Rotor-wing floating brush mineral flotation machine

A floating brush and flotation machine technology, used in flotation, solid separation and other directions, can solve the problems of lack of strengthening effect, large consumption of chemicals, low mineral processing efficiency, etc., and achieve a simple and reliable system structure, low cost and high efficiency flotation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with accompanying drawing, the present invention is described in further detail.

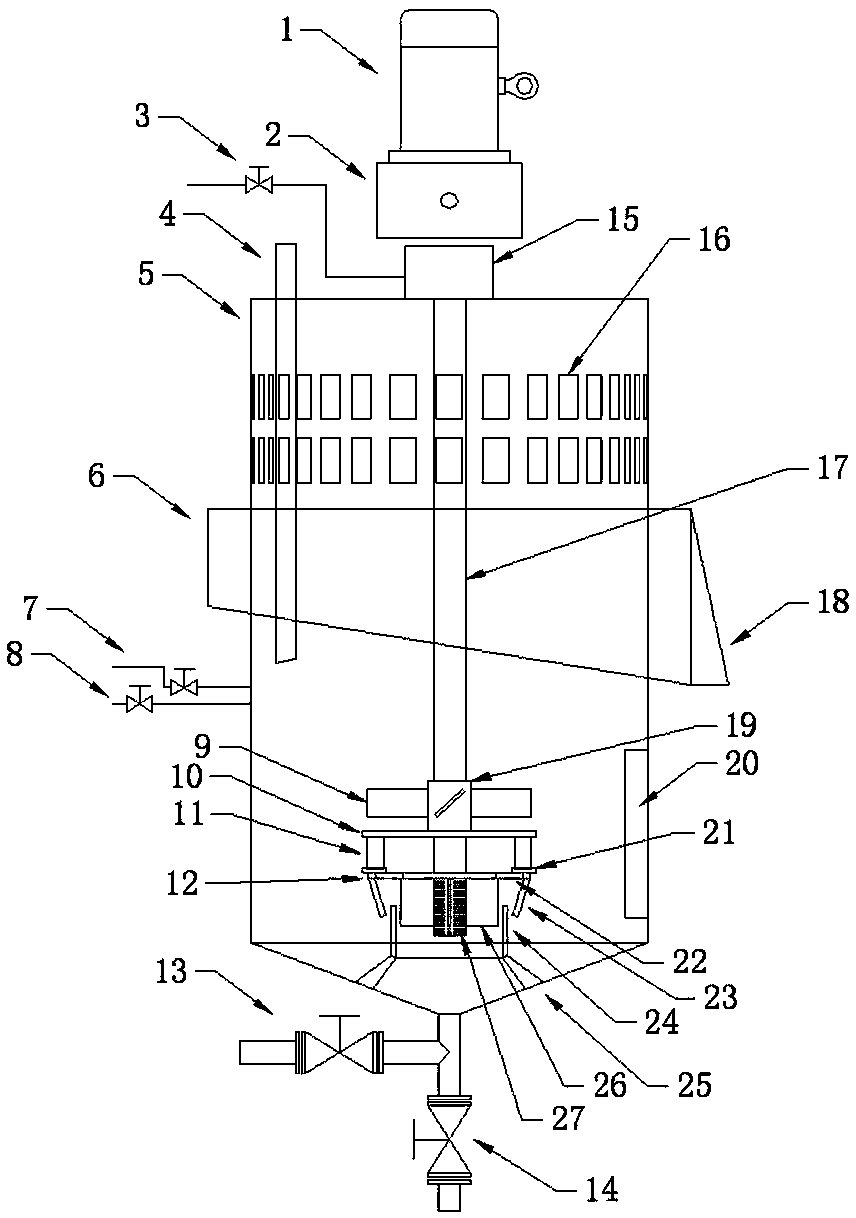

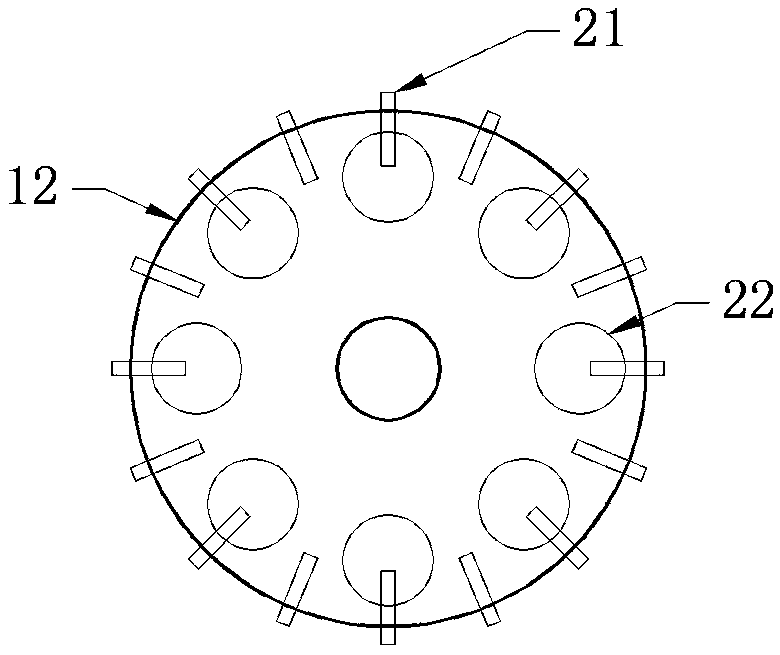

[0027] Such as figure 1 with figure 2 The shown rotor floating brush mineral flotation machine includes a barrel body 5, a hollow main shaft 17, an ore powder feeding chute 4, a water inlet valve 7, a medicine valve 8 and a slurry discharge valve 14, and the barrel body 5 is provided with a foam overflow hole 16 and the cofferdam 6, the cofferdam 6 is provided with a foam material outlet 18, the barrel body 5 is a cone bottom structure, and the cone bottom is provided with a lower air intake valve 13; the hollow main shaft 17 is provided with a vent hole 27, which can rotate and also serve as an air guide Function, the porous turntable 12, the cone cover 23 and the blade 26 are welded together with the hollow main shaft 17, and the porous turntable 12 is provided with openings 22 and protruding ribs 21; 10 is welded into one ring brush part, and the movable bushing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com