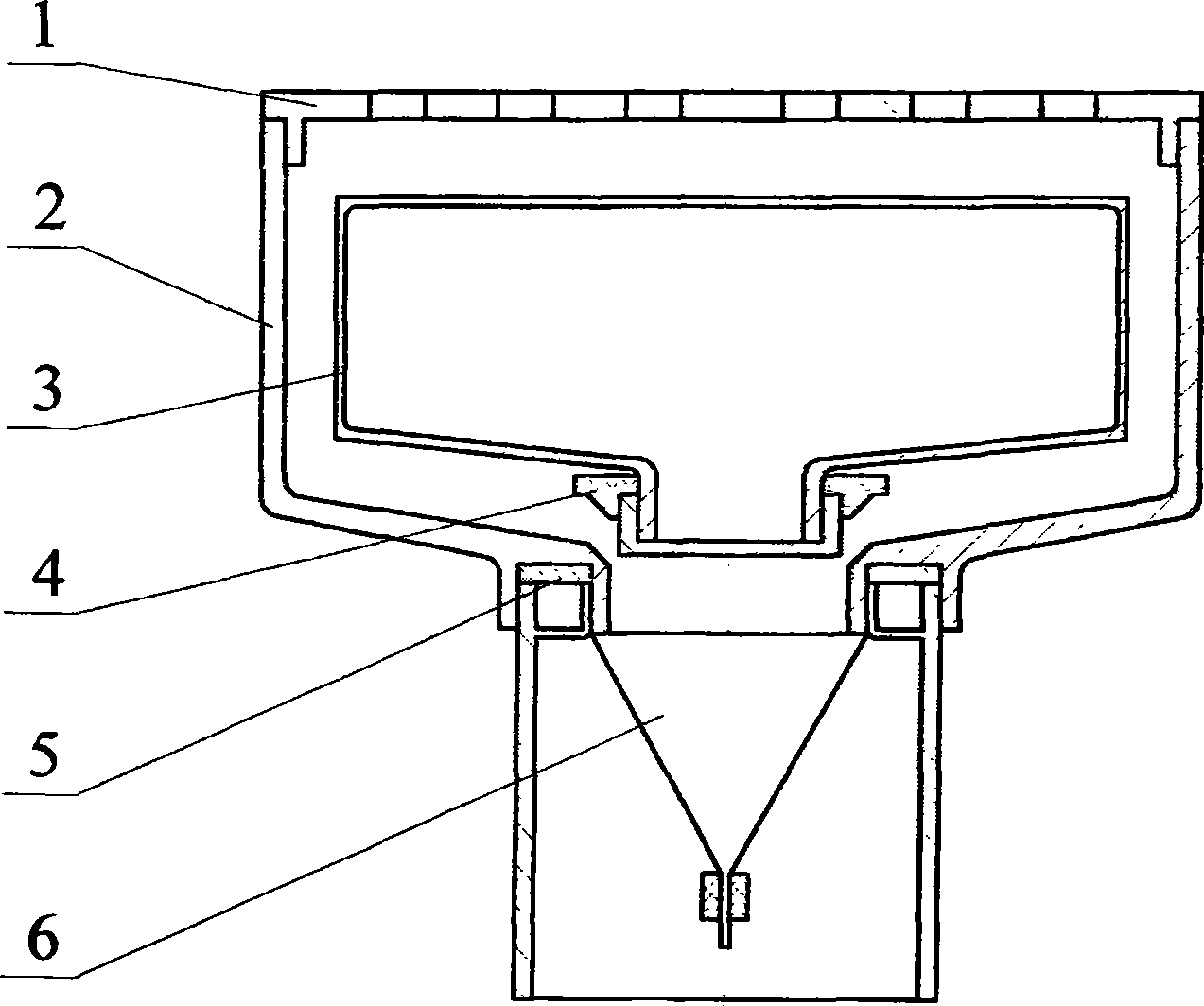

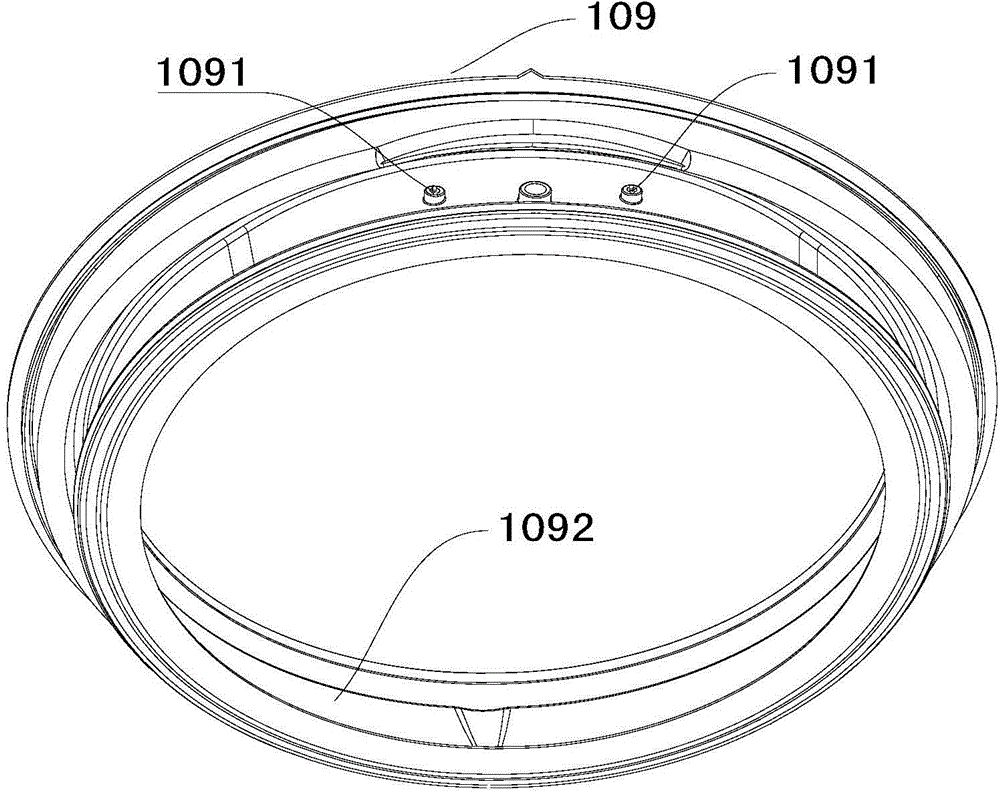

Dual mechanical seal floor drain core

A dual mechanical seal floor drain core is composed of an upper floor drain core body, a floater, a lower floor drain core body and a valve. The floater is mounted in the upper floor drain core body, the lower end of the floater is matched with the water outlet of the upper floor drain core body, and the lower end of the floater seals the water outlet of the upper floor drain core body through gravity or magnetic force; the lower floor drain core body is connected with the lower end of the upper floor drain core body, the valve is mounted on the water outlet of the lower floor drain core body to seal the water outlet of the lower floor drain core body through gravity or magnetic force. The open-close of the dual mechanical seal floor drain core is realized through the changes of water flow entering the floor drain core. The dual mechanical seal floor drain core has the advantages of rapid opening and closing, small passing resistance of water flow, good sealing effect and uneasy blockage, also can prevent the positive and negative pressure in the sewer from damaging the sealing performance of the floor drain core and has good anti-overflow performance.

Owner:戴长虹

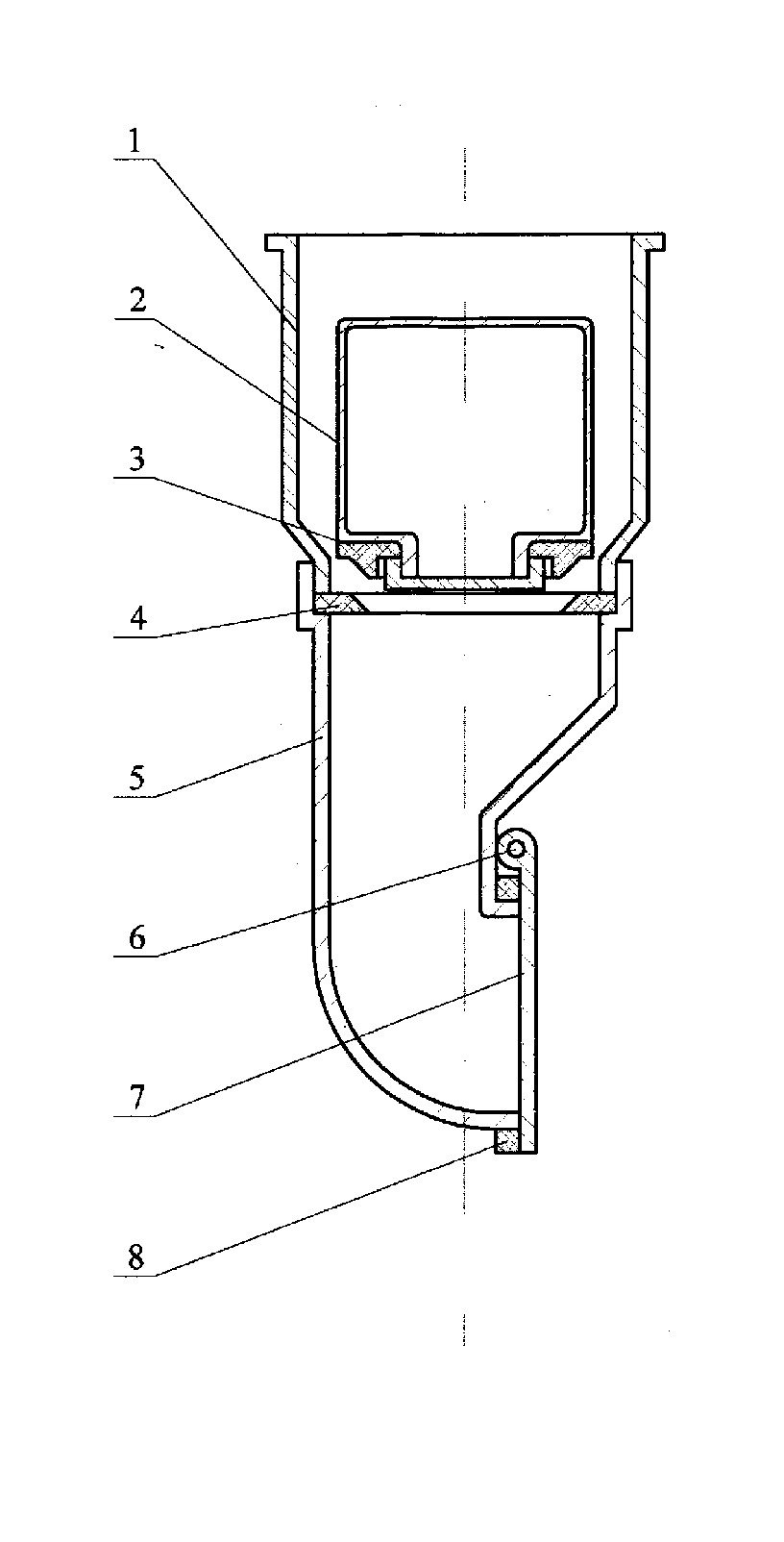

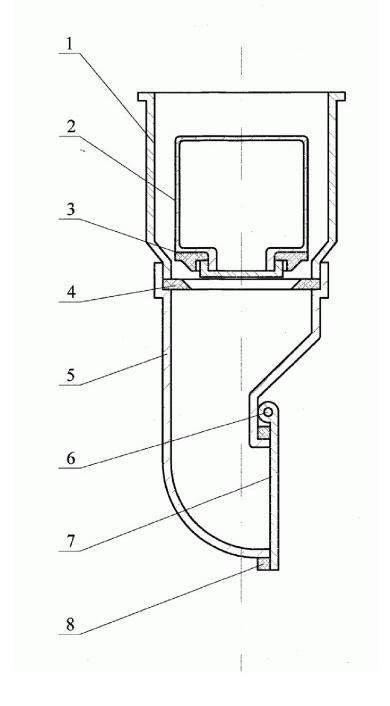

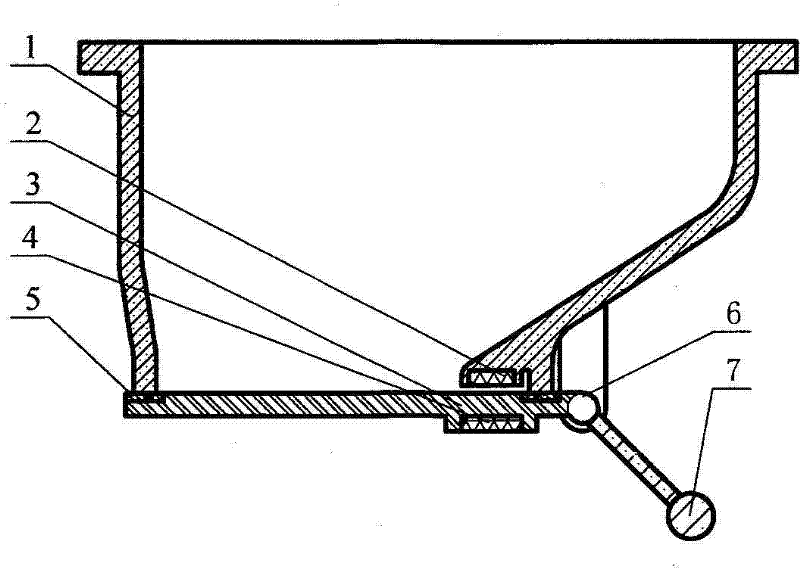

Multiple sealing floor drain

InactiveCN101463623ASealing is not affectedGood anti-backflow performanceDomestic plumbingWater flowEngineering

A multi-seal floor drain consists of a floor drain cover, an upper main floor drain body, a float, a lower main floor drain body and a movable door. The float is arranged inside the upper main floor drain body, the lower end of the float is matched with a water outlet of the upper main floor drain body, and the water outlet of the upper main floor drain body is sealed with the lower end of the float by gravity or magnetic force; the lower main floor drain body is connected with the lower end of the upper main floor drain body, the lower end of the lower main floor drain body is provided with a trap, the movable door is arranged at a water outlet of the trap, and the water outlet of the trap is sealed by the gravity or the magnetic force. Opening and closing of the multi-seal floor drain are realized by the change of water flow entering the floor drain. The multi-seal floor drain has the advantages of quick opening and closing, small resistance when the water passes through, good sealing effect, uneasy blockage and the like, can prevent positive and negative pressure in a sewer from damaging the sealing performance of the floor drain, and also has good overflow resistance performance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Check valve core sealed by mechanical and magnetic force

The invention provides a check valve core sealed by mechanical and magnetic force, which consists of a check valve core main body, a movable gate and a balance weight. Magnetic force acts between the check valve core main body and the movable gate, the opened movable gate is gradually closed by the balance weight, and a water outlet of the check valve core is sealed by the movable gate under the action of magnetic force. The check valve core sealed by mechanical and magnetic force is opened and closed through the variation of water flow entering the check valve core. The check valve core sealed by mechanical and magnetic force has the advantages of small volume, rapid opening and closing, large water draining capability, good seal effect, strong self-clearing capability, simple structure, low manufacture cost, convenience for use and maintenance and the like.

Owner:戴长虹

Magnetic mechanical sealing floor drain core

The invention relates to a magnetic mechanical sealing floor drain core comprising a floor drain core main body, an inner bracket and a movable door. The inner bracket is mounted in the floor drain core main body, the lower end of the inner bracket is suspended at the water outlet of the floor drain core, magnetic force action exists between the inner bracket and the movable door, and magnetic force is utilized so that the water outlet of the floor drain core is sealed by the movable door. Through the change of water flow entering the floor drain core, the magnetic mechanical sealing floor drain core is opened and closed. The magnetic mechanical sealing floor drain core has the advantages of small size, rapid switching, great drainage capacity, good sealing effect, strong self-cleaning capability, simple structure, low manufacture cost, convenience in use and maintenance, and the like.

Owner:戴长虹

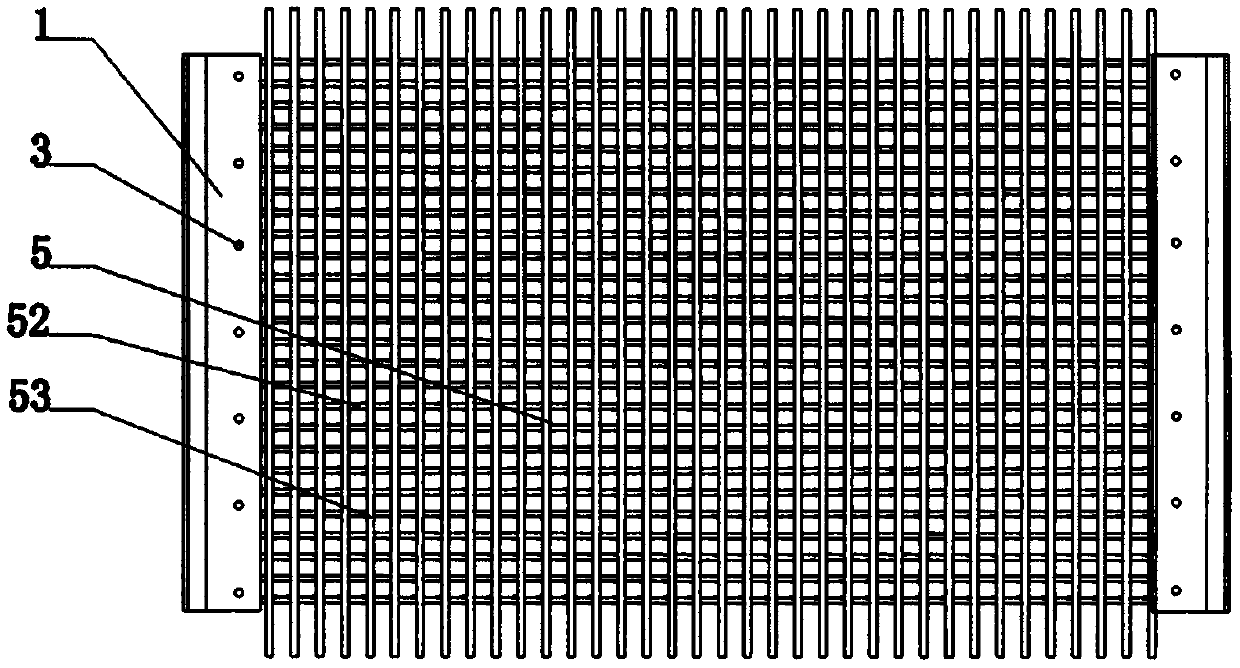

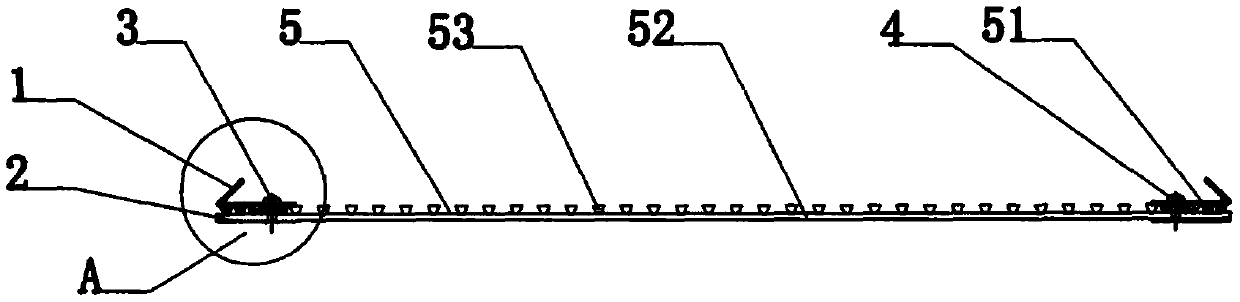

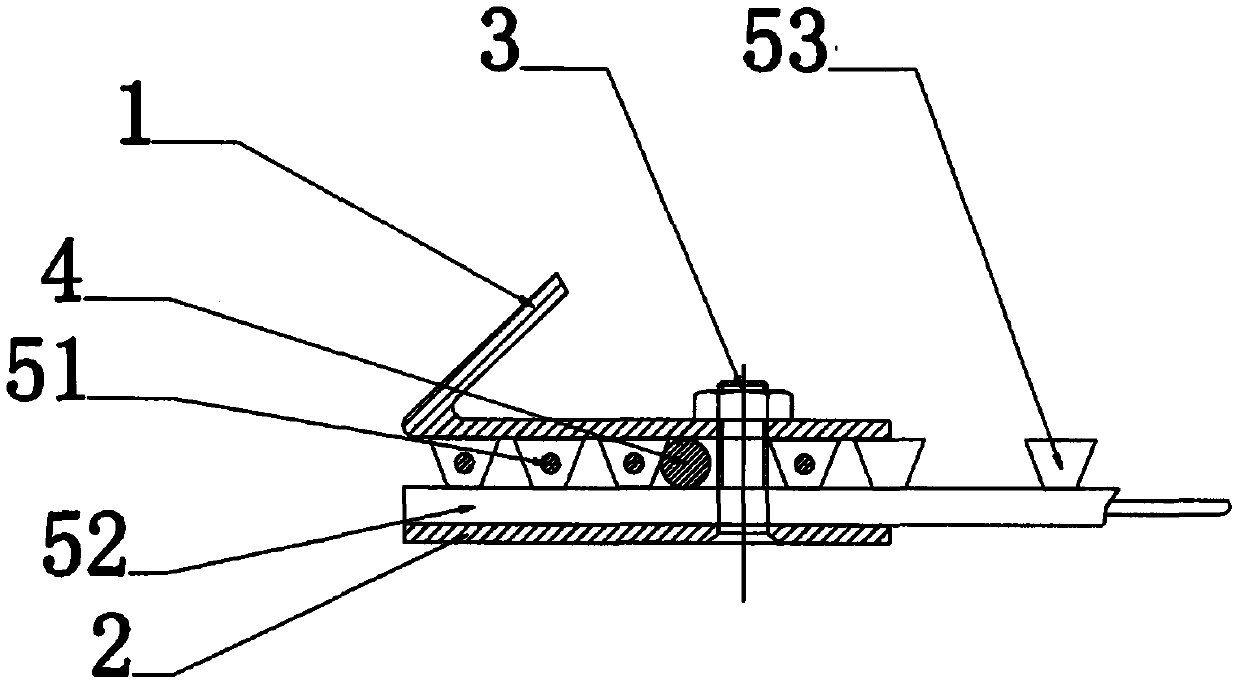

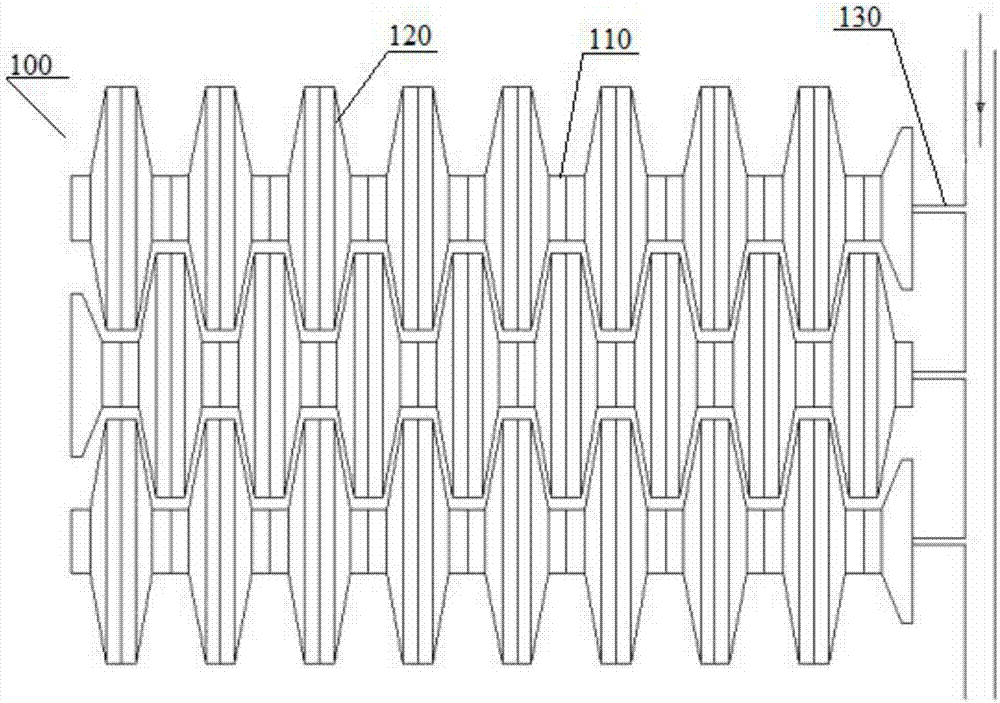

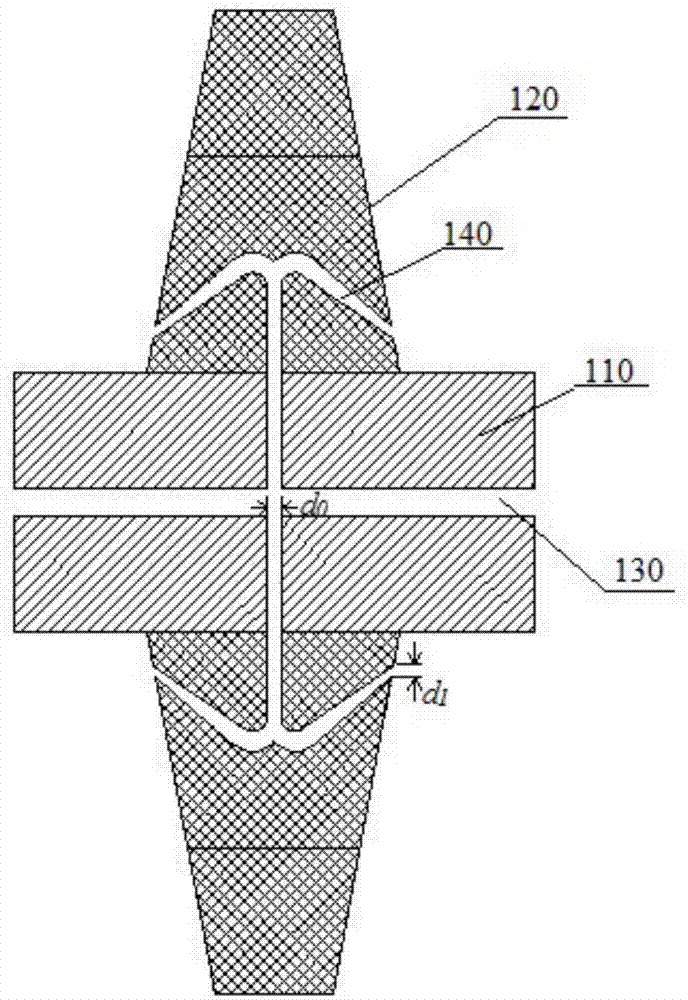

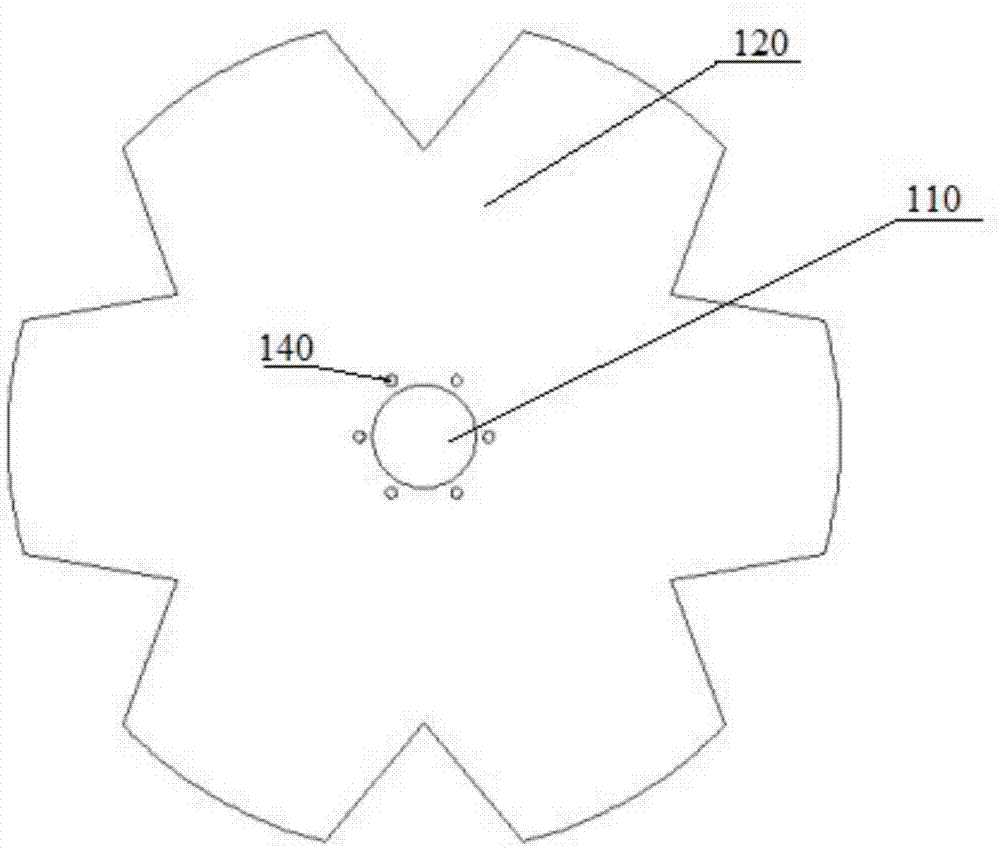

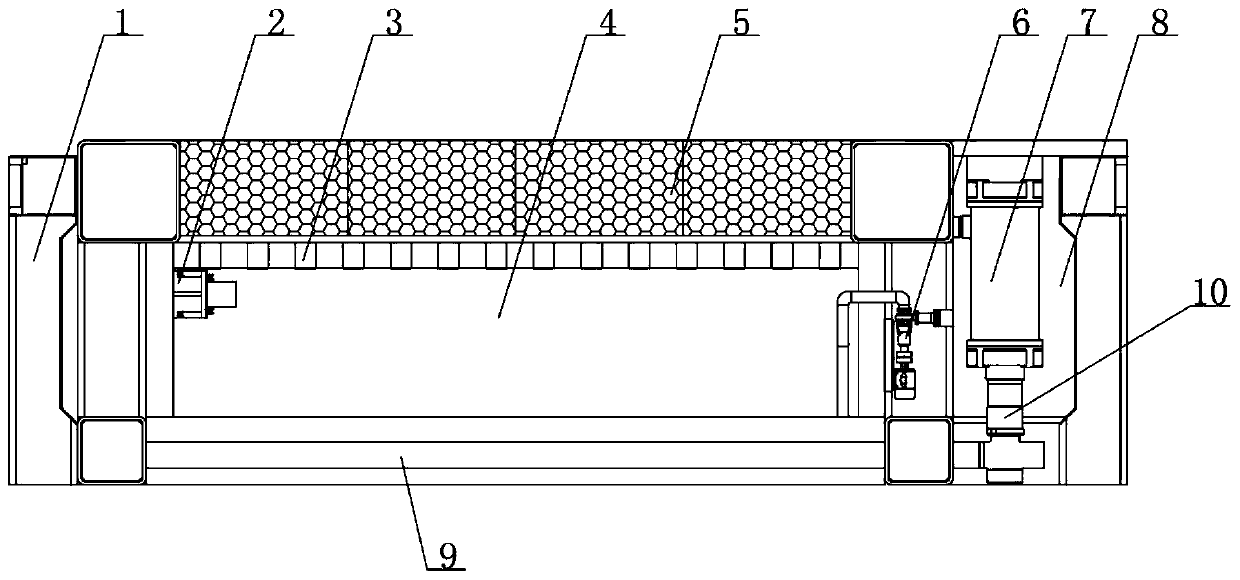

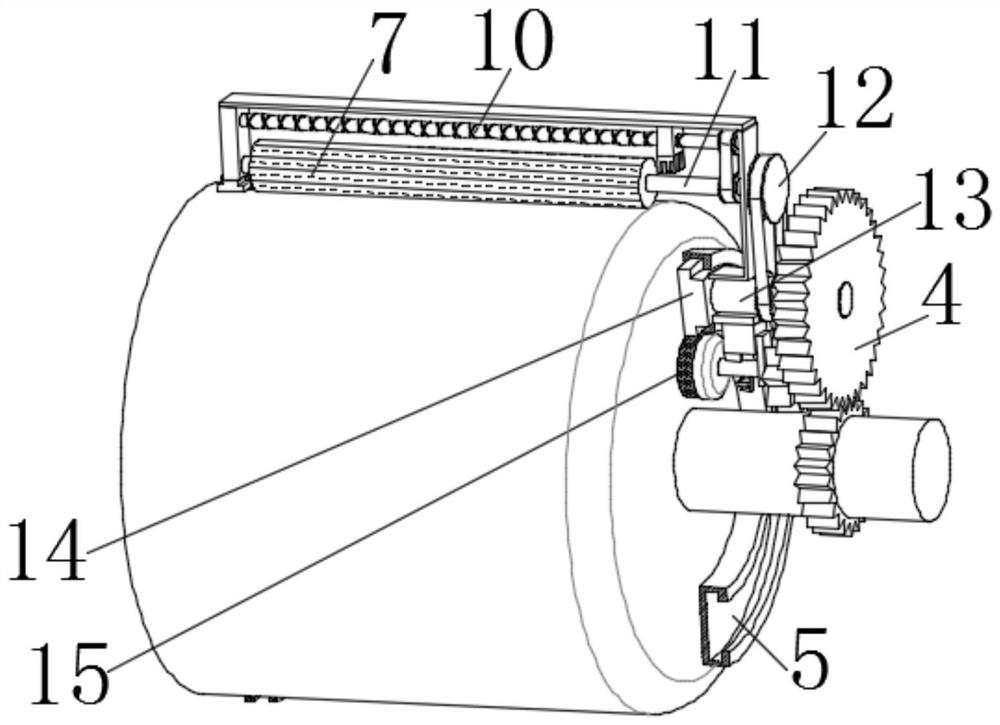

Screen mesh, coal screening machine and control method of coal screening machine

ActiveCN107321610AIncrease contact areaStrong self-cleaning abilitySievingScreeningEngineeringDrive motor

The invention discloses a screen mesh. The screen mesh comprises a plurality of screen shafts, screen pieces, air current channels and exhaust holes, wherein the screen shafts are placed in parallel and form an oblique plane; the screen pieces are perpendicular to the screen shafts and are mounted on each screen shaft at equal intervals in a matched mode, and the screen pieces of different screen shafts are inserted into the gaps between the screen pieces of the adjacent screen shafts in an interlaced mode; the air current channels are arranged inside the screen shafts and the screen pieces and communicate the screen shafts with the screen pieces; and the exhaust holes are evenly and circumferentially arranged on the screen pieces close to the matching position of the screen pieces and the screen shafts, extend in the axial direction of the screen shafts, and oblique at a certain angle towards the direction of the screen shafts. According to the screen mesh, coal attached to the corners of the connection between the screen pieces and the screen shafts is blown off through high-pressure high-speed gas to prevent sticking of the coal. The invention further provides a coal screening machine and a control method thereof. According to the coal screening machine and the control method thereof, the rotating speed of a driving motor is controlled through a control device according to the pressure of the high-pressure gas output by a fan, the screen mesh is effectively controlled to avoid sticking of the coal, the screening efficiency is improved, and the energy is saved.

Owner:JILIN UNIV

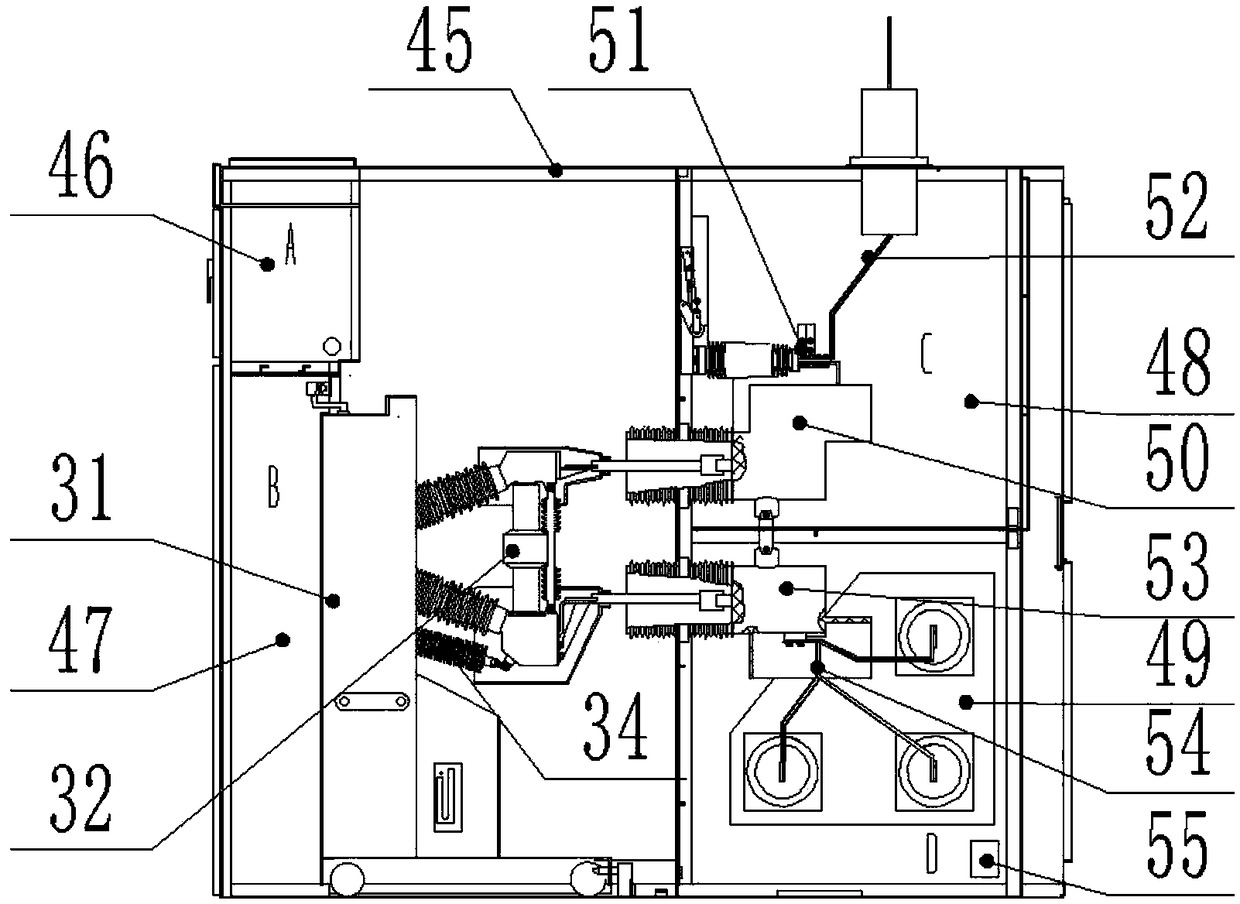

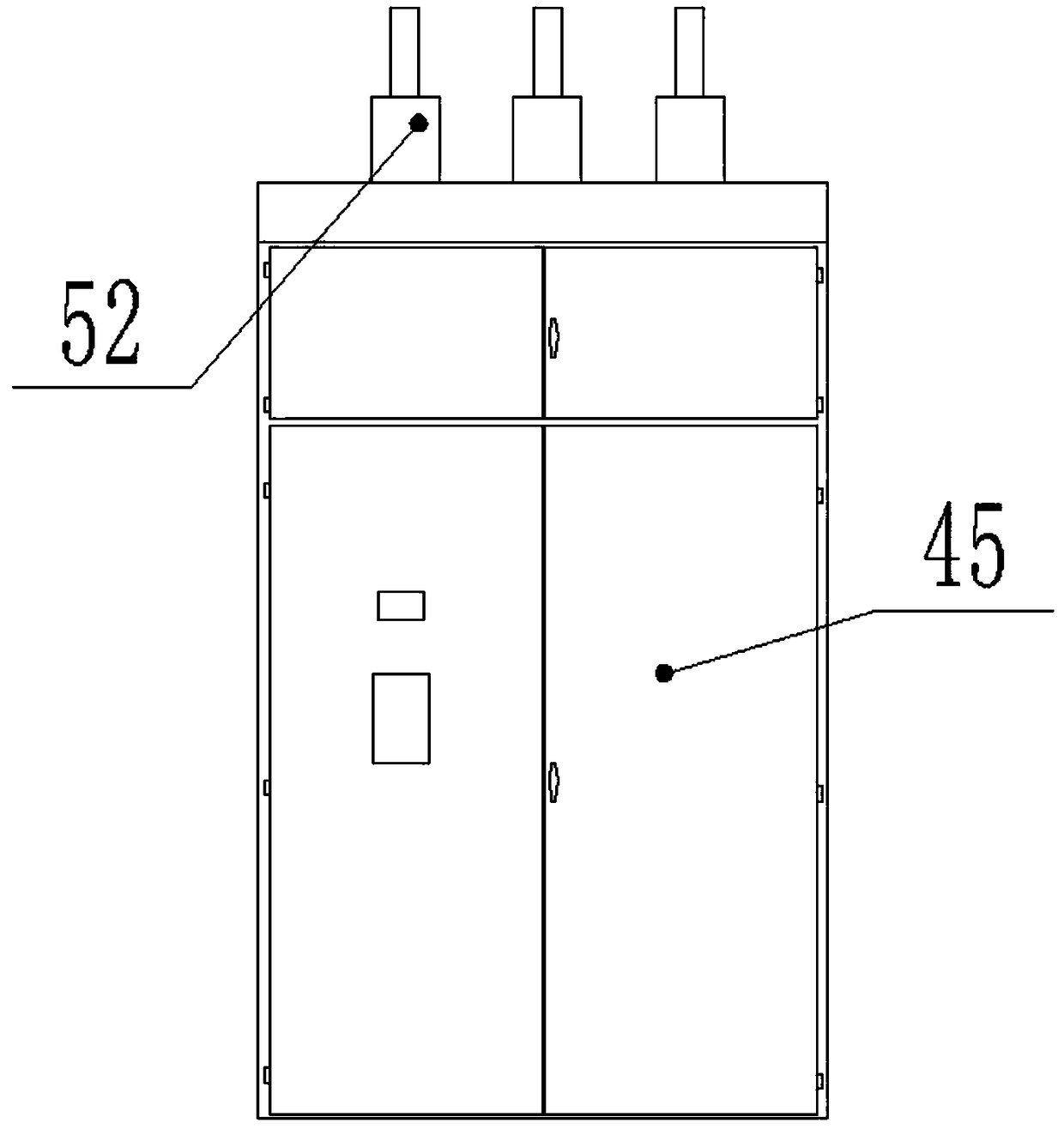

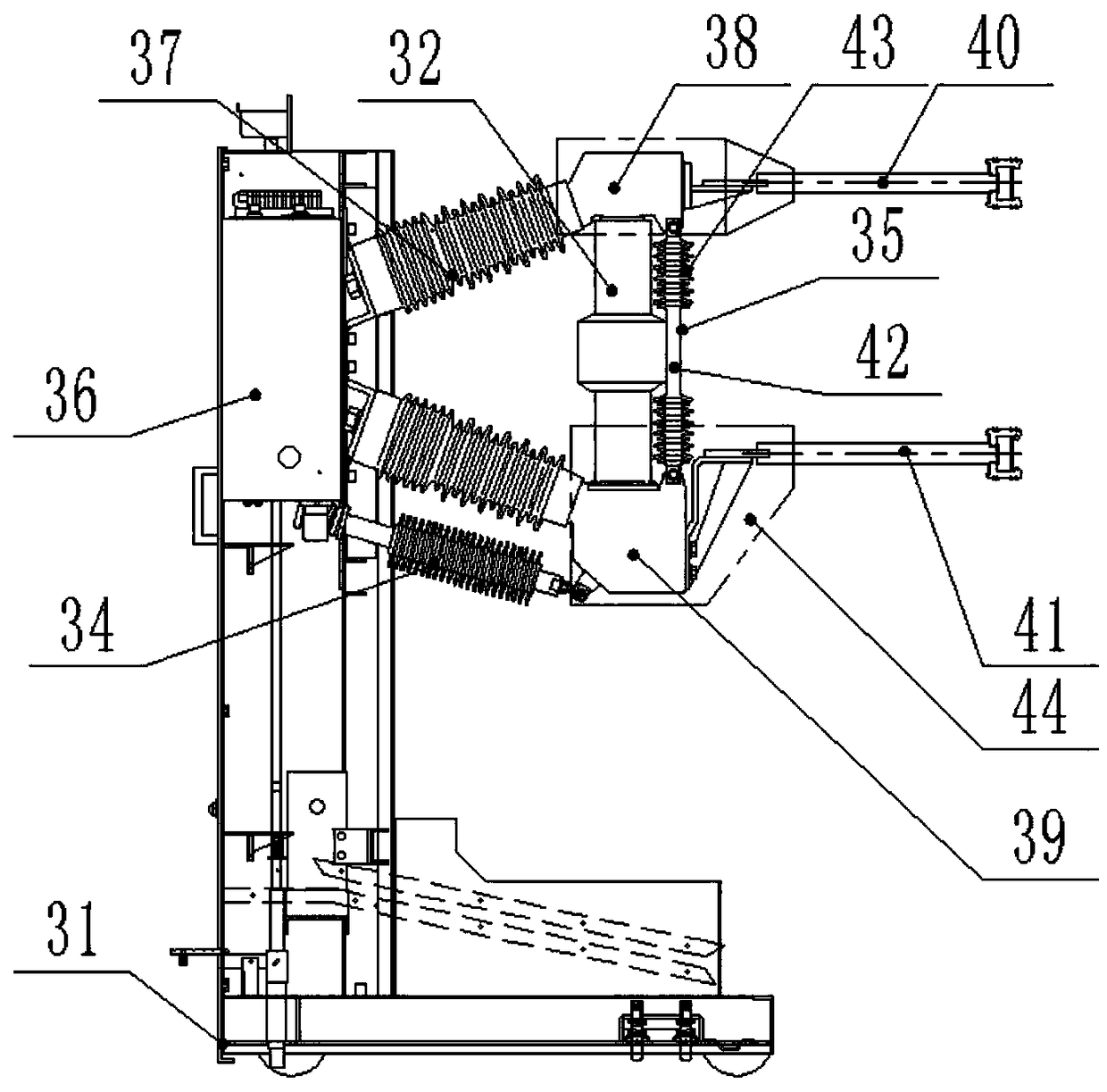

40.5kV switch equipment system

ActiveCN108767726AImprove insulation performanceAvoid compromising operational safetyBus-bar/wiring layoutsSwitchgear detailsFeeder lineSwitchgear

The invention discloses a 40.5kV switch equipment system. The system comprises a switch cabinet; an instrument chamber, a handcart chamber, a feeder line chamber and a bus chamber are formed in the switch cabinet; the feeder line chamber is arranged above the bus chamber, the handcart chamber is arranged at the left side of the feeder line chamber and the bus chamber, the instrument chamber is arranged at the left upper corner of the handcart chamber, and a circuit breaker module is arranged in the handcart chamber; an upper conductive connector on the circuit breaker module is connected withan upper contact box type current transformer outlet arranged at the feeder line chamber, the inlet of the upper contact box type current transformer is connected with an upper branch bus connector through a grounding switch; a lower conductive connector on the circuit breaker module is connected with a lower contact box type current transformer outlet arranged at the bus chamber, and the lower contact box type current transformer inlet is connected with a lower branch bus connector; and the circuit breaker module comprises a frame, a vacuum arc extinguish chamber, an operating mechanism, a connecting insulation pull rod and an insulating brace rod.

Owner:四川电器集团股份有限公司

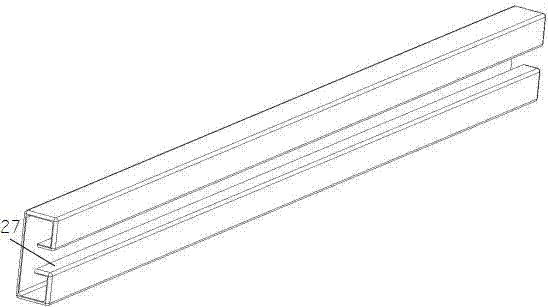

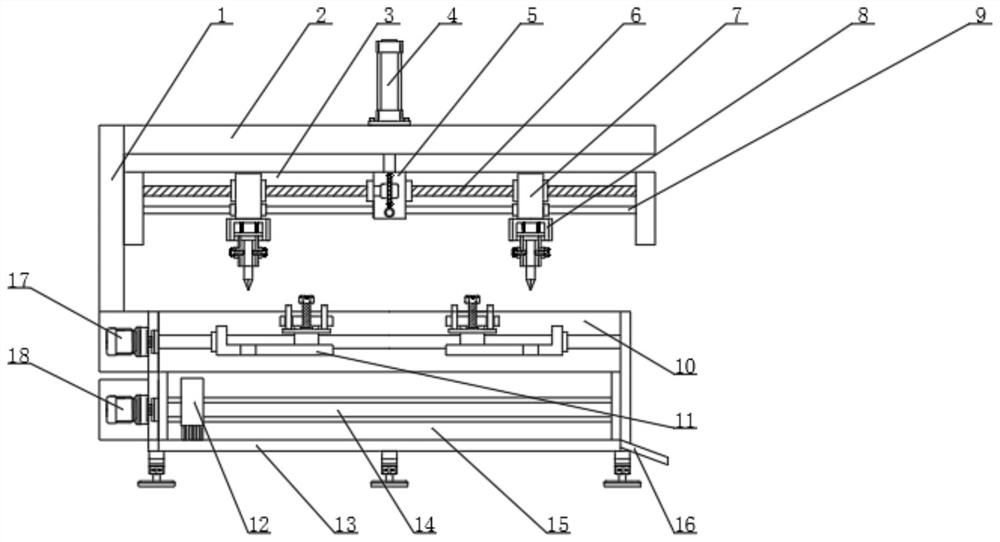

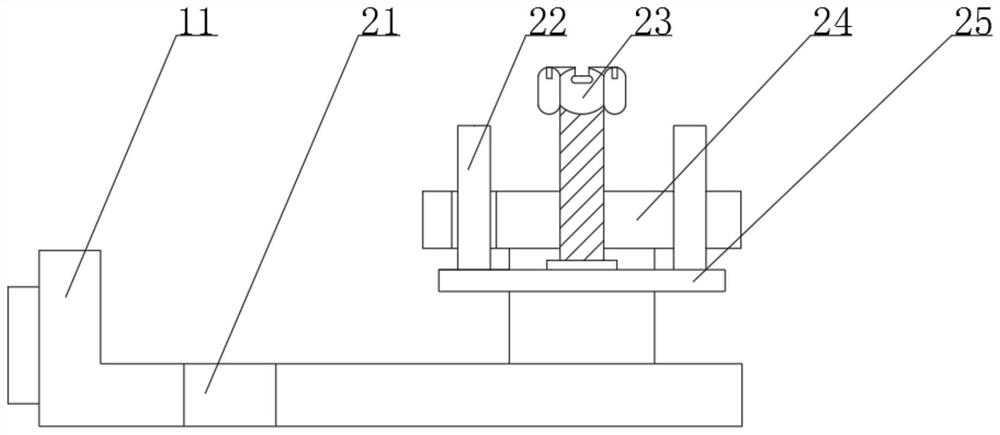

Bus duct punching tooling with adjusting function and using method thereof

ActiveCN112719053AAvoid offsetAvoid manual cleaningShaping toolsPerforating toolsPunchingScrew thread

The invention discloses a bus duct punching tooling with an adjusting function and a using method thereof. The bus duct punching tooling comprises a longitudinal guide rail and a base; the longitudinal guide rail is longitudinally arranged on the left side of the upper portion of the base; a cross beam is arranged on the upper portion of the longitudinal guide rail, and an electric cylinder is installed in the middle of the upper portion of the cross beam; a punching base is arranged below the cross beam; the punching base is connected with the longitudinal guide rail in a sliding mode; a piston rod of the electric cylinder is connected with the punching base; and a transmission box is installed in the middle of the interior of the punching base. The device is provided with an adjusting two-way threaded rod, a first two-way threaded rod, an objective table and a pressing base, so that the device can adjust the positions of a punch and the objective table according to the machining position of a to-be-machined plate, the use range and the machining range of the device are increased, meanwhile, a pressing plate and the pressing base are matched with each other, and the to-be-machined plate is prevented from deviating during machining, and the machining stability of the device is improved.

Owner:江苏冠卓电气有限公司

Feed forming device

InactiveCN113786778AImprove the mixing effectWet evenlyShaking/oscillating/vibrating mixersFeeding-stuffElectric machineCoupling

The invention provides a feed forming device, and relates to the field of feed processing. The feed forming device comprises a water inlet pipe, a rotating motor, a feeding hopper, a processing tank, a control panel and a fixing seat, the rotating motor is arranged on the outer wall of the top end of the processing tank, the output shaft of the rotating motor is connected with a rotating shaft through a coupler, a stirring mechanism is arranged on the outer wall of the rotating shaft, and the water inlet pipe is arranged on the outer wall of one end of the processing tank. The water inlet pipe is communicated with an external water conveying mechanism, the feeding hopper is arranged on the outer wall of the other side of the processing tank, the control panel is arranged on the outer wall of the processing tank, the fixing seat is arranged on the outer wall of the bottom end of the processing tank, and a forming mechanism is arranged on the inner wall of the bottom end of the fixing seat. According to the feed forming device, the stirring effect on feed can be enhanced, the feed can be evenly wetted, the forming effect is improved, meanwhile, generated vibration enables the feed attached to the stirring rods to fall off more easily, and the self-cleaning capacity is improved.

Owner:荣地加措

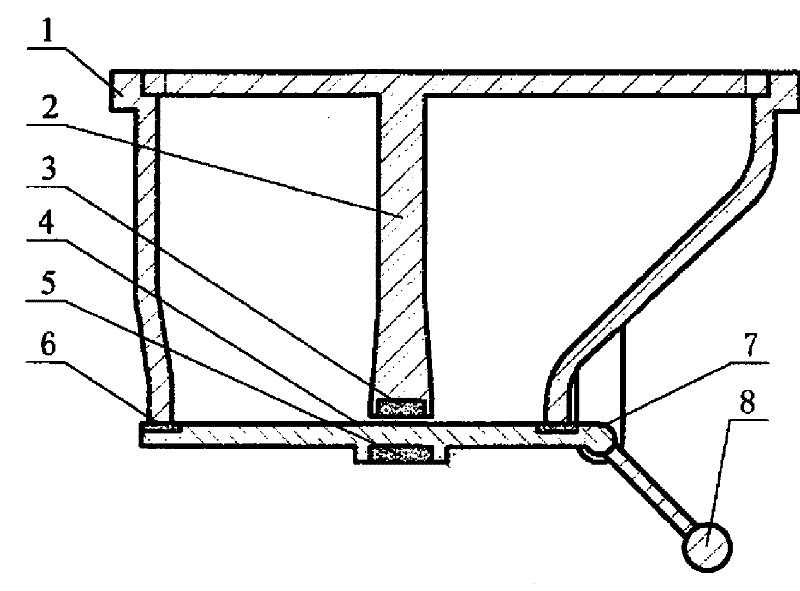

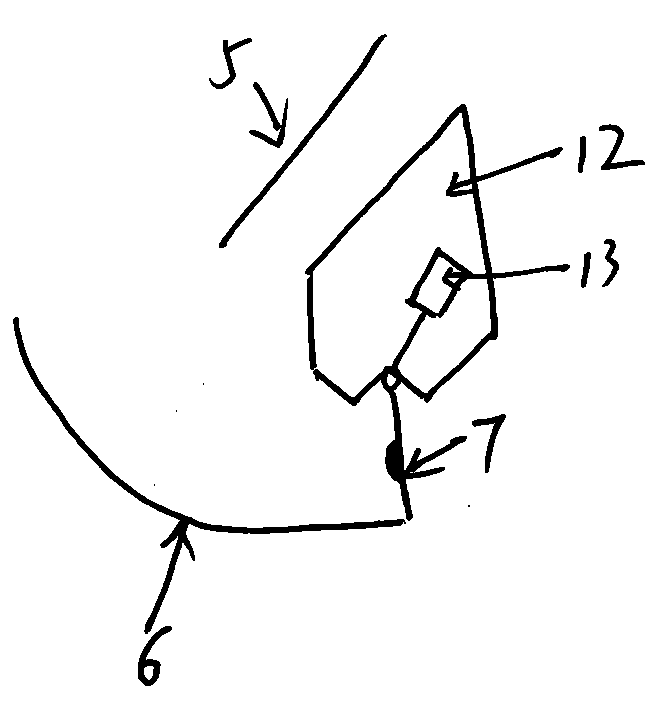

Eccentric floor drain

InactiveCN104763042APrevent water seal from drying outStrong self-cleaning abilitySewerage structuresClimate change adaptationWater storage tankEngineering

The invention discloses an eccentric floor drain. The side wall of the bottom part of a water storage tank of the eccentric floor drain is provided with a turning plate; through the turning plate, dirt settled at the floor drain of the water storage tank is discharged; particularly, when a lot of water in a water replenishing opening is flowed out, the turning plate corresponding to the water replenishing opening is flushed away by the water replenishing opening, and thereby the sediment can be discharged along with water flow. Especially, under the condition that the replenishing opening and the bottom part of the water storage tank are inclined downwards and the gradients are the same, the self-cleaning ability is stronger. On the circumstance of arranging a hydraulic sensor, the water pressure can be sensed by the hydraulic sensor when the setting value of the hydraulic sensor is set as full water in the water storage tank, thus water flow from the water replenishing opening can flush the turning plate away when the water pressure is more than the setting value; and thereby the frequent starting of the turning plate is limited. When the water amount is small and is not enough to flush the turning plate away, a water seal forms at the water storage tank still. The unique technical concept has certain influence on the development trend of the existing floor drain.

Owner:梁诺

Oil stain treatment device with linkage impurity removal function

ActiveCN114225492ARealize self-cleaningStrong self-cleaning abilityGeneral water supply conservationStationary filtering element filtersSewageSewage treatment

The invention discloses a greasy dirt treatment device with a linkage impurity removal function, and belongs to the technical field of sewage treatment.The greasy dirt treatment device comprises an impurity removal box, a liquid discharge pipe is arranged at the bottom of the impurity removal box, a slag discharge pipe is arranged at the end, close to the liquid discharge pipe, of the impurity removal box, a discharging hopper is arranged at the end, away from the liquid discharge pipe, of the impurity removal box, and an impurity removal mechanism is arranged in the impurity removal box; the impurity removing mechanism comprises a filtering assembly used for filtering sewage and a cleaning assembly used for cleaning the filtering assembly, the filtering assembly is arranged at the end, away from the liquid discharging pipe, of the cleaning assembly, and a driving mechanism used for driving the filtering assembly to reciprocate is further arranged at the end, away from the liquid discharging pipe, of the impurity removing box. The device is simple in structure and convenient to use, sewage is filtered and purified through the filtering assembly during use, and self-cleaning of the filtering structure is achieved through linkage cooperation of the driving mechanism, the filtering assembly and the cleaning assembly.

Owner:嘉峪关刘氏泰和环保科技有限公司

Easy-to-clean domestic ceramic and preparation method thereof

The invention belongs to the technical field of ceramics, and particularly relates to easy-to-clean domestic ceramic and a preparation method of the easy-to-clean domestic ceramic. The easy-to-clean domestic ceramic comprises the following ingredients in percentage by weight: 58-62% of silicon dioxide, 2-3% of aluminum oxide, 2-4% of calcium oxide, 22-26% of magnesium oxide, 0.7-0.9% of potassium oxide, 0.11-0.15% of sodium oxide, 3-5% of zinc oxide and 2-3% of anion powder. The preparation method comprises the steps of mixing the raw materials for wet ball milling to form slurry, removing iron from the slurry, sieving and staling the slurry, then performing fine treating, grouting and roll forming, and performing drying and firing at last. The easy-to-clean domestic ceramic contains multiple rare earth metal oxides that generate a synergistic effect to raise an easy-to-clean degree of the easy-to-clean domestic ceramic, and the easy-to-clean domestic ceramic has significant self-cleaning ability and an effective effect of sterilization and bacterial inhibition.

Owner:GUANGDONG SHUNXIANG PORCELAIN

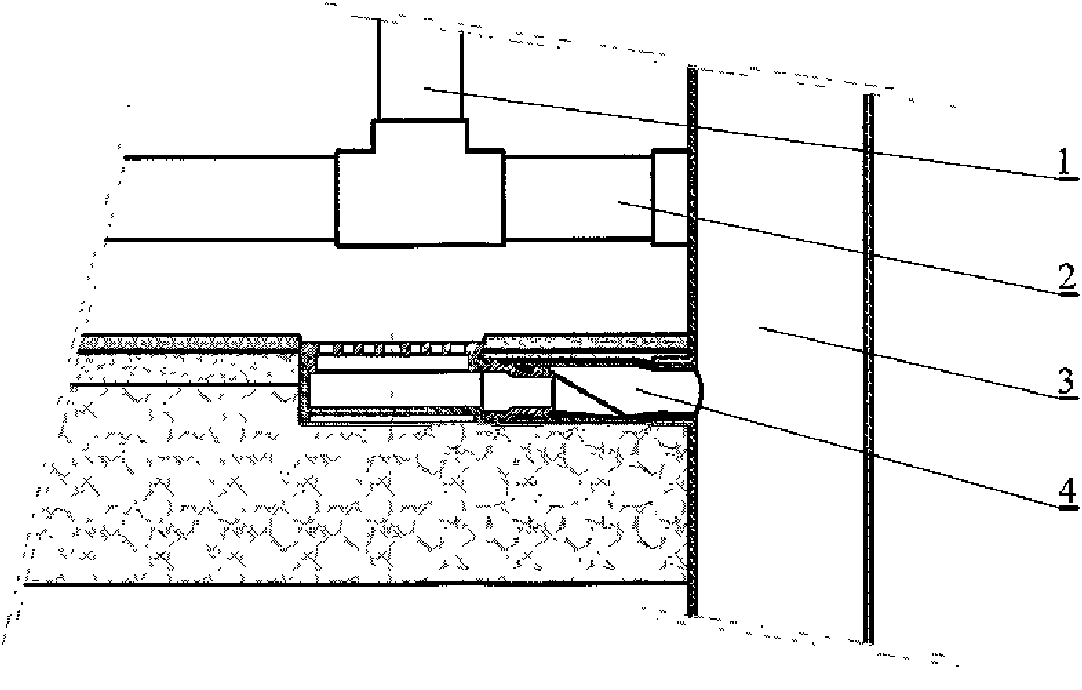

Permeable device for sponge city

PendingCN110130170AImprove filtering effectEasy to handleFatty/oily/floating substances removal devicesSewerage structuresActivated carbonBrick

The invention relates to a permeable device for a sponge city. The permeable device comprises an installation frame, a content gauge, a supporting mesh plate, a reservoir, permeable bricks, a water pump, a filter box, a treatment box, a sewage pipeline, an electromagnetic valve, an activated carbon box and a water storage tank, wherein the filter box is composed of a shell, a waterproof box, a motor, a water inlet pipe, a filter mesh barrel, a scraper plate, a waste pipe, a mixing shaft and a water outlet pipe, and has a self-cleaning function. The permeable device has the beneficial effects that the filter box with the self-cleaning function and the activated carbon box are adopted to filter and purify rainwater, the treatment effect of the rainwater is improved, the rainwater can be morewidely reused, and the problem of low recycling utilization rate of water resources is solved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Mechanical sealing and water sealing combined floor drain

A mechanical seal and water seal combined floor drain consists of a floor drain cover, a main floor drain body, a float and a hose type magnetic seal valve. The float is arranged inside the main floor drain body, the lower end of the float is matched with a water outlet of the main floor drain body, the water outlet of the main floor drain body is sealed with the lower end of the float by gravity or magnetic force; and the hose type magnetic seal valve is arranged at the water outlet of the main floor drain body, and the water outlet is sealed by the magnetic force. Opening and closing of the mechanical seal and water seal combined floor drain are realized by the change of water flow entering the floor drain. The mechanical seal and water seal combined floor drain has the advantages of quick opening and closing, small resistance when water passes through, good sealing effect, uneasy blockage and the like, can prevent positive and negative pressure in a sewer from damaging the sealing performance of the floor drain, and also has good overflow resistance performance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

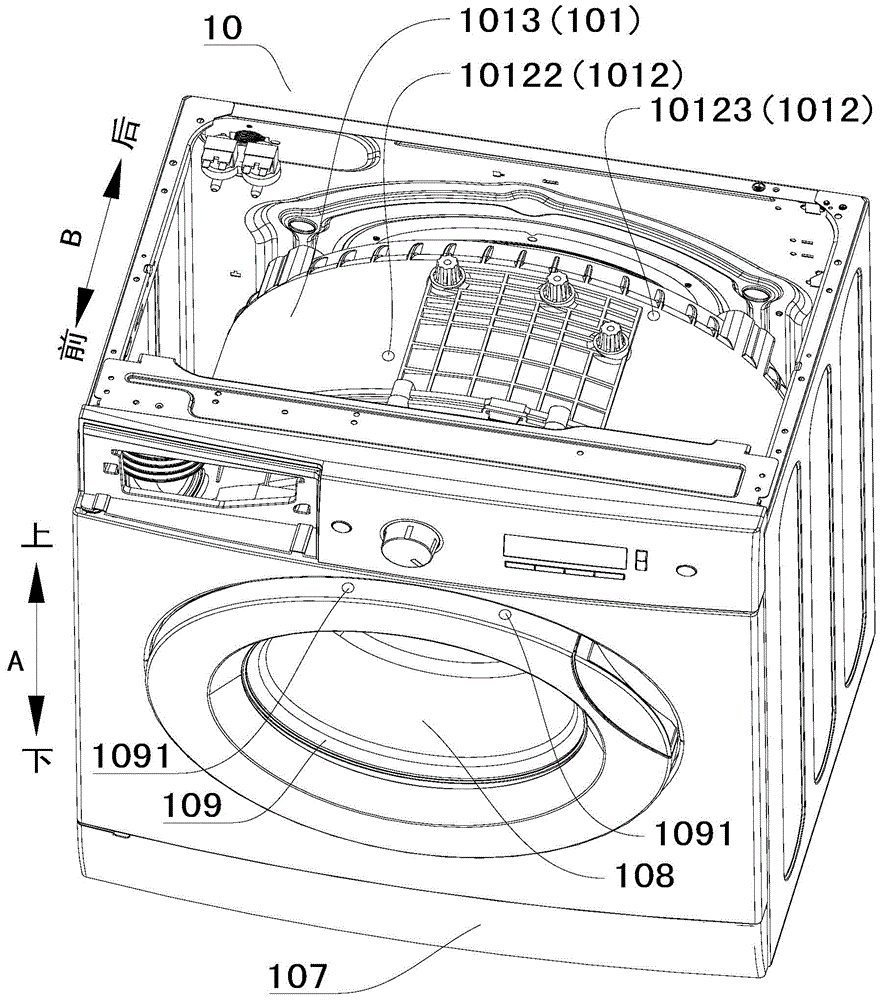

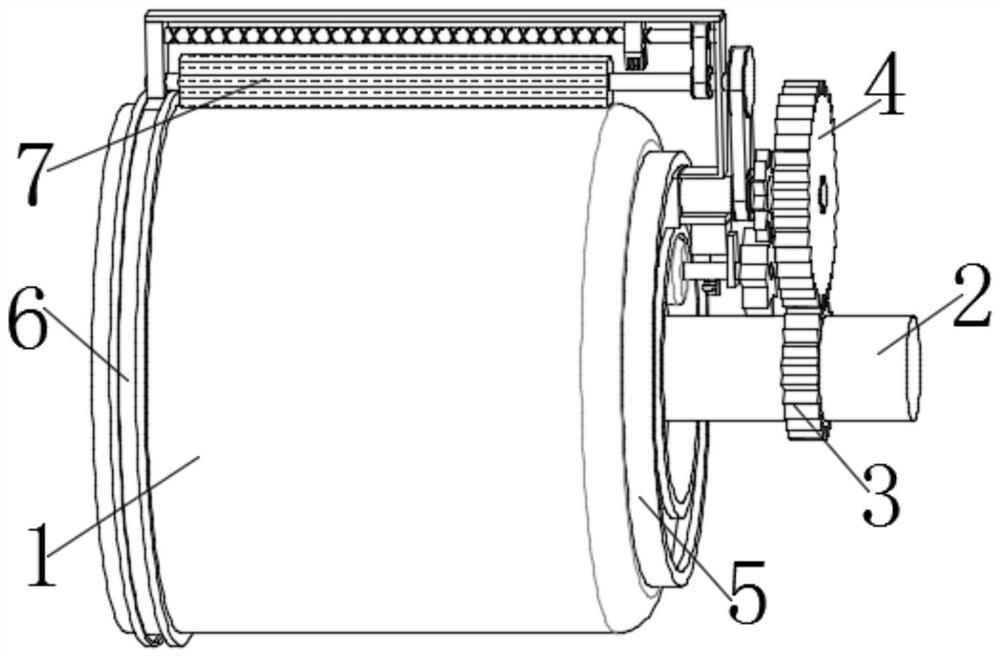

Drum washing machine

InactiveCN105088622AImprove rinsing performanceEasy to cleanOther washing machinesWashing machine with receptaclesEngineeringSelf cleaning

The invention discloses a drum washing machine. The drum washing machine comprises a housing, an outer drum, a circulatory spraying system, a door seal, a door body, an inner drum and a tripod. The circulatory spraying system comprises first spraying holes, second spraying holes and third spraying holes. The first spraying holes are arranged in the vicinity of the door seal and comprise a first branch for the first spraying holes and a second branch for the first spraying holes. The first branch for the first spraying holes is used for spraying towards the door seal. The door body comprises door glass. The second branch for the first spraying holes is used for spraying towards the door glass. The inner drum can be rotatably arranged in an accommodating cavity internally provided with the multiple second spraying holes arranged at intervals along the front-back direction. Each second spraying hole is used for spraying towards the middle portion of the outside of the inner drum. The tripod is arranged opposite to the third spraying holes used for spaying towards the tripod.The drum washing machine is advantaged by being fine in rinsing performance and high in self-cleaning capability.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Industrial method for preparing PPTA spinning slurry with solid sulphuric acid

ActiveCN101555631BIncrease contact areaFast dissolutionSpinning solutions preparationMonocomponent polyamides artificial filamentLiquid crystallineSlurry

The invention discloses an industrial method for preparing PPTA spinning slurry with solid sulphuric acid, comprising the following steps: (1) granular solid sulphuric acid and dried PPTA resin with logarithmic viscosity number of 4.0-8.0dl / g are fully mixed, and are prepared into a liquid crystalline solution containing 16-23 percent of PPTA by weight percent via heating dissolving and pre-deaeration; (2) the obtained liquid crystalline solution is mixed, kneaded and sheared to form uniform liquid crystalline slurry under the temperature of 60-100 DEG C; and (3) the formed liquid crystallineslurry is further mixed and deaearted under the conditions of the temperature of 60-100 DEG C and the pressure of 0.09MPa to obtain stable and uniform PPTA / H2SO4 liquid crystalline solution, i.e. spinning solution. The method has good mixing effect, can rapid extrude under high shearing rate without the degradation of the liquid crystalline solution caused by high shearing rate and high temperature.

Owner:中国平煤神马控股集团有限公司

Aqueous concrete sealer

The invention discloses an aqueous concrete sealer, which comprises the following components in percentage by weight: 45 to 65 percent of modified acrylic acid emulsion, 10 to 20 percent of modified fluorocarbon emulsion, 5 to 15 percent of film-forming assistant, 3 to 5 percent of dispersant, 3 to 8 percent of thickener, 1 to 3 percent of defoaming agent and 10 to 20 percent of wetting agent. The aqueous concrete sealer has high self-cleaning performance, can reinforce cement-based self-leveling floors, and is environment-friendly and durable. The aqueous concrete sealer disclosed by the invention can be used as finish for indoor self-leveling material, the construction process of the aqueous concrete sealer is simple, convenient and quickly, and the aqueous concrete sealer can improve the surface effect and antifouling capacity of the cement-based self-leveling material.

Owner:上海耐齐建材有限公司

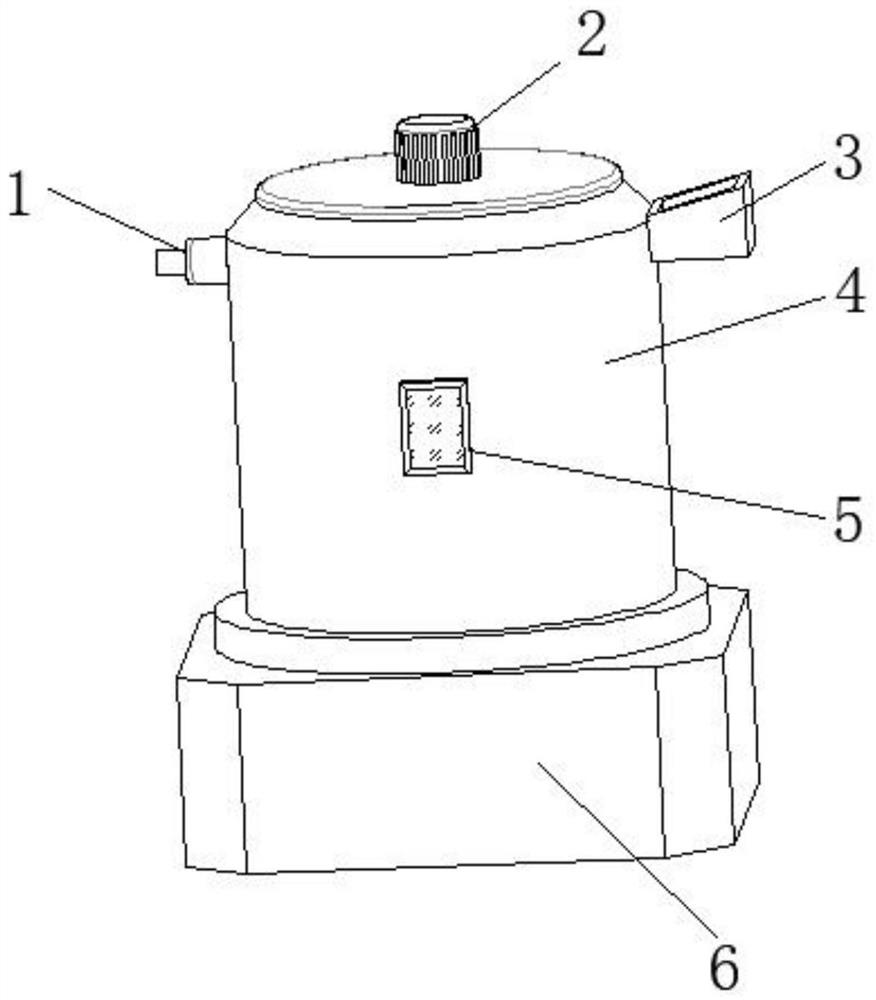

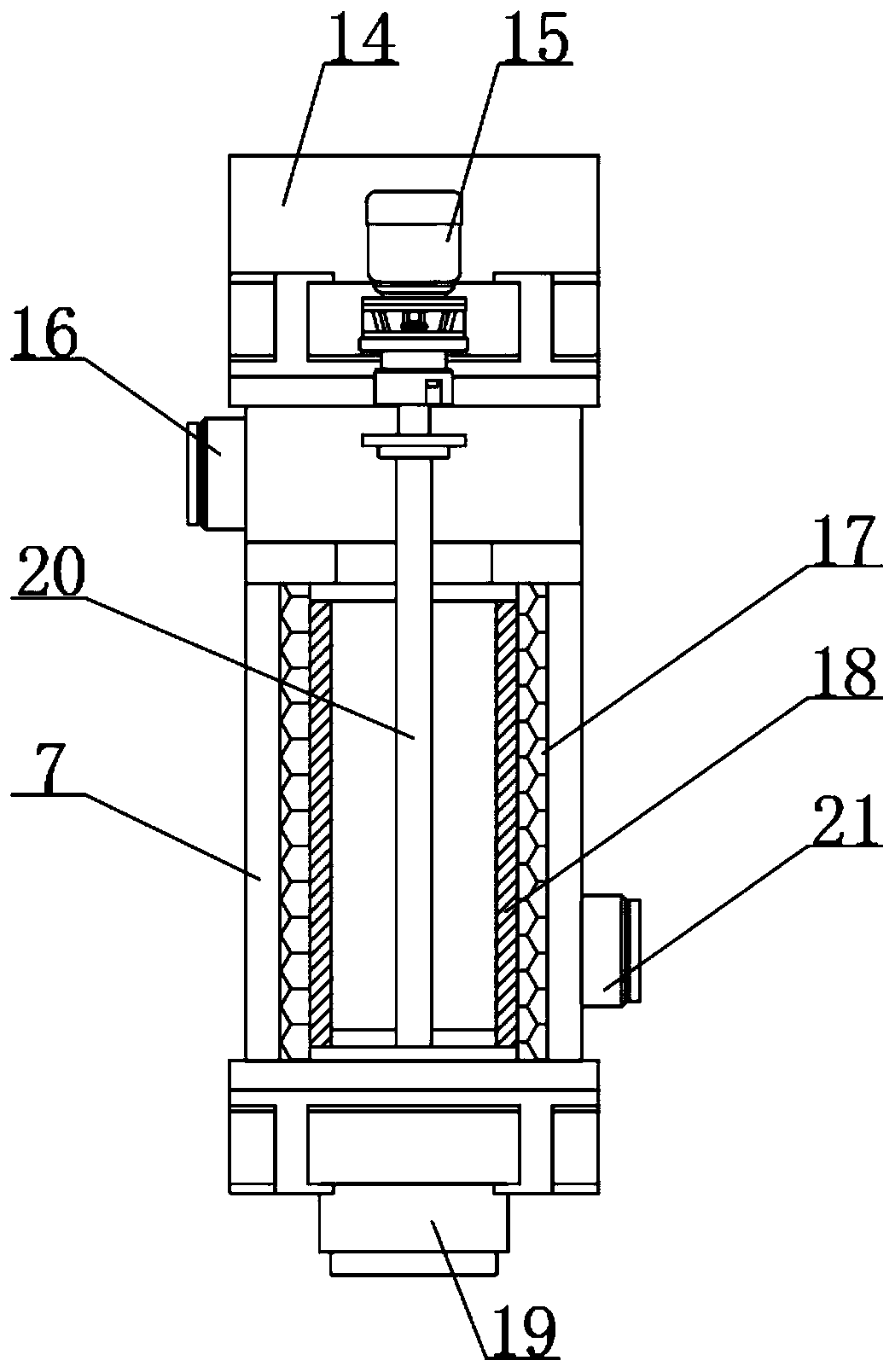

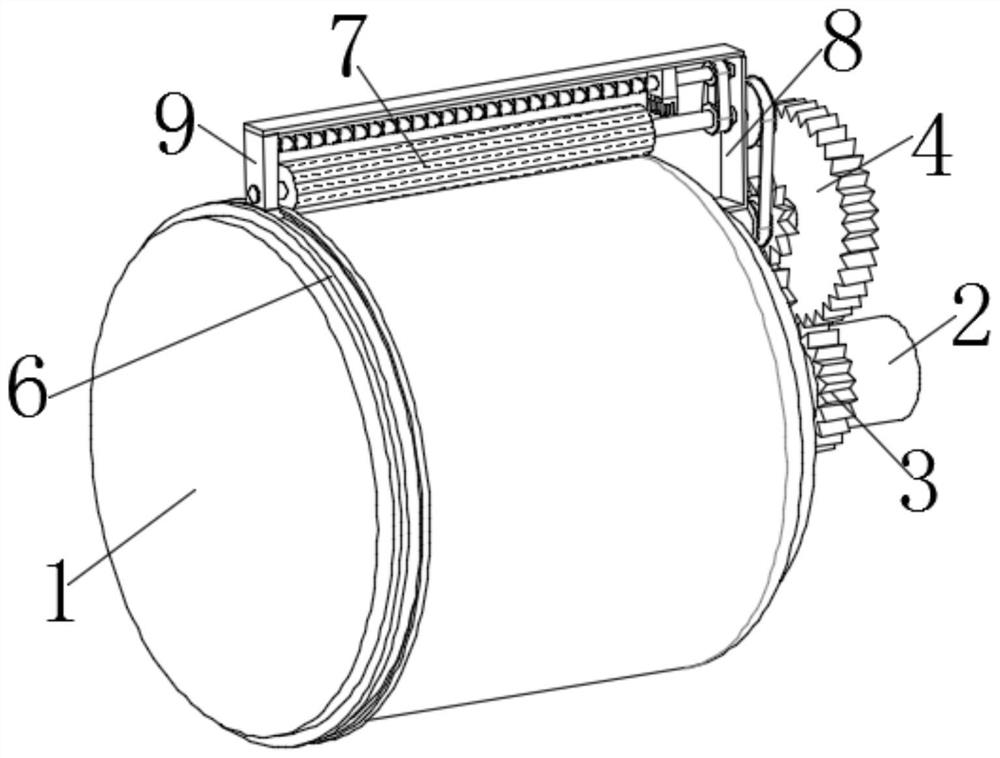

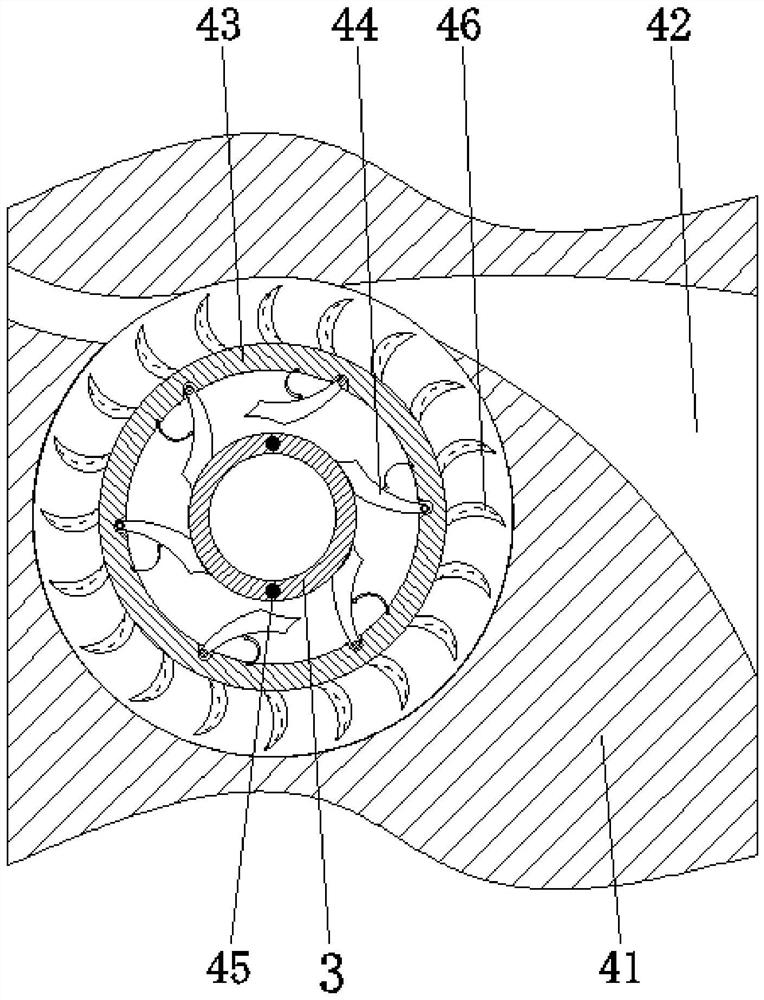

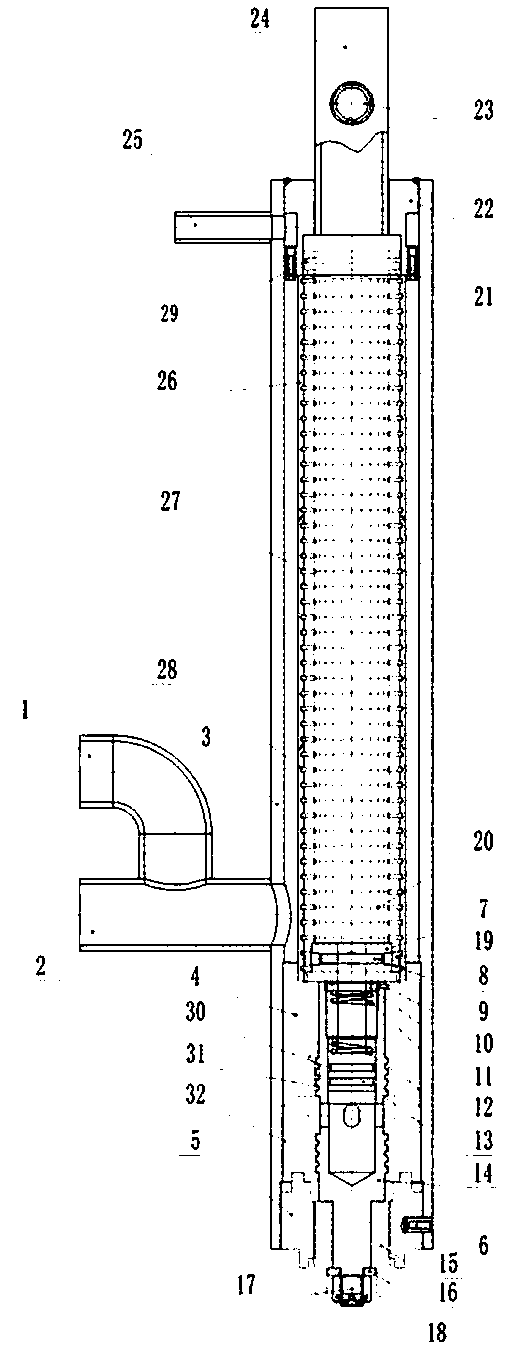

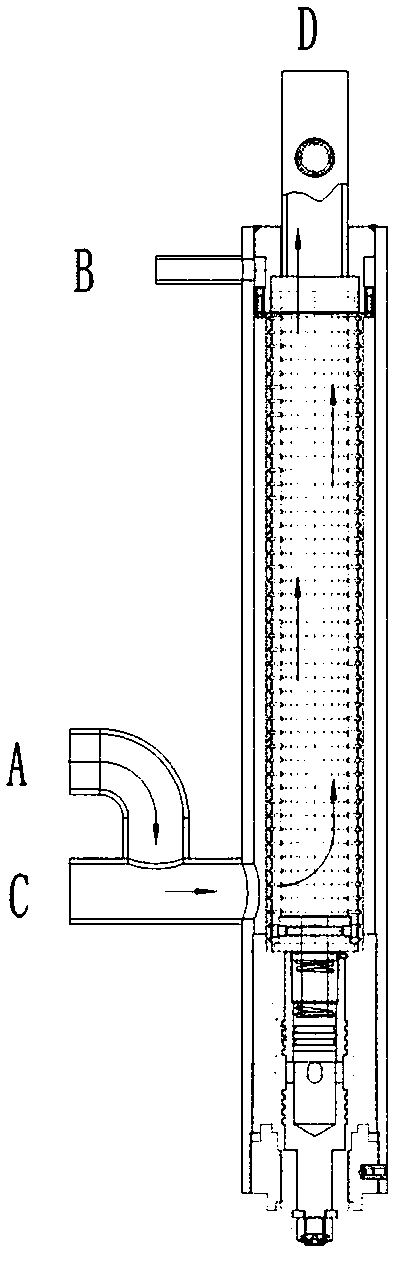

Brushless submersible motor for anti-erosion self-cleaning through motor driving

ActiveCN113285550AImprove self-cleaning functionNot prone to corrosionClimate change adaptationCleaning using toolsMotor driveMarine engineering

The invention discloses a brushless submersible motor for anti-erosion self-cleaning through motor driving, which relates to the technical field of brushless submersible motors. The brushless submersible motor comprises a submersible motor body and a motor output shaft installed on the submersible motor body, and the end part of the submersible motor body is fixedly provided with a built-in ring. The built-in ring and the motor output shaft are located on the same central axis, and the built-in ring is provided with a motor side part cleaning part used for self-cleaning the side part of the submersible motor body and a motor end part cleaning part used for self-cleaning the end part of the submersible motor body. According to the brushless submersible motor, the structure is reasonable, when the brushless submersible motor works, dirt on the end portion and the side portion can be brushed and swept in time, the brushless submersible motor has a good self-cleaning function, the brushless submersible motor is not prone to corrosion, the service life of the brushless submersible motor is longer, and the stability of the brushless submersible motor is better when the brushless submersible motor is used.

Owner:深圳市恒然电机有限公司

Lithium battery heat dissipation device

InactiveCN112701397AImprove cooling effectImprove cooling efficiencyBattery isolationSecondary cellsDust controlEngineering

The invention discloses a lithium battery heat dissipation device which comprises a shell, a lithium battery, a condensation pipe, a dust removal device, a reset spring, a driving device and an air cooling mechanism are arranged in the shell, the lithium battery is arranged in the center of the bottom of the inner wall of the shell, and the condensation pipe is fixed to the bottom of the inner wall of the shell and is close to the end of the lithium battery. The dust removal device is arranged on the surface of the condensation pipe, the reset spring is fixed between the surface of the dust removal device and the two corresponding sides of the interior of the shell, the driving device is arranged in the position, close to the condensation pipe, of the interior of the shell, and the air cooling mechanism is fixed in the shell and close to one side of the condensation pipe. The invention relates to the technical field of lithium batteries. According to the lithium battery heat dissipation device, the purpose of self-cleaning is achieved, rapid heat dissipation can be conducted on the lithium battery, meanwhile, self-cleaning is conducted on dust adhering to the heat dissipater, the heat dissipation efficiency can be improved, overheating of the lithium battery is avoided, the service life is prolonged, and the use performance is improved.

Owner:潘屿芬

Screening device for wear-resisting ball machining

InactiveCN111330833AFlexible Mesh SizeChange mesh sizeSievingScreeningScreens (device)Structural engineering

The invention discloses a screening device for wear-resisting ball machining, and relates to the technical field of wear-resisting ball production. The screening device for wear-resisting ball machining comprises an inner roller screen and an outer roller screen; the inner surface of the inner roller screen is fixedly connected with a transmission shaft through a connecting rod; first screen holesare arrayed in the peripheral side surface of the inner roller screen; external threads are arranged on the peripheral side of the transmission shaft; the inner surfaces of the two ends of the outerroller screen are fixedly connected with a first connecting sleeve and a second connecting sleeve through connecting rods correspondingly; and the first connecting sleeve is connected with the transmission shaft through an adjusting sleeve. According to the screening device for wear-resisting ball machining, the inner roller screen and the outer roller screen which can be in sliding fit with eachother are arranged, and the size of a screen mesh is changed through utilizing mutual dislocation between the first screen holes and second screen holes, so that the problems that screen equipment cannot adapt to screening of multi-size wear-resisting balls and consequently is poor in adaptability are solved; and meanwhile, through mutual dislocation adjustment between the first screen holes and the second screen holes, the wear-resisting balls clamped in the screen holes can be effectively removed, and the problems that the production efficiency and the production cost are influenced due to the fact that manual cleaning is needed can be solved.

Owner:合肥新士鑫机械科技有限公司

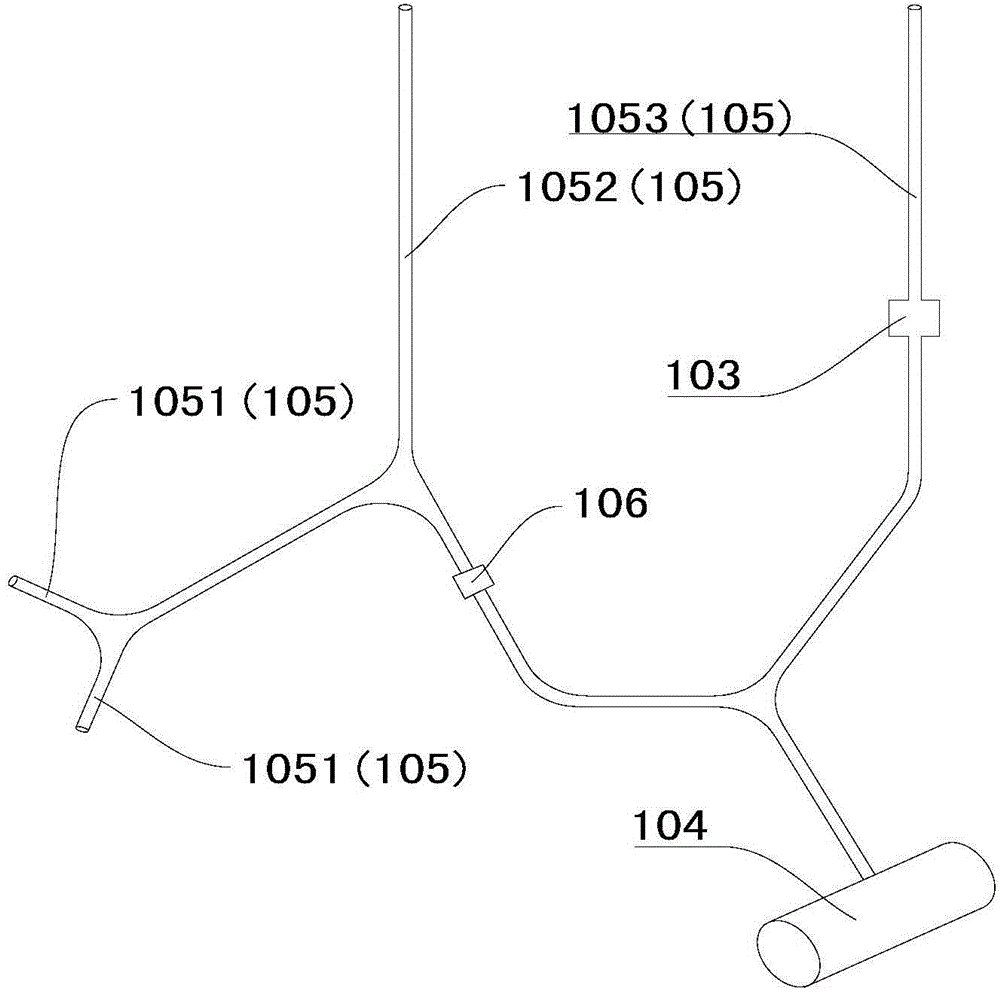

Homofloor drainage system

The invention relates to a homofloor drainage system comprising branch drains, a horizontal drainage tube, a hose sealed floor drain and a vertical drainage tube. The homofloor drainage system is suitable for a descending-plate drainage mode and a non-descending plate drainage mode. The hose sealed floor drain can be replaced by a hose sealed pipeline one-way valve; and the hose sealed floor drainand the hose sealed pipeline one-way valve can be simultaneously mounted in the drainage system. Because the hose sealed floor drain and the hose sealed pipeline one-way valve have low self height, little stream flowing resistance, good sealing effect, strong self cleaning capability and convenient mounting and use, the horizontal drainage system rapidly drains deposited water on the ground, ensures the sealing effect in a waterless occasion, reduces the descending plate height of a bathroom or does not descend the plate, thereby decreasing the engineering manufacture cost, improving the useeffect and being beneficial to the popularization and the application of the horizontal drainage system.

Owner:戴长虹

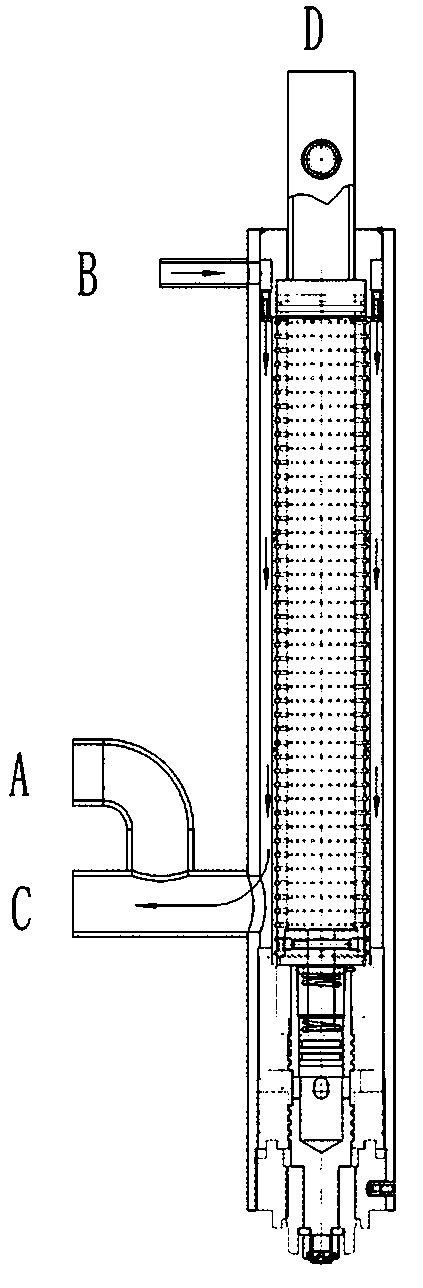

High-speed jet self-cleaning filtering device

PendingCN107673419AStrong self-cleaning abilityOperational securityWaste water treatment from quariesSpecific water treatment objectivesEngineeringOutfall

The invention relates to a high-speed jet self-cleaning filtering device, which comprises a casing, a liquid inlet connecting pipe, a sewage discharging opening connecting pipe and a jet cleaning water inlet pipe, wherein the casing is arranged in the horizonal direction; the jet cleaning water inlet pipe is arranged at the lower side of the left end of the casing; the sewage discharging opening connecting pipe is arranged at the lower side of the right end of the casing; the liquid inlet connecting pipe is arranged at one side of the sewage discharging opening connecting pipe and is communicated with the sewage discharging opening connecting pipe; a jet device is welded at the left end of the casing; a copper spray nozzle is positioned inside the casing and is connected with the jet device through screw threads. The high-speed jet self-cleaning filtering device has the advantages that the self-cleaning capability is high; the operation is safe, simple and convenient; the automation degree is higher.

Owner:康庆刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com