40.5kV switch equipment system

A switchgear and switchgear technology, applied in the field of 40.5kV switchgear system, can solve the problems affecting the effective control of the arc extinguishing chamber, the insulation failure of the insulation rod, and the unreasonable layout of the switchgear, etc., so as to optimize the surrounding electric field and avoid the cabinet. Overheating, not easy to discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

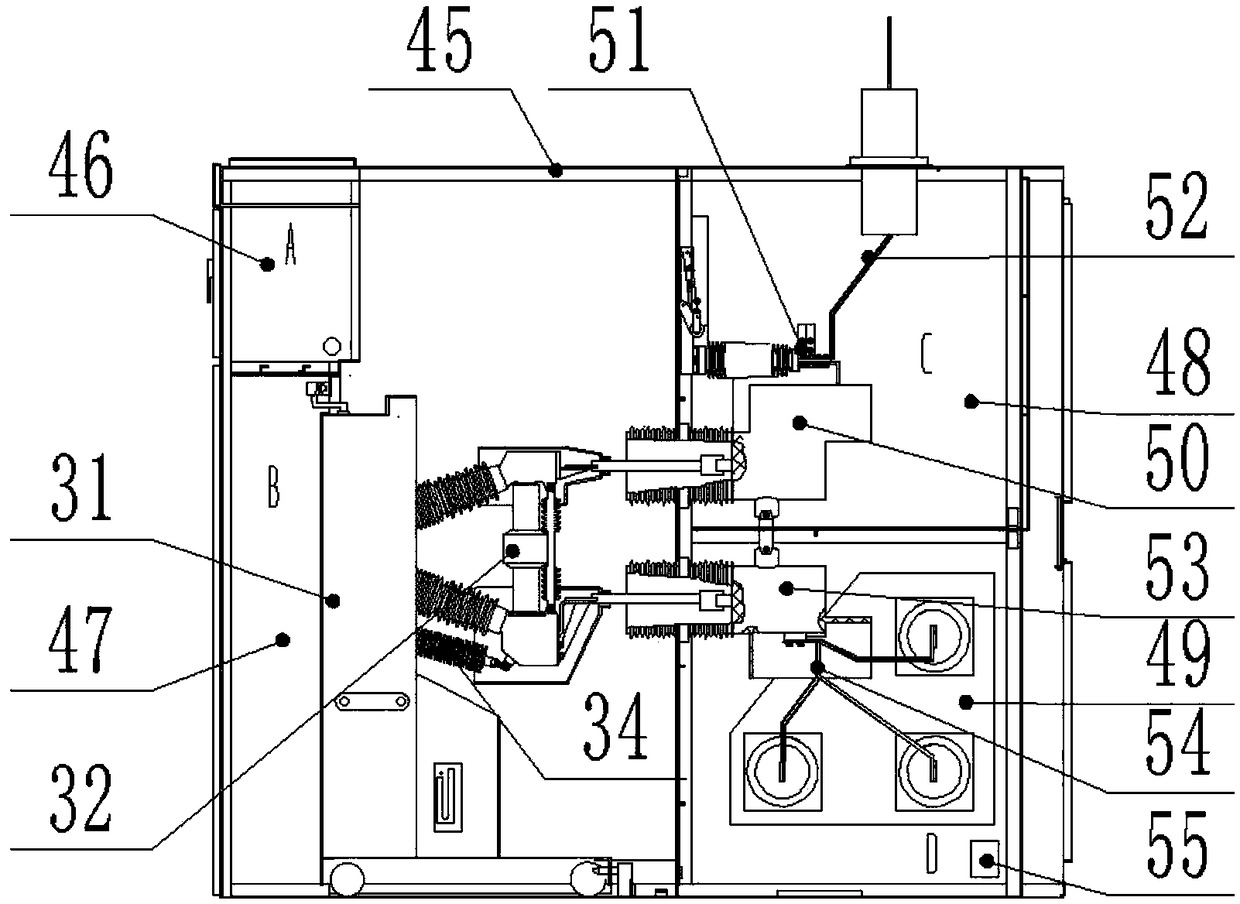

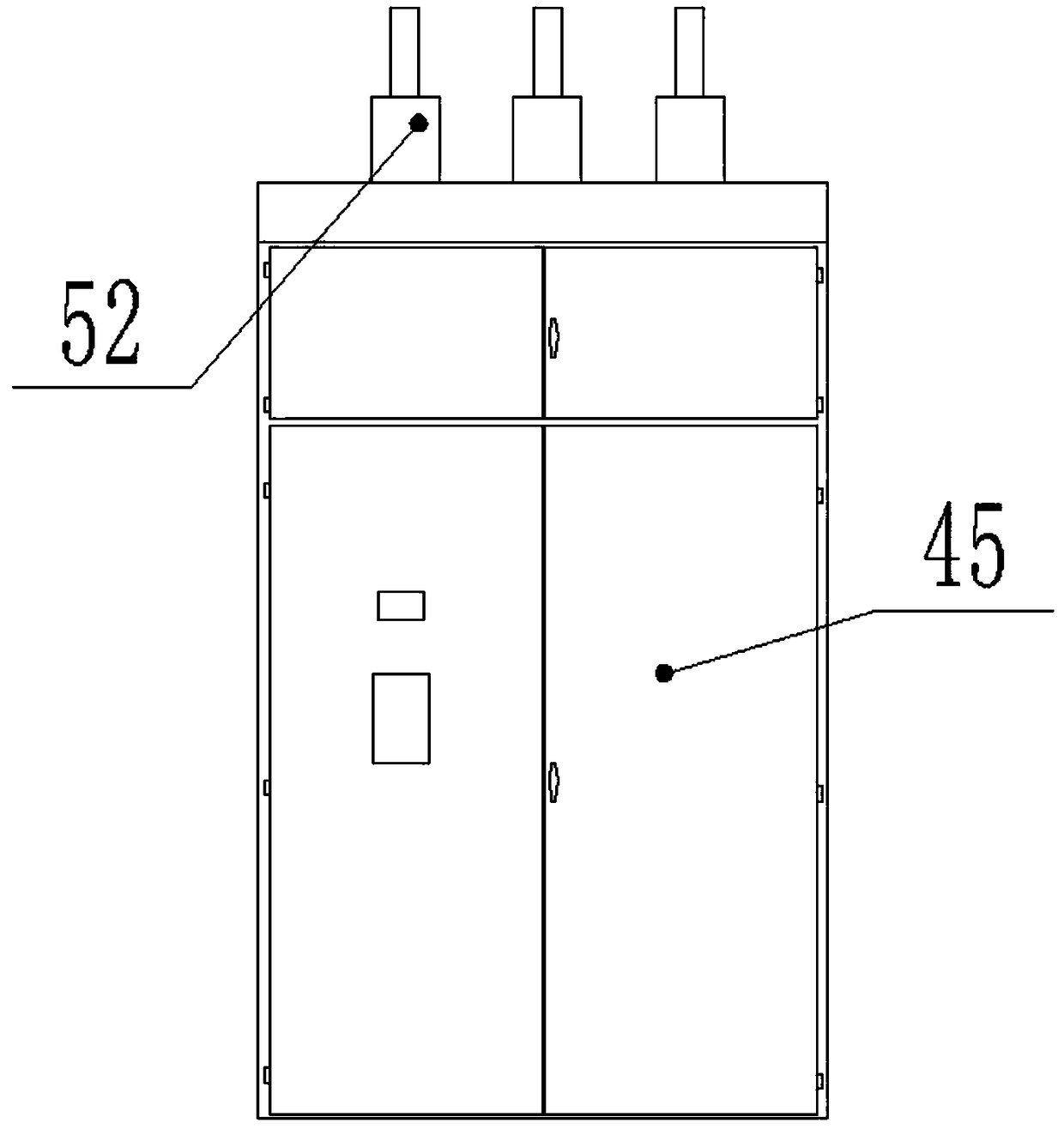

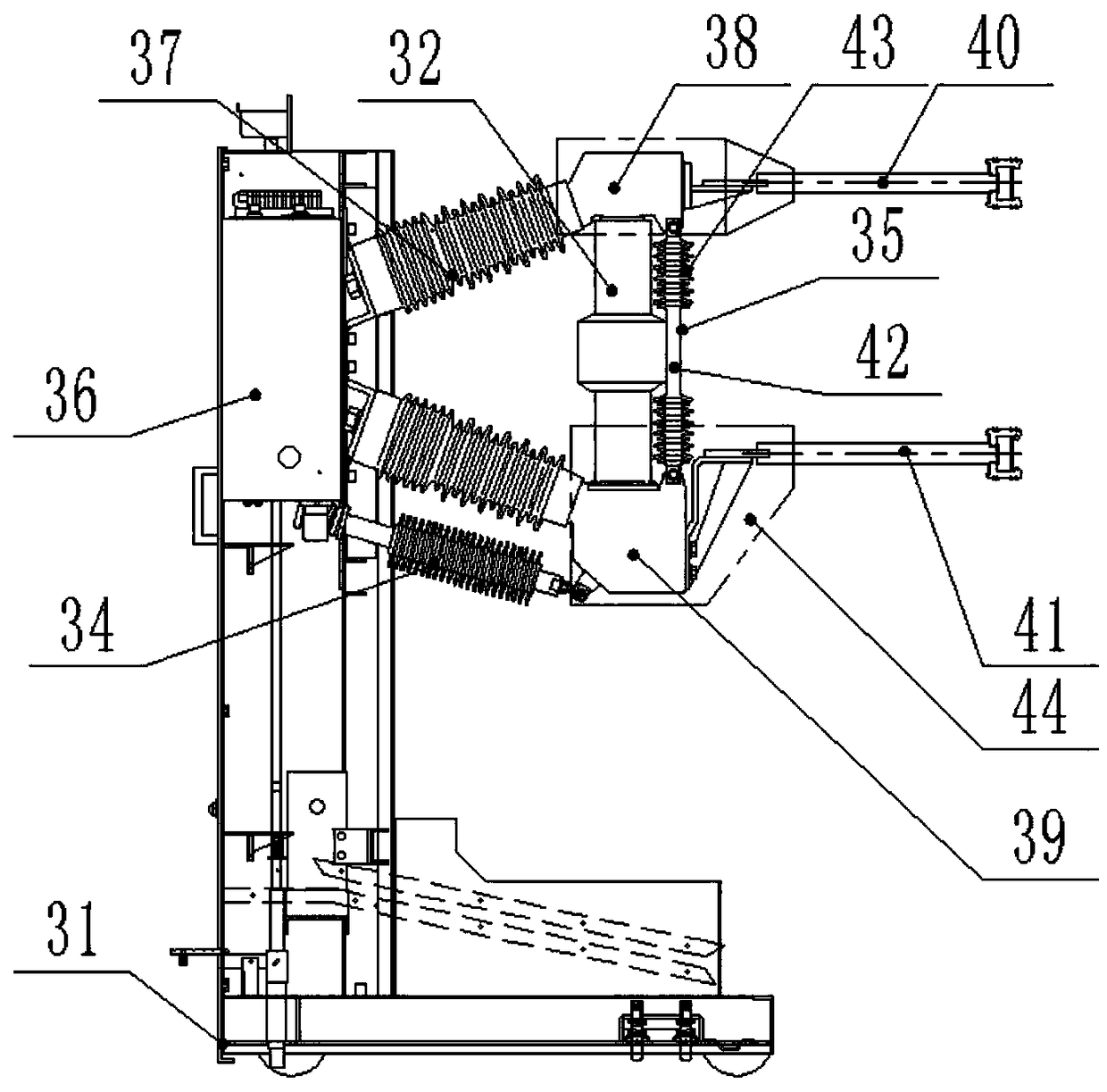

[0046] Such as Figure 1-9 As shown, a 40.5kV switchgear system of the present invention includes a switchgear 45, and the switchgear 45 is divided into an instrument room 46, a handcart room 47, a feeder room 48 and a busbar room 49, and the feeder room 48 is arranged on the busbar Above the handcart room 49, the handcart room 47 is arranged on the left side of the feeder room 48 and the busbar room 49, the instrument room 46 is arranged in the upper left corner of the handcart room 47, and the circuit breaker assembly is arranged in the handcart room 47, so The upper conductive joint 40 on the circuit breaker assembly is connected to the outlet of the upper contact box-type current transformer 50 arranged in the feeder room 48, and the inlet of the upper contact box-type current transformer 50 is connected to the upper branch bus through a grounding switch 51 connector 52; the lower conductive connector 41 on the circuit breaker assembly is connected to the outlet of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com